Hubner U-ONE-SAFETY Compact USC 42, U-ONE-Compact UOC40, ECU C, ERC40, ERC C-R Configuration Instructions

...

English

Translation of the original configuration

manual

issued

August 2018

ID 74237

Configuration manual

U-ONE® -SAFETY-Compact USC 42

Universal-Encoder-System

For the following modules:

SCU-C (Safety Control Unit)

SRC C-R (Safety position switch)

SGS C-R (Safety overspeed switch)

Read the configuration manual prior to assembly,

starting installation and handling!

Keep for future reference!

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

2

USC42_SCU-KonfigManual-en_R5

Trademark

Brand names and product names are trademarks or registered trademarks of their respective

owner.

Protected trademarks bearing a ™ or ® symbol are not always depicted as such in the manual.

However, the statutory rights of the respective owners remain unaffected.

Manufacturer / publisher

Johannes Hubner

Fabrik elektrischer Maschinen GmbH

Siemensstraße 7

35394 Giessen

Germany

Phone: +49 641 7969 0

Fax: +49 641 73645

Internet: www.huebner-giessen.com

E-Mail: info@huebner-giessen.com

The manual has been drawn up with the utmost care and attention. Nevertheless, we cannot

exclude the possibility of errors in form and content. It is strictly forbidden to reproduce this

publication or parts of this publication in any form or by any means without the prior written

permission of

Johannes Hubner Fabrik elektrischer Maschinen GmbH.

Subject to errors and changes due to technical improvements.

Copyright © Johannes Hubner Fabrik elektrischer Maschinen GmbH.

All rights reserved.

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

3

Table of contents

1 Generally ......................................................................................................................... 5

1.1 Abbreviations and terminology used .......................................................................... 5

1.2 System requirements ................................................................................................. 5

2 Installing the software .................................................................................................... 5

2.1 Installing the driver manually ...................................................................................... 6

2.2 Manual driver installation under Windows XP SP3 ..................................................... 7

3 Setting up USC 42 ........................................................................................................... 8

3.1 Planning ..................................................................................................................... 8

4 Software description US42Pro ....................................................................................... 9

4.1 Fundamental procedure ............................................................................................. 9

4.1.1 User interface head section ................................................................................................. 10

4.1.2 Pulldown menu: File Import Parameters ......................................................................... 10

4.1.3 Pulldown menu: File Export Parameters ........................................................................ 10

4.1.4 Pulldown menu: File Report ............................................................................................ 10

4.1.5 Pulldown menu: File Offline ............................................................................................ 11

4.1.6 Pulldown menu: Options Language ................................................................................. 11

4.1.7 Pulldown menu: Options Login ........................................................................................ 11

4.1.8 Pulldown menu: Options Change password .................................................................... 11

4.1.9 Pulldown menu: Options firmware update ...................................................................... 12

4.1.10 Pulldown menu: Options Reset to factory settings .................................................... 13

4.1.11 Pulldown menu: Options Recover password ............................................................. 13

4.1.12 Pulldown menu: Options FitCalc ................................................................................ 14

4.1.13 Pulldown menu: Options Determine calibration factor ............................................... 14

4.1.14 Pulldown menu: “Analysis” switch test ...................................................................... 14

4.1.15 Pulldown menu „?“ ......................................................................................................... 15

4.1.16 Generate support file ..................................................................................................... 15

4.1.17 Display calibration settings ............................................................................................ 15

4.1.18 Display device data........................................................................................................ 15

4.1.19 Fault memory ................................................................................................................. 16

4.2 User interface - display section .................................................................................16

5 Configuring USC 42 .......................................................................................................17

5.1 Launching the software US42Pro ..............................................................................17

5.2 Operating mode ........................................................................................................17

5.2.1 Speed mode ........................................................................................................................ 17

5.2.2 Position and speed mode .................................................................................................... 17

5.3 Calibrating the position system .................................................................................18

5.3.1 Calibration ............................................................................................................................ 19

5.3.2 Determining the calibration factor with two calibration points ............................................. 19

5.3.3 Determining the calibration factor by calculation ................................................................. 19

5.4 Saving configuration- or parameterisation data in the USC 42 ..................................20

6 Functions .......................................................................................................................21

6.1 SCU C module ..........................................................................................................21

6.1.1 Digital inputs ........................................................................................................................ 21

6.1.2 Digital outputs ...................................................................................................................... 22

6.1.3 Current output (non safety related) ..................................................................................... 23

6.1.4 Configuring the incremental output (non safety-related) ..................................................... 23

6.2 SRC C module ..........................................................................................................24

6.2.1 Depiction in the display section ........................................................................................... 25

6.3 SGS C module ..........................................................................................................25

6.3.1 Underspeed ......................................................................................................................... 26

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

4

USC42_SCU-KonfigManual-en_R5

6.3.2 Rotation direction dependent............................................................................................... 26

6.3.3 Switching delay .................................................................................................................... 27

6.3.4 Display in the display area ................................................................................................... 27

6.4 Input accuracy of switching points .............................................................................27

6.5 Error handling ...........................................................................................................28

6.5.1 Error table ............................................................................................................................ 29

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

5

1 Generally

The U-ONE®-SAFETY-Compact is referred to as “USC 42” in the following documentation.

This document explains how to set the parameters of the U-ONE®-SAFETY-Compact using

the software US42Pro and then transfer the settings to the device.

1.1 Abbreviations and terminology used

USC 42 U-ONE®-SAFETY-Compact universal encoder system

SCU C Module Safety Control Unit

SRC C-R Module safe position switch with positively driven contacts

SGS C-R Module safe speed switch with positively driven contacts

1.2 System requirements

For configuration purposes it is possible to use any commercially available Windows® notebooks/PCs that fulfil the following system requirements:

• Windows® XP SP3 / Vista / 7 / 8 / 8.1 / 10

• Free space on the HDD: 150 MB (+ Dot Net Framework)

• Available USB 2.0 port

• 1 GB RAM, CPU: 1GHz, screen resolution 1024 x 768

2 Installing the software

Ensure the device and your notebook/PC are connected via the USB cable.

Close the automatically started „Found new hardware wizard“ with a click on “Cancel“.

Place the supplied CD containing the software into the CD drive or, alternatively, download

the Setup.exe. If the Setup.exe does not run automatically, navigate via Explorer on the CDROM drive and there start the Setup.exe.

1. The Setup guides you through the installation. Please follow the instructions on the

monitor.

If you use Windows XP, Vista or 7, continue with step 2, users higher operating system versions go on to step 3.

