Page 1

Installation, Operation and

Maintenance Manual

Motor Operator

for

Overhead Distribution Switch

with Reciprocating Controls

®

OWER SYSTEMS, INC.

A.B. Chance Company

210 North Allen Street,

Centralia, MO 65240-1395

Tel: (573) 682-5521

P817-1187 Rev A

®

IMPORTANT!

For future reference:

• Keep this manual with the motor operator.

• Store it inside the plastic bag and information holder

located on the right hand wall of the enclosure.

1

Page 2

Warnings

!

DANGER

Electrical equipment contains hazardous voltages and

high speed moving parts. Contact with these hazar ds will

cause death, serious personal injury or damage equipment.

Only qualified personnel should perform maintenance. Always properly

ground equipment and lock out electric power (de-energize) before

maintenance. Using non-specified/ unauthor ized parts or components to

repair equipment, or tampering with safety devices/systems will result in

dangerous conditions which can cause death, severe personal injury or

damage to equipment. Take note of and follow all safety instructions

contained in this installation, operation and maintenance manual.

IMPORTANT

These installation, operation and maintenance instructions do not claim to cover all details or v ariations in equipment. Nor do they provide for

all possible conditions encountered while installing, operating or maintaining this equipment. If fur ther information is desired or needed to

address any particular installation, operation or maintenance problem not covered in this document, contact your authorized factory

representative.

The information in this document does not reliev e the user from e x ercising good judgment in selecting equipment f or suitability of application.

Nor does it relieve the user from using sound practices in installation, operation and maintenance of the equipment purchased.

Note: Because A.B. Chance Company has a policy of continuous product improvement, we reserve the right to change design and

specifications without notice. Should a conflict ar ise between the general information in this document and the contents of drawings or

supplementary material, or both, the latter shall take precedence.

QUALIFIED PERSON

For the purpose of this manual, a qualified person is:

(a)

familiar with the installation, construction or operation

installation, operation and maintenance.

(b)

trained and authorized

practices.

(c)

trained

clothing, etc., in accordance with established utility safety practices.

(d)

trained

in the proper care and use of protective equipment such as rubber gloves, hard hat, safety glasses or face shields, flash

to render first aid.

to de-energize, clear, ground, and tag circuits and equipment in accordance with established safety

of the subject equipment and the hazards involved with its

SUMMARY

The information in this document does not claim to cover all details or variations in equipment, nor to provide for every possible contingency

encountered with installation, operation, or maintenance. Should fur ther information be needed or problems arise that are not covered

sufficiently, contact your factory representative.

The contents of this document are not part of, nor do they modify, any prior or existing agreement, commitment or relationship. The A.B.

Chance Company terms and conditions of sale constitute the entire obligation of A.B. Chance Company. The warranty in the terms and

conditions of sale is the sole warranty of A.B. Chance Company. Any statements in this document do not create new warranties or modify

any existing warranty.

2

P817-1187 Rev A

Page 3

Contents

IMPORTANT!

For future reference:

• Keep this manual with the motor operator.

• Store it inside the plastic bag

and information holder

located on the right hand wall

of the enclosure.

Section Subject Page Number

1 — Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 — Installation Notes . . . . . . . . . . . . . . . . . . . . . . . 6

3 — Customer Supplied Requirements . . . . . . . . . 7

4 — Receiving and Handling . . . . . . . . . . . . . . . . . 8

5 — Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 — Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 — Pre-Operation Checks . . . . . . . . . . . . . . . . . . 16

8 — Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9 — Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10 — Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 22

