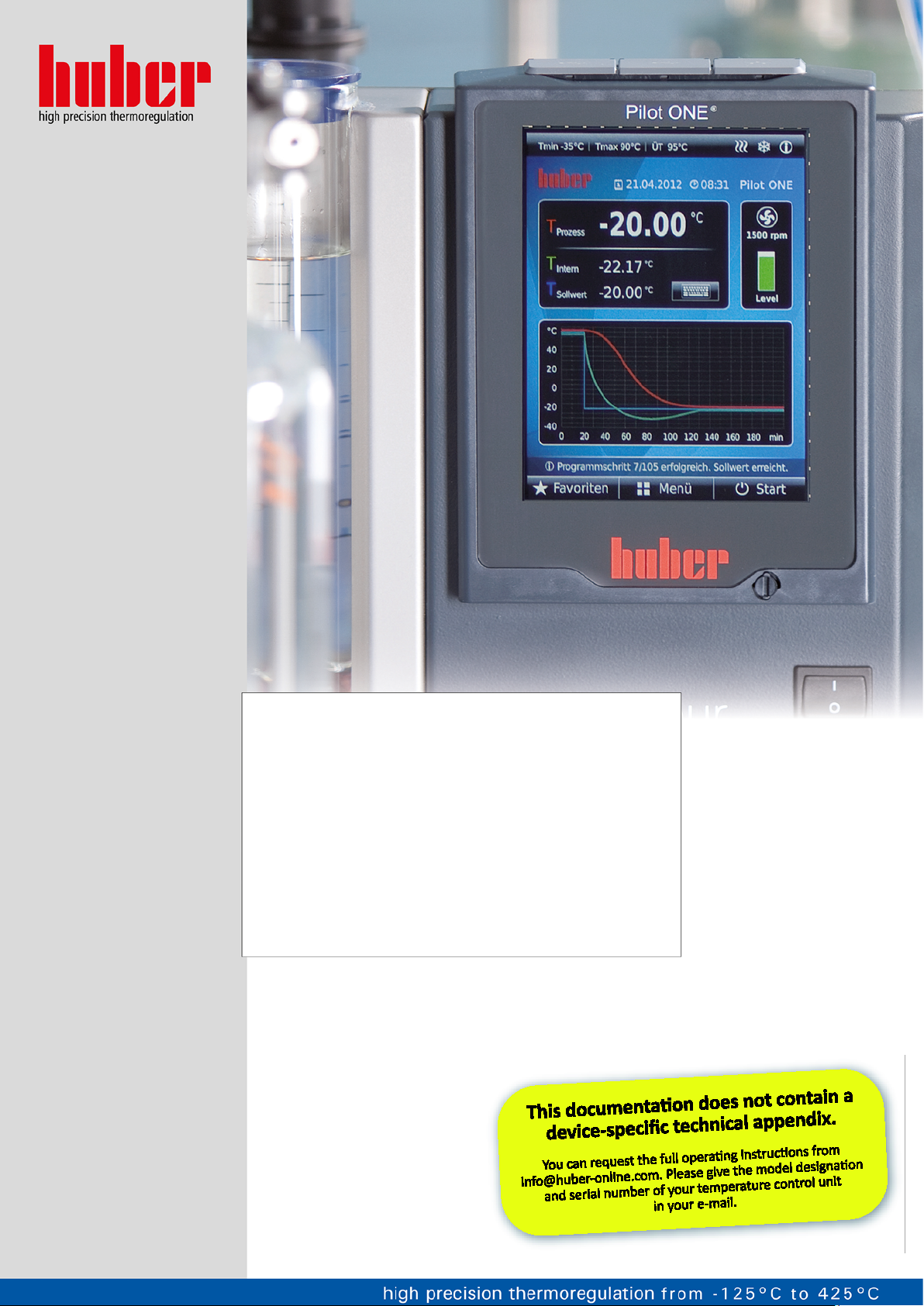

Huber Unichiller 007 OLÉ, Unichiller 015 OLÉ, Unichiller 025 OLÉ, Unichiller 012 OLÉ, Unichiller 010 OLÉ Instruction Manual

Minichiller® OLÉ

Unichiller® OLÉ

Operation Manual

V1.2.0

Minichiller® OLÉ

OPERATION MANUAL

Unichiller® OLÉ

V1.2.0

OPERATION MANUAL

5

Unichiller®

TABLE-TOP MODELS

Minichiller® 280 OLÉ

Minichiller® 300 OLÉ

Minichiller® 600 OLÉ

Minichiller® 900 OLÉ

Unichiller® 007 OLÉ

Unichiller® 01x OLÉ

Unichiller® 02x OLÉ

Minichiller®

OLÉ

This operation manual is a translation of the original operation manual.

Also for models with heater.

VALID FOR:

Abbreviations used in model names:

Without = with air cooling, P = stronger Pump, w = with water cooler, -H = with heater,

V1.2.0en/12.01.18//1.0.0 Minichiller® OLÉ, Unichiller® OLÉ

plus = with RS232 Interface

OPERATION MANUAL

6

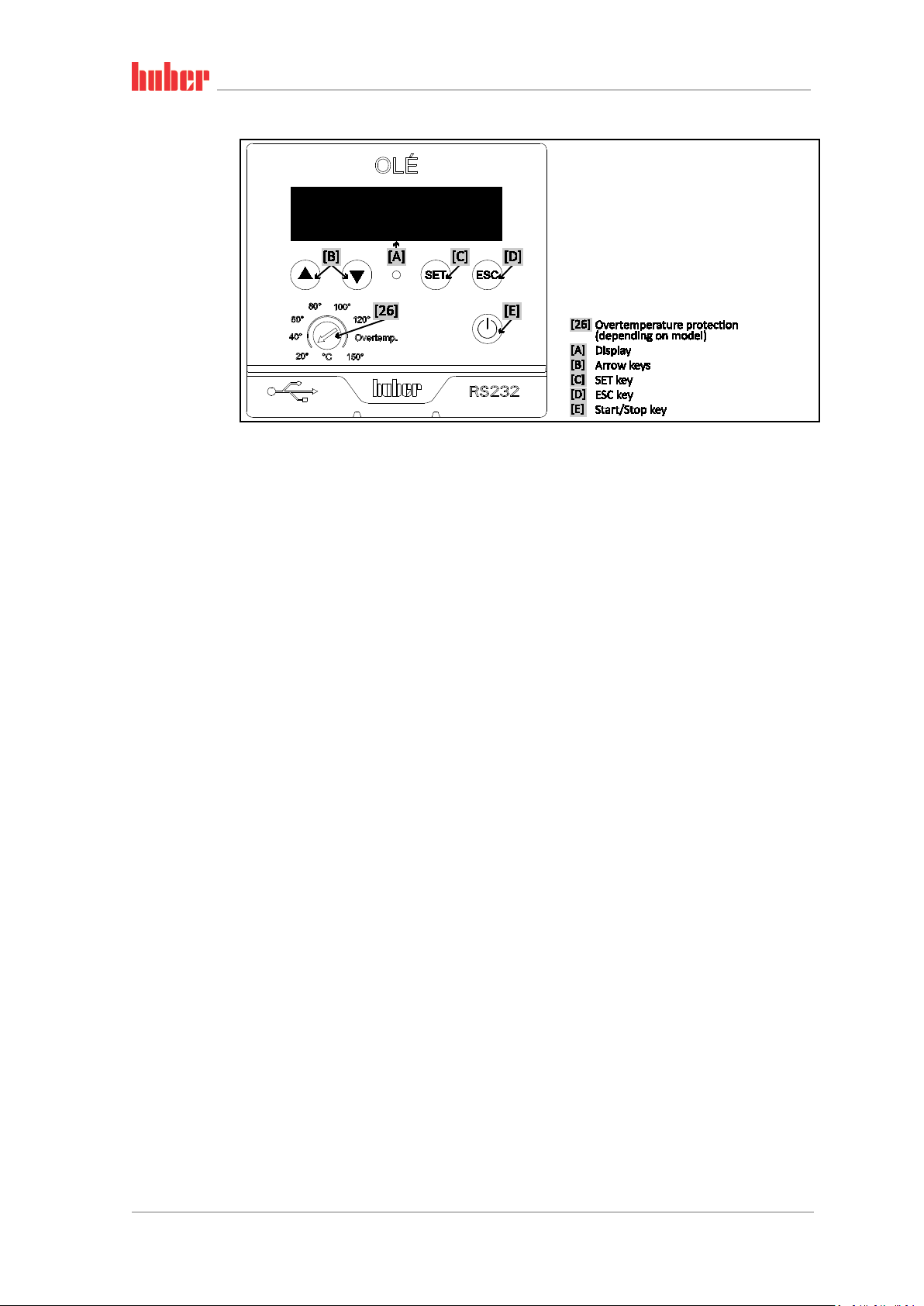

The control panel:

Displays and keys

Minichiller® OLÉ, Unichiller® OLÉ V1.2.0en/12.01.18//1.0.0

7

OPERATION MANUAL

Table of contents

V1.2.0en/12.01.18//1.0.0

1 Introduction 12

1.1 Details on the declaration of conformity ....................................................... 12

1.2 Safety .......................................................................................................... 12

1.2.1 Symbols used for Safety Instructions .............................................................. 12

1.2.2 Proper operation ............................................................................................. 13

1.2.3 Reasonably foreseeable misuse ...................................................................... 13

1.3 Responsible bodies and operators – Obligations and requirements............... 14

1.3.1 Obligations of the responsible body ............................................................... 14

1.3.1.1 Proper disposal of resources and consumables ......................................... 14

1.3.1.2 Temperature control unit with natural refrigerants (NR) .......................... 15

1.3.1.3 Temperature control units with fluorinated greenhouse gases/refrigerants17

1.3.2 Requirements for operators ........................................................................... 17

1.3.3 Obligations of the operators ........................................................................... 17

1.4 General information ..................................................................................... 17

1.4.1 Description of workstation ............................................................................. 17

1.4.2 Safety devices to DIN 12876 ........................................................................... 18

1.4.2.1 Mechanical overtemperature protection ................................................... 18

1.4.2.2 Low level protection ................................................................................... 18

1.4.3 Further protective devices .............................................................................. 19

1.4.3.1 Power interruption ..................................................................................... 19

1.5 Exemplary illustrations of the cooling variants .............................................. 19

1.5.1 Air cooling ....................................................................................................... 19

1.5.2 Water cooling .................................................................................................. 20

1.5.3 Consequence of inadequate energy dissipation ............................................. 20

2 Commissioning 21

2.1 In-plant transport ......................................................................................... 21

2.1.1 Lifting and transporting the temperature control unit ................................... 21

2.1.1.1 Temperature control unit with lifting eyes ................................................ 21

2.1.1.2 Temperature control unit without lifting eyes ........................................... 22

2.1.2 Positioning the temperature control unit ....................................................... 22

2.1.2.1 Temperature control unit with casters ...................................................... 22

2.1.2.2 Temperature control unit without casters ................................................. 22

2.2 Unpacking .................................................................................................... 22

2.3 Ambient conditions ...................................................................................... 23

2.3.1 EMC-specific notes .......................................................................................... 24

2.4 Installation conditions .................................................................................. 24

2.5 Recommended temperature control and cooling water hoses ...................... 25

2.6 Wrench sizes and torques ............................................................................. 25

2.7 Temperature control units with water cooling .............................................. 25

2.8 Preparations for operation ........................................................................... 27

2.8.1 Unscrewing/activating the leveling feet (if any) ............................................. 27

2.8.2 Opening/closing the bypass valve ................................................................... 27

2.8.3 Enable / Disable silent operation (optional) ................................................... 28

2.9 Connecting externally closed application ...................................................... 28

2.9.1 Connecting an externally closed application .................................................. 28

2.10 Connecting to the power supply ................................................................... 29

V1.2.0en/12.01.18//1.0.0 Minichiller® OLÉ, Unichiller® OLÉ

OPERATION MANUAL

8

2.10.1 Connection using socket with protective earth (PE) ....................................... 29

2.10.2 Connection via hard wiring ............................................................................. 30

3 Function description 31

3.1 Function description of the temperature control unit ................................... 31

3.1.1 General functions ............................................................................................ 31

3.1.2 Other functions ............................................................................................... 31

3.2 Information on the thermal fluids ................................................................ 31

3.3 To be noted when planning the test ............................................................. 32

3.4 Display and control instruments ................................................................... 33

3.4.1 Display ............................................................................................................. 33

3.4.2 Control instruments ........................................................................................ 34

3.4.2.1 Arrow keys .................................................................................................. 34

3.4.2.2 SET key ........................................................................................................ 34

3.4.2.3 ESC key ....................................................................................................... 35

3.4.2.4 Start/Stop key ............................................................................................. 35

3.4.3 Adjusting settings ............................................................................................ 35

3.5 Menu function ............................................................................................. 36

3.6 Functional examples .................................................................................... 37

3.6.1 Selecting a language ....................................................................................... 37

3.6.2 Setting the setpoint ........................................................................................ 37

3.6.3 Changing the Auto-Start function ................................................................... 37

4 Setup mode 38

4.1 Setup mode ................................................................................................. 38

4.1.1 Turning on the temperature control unit ....................................................... 38

4.1.2 Setting the overtemperature (OT) protection ................................................ 38

4.1.2.1 General information on the overtemperature protection ......................... 38

4.1.2.2 Setting the overtemperature protection .................................................... 39

4.1.3 Testing the overtemperature protection for functionality ............................. 39

4.2 Filling, venting, degassing and draining ......................................................... 40

4.2.1 Filling and venting externally closed application ............................................ 40

4.2.1.1 Filling and venting with >Sight glass< [23] ................................................. 41

4.2.1.2 Filling and venting with >Level indicator and drain< [38] .......................... 42

4.2.2 Draining externally closed applications .......................................................... 43

4.2.2.1 Draining with >Sight glass< [23] ................................................................. 43

4.2.2.2 Draining with >Level indicator and drain< [38] .......................................... 44

5 Normal operation 45

5.1 Automatic operation .................................................................................... 45

5.1.1 Temperature control ....................................................................................... 45

5.1.1.1 Starting the temperature control process .................................................. 45

5.1.1.2 Ending the temperature control process ................................................... 45

6 Interfaces and data communication 46

6.1 Controller interfaces .................................................................................... 46

6.1.1 USB-2.0 interface ............................................................................................ 46

6.1.1.1 USB-2.0 interface, device ........................................................................... 46

6.1.2 RS232 jack ....................................................................................................... 46

6.2 Interfaces on the temperature control unit (optional) ................................... 46

6.2.1 RS232 jack ....................................................................................................... 47