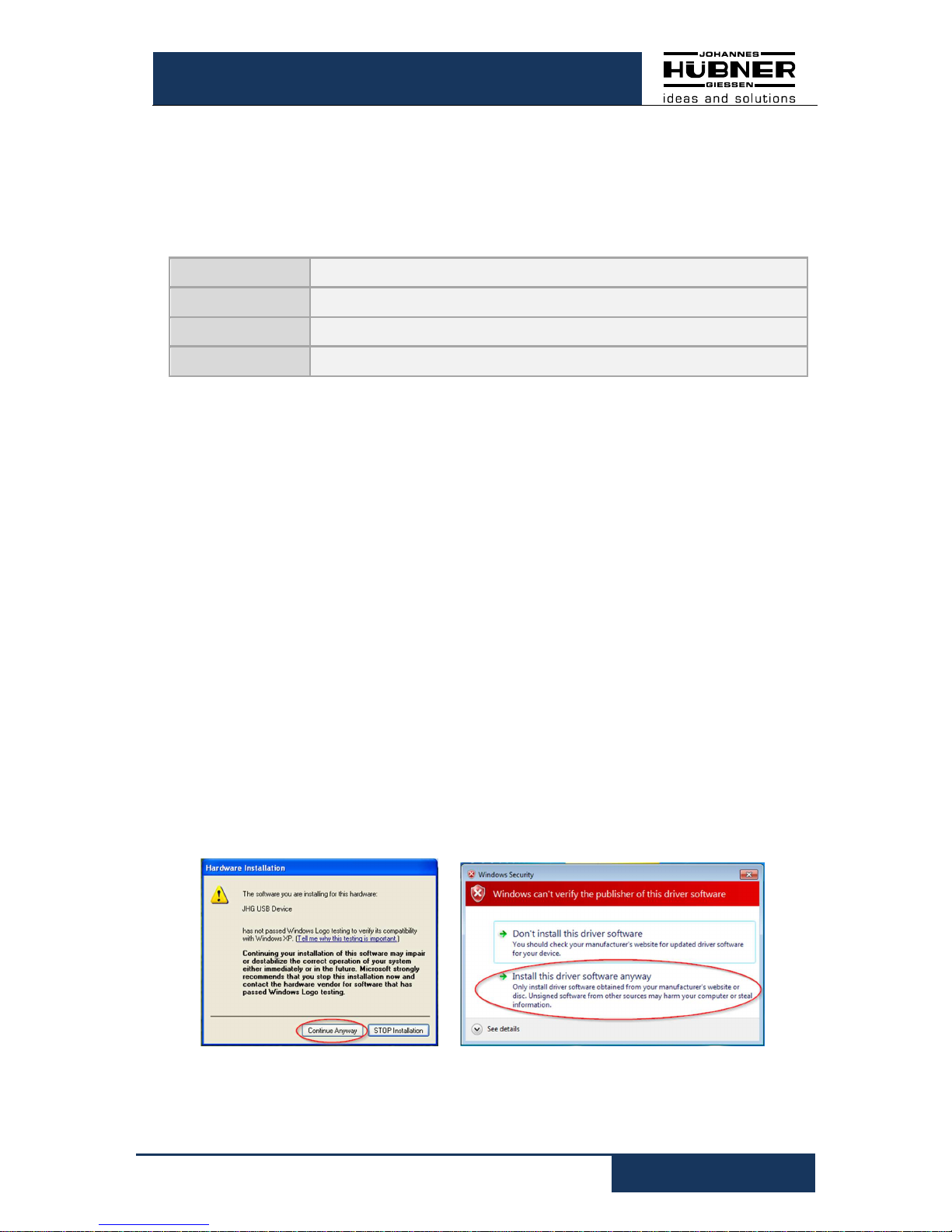

2. Windows XP SP3/ Vista / 7

Due to the ended support for your operating system, it is no longer possible for us to

sign the driver; therefore you need to confirm the installation manually. To do this, in

Windows XP, click on “ Continue Anyway ”. In Windows Vista and 7 click on “ Install

this driver software anyway ”. After that, the setup routine will continue.

3. Completion

The software has been installed and starts automatically.

Fig. 2-1: Software Installation 1

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

6

USC42_SCU-KonfigManual-en_R5

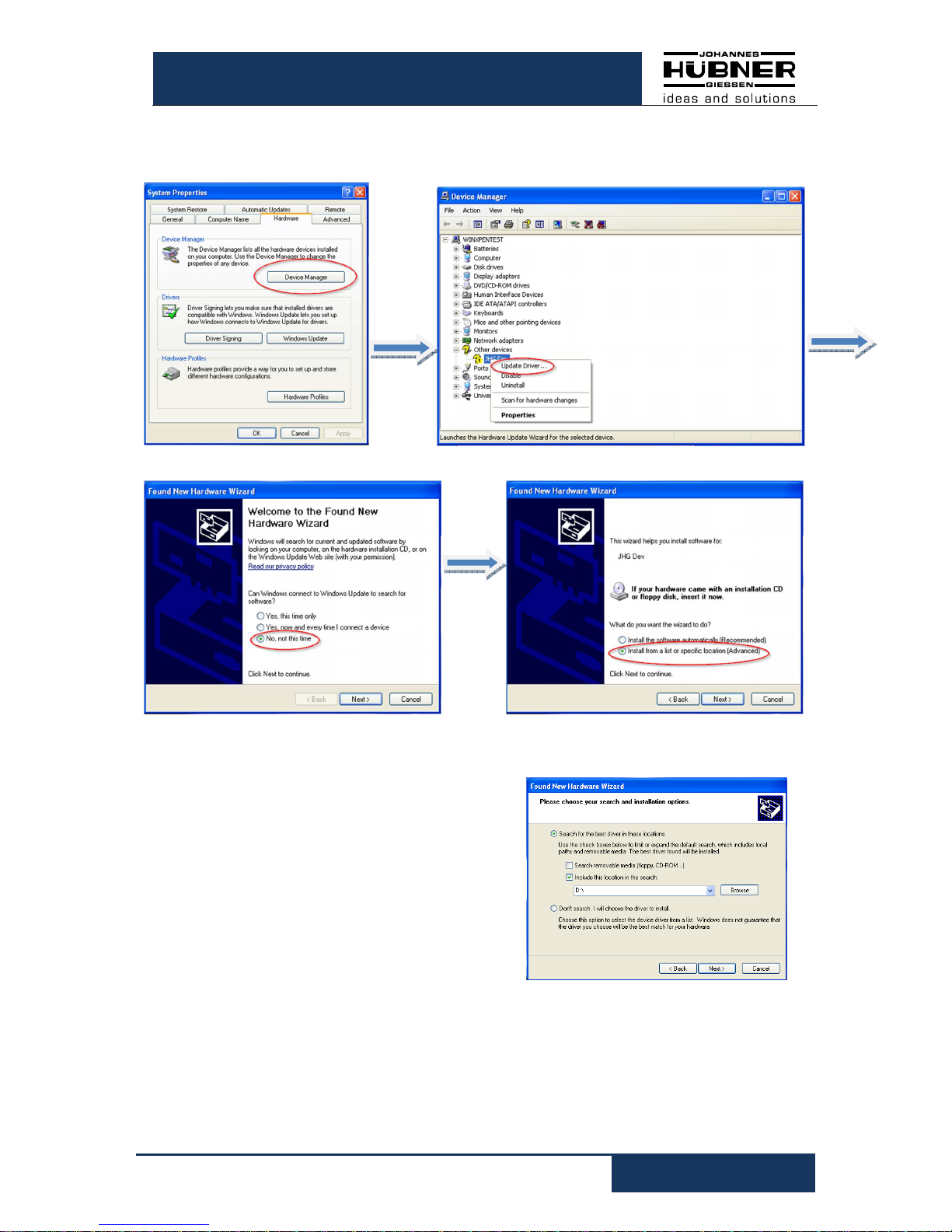

2.1 Installing the driver manually

PLEASE NOTE!

You must log into a user account with administrator rights to install the software.

Ensure all programs are closed.

If it is necessary to install the driver manually, depending on your operating system, please

check the following steps.

Connect the supplied USB cable with the USC 42 device and your notebook/PC

By pressing “Windows key” “Pause/Break” or desktop “Computer” (right click) “Properties”

you get into the System Properties.

Open the device manager, which lists all the connected devices. Select “JHG Dev” (right

click) “Update Driver”.

Now select the installation source via “Browse” and point to path of your installation, there

select the folder drivers. The Installation begins with a click on Next.

Click Next, the installation of the driver

software for the USC 42device has been

completed.

Finish the installation with “close”.

The USC 42device is now ready to be used.

Fig. 2-2: Driver software Installation 2

Fig. 2-3: Driver software Installation 3

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

7

2.2 Manual driver installation under Windows XP SP3

Now select the installation source via “Browse” and point to path of your installation, there

select the folder drivers. The Installation begins with

a click on Next.

Click Next, the installation of the driver software for

the USC 42device has been completed.

Finish the installation with “close”.

The USC 42device is now ready to be used.

Fig. 2-4: Software Installation XP SP3

Fig. 2-5: Driver Software Installation XP SP3

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

8

USC42_SCU-KonfigManual-en_R5

3 Setting up USC 42

Allow sufficient time to plan the integration and configuration of the USC 42. Please remember that planning and configuration errors can put people at risk. Put organizational

measures in place to guarantee the safe systemstate during configuration procedures!

Ensure that the system cannot enter any dangerous states during the configuration procedures including in that part of the system monitored by devices connected to the USC 42.

To configure the USC 42 you require the following:

• Operating-and configuring instructions belonging to the USC 42

• Notebook/PC running a Windows® operating system

• The configuration software US42Pro (administrator rights are required to install the

software)

• USB-Connecting cable to connect the notebook/PC with the USC 42

3.1 Planning

Caution!

Ensure you have planned the application thoroughly before you begin to configure the USC 42!