11 — Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . 23

Tables, Figures & Photographs Page Number

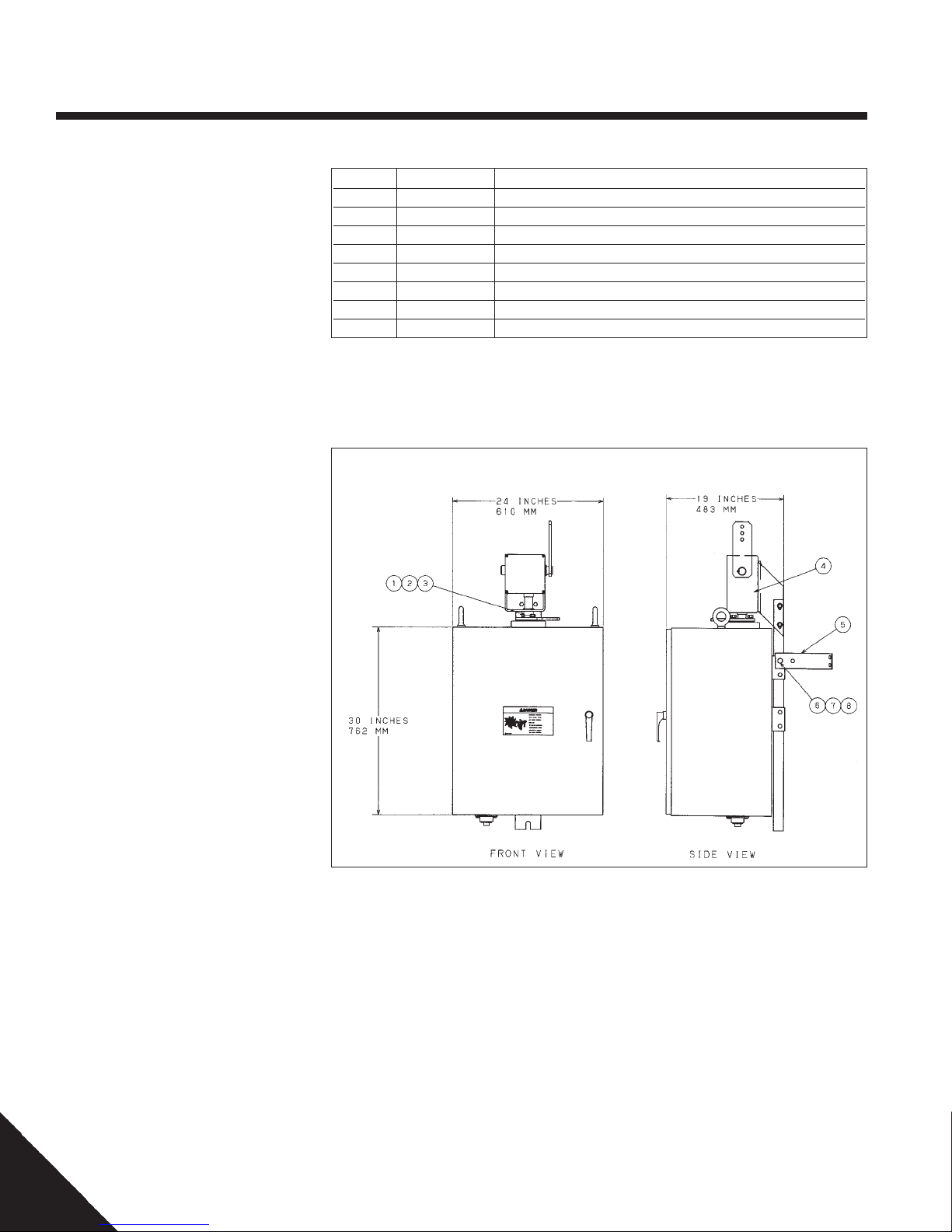

Table 1 Parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 2 Trouble shooting guide . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 1 Parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2 Component locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 3a Switch handle before modification . . . . . . . . . . . . . . . . . . . 10

Figure 3b Switch handle after modification . . . . . . . . . . . . . . . . . . . . 10

Figure 4 Mounting holes in utility pole . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 5 Mounting motor operator . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 6 Key components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 7 115VAC power connection . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 8 230VAC power connection . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 9 Control box switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 10 Manual operating handle . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 11 Adjusting limit switches . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Photograph A Shift handle – DECOUPLED . . . . . . . . . . . . . . . . . . . . . . . 13

Photograph B Shift handle – COUPLED . . . . . . . . . . . . . . . . . . . . . . . . . 13

Photograph C Control box thumbscrews . . . . . . . . . . . . . . . . . . . . . . . . . 14

Photograph D Quick disconnect plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Photograph E Terminal block cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Photograph F Control box 115VAC/230VAC selector switch and

circuit breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Photograph G Control box thumbscrews . . . . . . . . . . . . . . . . . . . . . . . . . 16

Photograph H P2A & P2B Plug positions for direction of movement . . . . 16

Photograph I Motor lead terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Photograph J Shift handle – DECOUPLED . . . . . . . . . . . . . . . . . . . . . . . 18

Photograph K Manual motor rotation knob . . . . . . . . . . . . . . . . . . . . . . . 18

Photograph L Shift handle – COUPLED . . . . . . . . . . . . . . . . . . . . . . . . . 18

Photograph M Manual operating handle . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Photograph N Typical RTU installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Photograph O Universal RTU receptacle . . . . . . . . . . . . . . . . . . . . . . . . . 20

Photograph P Limit switch thumbscrews . . . . . . . . . . . . . . . . . . . . . . . . . 21

P817-1187 Rev A

©Copyright 1998 A.B. Chance Company, 210 North Allen Street, Centralia, MO 65240

3

Page 4

1—Overview

Introduction

This manual is to guide you through the installation of the motor operator for an

overhead distribution switch with reciprocating controls. This manual does not claim to

cover all situations that may ar ise dur ing installation. If additional information is needed,

contract your factory representative. Nor

does this manual supersede your utility’s established guidelines and practices for similar

equipment. Take note of and heed all danger,

warning and cautions contained in this document.

Qualified Person

Only qualified trained and competent

personnel that understand proper safety procedures must select, install and service this

equipment.

Read and understand these instructions before installing, operating or maintaining this

equipment.

This guide is not a substitute for adequate

training and experience in safety procedures

for this type of equipment.

