Page 1

OPERATING AND MAINTENANCE MANUAL FOR

POWER BURNER SERIES FORCED DRAFT

COMMERCIAL WATER HEATER

ELECTRIC HEATER COMPANY

BASE MODEL “ DF ”

Page 2

HUBBELL ELECTRIC HEATER COMPANY

P.O. BOX 288

STRATFORD, CT 06615

PHONE: (203) 378-2659

FAX: (203) 378-3593

INTERNET: http://www.hubbellheaters.com/

-- IMPORTANT --

Always reference the full model number and serial number when calling the factory.

WARNING / CAUTION

¾ Do not use or store gasoline or any other flammable vapors, liquids, or materials in the

vicinity of this or any other appliance.

¾ Due to the rigors of transportation, all connections should be checked for tightness before heater

is placed in operation.

¾ Safety relief valve must be installed in tapping provided.

¾ KEEP AWAY FROM LIVE ELECTRICAL CIRCUITS.

Do not perform any maintenance, make any adjustments, or replace any components inside the

control panel with the high voltage power supply turned on. Under certain circumstances,

dangerous potentials may exist even when the power supply is off. To avoid casualties, always

turn the power supply safety switch to off, turn the charge or ground the circuit before

performing any maintenance or adjustment procedure.

¾ Installation and service must be performed by a qualified installer, service agency or the gas

supplier. City, state, and national codes governing installation of commercial water heaters

must be followed and take precedence over recommendations in this manual.

¾ The manufacturer’s warranty on this water heater is in effect only when the water heater is

installed and operated in accordance with these instructions and local codes and ordinances or,

in the absence of local codes and ordinances, the National Fuel Gas Code (the latest ANSI

Z223.1). In Canada, installation should conform to the latest CAN/CGAB149 installation

codes and/or local codes. The manufacturer of this water heater will not be held liable for any

damage from failure to comply with these installation and operating instructions.

2

Page 3

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

¾ DO NOT try to light any appliance.

¾ DO NOT touch any electrical switch.

¾ DO NOT use any phone in the building.

¾ Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions. If you cannot reach your gas supplier, call the fire department.

¾ WARNING: If these instructions are not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

PRECAUTIONS

TANK LINING - DAMAGE PREVENTION

The water heater lining has been electronically inspected for continuity prior to final assembly. It was

found to be free of defects. In order to protect the lining, do not apply heavy blows or weld to the

exterior pressure vessel. Damage to the interior lining will void the warranty and ASME HLW stamp.

TANK MAINTENANCE - REMOVAL OF SEDIMENT AND SCALE

To keep the water heater efficient and in good working condition, inspect and clean two weeks after

installation to remove any piping system debris that may have accumulated. Do not acidize this unit.

Monthly inspections should be performed to determine a time span for removing any sediment

within the unit. This should become the basis for a routine maintenance schedule. It is recommended

that high-pressure water be used to purge any accumulation of sediment through the drain valve

opening or the hand hole.

ANODE MAINTENANCE

The water heating industry knows that many water heaters are installed in areas where the water supply

can be abnormally corrosive due to low pH or an excessive amount of dissolved oxygen. Because of

our commitment to provide clear water in all areas, an anode has been provided to help counteract the

effects of these factors. Periodic inspection and, if necessary, replacement is required to assure the

anodes effectiveness.

WATER QUALITY - pH LEVEL

Materials used in the water heater to prevent corrosion have been selected for their compatibility with

most domestic water supplies. However, significantly alkaline water (pH 7.5 or higher) or acidic water

(pH 6.5 or lower) can result in abnormal scale formation or seriously attack these materials and cause

premature corrosion. If the pH of incoming supply water does not fall between 6.5 and 7.5, it must be

treated to prevent damage to internal water heater surfaces and other building plumbing components.

3

Page 4

SAFETY TEMPERATURE AND PRESSURE RELIEF VALVE (T&P)

A listed and properly rated combination temperature and pressure relief valve shall be installed in the

opening provided and marked for this purpose at the time of installation. Local codes shall govern

installation of relief devices. The pressure rating of the relief valve must not exceed the working

pressure shown on the rating plate affixed to the front of the water heater. The BTU/H rating of the

relief valve must equal or exceed the water heater input shown on the rating plate. The relief valve

discharge line must terminate 6 inches above the floor drain or externally to building. The discharge

line must be able to withstand water temperature in excess of 210°F.

¾ DO NOT install a valve between tank and the relief valve.

¾ DO Install a discharge line directly to an adequate open drain. The discharge line must be

shielded, secured and plumbed to an appropriate drain to prevent scald injury.

¾ DO NOT install a reducing coupling or other restriction in the discharge line.

¾ DO NOT install the discharge line where it may be subject to blocking, plugging or freezing.

¾ DO NOT allow water from discharge line to contact any live electrical part.

Failure to install a listed and properly rated temperature and pressure relief valve could result in

hazard to life, bodily injury or property damage and will release the manufacturer of this water heater

from any claim which might result from excessive water temperature or pressure.

CAUTION

KEEP CLEAR OF DISCHARGE LINE OUTLET. It is hot enough to cause scald injury, is under

pressure and may splash.

IMPORTANT

¾ Periodically check combustion products to assure that carbon monoxide is kept below 0.02%

(200 PPM) or that the CO

¾ Drain the water heater for 5 minutes every day to help prevent accumulation of sediment and

scale. Periodically check for the presence of scale and sediment. If present, physically

loosen and flush using high-pressure water.

