Page 1

INSTALLATION INSTRUCTIONS FOR

SLS REMOTE BALLAST SYSTEM

Catalog Logic: R E M - XXXXH X-X-X X

Fixture Watts:

1000 1500 1650

Fixture Voltage:

(2) 208v (3) 240v (E) 220v/50hz

(4) 277v (5) 480v (6) 347v

Ballast Quantity:

2 through 6

A complete system includes the ballast enclosure, lighting fixtures, wiring harness, crossarms and poles.

Warning!

• Dangerous voltages exist within this product.

• To reduce fire and shock hazards disconnect power before servicing.

• To reduce the risk of injury, operate and maintain to meet

all applicable codes.

• Installation is to be performed by a qualified electrician

only.

• Provide proper ground for all system components.

This ballast enclosure should be installed at a minimum

ÞÞ

Þ

ÞÞ

height of 10 feet (3 meters) above grade.

Catalog Logic: R E M - X X X X H X - X - X X

Optional Features:

(SH) Solution Harness Ready

(TB) **Thermal Magnetic Breaker

**Standard for 240v and below

(WP) Wood or other Solid Pole

(T) Wire Three Phase

• Read and follow all instructions and labels before and during installation.

• Failure to properly install this product will void

manufacturer's warranty .

• Handle and secure so ballast enclosure cannot fall.

• Use protective equipment to avoid injury during installation of this heavy product.

• Do not route wiring through top of enclosure.

