Page 1

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL FOR

ELECTRIC HEATER COMPANY

COMMERCIAL INDIRECT

POWERED WATER HEATER

BASE MODEL “ T ”

Edition 2011

Page 2

HUBBELL

ELECTRIC HEATER COMPANY

P.O. BOX 288

STRATFORD, CT 06615

PHONE: (203) 378-2659

FAX: (203) 378-3593

INTERNET: http://www.hubbellheaters.com/

-- IMPORTANT --

Always reference the full model number and serial number when calling the factory.

WARNING / CAUTION

1. Tank is to be completely filled with water and all air is to be vented before energizing.

2. Due to the rigors of transportation, all connections should be checked for tightness before

heater is placed in operation.

3. Safety relief valve must be installed in tapping provided.

4. KEEP AWAY FROM LIVE ELECTRICAL CIRCUITS.

Do not perform any maintenance, make any adjustments, or replace any components

inside the control panel with the high voltage power supply turned on. Under certain

circumstances, dangerous potentials may exist even when the power supply is off. To

avoid casualties, always turn the power supply safety switch to off, turn the charge or

ground the circuit before performing any maintenance or adjustment procedure.

5. The unit is designed to operate at pressure not more than 150 psi.

6. Generalized instructions and procedures cannot anticipate all situations. For this reason,

only qualified installers should perform the installations. A qualified installer is a person

who has licensed training and a working knowledge of the applicable codes regulation,

tools, equipment, and methods necessary for safe installation of an electric resistance

water heater. If questions regarding installation arise, check your local plumbing and

electrical inspectors for proper procedures and codes. If you cannot obtain the required

information, contact the company.

2

Page 3

SECTION TITLE PAGE No.