¾ All startup, periodic tuning and service must be performed by a trained technician familiar

with the water heater and forced draft burner. It is mandatory that the startup test report,

contained in the burner installation and operation manual, be completed and a copy returned

to the factory. It is also important that an operating log be maintained to provide a history of

water heater performance.

is kept between 9 & 9 ½%.

2

4

Page 5

TABLE OF CONTENTS

SECTION TITLE PAGE #

I GENERAL DESCRIPTION 9

II INSTALLATION 10

III START UP AND OPERATION 16

IV SCHEDULED MAINTENANCE AND SERVICING 18

V TROUBLESHOOTING 25

VI MISCELLANEOUS CHARTS AND FORMULAS 26

5

Page 6

6

Page 7

7

Page 8

8 9

Page 9

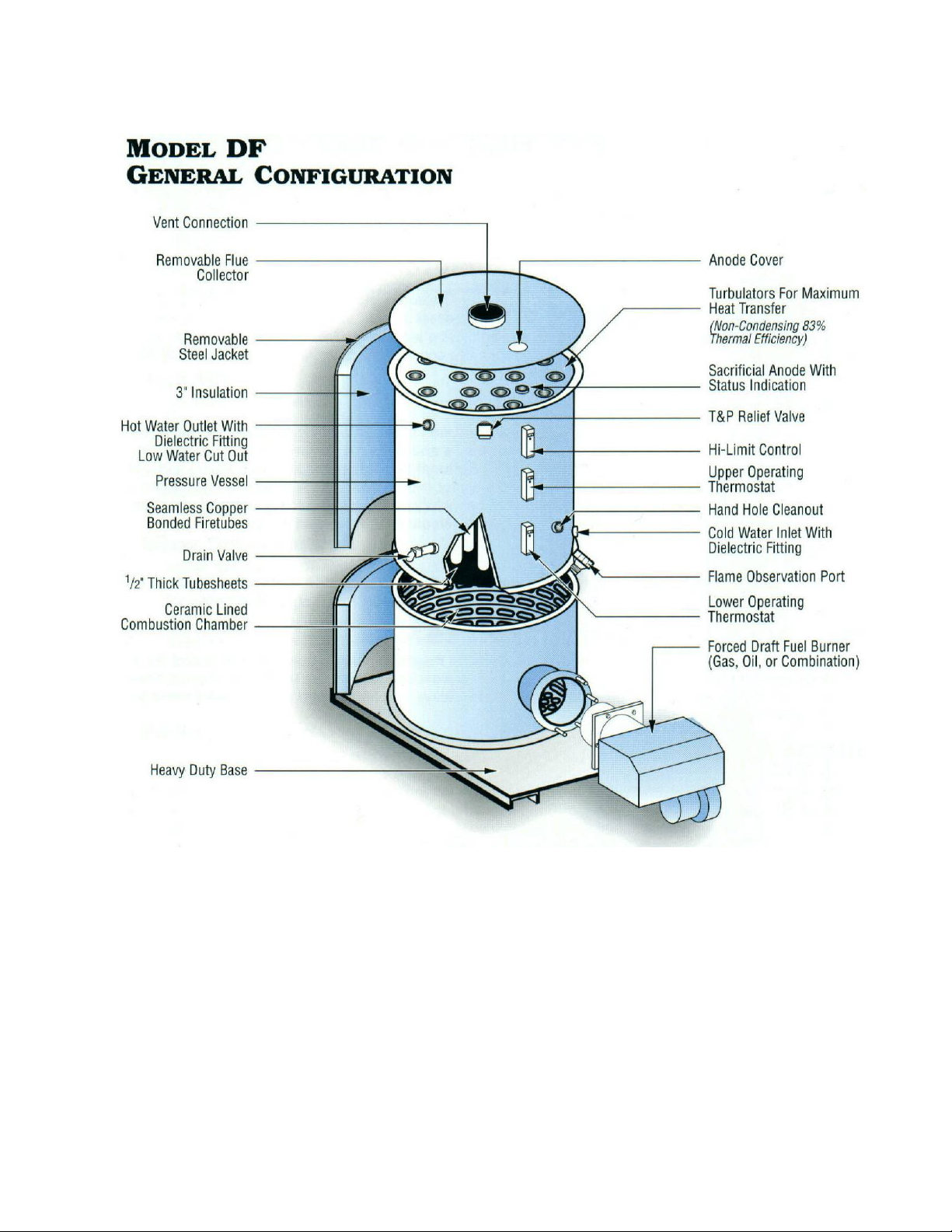

SECTION I - GENERAL DESCRIPTION

GENERAL DESCRIPTION

This is a commercial storage water heater designed and constructed in accordance with UL and

ASME requirements. Its thermal efficiency and standby loss exceed the levels established by

ASHRAE 90.1 and incorporated by federal EPACT legislation. Given a reasonable amount of

maintenance, this water heating product will perform reliably for many years. Its basic design is well

proven over time, and operating components have been selected for their reliability and widespread

use in the water heating industry. This philosophy also promotes availability of both parts and trained

service personnel. It is essential that all aspects of installation, maintenance, routine servicing,

troubleshooting and repair be planned with safety as the primary consideration. If the installer or

service technician has any questions about this water heater's operation, the factory should be

contacted immediately. It is also very important to properly maintain this water heater to obtain long

life and maintain its high efficiency.

