Page 1

Marine Products Division

Model MSH & MH

Shipboard Electric

Water Heater

80-5000 Gallon Capacity

15-1600 KW — All Voltages & Phases

The MSH is a storage

packaged water heater for

marine use.

Reliable

■

Only high grade materials

used in construction to

ensure long operating life

■

Hydrastone cement

lining provides superior

protection and tank

longevity

■

Heavy duty construction

withstands demanding

marine use

Marine Approvals

■

United States Coast Guard

(USCG) conformance

and Type Approved by

American Bureau of

Shipping (ABS)

■

USCG conformance

and ABS Type Approval

eliminates costly delays

and uncertainties during

ship inspection

Mounting Systems

■

Heavy-duty legs secure

the tank to deck

■

Side-sway bulkhead

attachment points provide

added mounting stability

■

The entire mounting

system is integrally welded

to tank for maximum

stability and safety

Packaged System

■

Fully packaged water

heater saves time and

money during installation

■

All electrical operating

controls are factory

selected and wired to

ensure reliable operation

■

Full range of styles, sizes,

and optional features to

meet your exact water

heating needs

A Heavy Duty Storage Electric Water

Heater For Marine Use

The Hubbell Model MSH and MH water heater is specically

designed for marine use on board a surface vessel or platform

and is in USCG conformance and is ABS Type Approved. By

utilizing deck and bulkhead mounting supports, the water

heater is securely fastened to the ship structure, thus providing

a secure and reliable water heater installation. The heavy-duty

carbon steel storage tank is lined with specially formulated

hydrastone cement that provides superior protection, tank

longevity and withstands demanding marine use.

When you specify and install a Hubbell model MSH or MH,

knowing that it is in conformance with USCG regulations and

is ABS Type Approved, you will have condence that the ship

owner will be provided with a quality product that is a long

lasting and trouble free source for hot water.

