Page 1

M

ODEL EMV

Commercial Electric

Commercial Electric

Water Heater

Water Heater

Provides Tepid Water For Emergency Fixtures

Features

■

Heavy Duty Construction

� Hydrastone cement lining provides tank longevity

� Copper-silicon alloy tappings cannot rust or

corrode

� High impact composite jacket cannot rust or

corrode and eliminates potential damage during

installation and transit

� 3" thick polyurethane foam insulation reduces

standby heat loss by over 24% compared to

industry standard 2" insulated tanks

■

Packaged System

� Factory packaged and piped mixing valve

simplies installation and ensures the safe and

reliable supply of tepid water

� All electrical operating controls are factory

selected and wired to ensure reliable operation

� Dial gauge provides visual indication of water

temperature and pressure

■

Safety

� Mixing valve designed specically for emergency

drench systems ensures a constant ow of tepid

water

� Mixing valve prohibits delivery of overheated water

to prevent scalding

� Provides tepid water even when an accident

causes a loss of electric power

� Reduces the risk of Legionella because water is

stored at an elevated temperature

■

Reliable

� Full ve (5) year non pro-rated tank warranty

� Each valve is performance tested

at the factory to ensure proper

operation

GLASS

GLASS

LINING

LINING

NO

NO

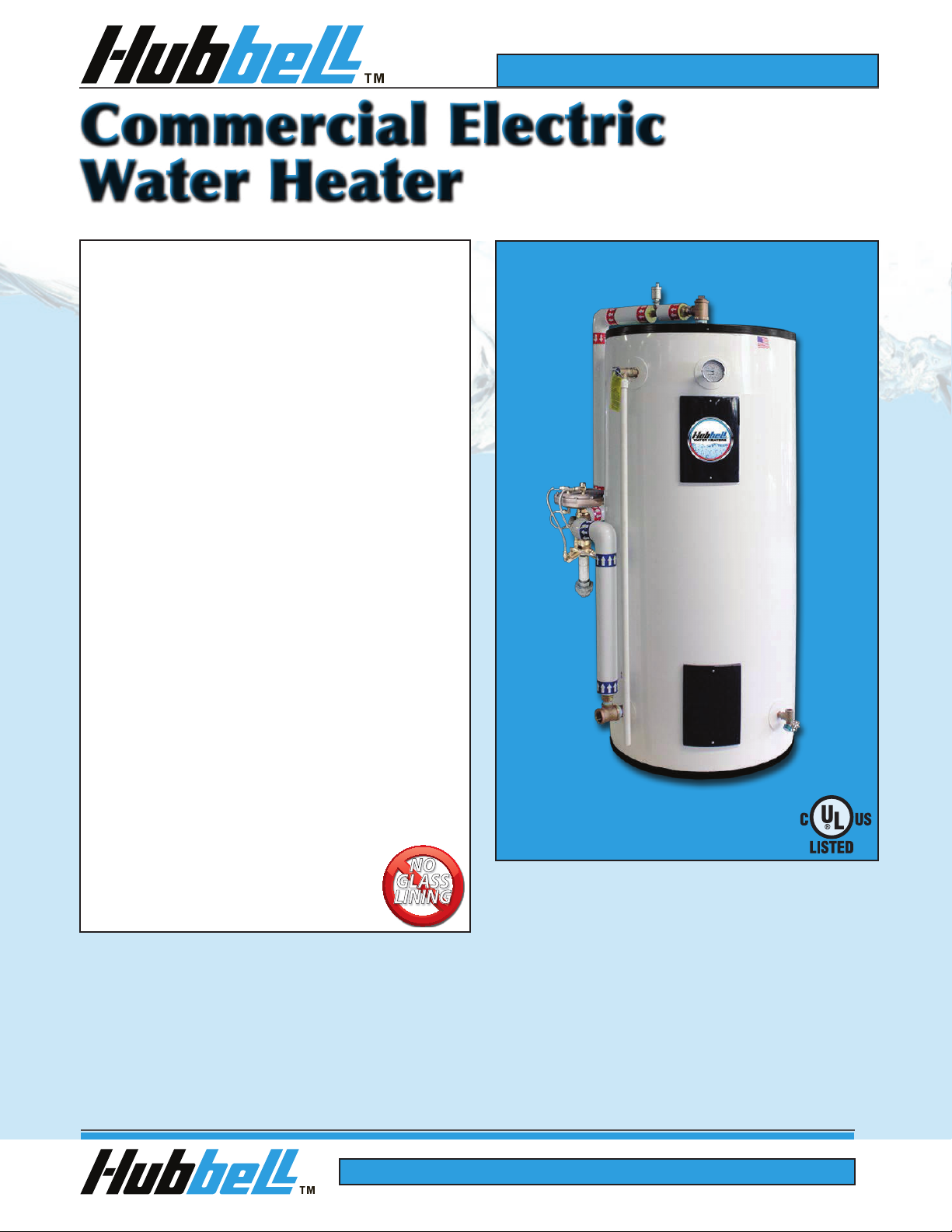

Model EMV

The model EMV is designed specically for tepid water

delivery to an emergency drench system

A Heavy Duty, Reliable Source For Tepid Water Delivery

The Hubbell model EMV water heater is a packaged

system designed to meet the requirements of ANSI

Z358.1-2014 for tepid water delivery to an emergency

drench system. This heavy-duty water heater is constructed

of a carbon steel tank and internally lined with

Hydrastone cement to ensure tank longevity when operating

at elevated temperatures, and is fully insulated with 3"

thick polyurethane foam to minimize stand-by heat loss.

The water heater is packaged with a mixing valve specically

/ISEA

1

/2" thick

Packaged Heater Provides High Volume Tepid Water

designed, tested and proven for use in emergency safety

shower/face/eyewash applications. The entire package

including the mixing valve is factory piped and mounted

to the water heater to provide single source responsibility.