Page 10

SECTION II – INSTALLATION

WARNING / CAUTION

For protection against excessive pressures and temperatures, local codes require the installation of a

temperature-and-pressure (T&P) relief valve certified by a nationally recognized laboratory that

maintains periodic inspection of production of listed equipment of materials, as meeting the

requirements for Relief Valves and Automatic Gas Shutoff for Hot Water Supply Systems. ANSI

Z21.22-1971.

The National Fuel Gas Code, (ANSI Z223.1 and Can 1 -Bl 49.1 or Bl 49.2), expressly prohibits the

following:

1. Installation of water heater in a bathroom, bedroom, or any occupied room normally kept

closed.

2. Installation of a water heater in a garage unless the unit is installed so that the burner and

ignition devices are at least eighteen (18) inches above floor level and protected to avoid

damage by a moving vehicle.

If unit is painted or insulated on the job site, care should be taken not to paint or insulate over the

A.S.M.E. nameplate. This plate should be accessible and legible at all times to inspectors, and

information from this plate must be used when ordering parts from the factory.

HANDLING

Some models have been constructed with lifting lugs to permit lifting with a crane. Fork lift

movement (rear access only) is also acceptable.

To lift with a crane, remove flue outlet adapter and connect a lifting cable to the two lifting lugs

attached to the top tubesheet. Be sure lifting cable and crane can support the shipping weight as

shown on Bill of Lading.

The skids are compatible with the forks of most fork lift equipment. When moving a heater into

place, pick water heater up from rear (do not pick up from front or sides) with forks inside the skids.

Picking up heater on outside of skids may allow forks to puncture bottom of combustion chamber.

INSPECTION

Inspect the water heater and burner for possible damage that may have occurred in shipping or during

storage. Check rating plate on the water heater and burner for compliance with specifications. Be

sure the electrical supply, gas and/or oil supply lines are adequate for the installation.

10

Page 11

LOCATION

NOTE: Do not run uninsulated water pipes in front of or directly above a fresh air opening. If an

exhaust fan is installed in the mechanical room, the combustion air inlet must allow for the fan's

exhaust air volume. An undersized opening may cause down drafts resulting in poor combustion,

sooting and carbon monoxide.

1. Position the water heater in a clean and dry location as close as possible to the greatest use of

hot water (and the oil storage tank if used). Minimum clearances for servicing are listed on a

label near the burner. Greater clearances may be required by local code.

2. An adequate uncontaminated air supply for combustion is needed. If air is directly obtained

1

from outdoors, a free area of 1 square foot per 1,000 CF/Hr

of input is required. If air is

obtained from an adjacent indoor area, 1 square inch per 1,000 BTU/Hr of input is required.

If oil-fired, 1 gallon per hour equals 140,000 BTU/Hr. Combustion air inlets should be

located on an outside wall, away from prevailing winds, and be sized to accommodate all fuel

burning equipment located in the mechanical room. Combustion air calculations should

assume simultaneous operation of all fuel burning equipment in the equipment room.

3. The water heater should not be installed in an area where combustible liquids or vapors may

be present that could be ignited by the burner. The installation area should not contain air

contaminated with chlorinated hydrocarbons, perchlorethylene or any strong oxidizing agent.

Combustion air containing these agents will seriously damage the burner and vessel parts

thus voiding all warranties. If required, combustion air should be ducted from outside the

building to avoid such contaminants. Burners require special construction for outside

combustion air applications. Consult factory for details.

4. The water heater should be located on a pitched floor near a suitable drain, or other

provisions must be made to prevent damage to areas of the building subject to water damage

should the heater or plumbing leak. A drain is required for relief valve discharge as well as

routine cleaning and flushing of the tank. The heater must be installed in a level position.

Shim under skids if necessary.

WATER CONECTIONS

NOTE:

The most effective means for preventing deterioration from accelerated corrosion due to

galvanic and stray current is the installation of dielectric fittings/unions. The installation of these

fittings is the responsibility of the installing contractor.

Water connections are made to the cold water inlet and hot water outlet as shown on the supplied

water heater drawing. Dielectric fittings are provided to minimize the formation of galvanic

corrosion (some jurisdictions require the use of dielectric fittings). Shut-off valves and unions should

1

1,000 CF/Hr of Gas = 1,000,000 BTU/Hr = 7.14 GPH of #2 fuel oil

11

Page 12

be installed so the heater may be disconnected for servicing if necessary. Hot water and return

circulation lines should be insulated. The cold water supply line should be insulated if subjected to

freezing temperatures. When a check valve is installed in the cold water line to the water heater, a

diaphragm type expansion tank suitable for potable water shall be installed in the system.

PIPING MULTIPLE WATER HEATERS

A parallel connection, see the following diagram, allows heated water from multiple heaters to flow

into the system to serve peak loads that can occur in a short time period. Pressure drop is reduced

and total storage capacity is available for immediate use.

12

Page 13

ELECTRICAL CONNECTIONS

Electrical connections to the water heater should conform to the National Electrical Code or the code

legally authorized in your locality. A fused disconnect switch should be used in the burner control

circuit. The contractor shall run the properly sized electrical service to the terminals indicated on

burner wiring diagram. Refer to burner manufacturer's manual for specific electrical requirements.

VENTING

This non-condensing water heater is designed to exhaust into its own independent vent or into an

existing vent system that serves other appliances. In all cases, a negative pressure must be

maintained within the venting system to prevent the leakage of combustion products.

Several basic venting rules must always be followed.