ISO 9001:2008

The Electric Heater Company

P.O. Box 288 ■ Stratford, CT 06615-0288

Phone: 203-378-2659

E-mail: info@hubbellheaters.com

ISO

■

FAX: 203-378-3593

■

www.hubbellheaters.com

Page 2

Cement Lined Tanks

Provide Longer

Service Life

NO

NO

GLASS

GLASS

LINING

LINING

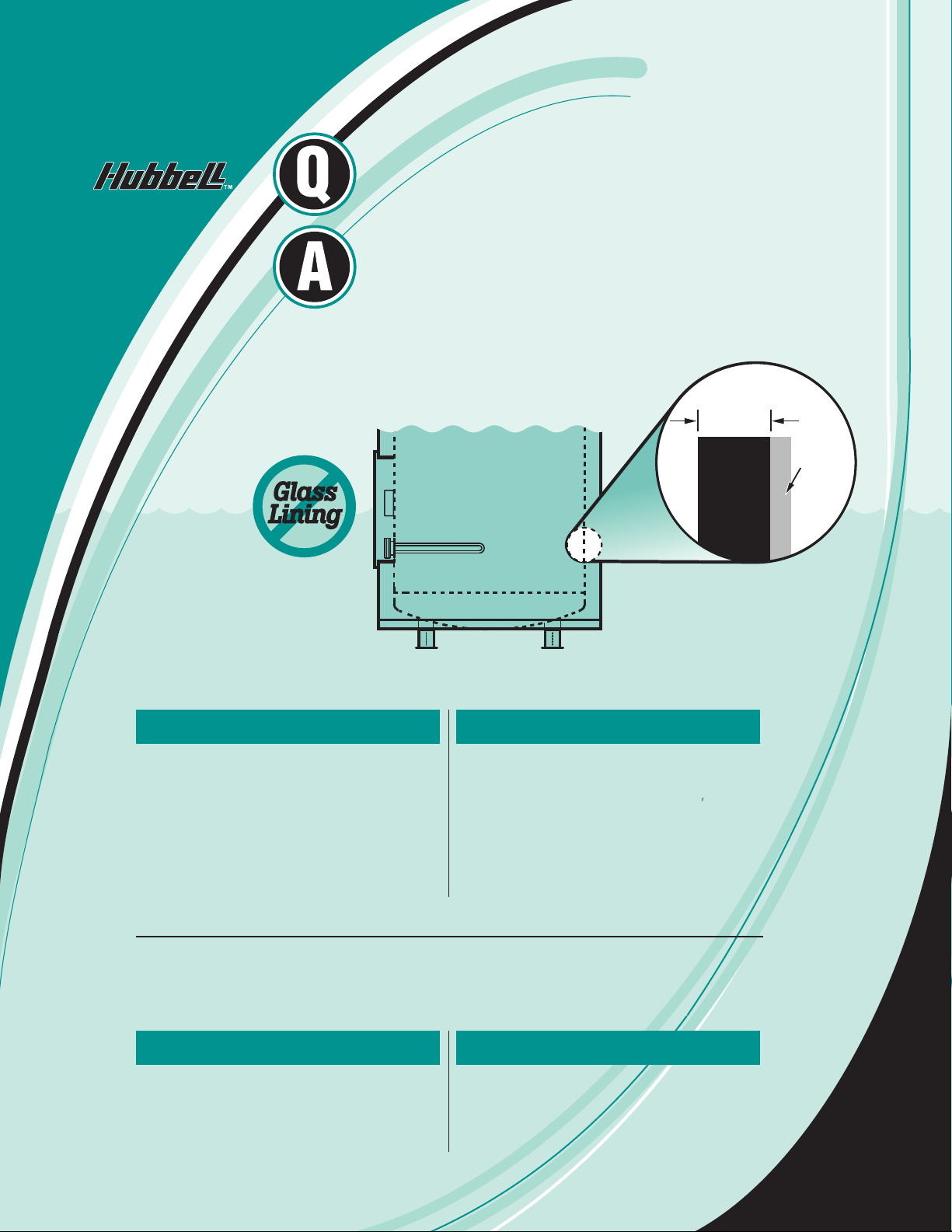

What is the most common reason

why a water heater fails?

Failure of a tank’s protective lining allows

water to come into direct contact with the

steel tank causing it to corrode and leak.

Therefore, the type of protective lining is

the single most important feature when

determining the quality of any water heater.

The ability of a lining to protect the steel tank

is primarily based upon its thickness and

complete coverage of all steel surfaces.

Tank Cross Section

5

/8"

Hydrastone

Cement

Lining

Steel

Pressure

Vessel

Linings Available For A Steel Tank

Cement Lining

A specially formulated Hydrastone cement

applied to a minimum of

surfaces. The cement lining covers 100% of

all interior surfaces and is 125 times thicker

than glass lining. Due to the thickness and

guaranteed coverage of cement lining there is

no need for a sacricial anode. An extremely

durable and long lasting lining suitable for

hot and cold potable water storage in marine

applications.

5

/8" thickness on all

Phenolic Lining

An epoxy coating applied in 2 coats to a total

of 10-12 mils DFT. Typically used in process

applications using low conductivity D

or food grade water.

I, distilled

Non-Ferrous Tanks

A solid Non-Ferrous tank does not require a lining because the pressure vessel itself is

constructed from material which is impervious to the corrosive eects of hot water. This type of tank

will provide a signicantly longer service life than all lined steel tanks, but is initially more costly.

90/10 Copper-Nickel

A 90% Copper 10% Nickel alloy provides

excellent strength and corrosion resistance.

Typically used in applications with corrosive

environments (salt water) or in critical marine

applications requiring long tank life.

Stainless Steel

Stainless Steel (Specify: Type 304, 316, or

316L) is suited for applications requiring a

corrosion resistant tank with minimal leaching

of impurities into the water. Well suited for

process, RO and D

I water systems.

Note: Unlined non-ferrous tanks do not require a manway. Inspection openings will be provided as required.