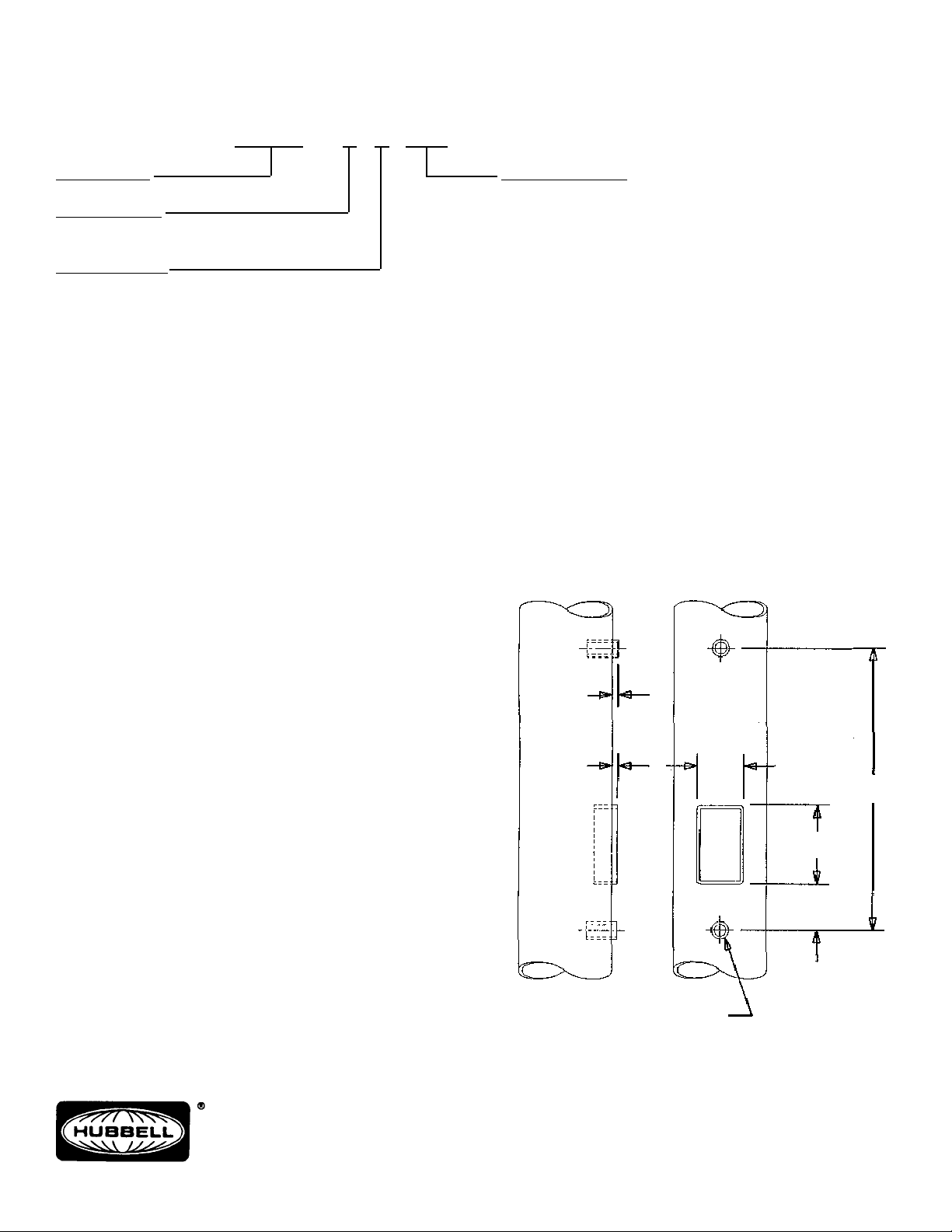

Enclosure Installation - Steel and Concrete Poles

(Figures 1, 2, & 3) (See Enclosure Installation - Wood Poles)

Important: Installation requires the use of a pole equipped

with mounting couplings and wireway . (Figure 1)

1. Remove peel strip from gasket supplied in hardware bag.

2. Apply gasket to the back of enclosure around the 2-1/2"

x 4-1/2" (63.5mm x 1 14.3mm) hole. (Figure 3)

Important: Clean the surface around the opening in the

back of enclosure to remove oil and dirt before applying

the gasket.

3. Install bolt (2) and lockwasher (3) in the top coupling.

(Figure 2) Leave 1" (25.4mm) of thread exposed.

4. Position lift bracket (4) over the bolt (2) and lockwasher

(3).

NOTE: The top of keyhole in bracket must contact the

bolt to support the 280 pound (127Kg) enclosure.

5. Align the wireway opening in the enclosure with the wireway opening in the pole. Do not damage gasket!

6. Install bolt, lockwasher and flatwasher through hole inside of enclosure and into the coupling in pole.

7. Tighten both bolts to a minimum of 40ft/lbs.

8. Seal all openings between pole and enclosure.

3/8"

TYP.

3/8"

COUPLING W/ 3/4 - 10

INTERNAL THREADS

FOR 3/4" BOL T

3"

41"

5"

4 - 7/8"

Hubbell Lighting, Inc.

A Subsidiary of Hubbell Incorporated

2000 Electric Way

Christiansburg, VA 24073-2500

(540) 382-6111

FAX (540) 382-1526

FIGURE 1

268-1157-9901

Page 2

Enclosure Mounting - Wood Pole -WP) Figures 2, 3

1. Install one 3/4" (19mm) diameter bolt (2) (by others) and

lockwasher (3) in pole at location for top enclosure support. (Figure 2) Leave 1" (25.4mm) of thread exposed.

2. Position the lift bracket (4) over bolt (2) and lockwasher

(3).

NOTE: The top of keyhole in bracket must contact the

bolt to support the 280 pound (127Kg) enclosure.

3. Install bolt, lockwasher and flatwasher through hole inside of enclosure and into the wood pole.

4. Tighten both bolts securely to a minimum of 40ft/lbs.

5. Seal all openings between pole and enclosure.

6. Drill wire way hole of desired size from inside of enclosure at center of hole “A” in electrical panel. (Figure 4)

NOTE: This wireway hole may be drilled in the bottom of

enclosure. Do not damage wires or components!

7. Attach conduit to enclosure with watertight fittings.

Wiring and Electrical Instructions

3 The enclosure voltage must match the supply voltage.

3 Standard wiring is single phase. Three phase requires

a “-T” on the catalog number. (Consult factory)

3 Total operating amperage is shown on the inside of door .

3 Enclosures are factory wired to operate as a separate

unit.

(Contact factory for wiring multiple enclosures in series)

3 Enclosure includes factory fusing of all branch circuits.

3 Enclosure includes internal electrical switching:

• Thermal Magnetic Breaker is standard for 208v, 220v

and 240v

• Load Break Switch is standard for 277v, 347v and 480v

• “-TB” indicates Thermal Magnetic Breaker for 277, 347v

and 480v .