1. The vent must be independently supported so its weight does not bear on the water heater's

flue collector.

2. The vent must never be sized smaller than the flue collector outlet. It can be up to two sizes

larger but, in all cases, must be sized in accordance with National Fuel Gas Code

Requirements given the particular installations vent configuration and water heater input rate.

3. When a relatively high negative draft occurs in a vent, a draft regulator sized to the vent

diameter should be installed and adjusted to begin opening at a negative draft of -0.1 in.

W.C. A draft regulator should be installed no further than two feet away from the water

heater flue outlet.

4. A vent must never be welded to the flue collector outlet.

5. All vents must be constructed in accordance with the National Fuel Gas Code and terminated

on the outside of the building using a UL listed vent cap. Horizontal venting through an

outside wall is acceptable, but an induction blower may be needed to maintain a negative

draft in the vent.

If the water heater is vented into an existing overhead vent (or breaching), it is recommended the

vent be designed for positive pressure in case there is positive pressure in the overhead vent.

13

Page 14

GAS CONNECTION PIPING FOR GAS AND COMBINATION GAS/OIL BURNERS

WARNING / CAUTION

LP UNITS; liquefied petroleum (L.P.) gas is heavier than air and will remain at floor level if there is

a leak. Basements, crawl spaces, closets and areas below ground level will serve as pockets for

accumulation of leaking L.P gas. Before operating the water heater, sniff at floor level. IF YOU

SMELL GAS, follow applicable instructions on cover page. DO NOT OPERATE APPLIANCE

UNTIL LEAKAGE IS CORRECTED AND AREA IS PURGED OF ANY GAS

ACCUMULATION.

Be sure gas supply lines have been cleaned of all debris which could enter the regulators or the

burner system and cause malfunctions or unsafe conditions. Pipe connection compounds must be

used AT ALL TIMES. DO NOT use Teflon tape as a thread sealant.

1. The gas supply line must be sized, considering pressure drop, to furnish gas at a pressure

necessary for the burner to develop rated capacity and the CFH to handle all fuel burning

equipment attached to the line. A drip leg should be installed ahead of the burner piping

connection. See burner manufacturer's manual for piping detail.

2. Piping or tubing from regulator vents shall be routed outside the building and must be the

same diameter as the regulator venting ports. Provide no traps in the vent lines and terminate

away from all doors, windows and air intakes serving HVAC equipment. Vent termination

shall face downward with a screen mesh cover to prevent insects and debris from entering. If

regulator vents are combined, use tubing or pipe equal to the total cross sectional area of the

individual vents. Normally open vent valves must be separately vented.

NOTE:

pilot regulators. Termination of vents shall be the same as for regulators.

OIL TANK AND PIPING

High and low gas pressure switches must be vented separately from those of the main and

3. Before gas is turned on, be sure the gas line has been checked for leaks. Check to see that

there are no open fittings and that the burner main manual valve and pilot manual valve are

closed.

1. Tank construction and installation must meet all local codes and should meet the

specifications recommended by Underwriters Laboratories.

2. REFER TO YOUR BURNER STARTUP MANUAL FOR OIL PUMPING AND

PIPING DETAILS.

14

Page 15

3. A Rule of Thumb to determine total suction for suction line sizing is to add 10% to suction

determined from the burner manufacturer's instruction manual.

4. It is good practice to size the oil pump return-line (to the tank) the same size as the selected

suction line.

PRESSURE AND TEMPERATURE SAFETY RELIEF VALVE

1. Install the combination temperature and pressure safety relief valve in the tapping provided.

Note that this is required by law for safety considerations.

Outlet to floor drain

Install into provided tapping

Manual Release

Lever

Temperature Probe

2. Install a relief valve overflow pipe to a nearby floor drain. CAUTION: No valve of any type

should be installed between the relief valve and tank or in the drain line.

15

Page 16

SECTION III – START UP AND OPERATION

WARNING / CAUTION

Temperatures above 130ºF (54º C) can cause scalding. Scalding temperatures are especially

hazardous to young children, aged or handicapped persons. A serious or disabling injury can occur.

Note that a mixing valve installed at the hot water outlet can reduce the risk of scalding at such

points of use as lavatories, sinks and bathing facilities

Excessively hot water may suggest that the upper operating thermostat has failed. If you determine

an operating control thermostat has failed, it should be replaced IMMEDIATELY by a qualified

service technician.

If the burner turns on and off every 3 to 4 minutes on a regular basis, the lower control thermostat

setting may have to be decreased. Such a "short cycling" condition accelerates wear of burner

components which can lead to early failure.

IMPORTANT

THE MANUFACTURER'S START UP REPORT MUST BE COMPLETED AND

RETURNED. FAILURE TO DO SO WILL VOID THE WARRANTY.

ALWAYS CONTACT A TRAINED SERVICE TECHNICIAN TO PERFORM START UP.

SHOULD FACTORY ASSISTANCE BE REQUIRED, PLEASE HAVE THE WATER

HEATER SERIAL NUMBER AVAILABLE.

Combination gas/oil burners require a supply of oil for oil pump lubrication even when operating on

gas.

Some oil burners require a supply of either natural or L.P gas to operate the pilot. Check burner

construction for the presence of gas pilot tubing and a pilot gas pressure regulator.