2

2

Page 3

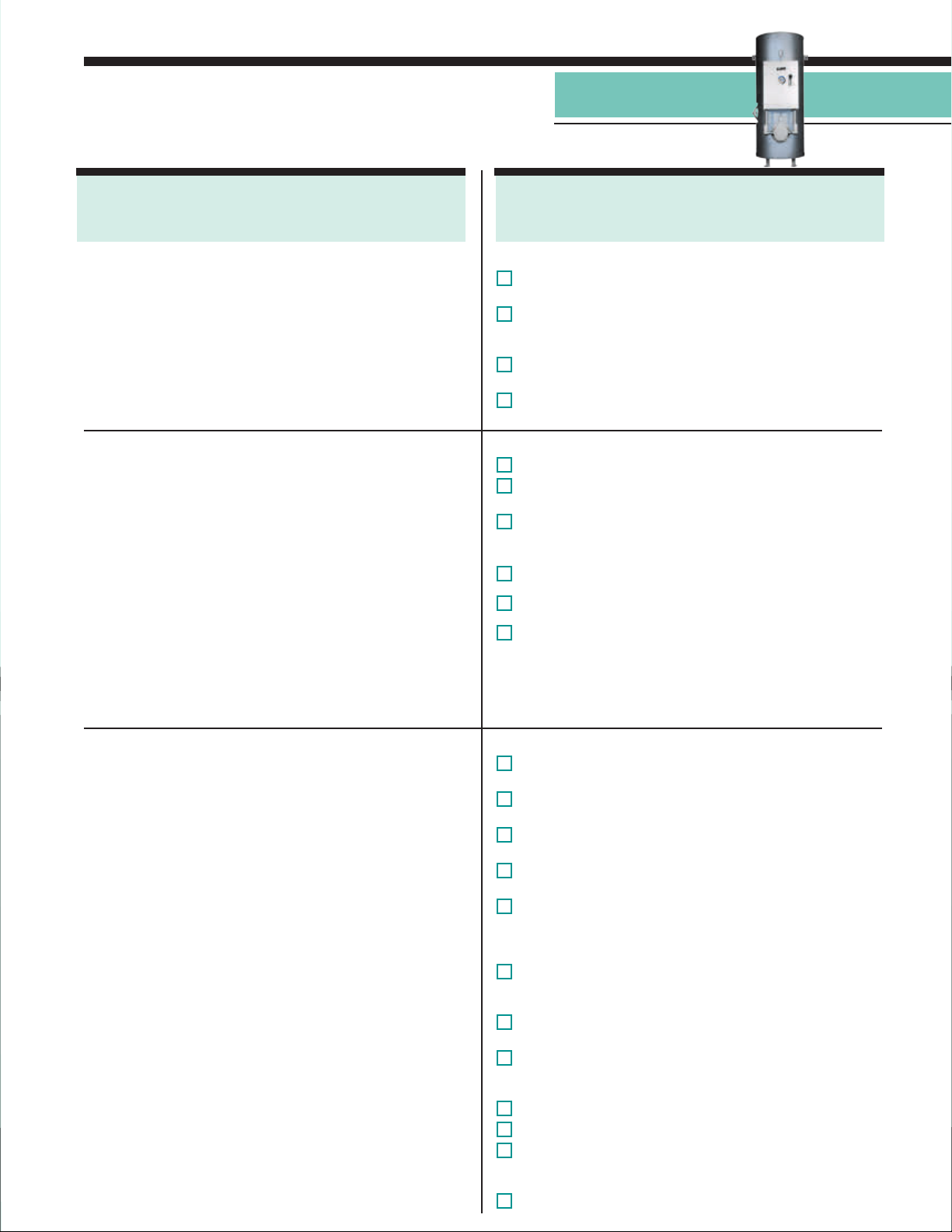

Model MSH & MH

Shipboard Electric

Water Heater

Model MSH and MH

Standard Equipment

Vessel Construction

1. All welded carbon steel vessel designed and built in

strict accordance with the ASME Code Section IV and

stamped, certied and registered with the National Board

of Boiler and Pressure Vessel Inspectors.

2. All internal tank surfaces are lined with a minimum of

thick Hydrastone cement for superior protection and tank

longevity.

3. Designed for 100 psi working pressure and hydrostatically

tested at 150 psi (1 1/2 times the WP).

General

1. Heavy duty 2" thick berglass blanket insulation covers

the pressure vessel for maximum operating eciency and

minimal standby heat loss.

2. Heavy gauge galvanized steel protective jacket holds

insulation in place and protected to ensure highly ecient

operation.

3. Integrally welded bulkhead attachment points.

4. Entire vessel is supported on heavy duty integrally welded

steel supports for sturdy deck mounting.

5. Full ve (5) year Non Pro-Rated tank warranty and one (1)

year electrical component warranty.

6. Bronze ASME rated combination temperature and

pressure safety relief valve set at the vessel working

pressure and 210ºF.

7. ABS Type Approved and in conformance with USCG

regulations.

5

/8"

Model MSH and MH

Optional Equipment

Vessel

1A. Alternate protective lining:

Phenolic epoxy resin.

1B. Alternate vessel construction:

Stainless Steel (Please specify Type: 304, 316 or 316L)

90/10 Copper-Nickel, other.

1C. Alternate working pressure:

Please specify

1D. Alternate tank design:

ASME stamped to Section I or VIII

General

1. Skid mounting on heavy duty all welded I Beam

2. Type 304 stainless steel protective jacket,

please specify if painted.

. Dual energy package provides operational exibility

3

for electric and steam or boiler

See page 8 for details.

. Manway 12" x 16" size

4

. Inspection opening 3" NPT

5

. Specic third party approval including BV, NR-13,

6

Lloyds or MIL spec.

water power.

Electrical Operating Controls

1. All electrical operating controls are factory sized,

selected, wired, tested, and mounted in a NEMA 1

enclosure to ensure safe and reliable operation.

2. A power distribution block is supplied for single point

electrical installation.

3. Power fuses rated at a maximum of 60 Amps protect

each heating element branch circuit per NEC and UL

requirements. Each branch circuit has a maximum rating

of 48 Amps.

4. Heavy duty denite purpose magnetic contactor with

integrally mounted power fuse block assembly switches

power on/o to each branch circuit.

5. Heavy duty removable ange type immersion heating

element provides long service life.

6. Fully adjustable thermostat maintains accurate water

temperature and is sized by the factory to control the

appropriate number of heating element circuits.

7. A generously sized transformer provides fused 120V to

the control circuit

8. A fully adjustable (100-240 ºF) safety hi-limit device with

manual reset interrupts power to the control circuit in the

event of over-temperature water in the storage tank.

9. Safety door interlock mechanism interrupts power to the

control circuit upon opening the electrical control panel.

10. Louvers in the control panel allow for cooling of the

electrical components to ensure maximum electrical

component longevity (when required).

Electrical

1. NEMA 4 weather resistant enclosure for outdoor/wet

locations.

2. Explosion resistant enclosure for hazardous locations.

Please specify class, division, and group.

3. Built-in circuit breaker (with or without shunt trip) or a

built-in non-fused On/O disconnect switch.

4. Alternate element sheath material (Please specify:

Incoloy, Stainless Steel, other).

5. Specialized heating element construction including:

Special watt density rating, passivation, electropolishing,

hermetic seals or any other feature required to meet the

needs of your application.

6. Factory installed low water cut out device to disengage

electrically the heating element(s) in the event of

insucient water in the tank.

7. Dial thermometer and pressure gauge factory installed in

the tank.

8. Intra-tank circulation pump package with On/O switch to

continuously circulate water within the tank and thereby

reduce stratication.