When you specify and install a Hubbell Model EMV, you

will have the condence in knowing that the owner will be

provided with a long lasting, safe and dependable source of

tepid water for their emergency drench system needs.

Page 2

Safety StandardS

OSHA 29 CFR 1910.151 states the following:

When the eyes or body of any person may be exposed to injurious corrosive, toxic, or ammable

materials, suitable facilities for quick drenching or

ushing of the eyes and body shall be provided

within the work area for immediate emergency

use.

ANSI/ISEA Z358.1-2014 Standard states the

following: Delivered flushing fluid temperature

shall be tepid. This standard also establishes

minimum performance and use requirements for

eyewash and shower equipment for the emergency treatment of the eyes or body of a person who

has been exposed to injurious materials.

■

The shower must have a minimum of

20 GPM at 30 psi for 15 minutes of controlled

low [Para 4.1.3]

■

The eyewash must have a minimum of

0.4 GPM at 30 psi for 15 minutes of controlled

low [Para 5.1.6]

■

The eye/face wash must have a minimum of

3.0 GPM at 30 psi for 15 minutes of controlled

low [Para 6.1.6]

■

Units must meet all individual performance

requirements when all components are

operated simultaneously [Para 7.1]

■

In circumstances where chemical reaction

is accelerated by ushing uid temperature,

a facilities safety/health advisor should be

consulted for the optimum temperature.

[Para 6.4.6]

How Does THe Hubbell uniT

AcHieve THese RequiRemenTs?

The Hubbell EMV water heater system

provides high volume tepid water for safety

drench systems by integrating a specially designed mixing valve with a high quality cement

lined electric storage water heater. The model

EMV is designed to maintain 120 gallons of

water at 170°F. The volume of water at this

temperature is necessary to achieve the final

flow rate of 23 GPM for 15 minutes of tepid

water. When an emergency drench apparatus

is used, the integrated mixing valve blends

170°F water from the tank with incoming cold

water to achieve a continuous flow of app oximately 85°F tepid water to operate simultaneously a safety shower and an eye/face wash

fixture.

Note: For 30 GPM shower heads the Hubbell

EMV will provide 75

o

F water for 15 minutes.

The Hubbell model EMV satisfies the tepid

water requirements for a safety drench

system.

