Page 1

Marine Products Division

Model MTX

Tankless On Demand

Electric Water Heater

Available Up To 54 KW in Single or

Three Phase Voltages

The Hubbell Model MTX Tankless Water

Heater is the perfect choice for Marine

applications.

SAVES WEIGHT

✓

SAVES SPACE

✓

SAVES TIME

✓

Marine Approvals

■ American Bureau of

Shipping (ABS) Type

Approved

■ ABS Approval eliminates

costly delays and

uncertainties during ship

inspection

Heavy Duty Construction

■

Simple to specify

and easy to operate

■ Factory wired electrical

controls provide troublefree installation and

operation

Weight and Space Saving

■

Signicantly reduces weight

and saves space compared to

storage tank water heaters

■

On demand heating

eliminates costly and

cumbersome storage tanks

■

Instantaneous design reduces

stand-by heat loss and lowers

operating costs

Reliable

■

Engineered for your

specic application

to ensure reliable operation

■ Constructed with high grade

materials to ensure long

operating life

Tankless On Demand Water Heater for

Marine Applications

The Hubbell MTX Tankless model is a highly reliable and easily

maintained electric water heater designed for operation in a

marine application. The Hubbell MTX Tankless is compact,

highly efcient, takes up minimal space, and reduces operating

costs. Hubbell’s vast experience, meticulous engineering, and

advanced manufacturing processes ensure that you can rely on

the MTX Tankless for your water heating needs in even the most

demanding and critical applications. It makes sense to specify

and install a Hubbell MTX Tankless model for your heating

requirements, and as the owner you will be provided with a

quality product that is long lasting, trouble-free, and energy

efcient.

C

I

F

I

E

F

N

E

T

•

E

N

E

R

G

Y

&

W

A

T

E

R

S

•

A

V

G

I

N

High Efciency Compact

Electric Tankless

Water Heater

%

8

9

•

Y

L

D

N

E

I

R

F

O

C

E

ANSI/NSF 5

ISO 9001:2008

The Electric Heater Company

P.O. Box 288 ■ Stratford, CT 06615-0288

Phone: 203- 378-2659

info@hubbellheaters.com

■

FAX: 203- 378-3593

■

www.hubbellheaters.com

ISO

Page 2

Marine Products Division

Hubbell Tankless Features

How It Works

The Hubbell Model MTX electric tankless water heater contains high powered heating elements that

heat water only when there is demand for hot water. When hot water is needed, a built in ow sensor

measures the exact ow rate, and that data combined with temperature readings at the heater’s inlet

and outlet are processed by the electronic temperature controller. This data is continuously transmitted

to the temperature controller, which constantly calculates the precise amount of power (kW) needed to

achieve the desired temperature. A zero cross over ring signal is sent to the fast acting triacs in order to

modulate the heating elements to the precise level needed to meet demand. The Hubbell tankless heater

uses only as much power as is needed, while delivering accurate and consistent hot water temperature.