START UP

1. Fill water heater and drain to remove any residue that may have accumulated during the

installation process. Remove hand hole cover and remove any material not flushed through

drain. Reinstall hand hole cover, fill with water and open a nearby hot water faucet to bleed out

any entrapped air. Be sure all tank connections are tight. Leaking water causes corrosion and

insulation damage.

16

Page 17

2. The burner manufacturer's installation and operation manual, included with this manual,

contains a detailed start up procedure that should be studied and followed precisely.

NOTE: Rated gas input for this water heater can be established by adjusting manifold gas pressure

to the value listed on the burner data plate. Rated oil input can be established by adjusting oil

pressure to the burner at 300 psi (pressure may have to be slightly reduced to obtain clean, smokefree combustion).

TEMPERATURE ADJUSTMENT

The upper operating control thermostat shuts off the burner when its temperature setting is reached.

The lower operating control thermostat can be adjusted to vary the temperature that activates the

burner. The unit is also equipped with a high limit safety control preset at 180°F. For energy efficient

operation of your water heater, the recommended upper temperature setting is approximately 130°F.

Facilities with small children or invalids may require a 120°F or lower temperature setting to reduce

the risk of scald injury. Some states require a lower temperature setting. Check with your gas

supplier for local requirements governing the temperature setting.

Remember that no water heating system will provide an exact temperature at all times. Allow a few

days of operation to determine the correct temperature setting consistent with your needs.

A lower temperature setting can cause condensation, but that does not mean your tank is leaking.

Many reported tank leaks on installation are proven to be condensation. To avoid unnecessary

inconvenience and expense, make sure the tank is leaking before calling a service person.

17

Page 18

SECTION IV - SCHEDULED MAINTENANCE AND SERVICING

WARNING / CAUTION

Before performing any maintenance procedure, turn off the water heater main disconnect switch

before performing any cleaning or service. Also close both the pilot and main manual shutoff valves.

Keep the equipment room clean. Clean the burner at regular intervals. The blower inlet can collect

dust and debris from the air during operation. Clean blower wheel and flame scanner when

necessary. The burner should be cleaned each year according to the burner manufacturer's

recommended procedures. A DIRTY BLOWER WHEEL WILL REDUCE EFFICIENCY AND

MAY CAUSE POOR COMBUSTION, SOOTING OR THE PRODUCTION OF CARBON

MONOXIDE.

IMPORTANT

A preventive maintenance program should be established to help assure a long, trouble-free water

heater life. AN ANNUAL INSPECTION SHOULD BE PERFORMED AND DOCUMENTED.

A COPY OF THE INSPECTION REPORT MUST BE FORWARDED TO THE

MANUFACTURER. FAILURE TO DO SO WILL VOID THE WARRANTY.

18

Page 19

RECOMMENDED PERIODIC INSPECTION

DAILY

1. Inspect area around water heater for moisture. If present, determine if cause is condensation

or leakage.

a. If cause is condensation - May be due to very cold incoming water. Consider

installation of intra-tank circulator; contact manufacturer for details.

b. If cause is leakage - May be due to leaking fitting; repair as soon as possible. If tank

leak is suspected, contact manufacturer.

2. Inspect vent for corrosion. If present, replace corroded vent section as soon as possible.

Determine if cause is low temperature of combustion products (less than 280º F net flue

temperature), or the presence of contaminated combustion air. Correct either condition

immediately.

MONTHLY

1. Drain heater, remove hand hole cover and inspect for sediment accumulation. Remove any

sediment and inspect more frequently to determine an appropriate schedule for sediment

removal. NOTE: FAILURE OF THE WATER HEATER DUE TO SEDIMENT OR

SCALE ACCUMULATION IS NOT COVERED BY THE WARRANTY.

2. Test combustion products for the presence of carbon monoxide (CO) above a 200 ppm

concentration. If necessary, adjust burner to reduce CO concentration.

19

Page 20

RECOMMENDED PERIODIC TESTING

TESTING

ITEM

Gauges, monitors and operating log Daily Operator Make visual inspection and record readings

Instrument and equipment settings Daily Operator Make visual check against recommended

Firing rate

Flue, vent, stack or outlet dampers Monthly Operator Make visual inspection of linkage; check for

Igniter

Fuel valves: pilot and main

(primary and secondary)

Pilot and main gas or oil train Annually Service Tech Perform leakage tests - refer to instructions

Combustion safety controls (flame

failure)

Flame signal strength

Pilot turndown test

Low-water fuel cutoff and alarm Daily/weekly

High limit safety thermostat control Annually Service Tech Refer to instructions

Operating thermostat control Annually Service Tech Refer to instructions

Vent draft fan, and air pressure

switches

High and low gas pressure interlocks Monthly Operator Refer to instructions

High and low oil pressure interlocks Monthly Operator Refer to instructions

Fuel valve interlock switch Annually Operator Refer to instructions

Low fire start interlock Annually Operator Refer to instructions

Automatic changeover control (dual

fuel)

T&P valves

Inspect Burner Components Semiannually Operator Refer to burner instructions

HOW

OFTEN

Weekly Operator Verify factory settings

Semiannually Service Tech Verify factory settings

Annually Service Tech Check with combustion test

Weekly Operator Make visual inspection, check flame signal

Weekly Operator Operate burner. Using a manometer or pressure

Weekly Operator Close manual fuel supply for the pilot and main

Weekly Operator With flame signal meter installed, read and log

As required /

annually

Semiannually

Monthly Operator Refer to instructions

At least

annually

As required Operator In accordance with procedure in Section VI

COMPLETED

BY

Service Tech Required after any adjustment to flame scanner

Operator

Service Tech Under supervision of gas utility

REMARKS

specifications

proper operation

strength if meter-fitted (see "Combustion Safety

Controls")

gauge, check pressure to the burner as required

on rating label.

fuel valve(s); check safety shutdown timing; log

result.

for both pilot and main flames. Notify service

organization if readings are very high, very low

or fluctuating. Refer to instructions for nominal

values

mount or pilot burner; verify annually - refer to

instructions.