6.2.2 Connection jack for Pt100 process display sensor .......................................... 47

6.2.3 Jack ECS (External Control Signal) standby ..................................................... 47

Minichiller® OLÉ, Unichiller® OLÉ V1.2.0en/12.01.18//1.0.0

9

OPERATION MANUAL

6.2.4 Connector POKO (floating contact) alarm ...................................................... 48

6.3 Data communication .................................................................................... 48

6.3.1 LAI commands ................................................................................................. 49

6.3.1.1 Command “V” (Verify) ................................................................................ 49

6.3.1.2 Command “L” (Limit) .................................................................................. 50

6.3.1.3 Command “G” (General) ............................................................................ 50

6.3.2 PP commands .................................................................................................. 52

7 Service/maintenance 53

7.1 Displays in the event of faults ....................................................................... 53

7.2 Maintenance ................................................................................................ 54

7.2.1 Function check and visual inspection ............................................................. 54

7.2.2 Replacing temperature control or coolant hoses ........................................... 55

7.2.2.1 Replacing temperature control hoses ........................................................ 55

7.2.2.2 Replacing coolant hoses ............................................................................. 55

7.2.3 Clean liquefier fins (air-cooled temperature control unit) ............................. 56

7.2.4 Clean hat-type strainer (dirt trap) (water-cooled temperature control unit) . 57

7.3 Thermal fluid inspection, replacement and circuit cleaning ........................... 57

7.3.1 Thermal fluid replacement ............................................................................. 58

7.3.1.1 Externally closed application ...................................................................... 58

7.3.2 Rinsing the thermal fluid circuit ...................................................................... 58

7.3.2.1 Rinsing a thermofluid circuit with >Sight glass< [23] ................................. 58

7.3.2.2 Rinsing the thermofluid circuit with >Level indicator and drain< [38] ....... 59

7.4 Cleaning the surfaces ................................................................................... 60

7.5 Inspect the mechanical seal .......................................................................... 60

7.6 Plug contacts ................................................................................................ 61

7.7 Decontamination/repairs ............................................................................. 61

8 Shutting down 62

8.1 Safety instructions and basic principles ........................................................ 62

8.2 Switch-off .................................................................................................... 62

8.3 Draining the cooling water ........................................................................... 63

8.3.1 Draining process ............................................................................................. 63

8.4 Packing ........................................................................................................ 63

8.5 Shipping ....................................................................................................... 63

8.6 Disposal ....................................................................................................... 64

8.7 Phone number and company address ........................................................... 65

8.7.1 Telephone number: Customer Support .......................................................... 65

8.7.2 Telephone number: Sales ............................................................................... 65

8.7.3 Email address: Customer Support ................................................................... 65

8.7.4 Service/return address .................................................................................... 65

8.8 Certificate of Compliance ............................................................................. 65

9 Annex 66

V1.2.0en/12.01.18//1.0.0 Minichiller® OLÉ, Unichiller® OLÉ

OPERATION MANUAL

10

Minichiller® OLÉ, Unichiller® OLÉ V1.2.0en/12.01.18//1.0.0

OPERATION MANUAL

11

Foreword

Dear Customer,

Thank you for choosing a temperature control unit from Peter Huber Kältemaschinenbau AG. You

have made a good choice. Thank you for your trust.

Please read the operation manual carefully before putting the unit into operation. Strictly follow all

notes and safety instructions.

Follow the operation manual with regard to transport, start-up, operation, maintenance, repair,

storage and disposal of the temperature control unit.

We fully warrant the temperature control unit for the specified normal operation.

The models listed on page 5 are referred to in this operation manual as temperature control units

and Peter Huber Kältemaschinenbau AG as Huber company or Huber.

Liability for errors and misprints excluded.

The following trademarks and the Huber logo are registered trademarks of Peter Huber Kältemaschinenbau AG

in Germany and/or other countries worldwide: BFT®, CC®, CC-Pilot®, Com.G@te®, Compatible Control®,

CoolNet®, DC®, E-grade®, Grande Fleur®, KISS®, Minichiller®, Ministat®, MP®, MPC®, Peter Huber Minichiller®,

Petite Fleur®, Pilot ONE®, RotaCool®, Rotostat®, SpyControl®, SpyLight®, Tango®, TC®, UC®, Unical®, Unichiller®,

Unipump®, Unistat®, Unistat-Pilot®, Unistat Tango®, Variostat®, Web.G@te®. The following trademarks are

registered in Germany to DWS Synthesetechnik: DW-Therm®, DW-Therm HT®

V1.2.0en/12.01.18//1.0.0 Minichiller® OLÉ, Unichiller® OLÉ

Introduction

12

OPERATION MANUAL Chapter 1

1 Introduction

1.1 Details on the declaration of conformity

The equipment complies with the basic health and safety requirements of the European Directives

listed below:

▪ Machinery Directive 2006/42/EC

▪ Low Voltage Directive 2006/95/EC

▪ EMC Directive 2004/108/EC

1.2 Safety

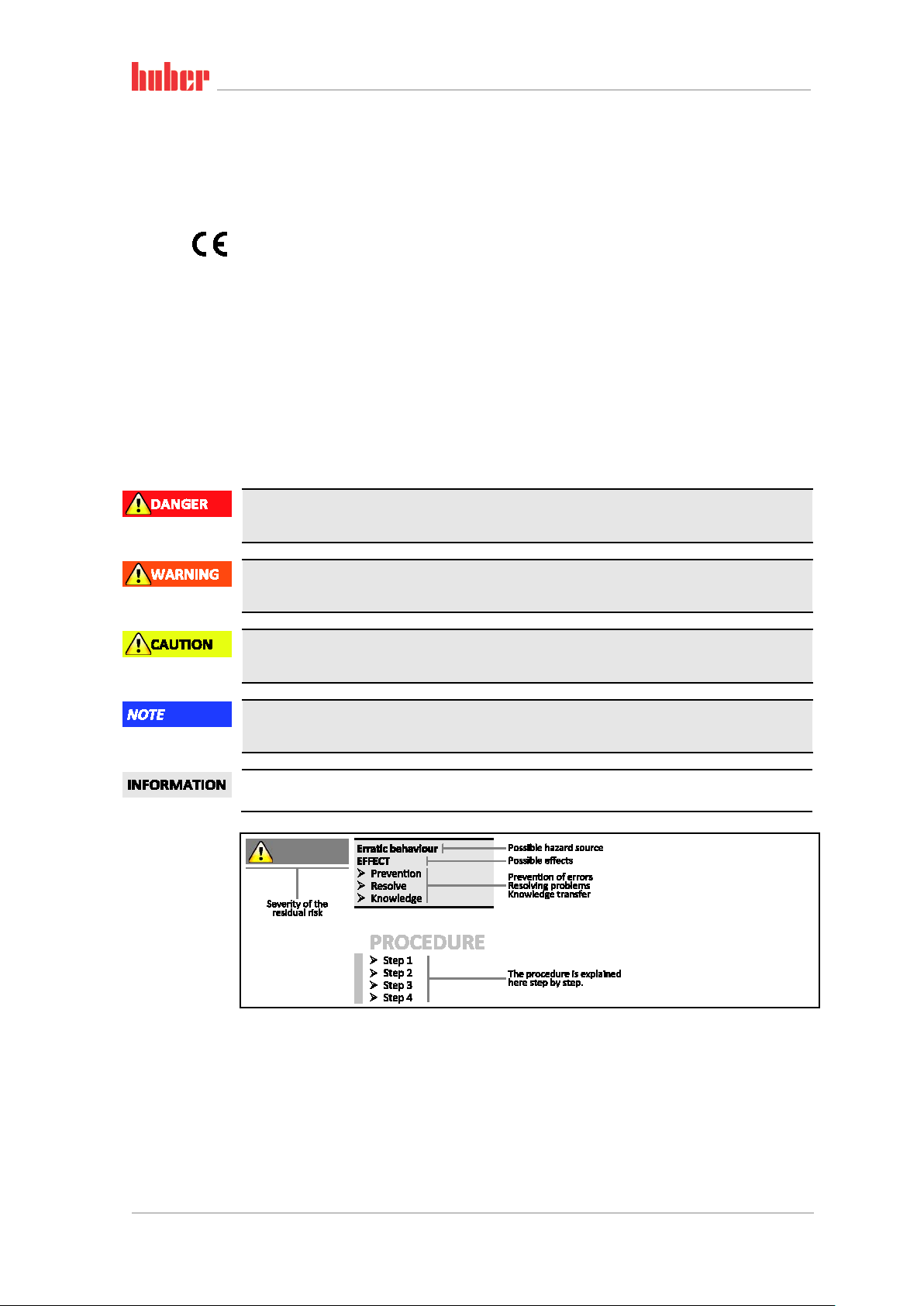

1.2.1 Symbols used for Safety Instructions

Safety instructions are marked by the below combinations of pictograms and signal words. The

signal word describes the classification of the residual risk when disregarding the operation manual.

Denotes an immediate hazardous situation that will result in death or serious injuries.

Safety information and

procedure

Denotes a general hazardous situation that may result in death or serious injuries.

Denotes a hazardous situation that can result in injury.

Denotes a situation that can result in property material damage.

Denotes important notes and usable hints.

The safety information in this operation manual is designed to protect the responsible body, operator and the equipment from damage. Safety information must always appear BEFORE instructions

and at the beginning of each chapter. You should be first informed about the residual risks due to

misuse before you begin an operation.

Minichiller® OLÉ, Unichiller® OLÉ V1.2.0en/12.01.18//1.0.0

Introduction

13

Do NOT install or start up the temperature control unit within an ATEX zone.

ages!

Do not ignore, bypass, dismantle or disconnect any safety devices!

Chapter 1 OPERATION MANUAL

1.2.2 Proper operation

Operating the temperature control unit in a potentially explosive area

DEATH THROUGH EXPLOSION

Improper use

SERIOUS INJURY AND PROPERTY DAMAGE

Store the operation manual where it is easy to access in close proximity to the temperature

control unit.