9. Status indicating lamp(s).

10. Audible alarm system.

11. Digital display electronic temperature controller. Please

specify with or without RS485 communication port for

remote operation of the temperature controller.

12. Additional ground connections

3

Page 4

Marine Products Division

Outline Dimensions

Model MSH (vertical)

Storage Tank

Protective Jacket

Hot Water Outlet

o

45

6" 6"

T&P Relief Valve

Mounting Hole

4 Places Equally

Spaced 90° Apart.

Tanks 26" diameter

and smaller 4" x 4" x

1

/4" Base Pads with 5/8"

mounting hole

Tanks 30" - 42" dia.

5” x 5” x 1/4" Base Pads

with9/16" mounting hole.

Tanks 48" diameter

and larger 6" x 6" x 1/4"

Base Pads with 9/16"

mounting hole.

Protective Jacket

Pressure Vessel

Insulation

Electric Control Panel

12" x 16" Manway

(when required)

Electric Heating

Element

10"

G

Base View

F

1 1/2"

Lifting

Lug

Hot Water

Outlet

Top View

Lifting

T&P Relief

Lug

Valve

3 1/4"

4"

B

Cement

Lining

7/8"

Bulkhead

Mounting Holes

2 Places

Tank Cross

Section

Hydrastone

5

/8"

Steel

Pressure

Vessel

Model MH (horizontal)

Electric Control

Electric Heating

Supports (Specify

Saddles Or Skids)

4

Panel

Element

D

Front View

Withdrawal

Space

6"

Combination Cold

Water Inlet And Drain

Side View Front View

4"

E

10"

Withdrawal

Space

Cold

Water

Inlet

Lifting

Lugs

T&P Relief

Valve

Side View

(Note: optional skid base shown)

A

C

Hot Water

Outlet

Pressure

Vessel

Insulation

Protective

Jacket

12" x 16"

Manyway

(when required)

Drain

Page 5

Model MSH & MH

Shipboard Electric

Water Heater

Dimensional Data, Model MSH & MH

Overall Dimensions (Inches)

Storage

Capacity

(Gallons)

80 26

120 28

150 30

175 34 73 67 34 40 20 24 30 x 63 1½ 1500

200 34 82 76 34 40 20 24 30 x 72 1½ 1700

225 34 89 83 34 40 20 24 30 x 79 1½ 17 50

250 40 74 68 40 46 20 30 36 x 64 1½ 1850

275 40 80 74 40 46 20 30 36 x 70 1½ 2000

300 40 88 82 40 46 20 30 36 x 78 1½ 2180

325 40 92 86 40 46 20 30 36 x 82 1½ 2300

350 40 94 88 40 46 20 30 36 x 84 1½ 2500

375 46 81 75 46 52 22 36 42 x 71 1½ 2600

400 46 85 79 46 52 22 36 42 x 75 1½ 2700

425 46 88 82 46 52 22 36 42 x 78 1½ 2900

450 46 93 87 46 52 22 36 42 x 83 1½ 3000

475 52 79 73 52 58 24 42 48 x 69 2 3100

500 52 82 76 52 58 24 42 48 x 72 2 3225

525 52 85 79 52 58 24 42 48 x 75 2 3350

550 52 89 83 52 58 24 42 48 x 79 2 3400

575 52 93 87 52 58 24 42 48 x 83 2 3500

600 52 95 89 52 58 24 42 48 x 85 2 3650

700 52 107 101 52 58 24 42 48 x 97 2 4000

800 52 119 113 52 58 24 42 48 x 109 2 4300

900 52 132 126 52 58 24 42 48 x 122 2 4800

1000 52 145 139 52 58 24 42 48 x 135 2 5200

1250 58 14 9 14 3 58 64 26 48 54 x 139 2 5600

150 0 58 174 168 58 64 26 48 54 x 164 2 6000

175 0 64 168 162 64 70 28 54 60 x 158 3 74 0 0

2000 64 185 179 64 70 28 54 60 x 175 3 8100

2500 76 169 163 76 82 32 60 72 x 159 3 8200

3000 76 197 191 76 82 32 60 72 x 187 3 8300

3500 88 174 168 88 94 36 72 84 x 164 6 FLG. 8900

4000 88 195 189 88 94 36 72 84 x 185 6 FLG. 9800

4500 N/A N/A 178 94 100 40 84 90 x 174 6 FLG. 10700

5000 N/A N/A 200 94 100 40 84 90 x 196 6 FLG. 1160 0

Vertical

Diameter

A

HeightBLength

C

64

72

78

60 26 32 15 18 22 x 54 1½ 1000

71 28 34 15 18

75 30 36 20 20 26 x 68 1½ 130 0

Width

D

Height

E

Bulkhead

Mounting

F

Bolt

Circle

G

Storage

Tan k

Diameter

x Length

24 x 62

Inlet

Outlet

Sizing

(NPT)

1½ 1150

Approx.

Shipping

Weight

(Lbs.)

Note: All dimensions are approximate and subject to change. Please reference the submittal drawing for actual dimensions.

The tank selections above are shown for convenience. A full selection of storage capacities are available by entering the desired

capacity into the model number.