I GENERAL DESCRIPTION AND CONSTRUCTION 4

II INSTALLATION 6

III SCHEDULED MAINTENANCE AND OPERATION 8

IV TROUBLESHOOTING 10

V SERVICING AND REPLACEMENT OF PARTS 11

VI MISCELANEOUS CHARTS AND FORMULAS 19

3

Page 4

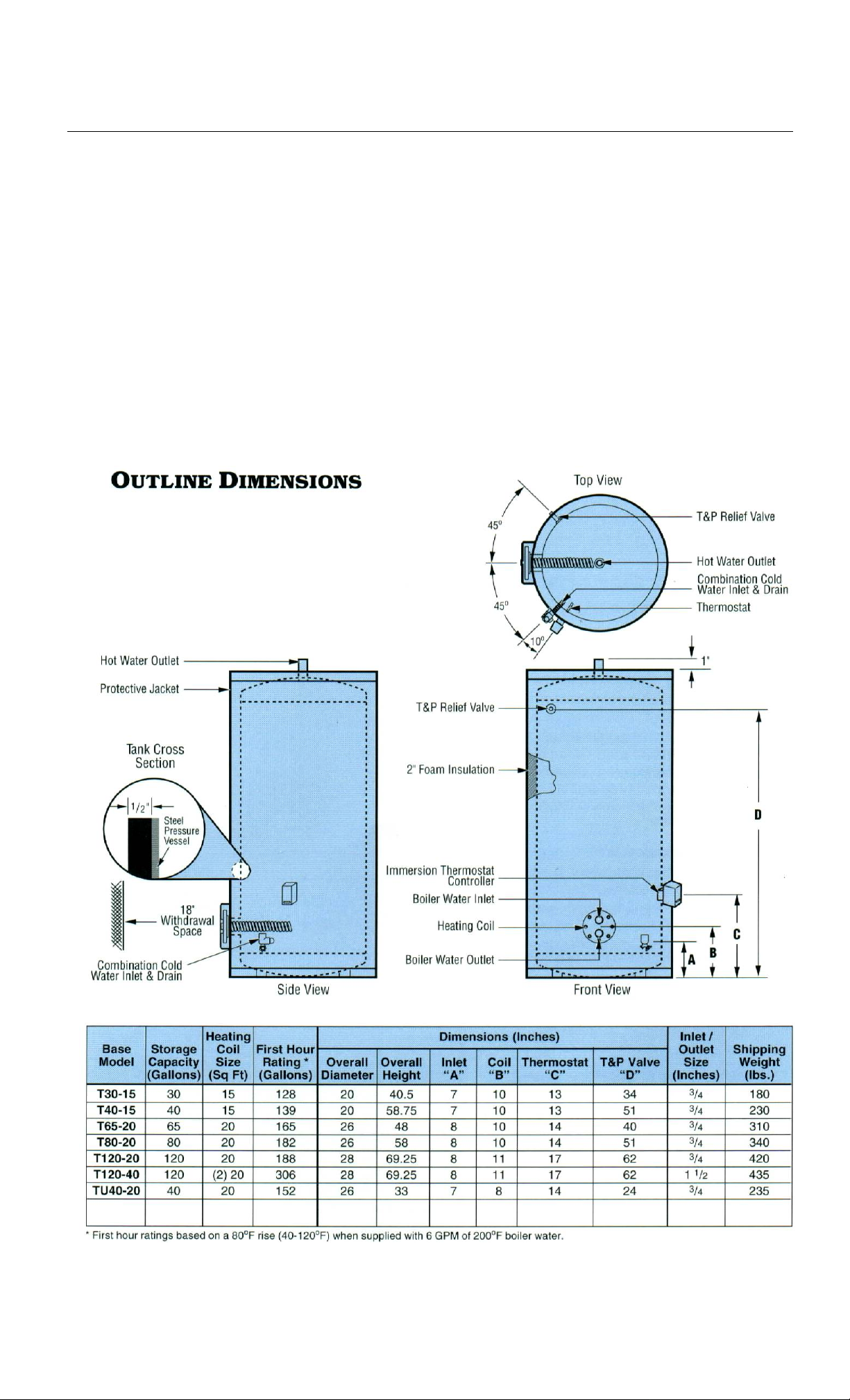

SECTION I - GENERAL DESCRIPTION AND CONSTRUCTION

GENERAL DESCRIPTION

This book describes a packaged boiler water powered indirect water heater that is a stationary,

self-contained unit. The complete assembly on a standard unit consists of the storage tank,

immersion heating coil, and an ASME rated combination temperature and pressure safety relief

valve. Optional equipment may be supplied with your unit. Please consult the product drawing

for details specific to your assembly. The unit is factory assembled, insulated, jacketed, wired,

tested, and ready for electrical and plumbing service connections.

CONSTRUCTION

TANK

The standard storage tank is constructed of steel and internally lined with specially formulated

Hydrastone cement to a ½-inch minimum thickness. The tank is designed for a maximum

allowable working pressure of 150 psi (300 psi TP).

TANK CONNECTIONS

The heater is supplied with separate cold water and hot water connections. Water entering the

cold water inlet is deflected by means of a baffle within the tank. The hot water outlet includes a

built in heat trap to prevent hot water from radiating out from the heater. A ¾-inch FNPT

connection is located on the side of the heater for mounting a combination safety temperature

and pressure relief valve. An overflow line should be installed from the relief valve outlet to a

floor drain. A ¾-inch GHT connection is supplied for draining. See drawing for locations and

sizes.

OUTER SHELL AND INSULATION

The tank is encapsulated in 2-inch thick polyurethane foam insulation. The insulation is

protected by a high impact non-corroding colorized composite protective jacket.