Amongst other considerations the planning must include:

• A detailed safety analysis of the planned application

• A complete list of all required devices, their connections as well as the signals and

switching points provided or required by USC 42.

In addition, the following conditions must be fulfilled:

• The USC 42 must be connected to the power supply.

• The components must be electrically connected to the USC 42.

Read also the appropriate operating and assembly instructions.

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

9

4 Software description US42Pro

In this chapter you will learn how to configure the USC 42in its respective device combination

using the configuration software US42Pro. For the purpose of clarity the user interface is

divided up into different sections.

The drawing below offers a schematic overview:

Head section

Display section Configuration section

Head section:

This is where the elements used to control

the software are displayed (see Chapter

4.1.1).

Display section:

The display section is always visible and is

used to show the available modules and their

status. (See chapter 6.2.1).

In the upper section the current speed, the

current position and the optional analog output current is displayed.

Configuration section:

This is where the module parameters are

entered on the tab pages (see chapter 5).

4.1 Fundamental procedure

The USC 42 is configured by taking the following steps:

1. Turn on the notebook/PC

2. Connect the USC 42 to the USB port of the notebook/PC

3. Switch on the USC 42

4. Launch the software US42Pro and set up connection (see chapter 5.1)

5. Establish communications and log onto the USC 42 (see chapter 4.1.6)

6. Configure USC 42 (see chapter 5).

7. Check parameter settings

8. Approve the parameters in the USC 42

9. Test the parameter settings of the USC 42 on a secured system

The USC 42 is ready for operations after completing these steps.

Fig. 4-1:

schematic overview of the

user inter-

face

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

10

USC42_SCU-KonfigManual-en_R5

4.1.1 User interface head section

The menu bar containing basic commands to operate the software is located in the head

section.

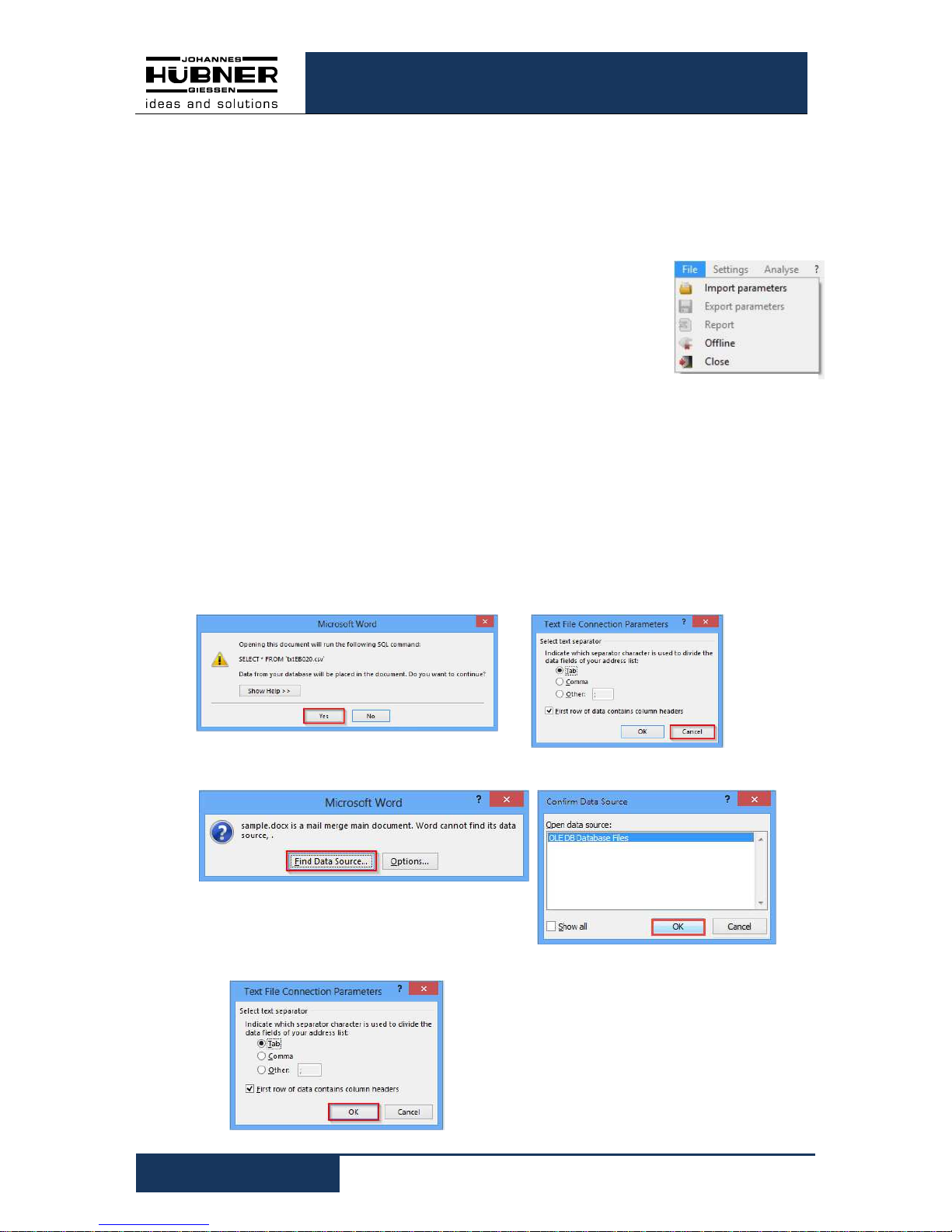

4.1.2 Pulldown menu: File Import Parameters

• To check the content of saved parameter sets when the device is

not connected click “Import Parameters”.

• When the device is connected it is possible to load parameters

into the input masks that were saved using the “Export

Parameters” function.

• When the device is connected and the user signed in, it is

possible to save imported parameters to the device.

4.1.3 Pulldown menu: File Export Parameters

To save device parameters to a notebook/PC click “Export Parameters”.

4.1.4 Pulldown menu: File Report

Click “Report” to save device parameters to a CSV file.

Using the Form Letter function in Word (for example, Word 2013) it is possible to save

device parameters for documentation purposes in Word templates as follows:

1. Open the associated template file for the device (for example,

USC 42_ReportDDA_Rx.dotx). Then select the (successive) buttons framed in red.

2. Open the previously saved “CSV file”.

3. Click OK 2x to confirm

The parameters have been saved

to the

template. You can make any changes

you like to the template. Using the Word

function “Insert Merge Field” it is possible to add more parameters.

Fig.

4-2

: File

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

11

4.1.5 Pulldown menu: File Offline

In offline mode, a device parameter set can be created without USC 42as follows:

• A virtual USC 42 is created by entering

the type designation.

• The configuration of the virtual USC 42

can be carried out.

• With „Export parameters“ the

parameters are stored and can be

loaded by a USC 42 with the same type

designation.

