Hubner FGH 40, K-2048G-90G-NG/20P, KK-2048G-90NG/20P, KK-2048G-90G-NG-S/20P, K-1024S-N/20P Operating And Assembly Instructions Manual

English

Operating and Assembly Instructions

Incremental Hollow-Shaft Encoder FGH 40

Read the Operating and Assembly Instructions prior to

assembly, starting installation and handling!

Keep for future reference!

Translation of the original Operating and Assembly Instructions FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

ID 74492

Incremental Hollow Shaft Encoder FGH 40

2

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

Trademark

Brand names and product names are trademarks or registered trademarks of their respective owner.

Protected trademarks bearing a ™ or ® symbol are not always depicted as such in the manual.

However, the statutory rights of the respective owners remain unaffected.

Manufacturer / publisher

Johannes Hubner

Fabrik elektrischer Maschinen GmbH

Siemensstraße 7

35394 Giessen

Germany

Phone: +49 641 7969 0

Fax: +49 641 73645

Internet: www.huebner-giessen.com

E-Mail: info@huebner-giessen.com

The manual has been drawn up with the utmost care and attention. Nevertheless, we cannot exclude

the possibility of errors in form and content. It is strictly forbidden to reproduce this publication or parts

of this publication in any form or by any means without the prior written permission of Johannes

Hubner Fabrik elektrischer Maschinen GmbH.

Subject to errors and changes due to technical improvements.

Copyright © Johannes Hubner

Fabrik elektrischer Maschinen GmbH

All rights reserved.

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

3

Directory

1 General ............................................................................................................................ 5

1.1 Information about the Operating and Assembly Instructions ....................................... 5

1.2 Scope of delivery ....................................................................................................... 5

1.3 Explanation of symbols .............................................................................................. 5

1.4 Disclaimer .................................................................................................................. 6

1.5 Copyright ................................................................................................................... 6

1.6 Guarantee terms ........................................................................................................ 6

1.7 Customer service ....................................................................................................... 6

2 Safety ............................................................................................................................... 6

2.1 Responsibility of the owner ........................................................................................ 6

2.2 Intended use .............................................................................................................. 6

2.3 Non- intended use ...................................................................................................... 7

2.4 Personnel ................................................................................................................... 7

2.5 Personal protective equipment ................................................................................... 7

2.6 Special dangers ......................................................................................................... 7

2.6.1 Electrical current .................................................................................................... 7

2.6.2 Rotating shaft / Hot surfaces ................................................................................. 7

2.6.3 Safeguarding against restart .................................................................................. 7

3 Technical Data ................................................................................................................ 8

3.1 Type plates ................................................................................................................ 8

3.2 Electrical and mechanical data ................................................................................... 9

3.2.1 For pulse rates (square wave pulses) .................................................................... 9

3.2.2 Output signals Sine / Cosine ................................................................................10

3.3 Type code .................................................................................................................14

3.3.1 For pulse rates (square wave pulses) ...................................................................14

3.3.2 For output signals Sine / Cosine ...........................................................................15

4 Transport, packaging and storage ...............................................................................16

4.1 Safety instructions for transport .................................................................................16

4.2 Incoming goods inspection ........................................................................................16

4.3 Packaging / disposal .................................................................................................16

4.4 Storage of packages (devices) ..................................................................................16

5 Installation and commissioning ....................................................................................17

5.1 Safety instructions .....................................................................................................17

5.2 Technical information ................................................................................................17

5.3 Required tools ................................................................................................ ...........17

5.4 Mounting preparations ..............................................................................................18

5.5 Mounting hollow-shaft type FGH 40 ..........................................................................18

5.6 Dismantling ...............................................................................................................20

5.6.1 Safety instruction ..................................................................................................20

Incremental Hollow Shaft Encoder FGH 40

4

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

5.6.2 Dismantling hollow- shaft type FGH 40 .................................................................20

5.7 Electrical connection and start up ..............................................................................21

5.7.1 Preparing cables ..................................................................................................21

5.7.2 Electrical connection .............................................................................................21

6 Faults ..............................................................................................................................23

6.1 Faults table ...............................................................................................................23

7 Inspections .....................................................................................................................24

7.1 Safety instructions .....................................................................................................24

7.2 Maintenance information ...........................................................................................24

7.3 Inspection schedule ..................................................................................................24

8 Disposal ..........................................................................................................................24

8.1 Disposal procedure ...................................................................................................24

9 Spare Parts .....................................................................................................................24

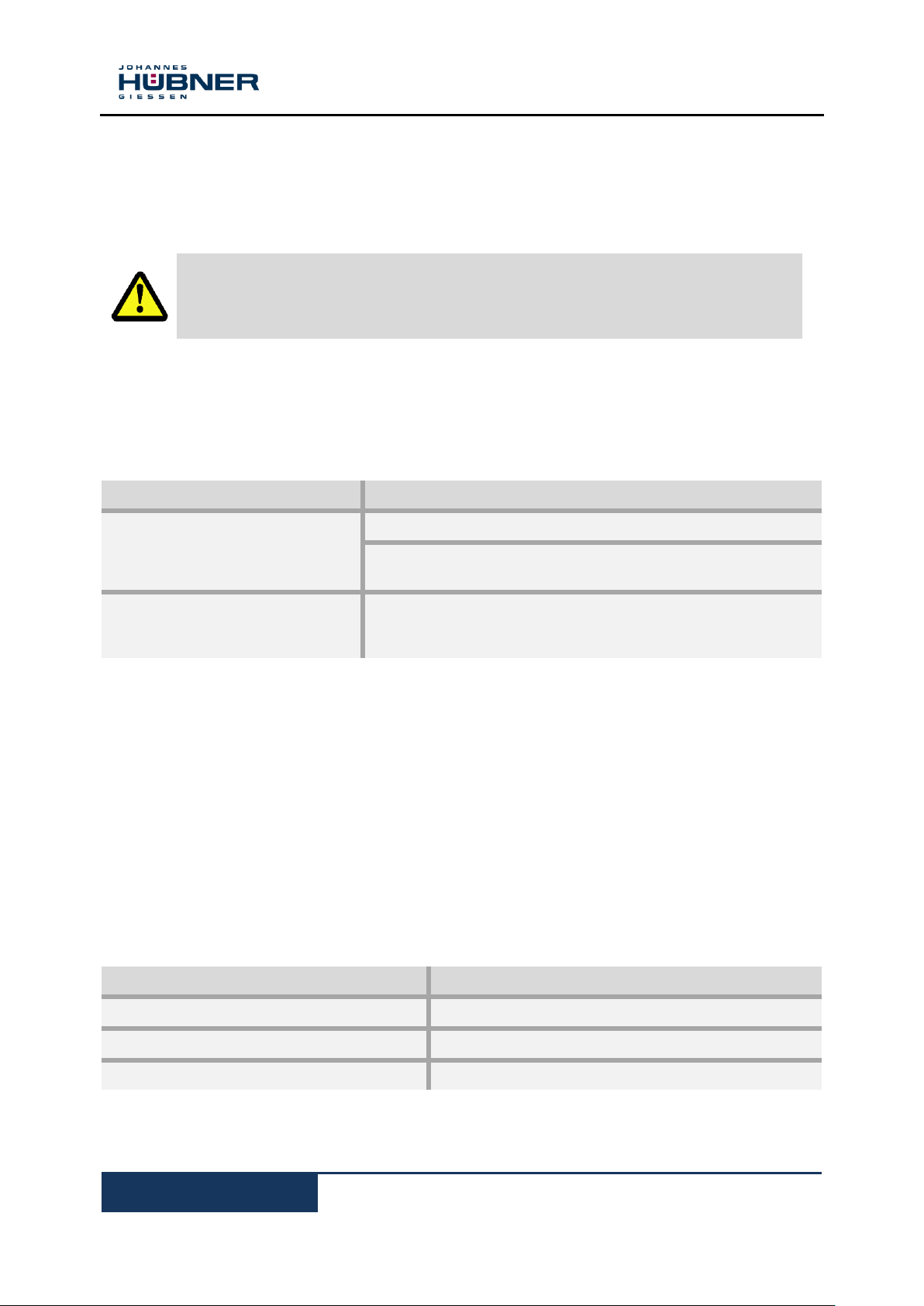

10 Dimension drawings ......................................................................................................25

10.1 Construction type hollow- shaft .................................................................................25

11 Connection diagrams ....................................................................................................32

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

5

WARNING!

Indicates a possibly dangerous situation that can result in death or serious injury if it is

not avoided.

CAUTION!

Indicates a possibly dangerous situation that can result in minor injury if it is not

avoided.

CAUTION!

Indicates a possibly dangerous situation that can result in material damage if it is not

avoided.

NOTES!

Indicates useful tips and recommendations as well as information for efficient and

trouble-free operation.

NOTES!

Do not use a hammer or similar tool when installing the device due to the risk of damage

occurring to the bearings or coupling!