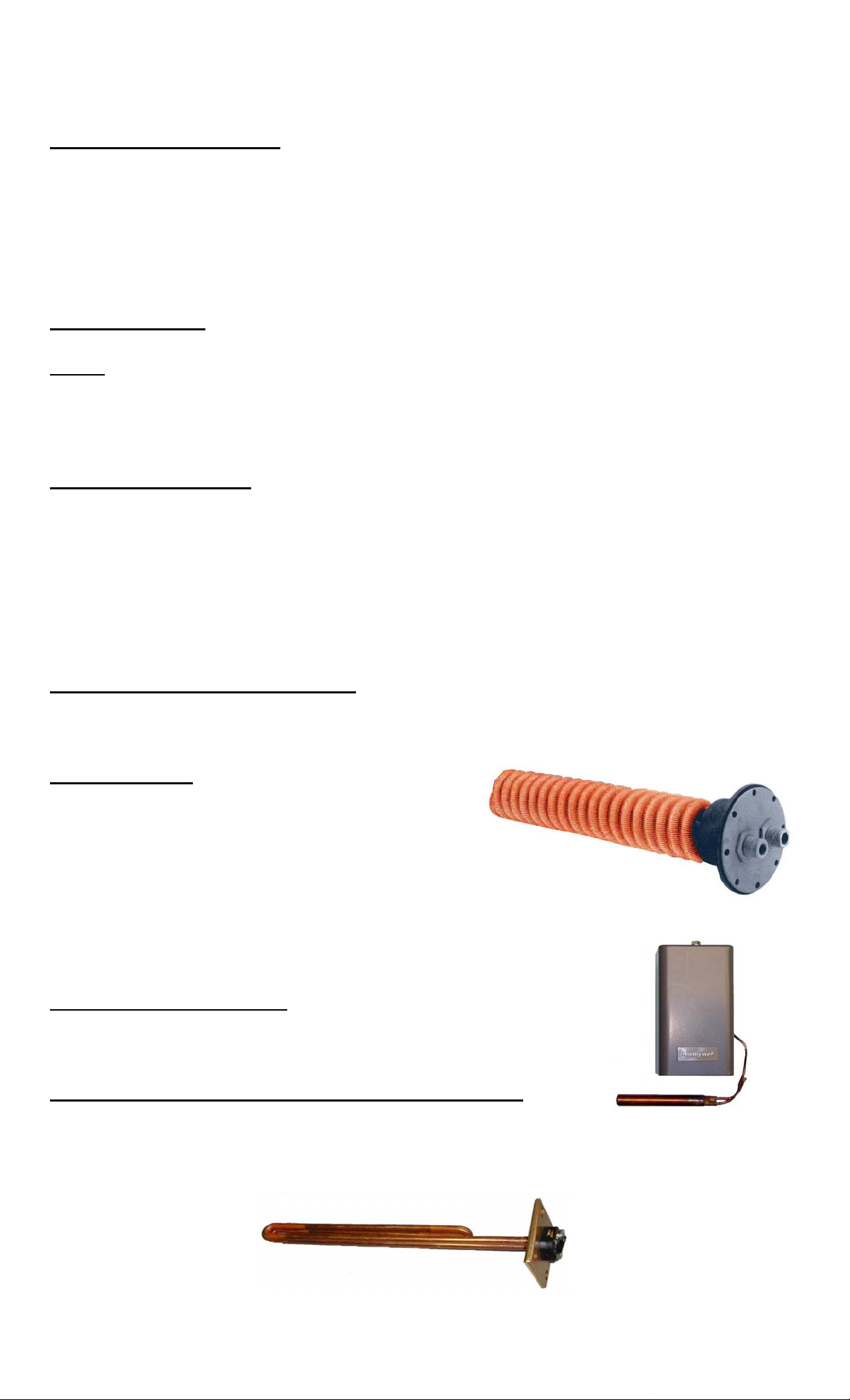

HEATING COIL

The water heater is supplied with a high quality,

factory installed, high efficiency, single walled,

copper finned heating coil designed for a maximum

working pressure of 150 psi. The tubing is installed

in a heavy-duty fabricated steel head with threaded

NPT connections. Each assembly is fastened to a

corresponding tank flange using a gasket and hex head steel bolts and

nuts.

CONTROL THERMOSTAT

The water heater is supplied with an immersion thermostatic switch. The

thermostat can be adjusted through a range of 120° - 140° F.

OPTIONAL BACK-UP ELECTRIC HEATING SYSTEM

Back-up Electric Heating Element

The water heater may be supplied with an electric immersion heating element assembly(s).

Each assembly is fastened to a corresponding tank flange using a gasket and four (4) 3/8-16 x 1inch long hex head steel bolts and nuts. See drawing for voltage and power ratings.

4

Page 5

Control Thermostat

The water heater may be supplied with either a surface mounted or immersion thermostatic

switch to control the back-up electric heating system. See drawing for specific details. The

surface mounted thermostat can be adjusted through a range of 110° - 170° F. The immersion

thermostat can be adjusted through a range of 100° - 190° F. Both thermostats are adjustable

with a flat tip screwdriver.