Refer to instructions and perform a slow drain

test.

ASME Boiler and Pressure Vessel Code,

Recommended Rules for Care and Operation of

Heating Boilers.

20

Page 21

SCALE AND SEDIMENT REMOVAL

THE MANUFACTURER CANNOT CONTROL USE OF THE WATER HEATER, WATER

CONDITIONS OR MAINTENANCE. THE WATER HEATER WARRANTY DOES NOT

COVER POOR PERFORMANCE, STRUCTURAL FAILURE OR LEAKING DUE TO AN

EXCESSIVE ACCUMULATION OF SCALE.

The tank should be flushed to remove accumulated sediment at intervals depending on water

conditions. To flush, turn off electrical disconnect to heater. Open drain valve and allow water to

flow through the tank until it runs clear of sediment. Close the drain valve and turn electrical

disconnect on.

Scale can form during operation and will accumulate on the bottom of the tank. Scale is formed from

natural chemicals in the water which precipitate out during heating cycles. Some water supplies

contain more scaling chemicals than others. The rate of scale accumulation increases as the

temperature of stored water increases.

Sediment and scale accumulation in a tank reduce the water heater's ability to heat water. When

heating energy cannot be effectively transferred to the water, tank metal can overheat. Overheating

can cause the metal to lose its structural strength which can result in tank leakage.

The tank has a hand hole for inspection and cleaning. Remove hand hole cover on a regular basis and

inspect tank for scale buildup. If scale is present, it can be loosened with a high pressure stream of

water. Smaller flakes can be flushed through the drain, but larger flakes can be removed by hand

through the hand hole. The frequency of inspection should be determined by the rate of scale

buildup.

FIRETUBE CLEANING

The water heater contains a turbulator in each firetube, which increases flue gas velocity against the

tube wall. This increased velocity does two things.

1. Transfers more heat into the water thus reducing fuel cost.

2. Helps in maintaining a cleaner tube wall should combustion adjustment change (which can

produce sooting).

By maintaining the burner, and keeping CO2 in the 9.0 to 9.5% range (gas), or 13.5% (#2 oil), you

will help reduce sooting. This will also keep fuel cost down.

To check for and remove sooting, remove the top pan and turbulators and wire brush each tube.

Clean all soot from turbulators and reinstall into the firetubes.

After tube cleaning, remove the burner, clean combustion head internals and vacuum the combustion

chamber before placing water heater back into service.

21

Page 22

BURNER SERVICE

IMPORTANT

IT IS HIGHLY RECOMMENDED THAT REPLACEMENT PARTS OR ASSEMBLIES BE

OBTAINED FROM THE WATER HEATER OR BURNER MANUFACTURER.

The enclosed burner installation and operation manual contains a service suggestion

(troubleshooting) section and a periodic checklist that recommends a variety of component tests

designed to help maintain the water heater's reliable, efficient and safe operation.

For additional assistance, contact the burner manufacturer's customer service department.

Availability of spare parts varies from area to area. The burner material list provides the part number

you require for obtaining replacements. If the item is not available locally, contact the service

department at the location listed on the cover page.

WATER HEATER SERVICE

Serviceable water heater components include the control and high limit thermostats, the temperature

and pressure relief valve(s), the drain valve and , low water cut off. Optional components such as a

temperature and pressure gauge may also be installed. Replacement instructions for some of these

items are listed below.

For additional assistance, contact the water heater manufacturer's customer service department.

22

Page 23

RELIEF VALVE

1. Disconnect power from unit.

2. Shut off incoming water and boiler water supply.

3. Lift test lever on relief valve to relieve pressure in tank.

4. Disconnect overflow piping.

5. Unscrew relief valve, remove assembly and replace with new one.

6. Connect overflow piping.

7. Turn on incoming water supply and check for leaks.

8. Turn safety switch to ON position.

Test Lever

Overflow Piping Outlet

Tank Connection

Temperature Probe

23

Page 24

IMMERSION TEMPERATURE HIGH LIMIT CUT-OFF, HIGH, OR LOW THERMOSTAT

1. Disconnect power from unit.

2. Remove access cover.

3. Remove high limit cover screw and cover.

Cover

Cover Screw

Reset Tab (High Limit Only)

4. Disconnect the two (2) 14 gauge wires.

Wires

Capillary Tube

5. Remove capillary tube and bulb from

thermowell

6. Remove two (2) mounting screws.

Mounting Screws

7. Remove control and install new high limit switch by performing above steps in

reverse order. (Note: Be sure to place capillary tube into slot in base prior to installing cover.)

24

Page 25

Symptom Probable Cause Corrective Action / Remedy

No hot water.

SECTION V – TROUBLESHOOTING

(See separate component O&M for additional details.)

Flame safeguard locked out. Reset flame safeguard.

Manual gas valve closed. Open gas valve and reset flame

safeguard.

Blown control circuit. Replace fuse.

No power. Reset circuit breaker.

Water not hot enough.

Water temperature too hot.