Signal Words

The signal words “DANGER,” “WARNING”

and “CAUTION” (along with their assigned

symbol) throughout this manual indicate the

degree of hazard the user may encounter.

These symbols and words are defined as:

Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

Hazardous voltage.

Will cause severe personal injury, death, or property damage.

Only qualified personnel should work on or around this equipment

after becoming thoroughly familiar with this document and other

publications regarding this equipment.

Fast moving parts can be hazardous.

Contact can result in death, severe personal injury and/or substantial

property damage.

The motor operator cycles in less than 1⁄2 second. Exercise extreme

caution when operating this device. Be sure you and others are clear

of any moving parts. Do not attempt to defeat any interlocking safety

devices.

!

DANGER

▲

!

W ARNING

!

DANGER

!

W ARNING

Product

The product covered by this installation, operations and maintenance manual is the motor operator for an overhead distribution

switch with reciprocating controls.

This product is designed for an overhead distribution switch with reciprocating controls

only. It cannot be field modified for an overhead distribution switch with torsional controls. If the overhead distribution switch has

torsional controls, do not attempt to install

this product. Contact your supervisor or factory representative to secure the appropriate

motor operator.

4

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

!

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury.

Function

This product converts a manually-operated

overhead distribution switch with reciprocating controls to motor-operated. The motor operator uses an electric motor and drive

mechanism to open and close the overhead

distribution switch.

CAUTION

Used without the safety alert symbol indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

P817-1187 Rev A

Page 5

1—Overview

Application/Mounting

The motor operator for an overhead distribution switch with reciprocating controls is designed for mounting on wooden utility poles.

If the utility pole is steel or concrete, mounting may be accomplished if holes can be

made in the pole or by using brackets. Contact your factory representative for details on

mounting the motor operator on steel or concrete utility poles.

!

WARNING

In areas accessible to the general public, this motor operator should

be installed with a minimum vertical height of 8 feet (2.4 meters) from

the ground to the bottom of the enclosure. If this minimum height cannot be achieved, use shields, guards, enclosures or fencing to isolate

the motor operator from the general public.

Operating Environment

The motor operator for an overhead switch

with reciprocating controls is designed for

outdoor installation and can be mounted in

direct sunlight in ambient temperatures between -40°C and +60°C.

Specifications

Electrical

• Input: 115VAC-5 amp, or

230VAC-4 amp

• Output: 12VDC-3 amp or

27.8VDC-1 amp, continuous

Mechanical

• Thrust 1200 lbs. (5300 N) @ 5" Lever Arm

• Travel: 90° movement or 5":

• Speed: 0.3 second min., 0.5 second max.

• Range: Capable of 5" to 14" control pipe displacement

• Mechanical: Life: a minimum of 1000 open/close

operations

• Connection: Couples with existing crank (1/2 inch

hole) @ bottom of reciprocating control pipe

Physical

Weight: 300 lbs (136 kg)

Dimensions: Height 50-1⁄2 inches (1280 mm)

Width 24 inches (610 mm)

Depth 19 inches (485 mm)

Enclosure Type: NEMA 4/12

P817-1187 Rev A

5

Page 6

2—Installation Notes

For future reference, use this space to make

notes specific to this unit’s installation, operation and maintenance.

Date Installed:

Model Number:

Serial Number:

RTU:

Protocol

Radio

Sensors

6

P817-1187 Rev A

Page 7

3—Customer Supplied Requirements

The following is required for installation. Be

sure to have these items on hand before

beginning installation.

Safety Equipment

• Hard hat

• Steel-toe work boots

• Appropriate eye protection per your utility’s

policy

• Other safety equipment as required by your

utility’s policies

Hardware

• Two 5⁄8 inch diameter galvanized bolts long

enough to pass through the center of the

utility pole, plus 3 inches

(75 mm)

• Four galvanized 5⁄8 inch ID/1-3⁄4 inch OD

washers

• Two 5⁄8 inch inside diameter galvanized nuts

to go with the bolts

• Two 3⁄8 inch diameter by three inch

galvanized lag screws

• One 1/2 inch x 13/4 inch bolt

• Two 1/2 inch nuts

Electronic

• Correct communications equipment applicable for this installation

• Current/voltage sensors with cables if applicable for this installation

• IBM compatible lap-top computer with appropriate software and cables for this installation

Power Supply

• 115VAC-5 amp or 230VAC-4 amp

service

• Appropriate fuse/circuit breaker

protection and power disconnect switch

with lockout provision

• Other conduit, boxes, fittings, etc. as normally used in similar installations

Electrical

• Color-coded conductors for power hook-up

per your utility’s specifications

• 1-1⁄2 inch NPT male conduit fitting

• Service/weather head for conduit

• Sufficient conduit to reach from

service/weather head to the conduit

fitting on the bottom of the enclosure

• #6 ring or spade terminals

• Suitable grounding source

P817-1187 Rev A

7

Page 8

4—Receiving & Handling

Inspect Packaging

• Upon receipt, immediately inspect packaging for signs of damage

• Start inspection with the packaging material and proceed to the equipment within

• Look for concealed damage

• If damage is found, note damage on “Bill of

Lading” prior to accepting

delivery, if possible

Note: Documentation of visible

shipping damage can determine

the outcome of any damage claim.