2

2

3

3

FIGURE 2

7

4

CLOSE

GAPS

FIGURE 3

5

CUSTOMER

SUPPLY

LEADS

Supply Wiring:

1. Connect the supply wires to the proper lugs on switch.

2. Connect ground wire (6) to the ground lug (7).

3. Provide effective strain relief to prevent wire damage.

4. Comply with all national and local electrical codes.

Caution: Protect exposed wires with approved insulators.

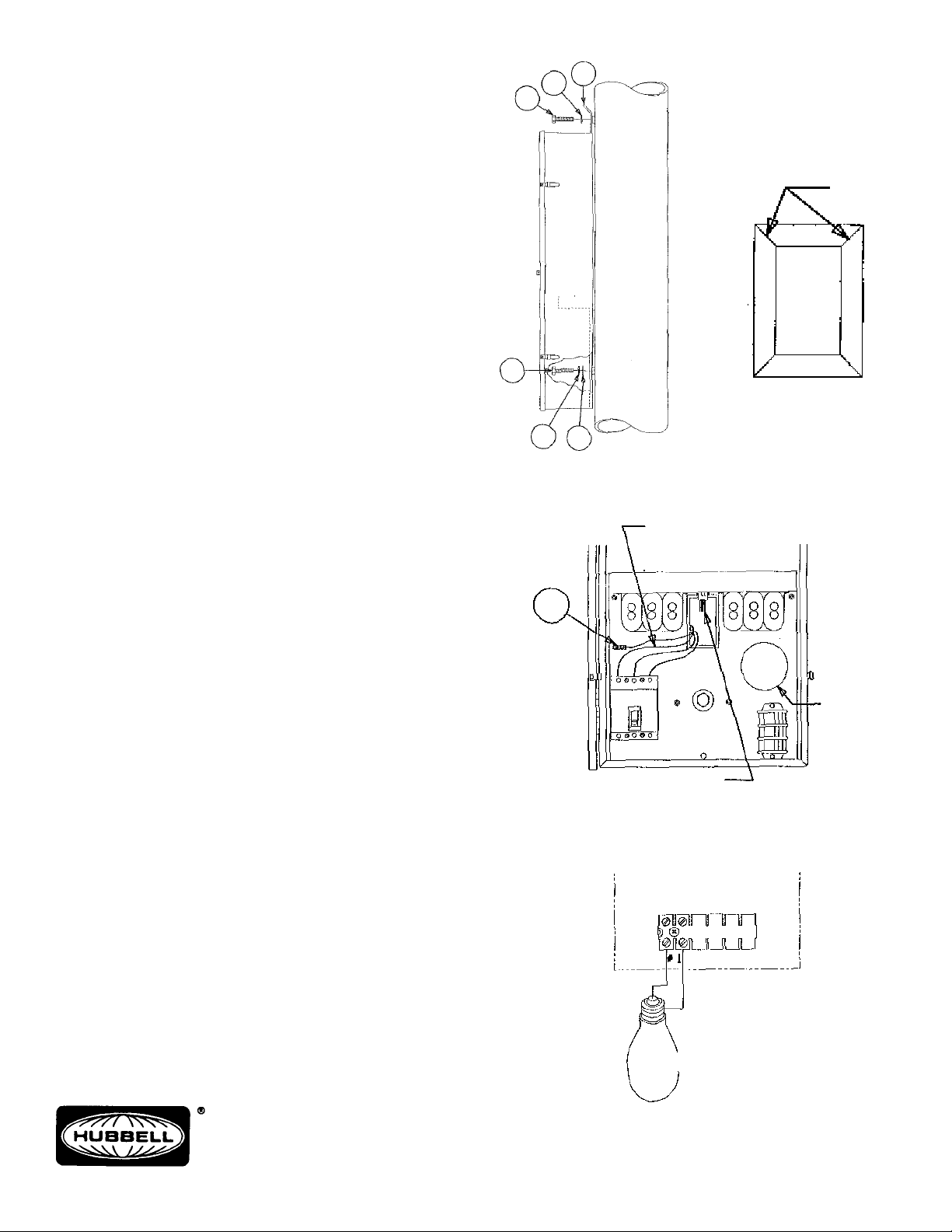

Fixture Wiring into Enclosure:

1. Connect the socket wires to the socket terminal block

inside enclosure. (Figure 5) or

If catalog number includes “-SH”, connect the male plug

of wiring harness and the female harness plug. (Figure

4) Snap securely .