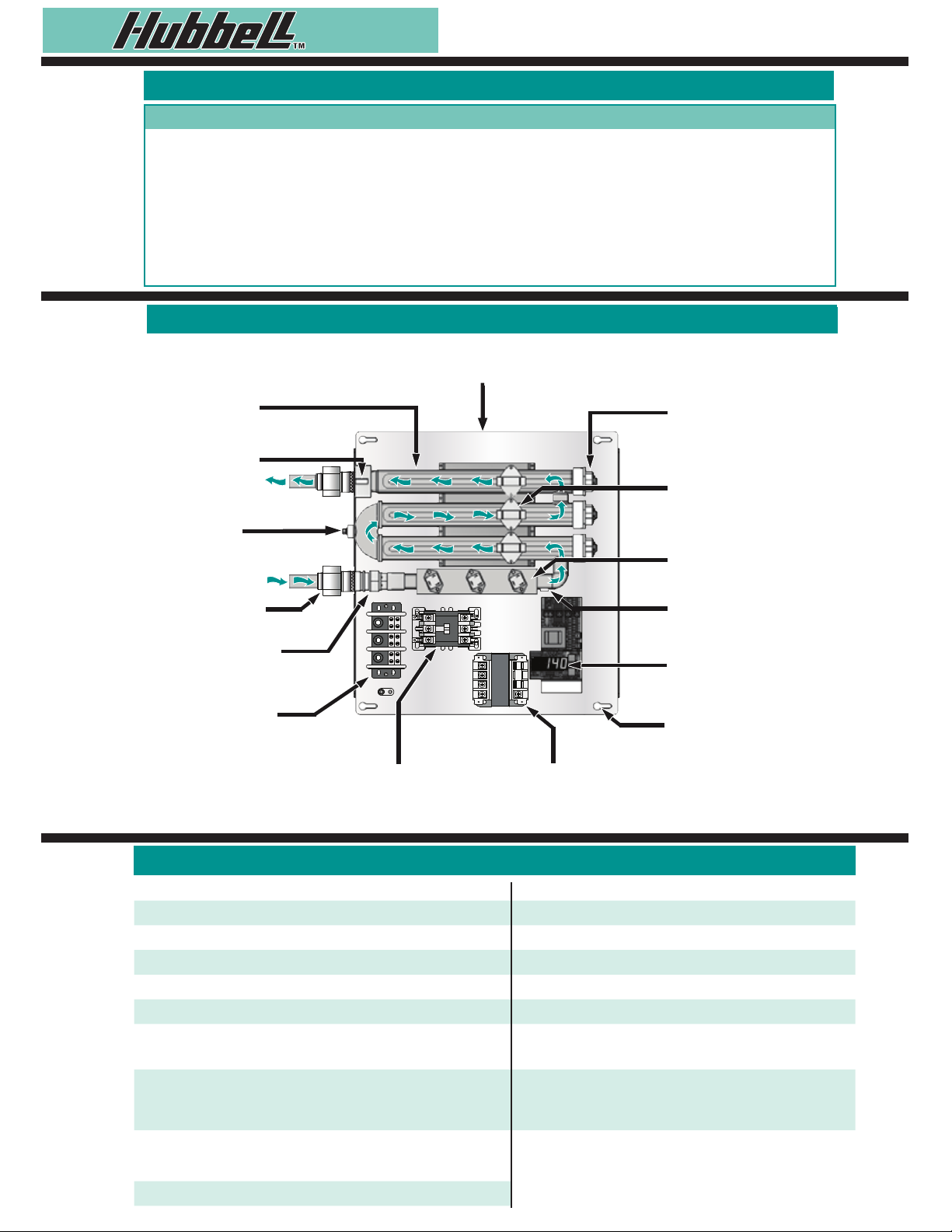

Heater Overview - 3 Element Model Shown

Stainless Steel Exterior

Heating Chamber

All copper and bronze

construction

Outlet Thermistor

Provides feedback to ensure

consistent outlet temperature

HOT WATER OUT

Drain Port

Simplies maintenance

COLD WATER IN

Dielectric Unions

Simplies plumbing installation

Flow Meter

Measures the exact ow rate which

enables the control system to provide

perfectly matched heating power with demand

Power Distribution Block

Provides a heavy duty single point

power connection

(Only Required on Certain Models)

Fully disengages the heating

elements in a fault condition

Sleek design and corrosion resistant

Magnetic Contactor

(Only Required on 3 Phase Units)

for long life

Control Transformer

Step down transformer provides

240 Volt control circuit power

(Only Required on Models over 240 Volt)

Commercial Quality

Heating Elements

Incoloy sheathed for long life

Safety Thermostats

Auto resetting Hi-Limit thermostats

protect against over heating

Solid State Switches

Modulate heating elements 0-100%

to ensure accurate and consistent

temperature and long element life

Inlet Thermistor

Senses cold water temperature

Numeric Digital Display

Electronic Temperature Controller

is adjustable in 1° increments in either

°F or °C

Bulkhead Mounting

Securely mounts to the bulkhead and

saves valuable deck space

Tankless Model MTX Standard Specications

Heating Chamber:

Capacities:

Mounting:

Voltages:

Phase:

Power Factor:

Thermal Efciency:

Copper and Bronze

5 thru 54 kW

Bulkhead Mounted

208 thru 600 Volt 50/60 Hz

Φ

and

3

(balanced)

Φ

1

0.999

98% +

Inlet/Outlet Size:

MTX:

MHX:

3

/4" Dielectric Union Copper Sweat

1" Dielectric Union Copper Sweat

Min/Max Flow:

MTX:

MHX:

2

Thermostat Range:

0.2 GPM Min, 8.0 GPM Max

0.5 GPM Min, 40 GPM Max

32 -194°F / 0-90°C

Hi-Limit:

Design WP:

Design TP:

Elements:

Standby Power:

Chamber

Electrical

Warranty:

Enclosure:

Approvals:

200°F (Fixed)

100 psi

300 psi

Incoloy 800

< 3 Watts

5 Year

1 Year

Stainless Steel Brushed Finish

ABS, cULus, UL EPH ANSI/NSF 5

Page 3

Marine Products Division

Technical Features

Temperature Controller

A sophisticated electronic temperature controller with LED digital display provides the user interface. The temperature controller

processes all ow and temperature data and calculates the precise amount of power needed to meet demand.

Operator Control Capabilities

✓

Power Limiting:

✓

Diagnostics:

✓

Cost Calculator:

✓

Temperature Control:

Full Heater Modulation

Each heating element is switched on/off using a fast acting solid state triac with zero cross over ring control. This switching

schema provides full modulation of each heating element, ensuring that the precise amount of heat is added to meet demand. To

improve operating efciency and component longevity, each triac is mounted to a heat sink located on the incoming supply piping

so that heat generated by the triac during the switching process is dissipated into the water.

Proper Power Integrity

All Hubbell tankless water heaters, including all 3 phase models, are engineered to operate as a balanced load and operate

at 0.999 Power Factor. All Hubbell 3 phase models are designed for 3 wire (3 live, 1 ground) and 4 wire power systems and draw

equal current across all conductors to maintain the power integrity of the users electrical system. Hubbell does not recommend the

use of heaters that operate as an unbalanced load, as is common with staged heaters designed for star systems (3 live, 1 neutral, 1

ground) that require use of the neutral leg. All load switching in Hubbell tankless models is performed as zero cross over, eliminating

phase angle ring interference and associated EMI issues.

Full Resource Staging

The Hubbell tankless control schema ensures that usage is equalized across all heating circuits. To achieve this, once the

controller has calculated the precise amount of kW required, all circuits are energized in a staggered fashion such that each circuit is

proportionally and independently energized and then time staggered between circuits. This Full Resource Staging Schema reduces

EMI output, increases component longevity, and provides highly accurate and consistent hot water temperatures. For three phase

models, all circuits are fully modulated and synchronized to operate as a balanced load.

Shipboard Machinery Control Integration

Remote Control: Ability to remotely enable or inhibit the heating operation of the unit using one of the following two methods:

1. Customer supplied 24VDC signal is user congured for either Inhibit Mode or Normal Operation Mode.

2. Customer supplied volt free contact is user congured for either Inhibit Mode or Normal Operation Mode.

Priority Control: An integrated SPDT potential free dry contact (NO/NC 10A @ 240VAC) energizes when the unit is heating and

Allows the operator to reduce the power consumption by any percentage to provide installation and

operational flexibility and savings.

Display inlet and outlet temperatures, flow rate and error codes to assist in troubleshooting.

Determine the exact cost of operating the heater. Input your cost per KW·Hr and the controller displays total

KW·HRs consumed, total cost of operation, and total hot water usage (shown in gallons or liters).

Set the digital display to the desired water temperature in °F or °C. Fully adjustable in 1° increments from

32-194°F (0-90°C). A user adjustable +/- 3° calibration feature provides additional control for superior accuracy.

de-energizes when not heating. This feature is useful when it is desirable to give the water heater priority over

another electrical load to ensure that both are not operational at the same time.

Options

A. High ow construction specify model MHX for up to

40 GPM ow (min 0.5 GPM actuation).

B. Type 316L stainless steel heating chamber for added

corrosion resistance.

C. Special construction features available. Consult factory.

D. Inlet/Outlet assembly simplies installation and includes

unions, shut offs, checkvalve, drain and pressure

relief valve.

E. NEMA 4x construction when heater is located in a wet

environment. Overall dimensions 24" x 20" x 6"

F. Heating chamber built to ASME Section VIII and "UM"

stamped.

