English

Operating and Assembly Instructions

D.C. tachometer generator

TDP 1,2

Read the Operating and Assembly Instructions prior to

assembly, starting installation and handling!

Keep for future reference!

Translation of the original Operating and Assembly Instructions TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

ID 74713

D.C. tachometer generator TDP 1,2

2

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Brand names and product names are trademarks or registered trademarks of their respective owner.

Protected trademarks bearing a ™ or ® symbol are not always depicted as such in the manual.

However, the statutory rights of the respective owners remain unaffected.

Manufacturer / publisher

Johannes Hubner

Fabrik elektrischer Maschinen GmbH

Siemensstraße 7

35394 Giessen

Germany

Phone: +49 641 7969 0

Fax: +49 641 73645

E-Mail: info@huebner-giessen.com

www.huebner-giessen.com

Headquarters: Giessen

The manual has been drawn up with the utmost care and attention. Nevertheless, we cannot exclude

the possibility of errors in form and content. It is strictly forbidden to reproduce this publication or parts

of this publication in any form or by any means without the prior written permission of

Johannes Hubner Fabrik elektrischer Maschinen GmbH.

Subject to errors and changes due to technical improvements.

Copyright © Johannes Hubner Fabrik elektrischer Maschinen GmbH

All rights reserved.

D.C. tachometer generator TDP 1,2

3

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Directory

1 General ......................................................................................................... 5

1.1 Information about the Operating and Assembly Instructions ......................... 5

1.2 Scope of delivery ........................................................................................... 5

1.3 Explanation of symbols .................................................................................. 5

1.4 Disclaimer ...................................................................................................... 6

1.5 Copyright ....................................................................................................... 6

1.6 Guarantee terms............................................................................................ 6

1.7 Customer service........................................................................................... 6

2 Safety ............................................................................................................ 7

2.1 Responsibility of the owner ............................................................................ 7

2.2 Intended use .................................................................................................. 7

2.3 Improper use ................................................................................................. 7

2.4 Personal protective equipment ...................................................................... 7

2.5 Personell ....................................................................................................... 7

2.6 Special dangers ............................................................................................. 8

2.6.1 Electrical current ........................................................................................................... 8

2.6.2 Rotating shafts and hot surfaces ................................................................................ 8

2.6.3 Ensure the power supply cannot be reconnected ................................................... 8

3 Technical Data.............................................................................................. 9

3.1 Type plate ...................................................................................................... 9

3.2 Type key ...................................................................................................... 10

3.3 Type explanation ......................................................................................... 11

3.4 Dimensions, Power consumption, Environment, Speed .............................. 12

3.5 Elektrical and mechanical data .................................................................... 12

3.6 General technical data, electric implementation .......................................... 19

4 Mechanical design ..................................................................................... 27

5 Design and function .................................................................................. 29

5.1 Block diagram .............................................................................................. 29

5.2 Short description.......................................................................................... 29

5.3 Connections ................................................................................................ 29

6 Transport, packaging and storage ........................................................... 30

6.1 Safety instructions for transport ................................................................... 30

6.2 Incoming goods inspection .......................................................................... 30

6.3 Packaging (disposal) ................................................................................... 30

6.4 Storage of packages (devices) .................................................................... 30

7 Installation, commissioning and dismantling ......................................... 31

7.1 Uses ............................................................................................................ 31

7.2 Place of installation...................................................................................... 31

7.3 Installation work ........................................................................................... 32

7.3.1 Installation and commissioning ................................................................................. 32

7.4 Dismantling .................................................................................................. 34

8 Disorders .................................................................................................... 36

8.1 Diagnosis Chart ........................................................................................... 36

9 Recommended Inspections ...................................................................... 39

9.1 Inspection and maintenance schedule ........................................................ 39

10 Disposal ...................................................................................................... 41

D.C. tachometer generator TDP 1,2

4

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

11 Annex .......................................................................................................... 41

11.1 Connection diagram .................................................................................... 41

12 Spare parts ................................................................................................. 42

13 Dimension drawings .................................................................................. 43

13.1 Screw tightening torques ............................................................................. 54

D.C. tachometer generator TDP 1,2

5

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

1 General

1.1 Information about the Operating and Assembly Instructions

These Operating and Assembly Instructions provide important instructions for working with the device.

They must be carefully read prior to starting all tasks, and the instructions contained herein must be

followed.

In addition, applicable local regulations for the prevention of industrial accidents and general safety

regulations must be complied with.

1.2 Scope of delivery

Scope of delivery includes the D.C. tachometer generator TDP 1,2 and the Operating and Assembly

Instructions.

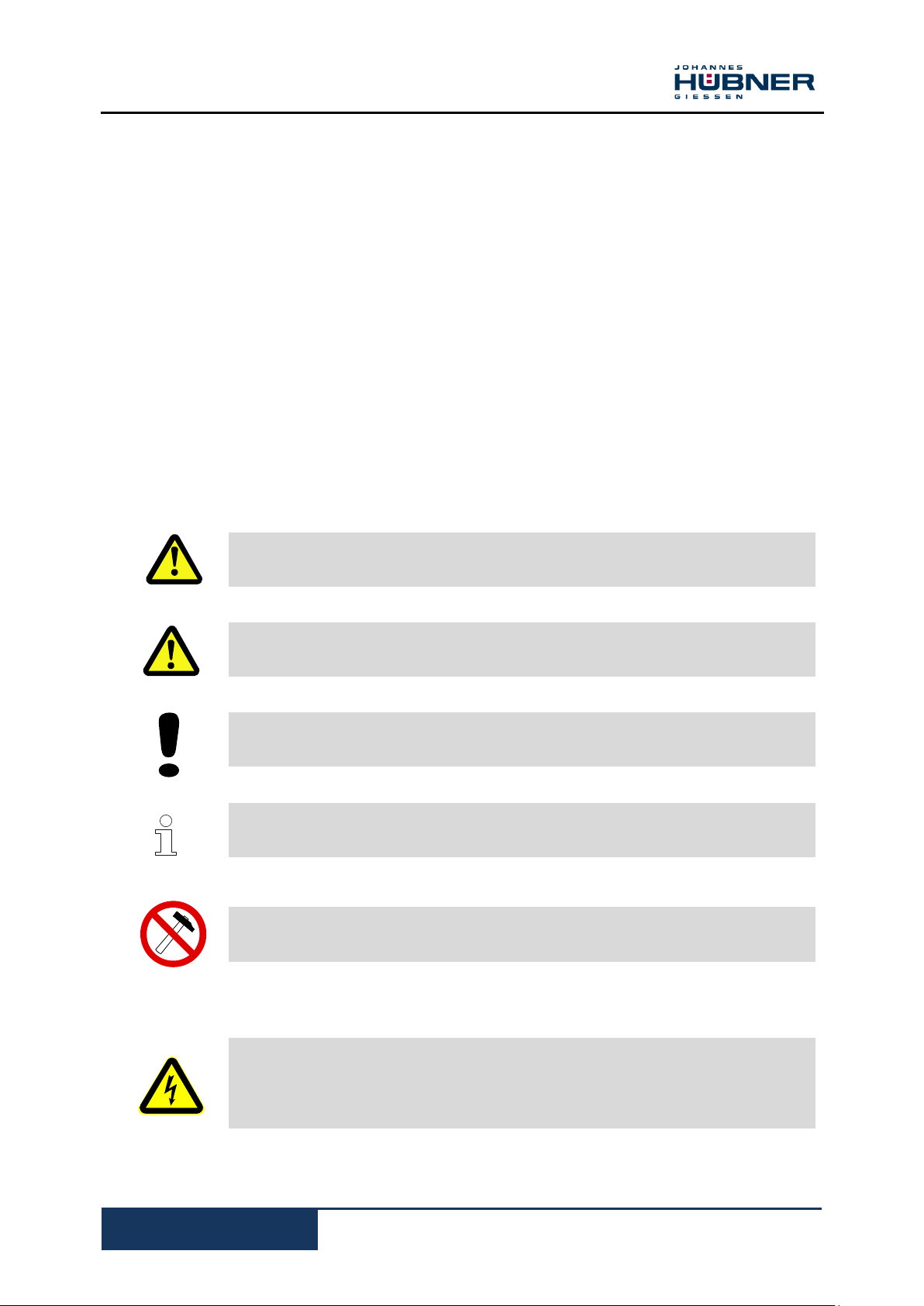

1.3 Explanation of symbols

Warnings are indicated by symbols in these Operating and Assembly Instructions. The warnings are

introduced by signal words that express the scope of the hazard.

The warnings must be strictly heeded; you must act prudently to prevent accidents, personal injury,

and property damage.

WARNING!

Indicates a possibly dangerous situation that can result in death or serious injury if it

is not avoided.

CAUTION!

Indicates a possibly dangerous situation that can result in minor injury if it is not

avoided.

CAUTION!