DANGER!

Life-threatening danger due to electric shock!

Indicates a life-threatening situation due to electric shock. If the safety instructions are

not complied with there is danger of serious injury or death. The work that must be

executed should only be performed by a qualified electrician.

1 General

1.1 Information about the Operating and Assembly Instructions

These Operating and Assembly Instructions provide important instructions for working with the device.

They must be carefully read prior to starting all tasks, and the instructions contained herein must be

followed.

In addition, applicable local regulations for the prevention of industrial accidents and general safety

regulations must be complied with.

1.2 Scope of delivery

Incremental Hollow-Shaft Encoder FGH 40, Operating and Assembly Instructions.

1.3 Explanation of symbols

Warnings are indicated by symbols in these Operating and Assembly Instructions. The warnings are

introduced by signal words that express the scope of the hazard.

The warnings must be strictly heeded; you must act prudently to prevent accidents, personal injury,

and property damage.

Incremental Hollow Shaft Encoder FGH 40

6

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

NOTES!

Content information, text, drawings, graphics, and other representations are protected

by copyright and are subject to commercial property rights.

It is strictly forbidden to make copies of any kind or by any means for any purpose other

than in conjunction with using the device without the prior written agreement of the

manufacturer. Any copyright infringements will be prosecuted.

DANGER!

This section provides an overview of all the important safety aspects that ensure

protection of personnel, as well as safe and trouble-free device operation.

If these safety instructions are not complied with significant hazard can occur.

1.4 Disclaimer

All information and instructions in these Operating and Assembly Instructions have been provided

under due consideration of applicable guidelines, as well as our many years of experience.

The manufacturer assumes no liability for damages due to:

Failure to follow the instructions in the Operating and Assembly Instructions

Non-intended use

Deployment of untrained personnel

Opening of the device or conversions of the device

In all other aspects the obligations agreed in the delivery contract as well as the delivery conditions of

the manufacturer apply.

1.5 Copyright

1.6 Guarantee terms

The guarantee terms are provided in the manufacturer’s terms and conditions.

1.7 Customer service

For technical information personnel is available that can be contacted by telephone, fax or email. See

manufacturer’s address on page 2.

2 Safety

2.1 Responsibility of the owner

The device is used in commercial applications. Consequently the owner of the device is subject to the

legal occupational safety obligations and subject to the safety, accident prevention and environmental

protection regulations that are applicable for the device’s area of implementation.

2.2 Intended use

The device has been designed and constructed exclusively for the intended use described here.

Series FGH 40 Incremental Hollow- Shaft Encoders are used for measurement of rotations, for

instance of electrical and mechanical drives and shafts.

Claims of any type due to damage arising from non-intended use are excluded; the owner bears sole

responsibility for non-intended use.

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

7

DANGER!

Life-threatening danger due to electrical shock!

There is an imminent life-threatening hazard if live parts are touched. Damage to

insulation or to specific components can pose a life-threatening hazard.

Therefore:

Immediately switch off the device and have it repaired if there is damage to the

insulation of the power supply.

De-energize the electrical equipment and ensure that all components are connected for

all tasks on the electrical equipment.

Keep moisture away from live parts. Moisture can cause short circuits.

WARNING!

Danger of injury due to rotating shafts and hot surfaces!

Touching rotating shafts can cause serious injuries.

Therefore:

Do not reach into moving parts/shafts or handle moving parts/shafts during operation.

Close to protect from injury all access openings in flanges with the corresponding plug

screw, and provided you exposed rotating components with protective covers.

Do not open covers during operation. Prior to opening the covers ensure that all parts

have come to a standstill.

The encoder can become hot during prolonged use.

In case of contact risk of burns is existing.

DANGER!

Life-threatening danger if restarted without authorization!

When correcting faults there is danger of the power supply being switched on without

authorization.

This poses a life-threatening hazard for persons in the danger zone.

Therefore:

Prior to starting work, switch off the system and safeguard it from being switched on

again.

2.3 Non- intended use

Do not use the device in potentially explosive areas.

The device must not be subjected to mechanical loads in addition to its own weight and

unavoidable vibration and shock loads that arise during normal operations.

Examples for non-permitted mechanical loads (incomplete list):

- Fastening transport or lifting tackle to the device, for example a crane hook to lift a motor.

- Fastening packaging components to the device, for example ratchet straps, tarpaulins etc.

- Using the device as a step, for example by people to climb onto a motor.

2.4 Personnel

Installation and commissioning as well as disassembly routines must be carried out by skilled technical staff only.

2.5 Personal protective equipment

Wear personal protective equipment such as safety shoes and safety clothing to minimise risks to

health and safety when carrying out work such as installation, disassembly or commissioning. Adhere

to all applicable statutory regulations as well as the rules and standards determined by the owner.

2.6 Special dangers

Residual risks that have been determined based on a risk assessment are cited below.

