Page 1

SSSSEEEERRRRIIIIEEEESSSSSSSSMMMMAAAA

SSSSUUUUBBBBMMMMIIIINNNNIIIIAAAATTTTUUUURRRREEEECCCCOOOONNNNNNNNEEEECCCCTTTTOOOORRRRSSSS

Description

SUHNER SMA connectors are precision connectors for microwave applications up to 18 GHz/

26.5 GHz. They distinguish themselves through

their high mechanical strength, high durability,

high reliability and low VSWR.

SMA launchers are the preferred connection elementforvariedmicrowavecircuits.Thereisahuge

variety of applications for SUHNER SMA connectors, such as mobile communication, test & measurement, instruments, avionics, etc.

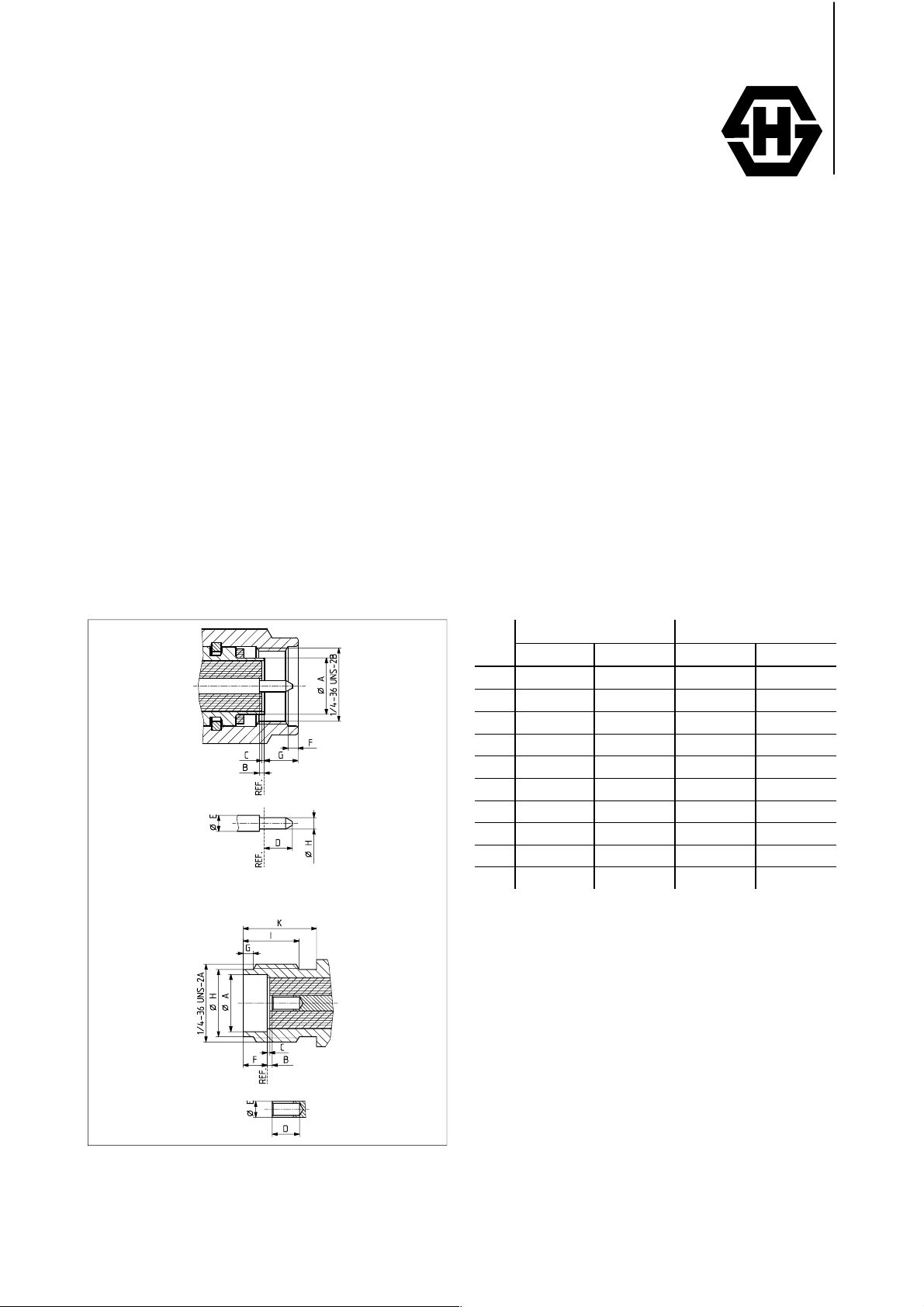

Interface Dimensions

Plug (male)

Jack (female)

Interface Dimensions in mm /

Plug Jack

min. max. min. max.

A --- 4.59/.

B 0.00/.

C 0.00/.

D --- 2.54/.

E 1.24/.

F 0.38/.

G --- 3.43/.

H 0.90/.

I --- --- 4.32/.

K --- --- 5.54/.

000

000

049

015

036

0.25/.

0.25/.

1.29/.

1.14/.

0.94/.

181

010

010

100

051

045

135

037

4.59/.

0.00/.

0.00/.

2.67/.

1.24/.

1.88/.

0.38/.

5.28/.

181

000

000

105

049

074

015

208

170

218

inches

---

0.25/.

010

0.25/.

010

---

1.29/.

051

1.98/.

078

1.14/.

045

5.49/.