Indicates a possibly dangerous situation that can result in material damage if it is not

avoided.

NOTES!

Indicates useful tips and recommendations as well as information for efficient and

trouble-free operation.

NOTES!

Mounting and disassembly by means of a hymmer or similar tools is not permitted.

(Warranty void).

DANGER!

Life-threatening danger due to electric shock!

Indicates a life-threatening situation due to electric shock. If the safety instructions

are not complied with there is danger of serious injury or death. The work that must

be executed should only be performed by a qualified electrician.

D.C. tachometer generator TDP 1,2

6

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

1.4 Disclaimer

All information and instructions in these Operating and Assembly Instructions have been provided

under due consideration of applicable guidelines, as well as our many years of experience.

The manufacturer assumes no liability for damages due to:

Failure to follow the instructions in the Operating and Assembly Instructions.

Non-intended use

Deployment of untrained personnel

Opening of the device or conversions of the device

In all other aspects the obligations agreed in the delivery contract as well as the delivery conditions of

the manufacturer apply.

1.5 Copyright

NOTE!

Content information, text, drawings, graphics, and other representations are protected

by copyright and are subject to commercial property rights.

It is strictly forbidden to make copies of any kind or by any means for any purpose

other than in conjunction with using the device without the prior written agreement of

the manufacturer. Any copyright infringements will be prosecuted.

1.6 Guarantee terms

The guarantee terms are provided in the manufacturer´s terms and conditions.

1.7 Customer service

For technical information personnel is available that can be reached per telephone, fax or email. See

manufacturer´s address on page 2.

D.C. tachometer generator TDP 1,2

7

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

2 Safety

DANGER!

This section provides an overview of all the important safety aspects that ensure

protection of personnel, as well as safe and trouble-free device operation.

If these safety instructions are not complied with significant hazard can occur.

2.1 Responsibility of the owner

The device is used in commercial applications. Consequently the owner of the device is subject to the

legal occupational safety obligations, and subject to the safety, accident prevention, and

environmental protection regulations that are applicable for the device´s area of implementation.

2.2 Intended use

The device has been designed and constructed exclusively for the intended use described here.

Series TDP 1,2 are used for speed monitoring, for instance of electrical and mechanical drives,

hoisting gear, and conveying machines.

Claims of any type due to damage arising from non-intended use are excluded; the owner bears sole

responsibility for non-intended use.

2.3 Improper use

Do not use the device in potentially explosive areas.

The device must not be subjected to mechanical loads in addition to its own weight and

unavoidable vibration and shock loads that arise during normal operations.

Examples for non-permitted mechanical loads (incomplete list):

- Fastening transport or lifting tackle to the device, for example a crane hook to lift a

motor.

- Fastening packaging components to the device, for example ratchet straps, tarpaulins

etc.

- Using the device as a step, for example by people to climb onto a

motor.

It is not permitted to use the device in locations higher than 1000 m above sea level.

2.4 Personal protective equipment

Wear personal protective equipment such as safety shoes and safety clothing to minimise risks to

health and safety when carrying out work such as installation, disassembly or commissioning. Adhere

to all applicable statutory regulations as well as the rules and standards determined by the owner.

2.5 Personell

Installation and commissioning as well as disassembly routines must be carried out by skilled

technical staff only.

D.C. tachometer generator TDP 1,2

8

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

2.6 Special dangers

Residual risks that have been determined based on a risk analysis are cited below.

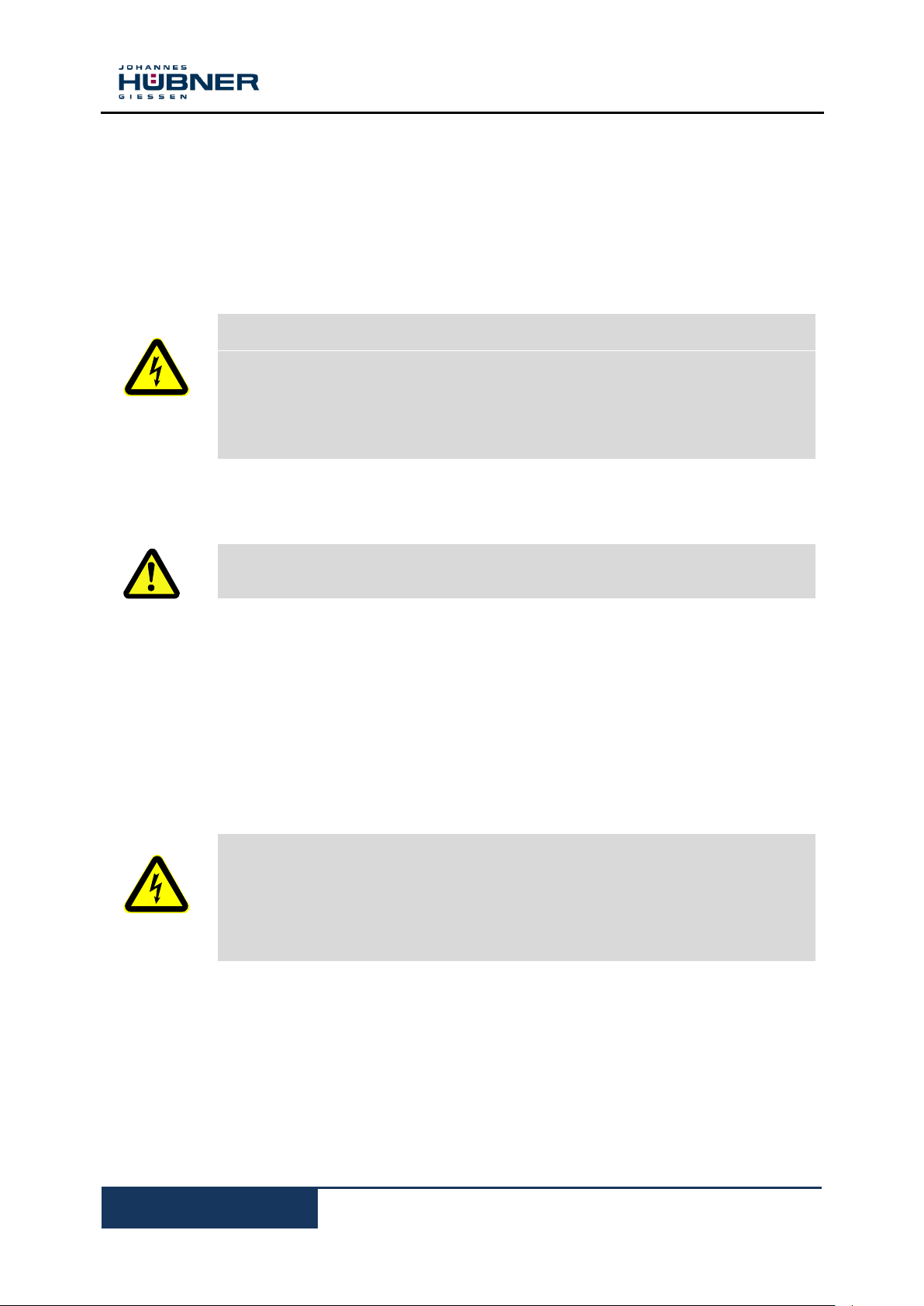

2.6.1 Electrical current

Danger of death from electricity!

There is an immediate danger of death from contact with live components. Damage to

the insulation or individual components can be lethal.

Therefore: If the insulation is damaged turn off and isolate the power supply

immediately; ensure the insulation is repaired. Before commencing any work on the

electrical installation turn off and isolate the power supply to the installation. Ensure

live components do not come into contact with moisture. Otherwise, this can lead to a

short-circuit.

2.6.2 Rotating shafts and hot surfaces

WARNING!

Risk of injury from rotating shafts and hot surfaces!

Touching rotating shafts can result in serious injuries.

Therefore: Do not tinker with moving parts/shafts or work on rotating shafts. Do not

open covers during operations. Ensure no parts are moving before opening any

covers. The encoder can become very hot when operated for longer periods of time.

There is a risk of burns on contact!

2.6.3 Ensure the power supply cannot be reconnected

DANGER!

Danger of death from unauthorized reconnection of the power supply!

There is a risk that the power supply will be reconnected without authorization when

carrying out work, for example when rectifying faults. This represents a serious risk to

the life of those in the danger zone.

Therefore: Turn off and isolate all power supplies to the equipment before

commencing work. Ensure the power supplies cannot be reconnected.

