Page 1

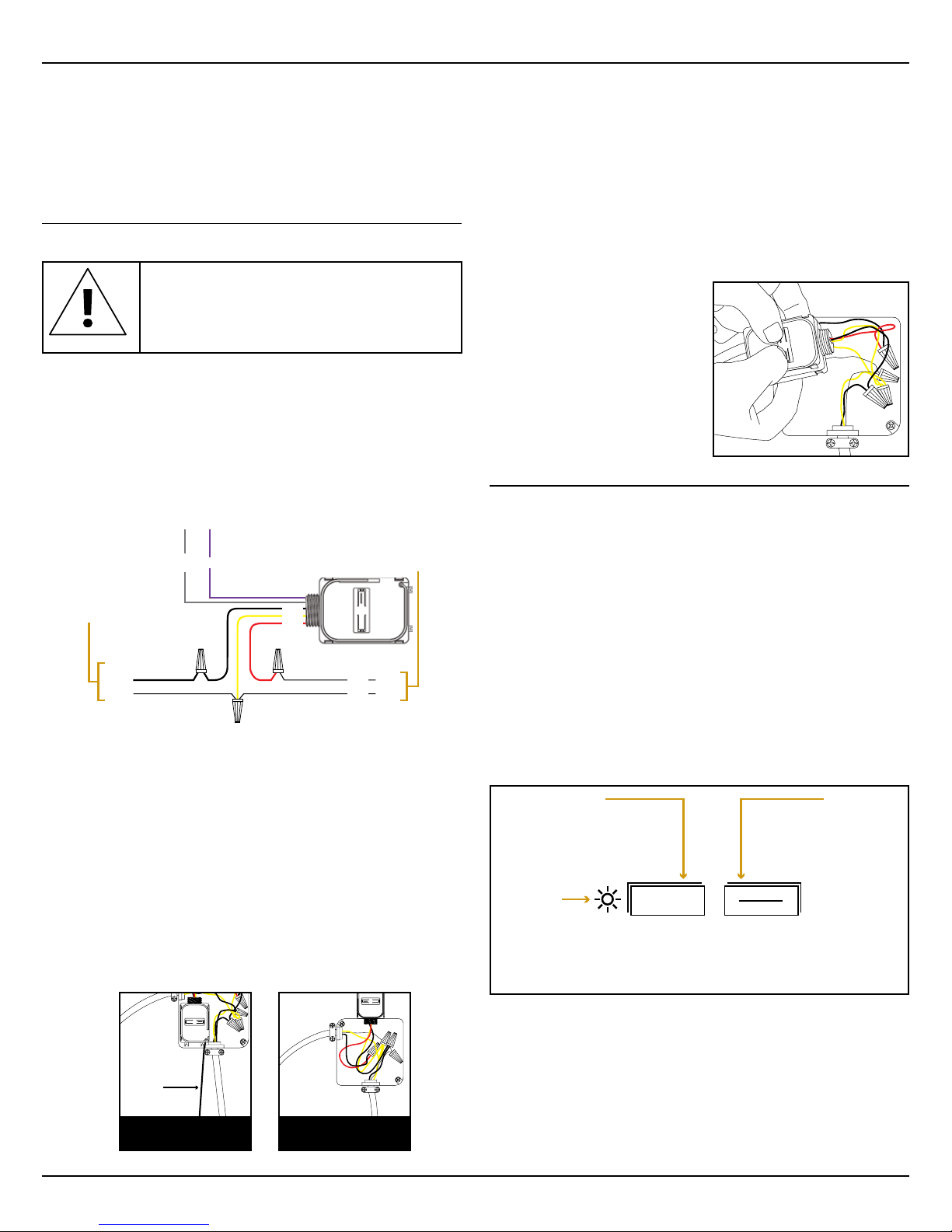

Wires: Black, White,

wiSTAR™ Installation Guide:

0-10V Dimming Relay Module

WIS-IDM

Technology From:

Red, Grey, Purple

Threaded connector

and lock nut

Orange Antenna

(insulated end)

LRN (O) button

DIM (I) button

Package Contents

▪ 0-10V Relay Module

2.78”

73mm

1.65”

42mm

Tools Required

▪ Screwdriver

1.1”

28mm

2.24”

57mm

▪ Wire nuts

Product Description

The LED relay zone controller uses wireless technology to communicate with other self-powered EnOcean based products and

provides an amazingly simple solution for dimming control of

LED lighting.

The compact size enables exible installation inside of or next

to electrical boxes and xtures so it can be easily wired out of

sight using standard wiring practices.

Simply link the module to an EnOcean-based motion sensor,

light level sensor or rocker switch and experience levels of

efciency and convenience that can only be achieved through

wireless controls.

It is also possible to link TWR-D10 to a central controller or via a

gateway to building automation systems like BACnet.

Features Include:

▪ Enables wireless dimming of a single xture or a zone of

multiple daisy chained LED xtures (e.g. 20 each 30W or

10 each 60W).

