Page 1

MODEL D

Deionized (DI) Water HeaterDeionized (DI) Water Heate

1-120 Gallon Capacity, Up To 58 KW, Single Or Three Phase Voltages

Features

■ Industrial Grade Construction

� High grade construction materials provide

maximum longevity

� Packaged with all electrical operating controls

for trouble-free installation and operation

� Designed to operate in even the most

demanding application

■ Corrosion Resistant

� All Type 316L stainless steel tank construction

resists corrosion

� Heating elements are all 316L SS to ensure long

operating life

■ Proven Design

� Storage capacity lowers peak power demand

and reduces operating costs

� Many units can be easily upgraded to handle

future expansion

� Full range of sizes available to meet your exact

heating needs

Applications

■

Industrial Finishing & Cleaning Systems for

electronic & fabricated metal parts such as PC

Boards, Microchips, Capacitors, Metal Parts,

Jewelry, Aerospace Quality Bearings; Cosmetic

and Drug Packaging Systems, Glass Products.

■

Ultrasonic Cleaning Systems

■

Food Processing Equipment

■

Water Purication and RO Systems

■

Sanitary CIP Cleaning Systems

Model D

The model D provides a large supply of hot D

immediate use

I water for

Storage Type DI Water Heater Reduces Peak Power Demand

The Hubbell D model deionized water heater is

specically designed for systems requiring large draws of

I water with a xed period of time between cycles.

hot D

The KW rating is sized to recover enough capacity during

Heavy Duty DI Water Heater For Industrial Use

the idle period so that the tank will be fully hot when the

next draw down begins. The longer the time of recovery

between the required usages, the lower the KW input

required to heat the water.