2. Enclosure shall be properly grounded.

3. Close door and engage the latches. A lock is optional.

These instructions are not intended to be a comprehensive

guide to all Installation issues.

The installer is responsible for safe, secure mounting suitable for the application.

Once the enclosure is installed, give these instructions to

the equipment owner.

Hubbell Lighting, Inc.

A Subsidiary of Hubbell Incorporated

2000 Electric Way

Christiansburg, VA 24073-2500

(540) 382-6111

FAX (540) 382-1526

HOLE

“A”

“-SH” HARNESS

PLUG

FIGURE 4

REMOTE ENCLOSURE

SOCKET TERMINAL BLOCK

FIXTURE #1

FIGURE 5

268-1157-9901

Page 3

SYSTÈME BALLAST SÉPARÉ SLS

DIRECTIVES DE MONTAGE

Logique Du Catalogue - R E M - XXXXH X-X-X X

Catalog Logic: R E M - XXXXH X-X-

XX

Puissance - Watts

1000 1500 1650

Tension

(2) 208v (3) 240v (E) 220v/50hz

(4) 277v (5) 480v (6) 347v

Nombre de ballasts

Optional Features:

(SH) Solution Harness Ready

(TB) **Thermal Magnetic Breaker

**Standard for 240v and below

(WP) Wood or other Solid Pole

(T) Wire Three Phase

2 à 6

Le système complet comprend le boîtier du ballast, les luminaires, les câbles, les consoles et les poteaux.

AVERTISSEMENT!

• Ce dispositif contient des tensions dangereuse.

• Débrancher le circuit avant de procéder à la maintenance afin de

réduire tout risque d’incendie ou de choc électrique.

• Afin de réduire tout risque de blessure, effectuer le montage,

l’exploitation et la maintenance en conformité avec tous les codes

applicables.

• Doit être installé par un électricien qualifié.

• S’assurer de la mise à la terre adéquate de tous les composants.

Il est recommandé d’installer ce boîtier de ballast séparé à une

ÞÞ

Þ

ÞÞ

hauteur minimum de 3 m au-dessus du sol.

MONT AGE DU BOÎTIER SUR POTEAUX EN ACIER ET EN BÉTON

- (figures 1, 2 et 3)

(Figures 1,2 et 3). (Voir montage pour poteaux en bois).

IMPORT ANT - L’installation requiert l’utilisation d’un poteau équipé

de manchons de fixation et d’orifices de câblage tel qu’illustré dans

la figure 1.

• Avant le montage, lire attentivement et suivre toutes les directives et les étiquettes.

• Le montage inapproprié de ce produit annule la garantie du

fabricant.

• Manipuler et fixer de façon à s’assurer que le boîtier du ballast ne

pourra pas tomber.

• Utiliser l’équipement de protection pour éviter les blessures pendant le montage de ce produit très lourd.

• Ne pas acheminer les câbles par le dessus du boîtier

1.Enlever la pellicule de la garniture de joint incluse dans le sac de

visserie.

2.Appliquer la garniture de joint sur l’arrière du boîtier autour de

l’ouverture de 63,5 mm x 114,3 mm (figure 3).

3.Visser un boulon (2) avec une rondelle de blocage (3) dans le

manchon supérieur (figure 2) en laissant environ 25 mm de filet à

découvert.

4.Placer le crochet de retenue (4) sur le boulon (2) et la rondelle de

blocage (3).

REMARQUE- Le haut de l’ouverture du crochet doit reposer sur

le boulon pour supporter les 127 kg du boîtier.

5. Aligner l’ouverture de câblage du boîtier avec l’ouverture de

câblage du poteau. Ne pas endommager la garniture de joint.

6.Insérer le boulon avec la rondelle de blocage et la rondelle plate

dans l’ouverture à l’intérieur du boîtier et dans le manchon du

poteau.