2.6.1 Electrical current

2.6.2 Rotating shaft / Hot surfaces

2.6.3 Safeguarding against restart

Incremental Hollow Shaft Encoder FGH 40

8

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

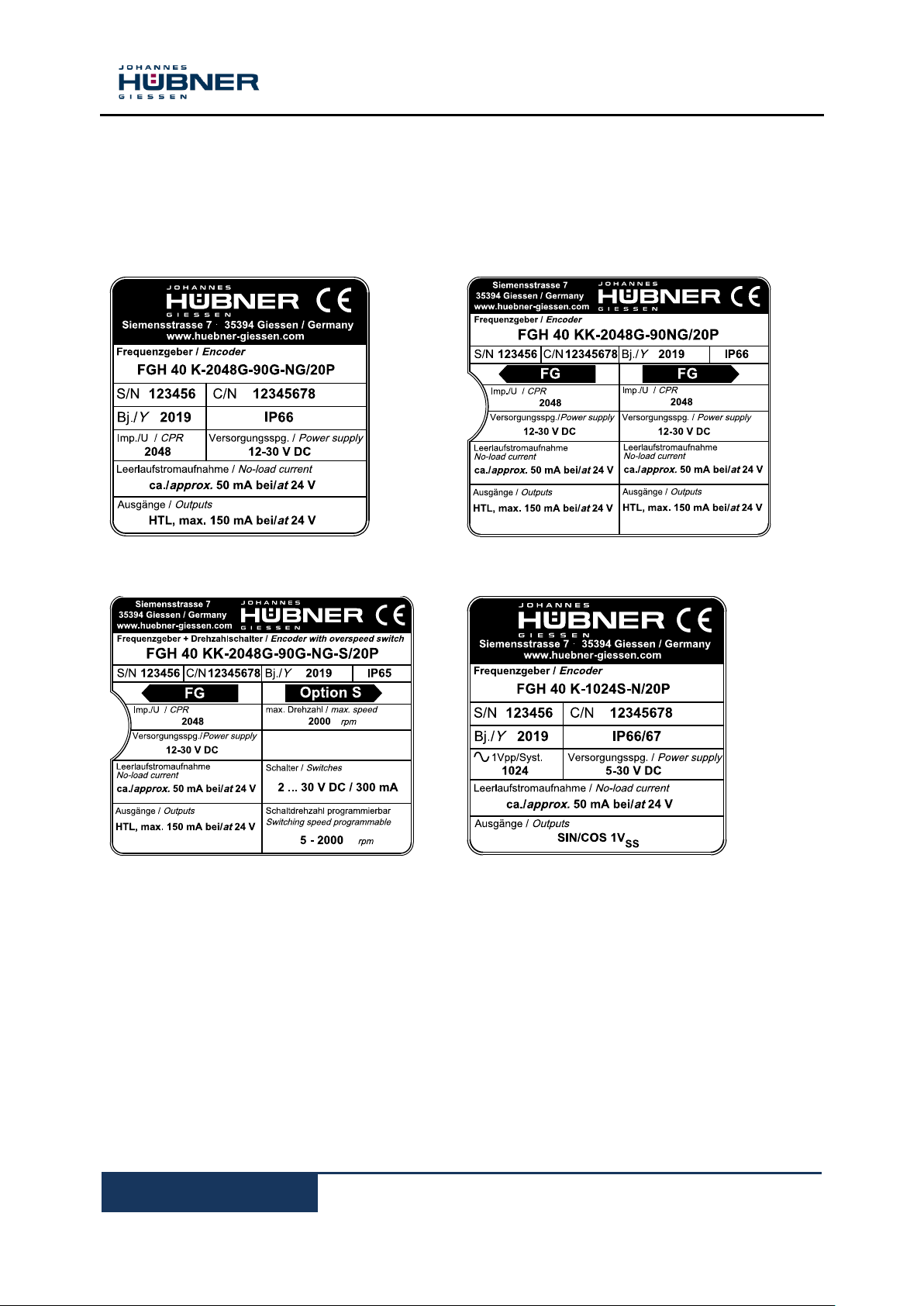

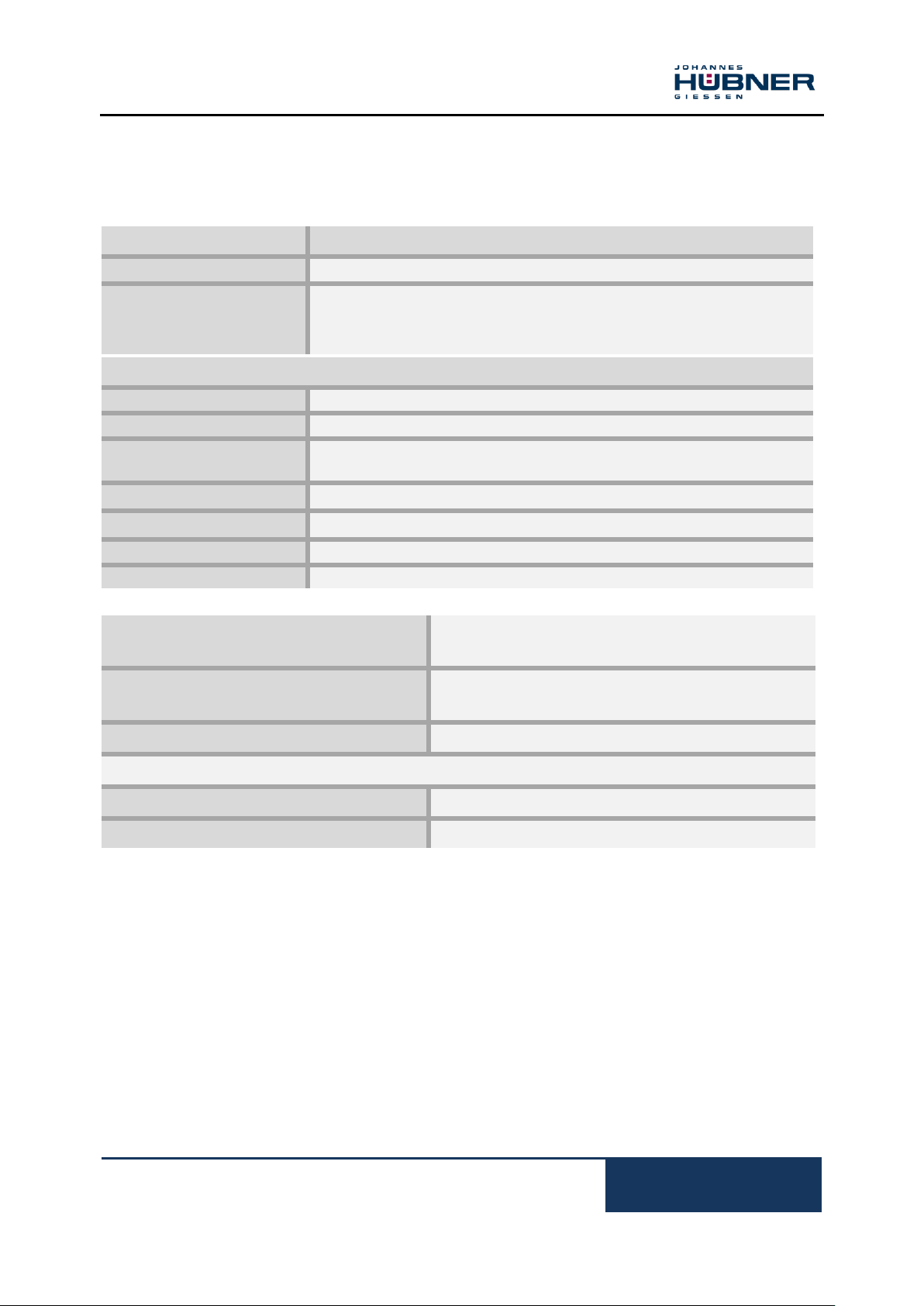

Encoder with 1 terminal box

Encoders with 2 terminal boxes (redundant version)

Encoder with integrated option S

Encoder with 2 sinusoidal signals

3 Technical Data

3.1 Type plates

Below are some Example nameplates for different device models shown.

Type plates are located on the outside of the housing and contains the following information:

Manufacturer, Address

Type

CE marking

Serial number (S/N)

Commission number (C/N)

Year of construction

Pulse rate

Protection class

Power supply

No-load current

Outputs

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

9

Pulse rates

Value

Standard pulse rates

500, 600, 1000, 1024, 1200, 2000, 2048, 2400, 2500

Special pulse rates

4000, 4096, 4800, 5000, 8192, 10000, 12000, 16000, 16384, 20000,

25000, 40000, 50000

(further pulse rates according to customers specification)

Connection data

Supply voltage

12 V … 30 V DC

No load-current

approx. 50 mA at 24 V

Outputs

Current limited, short-circuit proof push-pull line driver with integrated

impedance adaptation for 30 to 140 Ω lines.

Pulse height (HTL)

approx. as supply voltage, output saturation voltage < 0.4 V at IL 30 mA

Output current

max. 150 mA at 24 V (observe derating)

Internal resistance

75 Ω bei 24 V

Slew rate

200 V / µs with CL 100 pF

Duty cycle

1 : 1 ± 3 % for standard pulse rates

1 : 1 ± 5 % for special pulse rates up to 25000 pulses

Square wave displacement 0°, 90°

90° ± 3 % for standard pulse rates

90° ± 5 % or special pulse rates up to 25000 pulses

Max. frequency

200 kHz, Higher max. frequency on request

Special output voltage 5V (TTL)

Pulse height

5V, RS422-compatible (TIA/EIA-Standard)