D.C. tachometer generator TDP 1,2

9

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

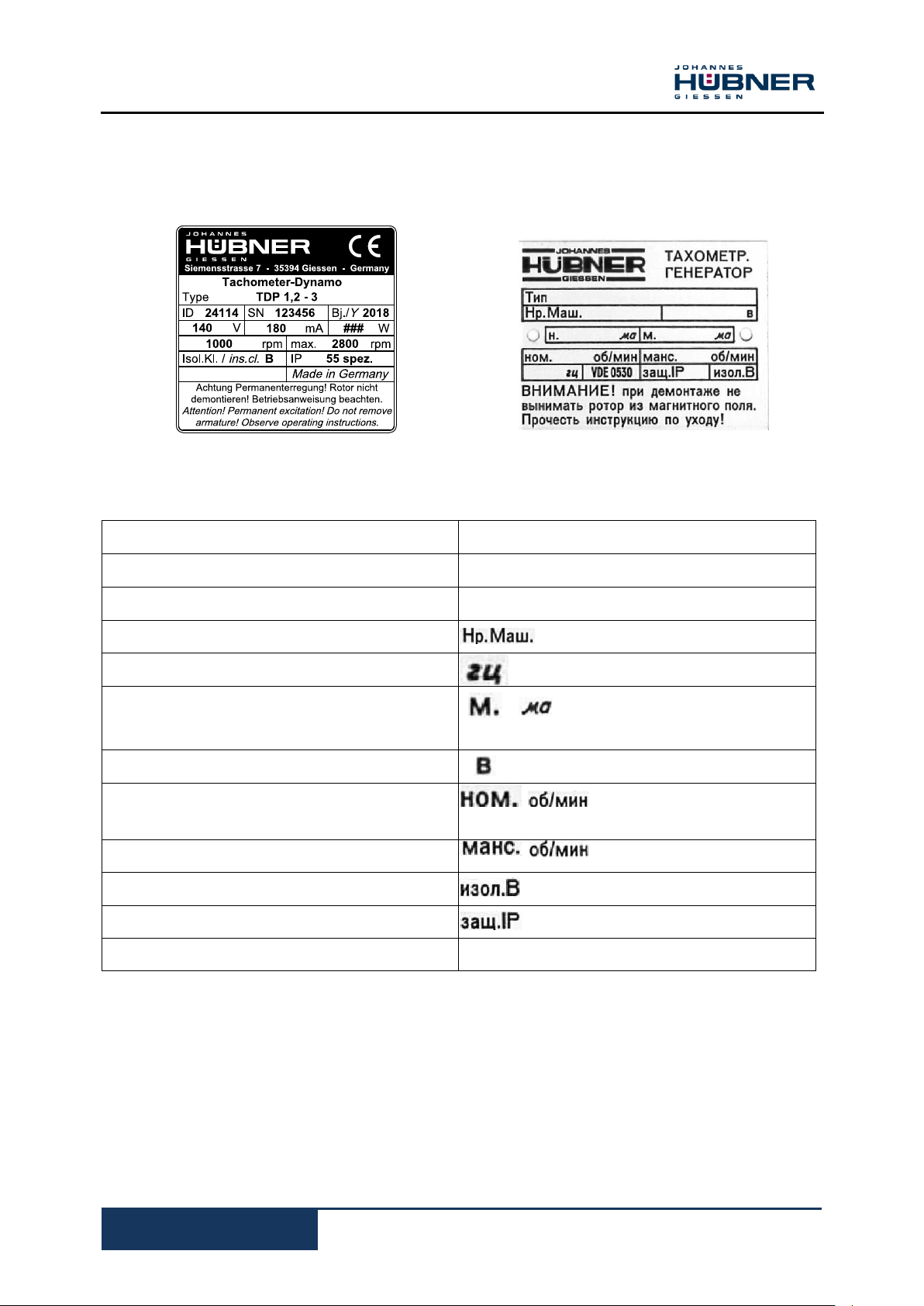

3 Technical Data

ENGLISH

RUSSIAN

Manufacturer, address

Manufacturer

CE mark

_

S/N = Serial number

= Serial number

Y = year of construction

= year of construction

[mA] = Maximum permissible current

= Maximum current [mA]

[W] = Rated power

= Rated voltage [V]

[rpm] = Rated speed

= nominal speed [rpm]

max. rpm = Maximum speed [rpm]

= Maximum speed [rpm]

Isol. Kl./ Cl = Isolation class

= Isolation class

IP = Degree of protection

= Degree of protection

ID = Artikel

Please note: The details on the nameplate apply exclusively to a purely resistive load. The details

differ for inductive or capacitive loads (please consult the manufacturer).

3.1 Type plate

The type plate is located on the side of the housing and contains the following information:

Electrical design to VDE 0530

D.C. tachometer generator TDP 1,2

10

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

TDP S 1,2 G N – 3 spez (Example)

+ FSE 102 overspeed switch

+ B16/3

+ FG 4 (FG 40)

Special version ( version different from normal)

Voltage version (Description 0,6 up to 14)

see tables preferred voltages/special voltages

page 13 – 18

Magnetic shunt ring

Galvanically and mechanically separate

Frame size

S-Short (short version)

L-Long (long version)

TDP = Tachometer - Dynamo – Permanent magnet

Optional

3.2 Type key

D.C. tachometer generator TDP 1,2

11

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Single tacho-generator

Type: TDP 1,2

TDPS 1,2

TDPL 1,2

- One magnet system

- One armature winding

- Voltage gradient TDP 1,2

20V up to 280V at 1000 rpm

TDPS 1,2

20V up to 200V at 1000 rpm

TDPL 1,2

45V up to 400V at 1000 rpm

Double tacho-generator

Type: TDP 1,2 + TDP 1,2

TDPS 1,2 + TDPS 1,2

- One magnet system

- Two galvanically separated armature winding

- Voltage gradient 20V up to 200V at 1000 rpm

Double tacho-generator

Type: TDPS 1,2 + TDPS 1,2 G

- Two magnet systems

- Two galvanically and mechanically separated

Armature windings

- Voltage gradient 20V up to 200V at 1000 rpm

Double tacho-generator

Type: TDP 1,2 + TDF 1,2

- One permanent magnet

- One separate magnet

- Two galvanically and mechanically

separated

Armature windings

Magnetic shunt

Type: TDP 1,2 N

TDPS 1,2 + TDPS 1,2 N

TDPS 1,2 + TDPS 1,2 GN

For the voltage adjustment of one system an additional magnet shunt ring can be installed in these tacho –

generators.

The voltage adjustment amounts to ± 15% referring to the nominal voltage and can be set during operation.

3.3 Type explanation

D.C. tachometer generator TDP 1,2

12

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Indication

Value

Unit

Weight

See chapter 13 dimension drawings /mechanical data

kg

Dimensions

See chapter 13 dimension drawings /mechanical data

mm

Open circuit voltage (DC)

See type plate on machine

V DC

Rated voltage with load (DC)