The offline-state will be exited via

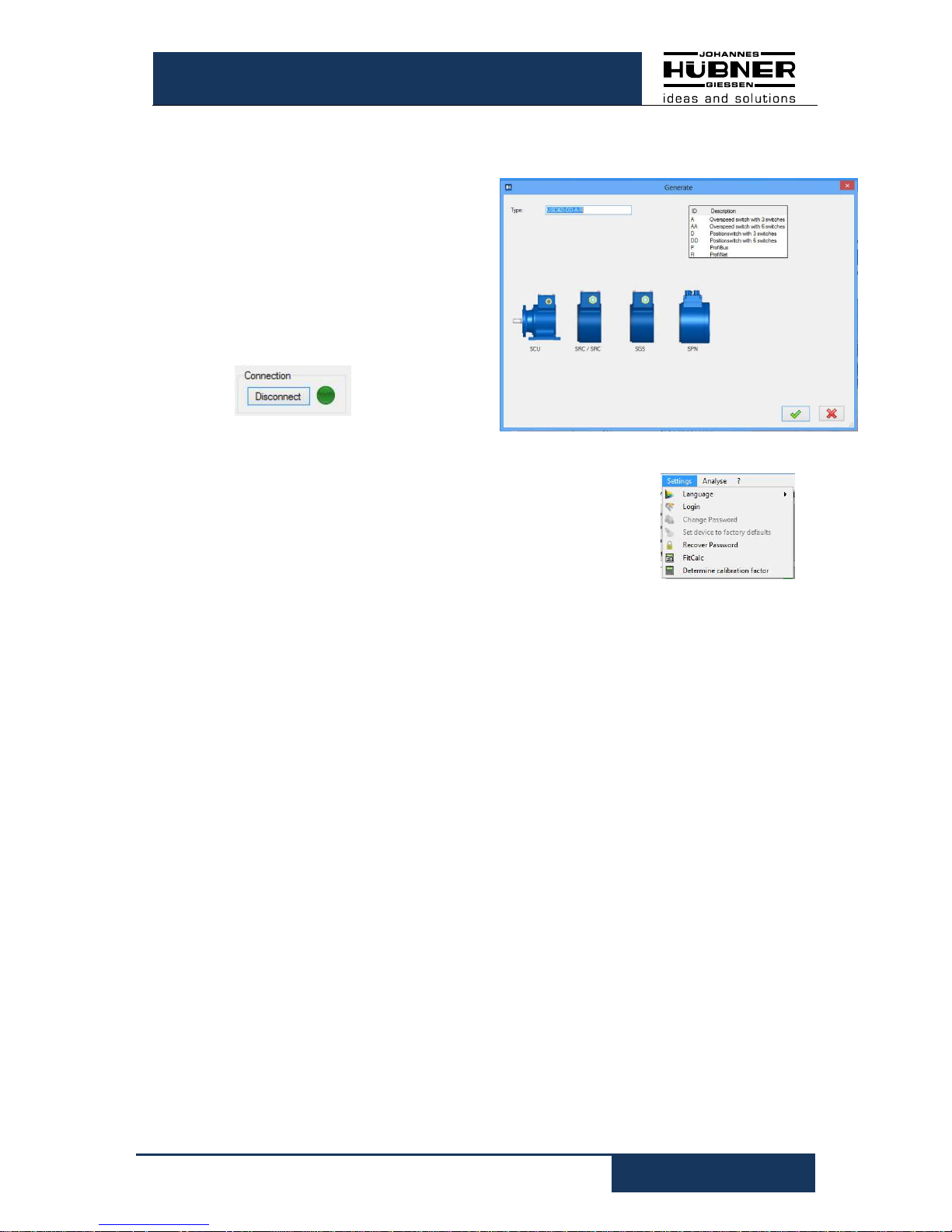

4.1.6 Pulldown menu: Options Language

Depending on the regional setting of your Windows operating

system the software language is determined. The language

'English' is selected if no corresponding data record is available. It

is possible to select a different language via the menu item

'Language'.

4.1.7 Pulldown menu: Options Login

To access and work on the assigned user level, the user must log into USC 42 via the

menu item 'Login password' with his or her password.

4.1.8 Pulldown menu: Options Change password

Admin and Tester passwords are assigned via the menu item 'Change password'. A

closed padlock in the header indicates that a user-specific password has been assigned.

Authorization levels:

Three authorization levels are available to the user; however, it is only possible to

activate two of these levels by means of password authentication. The password must

be between 6-12 ASCII characters (0x20 - 0x7E) in length.

Level 0: Observer (no password required)

The following functions are available on this level:

- Establish communications with USC 42

- Enter password

- Display assigned parameters

- Display saved parameter sets

Fig.

4-3

: Offline

Fig. 4-4: Settings

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

12

USC42_SCU-KonfigManual-en_R5

Level 1: Tester (password level 1)

On this level the following functions are available in

addition to those on level 0:

- Perform test of switch

- Generate test logs

Level 2: Admin (password level 2)

On this level the following functions are available in

addition to those on level 1:

- Change parameters

- Save parameter sets

Default passwords on delivery are 'huebner1' for

password level 1 and 'huebner2' for password level 2.

A padlock with an open shackle symbolizes that the

password “huebner2” has not yet been changed;

consequently, the configuration is not secured against unauthorized changes.

A closed padlock shackle indicates the configuration is securely protected against

unauthorized changes. How to save the configuration is described in chapter 5.4.

The authorization level is displayed in plain text to the left of the padlock symbol

(here the level is: Admin), with which the user is logged into the USC 42.

PLEASE NOTE!

The login password is set ex-works to 'huebner1' or 'huebner2'.

ATTENTION!

Change the Admin password as soon as possible to protect the configuration from

unauthorized access! (See chapter 4.1.8).

4.1.9 Pulldown menu: Options firmware update

The USC 42 is prepared for a firmware update by electrically connecting terminal 1 (+ U)

and terminal 2 (Error1) during power up. After switching on, this connection must be

removed again.

The button.………..selects the update file.

„Transfer“ starts the update process.

After the update process, the device must be restarted.

NOTE!

Before the restard, the connection

must be removed.

Fig. 4-5: Partial view header

Fig. 4-6: firmware update

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

13

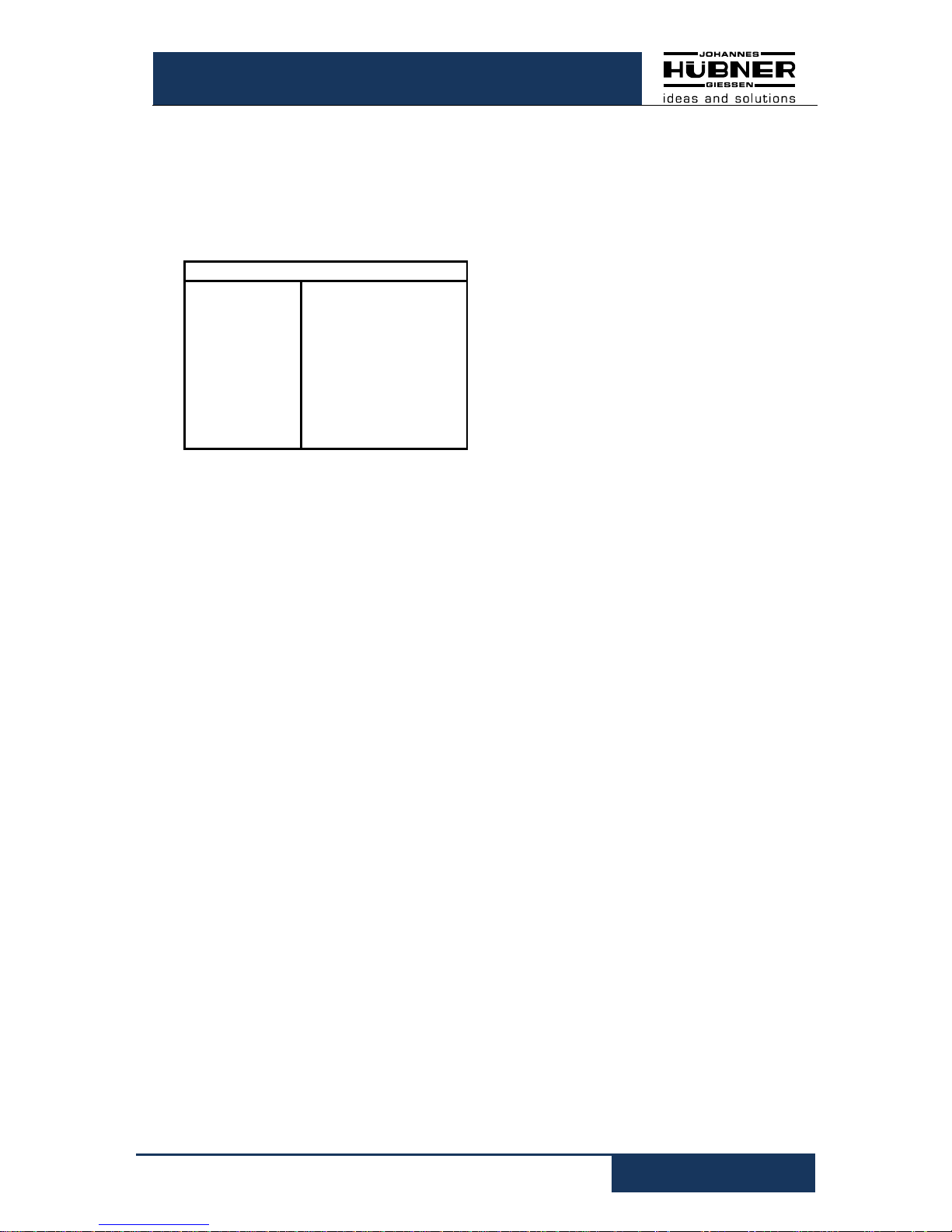

4.1.10 Pulldown menu: Options Reset to factory settings

All parameters and the USC 42 will be deleted and reset to factory settings.