Surface Mounted Thermostat Immersion Thermostat

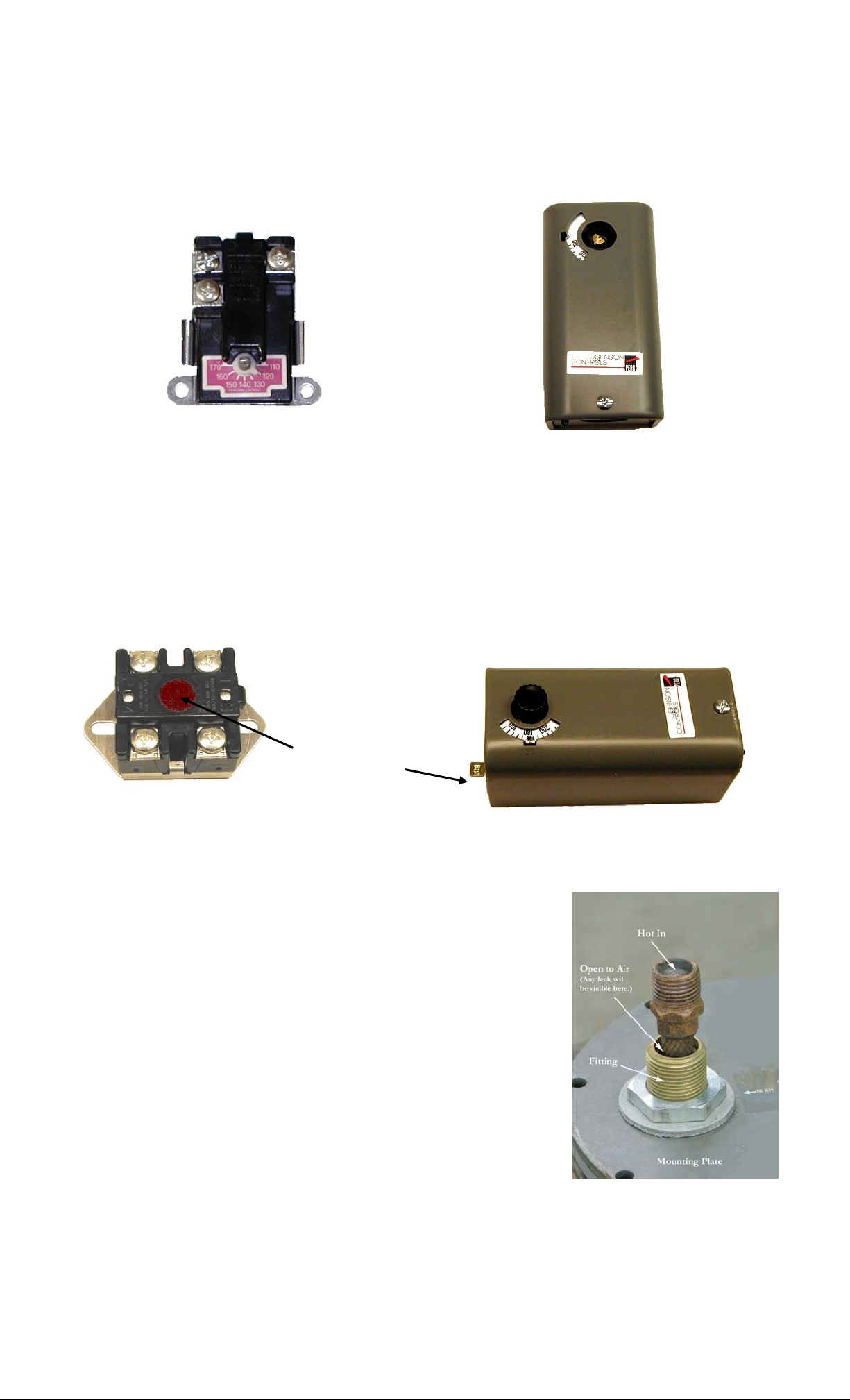

Temperature High Limit Switch

As a safety device, either a surface mounted high temperature cut-off switch with manual reset,

factory set at 190° F, or an immersion high temperature cut-off switch with manual reset,

factory set at 180° F, may be provided. In the event of an over-temperature condition, the

thermostat will disengage the power from the back-up electric heating system. The high limit

must be manually reset thereafter to restart the heater.

Manual Reset

Surface Mounted High

Temperature Cut-Off Switch Immersion High Temperature Cut-Off Switch

Double Wall Heating Coil

A Double Wall Heat Exchanger consists of two copper tubes,

one inside the other, wound into a coil. The outer tube is

soldered into the fitting that mates into the tank. The inner

tube is soldered into the fitting that mates with the hot water

supply. The gap between the two tubes is open to the air,

allowing visible detection of any leaks, as well as preventing

any leaks from mixing into the other liquid.

5

Page 6

SECTION II – INSTALLATION

WARNING / CAUTION

DO NOT TURN ON THE BOILER WATER SUPPLY to this equipment until heater is

completely filled with water and all air has been released. If the heater is NOT filled with

water when the power is turned on, damage to the heating coil may result.