See type plate on machine

V DC

Maximum rated current

See type plate on machine

A DC

Machine-Temperature range

- 40 to + 100

°C

Maximum speed

See type plate on machine

rpm

3.4 Dimensions, Power consumption, Environment, Speed

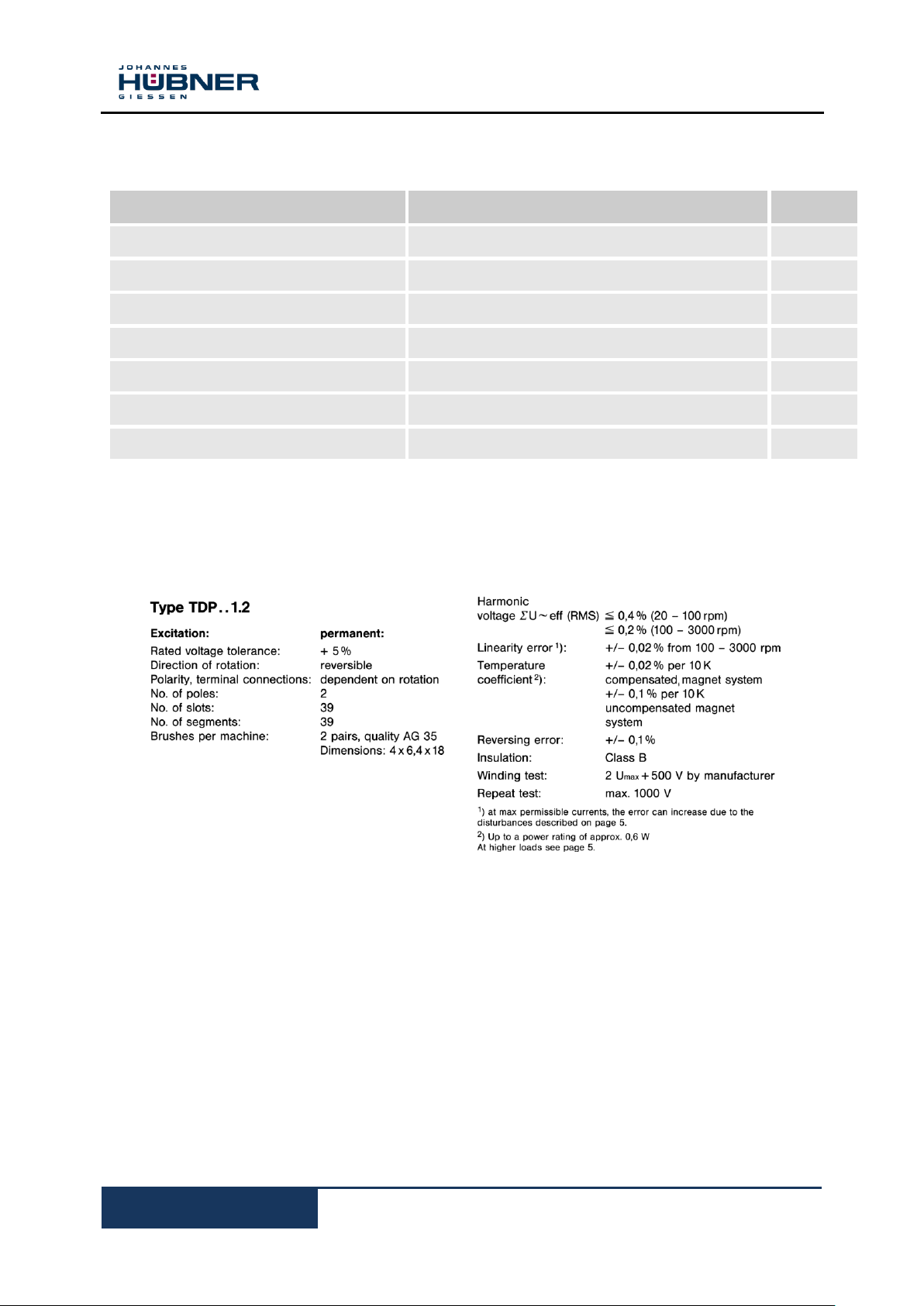

3.5 Elektrical and mechanical data

D.C. tachometer generator TDP 1,2

13

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Type

Rated voltage at

1000 rpm

[15W]

Max.

speed

Max. permissible

current

Optimum

load

resistance

Armature

resistance

at 20 0 C

approx.

No-load-

voltage

at

1000

rpm

[V]

[rpm]

[mA]

[kΩ]

[Ω]

[V]

TDPS 1,2- 1

200

2000

75

175

320

226

TDPS 1,2- 3

140

2800

107

83

178

158

TDPS 1,2- 5

100

4000

150

43

82

113

TDPS 1,2- 8

65

6000

230

17

30

73

TDPS 1,2- 12

30

6000

500

3,7

6,3

34

TDPS 1,2- 2

175

2300

86

135

221

198

TDPS 1,2- 4

115

3500

130

56

94

129

TDPS 1,2- 6

90

4400

167

36

58

101

TDPS 1,2- 7

75

5300

200

23

39

84

TDPS 1,2- 9

55

6000

273

14

23

62

TDPS 1,2- 10

45

6000

333

9

15

51

TDPS 1,2- 11

35

6000

428

5,5

8,8

40

TDPS 1,2- 13

25

6000

600

2,6

4,1

29

TDPS 1,2- 14

20

6000

750

2,1

2,5

23

Type TDPS 1,2

Rated power at 1000 rpm 15 W

Moment of inertia approx. 7 kgcm2

Breakaway torque approx. 12 Ncm

Weight approx. 8 kg

Preferred voltages

Special voltages

D.C. tachometer generator TDP 1,2

14

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Type

Rated voltage at

1000 rpm

[15W]

Max.

speed

Max. permissible

current

Optimum

load

resistance

Armature

resistance

at 20 0 C

approx.

No-load-

voltage

at

1000

rpm

[V]

[rpm]

[mA]

[kΩ]

[Ω]

[V]

TDP 1,2- 1

200

2000

125

96

255

220

TDP 1,2- 3

140

2800

180

42

114

154

TDP 1,2- 5

100

4000

250

24

52

110

TDP 1,2- 8

65

6000

385

9,5

21

72

TDP 1,2- 12

30

6000

830

1,8

5,1

33

TDPS 1,2- 0,8

280

1400

90

160

401

308

TDPS 1,2- 0,9

230

1700

110

110

285

253

TDPS 1,2- 2

175

2300

140

66

182

192

TDPS 1,2- 4

115

3500

220

28

75,5

126

TDPS 1,2- 6

90

4400

280

17

41

100

TDPS 1,2- 7

75

5300

333

11

31

82

TDPS 1,2- 9

55

6000

450

6,5

18,2

61

TDPS 1,2- 10

45

6000

550

4,2

12

50

TDPS 1,2- 11

35

6000

720

2,6

6,9

39

TDPS 1,2- 13

TDPS 1,2- 14

25

20

6000

6000

1000

1250

1,5

0,9

3,25

2,2

28

22

Type TDP 1,2

TDP 1,2 N

Rated power at 1000 rpm 25 W

Moment of inertia approx 8 kgcm2

Breakaway torque approx. 12 Ncm

Weight approx. 10 kg

Preferred voltages

Special voltages

D.C. tachometer generator TDP 1,2

15

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Type TDPL 1,2

Type

Rated voltage at

1000 rpm

[15W]

Max.

speed

Max. permissible

current

Optimum

load

resistance

Armature

resistance

at 20 0 C

approx.

No-load-

voltage

at

1000

rpm

[V]

[rpm]

[mA]

[kΩ]

[Ω]

[V]

TDPL 1,2- 0,6

400

1000

125

105

274

428

TDPL 1,2- 0,8

280

1400

180

61

151

299

TDPL 1,2- 1

200

2000

250

26,5

69

214

TDPL 1,2- 3

140

2800

355

15

38

150

TDPL 1,2- 5

100

4000

500

6,5

17

107

TDPL 1,2- 0,7

350

1140

145

99

240

374

TDPL 1,2- 0,9

230

1700

215

41

100

248

TDPL 1,2- 2

175

2300

285

24

52,4

187

TDPL 1,2- 4

115

3500

435

10,5

25

123

TDPL 1,2- 6

90

4400

555

6

15,3

96

TDPL 1,2- 7

75

5300

665

4,2

10

80

TDPL 1,2- 8

65

6000

770

3,7

7,1

70

TDPL 1,2- 9

55

6000

910

2,5

6,1

59

TDPL 1,2- 10

45

6000

1110

1,5

4,0

48

Rated power at 1000 rpm 50 W

Moment of inertia approx 14 kgcm2

Breakaway torque approx. 12 Ncm

Weight approx. 15 kg

Preferred voltages

Special voltages

D.C. tachometer generator TDP 1,2

16

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Type

Rated voltage at

1000 rpm

[2x12W]

Max.

speed

Max. permissible

current

Optimum

load

resistance

Armature

resistance

at 20 0 C

approx.

No-load-

voltage

at

1000

rpm

[V]

[rpm]

[mA]

[kΩ]

[Ω]

[V]

[V]

DE

NDE

TDPS 1,2 + TDPS 1,2-1

200

2000

60

175

350

320

220

TDPS 1,2 + TDPS 1,2-3

140

2800

86

83

167

153

154

TDPS 1,2 + TDPS 1,2-5

100

4000

120

43

86

73

110

TDPS 1,2 + TDPS 1,2-8

65

6000

185

17

34

29

72

TDPS 1,2 + TDPS 1,2-12

30

6000

400

3,7

7,4

6,7

33

TDPS 1,2 + TDPS 1,2-2

175

2300

68

135

270

246

192

TDPS 1,2 + TDPS 1,2-4

115

3500

104

56

112

102

126

TDPS 1,2 + TDPS 1,2-6

90

4400

133

36

72

65

100

TDPS 1,2 + TDPS 1,2-7

75

5300

160

23

47

42

82

TDPS 1,2 + TDPS 1,2-9

55

6000

218

14

28

25

61

TDPS 1,2 + TDPS 1,2-10

45

6000

267

9

18

16

50

TDPS 1,2 + TDPS 1,2-11

35

6000

343

5,5

11

10

39

TDPS 1,2 + TDPS 1,2-13

25

6000

480

2,6

5,2

4,7

28

TDPS 1,2 + TDPS 1,2-14

20

6000

600

2,1

4,2

3,8

22

Type TDPS 1,2 + TDPS 1,2

TDPS 1,2 + TDPS 1,2N

Rated power at 1000 rpm 2 x 12 W

Moment of inertia approx 8 kgcm2

Breakaway torque approx. 15 Ncm

Weight approx. 11 kg

Preferred voltages

Special voltages

The electrical data refer to one armature winding, two different voltage versions are available for each

machine.

D.C. tachometer generator TDP 1,2

17

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Type

Rated voltage at

1000 rpm

[2x25W]

Max.

speed

Max. permissible

current

Optimum

load

resistance

Armature

resistance

at 20 0 C

approx.