Supply voltage

12 … 30 V DC (optional: 5 V DC),

3.2 Electrical and mechanical data

3.2.1 For pulse rates (square wave pulses)

Incremental Hollow Shaft Encoder FGH 40

10

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

Pulse rates

Value

Standard pulse rates

500, 600, 1000, 1024, 1200, 2000, 2048, 2400, 2500

Connection data

Supply voltage

5 V … 30 V DC

No load-current

Approx. 120 mA at 5 V, approx. 50 mA at 24 V

Max. frequency

200 kHz, higher max. frequency on request

Output signals

2 sinusoidal signals A and B each with inverted signals

Reference pulse with inverted signal

Signal amplitude 1 V pp / RL = 120 Ω

Error signal and inverted signal

Signal amplitude 5V

Resolution

1024 signal periodes

Duty cycle

1 ± 0,1

Phase shift A, B

90° ± 1°

3.2.2 Output signals Sine / Cosine

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

11

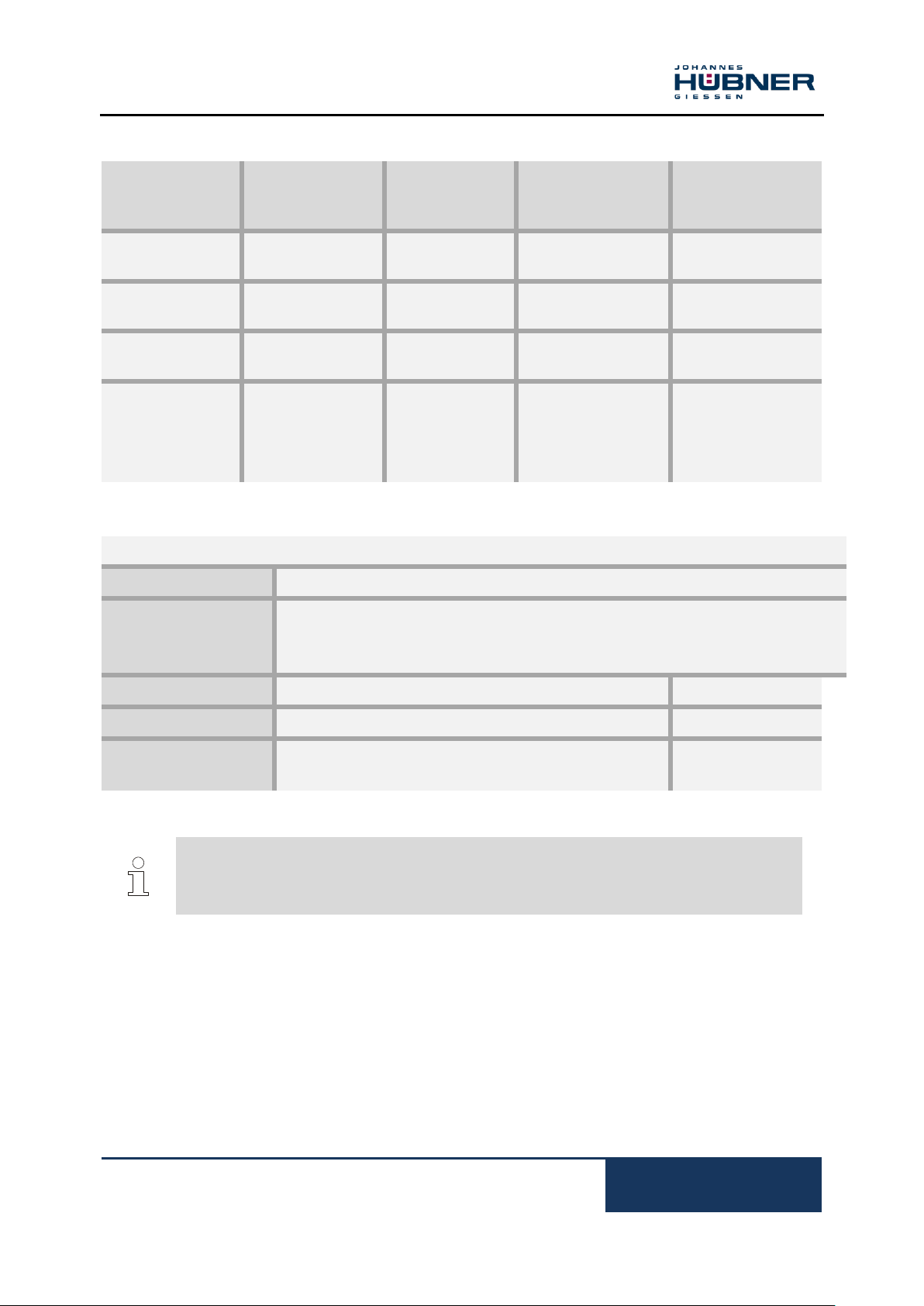

Protection class

acc. to

DIN EN 60529

Sealing

Permissible

speed

Rotor moment of

inertia

Breakaway torque

IP 65

Standard

≤ 4000 rpm

(*) ≤ 3000 rpm

approx. 1175 gcm²

approx. 10 Ncm

IP 66

with labyrinth seal

≤ 4000 rpm

(*) ≤ 3000 rpm

approx. 1325 gcm²

approx. 10 Ncm

IP 66

with axial shaft

seal

≤ 2000 rpm

(*) ≤ 2000 rpm

approx. 1175 gcm²

approx. 25 Ncm

IP 66

with radial shaft

seal (for special

applications, e.g.

wet areas in

rolling mills)

≤ 2000 rpm

(*) ≤ 2000 rpm

approx. 1175 gcm²

approx. 30 Ncm

Encoder temperature range

Standard

0°C… + 70°C

Special temperature

-25°C… + 85°C

-40°C… + 85°C

-5°C… + 100°C

Vibration resistance

DIN EN 60068-2-6 / IEC 68-2-6 (10 … 2000 Hz)

20 g (=200 m/s²)

Shock resistance

DIN EN 60068-2-27 / IEC 68-2-27 (6 ms)

150 g (=1500 m/s²)

Weight

Type FGH 40 K

Type FGH 40 KK

approx. 4,2 kg

approx. 4,5 kg

NOTES!

The hollow shaft device FGH 40 reduces the degree of protection to IP 65, if the cover

plate is not mounted. At maximum speed the permissible ambient temperature will be

reduced to 60°C.

(*) with isolated bearings – hybrid bearings –

Incremental Hollow Shaft Encoder FGH 40

12

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

Signal outputs for pulse rates (square wave pulses)

Basic version

Basic channel 0° (A) and pulse channel 90° (B)

Internal system diagnostics with error

output (ERROR)

Each with inverted signals

Option N

Reference pulse (N) mechanically defined; one

square-wave pulse per revolution; with inverted

signal

Option 2F

Twice as many pulses as basic channel by

combining the 0° and 90°channels

Option B

Rapid direction of rotation detection at each edge

of the 0° and 90°channels

Can be combined with Option F

Option B2

Rapid direction of rotation detection at each edge

of the 0° and 90° channels; additional standstill

recognition

Option B3

Rotation-dependent output signals. This option

supports counter cards with separate UP/DOWN

pulse inputs. Basic channel signals are issued at

option output 1 when rotation is clockwise and at

option output 2 when rotation is counterclockwise.

Option S

Electronic overspeed switch with two

independently programmable switching points

See separate Operating and Assembly

Instructions EGS® 40

Fiber optic option

As an alternative to conventional signal

transmissions via copper cables encoder signals

can also be transmitted via fiberoptic cables.

Max. frequency 100 kHz

N

N

The signal sequence 0°, 90° applies for clockwise rotation seen from the drive shaft direction.

To obtain the same signal sequence for counter clockwise rotation the clamp 0°, 90° has to be

connected see connection diagram.

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

13

Signal outputs for output signals sine / cosine

Basic channel 0° (A) and pulse

channel 90° (B).

Reference pulse (N) mechanically

defined; one square-wave pulse per

revolution; with inverted signal

Each with inverted signal.

Internal system diagnostics with error

output (ERROR).

Incremental Hollow Shaft Encoder FGH 40

14

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

FGH

J

40 K 1024

G

90G

NG

2F S /20P

Incremental

hollow-shaft encoder

Isolated bearings

Series

connections, radial design

K: Terminal box

R: Burndy®-plug

C: Connection cable

L: Fiber optic connection

S: 15-pole EMC industrial plug

KK: 2 terminal boxes, i.e. redundant

version or with option S

further combined connections available

Pulses per revolution

Basic signal output

Basic channel 0° (A)

Pulse channel 90° (B)

Each with inverted signals

NG: Option reference pulse with inverted signal

N2: Reference pulse, mechanically fixed with LED

check (red)

for display of reference pulse

2F: Option 2F

B: Option B

B2: Option B2

B3: Option B3

S: Option S

Inner diameter

(by hollow shaft design)

20 P (standard) P: feather key

16 P, 19P, (optional)

16 K, 25 K (optional K: clamping

3.3 Type code

3.3.1 For pulse rates (square wave pulses)

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

15

FGH

J

40 K 1024

S

N

/20P

Incremental

hollow-shaft encoder

Isolated bearings

Series

connections, radial design

K: Terminal box

R: Burndy®-plug

C: Connection cable

S: 15-pole EMC industrial plug

KK: 2 terminal boxes, i.e. redundant

version

Resolution

1024 signal periodes per revolution

Output signals

2 sinusoidal signals A and B each with inverted signals

NG: Option reference pulse with inverted signal

Inner diameter

(by hollow shaft design)

20 P (standard) P: feather key

16 P, 19P, (optional)

16 K, 25 K (optional K: clamping

3.3.2 For output signals Sine / Cosine

Incremental Hollow Shaft Encoder FGH 40

16

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

CAUTION!

Material damage caused by improper transport!

Observe the symbols and information on the packaging:

Do not throw - risk of breakage

Keep dry

Do not expose to heat above 40 °C or direct sunlight.

Keep dry

Keep packages dry and free from dust; protect from moisture.

Protect against heat

Protect packages from heat above 40 °C and direct sunlight.

NOTES!

Turn the shaft of the device every 6 month to prevent the bearing grease solidifying!

4 Transport, packaging and storage

4.1 Safety instructions for transport

4.2 Incoming goods inspection

Check delivery immediately upon receipt for completeness and possible transport damage.

Inform the forwarder directly on receipt of the goods about existing transport damages (prepare

pictures for evidence).

4.3 Packaging / disposal

The packaging is not taken back and must be disposed of in accordance with the respective statutory

regulations and local guidelines.

4.4 Storage of packages (devices)

If you intend to store the device for a longer period of time (> 6 months) we recommend you use

protective packaging (with desiccant).

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

17

NOTES!

Observe the safety instructions contained in Chapter 2 when installing or working on the

device!

NOTES!

Do not use a hammer or similar tool when installing the device due to the risk of damage

occurring to the bearings or coupling!

5 Installation and commissioning

5.1 Safety instructions

Personnel

Installation and commissioning must be carried out by skilled technical staff only.

5.2 Technical information

Ambient temperature

The max. permissible ambient temperature depends on the speed and degree of protection of the

device, the signal frequency, the length of the signal cable and the place of installation (please refer to

Chapter 3.2).

Degree of protection

To fulfil degree of protection requirements the diameter of the connection cable must correspond to

that of the cable gland (please refer to Chapter 10 Dimension drawings)!

Deep groove ball bearings

FGH 40 incremental hollow- shaft encoders are fitted with maintenance-free, greased "for-life" deep

groove bearings. Bearings must be changed by the manufacturer only. Opening the encoder renders

the guarantee null and void.

Screw retention

We recommend using Loctite® 243 thread locker (medium strength) on all fastening screws to prevent

loosening.

5.3 Required tools

Spanners: 10 mm, 14 mm, 22 mm, 24 mm

Allen keys: 5 mm

Flat-blade screwdrivers:

Assembly grease

Loctite® 243 (medium strength thread locker)

Incremental Hollow Shaft Encoder FGH 40

18

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

NOTES!

Fastening screws and earth cable are not included in the range of supply.

NOTES!

The maximum radial run-out of the adapter shaft is 0.05 mm.