For protection against excessive pressures and temperatures, local codes require the

installation of a temperature-and-pressure (T&P) relief valve certified by a nationally

recognized laboratory that maintains periodic inspection of production of listed equipment of

materials, as meeting the requirements for Relief Valves and Automatic Gas Shutoff for Hot

Water Supply Systems. ANSI Z21.22-1971. THE CUSTOMER IS RESPONSIBLE TO

PROTECT PROPERTY AND PERSONNEL FROM HARM WHEN THE VALVE

FUNCTIONS.

All water heaters have a risk of leakage at some unpredictable time. IT IS THE

CUSTOMER'S RESPONSIBILITY TO PROVIDE A CATCH PAN OR OTHER

ADEQUATE MEANS, SO THAT THE RESULTANT FLOW OF WATER WILL NOT

DAMAGE FURNISHINGS OR PROPERTY.

WATER HEATER PLACEMENT

1. Place the heater on a solid foundation in a clean, dry location nearest to the point of

most frequent hot water use. If the heater is to be raised off the floor, the entire bottom

of the heater should be supported by a solid surface.

2. The water heater should be protected from freezing and waterlines insulated to reduce

energy and water waste.

3. Leave a minimum of 18” clearance for element withdrawal, if necessary.

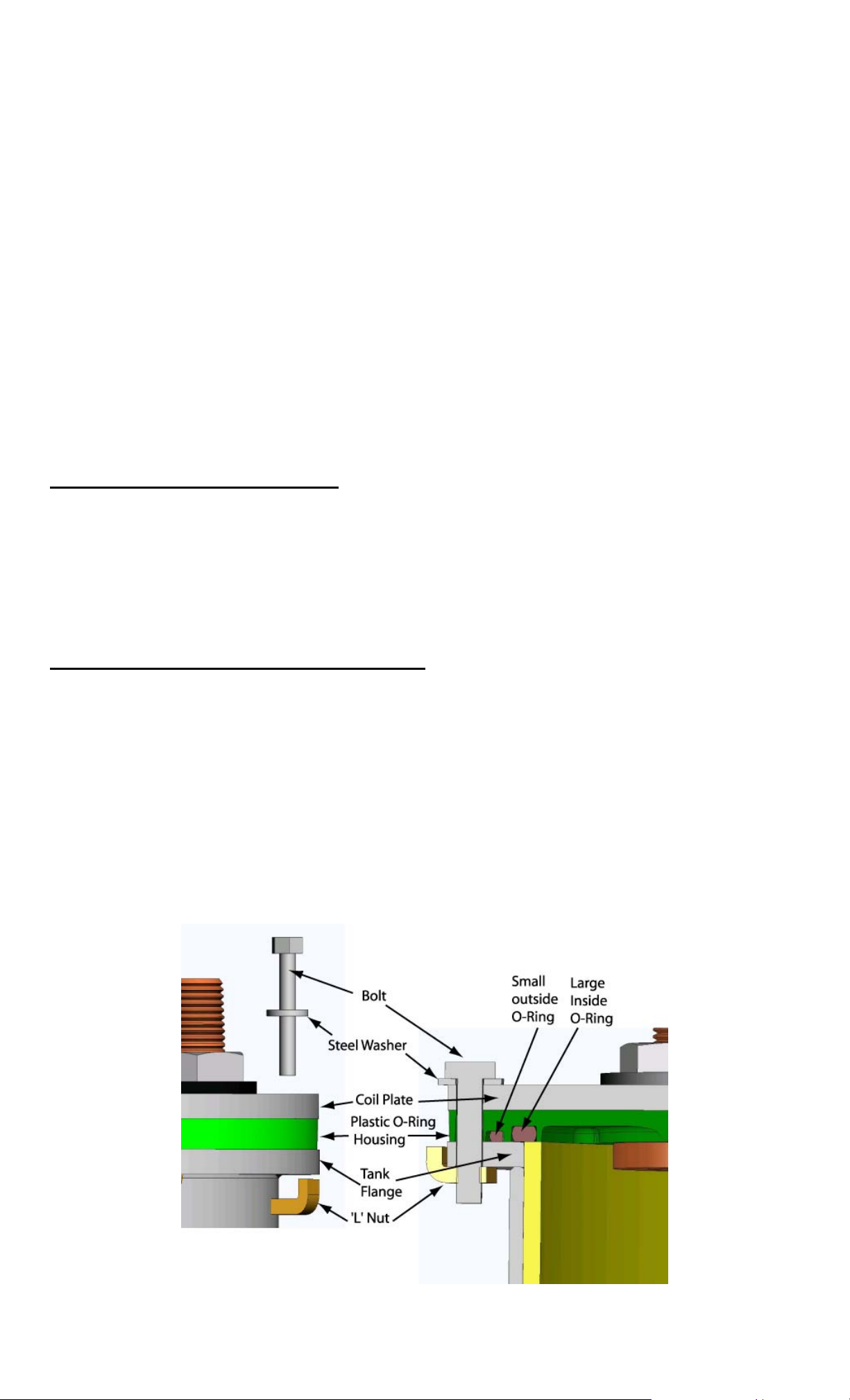

INSTALL THE HEAT EXCHANGER COIL

1. Remove the access panel.

2. Apply the included o-ring lubricant to o-rings.

3. Insert the o-rings into the grooves on the plastic o-ring housing.

4. Insert heat exchanger and align holes in cover plate with holes in flange.

5. WARNING: Plastic o-ring housing must be properly installed. Failure to do this

will void the warranty.

6. Insert and secure the bolts to the nuts one at a time in the following manner:

• Place the nut behind the flange opening.

• Hold the nut in place with one hand – insert the bolt with washer with the other.

• Thread the bolt through the washer and into the nut and tighten.

• NOTE: Be sure to place bolts in all of the openings.

6

Page 7

PIPING INSTALLATION

NOTE:

The most effective means for preventing deterioration from accelerated corrosion

due to galvanic and stray current is the installation of dielectric fittings/unions. The

installation of these fittings is the responsibility of the installing contractor.

1. All integral components have been properly sized to meet design conditions. Piping to

the unit should be sized to meet the design conditions, as dictated by good engineering

practices.

2. Connect boiler water supply and return lines to heating coil assembly.

Connect the cold water inlet and hot water outlet to the appropriate connections as

shown; refer to the drawing for location and sizes.

3. Install the combination temperature and pressure safety relief valve in the tapping

provided. Note that this is required by law for safety considerations.