Only adequately qualified operators may work with the temperature control unit.

Operators must be trained before handling the temperature control unit.

Check that the operators have read and understood the operation manual.

Define precise responsibilities of the operators.

Personal protective equipment must be provided to the operators.

Be sure to follow the responsible body’s safety rules to protect life and limb and to limit dam-

Modifications to the temperature control unit by third-parties

DAMAGE TO THE TEMPERATURE CONTROL UNIT

Do not allow third parties to make technical modifications to the temperature control unit.

In case of any modification of the temperature control unit not approved by the manufacturer,

the CE declaration of conformity becomes invalid.

Only specialists trained by the manufacturer may carry out modifications, repairs or mainte-

nance work.

The following must be observed without fail:

Only use the temperature control unit in a fault-free condition!

Have start-up and repairs carried out only by specialists!

The temperature control unit must not be used for any purposes other than temperature control in

accordance with the operation manual.

The temperature control unit is manufactured for industrial use. The temperature control unit maintains the temperature of certain applications, including glass or metal reactors or other expedient

items in laboratories and industry. Flow-through coolers and calibration baths must be used only in

combination with Huber temperature control units. Thermal fluids suitable for the overall system

are used. The chilling and heating capacity is provisioned at the pump connections or - where present - in the tempering bath. The technical specification of the temperature control unit is given in

the data sheet (from page 66 in section »Annex«). The temperature control unit must be installed,

configured and operated according to the handling instructions in this operating manual. Failure to

comply with the operation manual is deemed improper use. The temperature control unit conforms

to state-of-the-art technology and the recognized safety regulations. Safety devices are built into

your temperature control unit.

1.2.3 Reasonably foreseeable misuse

Use with medical devices (e.g. in Vitro diagnostic procedure) or for direct foodstuff temperature

control is NOT permissible.

The temperature control unit must NOT be used for any purposes other than temperature control in

accordance with the operation manual.

The manufacturer accepts NO liability for damage caused by technical modifications to the temper-

ature control unit, improper handling or use of the temperature control unit if the operation manual is not observed.

V1.2.0en/12.01.18//1.0.0 Minichiller® OLÉ, Unichiller® OLÉ

Introduction

14

OPERATION MANUAL Chapter 1

1.3 Responsible bodies and operators – Obligations and

requirements

1.3.1 Obligations of the responsible body

The operation manual is to be stored where it is easy to access in close proximity to the temperature

control unit. Only adequately qualified operators (e.g. chemists, CTA, physicists etc.) are permitted

to work with the temperature control unit. Operators must be trained before handling the temperature control unit. Check that the operators have read and understood the operation manual. Define

precise responsibilities of the operators. Personal protective equipment must be provided to the

operators.

▪ The responsible body must install a condensation water / thermofluid drip tray below the tem-

perature control unit.

▪ The responsible body must check whether national regulations require the mandatory installation

of a drain tray for the installation area of the temperature control unit/the entire system.

▪ Our temperature control unit complies with all applicable safety standards.

▪ Your system, which uses our temperature control unit, must be as safe.

▪ The responsible body must design the system so as to ensure it is safe.

▪ Huber is not responsible for the safety of your system. The responsible body is responsible for the

safety of the system.

▪ Whilst the temperature control unit provided by Huber meets all the applicable safety standards,

integration into a system may give rise to hazards that are characteristic of the other system’s design and beyond the control of Huber.

▪ It is the responsibility of the system integrator to ensure that the overall system, into which this

temperature control unit is integrated, is safe.

▪ The >Mains isolator< [36] (if present) may be provided with a facility to lock the main isolator in

the off position to facilitate safe system installation and maintenance of the temperature control

unit. It is the responsibility of the responsible body to develop any lock-out/tag-out procedure in

accordance with local regulations (e.g. CFR 1910.147 for the US).

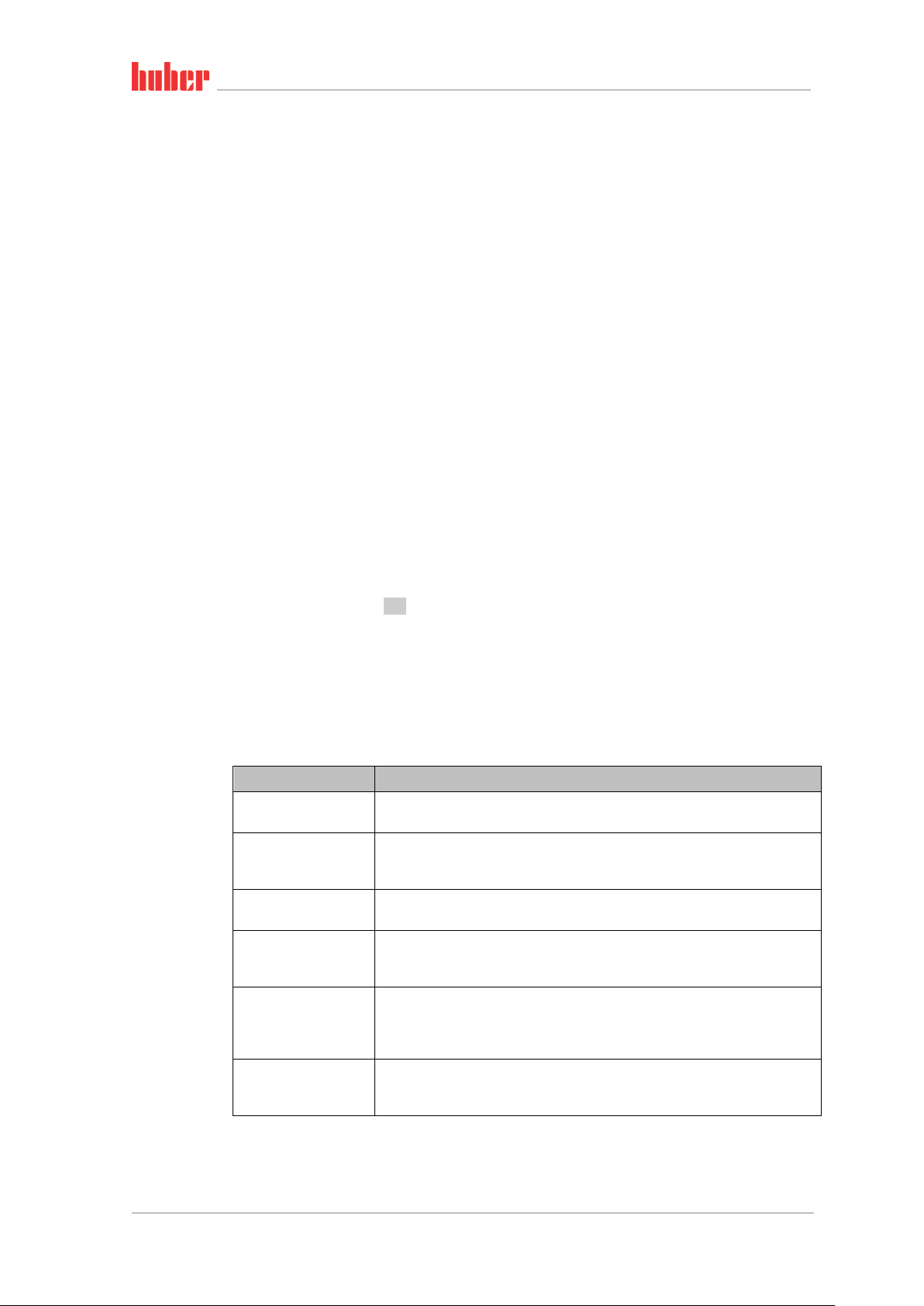

1.3.1.1 Proper disposal of resources and consumables

Do comply with all national disposal regulations applicable for you. Contact your local waste management company for any questions concerning disposal.

Overview

Material / Aids Disposal / Cleaning

Temperature control

unit packaging material

Thermal fluid

Filling accessories, e.g.

beaker

Aids such as towels,

cleaning cloths

Cleaning agents such as

stainless steel cleaning

agents, sensitive-fabrics

detergents

Consumables such as air

filter mats, temperature

control hoses

Keep the packaging material for future use (e.g. transport).

Please refer to the safety data sheet of the thermal fluid used for information on its

proper disposal.