If necessary, use the ball thrust adjustment screw to align the adapter shaft. Secure ball

thrust screws with Loctite® 243. Remove unused ball thrust screws or secure with

Loctite® 243. Max. tightening torque for M12 approx. 25 Nm, for M16 approx. 35 Nm.

Use parallel keys to DIN 6885.

Please also observe the supplement data sheet Mounting accuracy for hollow shaft

encoders.

You should also observe the Installation instructions supplied with the adapter shaft

when installing!

1 8 2

3

12

7

6

13

10

15

14

5

4

9

11

Figure.1

5.4 Mounting preparations

1. Ensure all accessories are available (please refer to Chapter 10 Dimension drawings).

2. Preparing the place of attachment: Clean the (motor) shaft, centering, bolting surfaces and

fastening threads; check for damage. Repair any damage!

5.5 Mounting hollow-shaft type FGH 40

1. Mount adapter shaft (1) and align using dial gauge.

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

19

NOTES!

When fitting to the device is possible to align the torque bracket in four different

directions. If possible fit the device in a manner that ensures the cable gland points

downwards! Exchange the position of the cable gland (12) and the blanking plug on the

opposite side, if necessary.

NOTES!

The axial tensioning disc is supplied with several hexagon head socket cap screws of

different lengths. To select the suitable hexagon head socket cap screw please refer to

the dimensioning drawings in Chapter 10.

The hexagon head socket cap screws are coated with a microencapsulated adhesive as

locking agent.

NOTES!

Once fitted the link rod must rotate easily around the link rod heads! Failure to observe

this point may result in damage to the bearings!

NOTES!

The link heads are maintenance free. However, ensure they remain free from soiling

and paint!

2. Lightly grease the adapter shaft.

3. Secure the torque bracket (3) to the hollow-shaft device (13) with 4 tensilock screws (2).

4. Mount the hollow-shaft device to the adapter shaft.

5. Secure the hollow-shaft device with the aid of the axial tensioning disc (6) and a hexagon socket

head cap screw (7).

6. Fit the cover (14) and secure with four countersunk screws (15) to seal the hollow-shaft device.

7. Fastening the torque bracket:

Fastening without base plate:

Secure the link rod head (11) of the link rod (8) to a fixed point (for example on the motor

housing).

Fastening with base plate:

Secure the base plate (9) to a fixed point with two hexagon head screws (10) – (for example on

the motor housing or the foundations).

Incremental Hollow Shaft Encoder FGH 40

20

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

WARNING!

Observe the safety instructions contained in Chapter 2 when dismantling the device!

NOTES!

Do not use a hammer or similar tool when installing the device due to the risk of damage

occurring to the bearings or coupling!

NOTES!

Use the withdrawal device D-53663a (available as an accessory) if you are unable to

remove the device manually from the adapter shaft after having removed the axial

tensioning disc)!

Special tool Withdrawal device D-53663a

Using the withdrawal device, which is screwed into the withdrawal thread M25 x 0.75 of

the hollow shaft allows you to remove the overspeed switch from the adapter shaft

without risking damage to the bearings.

5.6 Dismantling

5.6.1 Safety instruction

Personnel

Dismantling must be carried out by skilled technical staff only.

5.6.2 Dismantling hollow- shaft type FGH 40

Disconnect all electrical cable prior to beginning any work.

To dismantling the encoder follow the instructions given in Chapter 5.5 in the reverse order.

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

21

NOTES!

You must observe applicable EMC guidelines when routing cables!

CAUTION!

Do not allow moisture to enter the terminal box when the cover is open!

NOTES!

The signal cable shielding can be connected directly to the housing via the EMC cable

gland. A coil spring intergrated in the cable gland ensures all-round contact is made with

the bare cable shielding to ensure a good shield connection. This type fo shield

connection should be preferred.

Alternatively, if equipotential boning currents are anticipated it is possible to connect the

cable shielding to a shield terminal in the terminal box. A capacitor between the shield

terminal and the encoder housing prevents the flow of equalizing current.

To achieve an effective shielding the cable shield must also be connected in the

electrical cabinet.

NOTES!

Prior to delivery cable glands and blanking plugs are tightened finger tight only. To

ensure that the terminal box is reliably sealed tighten all cable glands and blanking plugs

before starting up for the first time.

5.7 Electrical connection and start up

5.7.1 Preparing cables

1. Strip cable insulation.

2. Crimp wire-end ferrules.

5.7.2 Electrical connection

1. Open the terminal box cover (16).

2. Remove the cap of the cable gland (12, Fig.1).

3. Feed the cable into the terminal box trough the cable gland.

4. Tighten the cable gland and blanking plugs using a spanner.

5. Use a spanner to tighten the cable gland until the cable is securely clamped and properly sealed.

Incremental Hollow Shaft Encoder FGH 40

22

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

NOTES!

Prevent lateral pulling forces acting on the cable and plugs so as not to impair the

degree of protection of the cable gland.

CAUTION!

Do not apply supply voltage to the signal outputs, as this will destroy the device!

NOTES!

To achieve a good shielding effect the cable shield be kept as short as possible.

NOTES!

Before closing the terminal box cover check and if necessary clean both seal surfaces

and the gasket.

CAUTION!

Ensure when closing the terminal box cover that no cable becomes jammed.

6. Connect the supply voltage and signal cable (please refer to the connection diagrams, Chapter 11).

7. Applicable to alternative shield connection only: fit cable lug to cable shield and connect to the

shield terminal (please refer to the connection diagrams, Chapter 11).

8. Close the terminal box cover.

9.Secure earth cable to earth terminal.