Notifying the carrier of concealed

damage within 15 days is essential

to resolving or minimizing unsettled claims. Immediately file

your claim and notify your factory

representative.

Unpacking

• Place shipping crate up-right on stable,

level ground near the utility pole

• Remove the top and all sides from the

shipping crate

• Leave motor operator on its pallet until

ready to install

Table 1 – Parts List

Item Quantity Description

12

22

32

4 1 Right angle drive

5 2 Pole Strap

62

72

82

1

⁄2" split lock washer (stainless steel)

1

⁄2" - 13 X 1-1⁄4" long bolt (stainless steel)

1

⁄2” flat washer

1

⁄2" - 13 galvanized nut

1

⁄2" galvanized lock washer

1

⁄2" 13 x 11⁄2" galvanized bolt

Figure 1 – Parts List

Parts List

• Compare motor operator with the

illustration in Figure 1 and the parts list in

Table 1 to be sure all items have been included

• Contact your factory representative if any

parts are missing

8

P817-1187 Rev A

Page 9

4—Receiving & Handling

Components

• Become familiar with the component

names and locations shown in Figure 2

• Open the motor operator door and identify

all the items shown in Figure 2

• Match the components in the following list

with those on the motor operator:

1. Lifting eyebolts

2. Rotation limit switches

3. Enclosure heater

4. Drive casting

5. Shift handle

6. Motor operator

identification nameplate

7. Control box

8. Manual motor rotation knob

9. Manual operating handle

10. Universal RTU receptacle

11. Ground lug and conduit fitting

12. Electrical terminal block 2

13. Radio Mount (if applicable)

14. RTU Panel (if applicable)

Figure 2 – Component Location

(3)

(2)

(1)

(14)

(13)

(12)

(11)

(4)

(1)

(5)

(6)

(7)

(8)

(9)

(10)

P817-1187 Rev A

9

Page 10

5—Installation

Preparation

Step 1. — Modify Existing

Switch Handle

• Refer to Figures 3a and 3b

• Make sure overhead switch is closed

• Loosen and reposition ground strap clamp

so it is out of the way

• Remove the existing manual switch handle,

pole mount bracket and crank.

(see Figure 3a & 3b)

• Establish how high the bottom of the enclosure will be above the ground

• Cut off the control pipe 46 inches (1168

mm) higher than where the enclosure's

bottom will be

!

External parts can move suddenly and unexpectedly.

This can pose a danger to the general public.

In areas accessible to the general public, this motor operator should

be installed with a minimum vertical height of 8 feet from the ground to

the bottom of the enclosure. If this minimum height cannot be

achieved, use shields, guards, enclosures or fencing to isolate the

motor operator from the general public.

Figure 3a – Switch Handle

Before Modification

WARNING

10

Figure 3b – Switch Handle

After Modification

P817-1187 Rev A

Page 11

5—Installation

Step 2. — Drill Mounting Holes

• Refer to Figure 4

• Mark upper hole location on the utility pole

by measuring 12.75 inches (324 mm)

down from the bottom of the control pipe

and 2.5 inches (63 mm) around the pole

from the control pipe centerline. (see Figure 4).

• Mark the lower hole location on the utility

pole 34-1⁄2 inches (875 mm) below the first

mark. This second mark must also be on

the same centerline as the first hole.

• Drill two 11⁄16 inch (18 mm) diameter holes

through the utility pole where marked as

shown in Figure 4. Be sure the holes are

drilled through the centerline of the pole.

• Assemble customer supplied 5⁄8 inch diameter bolts, washers and nuts to the utility

pole

• Leave bolts sticking out of the control pipe

side of the utility pole to receive the motor

operator

Figure 4 – Mounting Holes In Utility Pole

P817-1187 Rev A

11

Page 12

5—Installation

Mounting

Step 1 — Mounting The Motor Operator

• Refer to Figure 5

• Ready lifting equipment to hoist motor operator

NOTE: Lift motor operator by lifting eyebolts only.

• Attach lifting strap, chain or cable

safety hooks/shackles to lifting eyebolts

only. Strap, chain or cable and hooks must

be able to support 300 lbs (136 kg)

• Use spreader on lifting strap, chain or

cable so the motor operator is lifted

straight upward on the lifting eyebolts

• Hoist motor operator into position on utility

pole. Slip 5⁄8 inch bolt heads and washers

through the upper tear-drop shaped hole

and the lower slot in the mounting channel

• Lower motor operator until it is

supported by both bolts

• Torque nuts on mounting bolts to 25 - 28

ft.lbs (34 - 38 N.m)

• Assemble pole straps to each side of the

motor operator mounting channel where

shown in Figure 5 using supplied

bolts, lock washers and nuts

• Form the pole straps around the utility pole

(horizontally or diagonally) and tighten the

1

⁄2 inch bolts

• Secure pole straps to the utility pole by

driving in 3⁄8 inch diameter lag screws (customer supplied)

• Remove the lifting strap, chain or cable and

lifting eyebolts from the motor operator

• Place filler caps or 3/4" bolt & rubber

washer (supplied) into threaded eyebolt

holes on enclosure

1

⁄2 inch

Figure 5 – Mounting Motor Operator

Step 2. — Attaching The

Switch Control Pipe

NOTE: Do not stand on motor operator enclosure or use it as a step.