No-load-

voltage

at

1000

rpm

DE

NDE

[V]

[rpm]

[mA]

[kΩ]

[Ω]

[Ω]

[V]

TDP 1,2 + TDP 1,2-1

200

2000

125

67,5

169

154

220

TDP 1,2 + TDP 1,2-3

140

2800

180

33

82

77

154

TDP 1,2 + TDP 1,2-5

100

4000

250

18

38

35

110

TDP 1,2 + TDP 1,2-8

65

6000

385

8

15,5

14,3

72

TDP 1,2 + TDP 1,2-12

30

6000

830

2,3

3,7

3,4

33

TDP 1,2 + TDP 1,2-2

175

2300

140

55

133

122

192

TDP 1,2 + TDP 1,2-4

115

3500

220

23

55

51

126

TDP 1,2 + TDP 1,2-6

90

4400

280

13,5

30

27,6

100

TDP 1,2 + TDP 1,2-7

75

5300

333

11,5

22,5

20,7

82

TDP 1,2 + TDP 1,2-9

55

6000

450

5,5

13,3

12,2

61

TDP 1,2 + TDP 1,2-10

45

6000

550

3,7

8,7

8,0

50

TDP 1,2 + TDP 1,2-11

35

6000

720

2,7

5,0

4,6

39

TDP 1,2 + TDP 1,2-13

25

6000

1000

1,7

2,7

2,2

28

TDP 1,2 + TDP 1,2-14

20

6000

1250

1,0

1,6

1,5

22

Type TDP 1,2 + TDP 1,2

Rated power at 1000 rpm 2 x 25 W Moment of inertia approx 15 kgcm2

Breakaway torque approx. 15 Ncm

Weight approx. 16 kg

Preferred voltages

Shaft mounted constructions (overhung mountings) in B10 … construction speeds limited to max.

2500 rpm

Special voltages

The electrical data refer to one armature winding, two different voltage versions are available for each machine.

D.C. tachometer generator TDP 1,2

18

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Type

Rated voltage at

1000 rpm

[2x25W]

Max.

speed

Max. permissible

current

Optimum

load

resistance

Armature

resistance

at 20 0 C

approx.

No-load-

voltage

at

1000

rpm

DE

NDE

[V]

[1/min]

[mA]

[kΩ]

[Ω]

[Ω]

[V]

TDPS 1,2 + TDPS 1,2 G-1

200

2000

75

175

320

320

226

TDPS 1,2 + TDPS 1,2 G-3

140

2800

107

83

178

178

158

TDPS 1,2 + TDPS 1,2 G-5

100

4000

150

43

82

82

113

TDPS 1,2 + TDPS 1,2 G-8

65

6000

230

17

30

30

73

TDPS 1,2 + TDPS 1,2 G-12

30

6000

500

3,7

6,3

6,3

34

TDPS 1,2 + TDPS 1,2 G-2

175

2300

86

135

221

221

198

TDPS 1,2 + TDPS 1,2 G-4

115

3500

130

56

94

94

129

TDPS 1,2 + TDPS 1,2 G-6

90

4400

167

36

58

58

101

TDPS 1,2 + TDPS 1,2 G-7

75

5300

200

23

39

39

84

TDPS 1,2 + TDPS 1,2 G-9

55

6000

273

14

23

23

62

TDPS 1,2 + TDPS 1,2 G-10

45

6000

333

9

15

15

51

TDPS 1,2 + TDPS 1,2 G-11

35

6000

428

5,5

8,8

8,8

40

TDPS 1,2 + TDPS 1,2 G-13

25

6000

600

2,6

4,1

4,1

29

TDPS 1,2 + TDPS 1,2 G-14

20

6000

750

2,1

2,5

2,5

23

Type TDPS 1,2 + TDPS 1,2 G

TDPS 1,2 + TDPS 1,2 GN

Rated power at 1000 rpm 2 x 15 W Moment of inertia approx 15 kgcm2

Breakaway torque approx. 15 Ncm

Weight approx. 16 kg

Preferred voltages

Shaft mounted constructions (overhung mountings) in B10 … construction speeds limited to max.

2500 rpm

Special voltages

The electrical data refer to one armature winding, two different voltage versions are available for each machine.

D.C. tachometer generator TDP 1,2

19

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

3.6 General technical data, electric implementation

Magnet system design

The magnet system of these machines consists of two permanent block magnets, developed especially

for these machines and manufactured in AINi Co alloy.

The direction of magnetization is determined by the material's optimum direction of magnetization. In

order to guarantee operation free of ageing problems, the permanent magnets are aged artificially until

they reach optimum remanent energy density.

CAUTION!

Short circuits should be avoided because of their bad effect on the commutator; any burn

marks can give rise to additional harmonics.

Magnetization, external effects

The machines are magnetised when mounted via an external power source.

The magnetising field strength required to saturate the permanent magnets is about 4000A / cm

CAUTION!

After magnetization, the machine's magnetic circuit must not be interrupted, otherwise a

voltage drop of approx. 25 % occurs. It is vital to follow precisely the dismantling

instructions of the machine (please ask for special leaflet, see page 32).

Any effect on the tacho voltage due to magnetic or electrical field stray is largely prevented by

strongly formed machine yoke.

Insulation

The standard insulation complies with Insulation Class B (VDE 0530). Special insulation types can

be provided to enable the tacho to operate in the following conditions:

Insulation Class F (ambient temperature to max. 100 °C). See temperature coefficient.

Humid and tropical condition

Limited resistance to acid and alkaline fumes Winding test: max. 1000 V on repeat test.

D.C. tachometer generator TDP 1,2

20

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Voltage

The listed voltages are detailed in the technical tables for the different, available machine types.

Intermediate values and special voltages are possible (optional)

When values are lower than the listed voltages (<10 V) the listed power rating must be reduced to 1/50

(brush voltage drop). Use version G if voltage values below the listed values (<10 V) are required

when utilizing double tacho-generators.

Nominal voltage tolerance

The nominal voltage tolerance indicates the deviation of the set voltage from the nominal value. It is

obtained from the energy contents of the permanent magnets being used, which are also subject to

tolerance. This results in different values from machine to machine when setting the operating point.

The maximum tolerance is +5%. A tighter voltage tolerance ± 1% is possible.

Power available

The maximum available power given in the selection tables is always referred to the rated speed of

1000 rpm. Should this power be fully utilised, the user should note that the linearity error worsens

(approx. 0,5% at 1000 rpm). The maximum permissible current, which is given in the selection tables,

should not be exceeded at maximum permissible speed.

Connections, polarity

Connection: Single tacho to a 2-pole terminal board. Double tacho to two 2-pole terminal boards.

Terminal board bolt size M 4.

When rotation is clockwise, the machine (seen from DE) has terminal A 1 positive and terminal

A 2 negative polarity.

See page 29

Construction with 15 pin industry plug (optional).

Terminal box

1 terminal box for single tachos

2 terminal boxes for double tachos (Note: Double tacho with tapered shaft only, 1 terminal box).

Pg 11, cable Ø 7,5-9 mm

D.C. tachometer generator TDP 1,2

21

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

7

Maximum speed

The maximum speeds listed in the tables are restricted on the one hand by the max. permissible

segment voltage and on the other hand by the permissible peripheral speed. In special cases

appropriate design measures make it possible to exceed the maximum speeds listed in the tables. It

is possible that the maximum speed will have to be reduced when utilizing machines with built-in shaft

seals.

Reversing error

To obtain the same voltage values in both directions the carbon brushes are positioned in the

electrical "neutral zone". When reversing the tacho-generator voltage changes because the contact

surfaces of the brushes are practically never in the neutral zone. There are two causes for the change

in voltage, which results on the one hand from the distortion of the exciter field due to the reaction of

the armature when under load, and depends on the tilt of the brushes in the holder on the other. The

reversing error in the most unfavourable of circumstances is ± 0.5%.

Brushes, brushholder

The quality AG 35 (with 65% silver content) of the silver-graphite brushes guarantees long and

maintenance-free operation.

The combination of silver-graphite brushes with the commutator, which is also silver-plated, causes

a patina to form which ensures that the voltage drop due to contact resistance is very low and

remains nearly constant over a long period of operation. Useful brush life is highly dependent on

the ambient air conditions and the peripheral speed. Under normal operating conditions it is

approx. 20000 operating-hours.

In aggressive ambient air conditions the bakelitebound brush, Quality BG 62, has proved itself. It

does, however, have a higher contact resistance. If the commutator surface is smooth, the patina

should not be removed during regular machine maintenance.

The brush holders used are standard solid double type with a specific brush pressure of 3 N/cm2.

If the machine is likely to be exposed to heavy vibration and shock loads, it is recommended that the

brush holder has a relatively high specific brush pressure of approx. 6 N/cm2. Machines of protection

types IP 56/IP 55 spec. generally have a higher brush pressure.