Factory settings:

Password level1

Password level2

huebner1

huebner2

Operating mode

Position and

speed mode

Reset and preset

inputs

Deactivated

Speed and position

switching points

Deleted

Error reset with

software only

Active

Test pulse duration

1 ms

T/ti 1000

Current output

Deactivated

Current output

source

Position

dependent

Error reset with

software only

Active

Incremental output

(optional)

4096

pulses per

revolution

4.1.11 Pulldown menu: Options Recover password

If a user forgets his/her password, it is possible to

assign a new password using the “Recover Password” function and following the steps below:

• Select “Recover Password”.

• To generate a recovery key click the

button, then click the

button to send the request to the manufacturer immediately or later if there is no Internet connection.

• A recovery password will be generated

and sent back to the designated recipient.

• It is possible to assign a new password

once the recovery password has been entered in the appropriate field.

Fig. 4-7: recover password

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

14

USC42_SCU-KonfigManual-en_R5

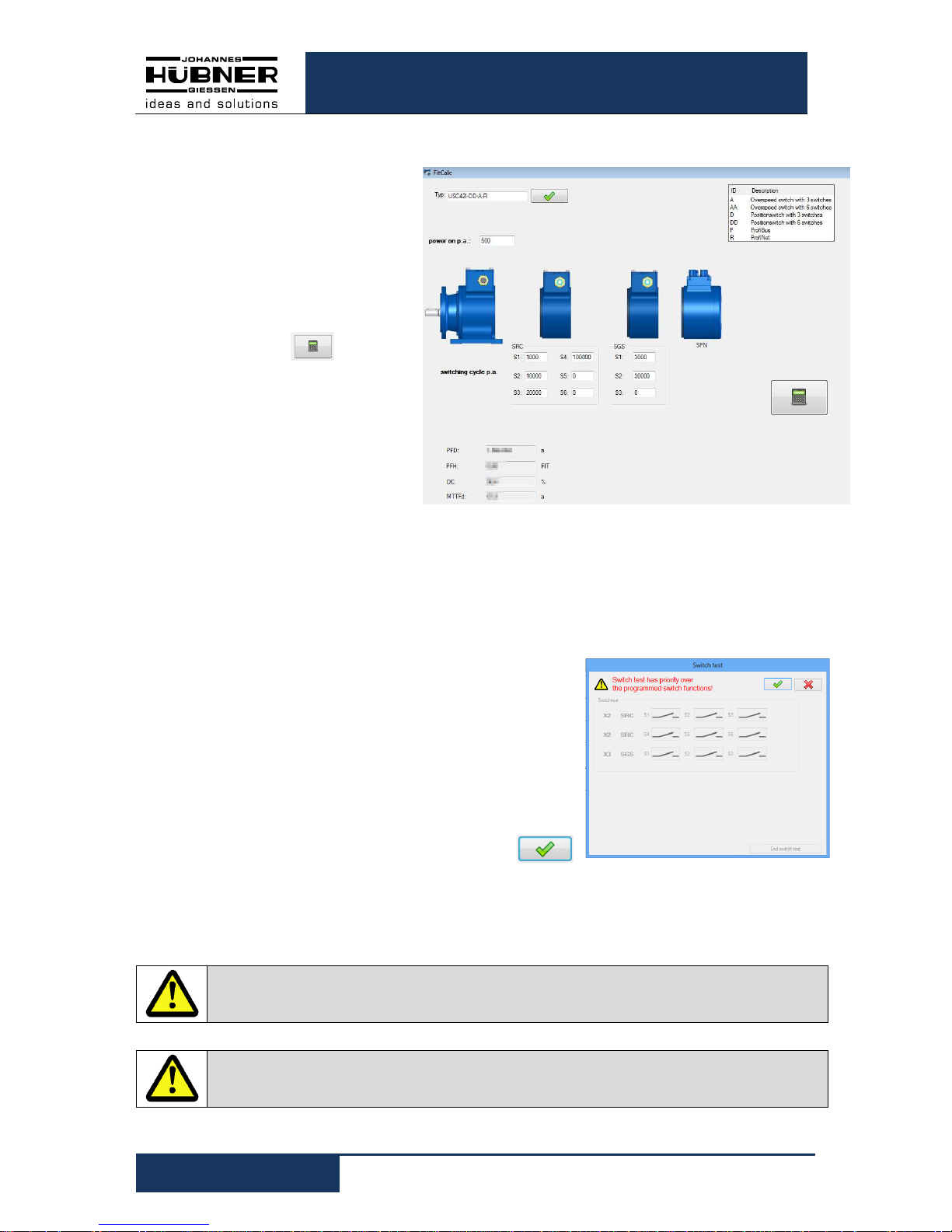

4.1.12 Pulldown menu: Options FitCalc

The characteristic safety values

of the device depend on the

number of relay switching cycles. The type determines the

number of relays.

Switching cycles p.a.: Number

of relay switching cycles per annum.

Click the button to calculate the characteristic safety values for a service life of

20 years

.

4.1.13 Pulldown menu: Options Determine calibration factor

see chapter 5.3.2

4.1.14 Pulldown menu: “Analysis” switch test

It is possible to alter the switch status by means of

a switch test incorporated in the configuration

software US42Pro. The switch test is only available

when the encoder shaft is at a standstill.

It is possible to oversee the changes to the

statuses of the switches via the Switch test dialog

box.

To confirm and activate the switch test click

CAUTION!

An error will be triggered if the encoder shaft turns during the switch test.

CAUTION!

The switch test has priority over programmed switching functions.

Fig. 4-9: Switchtest

Fig. 4-8: FitCalc

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

15

4.1.15 Pulldown menu „?“

• Info

Displays the software version and Johannes Hubner contact details.

• Help

Opens the current configuration data in PDF format.

• Documentation

Opens the folder containing the USC 42 documentation. This is where the connection

diagrams, dimension drawings and operating and assembly instructions and the

configuration manual are stored.

4.1.16 Generate support file

In the pull-down menu "?" Under "Info" with the

button a support file is

generated, which serves for the error analysis.

If the e-mail checkbox is activated, the file is

transferred directly to the installed e-mail program.

4.1.17 Display calibration settings

The calibration settings are displayed here and also changed with „Start parameterization“.

4.1.18 Display device data

All device data, grouped according to the terminal boxes, are displayed here.

NOTE!

Please send the support file with a

short description of the conditions under which the error occurred, by email

to the manufacturer.

Fig. 4-10: Info

Fig. 4-11: Device data

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

16

USC42_SCU-KonfigManual-en_R5

4.1.19 Fault memory

#: Memory

Time: Time of error occurrence

(Operating hours)

The error memory is a ring memory and can accommodate 100 error entries. Internal errors should be sent to the manufacturer for analysis.

The button in the display area of the fault memory generates an error log file,

which can then be saved.

4.2 User interface - display section

The display section (left column):

• Displays the device type

• Displays present position, speed and current values.

• Lists all modules of the USC 42.

The assignment to the individual terminal boxes is displayed as X1, X2, X3 in the

same sequence that mirrors how the modules are arranged (see

Fig. 5-3

).

X1 is always the terminal box of the SCU C.

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

17

5 Configuring USC 42

You must first calibrate the position system before configuring USC 42

(chapter 5.3). Device calibration and device configuration operations are only possible

on the password level “Admin”.

CAUTION!

It is only possible to assign parameters and calibrate the device when the

device is at a standstill!

The USC 42 enters a safe state if rotary motion is detected when parameters are

being assigned

5.1 Launching the software US42Pro

When the software is launched, the start

screen is displayed.

Click 'Connect' to establish communications with the USC 42 . The connection

status is indicated on the right of the button.

Display Status

grey not con-

nected

change

light green / dark

green

connected

After the connection setup, the device data are

read out. To calibrate and configure the

USC 42 the user must first log in using the

Admin password.

ATTENTION!

Change the Admin password 'huebner2' to protect the configuration from unauthorized access (chapter 4.1.6).