7.Serrer les deux boulons à un couple d’au moins 55 N·m.

8.Sceller toutes les ouvertures entre le poteau et le boîtier.

MONTAGE DU BOÎTIER SUR POTEAU EN BOIS (-WP).

Figures 2 et 3

1.Placer un boulon de 19 mm de diamètre (2) (non fourni) dans

une rondelle de blocage (3) à travers le poteau de bois à

l’emplacement désiré pour le support supérieur du boîtier (Figure

2) en laissant environ 25 mm de filet à découvert.

Hubbell Lighting, Inc.

A Subsidiary of Hubbell Incorporated

2000 Electric Way

Christiansburg, VA 24073-2500

(540) 382-6111

FAX (540) 382-1526

3/8"

TYP.

3/8"

MANCHON À FILETAGE

INTÉRIEUR 3/4 - 10 POUR

BOULON DE 19 MM DE

DIAMÉTRE

FIGURE 1

3"

41"

5"

4 - 7/8"

268-1157-9901

Page 4

2.Placer le crochet de retenue (4) sur le boulon (2) et la rondelle de

blocage (3).

REMARQUE- Le haut de l’ouverture du crochet doit reposer sur

le boulon pour supporter les 127 kg du boîtier.

3.Insérer le boulon avec la rondelle de blocage et la rondelle plate

dans l’ouverture à l’intérieur du boîtier et dans le poteau de bois.

4.Serrer les deux boulons à un couple d’au moins 55 N·m.

5.Sceller toutes les ouvertures entre le poteau et le boîtier.

6.De l’intérieur du boîtier, forer une ouverture de diamètre

convenable pour le câblage au centre de l’ouverture «A» dans le

panneau d’électricité (figure 4).

REMARQUE - L’ouverture pour le câblage peut être percée au

bas du boîtier. S’assurer de prendre toutes les précautions

nécessaires pour ne pas endommager le câblage et les

composants.

7.Raccorder le conduit au boîtier au moyen de raccords étanches à

l’eau.

CÂBLAGE et RENSEIGNEMENTS ÉLECTRIQUES:

3 La tension assignée du boîtier doit correspondre à la tension

d’alimentation.

3 Le câblage standard est monophasé. Un système triphasé requiert

un «-T» dans le numéro de référence (Consulter l’usine).

3 Le courant total est indiqué à l’intérieur de la porte.

3 Le boîtier est câblé en usine pour fonctionner en tant qu’unité

séparée. (Consulter l’usine pour le câblage de plusieurs boîtiers

en série).

3 Les boîtiers incluent les fusibles montés en usine pour chaque

circuit de dérivation.

3 Les boîtiers contiennent des dispositifs de commutation internes:

• Disjoncteur thermo-magnétique standard pour 208 V, 220 V et

240 V.

• Interrupteur sous charge standard pour 277 V, 347 V et 480 V .

• «-TB» indique un disjoncteur thermo-magnétique pour 277 V,

347 V et 480 V.

CÂBLAGE D’ALIMENT ATION

1.Raccorder les câbles d’alimentation aux bornes appropriées de

l’interrupteur.

2.Raccorder le file de MALT (6) à la borne de MALT (7).

3.Prévoir un détendeur pour éviter les dommages aux câbles

4. Respecter les consignes des codes nationaux et locaux de

l’électricité.

ATTENTION - Couvrir les conducteurs exposés au moyen

d’isolants homologués.

2

2

3

3

FIGURE 2

7

4

CLOSE

GAPS

FIGURE 3

5

FILS D'ALIMENTATION

DU CLIENT

OUVERTURE

«A»

CÂBLAGE DU LUMINAIRE DANS LE BO¸ITIER

1.Raccorder les fils de la douille à la plaque à bornes de la douille à

l’intérieur du boîtier (Figure 5) ou :

Si le numéro de référence contient «-SH», raccorder la fiche mâle

à la fiche femelle du faisceau de câbles (Figure 4). Les enclencher

fermement.

2.Le boîtier doit être mis à la terre adéquatement.

3.Fermer la porter et enclencher les loquets. Une serrure est facultative.