216

---

---

SU HNERâ SMA

Page 2

Interface dimensions conformable to

the Standards:

International: IEC 169-15

Europe: CECC 22110

USA: MIL-C-39012, SMA

Interface MIL-STD-348a/310

GB: BS 9210 N 0006

F: NF-C-93563 (KMR)

Technical Data

ELECTRICAL DATA

Cable type semi-rigid flexible

Cable dielectric diameter (mm/

Impedance 50 Ω

Frequency range for interface DC ... 18 GHz

VSWR (typical value) see table next page

RF-leakage measured

at 3 GHz (f in GHz)

Dielectric withstanding

voltage (at sea level,

in V rms, 50 Hz)

Working voltage (at sea level,

in V rms, 50 Hz)

Corona extinction voltage

(at 21 000 m/

in V rms, 50 Hz)

Working v ol tage

(at 21 000 m/

in V rms, 50 Hz)

RF withstanding voltage

at 5 MHz (V rms)

70 000 ft

70 000 ft

.,

.,

MIL-C-39012

in.

) 1.5 /

3.26 ≥ 100 dB-f ≥ 60 dB

3.17 1000 1500 750 1000

3.22 250 375 190 250

3.23 670 1000 500 670

.066

≤335 ≤500 ≤250 ≤335

≤85 ≤125 ≤65 ≤85

3/

.117

1.5 /

.066

3/

.117

Insulation resistance 3.11 ≥ 5·103MΩ

Contact resistance

- centre contact

-outercontact

3.16

≤ 3mΩ

≤ 2.5 mΩ

SU HNERâ SMA

Page 3

TYPICAL VSWR

CONNECTOR TYPE 1GHz 2.5 GHz 5GHz 12.4 GHz 18 GHz CABLE GROUP

straight connectors 1.03 1.03 1.03 1.07 1.08 Y3, Y11

1.03 1.03 1.04 1.07 1.15 Y5, Y12

1.05 1.07 1.08 U2, U4

1.04 1.05 1.07 U7, U9

right angle connectors 1.03 1.05 1.10 1.25 Y3, Y11

1.03 1.05 1.08 1.17 Y5, Y12

1.05 1.07 1.11 U2, U4

1.03 1.05 1.07 U7, U9

FREQUENCY RANGE

MECHANICAL DATA

Recommended coupling

nut torque

Coupling nut retention force 3.25 ≥ 270 N /

Contact captivation

-axial

2) While fastening the plug coupling nut, prevent the interface from rotating by holding the plug housing by hand.

MIL-C-39012 Gold/CuBe and stainless steel SUCOPLATEâ/brass

0.8 Nm ... 1.1 Nm /

7.1 in. lbs. ... 9.7 in. lbs

(max. 500 matings)

3.12 ≥ 27 N /

60.7 lbs

6.1 lbs

0.45 Nm /

0.70 Nm /

1.00 Nm /

≥ 270 N /

≥ 27 N /

4.0 in. lbs

6.0 in. lbs

8.8 in. lbs

60.7 lbs

6.1 lbs

ENVIRONMENTAL DATA

Temperature range –65°C ... +165°C/–85°

Climatic category IEC ! 55 / 155 / 21

Thermal shock 3.20 MIL-STD-202, Method 107, Condition B

Moisture resistance 3.21 MIL-STD-202, Method 106

MIL-C-39012

F ... +329°F

(max. 500 matings)

(max. 200 matings)

(max. 20 matings)

2)

Corrosion 3.13 Saltspray test acc. to MIL-STD-202, Method 101, Condition B

Vibration 3.18 MIL-STD-202, Method 204, Condition D

Shock 3.19 MIL-STD-202, Method 213, Condition I

SUHNERâSMA

Page 4

MATERIAL DATA

CONNECTOR PART STANDARDS MATERIAL PLATING

QQ-C-530

Bodies, outer contacts

Pin contact

Crimp ferrules

Socket contact

Insulators PTFE or PFA

Gaskets silicone rubber

ISO CuNi1Pb1P

QQ-S-763

QQ-B-626

QQ-C-530

QQ-B-626

SUHNERâspecification

QQ-B-626

QQ-C-530

ISO CuNi1Pb1P

beryllium-copper, hardened

copper (spring)

stainless steel

brass

beryllium-copper, hardened

brass

copper

brass

beryllium-copper, hardened

copper (spring)

gold

passivated

SUCOPLATE

gold

gold

gold

Material selection

Requirements

The pressure applied to the SMA outer contact area is extremely high:

â

Coupling nut torque Contact pressure

1.0 Nm /

1.7 Nm /

8.9 in. lbs

15.0 in. lbs

recommended torque 550 N/mm2/

coupling proof torque 980 N/mm2/

7.98 · 104psi

1.42 · 105psi

Inadequate strength of connector body material will result in a slight deformation of the outer contact.

Excessive reflections will occur as a result, above approximately 2 GHz.

SELECTION GUIDE

BERYLLIUM STAINLESS STEEL BRASS

Material beryllium-copper stainless steel brass

Plating gold SUCOPLATE

Features, applications

Recommended coupling nut torque

D highest quality and

reliability

D suitable for almost any

application

D outperforms gold plated

stainless steel

0.8 Nm ... 1.1 Nm /

7.1 in. lbs. ... 9.7 in. lbs

(max. 500 matings)

D suitable for direct mounting

on aluminium panels

0.8 Nm ... 1.1 Nm /

7.1 in. lbs. ... 9.7 in. lbs

(max. 500 matings)

D best price/performance ratio

D for commercial

applications only

0.45 Nm /

(max. 500 matings)

0.70 Nm /

(max. 200 matings)

1.00 Nm /

(max. 20 matings)

â

4.0 in. lbs

6.0 in. lbs

8.8 in. lbs

Some connectors may have a specification th at differs from the above mentioned data.

SU HNERâ SMA

Loading...

Loading...