Manifold Assembly Option

Single point connection

for redundancy and high

demand applications.

G. Remote Control Display allows the heater to be installed in remote

location. The 3" x 5" NEMA 4 display enclosure can be located up

to 250' from the heater and gives the operator full remote control

and monitoring capabilities.

H. Optional Inlet/Outlet union for connection to IPS pipe sizes.

Specify customer connection as sil-braze or NPT.

I. Special construction for use onboard Military Naval Vessels

including shock, vibration and EMI qualications.

J. Factory supplied manifold single point connection for redundancy

and high demand applications.

K. Right Hand orientation Inlet/Outlet on right hand side of unit.

3

Page 4

17

11

16

"

3

1

2

"

24"

25"

1

15

3

4

"

3

8

"

16

3

16

"

3

1

4

"

16"

17"

1

3

8

"

14

1

4

"

Outline Dimensions and Model Selection

Model Tankless MTX

Shipboard Electric

Water Heater

Hot Water

Outlet

Cold Water

Inlet

8-27 KW Models (2 and 3 Element)

KW

208V 240V 440V 480V 600V 208V 240V

KW Selection Chart

3 Phase Voltages 1 Phase Voltages

8 ✓ (2)

11 ✓ (3) ✓ (2)

12 ✓ (3) ✓ (2)

14 ✓ (3) ✓ (2) ✓ (2)

16 ✓ (3) ✓ (3) ✓ (3) ✓ (3) ✓ (2)

18 ✓ (3) ✓ (3) ✓ (3) ✓ (3) ✓ (2)

20 ✓ (3) ✓ (3) ✓ (3)

21 ✓ (3) ✓ (3) ✓ (3) ✓ (3) ✓ (3)

24 ✓ (3) ✓ (3) ✓ (3) ✓ (3) ✓ (3)

27 ✓ (3) ✓ (3) ✓ (3) ✓ (3) ✓ (3)

Note: • Chart indicates three element (3) and two element (2) model types

• Additional 440V 3Φ sizes available including 5, 6, 7 and 13 KW

Side View

1

15

"

16

3

1

"

16

Withdrawal

Space 12"

3"

3"

6"

Electrical knockout

3

Pressure Drop: 3 psi @ 8 GPM Dry Weight: 21 Lbs Wet Weight: 21.5 Lbs Shipping Weight: 24 Lbs

" x 1" x 11/4"

/4

9

3

"

16

3

1

"

8

1

4

"

8

24-54 KW Models (6 Element)

KW

208V 240V 440V 480V 60 0V 208V 240V

Hot Water

Outlet

24 ✓ (6) ✓ (6)

31 ✓ (6) ✓ (6) ✓ (6)

33 ✓ (6) ✓ (6)

KW Selection Chart

3 Phase Voltages 1 Phase Voltages

36 ✓ (6) ✓ (6) ✓ (6) ✓ (6)

40 ✓ (6) ✓ (6) ✓ (6)

42 ✓ (6) ✓ (6) ✓ (6) ✓ (6) ✓ (6)

48 ✓ (6) ✓ (6) ✓ (6) ✓ (6) ✓ (6) ✓ (6) ✓ (6)

54 ✓ (6) ✓ (6) ✓ (6) ✓ (6) ✓ (6)

Note: All models shown in this chart are six element (6) model types

Side View

1

23

"

16

9

4

"

16

3

1

"

8

3

4

"

14"

Electrical knockout

3

" x 1" x 11/4"

/4

4

Cold Water

Inlet

3

1

"

16

1

2

3" 4" 4"

"

2

Withdrawal

Space 12"

Pressure Drop: 4 psi @ 8 GPM Dry Weight: 38 Lbs Wet Weight: 39 Lbs Shipping Weight: 42 Lbs