D.C. tachometer generator TDP 1,2

22

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Rotational frequency

Pole frequency

Keyway frequency

Segment frequency

Temperature coefficient Temperature compensation

The temperature coefficient of the permanent magnets used is dependent on the material used and

is approx. +/- 0,10% per 10 degrees K of temperature change. This value applies to a temperature

range of approx. - 40°C to + 100 °C and is reversible.

The variation can be reduced by as much as 5 times by providing temperature compensation in the

form of soft magnetic material. If temperature compensation is required, this should be specified on

ordering (extra cost).

≙ Temperature error (due to change in resistance) [%]

≙ Temperature change [K]

≙ Armature resistance [Ω]

≙ Armature current [A]

≙ Load voltage [V]

The voltage drop measured between full load and no-load can also be utilized instead of the product

obtained by multiplying RA and IA. The temperature error stated in the tables was measured in the

laboratory whilst subject to a continual increase in temperature of approx. 20 K per hour. The error

can be higher if the rate of temperature increase is faster or the machine is subjected to radiated heat

on just one side. An optional version with temperature compensation is available. It is possible to

compensate the temperature course of the permanent magnet to a tolerance of ±0.2‰ per 10 K in

the temperature range 0 to 100 °C.

Harmonics

An essential characteristic of a good tacho voltage is one which, over a large speed range has a low

percentage harmonic content. In general, the RMS value of the total harmonic mix is measured by

thermionic voltmeter and referred to the D.C. voltage value. The harmonic voltage is approx. 0,2 %

at speeds between

100 and 3000 rpm. Machine harmonics result from the mechanical and electrical design and the

electrical utilisation, as well as production tolerances of symmetry.

Frequency analysis defines the following typical basic frequencies with their harmonics.

D.C. tachometer generator TDP 1,2

23

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Attachment harmonics, arising from coupling or fitting faults, influence the generator voltage because

Ub = Reference voltage

nb = Reference speed

Gb = Reference gradient

Um = Measured tacho voltage

nT = Tacho speed

Frel = relative linearity error

[‰]

they are superimposed on the machine harmonics. In general, two fitting faults occur: phase-angle

errors and parallel misalignment. The frequency of the resulting harmonics generated corresponds to

that occurring at twice a given speed (phase angle) or once that value (parallel misalignment). By

precise fitting of attachments it is possible to keep such harmonics relatively small.

Linearity

The usability of a tacho-generator in the broadest possible range of control applications is limited

by the linearity of the output voltage relative to speed.

Definition of the linearity error:

Every analysis of an error is relative, and for that reason depends on the method of measurement used

to determine the error. The quotient obtained from the deviation of the measured and the arithmetical

voltage calculated with the aid of the defined reference gradients at 1500 rpm and the reference voltage

at 1500 rpm is known as the linearity error.

D.C. tachometer generator TDP 1,2

24

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Description of the method of measurement used to determine linearity:

The tacho-generator to be tested is coupled to a prime mover fitted with a flywheel and operated

through a speed range of 100 to 3000 rpm. An incremental encoder (1000 pulses/rotation) is used to

measure the speed digitally to one decimal place. The tacho voltage is also measured digitally,

however, this is measured to three decimal places. A printer connected to both measuring devices

prints the voltage and speed. The measurements are taken at intervals of 100 rpm. At least 20

measured values are printed per measurement. The reference voltage at a speed of 1500 rpm is

selected as a reference point for all voltages and associated speeds.

The quotient obtained from the voltage at 1500 rpm and the speed of 1500 rpm is known as the

reference gradient. The voltages and speeds from 10 measured values respectively are

arithmetically averaged when evaluating the gradients and the gradient formed from these averaged

values.

Disturbance variables relative to linearity

Load current and armature reaction

If it is assumed that the speed-voltage curve at no load is a straight line at a particular angle, then

when load is applied (without taking account of armature reaction) the result is a straight line at a

less steep angle. The difference depends on

However, as the magnetic flux is distorted and weakened by the load current a further change

occurs to the voltage characteristic curve. The voltage drop resulting from the armature reaction

approximately follows the load current more or less according to a quadratic function and, therefore,

results in a slightly curved speed voltage curve when under load. Suitable design measures,

however, make it is possible to keep the field distortion caused by the armature reaction extremely

low. The max. permissible load current is provided for the respective machine type; however, the

linearity errors listed in the selection tables refer to the current resulting from termination with the

optimum load resistance. (Frel = 0.2‰, at max. permissible current 5‰.)

D.C. tachometer generator TDP 1,2

25

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Brush contact voltage

Silver-graphite brushes with very low contact voltage are mainly used for D.C. tacho-generators.

The total voltage drop at the sliding contact commutator is affected by peripheral speed, current

density under the brushes, brush pressure, and the condition of the patina on the brush contact face.

The load resistance should not be made too high.

The load resistance should be 200 to 1000 times the machine internal resistance in order to

guarantee the specified linearity.

Summary: it can be said that the load resistance must not exceed or fall below a set limit value if the

specified linearity error is to be maintained. If the terminal resistance is too low, then armature

reaction has an adverse effect on linearity; if it is too high the effects of the commutator can increase

the linearity error.

Special purpose machines

DC tacho-generator with separate exciter Type TDF 1,2

For special closed-loop control tasks it is imperative that the output voltage of a tacho-generator does

not change in proportion to the speed, but that it adheres to a certain mathematic function. For this

purpose it is possible to use separately excited DC tacho-generators, which operate in the nonsaturated range with the lowest possible remanent voltage. The output voltage is speed proportionate

when a constant excitation current is applied. However, if the excitation current is altered according to

the speed the output voltage depends on two variables, which makes it possible, for example, to

achieve a quadratic dependence between voltage and speed.

Technical data

Output power at 1000 rpm 10 W

Armature voltage user selectable between 20 and 200 V

Excitation voltage user selectable between 10 and 200 V

D.C. tachometer generator TDP 1,2

26

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Speed-voltage

curve of the

permanent

magnet DC

tacho

generator

Speed-voltage curve of

the separately excited

DC tacho-generator in

conjunction with speedproportional excitation

by the permanent

tachometer-generator

mounted on the same

shaft.

DC double-tacho-generator with permanent and separate excitation

Types TDP 1,2 + TDF 1,2

This is single-shaft machine comprising a permanent magnet tacho-generator and a separately

excited tacho-generator. The speed-proportional voltage of the permanent magnet machine is used to

excite the separately excited generator. As a consequence, the output voltage of the separately

excited tacho-generator changes with the speed according to a quadratic function. The voltage

characteristics are depicted in the diagrams below.

Technical data

Output power at 1000 rpm 10 W

Armature voltage user selectable between 20 and 200 V

D.C. tachometer generator TDP 1,2

27

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

4 Mechanical design

Construction types

To DIN EN 60 034-7; IEC 34-7 (replaces DIN 42950). Modified versions have an additional letter

added. (B 5 s, B 5 k, B 10 s, B 5 g ...).

The different construction types are shown in the dimension drawings. All flange construction types

can additionally be fitted with a foot (for example: B35...).

The use of strengthened spheroidal graphite iron is recommended when attachments are long and

heavy (specify when ordering).

All tachos can have a B 14 flange and 2nd shaft extension at the NDE (NDE end shield) (optional).

Construction reference example:

B 3/B 14 or B 14/B 14. The machines can also be mounted vertically, without modification. Tachos in

protection type IP 55 spec. may need a change of the air vent position.

Other construction types are available on request.

Degrees of protection:

Standard versions of the units meet the requirements of IP 55 to DINNDE 0530 part 5; IEC 34-5;

EN 60 034 part 5 for rotating electrical machines (replaces DIN 40050 sheet 2).

IP 55 - Fully enclosed. Protection against harmful dust deposits and against water spray from all

directions.

Special protection types - IP 56, IP 55 spec. are used where unfavourable environmental or ambient

conditions exist, such as: jet-water, temporary flooding,

oil mist, high humidity, heavy accumulations of dust (suitable for installation in open air), heavy

vibration and shock loads. Additionally, the machines are suitable for use in an extended temperature

range from - 40°C to + 100°C. The brush holders produce a relatively high brush pressure of

approximately 6 N/cm2.

The ball bearings, which have packing washers, also have a special grease for use in a temperature

range of - 60 °C to + 120 °C.

The shaft exit at the DE is sealed with an axial shaft sealing ring.

A condensation water drain hole is located at the NDE on the underside. The commutator can also be

cleaned and polished through this opening.

IP 56 - Totally enclosed, protected against damaging dust deposits and temporary flooding

IP 55 spec. - The special feature of this protection type is that the tacho - otherwise as IP 56 - has a

vent in addition.

An exchange of air between tacho interior and the environment can take place; the formation of

condensation is largely prevented or can leak out through the wire grid (wire gauze filter

approx. 0.2 x 0.2 mm). Please note that this vent on the underside of the tacho

should be located at the lowest point.

D.C. tachometer generator TDP 1,2

28

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Note must also be taken of the fitting position. See below for V-construction type vertical mounting

positions.