Page 2

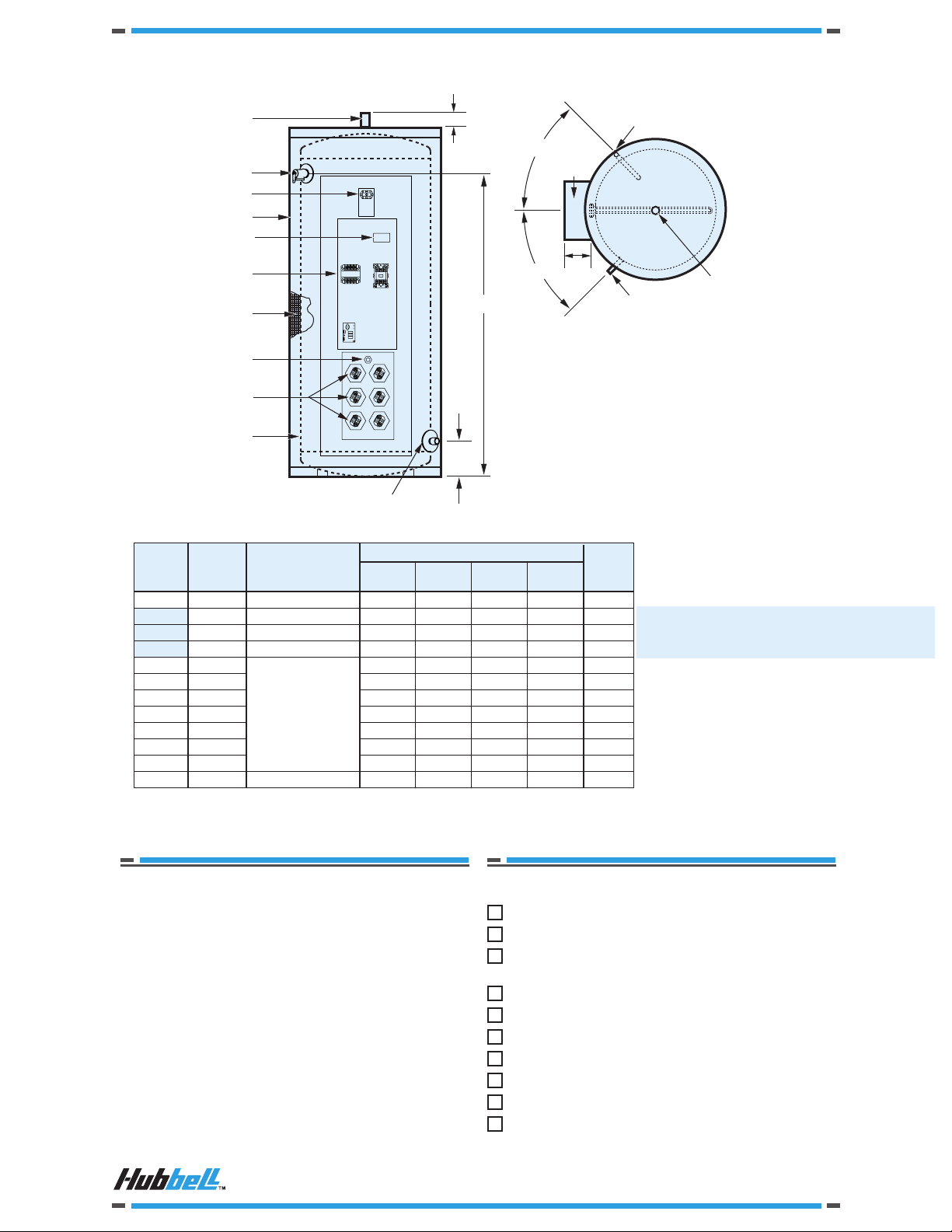

Outline Dimensions

Hot DI Water Outlet

T & P Relief Valve

Hi Temp Cut Out

Protective Jacket

Digital Display

Top ViewFront View

1"

o

45

Electrical

Control

Panel

Relief Valve

Electrical Control

Immersion Heaters

Pressure Vessel

Panel

2" Insulation

Temperature

Sensor

Cold D

B

A

I Water Inlet

6"

o

45

Note:

18" withdrawal space required for

removal of heating elements.

Model D Dimensional Data

Base Storage Dimensions (Inches)

Model Capacity KW Range

Number (Gallons) Available

D1 1 1 9 9 bottom 6 15

HD6-3* 6 1.5 - 18 13 19¾ 9

HD6-6* 6 24 - 58.5 18 18 8¹⁄

HD16* 16 6 - 88 31 23½ bottom 19.5 160

D30 30 20 52 5 44 210

D40 40 20 66 5 58 225

D50 50 24 44 6 39 325

D65 65 24 52 6 43 350

D80 80 24 61 6 52 450

D100 100 28 53 7 43 500

D120 120 28 66.5 7 57 575

1.5 - 58.5

Overall Overall Floor to Floor to

Diameter Height Inlet “A” T&P “B”

5

⁄8 15.5 95

8 14 110

Weight

(lbs.)

I

Hot D

Cold DI

Water Inlet

Water Outlet

Note: Model HD

For more Information on the HD Models please

see HD Brochure

Note: Model D1 is available in 1 KW, 120 Volt or 240 Volt, 1 Phase only.

*For 6 or 16 gallon capacities please refer to the HD Model brochure.

Standard Equipment

■ All Type 316L Stainless Steel construction

■

316L Stainless Steel immersion electric heating

elements, passivated and electropolished

■

Digital display temperature controller

■

Safety Hi-Temperature cut out with manual reset

■

Heavy gauge protective jacket

■

Heavy duty 2" thick energy efcient insulation

■

ASME rated combination temperature and pressure

bronze body safety relief valve set at 150 psi, 210

■

Low water cut out 316SS oat type

2

Optional Equipment

316 Stainless Steel Pressure only relief valve

1.

11/2” threaded inlet/outlet connections

2.

Flanged inlet/outlet connections

3.

(sanitary or ANSI Class 150)

Immersion safety hi-limit (100-240oF)

4.

304 Stainless steel protective outer jacket

5.

Fused low voltage control transformer (120 V)

6.

Power circuit fusing

7.

o

F

Passivated / Electropolished pressure vessel

8.

NEMA 4 construction for wash down areas

9.

ASME code stamped pressure vessel

10.

Page 3

Model D Sizing Information

Step 1

Determine the variables listed below.

Variables

1. Hot Water Flow Rate:

GPM

2.

Time hot water at above rate is required:

Minutes

3.

Recovery period until next usage:

Minutes

4.

Water Temperature:

6.

Power Supply:

Volts Phase

o

F Incoming Cold

o

F Outgoing Hot

Twice an hour the production line requires 8 GPM of hot DI water for

Example:

10 minutes. After this, the system remains off for 20 minutes before

beginning the cycle again. Incoming water is 60

temperature is 120

Step 1

Solve for the variables:

1. Hot water ow 8 GPM

2. Time On 10 Minutes

3. Time Off 20 Minutes

o

4. Incoming Cold Water 60

5. Outgoing Hot Water 120

F

o

F

Step 2

Flow Rate

0.70

(Variable 1)

x Time On

Step 3

Select the model D which has the

storage capacity solved for above.

Step 4

(Time On

x 0.80) + Time Off

(Variable 2)

Step 5

Storage Capacity

Y

= GPM

Step 6

Size the KW to match the GPM solved for in step 5 at

the desired temperature rise. See KW Selection Chart

for sizing.

o

o

F. Power available is 480 Volt, 3 Phase.

F and desired outlet

Step 3

Select the D120 because the storage

capacity of the D120 is the closest match

to the value solved for in Step 2.