Use the original thermal fluid container when disposing it.

Clean the filling accessories for reuse. Make sure that the materials and cleaning

agents used are properly disposed of.

Tools used to take up spilled thermal fluid must be disposed of in the same fashion

as the thermal fluid itself.

Tools used for cleaning must be disposed of depending on the cleaning agent used.

Please refer to the safety data sheet of the cleaning agent used for information on its

proper disposal.

Use the original containers when disposing of large quantities of cleaning agents.

Please refer to the safety data sheet of the consumables used for information on

their proper disposal.

Minichiller® OLÉ, Unichiller® OLÉ V1.2.0en/12.01.18//1.0.0

Introduction

15

The temperature control unit is not approved for operation in an ATEX zone.

Chapter 1 OPERATION MANUAL

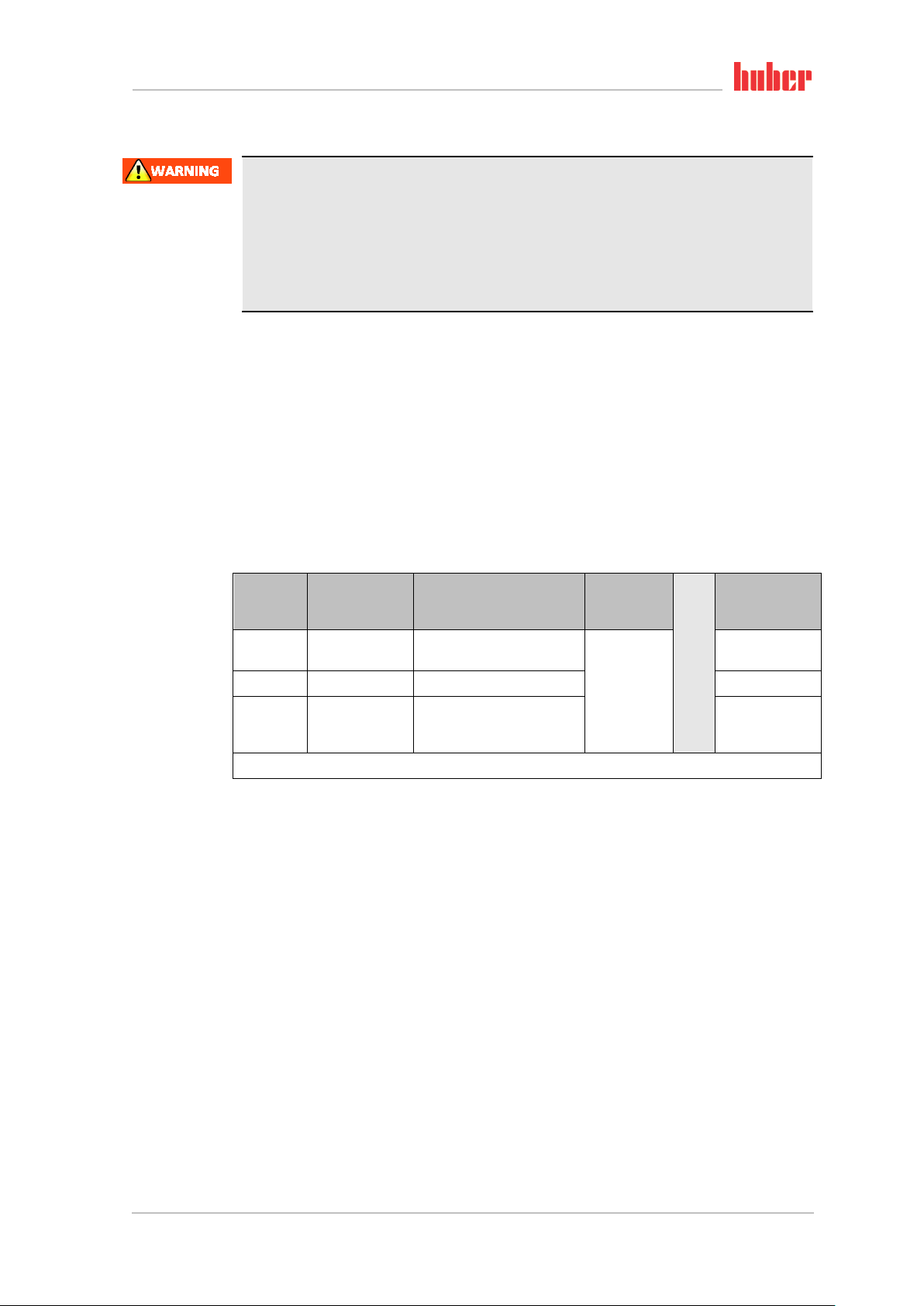

1.3.1.2 Temperature control unit with natural refrigerants (NR)

Over 8 g refrigerant per m³ room air

DEATH OR SERIOUS INJURY DUE TO EXPLOSION

Observe the rating plate (amount of natural refrigerant contained) and the room size (maxi-

mum room concentration of natural refrigerant in case of leakage) when installing the temperature control unit.

Over 8 g refrigerant per m³ room air: A gas warning sensor must be fitted and functioning.

The gas warning sensor must be calibrated and maintained at regular intervals (between 6 and

12 months).

Huber products with natural refrigerants work with numerous proven, safe and highly-sustainable

technologies. The relevant standards and regulations for temperature control units with natural

refrigerants contain a number of stipulations, the importance of complying with which is set out

below. Also observe on page 13 the section »Proper operation«.

Huber temperature control units are constructed to be permanently sealed and are carefully

checked for leak tightness. Temperature control units with more than 150 g natural refrigerant are

equipped with an additional gas warning sensor. To find out whether your temperature control unit

is equipped with a gas warning sensor, refer to the data sheet from page 66 in section »Annex«.

The fill quantity of your temperature control unit is stated on the data sheet (from page 66 in section »Annex«) or on the rating plate on the rear of the temperature control unit. Observe page 23,

section »Ambient conditions« and page 24, section »Installation conditions«.

Classifying the applica-

tion field

Class of

application

field

A General

B Monitored Laboratories 2.5 kg

C

Temperature control units with more than 1 kg refrigerant must not be installed below ground level (GL).

Application field

Access only for

authorized

persons

Example of the installation

location

Publicly accessible area in a

public building

Production equipment 10.0 kg

Max.

quantity of

refrigerant

3

8 g/m

ambient air

Max. permissible

quantity above

ground level (GL)

1.5 kg

AND

Temperature control units with up to 150 g natural refrigerant

▪ The temperature control unit has been constructed to the requirements of EU and EFTA coun-

tries.

▪ Use the table as guidance for classifying the application field. Respect the max. refrigerant quanti-

ty stated therein.

Temperature control units WITH pre-installed gas warning sensor and > 150 g natural refrigerant

▪ The temperature control unit has been constructed to the requirements of EU and EFTA coun-

tries.

▪ Use the table as guidance for classifying the application field. Respect the max. refrigerant quanti-

ty or the permissible highest quantity above ground level (GL) stated therein.

▪ Ventilation with optional supply and exhaust air connection: Use the temperature control unit’s

supply and exhaust air connection to connect it to the building’s exhaust system (see wiring diagram from page 66 in Section »Annex«). First, remove the cover to the air inlet connection; an air

filter mat is installed behind it. This air filter mat must be checked / replaced at regular intervals

so that the air flowing into the temperature control unit is not reduced (see page 54, Section

»Function check and visual inspection«). Connect the building’s exhaust system with the temperature control unit’s exhaust air port. The cover of the supply air port mustnot be removed if the

exhaust system provided in a building is not used.

V1.2.0en/12.01.18//1.0.0 Minichiller® OLÉ, Unichiller® OLÉ

Introduction

16

The temperature control unit is not approved for operation in an ATEX zone.

OPERATION MANUAL Chapter 1

▪ The mounting plate for mounting a gas warning sensor is located inside the temperature control

unit in the vicinity of the >Cable entry gas warning sensor<[100].