The Hubbell EMV package is specifically designed

to meet your emergency drench system needs by

incorporating the following critical features:

The carbon steel tank is internally lined with

A

specially formulated hydrastone cement and

does not require anodic protection. This lining is

critical to the longevity of the tank when storing

hot water at elevated temperatures.

A

The mixing valve is specifically designed for

B

emergency safety drench systems and is factory

piped and packaged with the water heater tank

to simplify installation and ensure a safe and

dependable system.

The Hubbell EMV Model has 3" foam insulation

C

which reduces stand-by heat losses by over 24%

compared to 2" insulated tanks. This provides

the owner with a highly efficient and economical

solution for emergency drench systems.

Unlike instantaneous heaters, the Hubbell model

D

EMV is unaffected by the loss of electric power

in its ability to provide tepid water. Furthermore,

the dial temperature gauge provides the operator

with positive visual verification that the unit is at

temperature.

2

Page 3

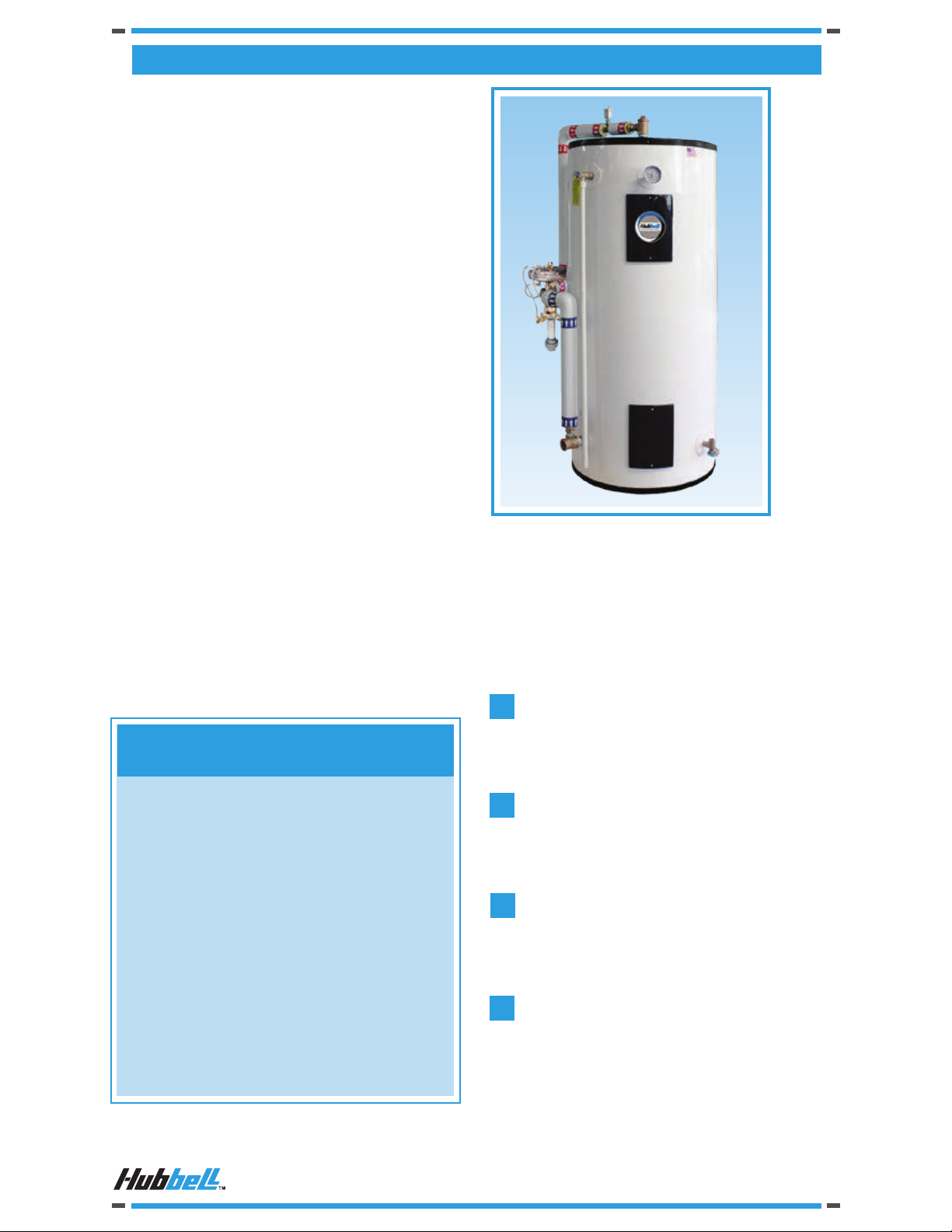

Mixing ValVe

OperatiOnal featureS

Packaged with the Hubbell model EMV is a triple

redundant, thermostatic pressure balanced

valve designed specifically for emergency safety

shower/face/eyewash applications. The valve is

factory mounted and piped to the water heater.

After water flow is activated at the emergency

station, the outlet water temperature from the

model EMV package will be maintained at 85°F

tepid temperature. The Hubbell EMV is able to