* 80, 120 and 150 gallon tanks do not come equipped with a manway. Please consult factory if desired on these sizes.

5

Page 6

Marine Products Division

Recovery Ratings And Amperage At Selected KW

KW

INPUT

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

110

120

125

150

175

200

225

250

275

300

325

350

375

400

450

500

1000

1200

1400

1600

BTU/HR

RATING

51,180 102 77 61 51 44 42 36 23 20 18

68,240 136 102 82 68 58 56 48 30 26 24

85,300 170 128 102 85 73 69 60 38 33 30

102,360 205 153 123 102 88 83 72 46 39 36

119,420 239 179 143 119 102 97 84 53 46 42

136,480 273 205 164 136 117 111 96 61 53 48

153,540 307 230 184 153 131 125 108 68 59 54

170,600 341 256 205 170 146 139 120 76 66 60

187,660 375 281 225 187 161 153 132 84 72 66

204,720 409 307 245 205 175 167 145 91 79 72

221,780 443 332 266 222 190 181 157 99 85 78

238,840 477 358 286 239 205 195 169 106 92 84

255,900 511 383 307 256 219 208 181 114 99 90

272,960 545 409 327 273 234 222 193 122 105 96

290,020 580 435 348 290 248 236 205 129 112 102

307,080 614 460 368 307 263 250 217 137 118 108

324,140 648 486 389 324 278 264 229 145 125 114

341,200 682 511 409 341 292 278 241 152 131 120

375,320 750 562 450 375 321 306 265 167 145 132

409,440 818 614 491 409 351 333 289 183 158 145

426,500 852 639 511 426 365 347 301 190 164 151

511,800 1023 767 614 511 438 417 361 228 197 181

597,100 1193 895 716 597 511 486 421 266 230 211

682,400 1364 1023 818 682 584 556 482 304 263 241

767,700 1534 1150 920 767 657 625 542 342 296 271

853,000 1705 1278 1023 852 730 695 602 380 328 301

938,300 1875 1406 1125 937 803 764 662 418 361 331

1,023,600 2046 1534 1227 1023 876 834 723 456 394 361

1,108,900 2216 1662 1329 1108 950 903 783 494 427 391

1,194,200 2386 1790 1432 1193 1023 973 843 532 460 421

1,279,500 2557 1917 1534 1278 1096 1042 903 570 493 452

1,364,800 2727 2045 1636 1363 1169 1112 963 608 525 482

1,535,400 3068 2301 1841 1534 1315 1251 1084 685 591 542

1,706,000 3409

3,412,000 6819 5113 4090 3409 2922 2779 2408 1521 1314 1204

4,094,400 8182 6135 4908 4090 3506 3335 2890 1825 1576 1445

4,776,800 9546 7158 5726 4772 4090 3891 3372 2130 1839 1686

5,459,200 10910 8181 6544 5454 4675 4446 3854 2434 2102 1927

60 °F

Gallons Per Hour (GPH) Heated At

Various Temperature Rises

Δ 80 °F Δ 100 °F Δ 120 °F Δ 140 °F Δ

2556 2045 1704 1461 1390 1204 761 657 602

208V 3F 240V 3F 380V 3F 440V 3F 480V 3F

Amperage Rating At Various Voltages

Notes: The KW selections above are shown for convenience. A full selection of KW ratings from 1 to 1600 KW is available by entering the

desired KW into the model number. For alternate voltages including 415, 575 and 600 volt, please consult factory.

Electrical

Note: Each branch

circuit is rated at

a maximum of 48

Amps and each

circuit is typically

operated as an

independent

temperature step.

6

KW x 1000

Volts

KW x 1000

Volts

÷ 1.73 = Amps 3 Φ

= Amps 1

Φ

Example: 150 KW at 480V 3Φ

150 x 1000

480

180 ÷ 48 Amps max circuit rating = 3.75

Round up the number of circuits to 4

÷ 1.73 = 180 Total Amp Draw

Page 7

Model MSH & MH

Shipboard Electric

Water Heater

Model MSH & MH Sizing Information

Step 1: Solve for the unknown using the formulas stated below

Variables To Solve For:

KW Requirement: GPH x °F ∆T x 0.00244 = KW

Temperature Rise: KW x 410 ÷ GPH = °F ∆T

Flow Rate: KW x 410 ÷ °F ∆T= GPH

Metric Conversions

Liters x 0.2641 = Gallons

Gallons x 3.79 = Liters

Gallons x 0.003785 = m

m3 x 264.2 = Gallons

1

°C ∆T = 1.8°F ∆T

°F = (°C x 1.8) + 32

°C = (°F - 32) x 0.556

Watts/Sq.Cm. x 6.4 =

3

Watts/Sq.In.

Watts/Sq.In. x 0.155 =

Watts/Sq.Cm.

psi x 0.06896 = Bar

Bar x 14.5 = psi

psi x 6.86 = kPa

kPa x 0.1456 = psi

Kg/cm2 x 14.28 = psi

psi x 0.07 = Kg/cm2

Lbs x 0.4536 = Kg

Kg x 2.2 = Lbs

Model Number Designation

— —

■

Step 1

Model:

MSH = Vertical

MH = Horizontal

■

Step 2

Storage Capacity:

80-5000 U.S. Gallons

Example: MSH250-0-80SLT5

A Hubbell marine vertical water heater with a storage

capacity of 250 gallons and an 80 KW electric heating

element. The tank is cement lined. Power required is 440

VAC, 3 phase, 60 Hz.