Ces directives ne constituent pas un guide exhaustif répondant à

tous les problèmes de montage.

L’installateur est responsable de la sécurité du montage pour cette

application.

Lorsque le boîtier est installé, remettre les directives au propriétaire

du matériel.

Hubbell Lighting, Inc.

A Subsidiary of Hubbell Incorporated

2000 Electric Way

Christiansburg, VA 24073-2500

(540) 382-6111

FAX (540) 382-1526

FICHE DU FAISCEAU

DE CÂBLES «-SH»

FIGURE 4

BOÎTIER SÉPARÉ

PLAQUE À BORNES

DE LA DOUILLE

LUMINAIRE N° 1

FIGURE 5

268-1157-9901

Page 5

SISTEMA DE REACTANCIA SEPARADA SLS

INSTRUCCIONES DE INSTALACIÓN

Referencia De Catálogo - R E M - XXXXH X- X-X X

Vatios des

artefacto

Tensión del artefacto

(2) 208v (3) 240v (E) 220v/50hz

(4) 277v (5) 480v (6) 347v

Candidad de reactancias

Catalog Logic: R E M - XXXXH X-X-X

Caracteristicas opcionales:

(SH) Mazo de conductores preparado

(TB) **Disyuntor magnético térmico

**Regular para V~240 y menos

(WP) Poste sólido de madera u otro material

(T) Cable trifásico

2 à 6

El sistema completo consta de una caja de reactancia, artefactos de alumbrado, un mazo de conductores, traviesas y

postes.

¡ADVERTENCIA!

• Dentro de este producto existen tensiones peligrosas.

• Desconectar la energía eléctrica antes de cualquier operación

de mantenimiento para reducir los riesgos de incendio y de

choque eléctrico.

• Para reducir el riesgo de lesiones, hay que hacer funcionar y

mantener el sistema de conformidad con todos los códigos

aplicables.

• La instalación sólo debe ser realizada por un electricista

competente.

• Asegurar la puesta a tierra apropiada para todos los

componentes del sistema.

• Antes de la instalación y mientras se realiza, se deben leer y

seguir todas las instrucciones e indicaciones en las etiquetas.

• Si este producto no se instala correctamente, dejará de tener

validez la garantía del fabricante.

• La reactancia debe manipularse y colocarse firmemente para

evitar que se caiga.

• Usar equipo protector para evitar lesiones durante la instalación

de este producto pesado.

• No pasar cables por la parte superior de la caja.

Esta caja de reactancia debería instalarse a una altura mínima

ÞÞ

Þ

ÞÞ

de 3 metros sobre el nivel del suelo.

INSTALACIÓN DE LA CAJA: POSTES DE ACERO Y DE HORMIGÓN

(Figuras 1,2 y 3) (Ver Montaje de la caja: postes de madera)

Importante: La instalación requiere un poste equipado con

manguitos de fijación y que tenga una abertura de cableado (Figura 1).

1. Retirar la cinta adhesiva del burlete provisto en la bolsa de

accesorios.

2.Adherir el burlete al dorso de la caja, alrededor del hueco de 63,5

mm x 114,3 mm (Figura 3).

3. Insertar el perno (2) con la arandela de seguridad (3) en el

manguito superior (Figura 2). Dejar visibles 25 mm de rosca.

4.Colocar la pestaña colgadera (4) sobre el perno (2) y la arandela

de seguridad (3).

NOTA: La parte superior del orificio en la pestaña colgadera debe

quedar apoyada en el perno para sostener una caja de 127 kg.

5.Alinear la entrada de cables de la caja con la abertura de cableado

del poste. ¡No dañar el burlete!

6.Insertar el perno, la arandela de seguridad y la arandela plana a

través del orificio dentro de la caja y en el manguito del poste.

7.Ajustar los dos pernos con un par mínimo de 55 N m.

8.Sellar todas las aberturas entre el poste y la caja.

MONTAJE DE LA CAJA: POSTES DE MADERA (-WP) (Figuras 2,3)

1.Insertar un perno (2) de 19 mm de diámetro (provisto por otros)

con una arandela de seguridad (3) en el poste, en el lugar deseado

para sostener la parte superior de la caja (Figura 2). Dejar visibles

25 mm de rosca.