Gas odors.

Gas pressure too high or too

low.

Operating control thermostat

set too low.

Recovery rate too low for

demand.

Operating control thermostat

failed.

Operating control thermostat

set too high.

Temperature and pressure

safety relief valve not closed.

If leakage source cannot be

determined.

Possible gas leak. Shut off gas supply and call the gas

Improper combustion. Call serviceman.

Blower wheel dirty. Call serviceman.

Down draft in vent. Call serviceman.

Gas train vents not vented

outdoors.

Blower wheel running

backward.

Reset gas pressure switch and reset

flame safeguard.

Increase control thermostat setting to

a higher temperature. Note: Higher

water temperatures increase the

danger of scalding.

Input rate too low/not operating at

peak efficiency.

Call serviceman to check input rate

and efficiency.

Check firetubes for soot. Inspect and

clean for scale and sediment build-up.

Call serviceman to replace control

thermostat.

Adjust operating control thermostat to

lower temperature.

Replace valve. Water leaks.

Shut off fuel and electrical supply,

close cold water inlet valve, and call

serviceman.

company.

Call serviceman.

Call serviceman.

25

Page 26

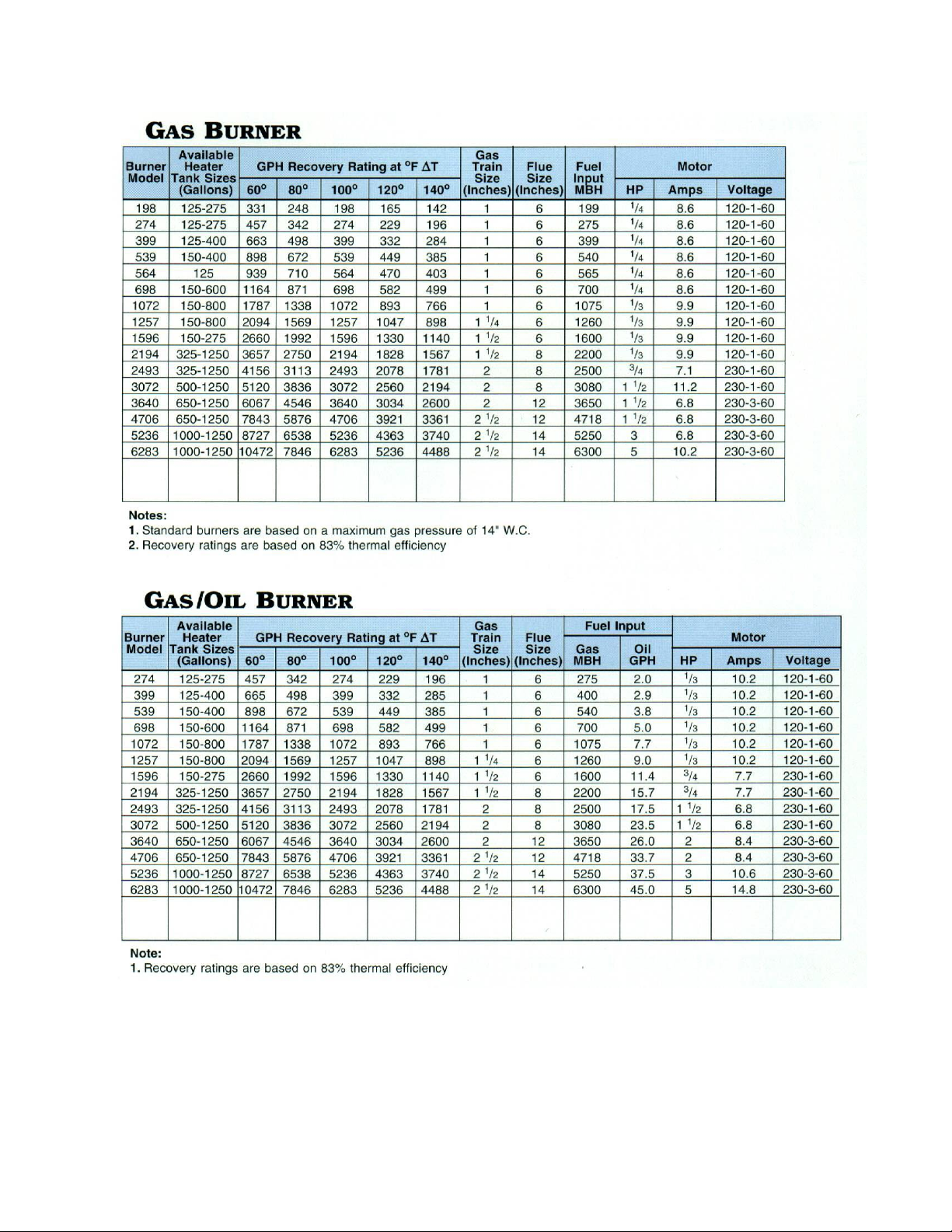

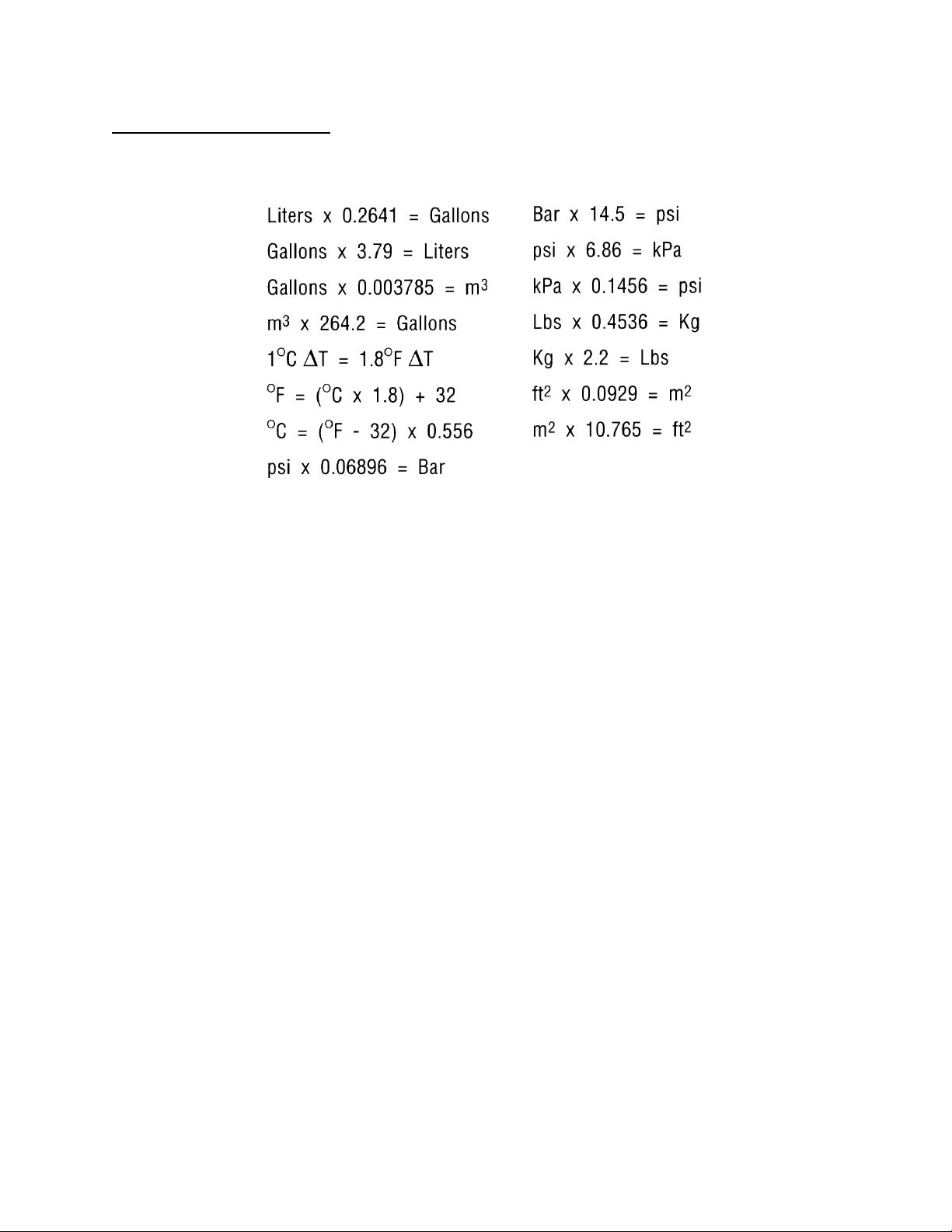