4

Page 5

Marine Products Division

Heating Capacity and Amperage Chart

Heating Capability in GPM at

KW

20

°

Rating

8 2.73 1.82 1.36 0.91 0.78 0.68 0.55 0.50 0.45 0.39 − − − − − 38 −

11 3.75 2.50 1.88 1. 25 1.07 0.94 0.75 0.68 0.63 0.54 31 − − − − − 46

12 4.09 2.73 2.05 1.36 1.17 1.02 0.82 0. 74 0.68 0.58 33 − − − − 58 −

14 4.78 3.18 2.39 1.59 1.36 1.19 0.96 0.87 0.80 0.68 − 34 − − − 67 58

16 5.46 3.64 2.73 1.82 1.5 6 1.36 1.09 0.99 0.91 0.78 44 39 21 − − 77 67

18 6 .14 4.09 3.07 2.05 1.75 1.54 1.23 1.12 1.02 0.88 50 − 24 22 − 87 75

20 6.82 4.55 3 .41 2.27 1.95 1.71 1.36 1.24 1.14 0.97 56 − 26 − − 96 −

21 7.17 4.78 3.58 2.39 2.05 1.79 1.4 3 1. 30 1.19 1.02 − 51 28 25 20 − 88

24 8 .19 5.46 4.09 2.73 2.34 2.05 1.64 1.4 9 1.36 1.17 67 58 32 29 23 115 10 0

27 9. 21 6 .14 4.61 3.07 2.63 2.30 1.84 1. 67 1.54 1. 32 − 65 36 33 26 − 113

31 10.58 7.0 5 5.29 3.53 3.02 2.6 4 2 .12 1.92 1.76 1.51 86 − 41 − − 149 −

33 11.26 7.51 5.63 3.75 3.22 2. 81 2.25 2.05 1.88 1.61 − 79 − − − − 138

36 12. 28 8 .1 9 6.14 4.09 3. 51 3.07 2.46 2.23 2.05 1.75 100 − 47 43 − 17 3 −

40 13. 65 9 .10 6.82 4.55 3.90 3 .41 2.73 2.48 2.27 1. 95 111 − 53 − − 192 −

42 14.3 3 9.55 7.17 4.78 4.09 3.58 2.87 2.61 2.39 2.05 − 101 55 51 41 − 175

48 16. 38 10.9 2 8 .19 5.46 4.68 4.09 3. 28 2.98 2.73 2.34 133 116 63 58 46 230 200

54 18. 42 12. 28 9.21 6.14 5.26 4.61 3.68 3.35 3.07 2.63 − 130 71 65 52 − 225

• Unshaded ows specify Base Model MTX, shaded ows must specify Base Model MHX due to high ow rate.

Note:

• Alternate voltages including 277, 380, 415, 460 and 575 volt available. Please consult factory for exact KW availability in these voltages.

30° ∆T40° ∆T60° ∆T70° ∆T80° ∆T100° ∆T110 ° ∆T120° ∆T140 °

∆T

o

F Temperature Rise (oF∆T) MAX Amps (at 100% heater output)

3 Phase Voltages 1 Phase Voltages

∆T

208V 240V 440V 480V 600V 208V 240V

Sizing Formulas

Step 1

Variables To Solve For:

KW Requirement:

Temperature Rise:

Flow Rate:

Step 2

Choose the Tankless model with the KW rating which meets the peak

demand (GPM) and required temperature rise (

Step 3

Choose the voltage and phase power supply available. Note the total

amperage draw of the unit and verify availability.

Solve for the unknown using formulas below.

GPM x oF∆T x 0.1465 = KW

KW x 6.824 ÷ GPM = oF∆T

KW x 6.824 ÷ oF∆T = GPM

o

F∆T) for your application.

Model Number Designation

MTX

—

Voltage De-Rating Factors

Rated Voltage Applied Voltage De-Rating Factor

600 V 575 V 92%

600 V 550 V 84%

480 V 460 V 92%

240 V 230 V 92%

240 V 220 V 84%

When the actual supply voltage (applied voltage) is different

than the design voltage (rated voltage) the resulting KW output

will be affected. Please see the chart for typical voltage

de-rating factors, or use the following formula.

Applied Voltage

Rated Voltage

2

X Rated KW = KW output at applied voltage

2

Example: MTX027-3T5

A Hubbell tankless electric water heater rated at 27 KW with

■

Step 1

Base Model No.

MTX = 8 GPM Max

MHX = 40 GPM Max

■

Step 2

KW Rating:

5 thru 54KW

(005 - 054)

■

Step 3

Number of

Heating Elements:

2

3

6

a total of 3 heating elements when powered with 440 volt, three

phase, 60 Hz.