▪ For the position of the >Cable entry gas warning sensor< [100], please refer to the wiring diagram

from page

▪ Additional information on the pre-installed gas detection sensor:

- The built-in gas detection sensor enables a safety shutdown at 20% of the lower explosive

- A 24 V DC external power supply must be available for the pre-installed gas warning sen-

- The responsible body is responsible for the calibration of the gas detection sensor prior to

Temperature control units WITHOUT pre-installed gas warning sensor and > 150 g natural refrigerant

Over 8 g refrigerant per m³ room air

DEATH OR SERIOUS INJURY DUE TO EXPLOSION

Observe the rating plate (amount of natural refrigerant contained) and the room size (maxi-

mum room concentration of natural refrigerant in case of leakage) when installing the temperature control unit.

Over 8 g refrigerant per m³ room air: A gas warning sensor must be fitted and functioning.

The gas warning sensor must be calibrated and maintained at regular intervals (between 6 and

12 months).

66 in Section »Annex«.

limit via a power disconnect relay that is to be installed by the responsible body. The

temperature control unit is thus switched off early and safely in case of fault.

sor. The alarm output of the gas warning sensor uses a 4 - 20 mA signal. Please refer to the

data sheet of the gas warning sensor for further technical information. A separate pro-

cessing unit is available as an accessory for the control of the power disconnect relay. The

processing unit provides a potential-free switching contact and simultaneously supplies

power to and analyzes the gas warning sensor. Both variants require the responsible body

to provide the necessary dimensioning and installation. Please refer to the data sheet of

the gas warning sensor for the technical installation information. The alarm of the gas detection system can be connected to the responsible body’s alarm control unit. The responsible body is responsible for this and other measures.

initial operation and the observance of calibration and maintenance intervals specified in

the operating manual. We recommend to set calibration and maintenance intervals between 6 and 12 months if no information is provided. For increased safety requirements,

shorter intervals can be specified. On request, we will recommend a specialist company to

carry out calibration and maintenance.

▪ The temperature control unit has been constructed to the requirements of EU and EFTA coun-

tries.

▪ Use the table as guidance for classifying the application field. Respect the max. refrigerant quanti-

ty or the permissible highest quantity above ground level (GL) stated therein.

▪ Ventilation with optional supply and exhaust air connection: Use the temperature control unit’s

supply and exhaust air connection to connect it to the building’s exhaust system (see wiring diagram from page 66 in Section »Annex«). First, remove the cover to the air inlet connection; an air

filter mat is installed behind it. This air filter mat must be checked / replaced at regular intervals

so that the air flowing into the temperature control unit is not reduced (see page 54, Section

»Function check and visual inspection«). Connect the building’s exhaust system with the temperature control unit’s exhaust air port. The cover of the supply air port mustnot be removed if the

exhaust system provided in a building is not used.

▪ NO gas warning sensor is installed in this temperature control unit! Make sure that the installa-

tion site of the temperature control unit is sufficiently protected in the event of malfunction.

These include:

- Installation of a gas warning sensor for the building (room monitoring).

- Permanent ventilation of the temperature control unit and/or the installation site.

- All-pole disconnection in the event of malfunction of the temperature control unit.

Minichiller® OLÉ, Unichiller® OLÉ V1.2.0en/12.01.18//1.0.0

Introduction

17

Chapter 1 OPERATION MANUAL

1.3.1.3 Temperature control units with fluorinated greenhouse gases/refrigerants

F gases regulation (EC) No. 517/2014 of April 16, 2014, on fluorinated greenhouse gases, and re-

pealing Regulation (EC) No. 842/2006.

These regulations deal with all systems that contain fluorinated refrigerants. The substances dealt

with in Directive (EC) No. 1005/2009 of the European Parliament and of the Council of 16 September

2009 that deplete the ozone layer are excluded (CFC/HCFC).

The directive regulates the reduction of the emission, utilization, recovery, and destruction of certain fluorinated greenhouse gases. It also regulates the identification and disposal of products and

devices that contain these gases. Since July 4, 2007, responsible bodies must check their stationary

refrigeration systems for leaks at regular intervals, and have any leaks eliminated immediately.

Directive (EC) No. 303/2008 contains stipulations on the training and certification of companies and

personnel that are permitted to execute the specified activities.

Obligations of the responsible bodies:

▪ Directive (EC) No. 842/2006 already imposed a number of obligations upon responsible bodies

regarding certain fluorinated greenhouse gases. The new Ordinance on Fluorinated Greenhouse

Gases upholds these to a large extent. Some duties are added while others are designed differently by this new ordinance. Please refer to the text of this ordinance for a complete overview of the

individual responsibilities of responsible bodies.

▪ General obligation to reduce emissions.

▪ Only certified companies may maintain, repair or decommission refrigeration systems. The re-

sponsible bodies must verify that these companies are certified.

▪ Regular leak tests of stationary refrigeration systems by certified personnel (such as Huber service

engineers). The required test interval is based on the refrigerant filling capacity and the type of

refrigerant, converted to CO

▪ Responsibility of responsible bodies operating a plant to recover F-gases by certified personnel.

▪ Obligatory documentation requirement in the refrigeration system’s operation manual, specifying

type and volume of refrigerant used or recovered. The responsible body must keep the records

for at least 5 years after their creation and present it to the responsible authority upon request.

▪ Temperature control units with natural refrigerants (NR) are exempt from this Directive.

▪ Please refer to the data sheet or name plate of your temperature control unit for the quantity and

type of refrigerant.

▪ Additional information about the definition of the inspection interval can be found on our web-

site.

2 equivalent.

2

1.3.2 Requirements for operators

Work on the temperature control unit is reserved for appropriately qualified specialists, who have

been assigned and trained by the responsible body to do so. Operators must be at least 18 years old.

Under 18-year olds may operate the temperature control unit only under the supervision of a qualified specialist. The operator is responsible vis-a-vis third-parties in the work area.

1.3.3 Obligations of the operators

Carefully read the operation manual before operating the temperature control unit. Please observe

the safety instructions. When operating the temperature control unit, wear appropriate personal

protective equipment (e.g. safety goggles, protective gloves, non-slip shoes).

1.4 General information

1.4.1 Description of workstation

The workstation is located at the control panel in front of the temperature control unit. The workstation is determined by the customer's connected peripheries. Accordingly, it must be designed

safe by the responsible body. The workstation design also depends on the applicable requirements

of the German occupational health and safety regulations [BetrSichV] and the risk analysis for the

workstation.