Vent plug and cover screw are interchangeable, depending on fitting position.

With flange construction type V1, V3, V18 and V19 on request.

2nd shaft extension exit complies with IP 55; higher degrees of protection are obtained only after

fitting the appropriate attachment or shaft cover.

Bearings

The sealed or covered deep-groove ball bearings 1) to DIN 625 are greased for life. They are greased

with lithium-based grease having a dropping point of 180°C, suitable for a temperature range of 60°C to + 120°C.

Fixed Bearing DE (drive end)

Floating Bearing NDE (non-drive end)

Shaft extensions

The tacho normally has 1 free shaft extension,Ø14 k6 x 30 with closed feather keyway to

DIN 6885 P 1. The feather key is also supplied.

In construction types B 10- and B 3-K 20 and ... K 32 a tapered shaft extension (taper 1 : 20) is

supplied having a fine thread. Self-locking hexagon nut which can be used several times is supplied

with the unit.

A cover screw at the NDE guarantees access to the tacho shaft (manual speed measurement).

Special shafts, of smaller diameter and different lengths can be supplied.

The 2nd shaft extension is normally Ø 14 K6 x 30 mm.

Shaft sealing

At DE all tachos can be fitted with a sealing ring 2).

1

) An axial shaft seal is normally fitted when protection is IP 56/IP 55 spec.

We recommend not to exceed speed ranges of approx. 4000 rpm.

2

) For arrangement details, see page 42

D.C. tachometer generator TDP 1,2

29

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

5 Design and function

Electrical connection:

Clockwise rotation: A1 terminal positive

A2 terminal negative

Winding test (repeat) max. 500 V

Suitable connection cable to maintain degree of protection

Fit cover plate and terminal box lid,

machine is ready for operations!

A1 (+) A2 (-)

5.1 Block diagram

Fig. 2: Block diagram clockwise rotation

5.2 Short description

The DC-Tacho-Generator TDP 1,2consists of a permanent magnet stator for excitation and a rotor from

which DC voltage is drawn via carbon brushes. The rotating rotor generates a DC voltage at a given

linear relationship in proportion to its speed.

5.3 Connections

The terminal box is fitted with cable glands. Suitable cables (Pg 11, cable Ø 7.5-9) are necessary to

maintain the degree of protection.

D.C. tachometer generator TDP 1,2

30

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

6 Transport, packaging and storage

6.1 Safety instructions for transport

CAUTION!

Improper transport can cause property damage!

Comply with the symbols and warnings on the packaging.

Handle with care

Protect from moisture

Protect from heat over 40°C and direct sunlight

Protect from moisture

Keep packed goods dry and protected against moisture.

Protect from heat

Protect packaged goods from heat over 40°C and direct sunlight.

6.2 Incoming goods inspection

Check delivery immediately upon receipt for completeness and possible transport damage.

Inform the forwarder directly on receipt of the goods about existing transport damages (prepare

pictures for evidence).

6.3 Packaging (disposal)

The packaging is not taken back and must be disposed of in accordance with the respective statutory

regulations and local guidelines.

6.4 Storage of packages (devices)

If stored for longer periods (> 6 months) we recommend sealing the devices in foil, possibly with a

desiccant.

D.C. tachometer generator TDP 1,2

31

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

7 Installation, commissioning and dismantling

7.1 Uses

DC-Tacho-Generators from the series TDP 1,2 are used to convert rotary motion (rpm) to DC voltage in

proportion to the rotating speed. These encoders are suitable for deployment with larger industrial

drives such as those used in steel and rolling mills, in coal mining operations, in process technology, in

railway systems, in power plants, in marine engineering and so on.

7.2 Place of installation

Installation height < 1000 m above msl. Consult the manufacturer if the installation height is >

1000 m (possible derating)

Permissible ambient temperature - 40 °C to + 100 °C.

Avoid too dry ambient conditions (ensure patina build-up on carbon brush/commutator).

Observe details on nameplate (ratings, protection class and so forth) when operating the DC

tacho-generator.

Do not attach or lean temperature sensitive components onto or against the machine; do not

position such components in the immediate vicinity of the machine.

Ensure sufficient space is available for maintenance work (please refer to 8.2 Inspection and

maintenance schedule)

We recommend installing a canopy for model designs and shaft ends facing downwards; fit a

cover on the plant side if the shaft end faces upwards.

The owner must ensure that no system resonance or vibration arise from interaction between

the machine and plant that could impair the functioning of the machine or result in damage to

the machine or the entire plant or accelerate the ageing process (of the bearings, for

example).

It is the owner's responsibility to undertake suitable measures at the place of installation that

ensure the devices and plant in their totality fulfil the relevant standards applicable to

electromagnetic compatibility.

D.C. tachometer generator TDP 1,2

32

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

7.3 Installation work

7.3.1 Installation and commissioning

Please note:

It is the owner's responsibility to ensure that all moving parts are properly safeguarded and ensure that

the machine is safe to operate!

Observe the max. permissible voltage when repeating the winding test (contact the manufacturer).

It is essential to prevent the ingress of oil or grease into the commutator area! Oil mist as well as

touching the carbon brushes with oily fingers will cause the carbon brushes to wear significantly; this

in turn will lead to the commutator becoming greasy and short-circuits between the segments.

1. Use a zero-play coupling. The armature must rotate easily; the carbon brushes must sit properly in

the brush holders.

2. Ensure precisely centred assembly. Angular misalignment and parallel displacement lead to

additional harmonics. Align added device referring to a harmonics oscillogram (<5‰). Fit and align

overhanging devices with due care and attention. Observe maximum permissible radial eccentricity

0.05 mm. Do not allow radial or axial forces to act on the tacho-generator shaft.

3. Secure machine using flange or foot.

Mount the machine securely without distortion and not subject to vibration. Securely fasten the feet or

flange using standard screws and washers in all of the through holes. It is important to ensure the

correct property class, size and length of engagement on the fastening side (in accordance with VDI

2230 Blatt 1) so that the entire system remains securely and reliably mounted under all operating

statuses. The thread engagement, its stability and strength on the fastening side must be guaranteed

at all times.

The screws must be tightened to the appropriate torque for the property class and thread; screws

must not become loose when the machine is in operation or at a standstill. Use a torque wrench.

Regularly check the fastening screws are seated correctly in accordance with the inspection and

maintenance schedule. Use only flexible couplings; align and adjust the tacho-generator exercising

due care and attention.

Fit coupling components or other fastenings with due care and attention. Support the opposite end of

the shaft (blows will damage the bearings).

If the second shaft is not used secure the key permanently to ensure it cannot be thrown out of the

keyway.

4. Connections in the terminal box.

Check the load against the technical data detailed on the nameplate. Please note: Take account of

surge protectors for downstream devices, if these are connected to the output voltage of the tachogenerator. The output voltage of the tacho-generator increases at a given (linear) relationship in

proportion to the speed.

Connect according to circuit diagram (see wiring diagram).

To guarantee a safe electrical connection the cross-section of the conductors must be sized

in accordance with the rated current as detailed on the nameplate.

Ensure any unused cable glands and the terminal box are sealed dust and water-tight

Create a safe earth connection!

D.C. tachometer generator TDP 1,2

33

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Before closing the terminal box you must ensure that

The connections have been terminated according to the wiring diagram.

All connections in the terminal box have been securely tightened.

All minimum clearance values have been maintained (greater than 8 mm up to 500 V,

greater than 10 mm up to 750 V)

The inside of the terminal box is clean.

Unused cable glands are sealed and the screw plugs including the seals are tightened

securely.

The gasket seal is clean and properly glued in the lid of the terminal box; ensure all

sealing surfaces are in a proper condition to guarantee the degree of protection.

The rating data match the data detailed on the nameplate.

5. Remove any transport locks before commissioning.

D.C. tachometer generator TDP 1,2

34

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

7.4 Dismantling

Observe and adhere to safety information (2)!

Shut down and ensure the machine cannot be restarted.

Turn off and isolate the power supply; turn off and isolate the power supply to any

additional or auxiliary circuits.

Ensure adjacent live components are insulated and safeguarded.

Examine components for damage and broken edges (for example risk of cuts from

broken off foot).

Exercise due care and attention when removing coupling parts and fastenings; support

the opposite end of the shaft (blows will damage the bearings). Coat the shaft with a thin

layer of oil and seal with screw cap. Ensure the terminal box and cable glands are

sealed dust and water-tight; ensure the degree of protection (see nameplate) is achieved

and guaranteed for transport.

Observe and adhere to transport information (6)!

Ensure that the packaging (carton + palette) used to transport the machine is correctly

sized and that the machine is secured by the packaging in such a manner that forces

resulting from the weight of the machine during transport cannot cause any damage to

the machine, to neighbouring parts or injury to personnel! Use transport locks to reduce

the load acting on the bearings.

Follow and observe the following dismantling instructions for armature exchange.