Outlet to floor drain Install into provided tapping

Manual Release

Lever

Temperature Probe

Temperature and Pressure Relief Valve

4. Install a relief valve overflow pipe to a nearby floor drain. CAUTION: No valve of

any type should be installed between the relief valve and tank or in the drain line.

7

Page 8

ELECTRICAL INSTALLATION

1. Connect electrical wiring from boiler controls and circulator pump to immersion

thermostat.

2. If supplied with a back-up electric heating element; enter electric enclosure with

properly sized feeder leads. Be sure to properly ground the water heater. Install these

power leads into the box lugs on the terminal block.

3. Torque screws per torque chart included in Section VI.

4. All other electrical connections are made at the factory; therefore, no other electrical

connections are necessary.

FILLING THE HEATER

1. Completely close the drain valve.

2. Open the highest hot water faucet to allow all air to escape from piping.

3. Open the valve to the cold water inlet and allow the heater and piping system to

completely fill, as indicated by a steady flow of water from the open faucet.

FINAL CHECKS

1. Check all connections for tightness.

2. Ensure that all the above steps are completed

3. After the water is heated for the first time, monitor the water temperature as described

in Section III, Quarterly Inspection.

SECTION III - SCHEDULED MAINTENANCE AND OPERATION

WARNING / CAUTION

Before performing any maintenance procedure, make certain boiler water and electric supply

is OFF and cannot accidentally be turned on.

MAINTENANCE AND OPERATION

The water heater is automatic in its operation. It will maintain a full tank of water at the

temperature setting of the thermostat. The water heater should not be turned on without first

making sure that the tank is full of water and that all air has been released.

8

Page 9

FREEZING

The tank should be fully drained in the event the boiler water has been turned off and if there

is danger of freezing.

QUARTERLY INSPECTION

1. Monitor thermostat

a. Let water heater completely heat to a designated thermostat setting.

b. After thermostat satisfies (that is, when the thermostat actually clicks off), draw water

from heater.

c. Compare water temperature of drawn water to the temperature setting of the

thermostat when it satisfies. Normal variation between the two points is

approximately +

5°F.

d. If these two readings do not coincide within acceptable tolerances and verification has

been made of the accuracy of the temperature-reading gauge, replace the thermostat.

2. Lift test lever on relief valve and let water run through valve for a period of

approximately 10 seconds. This will help flush away any sediment that might build up in

water passageways.