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

23

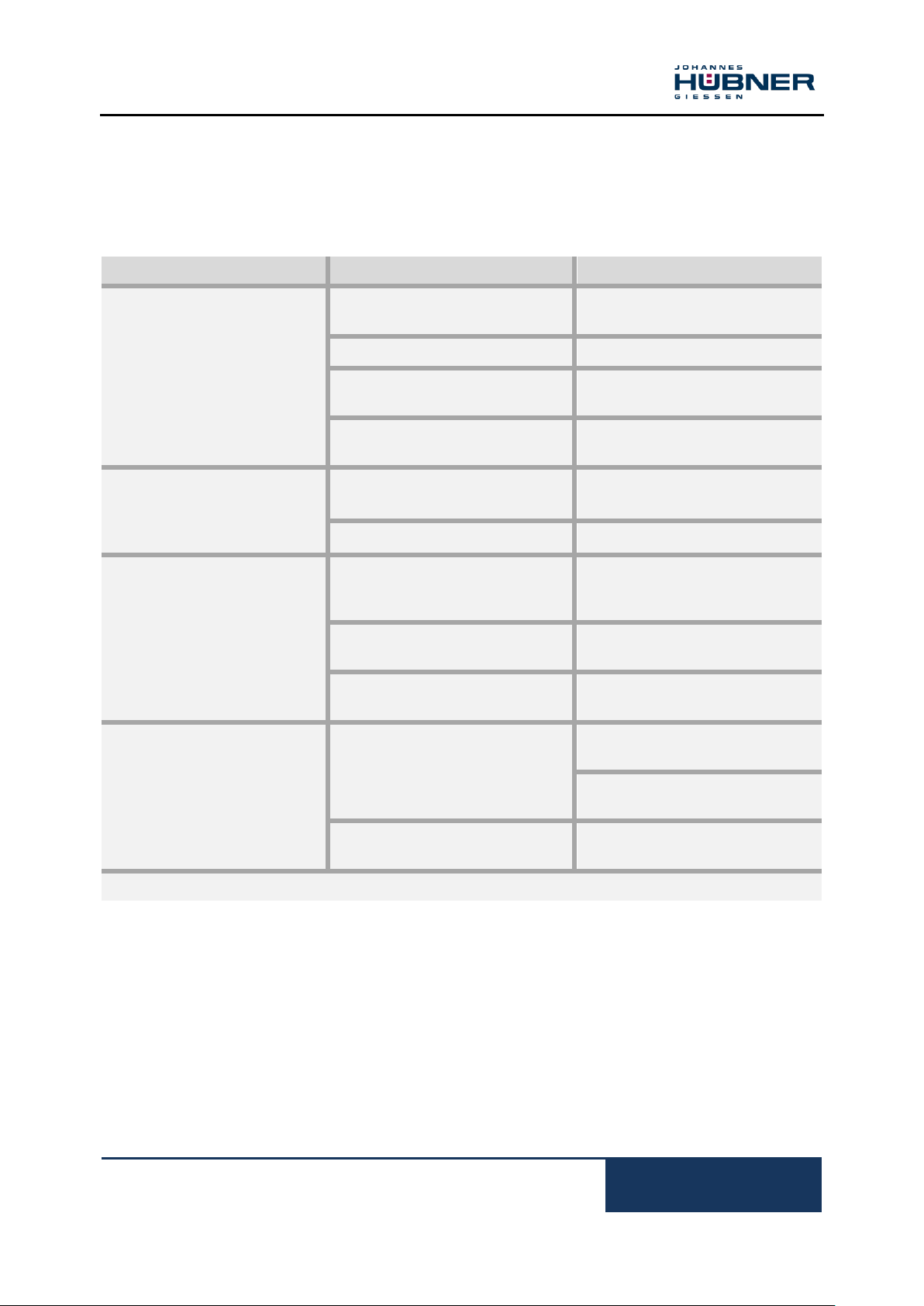

Faults

Possible cause

Remedy

Moisture in the terminal box

Soiled terminal box gasket or

seal surfaces

Clean terminal box gasket and

seal surfaces

Damaged terminal box gasket

Replace terminal box gasket

Cable gland/blanking plug not

tightened

Tighten cable gland/blanking

plug

Unsuitable cable for cable gland

Use suitable cable and cable

glands

No output signals

Supply voltage not connected

Connect supply voltage

Connection cable reversed

Wire correctly

Output signals subject to

interference

Unsuitable cable

Use data cable with conductors

arranged as twisted pairs and

common shield

Cable shield not connected

Connect cable shield at both

ends

Cable routing not EMC compliant

Observe applicable EMC

guidelines when routing cables

Signal interruptions

Signal end stage overloaded

Check pin assignment; observe

connection diagram

Do not assign unused outputs

Outputs short-circuited

Do not connect outputs with

supply voltage or GND

Contact Hubner-Service (page 2) if none of the remedies listed above provides a solution)!

6 Faults

6.1 Faults table

Incremental Hollow Shaft Encoder FGH 40

24

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

WARNING!

Skilled technical staff only are permitted to inspect the device and its installation.

Observe the safety instructions contained in Chapter 2 when inspecting or working on

the device!

Interval

Inspections

Yearly

Ensure the fastening screws are properly tightened

Ensure cable connections and connection terminals are

securely seated

Following approx 16 000 … 20 000

hours of operation / higher levels of

continuous load

Check deep groove ball bearings are running smoothly and

listen for running noises

Spare part

Remark

Cover

Cover of the hollow- shaft bore (non drive end)

Cable gland

M20 x 1,5

Terminal box cover

Incl. Sealing and screws

7 Inspections

7.1 Safety instructions

7.2 Maintenance information

The device is maintenance-free. However, to guarantee optimum fault-free operations we recommend

that you carry out the following inspections.

7.3 Inspection schedule

8 Disposal

8.1 Disposal procedure

The manufacturer is not obliged to take back the device.

The device is classed as electronic equipment and subject to the WEEE Directive; observe local,

country-specific laws when disposing of the device.

For information on environmentally sound disposal please contact your local authority or a specialist

disposal company.

9 Spare Parts

The in the following listed spare parts can be covered when required about the service address on the

page 2.

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

25

FGH 40 K../20 P Gew

Hollow- Shaft Ø 20, length of

customer shaft max. 83 mm

HM 09 M 102530

10 Dimension drawings

Further dimension drawings on our website or on request.

10.1 Construction type hollow- shaft

Incremental Hollow Shaft Encoder FGH 40

26

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

FGH 40 KK../20 P Gew

Hollow- Shaft Ø 20, length of

customer shaft max. 83 mm

HM 09 M 102531

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

27

FGH 40 KK../20 P Gew

Option S

Redundant version or with

integrated option S

HM 10 M 103037

Incremental Hollow Shaft Encoder FGH 40

28

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

FGH 40 K

Assembly with torque bracket

HM 09 M 102203

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

29

FGH 40 K

Assembly with torque bracket

HM 10 M 101771

Incremental Hollow Shaft Encoder FGH 40

30

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

FGH 40 L/LL

additional dimension drawing

electric connection implementation FGH 40 L/LL

fiber optic

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

31

FGH 40 S/SS

additional dimension drawing

electric connection implementation FG 40 S/SS

15 pole EMC

HM 12 M 105755

Incremental Hollow Shaft Encoder FGH 40

32

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

FGH 40

Standard

Terminal box

FGH 40

Standard without reference pulse

Terminal box

11 Connection diagrams

Shielding:

The shield of the signal cable can be

connected

directly to the housing of the encoder by the

cable gland. Alternatively the shield of the

signal cable can be connected to K11 via a

capacitor(10nF / 500V) to the housing of the

encoder.

10 pole printed circuit spring terminal block

type Phoenix ZFKDS

Connection data:

wire section

0,2-1,5 [mm²]

Alternative Shielding

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

33

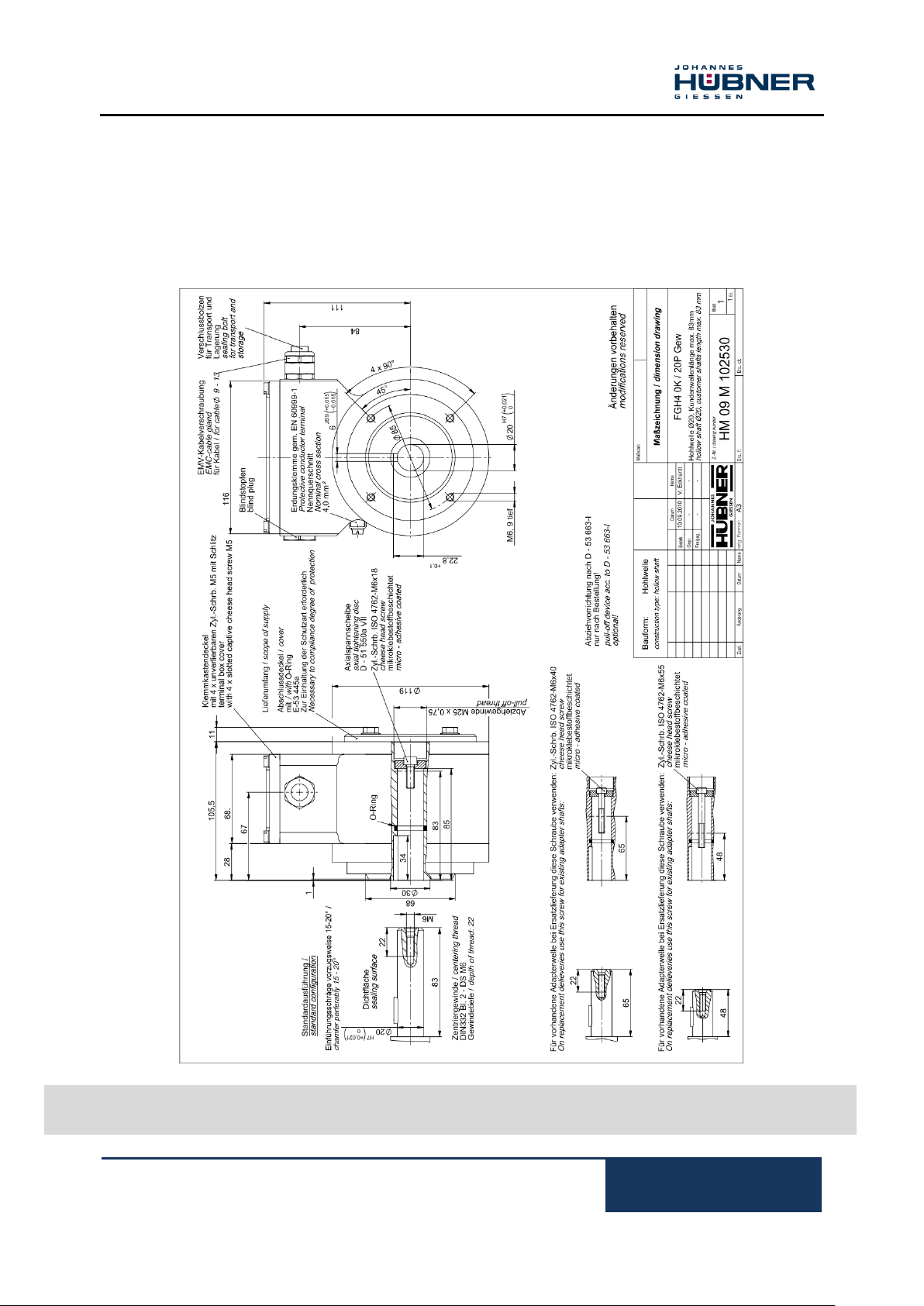

Socket insert view

Shield:

The shield of the signal cable is

directly to be connected with the

socket housing.