achieve the high volume demand required for a

safety drench system by mixing the 170°F water

in the tank with incoming cold water. The mixing

valve meets OSHA and ANSI requirements and

is capable of providing constant 85°F output

regardless of inlet pressure and temperature

variations, and the temperature setting is tamper

proof and cannot be inadvertently adjusted in the

field. The water temperature is not warm enough

to open skin pores and not cold enough

to deter usage. The valve is capable of providing

a full range of flows from the smallest flow of 0.4

GPM for an eyewash to the combined 23 GPM

flow for a simultaneous demand of shower,

eyewash, and face wash system.

Safety featureS

The mixing valve incorporates a pressure sensing

controller with a valve actuator that senses the

water pressure on both the hot and cold water

inlet connections. If hot water pressure is not

present then the actuator overrides the mixing

valve and a flow of cold water is allowed. If no

cold-water pressure is available at the mixing

valve inlet then the hot water port will close

to prevent overheated water from exiting the

mixing valve. The valve also includes a safety

override feature that continuously senses the

final mixed water temperature. If the final water

temperature is overheated, the valve

automatically closes the hot water port and

fully opens the cold water port. In any of these

fault conditions, the Hubbell EMV valve will

continue to provide a full flow of water as per

the ANSI standard with no additional pressure

drop.