CAUTION!

Dismantling (disassembly / removing the armature) the fully assembled tacho-generator

TDP 1,2 must always be undertaken by the manufacturer only.

D.C. tachometer generator TDP 1,2

35

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

D.C. tachometer generator TDP 1,2

36

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Disturbance

Possible cause

Troubleshooting

Voltage to low

Wrong speed

Speed measurement control

Winding short

Voltage check Consulting

producer

Maximum permissible current is

exceeded

Reduce current.

Irrreversibler damage the

magnets (aging)

Magnets magnetize new

(consult manufacturer).

Voltage values at different

rotation unequal

Neutral zone adjusted.

Consulting producer

Bias excitation field by armature

reaction.

Consulting producer

Reversion, tilt the brush in the

holder.

Consulting producer

Harmonics

Burn marks on the commutator,

for example by short circuits.

Cause for short circuits and

repair

Coupling or assembly errors

(misalignment and parallel

misalignment).

Correct the mounting mistake

System-related vibrations and

resonance

Possible causes, contact the

manufacturer.

Rotor rotating hard

Armature short circuit, defective

storage

Decouple machine to look

again, a hard place?

Contact the manufacturer.

Grinding noise

Carbon brush holder from fallen.

Brush back into holder, avoid

strong vibrations.

Rotating parts sand.

Grinding cause notice.

If possible! Remove foreign

matter otherwise contact

manufacturers.

8 Disorders

8.1 Diagnosis Chart

D.C. tachometer generator TDP 1,2

37

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Bearing makes noise or is

jammed

Note:

Exchange of the bearings only

by the manufacturer.

Mounting error / clutch problem

Mounting precision check

Corroded bearings

Replace bearing by

manufacturer

Insufficient lubrication.

contact the manufacturer.

Too little/much bearing play.

Replace bearings

Contact the manufacturer

Grind marks in the bearing

track, scoring.

Replace bearings; contact the

manufacturer.

Bearing jammed or distorted

Check bearing bore

contact the manufacturer.

Seals rub

Replace seal.

Please contact the

manufacturer

Insufficient lubrication

Please contact the

manufacturer

Bearing corroded

Please contact the

manufacturer.

Too little bearing play

Please contact the

manufacturer

Coupling pushes or pulls

Re-align machine

Belt tensioned too tightly

Adjust belt pulley in line with

specifications.

Bearings jammed or distorted

Contact the manufacturer

Heavy vibration

Rotor imbalance, rotor not

round, shaft distorted

Please contact the

manufacturer

Incorrect alignment

Align set of machines; check

coupling.

Imbalance with the coupled

prime mover

Rebalance the coupled prime

mover

Shocks from coupled

prime mover

Check prime mover

Resonance in the foundations

Strengthen foundations

following consultation with the

manufacturer

Changes in the foundation

Following consultation with the

manufacturer determine the

cause, eliminate error and

realign the machine.

D.C. tachometer generator TDP 1,2

38

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Carbon brushes wearing

excessively

Brush contact resistance too

high – badly formed patina

(brush contact face commutator contact face) as a

result of the air being too dry.

Change condition of circulating

air

(remedy lack of moisture; avoid

dust in ambient air).

Brush pressure too high

Contact the manufacturer.

Grease on brush contact face

Clean contact face (contact the

manufacturer)

Heavy vibration

* See above.

Surface temperature too high

(>100 °C)

Operated under short-circuit

conditions

Check device; please contact

the manufacturer.

Other faults

Please contact the

manufacturer.

D.C. tachometer generator TDP 1,2

39

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

9 Recommended Inspections

Interval

Inspections

To be carried out by

Regularly

Check fastening screws are seated

correctly

Skilled personnel

After approx. 2000 operating

hours

Check carbon brushes; blow carbon

brush dust out of the machine using dry,

oil-free compressed air; check ease of

movement. When changing carbon

brushes (service life approx. 10 000 –

20 000 operating hours depending on

environmental conditions and speed)

ensure the new brushes are of the same

quality and type. Please note: Double

tacho-generators have 2 commutators

and 2 brush rockers).

Skilled personnel

After approx. 2000 operating

hours

Clean soiled commutators using a clean,

oil-free cloth. Do not remove smooth

patina build-up from contact face.

Remove grooves and polish surface

using fine Emery cloth or skim on lathe

(possibly recut and duburr slots).

Skilled personnel

The here described device is partly maintenance free. Nevertheless, following check is recommended

to guarantee an optimum and undisturbed operation.

9.1 Inspection and maintenance schedule

NOTES!

No other actions are required to be carried out on the device in addition to the following

cyclical inspections described in this inspection schedule. Any attempt to tamper with the

device will result in the warranty being declared null and void!

Caution! Replace the sealing ring on special versions (tacho-generators with speed increasing gear)

after 5000 to 8000 hours of operation. Blow out metal filter of tacho-generators designed with

ventilation vents (IP 55 spec.).

Combined units: Tacho + Pulse encoder, type: TDP 1,2 + FG 4.

The pre - set pulse encoder electronics must not be dismantled by the user. If the pulse encoder is

tampered with in any way, the guarantee is invalidated. Changes of bearing or armature must

therefore be carried out only at our works in Giessen.

Contact the manufacturer when operating any other special version and combinations of devices (e.g.

TDP 1,2 + FSE 102).

D.C. tachometer generator TDP 1,2

40

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Every 48 months

Check ball bearings for noise, running

smoothly. Service life approx. 20 000

hours (lubricated for life); however,

service life depends on speed,

environmental conditions and load.

Caution! Do not remove the armature

before short-circuiting the magnetic

circuit using an appropriate shortcircuiting ring (otherwise voltage drop of

approx. 25%). Observe dismantling

instructions!

Bearings must be replaced

by the manufacturer or a

certified workshop only.

Regularly (depending on degree

of soiling)

Cleaning:

Blow-clean the machine using dry, oil-

free compressed air. Do not use

cleaning agents that damage the

coating. Do not use inflammable

cleaning agents.

Skilled personnel

Regularly

Check coating.

If the protective coating is sufficiently

damaged, repaint to prevent risk of

corrosion (recommended).

Skilled personnel

If the machine has not been in

use for a long time (more than 6

months).

Check the insulation resistance of the

windings (greater approx. 1-5 megaohm). To measure the insulation

resistance disconnect all outgoing lines

from the generator. Contact the

manufacturer if the resistance reading is

less than 1 mega-ohm.

Skilled personnel

D.C. tachometer generator TDP 1,2

41

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Electrical connection:

Clockwise rotation: A1 terminal positive

A2 terminal negative

Winding test (repeat) max. 500 V

Suitable connection cable to maintain degree of protection

Fit cover plate and terminal box lid,

machine is ready for operations!

10 Disposal

The manufacturer is not obligated to take back electronics waste. The device consists of hybrid

components, and in part must be disposed of as special waste (electronic scrap) according to countryspecific legislation.

Local municipal authorities or specialized disposal companies provide information on environmentally

responsible disposal.

NOTES!

When ordering replacement parts always specify the serial number of the device!

List of spare parts see on page 42.

11 Annex

11.1 Connection diagram

TDP 1,2 ...

Clamping strip (Terminal box):

D.C. tachometer generator TDP 1,2

42

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

12 Spare parts

Spare parts are available on demand via the service address on page 2.

NOTES!

When ordering spare parts, always state the serial number of the device.

D.C. tachometer generator TDP 1,2

43

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

TDP 1,2

Construction type B5/B3

HM 83 M 53 023

13 Dimension drawings

D.C. tachometer generator TDP 1,2

44

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

D.C. tachometer generator TDP 1,2

45

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

D.C. tachometer generator TDP 1,2

46

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

B35 construction HM 83 M 53023

D.C. tachometer generator TDP 1,2

47

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

D.C. tachometer generator TDP 1,2

48

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Single- or double tacho with mounted coupling

Type: HKI 97-112-K 20/…

According to dimension drawing HM 80 M 51411

D.C. tachometer generator TDP 1,2

49

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

Single tachos

Single- or double tacho with mounted coupling

Type: HKI 97-112-K 20/…

According to dimension drawing HM 80 M 51411

D.C. tachometer generator TDP 1,2

50

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

B35 construction HM 83 M 53044

D.C. tachometer generator TDP 1,2

51

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

D.C. tachometer generator TDP 1,2

52

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

D.C. tachometer generator TDP 1,2

53

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

D.C. tachometer generator TDP 1,2

54

TDP1,2-MANUALen_R5(2018-12-19)ID74713 .doc

13.1 Screw tightening torques

Screws used to mount the machine (screw material, the material pairings to be fastened and the

length of thread engagement) are to be calculated to VDI 2230 (Page 1). The materials used and the

construction to which the generator is to be fastened must guarantee a permanently secure and

reliable joint. The owner is obliged to inspect and ensure compliance with all specifications.

Loading...

Loading...