▪ Supports California Title 24 daylight harvesting scenarios,

occupancy control and manual dimming with input from

self-powered wireless switches and sensors. Implements

load shedding initiated by separate Demand Response

controllers

▪ Installs inside or mounts to electrical box using threaded

connector

▪ Supports wireless remote commissioning to link devices

and set parameters

Specications

Power Supply 120V - 277V VAC, 60 Hz

Maximum Load General Purpose: 16A @

120/277VAC

Resistive: 16A @ 120/277VAC

Tungsten: 960W @ 120VAC

Ballast: 600W @ 120VAC

0-10V output Tolerances +3%/-4% (1-10V range)

Current sinking 35mA*, sourcing 4mA

* For high sinking current and dim values

below 10%, the output voltage may exceed the

selected output value and reach 1V max.

Power Consumption 1.1W full load, 500mW quiescent

Surge Protection 3kV line to line, exceeding

IEC61000-4-5 installation class 4

Inputs/Outputs • Flying-lead style wires

• 2 power input wires

• 1 switched output wire

• 2 output wires for 0-10V control

Conguration Interface 2 Buttons, 1 LED for device

conguration & manual control

RF Standard EnOcean 902 MHz

Transmission Range 80 ft. (25 m)

EnOcean Equipment

Prole

Interoperable Products /

EEPs (EnOcean

Equipment Proles)

Dimensions 2.78” H x 1.65” W x 1.1” D

Weight 3.2oz. (90g)

Mounting • Install inside standard electrical box

Environment • Indoor use only

Agency Compliance

D2-40-00 for remote commissioning

with Navigan™

Rocker Pad Switch (F6-02-02)

Occupancy Sensor (A5-07-01)

Occupancy Sensor (A5-07-02)

Occupancy Sensor (A5-07-03)

Light Level Sensor (A5-06-02)

Light Level Sensor (A6-06-03)

Central Controller (A5-38-08)

Demand Response (A5-37-01)

(73mm x 42mm x 28mm)

• Connect to electrical boxes and

xtures using threaded nipple

• 32° to 104° F (0° to 60° C)

• 20% to 85% relative humidity

(non-condensing)

ETL, FCC, IC, UL2043 Plenum Rated

1) Planning

Take a moment to plan for the module’s successful operation

and optimal communication with other system components.

▪ Always use a qualied installer

▪ Install in an appropriate location

© 2016 Hubbell Control Solutions • www.hubbell-automation.com Page 1

Page 2

Dimming 0-10V Only

eaded connector

wiSTAR™ Dimming Control Module • Installation Guide

▪ Take care not to damage the radio antenna, the orange wire

that runs in a groove on the outside of the module that runs

in a groove on the outside of the module

▪ Consider the construction materials in the space

and obstacles that may interfere with RF signals

2) Installing

Read and understand instructions completely before starting.

ELECTRICAL SHOCK HAZARD

High Voltage. This device must be installed

by a qualied installer or electrician. Follow

all applicable electrical codes for installation.

1. Turn off power at the circuit breaker or fuse and

test that power is off before wiring the device.

NOTE: Use a non-metal electrical enclosure

for best wireless communication performance.

2. Identify the wiring connection at the installation site

to coordinate with the following wiring diagram.

NOTE: For display purposes, white wire is shown as yellow.

Power Input

120VAC/

277VAC

Neutral Neutral

3. Determine which of the two installation methods

is most appropriate:

A. Installed inside the electrical box.

NOTE: For best performance, remove the antenna from

its slot and elongate it outside and away from the box

and conduit. Install tubular sleeve (included) over

antenna and slide into relay housing.

B. Installed using the threaded connector:

i. Insert the threaded connector through

a ½” trade size (⅞” diameter) knockout.

ii. Thread the 5 module wires inside the electrical box

and through the lock nut.

Example:

antenna extended

in sleeve

A: Installed inside

electrical box

dark

grey

purple

+-

To Electrical Load

black

white

red

Hot

black

white

A: Installed using

thr

4. Connect the wires using wire nuts and cap any bare wires.

NOTE: After the module is linked and congured,

you can secure it in the installed location, see step 8.

5. Fold the wires neatly and either place the module in the

box or secure the threaded connector with the lock nut.

6. Position the module so that the setup interface

and antenna face forward (out).

TIP: If the RF reception is poor, use the antenna sleeve

provided to extend the antenna.

7. Restore power to the circuit.

8. Use the setup interface to

link devices and congure

settings (refer to the “Linking”

& “Conguring” sections).

Warning: Remove the

module from the electrical

box to use the setup

interface.

3) Device Conguration

The LED controller can be congured in two ways:

▪ By user input to the local setup interface

This approach is used for basic setup tasks

▪ Remotely using the remote commissioning interface

This approach is used for advanced conguration tasks

Local Setup Interface

The local setup interface has two buttons, LRN (O) and DIM.