5.2 Operating mode

5.2.1 Speed mode

Select the operating mode “Speed mode” if no position dependent switching points or

position dependent current values 4 mA…20 mA are used.

It is not necessary to calibrate the USC 42 in this operating mode.

5.2.2 Position and speed mode

Select the operating mode “Position and speed mode” if position dependent switching

points or position dependent current values 4 mA…20 mA are used.

In this operating mode it is necessary to calibrate the USC 42 (see Chap.5.3).

Fig. 5-1: Start screen

Fig. 5-2: Login

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

18

USC42_SCU-KonfigManual-en_R5

5.3 Calibrating the position system

To calibrate the position system (adapt the internal device processing to mirror actual

conditions at the place of installation) it is necessary to determine the system limits, calibration point, calibration factor and unit.

• The system limits define the max. possible working range. An error will be

triggered if values exceed or fall below the defined range.

PLEASE NOTE!

To avoid system limit errors ensure sufficient clearance between the system limits and the switching points.

• The operating range must not exceed 32768 rotations of the device shaft.

• The preset position value is a defined position point (calibration point).

• The calibration factor is the adaption factor between system units and device units.

It is assumed that this ratio is constant.

If unknown, it is possible to determine the calibration factor via the menu item

“Options Determine calibration factor” (see Chap.5.3.2).

In this instance it is possible to determine the calibration factor with the aid of 2

calibration points, the interval between which should be as great as possible but must

not exceed the system limits.

Fig. 5-3: Calibrating the system

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

19

5.3.1 Calibration

1. Select the desired unit via the pulldown menu

2. Enter the values for the system limits and the calibration point (preset).

The following constraint applies:

Lower system limit < calibration point < upper system limit

3. Enter calibration factor. For information on calculating the calibration factor see Chap.

5.3.3.

4. To save values to the USC 42 click , see Chap. 5.4.

5. Move to the calibration point (preset), shut down the drive and click the button.

Thecurrent position is saved as the calibration point.

6. To complete the calibration procedure click button. The USC 42 is

calibrated and can now be configured.

5.3.2 Determining the calibration factor with two calibration points

1. Enter calibration point 1 and calibration point 2.

The following constraints apply:

• Lower system limit < calibration point 1

• Calibration point 1 < calibration point 2

• Calibration point 2 < upper system limit

2. Move to calibration point 1 and shut down the drive,

click the button . The current position is saved as calibration point 1.

3. Move to calibration point 2 and shut down the drive, click the button . The

current position is saved as calibration point 2.

4. The calibration factor has been calculated, saved to the clipboard and can now be inserted in the appropriate dialog box.

5.3.3 Determining the calibration factor by calculation

Calibration factor = (device shaft rotations) x 8192 / Actual path in number of plant units

Example:

34.5 m travel corresponds to 125.7 rotations of the device shaft.

Calibration factor = 125.7 x 8192 / 34.5 = 29847.37

Fig. 5-4:

Determining the

calibration

factor

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

20

USC42_SCU-KonfigManual-en_R5

5.4 Saving configuration- or parameterisation data in the USC 42

All entries are formally checked prior to data transmission.

Incorrect entries are highlighted red and data transmission to the USC 42 are prevented.

If the entries comply with the conditions

above (chapter 5.3.2), the values are

transmitted to the USC 42, checked, activated and saved temporarily.

The compare dialog box displays the

values entered in the input mask and the

values read out of the USC 42 (Fig. 5-5).

The user confirms the values are correct

by clicking the green tick.

The values are only now permanently

stored.

Fig. 5-5:

Comparison dialog box

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

21

6 Functions

6.1 SCU C module

The SCU C module (Safety-Control Unit) is the central control unit of the USC 42.

To assign the module a user-defined designation click the symbol . That makes it easy

to allocate the device on site (for example, “drive 2"). The length of the designation is

limited to 12 characters.

On the tabbed page “Options” it is possible to make the following settings.

6.1.1 Digital inputs

The inputs must be activated prior to use. Both inputs are 2-channel types (Cat. 3) and

active low; in other words, when quiescent the inputs must be high. A falling edge at

both channels initiates the process. Valid rising edges initiate the process. The duration

of the low level signal T1 can be configured - and is the same for both inputs.

• Reset:

A reset procedure re-initializes the whole

USC 42 system; it also resets errors in

line with parameter assignments.

• Preset:

A preset procedure sets the current

position to the preset position configured

in the device. A low level signal at the

status output (approx. 1s) acknowledges

a valid preset procedure.

The time T1 can be set between 20

ms … 200 ms or 200 ms … 2000 ms

(factory setting: 200 ms … 2000 ms).

To alter the behaviour of the Reset and Preset

inputs from Low active to High active select the

“Preset/Reset 1 active” check box.

PLEASE NOTE!

If test pulses (Fig. 6-3) are used on the inputs they must not exceed max. ¼

of the min. duration of T1 (5ms or rather 50 ms).

CAUTION!

It is only allowed to set a preset “on the fly” if a risk analysis determines the

application is suitable to allow this function.

CAUTION!

A preset does not influence the position value of the bus module (SPB,

SPN). It is only possible to alter this position value via the bus interface.

Fig. 6-1

Preset inputs

Fig. 6-2

Digital inputs

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

22

USC42_SCU-KonfigManual-en_R5

6.1.2 Digital outputs

There are 2 digital outputs: Status and error output.

Both outputs are 2 channel (Cat. 3) types. Both channels

of an error output must have the same status

(open/closed) and both must be monitored by the application. An error will be flagged if the channels are not the

same.

• Error output:

When the status is error-free both channels of the error output are high and transmit

test pulses (factory setting see Fig. 6-3). The USC 42 monitors the output to ensure it

is functioning properly.

CAUTION!

If the error output is utilized to detect a device error it must be subject

to a safety-related evaluation (see document “USC 42_Manual-en_R..”

Chapter: Application examples).

The receiver must suppress the test pulses to avoid unwanted switching operations.

- The following settings are available to set the duration of the test pulses:

100 ms, 10 ms, 1 ms, off (factory setting: 1 ms).

- For the quotient ‘test pulse interval / test pulse duration’ (T/ti) it is possible to select

10, 100, 1000 (factory setting: 1000).

- The test pulse offset (test pulse offset between channels) tc = 2* ti cannot be set.

For non-safety relevant applications it is possible to deactivate the test pulses. An

error is indicated by a low-level signal at the error output, which can only be reset via

the configuration software "US42Pro" (factory setting). It is possible to set the error

performance via the software so that an error will also be reset by interrupting the

supply voltage (> 2s) or by initiating a reset at the reset input).

The reset always initiates a system reboot including a complete system test. If an

error is determined again, the device remains in an error condition. Error logs are

saved in the error memory.

CAUTION!

The "fault reset via the reset input or power supply interruption" option

may be used only if a risk analysis has shown that the application is

suitable.

• Status output:

The status output indicates the operating status in conjunction with the error output of

the USC 42 (see separate operating and assembly instructions. Chapter: Operating

conditions and indicators). The status output does not issue any test pulses.

Fig. 6-3: Error output

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

23

6.1.3 Current output (non safety related)

The current output can be set to speed or position dependent on the menu and must be

activated before use.

6.1.3.1 Configuring the position-dependent current output

To configure the position-dependent current output it is necessary to enter 2 position values, which must be within the

system limits.

The smaller position value is assigned current I

min

= 4 mA and

the larger position value I

max

= 20 mA.

The following restriction applies:

• Pos1 < Pos2

If the current position is outside of the defined position range,

the current output is switched to high impedance (I = 0 mA).

(Factory setting).

Alternatively, it is possible to select a setting to take effect in

the event the value falls below or exceeds the determined position range 4 mA or 20 mA.

6.1.3.2 Configuring the speed-dependent current output

To configure the speed-dependent current output it is necessary to enter the speed

n20 mA

. When at a standstill a current of

4 mA flows.

The following constraint applies:

• n

20 mA

< (approved mechanical speed -10%)

If the speed exceeds the speed range (n

current

> n

20 mA

), the current output is switched to high resistance

(I = 0 mA) – (factory setting).

Alternatively, it is possible to select a setting to take effect in

the event the value exceeds the determined position range

20 mA

.