Crimping tool: Burndy® No. MR 8 GE 5

FGH 40

Standard

Burndy® plug

Connection cable

6x2x0,56 twin-standard, shielded

Type: HE-2LVCC-CY AWG 20b

acc. to VDE 0881

Cross-section: 0,56 mm²

Temperature: -20 °C to + 105 °C

Outside dia: 10,1 mm

shield is connected to casing

other cables- / temperature ranges

on request

FGH 40

Standard

Connection cable

Crimp contacts for

cross-sectional

data of wire from

0,52 up to 1,5 mm²

Incremental Hollow Shaft Encoder FGH 40

34

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

FGH 40

Option F2

Terminal box

FGH 40

Option B

Terminal box

12 pole printed circuit spring terminal block type

Phoenix ZFKDS

Connection data:

Wire section

0,2-1,5 [ mm² ]

Shielding:

The shield of the signal cable can be connected

directly to the housing of the encoder by the

cable gland. Alternatively the shield of the cable

can be connected to K13 via a capacitor (10nF /

500V) to the housing of the encoder.

Alternative Shielding

10 pole printed circuit spring terminal block

type Phoenix ZFKDS

Connection data:

Wire section

0,2-1,5 [ mm² ]

Shielding:

The shield of the signal cable can be connected

directly to the housing of the encoder by the

cable gland. Alternatively the shield of the cable

can be connected to K13 via a capacitor (10nF /

500V) to the housing of the encoder.

Alternative Shielding

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

35

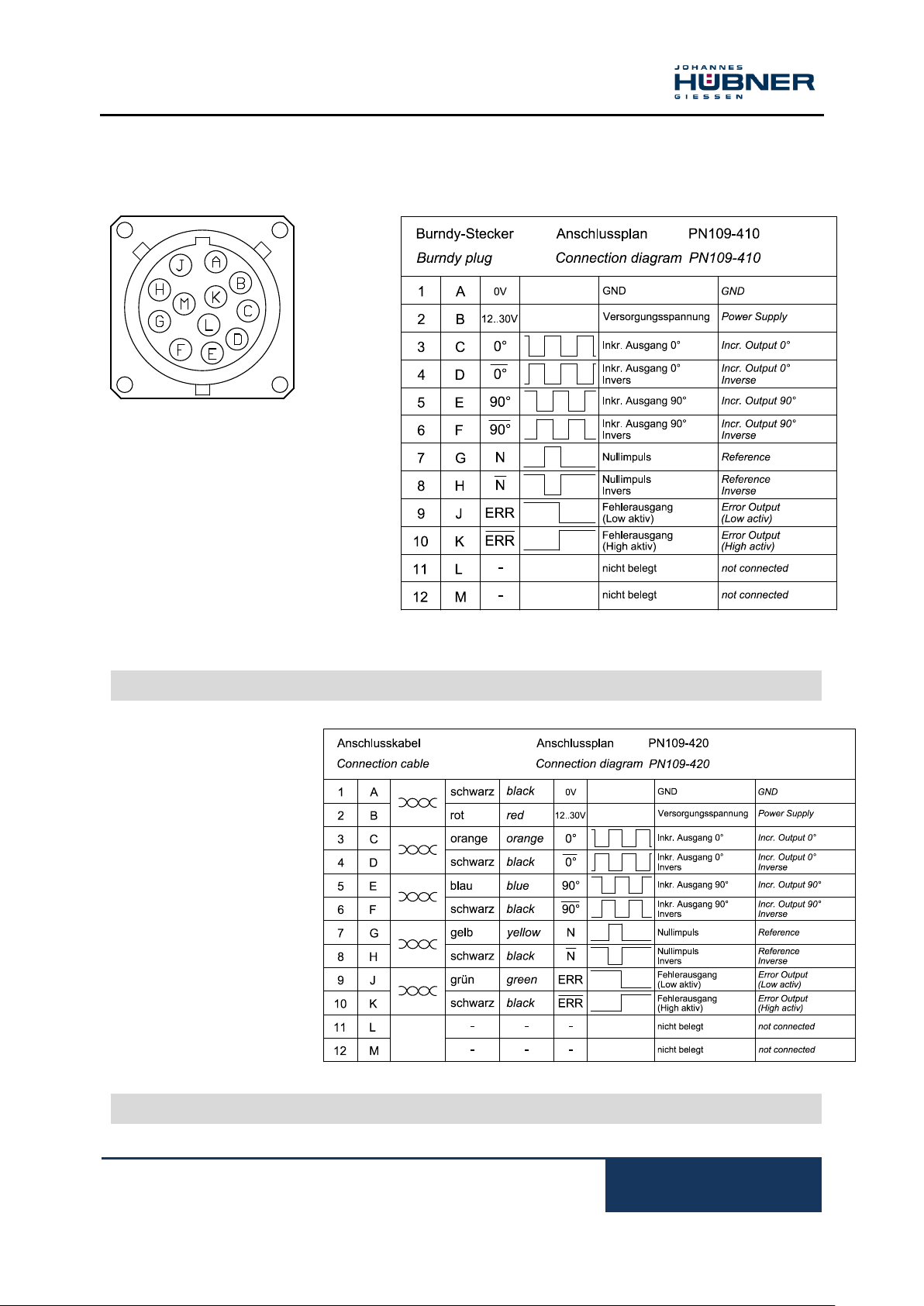

FGH 40

Option B2

Terminal box

FGH 40

Option B3

Terminal box

12 pole printed circuit spring terminal block type

Phoenix ZFKDS

Connection data:

Wire section

0,2-1,5 [ mm² ]

Shielding:

The shield of the signal cable can be connected

directly to the housing of the encoder by the

cable gland. Alternatively the shield of the cable

can be connected to K13 via a capacitor (10nF /

500V) to the housing of the encoder.

Alternative Shielding

10 pole printed circuit spring terminal block type

Phoenix ZFKDS

Connection data:

Wire section

0,2-1,5 [ mm² ]

Shielding:

The shield of the signal cable can be connected

directly to the housing of the encoder by the

cable gland. Alternatively the shield of the cable

can be connected to K13 via a capacitor (10nF /

500V) to the housing of the encoder.