Hubbell Lighting, Inc.

A Subsidiary of Hubbell Incorporated

2000 Electric Way

Christiansburg, VA 24073-2500

(540) 382-6111

FAX (540) 382-1526

3/8"

TYP.

3/8"

MANGUITOS CON ROSCAS

INTERIORES 3/4-10 PARA

PERNOS DE 19 MM

FIGURA 1

3"

41"

5"

4 - 7/8"

268-1157-9901

Page 6

2.Colocar la pestaña colgadera (4) sobre el perno (2) y la arandela

de seguridad (3).

NOTA: La parte superior del orificio de la pestaña colgadera debe

quedar apoyada en el perno para sostener la caja de 127 kg.

3.Insertar el perno, la arandela de seguridad y la arandela plana a

través del orificio dentro de la caja y en el poste de madera.

4.Ajustar los dos pernos con un par mínimo de 55 N m.

5.Sellar todas las aberturas entre el poste y la caja.

6.Perforar una abertura para cableado del diámetro que se desee

desde el interior de la caja en el centro del orificio “A” de la caja

eléctrica (Figura 4).

NOTA - Esta abertura para cableado puede perforarse por encima

de la caja. ¡No dañar los cables ni los componentes!

7.Unir el conducto a la caja con accesorios impermeables.

INSTRUCCIONES ELÉCTRICAS Y CABLEADO

3 La tensión de la caja debe coincidir con la tensión de alimentación.

3 El cableado ordinario es monofásico. El trifásico requiere la

indicación «-T» en el número de catálogo (Consultar a la fábrica).

3 Dentro de la tapa se indica el amperaje de servicio total.

3 Las cajas están cableadas en fábrica para funcionar como

unidades separadas (Comunicarse con la fábrica si se quiere

cablear múltiples cajas en serie).

3 La caja comprende fusibles instalados en fábrica para todos los

circuitos derivados.

• La caja comprende interruptores eléctricos internos:

• Un disyuntor termo magnético regular para V~208, V~220 y

V~240

• Un interruptor de carga regular para V~277, V~347 y V~480

• «-TB» indica disyuntor termo magnético para V~277, V~347 y

V~480

2

2

3

4

3

5

FIGURA 2

CERRAR EL

BURLETE

FIGURA 3

CABLES DE ALIMENT ACIÓN

PROVISTOS POR EL CLIENTE

CABLEADO DE ALIMENT ACIÓN

1.Conectar los cables de alimentación con los bornes

correspondientes del interruptor.

2.Conectar el cable de tierra (6) con el borne de puesta a tierra (7).

3.Aplicar un alivio de tensión apropiado para evitar daños en los

cables.

4.Cumplir con todos los códigos eléctricos nacionales y locales.

PRECAUCIÓN - Proteger los cables descubiertos con aislantes

aprobados.

CABLEADO DEL ARTEFACT O EN LA CAJA

1.Conectar los cables del portalámparas con el bloque de bornes

del portalámparas dentro de la caja (Figura 5), o

Si el número de catálogo incluye la indicación «-SH», conectar la

clavija macho y la clavija hembra del mazo de conductores (Figura

4). Enganchar firmemente.

2.La caja deberá estar correctamente conectada a tierra.

3.Cerrar la tapa y enganchar las trabas. Puede usarse un candado,

como opción.

Estas instrucciones no están concebidas como una guía exhaustiva

sobre todos los aspectos de la instalación.

El instalador es responsable de que el montaje resulte seguro, quede

firme y sea apropiado para la aplicación.

Una vez instalada la caja, entregar estas instrucciones al propietario

del equipo.

7

ORIFICIO

«A»

CLAVIJA «-SH» DEL

MAZO DE CONDUCTORES

FIGURA 4

CAJA SEPARADA

BLOQUE DE BORNES DEL

PORTALÀMPARAS

ARTEFACTO N° N

Hubbell Lighting, Inc.

A Subsidiary of Hubbell Incorporated

2000 Electric Way

Christiansburg, VA 24073-2500

(540) 382-6111

FAX (540) 382-1526

FIGURA 5

268-1157-9901

Loading...

Loading...