0

■

Step 3

Elec tric KW:

5-1600K W

■

Step 4

Ve s s e l Typ e:

SL = Hydrastone

Cement lined tank

GL = Phenolic Lined

Steel

CN = Solid 90/10

Copper-Nickel

SS = Solid Stainless

Steel (Specify Type

304 or 316L)

■

Step 5

Voltage / Phase / Hz:

RS = 208-1-60

R = 208-3-60

S = 240-1-60

T = 240-3-60

W = 277-1-60

T3 = 380-3-50/60

T7 = 415-3-50/60

T5 = 440-3-60

T4 = 480-3-60

T4S = 480-1-60

T6 = 600-3-60

Option Note

Any and all optional equipment for a water heater must be called

out in the written specication. A model number in and of itself

does not reect any optional equipment selected.

(Manufacturer reserves the right to change specications without notice.)

7

Page 8

Marine Products Division

Benet Of Dual Fuel Capability

The Hubbell model MSH and MH water heater is available

with a factory installed heat exchanger to provide heating

capability utilizing ships steam or boiler water. While the

ship is under way and the boilers are producing steam,

the water heater will operate in “primary” mode and use

steam to heat the water. When the ship is dockside, and

steam generation is reduced (or completely shut down), the

operator can switch the water heater over to electric heating

mode by simply turning a switch on the Hubbell control panel

which activates the factory packaged and installed electric

immersion heaters. This dual fuel capability provides ship

operators with complete exibility in determining which fuel

mode is most advantageous to operate at any given time.

Optional Steam Package

Electric

Control Panel

Electric

Heater

Steam Heating

Coil (steam

controls not

shown)

Standard Features

Steam / Boiler Water Heating Coil

1. A high quality factory installed 2 pass U-Tube heating

coil constructed from 18 BWG

copper tubing designed for a maximum working

pressure of 150 psi.

2. All wetted parts including the tube sheet and baes

are non-ferrous for maximum longevity.

3. Heavy duty fabricated steel head with threaded NPT

steam and condensate connections.

Steam Operating Controls

1. Steam operating controls are factory selected, sized,

piped and tested to ensure reliable operation.

2. All steam components are factory plumbed with

schedule 40 black iron pipe and ready for steam and

condensate connections.

3. High quality cast iron pilot operated steam control

valve modulates the ow of steam through the

heating coil to provide accurate water temperature

control.

4. Cast iron Y strainer with 20 Mesh screen protects the

steam controls and coil from dirt and debris in the

steam supply.

5. Thermostatic drip trap removes condensate from the

steam supply line.

6. Heavy duty cast iron oat and thermostatic main

condensate trap for optimum eciency.

7. Brass vacuum breaker and dial steam pressure

gauge installed in the heating coil head.

Note: Additional steam and boiler water design literature

is available in Hubbell brochures titled “ST”,“BW” and

“Heating Coils”.

3

/4" O.D. single wall

Optional Features

Optional vessel construction and optional general

construction features as shown on page 3.

Steam Heating Coil

1. Double wall tubing with a leak detection port

2. Alternate tubing material please specify:

(Stainless Steel, 90/10 Copper-Nickel, Other)

3. Fabricated steam head constructed from:

(Stainless Steel, Copper Alloy, Other)

Operating Controls

4. Steam controls are factory selected and sized, but

shipped loose for in the eld installation by others.

5. Various steam control valves are available to meet

the specic needs of your application, please

specify: Self-operated type, pneumatic operated,

electric motor operated, separate pressure

reducing pilot type.

6. Single solenoid safety system closes the control

valve should the water temperature in the tank

reach the hi-limit set point. Requires 120 volt 5

amp electrical service.

7. A double solenoid safety system dumps over

heated water in the storage tank to drain in

addition to closing the control valve. Requires 120

volt 5 amp electrical service.

8. Dial water thermometer and pressure gauge

factory installed in the tank.

9. Factory wrapped and baed steam coil with

integral pump package.

10. Steam Controls to be cast steel construction.

8

8

Page 9

Model MSH & MH

Model MSH & MH

Shipboard Electric

Optional Steam Package

Shipboard Electric

Water Heater

Water Heater

Steam Component General Conguration

The steam control valve maintains accurate water

temperature in a steam red water heater by regulating

the ow of steam through the heating coil.

Adjustable

Temperature Pilot

Steam Inlet

Y Strainer

Steam

Control

Valve

Thermostatic

Drip Trap

To sensing bulb

in tank

Pneumatic or electronic

controller (if required)

Steam Pressure Gauge

Vacuum Breaker

Steam Coil

Y Strainer

Condensate Outlet

There are four types of steam control valves available for

use on a steam red storage water heater.

Self Operating

The valve design includes a bulb and capillary assembly

charged with a thermally responsive vapor. The

expansion/contraction of the vapor acts upon the valve

bellows in order to control the ow of steam through

the valve. No external power source is required for

operation.