3. Inspect heating coil flange for leakage as follows:

a. Remove heating coil housing cover.

b. Visually inspect heating coil gasket for evidence of leaks.

c. Rub finger around gasket that is between the heating coil and tank flange for any

evidence of moisture. If moisture is present or a water drip is observed, follow

procedure outlined in Section V.

4. Check for loose electrical connections. Tighten as necessary.

ANNUAL INSPECTION

1. Flush tank as follows

a. Shut off power supply.

b. Close valve on hot water outlet piping.

c. Open valve on drain piping.

d. Cold water inlet line pressure will be strong enough to flush sediment from the bottom

of the tank out through the drain. Let water run for 3-4 minutes.

e. Close drain valve.

f. Open hot water valve.

g. Turn power supply ON.

2. Units subject to fouling or scaling should be cleaned periodically. A marked increase in

pressure drop and/or a reduction in performance usually indicates cleaning is necessary.

3. To clean inside of tubes, remove all heads and covers. (Caution: Do not loosen heads

until you are sure all pressure is off the equipment, and the unit is drained).

Clean the unit using the following methods.

a. Circulate hot fresh water at a reasonable velocity.

b. Try spraying with water hose.

c. Consult with manufacturers of cleaning compounds and chemicals. They will check

the nature of the deposit, recommend the right cleaning compound, and in many cases

provide equipment and personnel for a complete cleaning job.

4. If the unit is dismantled for any reason, it should be reassembled using new gaskets.

5. Do not tighten bolts until gaskets are properly seated.

6. When tightening bolts in the element head, tighten the bolts in a criss-cross pattern. This

will evenly distribute pressure around the flange, and help prevent warping.

9

Page 10

SECTION IV – TROUBLESHOOTING

Symptom Probable Cause Corrective Action / Remedy

Gradual loss of heating

capacity.

Overheating.

Immediate loss of heating

capacity.

Excessive vibration. High rate of flow beyond

Water hammer. Undersized return lines. Re-pipe return line using proper

Tubes are fouled. Clean tubes per Section III,

annual scheduled maintenance.

Excess silt in bottom of

tank.

Ruptured tube(s) in

heating coil.

Thermostat needs

adjusting.

Circulator not operating. Repair or replace per separate

Blockage in return line. Clean blockage from return line.

design conditions.

Under sized piping to the

unit.

Insufficient slope on

return lines causing

backup.

Drain and flush tank per Section

III , annual scheduled

maintenance.

Remove / replace heating coil.

Adjust thermostat

O&M.

Consult factory.

Re-pipe lines to unit using

proper sized lines.

sized lines.

Increase slope on return lines.

* Red symptom indicates that equipment should be shut down immediately and cause of

malfunction corrected before unit is re-started or serious damage may result.

BACK-UP ELECTRCIAL HEATER SYSTEM (if supplied)

Symptom Probable Cause Corrective Action / Remedy

No hot water Circuit breaker tripped at

source.

High limit switch tripped. Reset high limit switch.

Loose wires. Tighten wires. Torque screws per

Heating element inoperable. Check heating element operation by

Low line voltage. Have source electrical system

Faulty thermostat. Move thermostat dial through full

Reset circuit breaker.

torque chart included in Section VI.

clamping an Amprobe around each

wire to the element. The ampere

reading should agree with the

nameplate ‘AMP’ figure.

checked by an electrician.

range. A definite ‘click’ should be

heard. If not, replace thermostat.

10

Page 11

Water temperature

below settings at

all times

Relief valve

discharges

continuously

Faulty thermostat. Check thermostat adjustment.

Monitor thermostat as described in

Section III, Quarterly Inspection.

Replace if necessary.

Heating element not

working on all phases

Heater improperly sized Verify heater is properly sized for the

Excessive temperature or

pressure in tank

Check to see that heating element is

working on all phases, by checking

the resistance (ohms) value for each

element and comparing with

expected rating.

flow rate and temperature rise of your

system. Replace elements with proper

size as necessary.

Temperature and pressure relief

valves are made to operate if the

water temperature exceeds 210°F or

water pressure exceeds the pressure

rating of the safety relief valve. If

trouble is excessive temperature, then

thermostat is not shutting off at the

right setting and thermostat must be

replaced.

SECTION V - SERVICING & REPLACEMENT OF PARTS

WARNING / CAUTION

Before servicing or replacing any part make sure to turn the power supply switch to the OFF

position.