Step 4

10 x .80 = 8.0 + 20 = 28

Step 5

120 ÷ 28 = 4.3 GPM

(Variable 2)

=

(Variable 3)

Storage

Capacity

= Y

Step 2

8 x 10 = 80 ÷ 0.70 = 114

Step 6

Select the 40 KW size at a 60

o

F rise.

Specify Model: D120-0-40SST4

Note: In comparison, an instantaneous heater for this

application would have to be 70 KW.

GPM Heating Capacity With Amperage Chart

Recovery Rate in GPM

KW

Rating

40

6 1.0 0.7 0.5 0.4 0.3 0.2 29 17 25 15 7

8 1.4 0.9 0.7 0.6 0.5 0.4 38 22 33 19 10

10 1.7 1.1 0.8 0.7 0.6 0.5 48 28 42 24 12

12 2.0 1.4 1. 0 0.8 0.7 0.6 58 33 50 29 15

15 2.6 1.7 1. 3 1.0 0.8 0.7 72 42 62 36 18

20 3.4 2.3 1.7 1.4 1.1 1.0 96 56 83 48 24

24 4.1 2.7 2.0 1.6 1.4 1.2 115 66 10 0 58 29

30 5.1 3.4 2.6 2.1 1.7 1.5 144 83 125 72 36

35 6.0 4.0 3.0 2.4 2.0 1.7 169 97 14 6 84 42

40 6.8 4.5 3.4 2.7 2.3 2.0 192 111 167 96 48

45 7. 7 5 .1 3.8 3.1 2.6 2.2 216 125 188 108 54

54 9.2 6.1 4.6 3.7 3 .1 2.6 259 150 226 130 65

58 9.9 6.6 4.9 4.0 3.3 2.8 279 162 243 13 9 70

o

at

F Temperature Rise

o

60o80o100o120o140

Amp Draw By Voltage & Phase

208V 240V 480V

o

1Φ 3Φ 1Φ 3Φ 3Φ

Note:

For alternate voltages

including 120, 277,

380, 415, 440, 575

and 600 volt, please

consult factory.

3

Page 4

Model D

Water Heater Specications

Vessel: 316L Stainless Steel

Capacities: 1 thru 120 Gallons

Orientation: Vertical

Voltages: 120 thru 600 Volt

Phase: 1

I nlet / Outlet Size

1 Gallon Unit:

3-40 KW:

45-58 KW:

Relief Valve Opening:

Thermostat Range

Surface Type: 110 - 170

Immersion Type: 100 - 195

Electronic Type: 32 - 194

Φ or 3 Φ

¼" Male NPT

3

/4" Female NPT

11/2" Male NPT

3

/4" Female NPT

o

F

o

F

o

F

H i - Limit:

Surface Type: 190

Immersion Type: 100 - 240

Electronic Type: 210

Design WP: 150 psi

Design TP: 300 psi

Elements: 316L Stainless Steel

Insulation: 2" Fiberglass

Warranty

Tank: 3 Years

Electrical: 1 Year

Jacket: 20 GA Galvanized Steel

Finish: Grey Hammertone

Alternative DI/RO Water Heater Designs

■ For DI/RO water heaters greater than 120

gallons storage, please reference Hubbell SH

Model brochure

■

For instantaneous DI/RO water heaters

typically greater than 60 KW, please reference

Hubbell CR Model brochure

■

For semi-instantaneous point-of-use DI/RO

water heaters, please reference Hubbell HD

Model brochure

o

F (Fixed)

o

o

F (Fixed)

F

Model Number Designation

D

■

Step 1

Model:

D

■

Step 2

Storage Capacity:

1 thru 120 Gallons

—

Example: D120 - 0 - 40SST4

A model D with 120 gallon capacity and a 40 KW

heating element. Tank is stainless steel and operates

at 480 V, 3 phase, 60 Hz power.

Option Note

Any and all optional equipment for a D model water

heater must be called out in the written specications.

A model number in and of itself does not reect any

optional equipment selected.

—

O

■

Step 3

Upper KW

Rating:

Typically 0

■

Step 4

Lower KW

Rating:

1 thru 58

SS

■

Step 5

Vessel Type:

SS =Type 316L

Stainless Steel

■

Step 6

Voltage / Phase / Hz:

A = 120-1-60

RS = 208-1-60

R = 208-3-60

S = 240-1-60

T = 240-3-60

W = 277-1-60

T3 = 380-3-50/60

T7 = 415-3-50/60

T5 = 440-3-60

T4 = 480-3-60

T6 = 600-3-60

The Electric Heater Company

4

Continuing research results in product improvement; therefore specications are subject to

change without notice. For the most updated information, consult the factory directly.

■ P.O. Box 288 ■ Stratford, CT 06615-0288 ■ Phone: 203-378-2659 ■ Fax: 203-378-3593

info@hubbellheaters.com

Committed to continuous improvement...

■ www.hubbellheaters.com

[Rev A]

Loading...

Loading...