• Verify the motor operator and the overhead

switch open the same direction, refer to Section

"Reversing Motor Rotation" if necessary.

• Verify the motor operator is in the closed position

before connecting to the closed overhead switch,

refer to section "Energizing, Exercising and Inspecting" if necessary.

• Attach crank from existing switch to lowest hole

in lever arm with a 1/2 inch x 13/4 inch bolt and

nut. Ensure free movement between crank and

lever arm. Use a second jam nut to lock the first

nut in place - see illustration.

12

P817-1187 Rev A

Page 13

5—Installation

• Insert the switch control pipe in the crank

casting. Depending on crank style, the

control pipe length may need to be shortened for proper fit. Tighten fasteners until

switch control pipe is firmly held.

• Depending on the type of crank provided

with the switch, tightening of crank piercing bolt may be required.

Checking Installation

Step 1. — Checking Installation

• Refer to Figure 6

• Disengage the motor operator’s mechanism from the drive mechanism by pulling

the shift handle out and then down into the

DECOUPLED position

(see Photograph A)

• Attach manual handle at drive connection

with clevis pin. Open overhead switch and

check for binding.

• If binding occurs, look for source of binding

and realign drive connection until manual

operation shows no signs of binding

• If the overhead switch does not open completely, increase opening range by moving

crank to lever arm connection up one bolt

hole. Control pipe will need to be shortened for proper crank fit.

• Repeat manual overhead switch rotation to

assure switch opens completely. If overhead switch still does not open completely,

increase opening range again.

• Place overhead switch back into closed position with the manual handle.

• Re-couple the motor operator mechanism

by lifting the shift handle up and pushing it

in so that the handle tabs are engaged

(see Photograph B)

• Return manual handle to its original position within enclosure.

Figure 6 – Key Components

Photo A

Shift handle

in

DECOUPLED

position

Photo B

Shift handle

in

COUPLED

position

P817-1187 Rev A

13

Page 14

6—Wiring

Wiring Guidelines

1. If low voltage and high voltage wires cross

paths, make sure the intersection is made at a

right angle.

2. To minimize noise coupling, use twisted pair

sensor wires.

3. To avoid ground loops, each motor operator

must be grounded at a single ground point.

The grounding path to earth must:

• Be permanent

• Be continuous

• Safely conduct ground fault currents that

may occur in the system to ground

through minimum impedance

• Carry no current under nor mal

conditions

!

W ARNING

Hazardous V oltage.

Contact with an energized and/or ungrounded motor operator component will result in death, severe personal injury, erratic operation of

equipment or substantial property damage.

Make sure the motor operator is properly grounded. Turn “OFF” and

lock out all incoming power sources before attempting to internally

wire or work on the motor operator.

Photo C

Grounding & Surge Suppression

Step 1. — Install Safety Ground

• Use wire gauge and type and pole ground

in accordance with your utility’s instructions or specifications

• Ground motor operator by attaching safety

ground lead between ground lug (next to

the conduit fitting) and pole ground

Step 3. — Install Surge

Suppression Devices

• Apply surge suppression devices according

to your utility’s practices

• Motor operators with the radio option have

surge suppression for the radio antenna

factory installed

• For other communication devices, surge

suppression will be required as applicable.

Power Wiring

Step 1. — Accessing Terminal

Block 2

• Open enclosure door and firmly engage

door stop mechanism

Control box

thumbscrews

Photo D

Quick

disconnect

plugs

• Note number, size, orientation and location

of quick-disconnect plugs for reinstallation

• Unplug quick-disconnect plugs

• Remove control box by lifting and pulling

forward until control box clears its mounting slots

14

• Locate and loosen control box

thumbscrews (see Photograph C)

• Rotate top of control box downward until

it rests on its stops

(see Photograph D)

P817-1187 Rev A

Page 15

6—Wiring

• Set control box in a clean, dry area where

it will not fall or be subject to damage

• Locate and loosen terminal block cover retaining screw (see Photograph E)

• Remove terminal block cover and set it

aside with the control box

• Step 2. — Preparing Power Wiring.