V1.2.0en/12.01.18//1.0.0 Minichiller® OLÉ, Unichiller® OLÉ

Introduction

18

OPERATION MANUAL Chapter 1

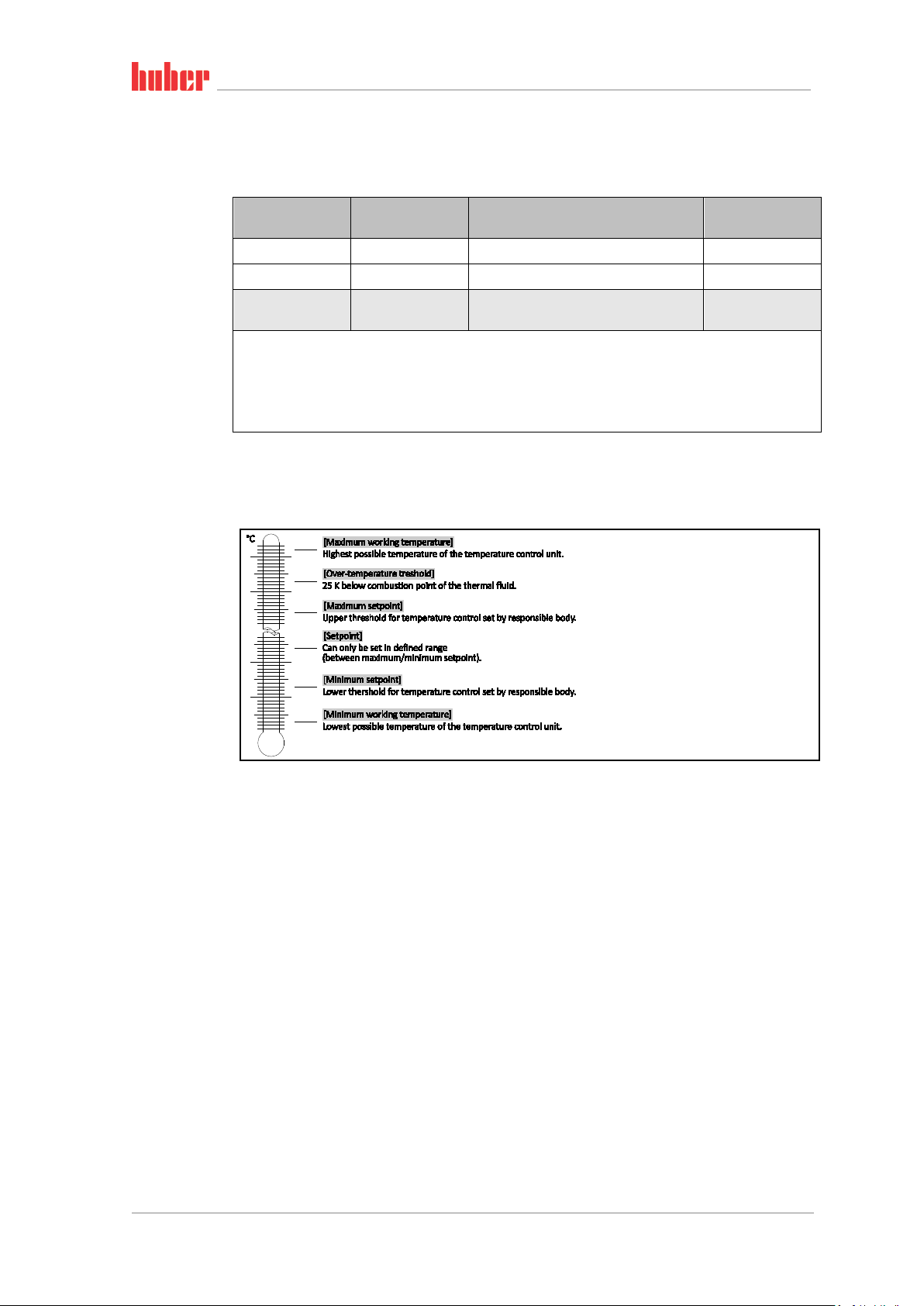

1.4.2 Safety devices to DIN 12876

The rating of your temperature control unit is stated on the data sheet in the appendix.

Rating of laboratory

thermostats and

laboratory baths

Overview of the tem-

perature thresholds

Classification

I Non-combustible a) Overheat protection c) NFL

II Combustible b) Adjustable overheat protection FL

III Combustible b)

a)

Usually water; other fluids only if non-combustible even within the temperature range of an individual fault.

b)

The temperature control media must have a combustion point of ≥ 65 °C.

c)

The overheat protection can, for instance, can be realized using a suitable fill level sensor or a suitable temper-

ature limiter.

d)

Optional at the choice of the manufacturer.

▪ Temperature control units with heating correspond to class number III/FL. These temperature

control units are characterized by an “H” in the device name.

▪ Temperature control units without heating correspond to class number I/NFL.

Temperature

control medium

Technical requirements Identification d)

Adjustable overtemperature protection

and additional low-level protection

FL

1.4.2.1 Mechanical overtemperature protection

Only temperature control units with a heater are fitted with a mechanical overtemperature protection. Set the overtemperature protection as described on page 38 in section »Setting the overtem-

perature (OT) protection«.

1.4.2.2 Low level protection

Minichiller with heater: A mechanical float is used for level monitoring. A floating body, which is

guided in a device, floats on the surface of the thermal fluid. Depending on the level of the thermal

fluid, the float device signals the electronics a state of good (in case of sufficient filling) or a state of

bad (in case of insufficient filling).The functionality of the float is checked at regular intervals during

continuous operation.

Unichiller with heater: The low level protection operates via a pressure sensor in the thermal fluid

circuit. The pump and the thermal fluid provide the required pressure at the pressure sensor. Air in

the system (fill level too low, inadequately vented) prevents the pressure from reaching the value

specified at the pressure sensor. Temperature control and circulation are interrupted.

Minichiller® OLÉ, Unichiller® OLÉ V1.2.0en/12.01.18//1.0.0

Introduction

19

Chapter 1 OPERATION MANUAL

1.4.3 Further protective devices

Emergency strategy – isolate the power supply!

Disconnect the temperature control unit from the power supply!

1.4.3.1 Power interruption

Following a power outage (or when switching on the temperature control unit), this function can be

used to determine how the temperature control unit is supposed to respond.

Auto-Start function is turned off

The temperature control is started only by manual input when the temperature control unit is

turned on.

Auto-Start function is turned on

The temperature control unit is set to the same state it was in before the power outage. For example, before the power outage: Thermoregulation is off; after power outage: Thermoregulation is off.

If temperature control is active during a power outage, the process will automatically continue after

the power outage.

Further information can be found on page 37 in section »Changing the Auto-Start function«.