Pneumatically Operated

In this conguration the ships air supply feeds a factory

installed temperature controller which operates the

steam control valve. The temperature controller sends

a precise air signal to the steam control valve which

adjusts the ow of steam into the heating coil. The

temperature controller is fully adjustable from 50-250°F

and requires 20 psi air at a maximum consumption of

0.5 SCFM.

Pilot Operated

A pilot operated control valve is the most widely used

type of valve for standard water heating applications.

In this type of valve, a temperature pilot device utilizes

steam to operate the main valve. No external power

source is required other than steam. This is a highly

dependable temperature control system which is suitable

for most applications. As an option, this valve may

include a pressure reducing pilot which limits the steam

pressure to a predetermined maximum.

Electronic Operated

This control valve is similar to a pneumatically operated

system, except in this case the temperature controller is

a sophisticated digital display electronic device which

outputs a 4-20ma signal to a compact motor mounted

on the steam control valve in order to proportionally

control the ow of steam to the heating coil. The

temperature controller displays set point as well as

actual water temperature and is available with an RS485

communications port for remote control.

F & T Main

Condensate Trap

9

9

Page 10

Marine Products Division

Marine Products Division

Optional Steam Package

Heating Coil General Conguration

Length B

10

10

Inlet

Outlet

Head

Rib Gasket

Tub e

Sheet

Tank

Flange

Tank Tank LiningRing Gasket

Tube Support Tub es

Please Complete The Following Information:

Tube Sheet Data

1

Outside Diameter

Thickness

Material

Number of Tube holes

in the tube sheet

Does the tube sheet have

Bolt Holes in it?

If Yes:

■ # of bolt holes

■ Dia. of bolt holes

■ Bolt circle

Do the bolt holes straddle

the centerline?

Yes No

Diameter of the neck nozzle on the tank.

2

Outside Diameter

Inside Diameter

(Include thickness of neck lining, if any)

Circumference Of Neck

Immersion length

3

of tubes “B”

Heating surface area

in Sq. Ft. (if known)

Tank Type: Verti cal Horizontal

Tank dimensions: Diameter

Height

Pull space

maximum length

Yes No

Tube O u t s i d e

4

Diameter

Material

Gauge BWG

Typ e

Design Pressure

Design Temperature

Number of passes

5

Number of tube

6

supports

Distance to each

tube support

Material

O.D. of supports

Thickness

Recovery rated

7

to heat GPH

from oF to oF

When supplied with the following

heat source:

Lbs. / Hou r

Steam Consumption

from oF to oF

from oF to oF

Pressure Drop

8

Steam psi

Boiler or HTHW psi

Single Wall Double Wall

Full Half type

Steam at psig

Boiler Water at GPM

HTHW at GPM

Page 11

Optional Steam Package

Steam Consumption Formula

GPH x °F ∆T x 8.33

Model MSH & MH

Model MSH & MH

Shipboard Electric

Shipboard Electric

Water Heater

Water Heater

=

Latent Heat of Steam

Steam Pressure (psi)

Latent Heat

0 2 5 10 15 20 25 30 40 50

970 966 960 953 946 939 933 929 920 912

Dual Fuel Model Number Designation

— —

■

Step 1

Model:

MSH = Vertical

MH = Horizontal

Example: MSH400-ST-120SLT5

A Hubbell vertically installed 400 gallon dual fuel marine water heater with

a factory installed steam heating coil as the primary heating source and

a 120 KW electric heating element to operate as the secondary heating

source. Tank is cement lined. Power required is 440 VAC, 3 phase, 60 Hz.

Please note that steam heating capacity and construction features are not

identied in the model number and therefore must be noted in the written

specications.

■

Step 2

Storage Capacity:

80-5000 U.S. Gallons

■

Step 3

Primary

Heating:

ST = Steam

BW = Boiler

Water

O = No steam

■

Step 4

Secondary

Heating

Electric:

5-1600K W

■

Step 5

Tan k :

SL = Hydrastone

Cement lined tank

GL = Phenolic

Lined Steel

CN = Solid 90/10

Copper-Nickel

SS = Solid

Stainless Steel

(specify Type 304,

316 or 316L)

Lbs / Hr Steam

■

Step 6

Voltage / Phase / Hz:

RS = 208-1-60

R = 208-3-60

S = 240-1-60

T = 240-3-60

W = 277-1-60

T3 = 380-3-50/60

T7 = 415-3-50/60

T5 = 440-3-60

T4 = 480-3-60

T4S = 480-1-60

T6 = 600-3-60

Option Note

Any and all optional equipment for a water heater must be

called out in the written specications. A model number

in and of itself does not reect any optional equipment

selected.

(Manufacturer reserves the right to change specications without notice.)

11

11

Page 12

Model MSH & MH

MadeintheU.S.A.

Master Specication

SHIP NAME

SHIPYARD

General

Provide a quantity of packaged type Marine Electric water heater(s)

Model No. as manufactured by HUBBELL

The Electric Heater Co., Stratford, CT. The water heater shall be constructed

specically for shipboard installation by utilizing deck and bulkhead mounting

suppor ts that are integrally mounted to the pressure vessel. The pressure vessel

section, including the electrical control panel, shall be mounted on structural

suppor ts and be suitably insulated, jacketed, painted and provided with lifting

lugs. The entire unit is to be packaged ready for plumbing and electric service

connections and shall bear the UL listing mark certifying the entire water heater.