6.1.4 Configuring the incremental output (non safety-related)

The incremental output is optional. To configure the incremental output it is possible to select a pulse rate of 1024 or

4096

(factory setting: 4096).

Fig. 6-4:

Configuring

position depend-

ent-current output

Fig. 6-6 Configuring incremental output

Fig. 6-5:

Configuring speed dependent

-

current output

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

24

USC42_SCU-KonfigManual-en_R5

6.2 SRC C module

The SRC C module is a position switch module and contains 3 or 6 position switches.

The position switch opens or closes depending on the position value. The position

switches are 2 channel types (2 NO contacts, Cat. 3).It is possible to implement a cam

with a single switch; in other words, a switch-on and switch-off position and the associated hysteresis switching points.

The position values to be entered must be within system limits. It is possible to assign

each position switch an application-specific designation (max. 12 characters). Switching

modules with 6 position switches are configured on 2 monitor display screens. The parameters are entered in the table as shown opposite.

The values are highlighted yellow if there is a risk that

the minimum changeover interval (2 ms) between 2

switching conditions could be undershot. If such an

event occurs the user must check the time interval in

his application.

• P1: Hysteresis switching point of P2.

• P3: Hysteresis switching point of P4.

The following condition applies:

P1 < P2 < P3 < P4

• Inverted: The switch operates inverted (see switch

S3).

• Error switch: Switch opens only in the event an

error occurs (see switch S2).

• Open if an error occurs:

Switch operates as configured, but opens if an error

occurs.

The switching points are depicted in their correct

position in the graphic opposite.

A marker indicates the current position.

Click "Write to device" to finish configuring the module

Fig. 6-7: Warning notice

Fig.: 6-8 Configuration SRC C module

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

25

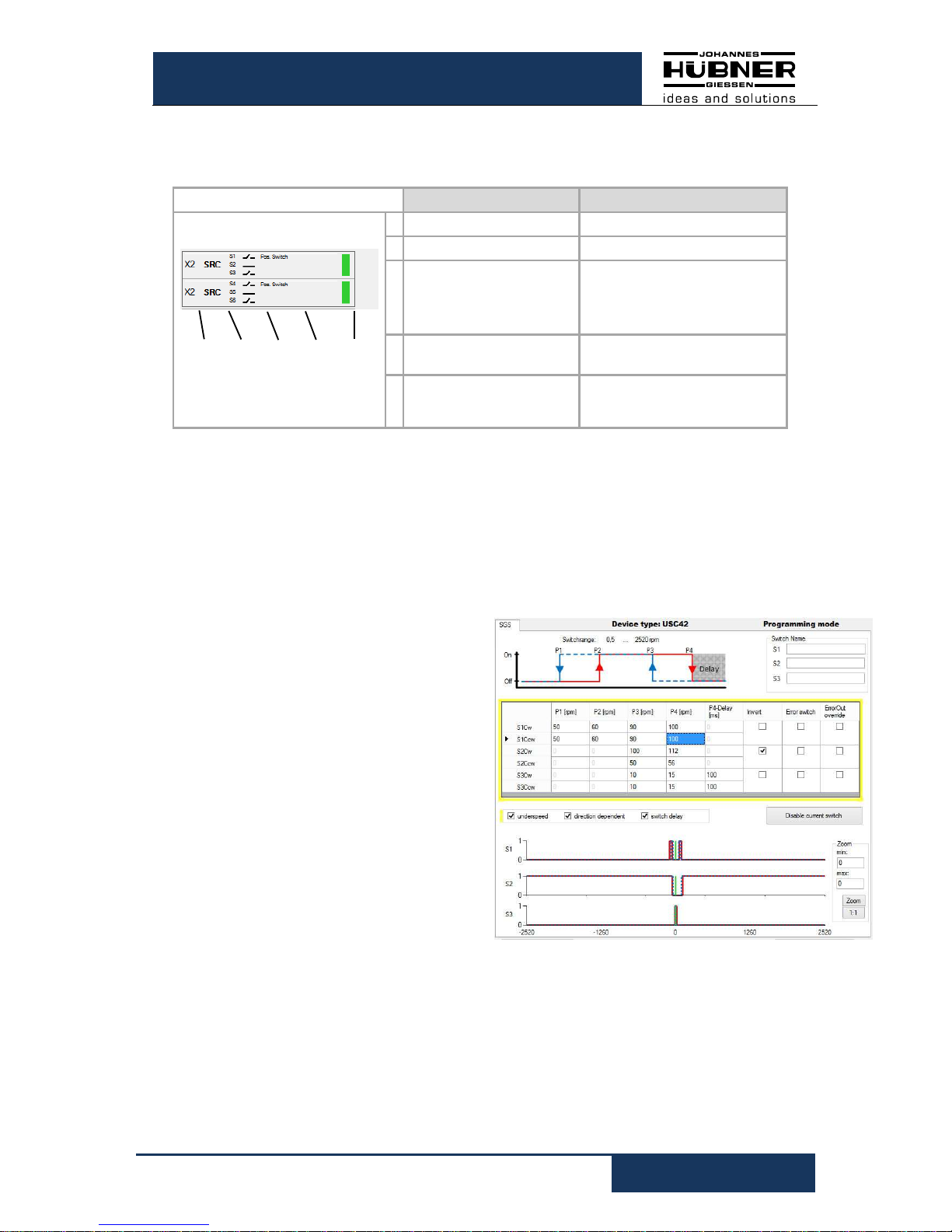

6.2.1 Depiction in the display section

The module is depicted as follows in the display section:

The switching states of the individual switches are represented by switch symbols .

Description Meaning

1 2 3 4 5

1 Module position

X2: 2. Terminal box

2 Module type

SRC: Position switch module

3 Switch statuses

Graphic switch symbol

Black: Error-free

Gray: Not configured

Red: Error

4 User designation

Switch designation assigned

by user

5 Module status

Gray: Not configured

Green: error-free

Red: Error

6.3 SGS C module

The SGS C-module is a speed switch module. The speed switch opens or closes depending on the speed. A speed switch module has 3 or 6 speed switches. Switching

modules with 6 speed switches are configured on 2 configuration screens. Fundamentally, all switching speed inputs must be within the device-specific switching range

0.5-2520 rpm.

The speed-dependent functions are depicted in a graphic in the top part of the

screen.

The input fields for entering speed switching points are displayed in the lower part of

the screen in table form. One line is allocated to each respective switch (S1-S3 or

S1R to S3L).

The columns are assigned to the respective speed switching points P1 to P4, and

the switching delay P4 (max. 300 ms).

The following condition applies:

P1 < 0.9 x P2 < 0.9 x P3 < 0.9 x P4

or P1 = P2 = 0

The switching points are depicted in the graphic opposite. A marker indicates the

current speed

Fig. 6-10: Configuration SGS C module

Fig.: 6-9 Display Area

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

26

USC42_SCU-KonfigManual-en_R5

The switches listed in the lines are allocated

as follows

The values listed in the columns are allocated

as follows

S1R

Switching speeds of switch 1 for

clockwise direction of rotation

P1

Hysteresis switching speed for

underspeed detection

S1L

Switching speeds of switch 1 for anticlockwise direction of rotation

P2

Cut-in speed for underspeed

detection

S2R

Switching speeds of switch 2 for

clockwise direction of rotation

P3

Hysteresis switching speed for

overspeed detection

S2L

Switching speeds of switch 2 for anticlockwise direction of rotation

P4

Cut-off speed for overspeed

detection

S3R

Switching speeds of switch 3 for

clockwise direction of rotation

P4 - Delay

Delay time before cut-off of the

switching point P4 [ms]

S3L

Switching speeds of switch 3 for anticlockwise direction of rotation

Only those lines and columns are displayed that are relevant to the respective function

selected by checking the appropriate boxes.

An input value "0" in the fields P1 … P4 deactivates the corresponding switch.

An input value "0" in the fields P1 … P2 deactivates underspeed detection

(see Chapters: 6.3.1, 6.3.2).

CAUTION!

When switching delay is activated the actual cut-off speed can be higher than the

set cut-off speed!

Observe also the information on determining switching accuracy described in the

Operating and Assembly Instructions " USC 42_Manual"!

The module is depicted in the display section as in

Fig. 6-10

Click "Write to device" to finish configuring the module.