• Remove the plug from the conduit

fitting

• Assemble conduit per your utility’s instructions and specifications

NOTE: Enclosure conduit threads are female 1-1⁄2 inch NPT

• Run appropriate sized power wiring

through the conduit and into the

enclosure to terminal block 2

Step 3. — Wiring 115VAC Power Supply

• Refer to Figure 7

• The motor operator is factory-wired for

115VAC power

• Connect 115VAC incoming power with ring

or spade terminals as shown in Figure 7

• Replace the terminal cover on terminal

block #2 and tighten the screw

Step 3a. — Wiring 230VAC Power Supply

Photo E

Terminal

block 2 cover

Terminal

block cover

retaining

screw

Figure 7 – 115VAC

Power Connection

• Refer to Figure 8

NOTE: Move red lead on top of terminal

block 2 as shown in Figure 8.

• Move the red wire on top of terminal block

2 from the neutral terminal to

the open 115VAC terminal

• Connect 230VAC incoming power with ring

or spade terminals as shown in Figure 8

• Replace the terminal cover on terminal

block #2 and tighten the cover

retaining screw

Figure 8 – 230VAC

Power Connection

P817-1187 Rev A

15

Page 16

7—Pre-Operation Checks

Energizing

Step 1. — Reassembly

Prior T o Energizing

• Refer to Photograph F

• Place control box into mounting slots

• Reconnect all of the plugs to the

control box

NOTE: Plugs P2A and P2B can be

interchanged. See next step for location of these plugs and how to

reverse direction of the motor operator.

• Set control box voltage selector switch to

match incoming power supply

voltage (see Photograph F)

• Turn the circuit breaker on the back of the

control box to “ON” position

(see Photograph F)

• Rotate control box to the upright

position and tighten thumbscrews

(see Photograph G)

Reversing Motor Rotation

!

CAUTION

Voltage selector switch must be set properly.

Misapplied voltage will result in mis-operation and/or damage equipment

Set voltage selector switch on the back of the control box back to match incoming power

voltage.

Photo F

Voltage

selector

switch

Circuit breaker

Photo G

Control box

thumbscrews

Step 1. — Reversing

Motor Operator Rotation

Note: The motor operator is factory

set to open the overhead distribution switch by pulling down on

control pipe and pushing up on the

control pipe to close. Proceed only

if the overhead switch opens by

pushing up on the control pipe.

• Skip this procedure if the overhead switch

opens by pulling down on the control pipe.

• Refer to Photograph H

• Factory set has plugs P2A at the back,

P2B in the middle and P2C at the front

(see Photograph H)

• To reverse the motor operator:

1) reverse plugs P2A and P2B

2) Pull apart the two quick disconnect motor lead terminals and reverse the

connections (see Photograph I)

• The motor operator will now operate by

pushing up on the control pipe to open

overhead switch.

Plug P2A

Plug P2B

Plug P2C

Photo H

To reverse motor

operator, switch

plugs P2A and P2B

Photo I

Motor lead

terminals

16

P817-1187 Rev A

Page 17

8—Operation

Energizing, Exercising &

Inspecting

Step 1. — Turn On Power

• Turn the power supply “ON” at the fuse/

breaker box if applicable

• Refer to Figure 9

• Turn control box main power switch “ON”

• Status lights for “POWER” and switch

“CLOSE” will illuminate

Step 2. — Exercising Overhead

Switch

• Place local/remote switch in local

position

• Open overhead switch by pressing the

“OPEN” push-button

• Close overhead switch by pressing the

“CLOSE” push-button

• Observe status light functions:

– “OPEN” illuminated when overhead

switch is open

– “CLOSE” illuminated when overhead

switch is closed

• If status light indication is opposite overhead switch position, review “Reversing

Motor Operator Rotation” in the Pre-Operation Checks section and correct as necessary

Step 3. — Inspecting Overhead

Switch

!

DANGER

Hazardous voltage.

Electrical contact with system voltage will cause severe injury or death.

Do not exercise overhead switch while it is energized.

!

WARNING

Moving parts.

Can cause severe injury.

Do not operate motor operator until hands and clothing are clear of all

moving parts.

Figure 9 – Control Box Switches

• Cycle the overhead switch 8 to 10 times

• Thoroughly inspect overhead switch for

proper opening and closing

• If overhead switch does not fully/adequately open or close, proceed to the

section on Adjustment, and return to Step

4 below

Step 4. — Set Local/Remote

Operating Mode

• Place local/remote switch in desired position

P817-1187 Rev A

Additional Functions

Battery Test

Press and hold the “Battery Test” switch for 10

seconds. The “Low Battery Alarm” will illuminate if there is a battery problem.

Lamp Test

Press and hold the “Lamp Test” switch.

All control box lights will illuminate.