The water heater shall conform to USCG regulations per 46 CFR 53.01-10 and be

ABS Type Approved.

Pressure Vessel

The pressure vessel shall be all welded construction and ASME Code Section

IV stamped for a working pressure of 100 psi and contain a minimum of

gallons of storage. The storage vessel shall be carbon steel and lined

with seamless Hydrastone cement applied to a minimum thickness of 5/8" on

100% of all interior tank surfaces, ( Optional Specications: Phenolic lined

steel tank, solid 90/10 copper- nickel tank, solid Type 304, 316 or 316L Stainless

Steel Tank. ) The pressure vessel is to be covered with 2" thick berglass blanket

insulation and enclosed in a heavy gauge galvanized steel metal jacket nished in

gray hammertone enamel. The vessel shall be protected by an ASME approved

automatic reseating combination temperature and pressure relief valve set at the

tank working pressure and 210 °F.

Electric Recovery

The recovery section shall be rated at KW which will heat

GPH of water at °F rise ( °F to °F).

Electric Controls

The heater shall be designed to operate at volts, phase,

HZ with a fused low voltage transformer providing 120 volt to all

operating controls. The immersion heating element(s) shall be high quality copper

sheathed (

steel ) and sized to obtain the rated recovery. Each element circuit is to be

independently operated through a denite purpose magnetic contactor having

a resistive load rating equal to or exceeding the ampere rating of that particular

circuit and shall be protected by individual power fuses rated approximately

125% of the ampacity of the circuit. Multiple circuit elements shall be provided

with a power distribution block for connecting of the incoming power feeds

(

Optional Specications: Built-in non-fused On/Off disconnect switch, built- in

circuit breaker with an On/Off handle. ) A safety door interlock switch shall interrupt

power to the control circuit when the control panel door is opened. The control

thermostat shall be immersion type and shall be consistent with the recovery rate

of the heating element as to the number of steps required. A hi-limit control with

a manual reset button shall be factory installed to disconnect all ungrounded

conductors to the heating element(s) in the event of an over-temperature condition

in the storage section.

Optional Specication: Incoloy, Type 304, 316 or 321 stainless

Option

Option

Option

ENGINEER / NAVAL ARCHITECT

CONTRACTOR / SHIP CHANDLER

Dual Fuel Package

Shall be required

Shall not be required

The heating coil shall utilize (

boiler water, HTHW ) and be rated to heat GPH of

water at a °F rise ( °F to °F)

when supplied with psi steam (boiler water) to

the control valve and consume lbs/hour steam.

The heating coil shall be a fully removable immersion U-tube

heating coil rated for 150 psi working pressure. The single wall

(

Optional Specication: Double wall ) coil shall be constructed

from 18 BWG 3/4" OD copper (

Copper-nickel, stainless steel ) tubes. The coil including the tube

sheet, baes, and spacers shall have all non-ferrous wetted

parts and a fabricated steel head. The water heater shall (shall

not) be supplied with steam operating controls. A self-contained

( Optional Specication: Pneumatic, pilot, electric ) type steam

control valve shall regulate the ow of steam to the heating coil in

order to control water temperature. A drip trap, main condensate

trap, Y strainers, vacuum breaker, and steam pressure gauge shall

be factor y sized and piped with the steam control valve.

In addition, the following steam options may be selected:

Option: The water heater shall be equipped with

a factory-packaged intra-tank circulator to

continuously circulate water within the tank to

reduce stratication.

Option: The heating coil shall be wrapped and baed

and piped with an integral pump package to force

circulate water over the heating coil in order to

reduce the coil size.

Option: Single solenoid safety system to close the control

valve should the water temperature in the tank

reach the hi-limit set point. Requires 5 Amp, 120

Volt service.

Option: Double solenoid safety system dumps over

heated water in the storage tank to drain in

Optional Specication: steam,

Optional Specication: 90/10

addition to closing the control valve. Requires

5 Amp, 120 Volt service.

Warranty

The water heater manufacturer shall warranty all

components against defects in workmanship and material for a period

of one (1) year from date of start up, and the pressure vessel for a full

ve (5) years Non Pro-Rated (

years Non Pro-Rated tank warranty ) from start-up, provided that the

unit is started within three (3) months of date of shipment and installed

and operated within the scope of the tank design and operating

capability. Each water heater shall be shipped with a complete set of

installation and operating instructions including spare parts list and

approved drawing.

Optional Specication: full ten (10)

Marine Products Division

ISO 9001:2008

Committed to continuous improvements

Continuing research results in product improvement; therefore these specications are

subject to change with out notice. For the most updated inform ation, consult the factory.

The Electric Heater Company ■ P.O. Box 288 ■ Stratford, CT 06615-0288

Phone: 203- 378-2659 ■ FAX: 203-378-3593 ■ info@hubbellheaters.com ■ www.hubbellheaters.com

ISO

[Rev D]

Loading...

Loading...