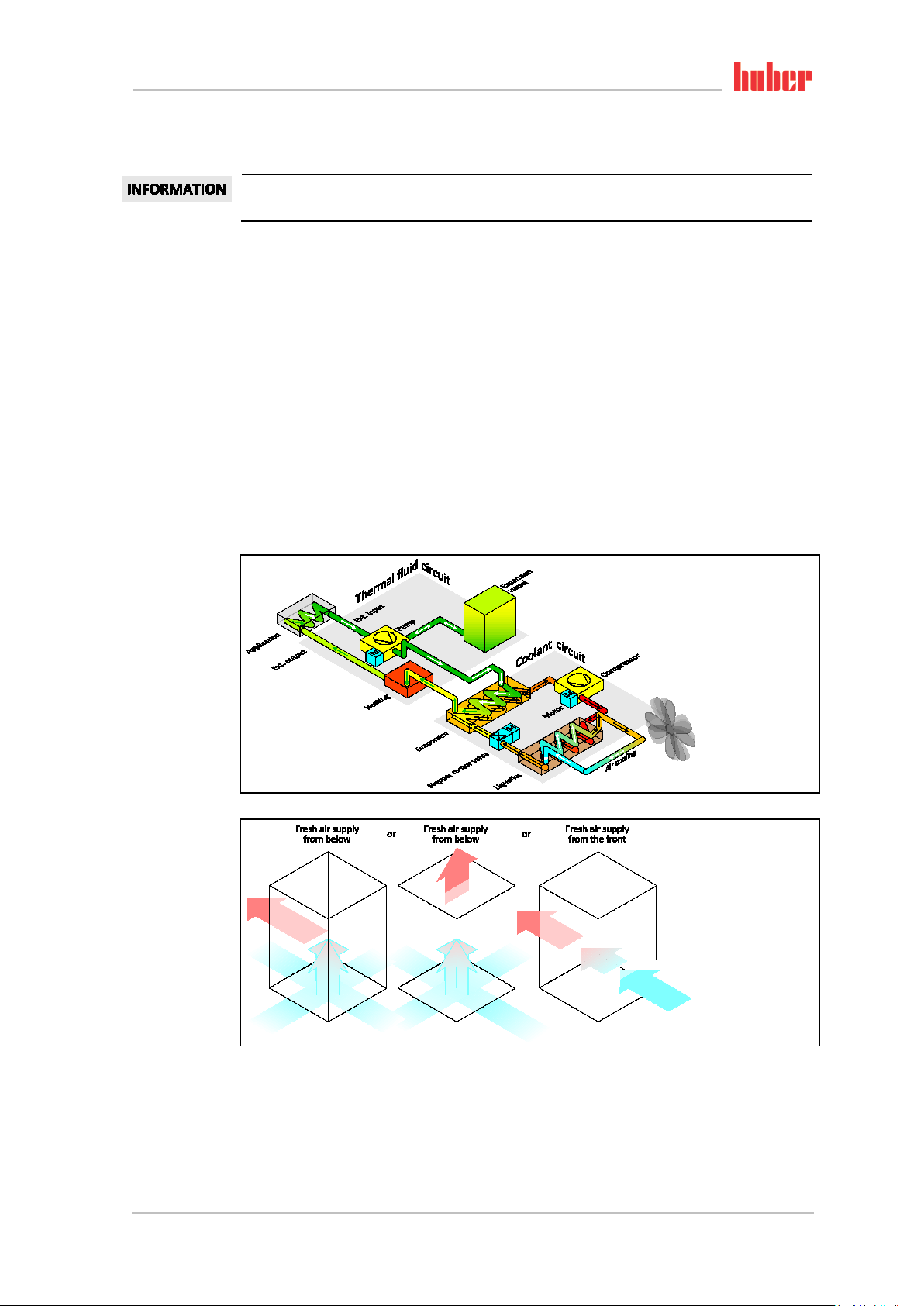

1.5 Exemplary illustrations of the cooling variants

1.5.1 Air cooling

Example: Air cooling

Air inlet

V1.2.0en/12.01.18//1.0.0 Minichiller® OLÉ, Unichiller® OLÉ

Introduction

20

OPERATION MANUAL Chapter 1

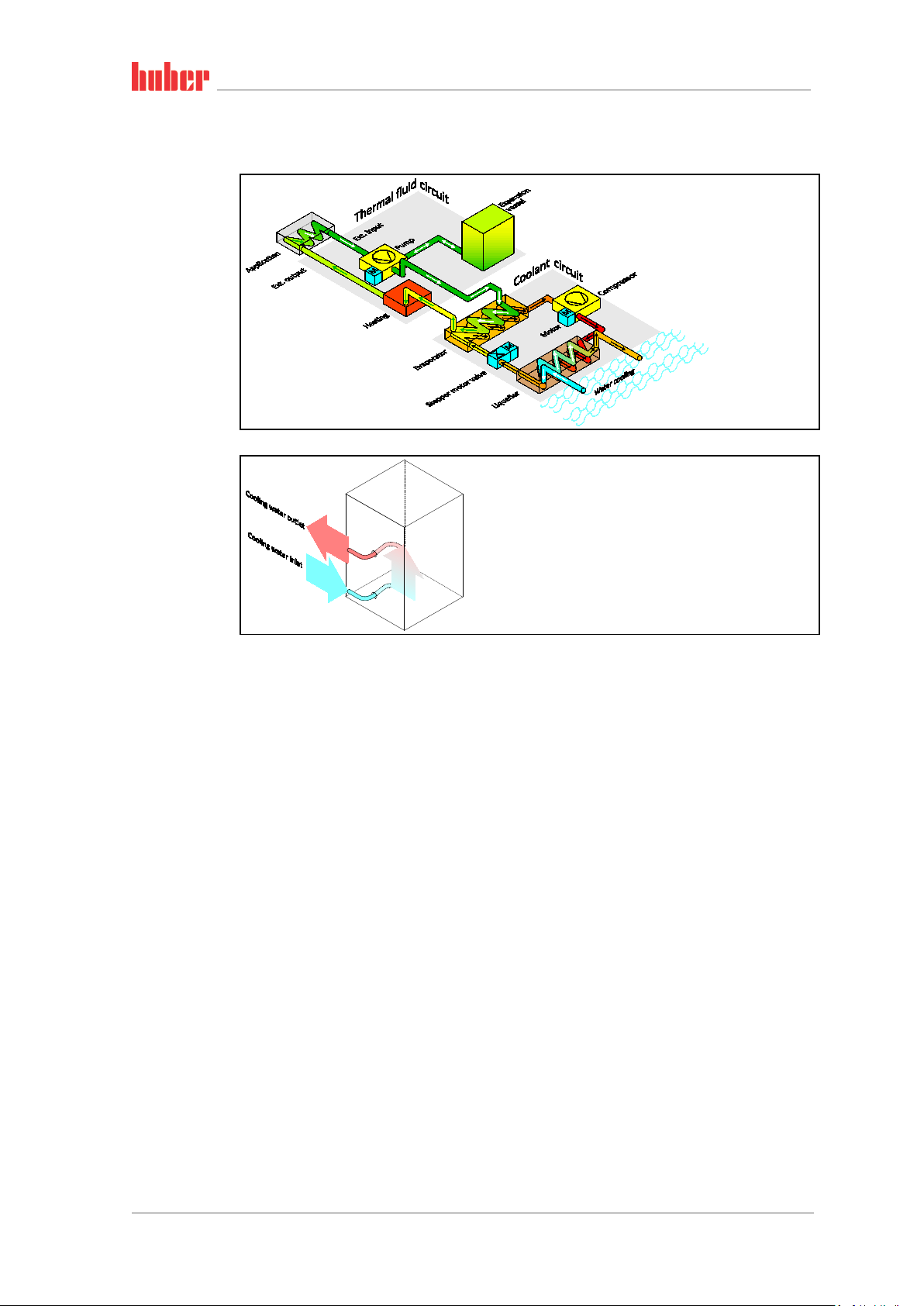

1.5.2 Water cooling

Example: Water cool-

ing

Water connection

1.5.3 Consequence of inadequate energy dissipation

Room air/cooling water

Consequences of, for instance, contamination of the liquefier fins, inadequate clearance between

temperature control unit to wall/bath wall, room air/cooling water too warm, cooling water differential pressure too low, suction strainer contamination: The refrigerant in the coolant circuit can no

longer fully discharge the admitted energy to the room air/cooling water. Thus there is not sufficient

liquefied refrigerant available, the condensation temperature and the energy consumption to rise.

Coolant circuit

Consequences of inadequate refrigerant quantity/rising condensation temperature: Not all the

cooling capacity from the coolant circuit is available at the evaporator. This means reduced energy

transmission from the thermal fluid circuit.

Thermal fluid circuit

Consequence of inadequate energy dissipation from the thermal fluid: The thermal fluid can only

dissipate the energy from your application to a limited extent.

Application

Consequences of inadequate energy dissipation from the application: The energy created (exothermic) in the application can no longer be fully dissipated.

Temperature control unit

An electronically-controlled expansion valve is used in the temperature control unit to optimize the

power adjustment. The expansion valve always provisions the maximum possible cooling capacity

within the permissible ambient temperature range. The temperature control unit switches off when

the upper range is reached (maximum permissible ambient temperature).

Minichiller® OLÉ, Unichiller® OLÉ V1.2.0en/12.01.18//1.0.0

Commissioning

21

activated parking brake!

Only transport the temperature control unit in an upright position.

weight of the temperature control unit into account.

Chapter 2 OPERATION MANUAL

2 Commissioning

2.1 In-plant transport

Temperature control unit is not transported / moved according to the specifications in this operation manual

DEATH OR SERIOUS INJURY DUE TO CRUSHING

Always transport / move the temperature control unit according to the specifications in this

operation manual.

Wear personal protective equipment during transport.

Always work with the specified number of persons when moving the temperature control unit

on casters (if any).

If the temperature control unit is equipped with casters and parking brakes:

2 parking brakes are always freely accessible when moving the temperature control unit. Activate the 2 parking brakes in an emergency!

If only one parking brake is activated on the casters in an emergency:

The temperature control unit is not stopped but rotates around the axis of the caster with the

Temperature control unit transported in a horizontal position

DAMAGE TO THE COMPRESSOR

▪ If available, use the lugs on the top side of the temperature control unit for transportation.

▪ Use an industrial truck for transport.

▪ The casters on the temperature control unit are not suitable for transport. The casters are sym-

metrically loaded with 25% of the total mass of the temperature control unit.

▪ Remove the packing material (e.g. the palette) only at the place of installation.

▪ Protect the temperature control unit from transport damage.

▪ Do not transport the temperature control unit alone and without aids.

▪ Check the load bearing capacity of the transportation route and the place of installation.

▪ The parking brakes must be activated at the casters (if any) and/or the leveling feet (if any) must

be unscrewed/activated before the temperature control unit is put into operation (see page 27,

section »Unscrewing/activating the leveling feet (if any)«).

2.1.1 Lifting and transporting the temperature control unit

2.1.1.1 Temperature control unit with lifting eyes

The temperature control unit is raised at the lifting eyes without load handling attachments

DAMAGE TO THE TEMPERATURE CONTROL UNIT

Always use load handling attachments when lifting and transporting the temperature control

unit.

The lifting eyes are only designed for a load without inclination (0°).

The load handling attachment used must be adequately dimensioned. Take the dimensions and

▪ Do not lift and transport the temperature control unit at the lifting eyes alone and without aids.

▪ Lift and transport the temperature control unit at the lifting eyes only with a crane or an industrial

truck.

▪ The crane or industrial truck must have a lifting force equal to or greater than the weight of the

temperature control unit. See the data sheet (from page 66 in section »Annex«) for the weight of

the temperature control unit.

V1.2.0en/12.01.18//1.0.0 Minichiller® OLÉ, Unichiller® OLÉ

Loading...

Loading...