SECTION VI – MISCELLANEOUS CHARTS AND FORMULAS

TORQUE VALUES

BOLT SIZE

4-40

4-48 6.6 5.4 6.1 3.6 6.9 6.7

5-40 7.7 6.3 7.1 4.2 8.1 7.8

5-44 9.4 7.7 8.7 5.1 9.8 9.6

6-32 9.6 7.9 8.9 5.3 10.1 9.8

6-40 12.1 9.9 11.2 6.6 12.7 12.3

8-32 19.8 16.2 18.4 10.8 20.7 20.2

8-36 22.0 18.0 20.4 12.0 23.0 22.4

10-24 22.8 18.6 21.2 13.8 23.8 25.9

10-32 31.7 25.9 29.3 19.2 33.1 34.9

1/4-20 75.2 61.5 68.8 45.6 78.8 85.3

1/4-28 94.0 77.0 87.0 57.0 99.0 106.0

5/16-18 132 107 123 80 138 149

5/16-24 142 116 131 86 147 160

3/8-16 236 192 219 143 247 266

3/8-24 259 212 240 157 271 294

7/16-14 376 317 349 228 393 427

7/16-20 400 327 371 242 418 451

1/2-13 517 422 480 313 542 584

1/2-20 541 443 502 328 565 613

9/16-12 682 558 632 413 713 774

9/16-18 752 615 697 456 787 855

5/8-11 1110 907 1030 715 1160 1330

5/8-18 1244 1016 1154 798 1301 1482

3/4-10 1530 1249 1416 980 1582 1832

3/4-16 1490 1220 1382 958 1558 1790

7/8-9 2328 1905 2140 1495 2430 2775

7/8-14 2318 1895 2130 1490 2420 2755

1-8 3440 2815 3185 2205 3595 4130

1-14 3110 2545 2885 1995 3250 3730

18-8 S/S

IN.-LBS.

5.2 4.3 4.8 2.9 5.5 5.3

BRASS

IN.-LBS.

SILICON

BRONZE

IN.-LBS.

ALUMINUM

2024-T4

IN.-LBS.

316 S/S

IN.-LBS.

MONEL

IN.-LBS.

26

Page 27

METRIC CONVERSIONS

27

Loading...

Loading...