6.3.1 Underspeed

Underspeed is detected. The respective switch closes first when speed P2 is exceeded;

the switch is opened again when the speed falls below the P1 threshold. The input columns for "P1" and "P2" are depicted if underspeed detection is activated.

6.3.2 Rotation direction dependent

The switching speeds S1R … S3R apply to clockwise direction of rotation. The speeds

S1L … S3L apply to anticlockwise direction of rotation.

The input lines for S1R-S3R as well as S1L-S3L are depicted if 'rotation direction dependent switching' is activated.

If no 'rotation direction dependent switching' is activated the switches S1 ... S3 are not

labelled with a direction of rotation indicator R or L; the entered switching speeds apply

independent of the direction of rotation.

PLEASE NOTE!

If 'rotation direction dependent switching and underspeed are selected, the underspeed function must be equal for both directions of rotation. Either active or inactive.

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

27

6.3.3 Switching delay

The adjustable switching delay makes it possible to prevent the overspeed switch

switching if the limit speed is exceeded only briefly. That can be appropriate during load

shedding, for example. If the speed P4 is exceeded the switches S1, S2 and S3 close,

and open only after the delay time set in the "Delay" field has elapsed. It is possible to

set the time between 0 and 300 ms. The cut-off function is not triggered if the speed

again falls below the P4 figure within the set delay time.

PLEASE NOTE!

The delay time applies only to the cut-off function when the speed P4 is exceeded.

All other switching operations are triggered immediately.

6.3.4 Display in the display area

In the display area, the module is depicted as shown in Fig.

6-11.

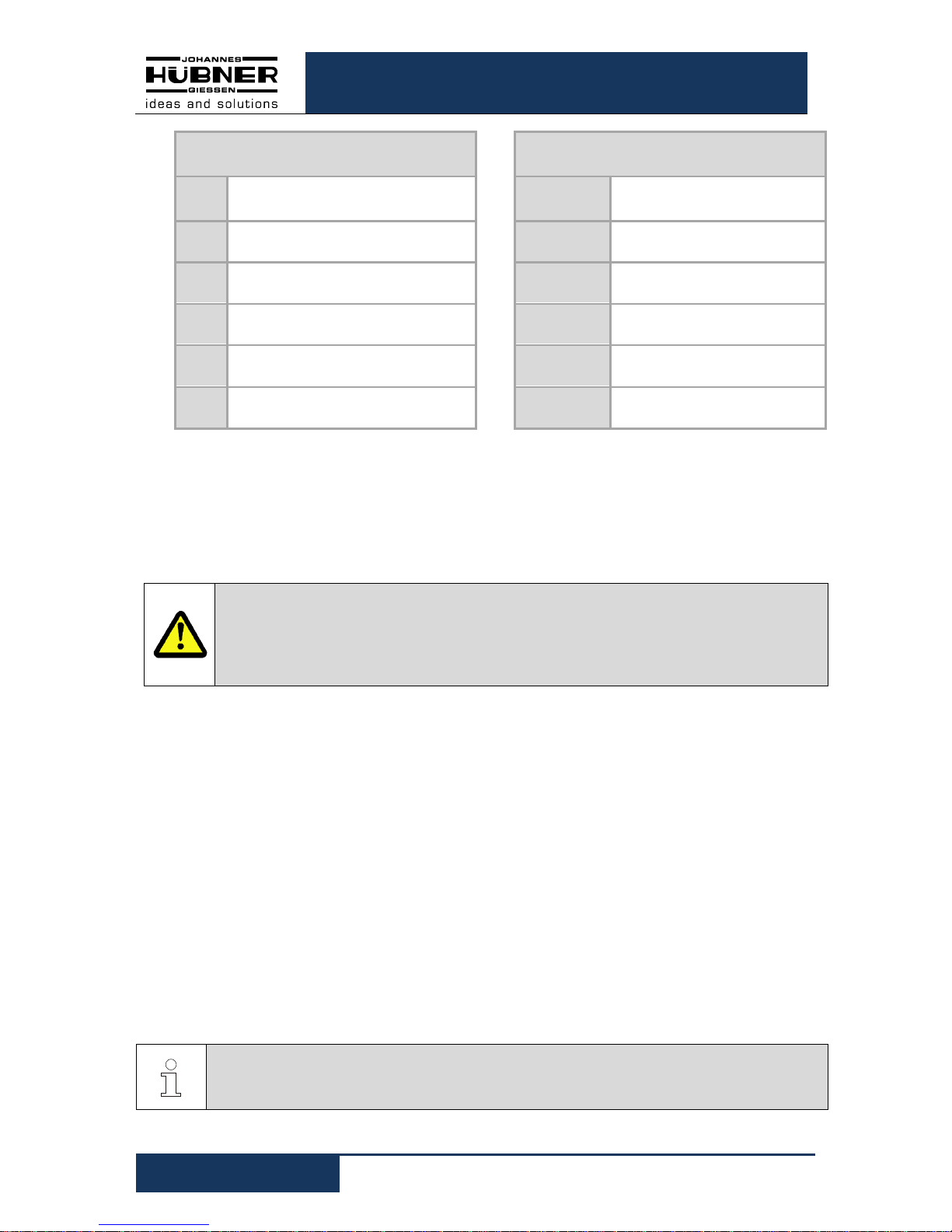

6.4 Input accuracy of switching points

SGS C-Modul:

Switching speed n

Input accuracy

X: Integer places

Y: Decimal places

n < 100 rpm XX.YY (e.g.: 15.87)

100 >= n < 1000 rpm XXX.Y (e.g.: 280.3)

n >= 1000 rpm XXXX (e.g.: 2050)

SRC C-Modul:

The input accuracy of the position switching points depends on the calibration factor.

The input of position switching points is limited to 9 decimal places. The number of

places after the decimal point is limited to 3 decimal places.

Calibration factor k

Input accuracy position

switching points

X: Integer places

Y: Decimal places

k < 10

XXXXXXXX

e.g.: 27354

10 >= k < 100

XXXXXXX.Y

e.g.: 27354.3

100 >= k < 1000

XXXXXX.YY

e.g.: 27354.34

k >= 1000

XXXXX.YYY

e.g.: 27354.345

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

28

USC42_SCU-KonfigManual-en_R5

6.5 Error handling

Numerous diagnostic measures check the functions and operating conditions of the

USC 42 at power up and during runtime.

In the event of a deviation, the error state (safe

state) is initiated and the error is stored in the error

memory.

An error distinction is made between "internal errors" and "external errors".

External errors are caused by external influences, e.g. exceeding the max.

permissible speed or exceeding the max. permissible temperature. The errors are

explained in the parameterization software with a brief description of the error, as

described in Chap. 6.5.1 displayed.

External errors are reset by a reset (reset input or reset button in the US42Pro

software) or by interrupting the supply voltage (> 2s).

Internal errors are e.g. triggered by deviations of the device-internal program

sequence. The errors are displayed in the parameterization software with error

number and the designation "internal error". An analysis of the cause of the error is

only possible with expert knowledge. To do this, the user must send the contents of

the fault memory to the manufacturer (see chapter 4.1.19).

Internal errors can only be reset via the reset

button in the US42OPro software (factory

setting).

Resetting the internal error can be set with the US42Pro software to match that of

the external error.

Resetting the error triggers a system restart with a complete system check. If an

error is detected again, the USC 42 remains in fault state.

The error state can be assigned to a switching output with the parameterization

software.

Fig. 6-12

: Error message

Fig. 6-13: Reset internal error

U-ONE®-SAFETY Compact

Configuration manual SCU C / SRC C / SGS C

USC42_SCU-KonfigManual-en_R5

29

6.5.1 Error table

Error no. Description

30 Undervoltage detected

31, 32 Overvoltage detected

35 Fell below min. temperature

36 Max. temperature exceeded

40 Error reset input

45 Error preset input

48 Error output

50 Fall below system limit

51 System limit exceeded

52 Operating range (system limit) too great

55 Maximum device speed exceeded

60 Start-up during parameterization

61 Start-up during switch test

62 Start-up during preset (software only)

63 Invalid condition for preset

65 Timeout during parameterization

66 Switched off during parameterization

67 Switched off while saving parameters

68 Start-up during factory reset

100-255 Internal diagnostics error detected

Loading...

Loading...