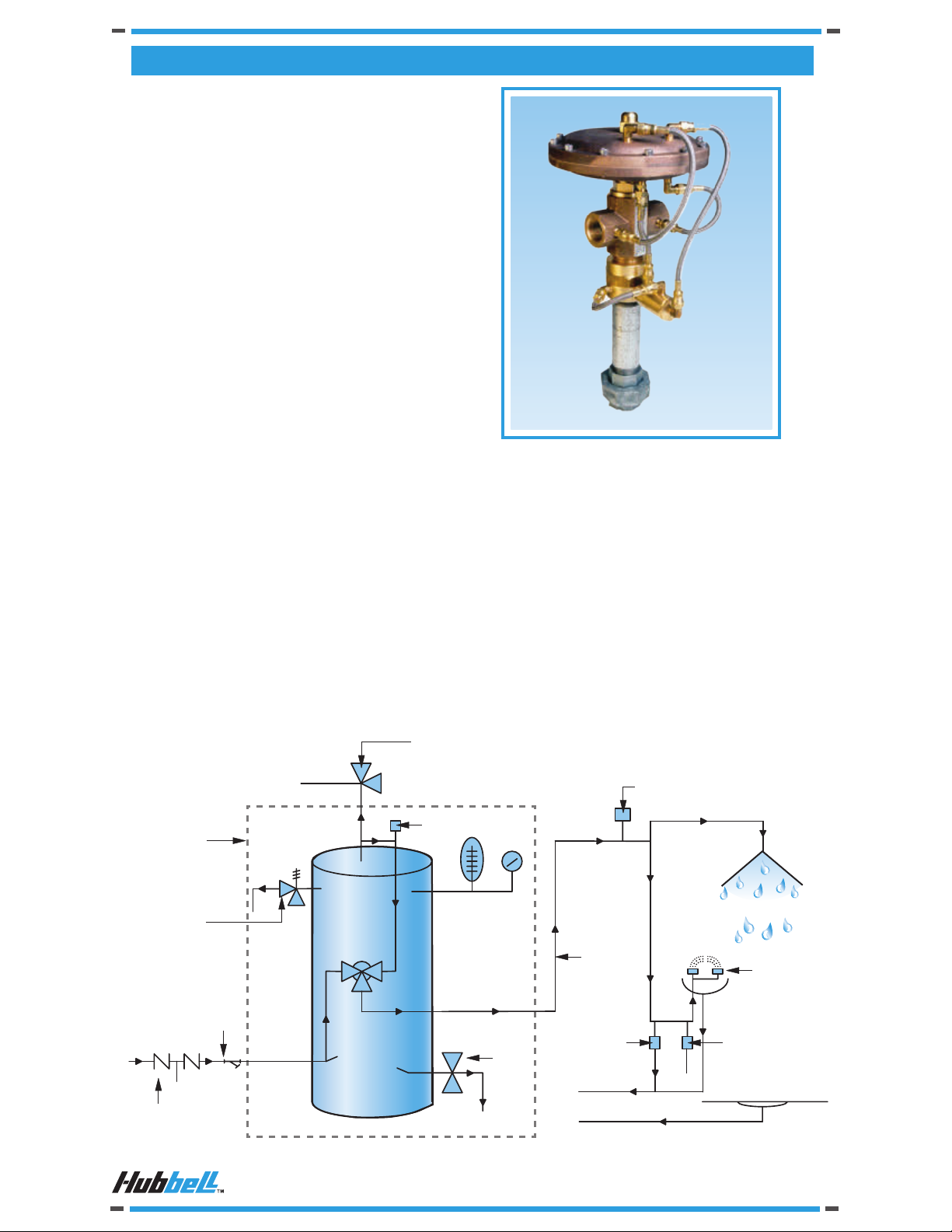

Hubbell EMV Package

T&P Relief Valve

Cold Water

Feed

Backow

Preventor

(If Required)

Y Strainer

Pressure Relief

Device or Thermal

Expansion Tank

Vacuum Breaker

Air Vent Valve

Combination

Temperature

& Pressure

Mixing

Valve

NOTE: For systems requiring recirculation see Hubbell IOM for typical pipping schematic.

Gauge

To D r a i n

Drain

Valve

Heat Trace

for Freeze

Protection

(If Required)

Solar Gain

Protection

Valve

To D r a i n

Safety Shower

Face/Eyewash

Freeze Protection

(To Atmosphere)

Floor Drain

3

Page 4

Outline Dimensions

A

F

19"

Withdrawal

Space

Automatic Air Vent Valve

Tank Cross Section

1

/2"

Steel

Pressure

Vessel

Protective Jacket

Tepid Water Outlet

Thermostat Sensor

3" Foam Insulation

Cement

Lining

Mixing Valve

Model EMV

Dimensional Data

T&P Gauge

Hi-Limit

Thermostat

Operating

Thermostat

D

C

Cold Water Inlet Cold Water Inlet

Heating

Element

E

B

Drain Valve

Dimensions (Inches)

Storage Base Floor to Floor to Piping Floor Shipping

Capacity Model Diameter Height Inlet Outlet Height to T&P Weight

(Gallons) Number "A" "B" "C" "D" "E" "F" (LBS)

120 EMV120 30 69.25 8 24 8 10 875

Note: Alternate storage capacities are available for smaller or larger requirements. Please

consult factory for sizing requirements.