Alternative Shielding

Incremental Hollow Shaft Encoder FGH 40

36

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

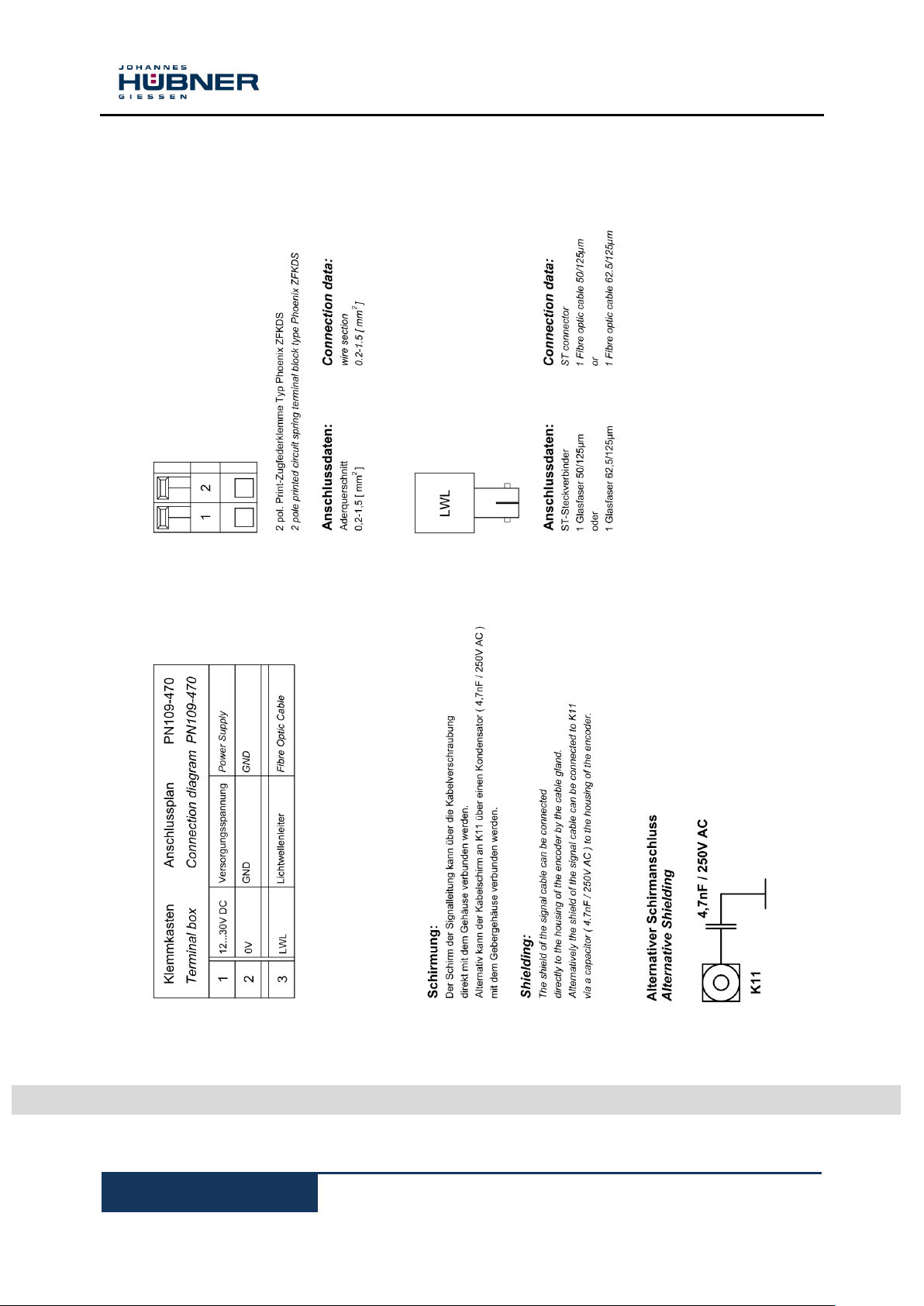

FGH 40

Connection sheme PN 109-470

Terminal box

Inkrementaler Hohlwellen Drehgeber FGH 40

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

37

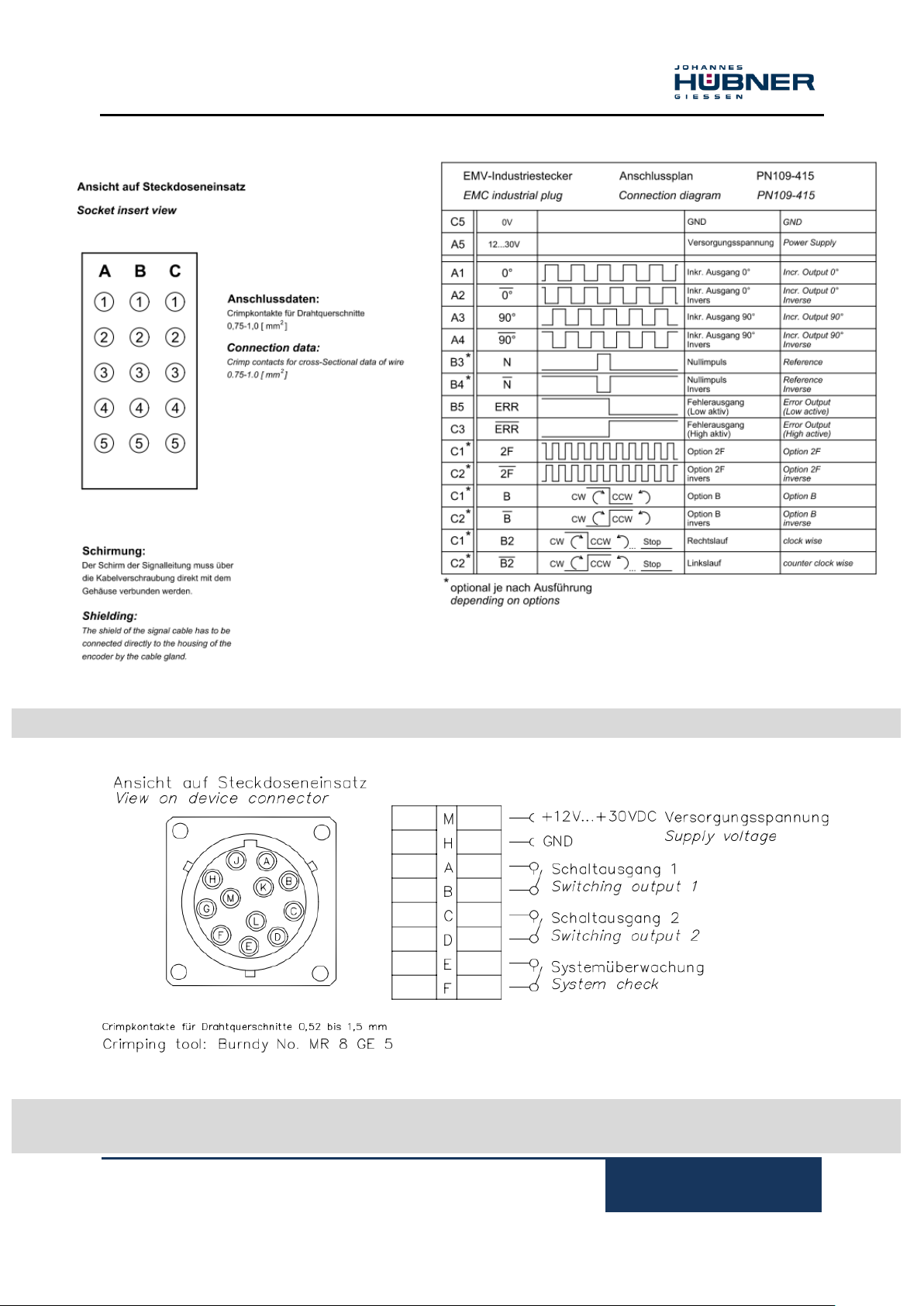

FGH 40

Connection sheme PN 109-415

EMC industrial plug

FGH 40

Connection sheme 649

Option S

Burndy® plug

Incremental Hollow Shaft Encoder FGH 40

38

FGH40_MANUAL-en_R10(2018-10-31)ID74492.doc

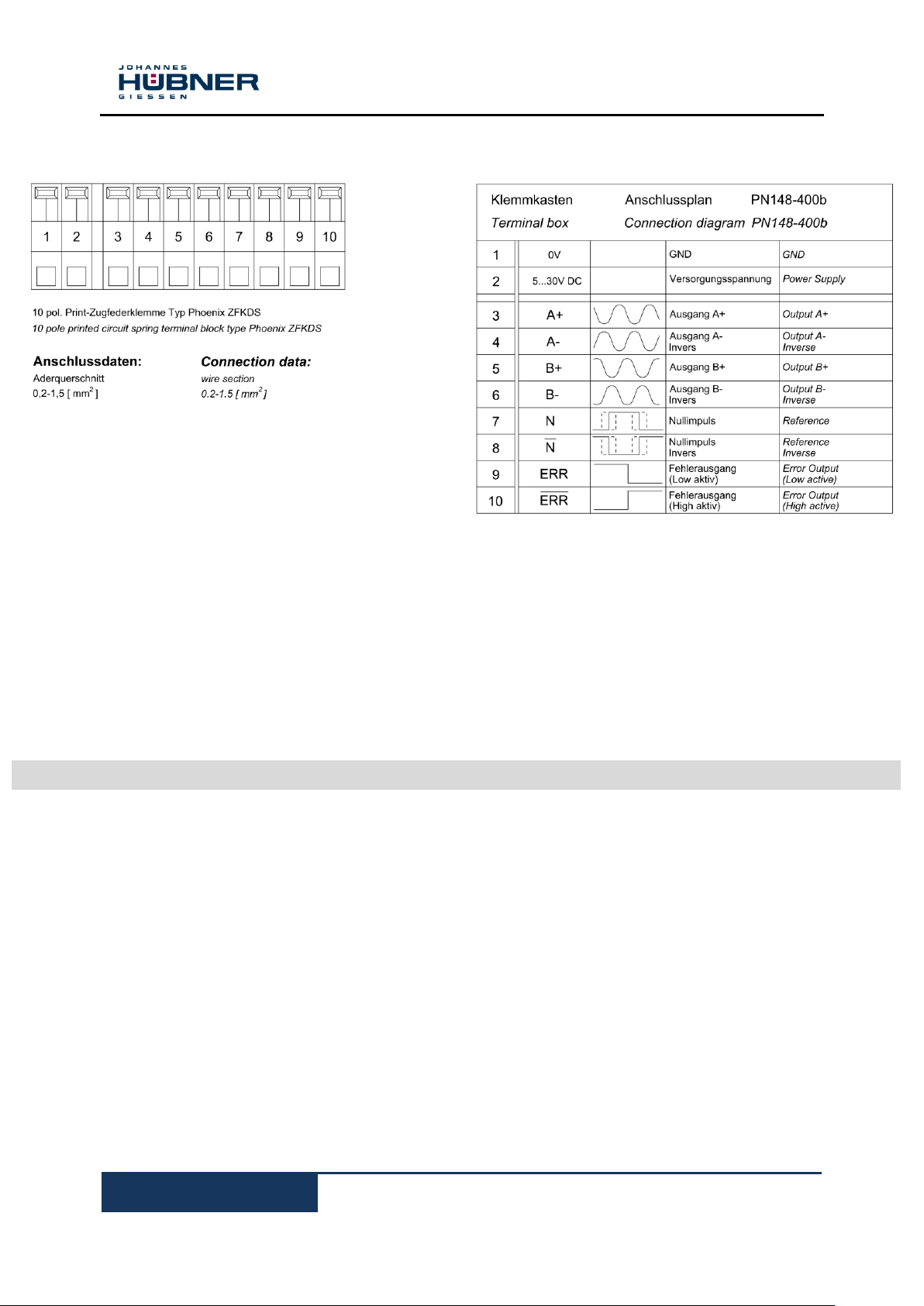

FGH 40

Connection sheme PN 148 400a

Sinue /Cosine Output

Loading...

Loading...