RELIEF VALVE

1. Disconnect power from unit.

2. Shut off incoming water and boiler water supply.

3. Lift test lever on relief valve to relieve pressure in tank.

4. Disconnect overflow piping.

5. Unscrew relief valve, remove assembly and replace with new one.

6. Connect overflow piping.

7. Turn on incoming water supply and check for leaks.

8. Turn safety switch to ON position.

Test Lever

Overflow Piping Outlet

Tank Connection

Temperature Probe

11

Page 12

HEATING COIL

1. Disconnect power from unit.

2. Shut off incoming cold and boiler water supply.

3. Attach hose to drain connection.

4. Lift manual release lever on relief valve to let air into system or break union on

outgoing water line.

5. Drain water from tank.

6. Disconnect supply and return lines from heating coil.

7. Remove bolts securing the heating coil to the tank flange.

8. Withdraw heating coil assembly.

9. Before installing new heat exchanger it is imperative that the edge of the steel pipe is

clean from rust and not damaged. A file may be used to dress up the surface.

10. Install new heating coil assembly, make piping connections, and fill the tank as shown

in section II.

11. Check around gasket for any leaks.

SURFACE TEMPERATURE HIGH LIMIT CUT-OFF (if supplied)

1. Disconnect power from unit.

2. Remove access cover.

3. Disconnect the four (4) 14 gauge wires or three (3) 14 gauge

wires and a jumper, as required.

Control Wires

4. Remove the two (2) mounting screws or disconnect from thermostat, as required.

Mounting Screws

5. Replace control and install new high limit switch by performing above steps in reverse

order.

12

Page 13

IMMERSION TEMPERATURE HIGH LIMIT CUT-OFF (if supplied)

1. Disconnect power from unit.

2. Remove access cover.

3. Remove high limit cover screw and cover.

Cover

Cover Screw

4. Disconnect the two (2) 14 gauge wires. Reset Tab

Capillary Tube

Wires

5. Remove capillary tube and bulb from thermowell

6. Remove two (2) mounting screws.

Mounting Screws

7. Remove control and install new high limit switch by performing above steps in

reverse order. (Note: Be sure to place capillary tube into slot in base prior to installing

cover.)

13

Page 14

HEATING ELEMENT (if supplied)

1. Disconnect power from unit.

2. Shut off incoming water supply.

3. Attach hose to drain connection.

4. Lift manual release lever on relief valve to let air into system or break union on

outgoing water line.

5. Drain water from tank.

6. Disconnect the wires from the heating element terminals.

Tank Flange

Wires

7. Remove the 3/8-16 nuts.

8. Withdraw element assembly and remove gasket.

Gasket

Element Assembly

Nuts

9. Install new gasket and insert new heating element.

10. Rewire element according to type of unit as shown below.

11. Fill tank and check around gasket for any leaks.

14

Page 15

L1 L2 L3

L1 L2

1

1

3

2

1

3

4

2

4

1

2

2

1 3

2

4

1

Single Element Operation

2

3 Ø Open Delta Wiring for

Simultaneous Operation

15

Page 16

L1 L2 L1 L2

1

2

1

3

1

4

2

1

4

3

4

4

2

2

1

1

2

2

Interlocked for Non-Interlocked for

Non-Simultaneous Operation Simultaneous Operation

16

Page 17

SURFACE MOUNTED THERMOSTAT (if supplied)

1. Disconnect power from unit.

2. Remove access cover and locate thermostat.

3. Disconnect the two (2) or three (3) 14 gauge wires and jumpers, as required.

Control Wires

4. Remove two (2) mounting screws and disconnect from high limit cut-off, if required.

Mounting Screws

5. Replace thermostat using the reverse procedure.

17

Page 18

IMMERSION THERMOSTAT (if supplied)

1. Disconnect power from unit.

2. Remove access cover and locate thermostat.

3. Remove high limit cover screw and cover.

Cover

Cover Screw

4. Disconnect the two (2) or three (3)

14 gauge wires, as required.

Wires

Capillary Tube

5. Remove capillary tube and bulb from thermowell.

6. Remove two (2) mounting screws.

Mounting Screws

7. Replace thermostat using reverse procedure. (Note: Be sure to place capillary tube

into slot in base prior to installing cover.)

18

Page 19

SECTION VI – MISCELLANEOUS CHARTS AND FORMULAS

FORMULAS

Pressure Drop Chart

19

Page 20

P.O. BOX 288

STRATFORD, CT 06615-0288

PHONE: (203) 378-2659

FAX: (203) 378-3593

INTERNET: http://www.hubbellheaters.com/

20

Loading...

Loading...