Why you need a safety shower/eyewash station

■

Water that is too cold can discourage workers from washing down

for the required 15 minutes. (It can cause hypothermia)

■ Water that is too hot can cause third degree burns in as little

as one second and can accelerate a harmful chemical reaction

■ What you need is an easy-to-use, reliable system that provides water at the recommended temperature

4

Page 5

Model EMV

Water Heater Specications

Tank: Hydrastone Cement

Lined Steel

Storage Capacity: 120 Gallons (see note)

Orientation: Vertical

Voltages: 120 thru 600 Volt

Phase: 1 or 3

Cold Water

Inlet Size: 1

Tepid Water

Outlet Size: 1

Drain Size:

Relief Valve Size:

Relief Valve Type: T&P, 210

Thermostat Range: 100 -180

Φ

1

/2" Female NPT

1

/4" Female NPT

3

/4" GHT

3

/4" Female NPT

o

F, 150 psi

o

F

Piping: Copper Tubing

Note: Alternate storage capacities are available for

smaller or larger requirements. Please consult factory

for sizing requirements.

Formulas To Solve For:

tO SOlVe fOr tepid Water preSSure drOp:

Mixing Valve Cv: 10.0

Pressure Drop at

20 GPM: 4 psi

Minimum

Supply Pressure: 30 psi

Hi-Limit: 190

o

F

Design WP: 150 psi

Design TP: 300 psi

Elements: Copper Sheathed

Insulation: 3" Polyurethane Foam

Tank Warranty

Standard: 5 Year Non Pro-Rated

Optional: 10 Year Non Pro-Rated

Electrical Warranty: 1 Year

Jacket: High Impact Colorized

Composite

Color:

WhitewithBlackTrim

Metric cOnVerSiOn

GPM2

2

Cv

= ∆P

The Hubbell EMV mixing valve Cv = 10.0

Example: Determine pressure drop across Hubbell

model EMV with a 20 GPM flo

202

102 100

400

=

= 4 psi pressure drop

Note: The Hubbell EMV valve maintains the same pressure drop

even when the valve is in cold water bypass mode.

tO SOlVe fOr the percentage Of hOt Water tO final

Mixed Water:

M-C

= % of hot to mixed water

H-C

Example: Determine the percent of 170°F hot water required for

a mixed temperature of 85°F when cold water is 50°F

85-50

170-50 120

M = Mixed water temperature

C = Cold water temperature

H = Hot water temperature

35

=

= 29%

Therefore, 29% of the mixed 85°F

water stream must be 170°F.

Watts Rating in GPH

Recovery

50-170°F 120 V 208 V 240 V 277 V 480 V

1500 5.1 13 7 6 5 N.A.

3000 10.2 N.A. 14 13 11 6

4000 13.6 N.A. 19 17 14 8

4500 15.3 N.A. 22 19 16 9

6000 20.5 N.A. 29 25 22 13

Note: For three phase rating please reference Hubbell

Model SE brochure for KW selection

Amperage Ratings

Single Phase Voltages

Liters x 0.2641 = Gallons

Gallons x 3.79 = Liters

Gallons x 0.003785 = m

m3 x 264.2 = Gallons

O

C ∆T = 1.8OF ∆T

1

O

F = (OC x 1.8) + 32

O

C = (OF - 32) x 0.556

psi x 0.06896 = Bar

Bar x 14.5 = psi

psi x 6.86 = kPa

kPa x 0.1456 = psi

2

x 14.28 = psi

Kg/cm

psi x 0.07 = Kg/cm

Lbs x 0.4536 = Kg

Kg x 2.2 = Lbs

Watts/Sq.Cm. x 6.4 = Watts/Sq.In.

Watts/Sq.In. x 0.155 = Watts/Sq.Cm.

3

2

5

Page 6

PC Number Description

1 Hydrastone cement Lined Tank

2 3" Polyurethane Foam Insulation

13

o

45

1

2

3

5

Top View

4

5

6

7

10"

8

9

12

Withdrawal

o

45

19”

Space

General Characteristics

3 Corrosion Resistant Jacket

4 Air Vent Valve

5 Relief Valve Connection

6 Dial Temperature Pressure Gauge

7 Hi-Limit Thermostat

8 Mixing Valve

9 Tepid Water Outlet

10 Tank Operating Thermostat

11 Heating Element

12 Cold Water Inlet

13 Drain Connection

Gallon Storage Capacity

Total KW Rating

Volts

Phase

50/60 Hertz

85°F Mixing Valve Set Temperature

Full Load Amperage

1 1/ 2" MNPT Cold Water Inlet Size

1 1/ 4" FNPT Tepid Water Outlet Size

Dry Weight (Lbs.)