Option Note

Any and all optional equipment for a tankless model heater must be called out in the

written specications. A model number in and of itself does not reect any optional

equipment selected.

■

Step 4

Voltage / Phase / Hz:

RS = 208-1-60

R = 208-3-60

S = 240-1-60

T = 240-3-60

T3 = 380-3-50/60

T7 = 415-3-50/60

T5 = 440-3-60

T4 = 480-3-60

T6 = 600-3-60

5

Page 6

Model MTX TANKLESS

MadeintheU.S.A.

Master Specication

General

Heating Chamber

Heating Capacity

Electrical

SHIP NAME

SHIPYARD

ENGINEER / NAVAL ARCHITECT / SPECIfIER

CONTRACTOR / SHIP CHANDLER

Provide a quantity of packaged type instantaneous electric tankless water heater(s) Model No.

MTX

as manufactured by HUBBELL Electric Heater Co., Stratford, CT. The

entire unit is packaged ready for plumbing and electrical service connections and shall be Type Approved by

the American Bureau of Shipping (ABS) and bear the

cULUs listing mark certifying the entire unit to UL499,

UL EPH Sanitation listed to ANSI/NSF Standard 5 and CSA C22.2 No. 64-M91 (single phase units) and CSA

C22.2 No. 88 (three phase units).

The heating chamber shall be all sil-brazed copper and bronze construction. (

Optional Specication: Type

316L Stainless Steel ). A plastic heating chamber shall not be acceptable. Water heater heating chamber

shall be rated for a maximum allowable working pressure of 100 psi. The heating chamber and all

electrical controls shall be completely enclosed in a heavy gauge stainless steel case.

The tankless heater shall be rated at

rise (

° to °F ). Heaters that require the use of a ow restrictor or specialized aerator

KW which will heat GPM of water at °F

shall not be acceptable.

The tankless heater shall be designed to operate at

volts, phase, 50/60Hz balanced

power and shall draw equal amperage across all phases at all times. For 3 phase heaters, power shall be a 3

wire (3 live, 1 ground) or a 4 wire (3 live, 1 neutral, 1 ground) system that does not require a neutral leg. The

heater will draw

amps only when operating at full power. The immersion heating elements shall be

high quality incoloy sheathed and sized to obtain the rated capacity. Each element is to be operated using

zero cross over solid state controls. The heating elements shall be fully modulated from 0-100% to provide

precise temperature control through the full range of ows. A Hi-Limit thermostat with automatic reset shall

be factory installed to disconnect each heating element in the event of an over-temperature condition. An

electronic digital display temperature controller shall be user adjustable in 1° increments in either °F or °C

and shall display ow rate, outlet temperature, inlet temperature and provide error indication. A turbine-type

ow meter shall be factory installed to provide precise temperature control for water ows as low as 0.2 GPM

up to a maximum ow of 8 GPM. Heaters that require greater than 0.2 GPM ow for actuation or heaters that

utilize on/off ow switch technology or restrict ow shall not be acceptable. (

Optional Specication: High

Flow Model MHX, provides up to 40 GPM ow with minimum actuation at 0.5 GPM ).

Warranty

Hubbell shall warranty all electrical components against defects in workmanship and material for a period of

one (1) year from date of start-up, and the heating chamber for ve (5) years from date of start-up, provided

that the unit is started within three (3) months of date of shipment and installed and operated within the scope

of the heater's design and operating capability. Labor is not covered under warranty. Each heater shall be

shipped with a complete set of installation and operating instructions including spare parts list and drawing.

All fabrication and assembly shall be performed in the U.S.A.

Options

In addition, the water heater shall be supplied with the following options:

Marine Products Division

Option

Option

Option

ISO 9001:2008

Committed to continuous improvements

Contin uing researc h resul ts in pro duct improvement; therefore these sp ecication s are

subject to chan ge without notice. For the most updated information, consult the factory.

The Electric Heater Company ■ P.O. Box 288 ■ Stratford, CT 06615-0288

Phone: 203- 378-2659 ■ FAX: 203-378-3593 ■ info@hubbellheaters.com ■ www.hubbellheaters.com

ISO

[REV C ]

Loading...

Loading...