17

Page 18

8—Operation

Decoupling & Coupling

Motor Operator

Step 1. — Decoupling Motor

From Drive Casting

• Refer to Photograph J

• Decouple the motor operator by pulling out

and down on the shift handle

(see Photograph J)

• It may be necessary to release tension in

the coupling assembly by turning the

manual motor rotation knob

(see Photograph K)

• Lower and release the shift handle into the

“DECOUPLED” position

• Place the shift handle tabs into the

“DECOUPLED” slot to ensure that the motor is fully “DECOUPLED”

Step 2. — Coupling Motor

With Drive Casting

Photo J

Shift handle in

DECOUPLED

position

Photo K

Manual motor

rotation knob

• Refer to Photograph L

• Couple the motor operator by pulling out

and up on the shift handle

(see Photograph L)

• It may be necessary to align the

coupling assembly by turning the

manual motor rotation knob

(see Photograph K)

• Raise and press the shift handle into the

"COUPLED" position

• Place the shift handle tabs into the

“COUPLED” slot to ensure that the motor

is fully coupled

Step 3. — Exercising The Motor

While Decoupled

• Decouple motor operator as detailed in

Step 1 above

• Exercise the motor by pushing either the

“OPEN” or “CLOSE” push-button switches

• The motor will run until power is turned

“OFF”

• Stop the motor by flipping the control box

main power switch to “OFF”

• Turn the control box main power switch to

“ON”

• Couple motor operator as detailed in Step

2 above

Photo L

Shift handle

in

COUPLED

position

18

P817-1187 Rev A

Page 19

8—Operation

Manual Operation

Step 1. — Manual Switch Operation

• Decouple the motor as outlined in the

Decoupling & Coupling Motor Operator

section

• Refer to Figure 10

NOTE: Removing the manual operating handle from the enclosure

activates a safety device that

makes the motor operator inoperable until the drive mechanism has

been decoupled, or the manual operating handle is returned to its

storage position. Do not attempt to

defeat this safety device.

• Remove the manual operating handle from

its cradle in the bottom of the enclosure

(see Photograph M)

• Attach the manual operating handle to the

overhead switch control pipe by using the

bent arm pin and cotter pin as shown in

Figure 10

• Manually operate the overhead switch as

directed by the switch manufacturer

Photo M

Manual

operating

handle

!

WARNING

Hazardous voltages and high speed moving parts.

These can cause death, serious personal injury or damage equipment.

Lock out power at circuit breaker/fuse box and turn control box main

power switch “OFF” before attempting to manually operate this unit.

P817-1187 Rev A

Figure 10 – Manual Operating Handle

Manual operating handle removed from enclosure and attached to switch control pipe with bent arm pin and cotter

pin

19

Page 20

8—Operation

Remote Operation

The switch can be operated from central

control via a communication link to the

RTU, allowing for remote configuration, diagnostics, and operation. Refer to the

SCADA system instruction manual for specific instructions. Regardless of the type or

make of the SCADA system, the user must

place the Remote/Local switch in the "Remote" position to allow remote operation.

Photo N shows typical Motor Operator with

RTU installed.

The Universal RTU Receptacle shown in

Photo O allows modular connection to an

RTU and communication back to central

control. Refer to supplemental drawing

SD817-1149 for signal pin outs and remote operation relay specifications. The

following controls and diagnostics are provided.

Remote Status

• Remote/Local switch position indicator.

Open Status

• Overhead switch position indicator.

Close Status

• Overhead switch position indicator.

Low Battery Alarm

• Low battery indicator.

Battery Charger Status

• Battery charger present indicator. Also indicates AC supply is present.

Battery Test

• Remote battery test control.

Remote Open

• Remote open control.

Remote Close

• Remote close control.

Photo N

Typical RTU Installation

20

Photo O

Universal RTU Receptacle

P817-1187 Rev A

Page 21

9—Adjustment

IMPORTANT NOTICE

The limit switches adjust the motor

operator for normal opening and

closing. Limit switches will not

compensate for an improperly adjusted overhead switch.

Limit switch adjustment on this

motor operator is normally not

necessary. The motor operator is

factory set for 90° of rotation. If the

overhead switch fails to close and

open completely with the factory

set 90° rotation travel, follow the

steps below.

Limit Switches

Step 1.— Adjusting Limit Switches

• Refer to Figure 11

• Turn off the control box main power switch

before making any limit switch adjustment

• The “OPEN” limit switch controls the

“OPEN” adjustment

• The “CLOSE” limit switch controls the

“CLOSE” adjustment

• Loosen thumbscrews (see Photograph P)

and move the limit switches as shown in

Figure 11 to increase or decrease the

amount of rotational travel as required for

proper overhead switch operation

• Tighten limit switch thumbscrews before

testing rotational travel

• When finished adjusting the limit

switch(es), make certain the control box

main power switch is “ON”

NOTE: If the motor operator’s rotation direction has been reversed

(as described in — Pre-Operation

Checks, Reversing Motor Rotation)

limit switch controlling functions

are reversed: “CLOSE” is the open

limit switch and “OPEN” is the

closed limit switch.

"CLOSE"

Limit switch

thumbscrew

"OPEN"

Limit switch

thumbscrew

Figure 11 – Adjusting Limit Switches

Note: Figure 11 indicates limit switch adjustments

for factory set clockwise rotation (non-reversed in-

Photo P

P817-1187 Rev A

21

Page 22

10—Maintenance

Enclosure Exterior

The enclosure has been factory painted to

deliver years of protection. If the paint finish

has been damaged, touch-up affected spots

with ANSI 61 gray enamel (Wiegmann Enclosure Company catalog number WAGSE). Be

careful not to paint over enclosure door

handle, drive casting or other parts that would

be adversely affected by painting.