Wet Weight (Lbs.)

10

11

12

Front View

Notes:

1. Storage tank rated for 150 psi WP

2. ASME rated T&P relief valve factory

installed and piped to 12" from floor

3. All electrical controls are factory wired and

tested

4. Mixing valve (pc. 8) is factory set,

calibrated and tested to deliver 85°F water

13

Tepid Water Delivery

GPM for

min @

85°F

Recovery Rating

GPH from

to

(

Tepid Water Heating System

The Electric Heater Company

Model No.:

Location:

QT Y:

Stratford, CT

■

°F ∆T)

Job Name:

Date:

6

Page 7

Optional Equipment

1. Low temperature alarm dry contacts (alarm

temperature is adjustable from 30-110°F).

2. Hi temperature alarm dry contacts (alarm

temperature is the hi-limit set point, which is

adjustable from 100-240°F).

3. Outdoor weather package. Includes a 304

Stainless Steel outer protective jacket, weather

resistant electrical housing and 6" high tank legs

to raise the entire unit off the floor.

Flow alarm indication dry contact to signal that

4.

there is tepid water flow (minimum flow rate to

activate 7GPM).

5. Explosion resistant construction for installation

in a hazardous location. Standard is class 1,

Division 2, Group B. If application requires other

please specify Class, Division and Group rating

required.

Three phase voltage please specify.

6.

volts kw amps.

ASME tank construction.

7.

8.

Alternate mixing valve tepid water set temperature

75°F. Note: 85°F is standard set temperature. Mixing

valves are not intended to

Mount and pipe multiple (two or three) storage

9.

be field adjustable.

tanks on one skid to meet the needs of larger

demand systems.

10.

NEMA 4X enclosure provides added protection

for the mixing valve in outdoor environments.

( Optional: Enclosure air purge fittings and

stainless steel inlet fittings for corr

osive

environments).

11.

Alternate heating source. Factory installed heat

exchanger to utilize (

Optional: steam or

boiler water). Consult factory for details

12.

Integrally welded seismic attachment points.

13.

All hot and cold water piping on the heater

package to be heat traced from the factory for

freeze protection, to include an insulation jacket for

the thermostatic mixing valve. Please note that all

external piping to the heater need to be heat

traced in the field.

Model EMV Number Designation

eMV

■

Step 1

Model:

EMV

■

Step 2

Storage Capacity:

120 U.S. Gallons

Optional storage

capacities available

—

Example: EMV120-85-3SLS

Model EMV emergency tepid water delivery system

with a storage capacity of 120 Gallons, 85°F set point

of the mixing valve and a 3 KW rating. Storage tank is

lined with Hydrastone cement and operates at 240 Volts

single-phase power.

Option Note

Any and all optional equipment for a water heater

must be called out in the written specications. A

model number in and of itself does not reect any

optional equipment selected.

—

85

■

Step 3

Tepid Water

Temperature:

85°F

Optional:

75°F

Sl120

■

Step 4

Standard

Ratings:

1.5, 3, 4,

4.5, 6

■

Step 5

Tank Type:

SL =

Hydrastone

Cement lined

tank

SS =

Solid Stainless

Steel

CS =

Solid CopperSilicon

Benets of a tepid water safety

shower/eyewash station:

■

Encourage user to wash down long enough to

be effective

■

Prevent further injury

■

Get employee back to work fast

■

Provide employee with a feeling of security about

his work environment

Occupational Injuries

■

Over 12,000 cases of non fatal chemical burns

involving days away from work annually

■

Non fatal chemical burns result in a median of 2

days away from work

■

Average of 118 fatalities annually from exposure

to caustic, noxious, or allergenic substances

(Source: Bureau of Labor Statistics)

■

Step 6

Voltage / Phase / Hz:

A = 120-1-60

RS = 208-1-60

R = 208-3-60

S = 240-1-60

T = 240-3-60

W = 277-1-60

T3 = 380-3-50/60

T7 = 415-3-50/60

T5 = 440-3-60

T4 = 480-3-60

T4S = 480-1-60

T6 = 600-3-60

7

Page 8

Job Name

RepReseNtative

eNgiNeeR

coNtRactoR

The Electric Heater Company

■ P.O. Box 288 ■ Stratford, CT 06615-0288 ■ Phone: 203-378-2659 ■ Fax: 203-378-3593

info@hubbellheaters.com

■ www.hubbellheaters.com

Committed to continuous improvement...

Continuing research results in product improvement; therefore specications are subject to

change without notice. For the most updated information, consult the factory directly.

MadeintheU.S.A.

Master Specication: Model EMV

GENERAL & APPROVALS

Contractor shall supply and install with all codes and authorities having jurisdiction a factory packaged water heater for

emergency drench application. System shall be Hubbell Model No.

Water Delivery System. Unit shall be designed to operate at

maximum load of

shower/face/eyewash fixtur

watts. The system shall be specifically designed for tepid water delivery to emergency safety

es in accordance with ANSI Z358.1-2014. Packaged system shall consist of a long-life electric

volts, phase, and 60 hertz with a

Emergency Tepid

water heater with integrally mounted, factory supplied, calibrated and performance tested, triple redundant thermostatic

pressure balanced mixing valve system. Unit shall be supplied ready for electrical and plumbing service connections. Field

assembled systems shall not be considered as equals. Substitutions must meet the following specifications minimum to be

considered for approval as equal.

CONSTRUCTION

A. The electric water heater shall be a 120 gallon capacity vertical carbon steel tank lined with 1/2" thick Hydrastone cement

to ensure maximum operating life at elevated temperatures. Heater shall not require any type of anodic protection.

1

B. Tank inlet and outlet water connections shall be a minimum of 1

tappings will not be acceptable.

C. Tank shall be covered by a minimum 3" thick polyurethane foam insulation to minimize stand-by heat loss over the life of

the system. Due to the increased cost of operation, systems with less than 3" insulation will not be acceptable.

D. Outer protective jacket shall be a dent resistant composite jacket to resist rust and corrosion.

E. Tepid water temperature control shall be provided by an integrally piped and packaged thermostatic mixing valve. Valve

shall be specifically designed, tested and manufacture-designated for use in emergency safety drench

applications. Delivery water set point shall be 85°F. (Optional 75°F temperature available.)

F. Temperature safety system shall consist of a diaphragm operated valve actuator to ensure a continuous delivery flow of

tepid water. The valve shall monitor pressure on both cold and hot water inlets. On loss of cold water pressure the valve

shall prevent delivery of hot water to avoid scalding. On loss of hot water pressure, the valve shall allow the full ANSI

required flow of cold water to the emergency safety fixture.

G. Water pressure drop across the system must not exceed 5psi at 20 GPM flow, mixing valve must have a Cv rating not

less than 10.0.

H. The system shall be supplied complete with all electrical operating controls. Safety devices and accessories shall include

but not be limited to:

1. Low watt density immersion heating element

2. Adjustable immersion temperature controller

3. Safety high limit switch with manual reset

4. Dial temperature and pressure gauge

5. ASME temperature and pressure relief valve

6. Automatic air vent valve

/4" NPT non-ferrous copper-silicon/brass. Steel tank

In addition, this packaged system shall be supplied with the following optional features:

Option

Option

Option

The water heater manufacturer shall warranty all electrical components against defects in workmanship and material for a

period of one (1) year from date of start-up, and the pressure vessel for a full five (5) years Non Pro-Rated

(

Optional Specication: full ten (10) years Non Pro-Rated ) from date of start-up, provided that the unit is started

within three (3) months of date of shipment and installed and operated within the scope of the tank design and operating

capability. Each water heater shall be shipped with a complete set of installation and operating instructions including spare

parts list and approved drawings.

[Rev C]

Loading...

Loading...