Do not paint over warning and other safety

related exterior labeling. If replacement labels

are needed, contract your factory representative

Remove tree branches and any other objects

that may come in contact with the motor

operator and/or the overhead switch control

pipe mechanism.

Batteries

The sealed, maintenance-free lead acid gel

batteries furnished with the motor operator

are rechargeable 26 amp-hour, 12 volt DC.

Test these batteries once a month by pressing

the battery test button for 10 seconds. The low

battery alarm will light if the batter ies are not

fully charged. This test can be perfor med and

monitored remotely.

If the batteries have a low charge or are 3

years old, replace both with B & B Battery part

number BP26-12, with fast-on connectors, or

Powersonic Battery part number PS-12260F

with fast-on connectors.

Light Bulbs & Control

Box Status Lights

Both the enclosure light and control box status

lights should come “ON” when the enclosure

door is opened. If the enclosure light does not

come “ON,” replace it with a Chicago Lamp

Part Number 308. If the control box status

lights do not come “ON” when the door is

open, then perform a lamp test. Lamp test

button is on the front of the control box. When

pressed, all status lights should come “ON.” If

some or all status lights do not come “ON,”

contact your factory representative.

Transmission Lubricant

The transmission is sealed, but a small

amount of lubricant may seep out to the

bottom of the enclosure or onto the batteries.

Minor seepage is not a problem. It may be

removed with a shop towel and then disposed

of at an appropriate waste facility in accordance with your local utility’s regulations.

Non-Functioning Motor

Operator

If the motor operator will not function, go to

Trouble Shooting Guide and follow the suggested corrective actions. If the motor operator still does not function, contact your factory

representative.

Battery Storage Life

Self-discharge characteristics of these batteries make it imperative they be charged after 6

months of storage. Otherwise per manent loss

of capacity might occur from sulfation.

22

P817-1187 Rev A

Page 23

11—Trouble Shooting

The following table presents the most common symptoms, their possible cause(s) and likely corrective action(s). These do not cover all

possible problems. If you are unable to correct a problem using this trouble shooting guide, contact your factor y representative.

Table 2 – Trouble Shooting Guide

Symptom Possible Cause(s) Corrective Action(s)

Motor operator a) Power status light not on. a) Turn on power.

will not run. b) Manual operating handle is not inside enclosure. b) Place manual handle in space provided.

c) Motor locked rotor breaker is tripped c) Turn off power switch; reset locked

(on back of control box). rotor breaker. Turn on power switch.

d) Remote/local switch in remote position. d) Place remote/local switch to local position.

e) Battery charge below 23 volts e) Recharge or replace batteries as needed

Motor will run, a) Decoupling handle is down. a) Move decoupling handle to coupled position.

but overhead b) Piercing bolt is not tightened completely. b) Tighten piercing bolt until no threads

switch will are showing.

not turn.

The overhead switch a) Limit switch improperly set. a) Adjust limit switch; refer to Section "Adjustment".

is not fully open or b) Loose hardware b) Tighten hardware

fully closed.

Can not decouple a) Excessive wrap-up on control pipe. a) Pull out shift handle and turn manual

drive mechanism. b) Inadequate limit switch setting. motor rotation knob to release tension.

b) Adjust limit switch position

Moisture in a) Disconnected power leads to heater a) Inspect and reconnect if needed

enclosure b) Faulty heater thermostat b) Contact factory representative

c) Burned out heating element c) Contact factory representative

Low Voltage a) Charger off a) Control box rear circuit breaker switched off.

Alarm b) Charger off b) AC supply not present; refer to "Power Wiring" Section

c) Batteries discharged c) Repair /replace batteries

Motor Operator not a) Local/Remote switch a) Place Local/Remote switch in "Remote" position.

responding to b) Control Box/Connection problem. b) If the control box/ connections are not functioning

remote commands Verify control box remote functions by simulating inputs/ contact factory representative.

outputs at Universal RTU receptacle refer to

supplemental drawing SD817-1149 (located in side

pouch). Output can be measured with a DVM.

Inputs can be simulated by shorting corresponding receptacle pins.

c) RTU connection problem. Ver ify signal connections c) If RTU connections problem exists, contact factory

to RTU by measuring outputs with DVM and simu- representative.

lating inputs at the RTU refer to supplemental drawings

d) RTU/configurations problem. Ver ify RTU operation using d) If RTU is not functioning, contact RTU manufacturer.

local pc connection refer to RTU manuals.

e) Communications/configuration problem. Verify communications e) If Communications are not functioning, contact

refer to communication manuals communications representative.

P817-1187 Rev A

23

Page 24

®

POWER

SYSTEMS, INC.

© Copyright 1999, A.B. Chance Company

210 North Allen Street, Centralia, MO 65240-1395

Printed in U.S.A.

24

P817-1187 Rev A

Loading...

Loading...