LRN (O) has a corresponding 2-color LED (green, red). This

simple interface is used to link and unlink transmitters, to dim up

and down manually and to set the minimum dimming value.

To use the local setup interface, hold the module so both

thumbs can click the buttons without obscuring the LED.

LRN (O) button

Press short to start or end

linking/unlinking mode.

Press long (>10s) to delete all

linked transmitters.

LRN (O) LED

The LED will toggle red/green every 2 seconds,

while in linking/unlinking mode. After linking

(unlinking) a device it will stay green (red) for 4

seconds. The connected load will toggle between

10% and 90% dimming level, respectively.

When the button is pressed

shortly (<0.5s), the connected

load is switched ON/OFF. If

pressed longer, the 0-10V output

starts dimming up and down the

connected load. If pressed

output value will be stored as

minimum dimming level. When

shortly (<0.5s) pressing the button

while in learn mode, TWR-D10

will transmit a teach-in telegram.

Remote Commissioning Interface

The LED controller provides a wireless remote commissioning

interface for all commissioning tasks.

This interface allows conguring all device parameters

wirelessly using a laptop computer equipped with Navigan

Wireless Commissioner (WIS-NWC-USB), consisting of a USB

stick and software.

DIM (I) button

simultaneously with

the LRN (O) button

the current 0-10V

© 2016 Hubbell Control Solutions • www.hubbell-automation.com Page 2

Page 3

wiSTAR™ Dimming Control Module • Installation Guide

4) Linking

Linking is the process by which different devices are congured

to work with each other in a system. Sometimes this process is

also called Teach-in or Learn-in.

The LED controller can work together with two types of devices:

▪ Transmitters (switches and sensors) can provide input data

to the LED controller.

▪ Transceivers (Gateways or controllers) can exchange data

and commands with the LED controller.

There are two basic types of devices in the system; transmitters

and transceivers:

Transmitters (Transmit-only)

Transmitters are energy-harvesting devices that send RF messages to communicate a condition, level, or state. The following

transmitter types can be linked to the LED controller:

▪ Switches

▪ Occupancy Sensor

▪ Light Level Sensor (only in addition to switches and

occupancy sensors, not alone)

Transmitters can only be linked to transceivers, not to other

transmitters.

Transceivers (Transmit & Receive)

The LED controller is a transceiver. Transceivers are control-

ling devices that send as well as receive RF messages. They

also process relevant control logic, and actuate the appropriate

outputs (switching a light ON or OFF for example).

The LED controller can be linked to other transceivers if desired. The following other transceiver types are supported:

▪ Demand Response Controller

▪ Central Controller

Linking to transmitters (sensors or switches)

To link the LED controller with a transmitter, the LED controller

must be powered, within wireless range of the transmitter it is to

be linked to, and set to linking mode to accept links.

Once these conditions are met, the desired transmitter is triggered to send a special link message.

The LED Controller receives this link message and stores the

link parameters permanently so that the two devices can interact to provide a variety of intelligent control options.

time to link / unlink multiple devices. The mode will stop

after 30 seconds if no LRN (O) telegram is received.

2. For the transmitter to be linked, do one of the following

according to the type of device:

A. Sensor: click the designated link button.

B. Rocker Pad: click the “I” button (top button marked on

the switch plastic or “I” symbol on the back of the switch) 3

times quickly.

3. If the device has been linked successfully, the LRN (O) LED

will display solid green for 4 seconds. The LED controller is

now ready to accept new links.

NOTE: After a device is linked, additional learn telegrams

received in operating mode (not in linking / unlinking mode)

from that device will cause the connected load to toggle

once between 10% and 90%, if the EnableLinkChecker

parameter is set to ON.

This allows quickly checking the connection between this

device and the LED Controller.

4. For a linked transmitter to be unlinked, please use the same

action as described in point 2 above.

5. If the device has been unlinked successfully then the LRN

(O) LED will display solid red for 4 seconds and the load will

be switched to a dimming level of 10% for 4 seconds.

6. To exit linking / unlinking mode and return to normal opera-

tion, wait 30s without sending new LRN (O) telegrams, or

shortly press the LRN (O) button again.

Clear all linked transmitters

In order to clear all linked devices press and hold the LRN (O)

button for 10 seconds. After that the LRN (O) LED will display

solid red for 10 seconds.

Linking to Transceivers (gateways or controllers)

1. Set the other device into linking mode

2. Shortly press the LRN (O) button.

The LRN (O) LED starts toggling indicating that linking /

unlinking mode is active. The connected load will toggle

between 10% and 90%.

3. Shortly press the DIM (I) button. This will cause the LED

Controller to transmit a teach-in message identifying the

status message EEP used by it.

4. Shortly press the LRN (O) button again to return to normal

operation.

Setting the minimum output voltage level

Link / unlink procedure

1. Shortly press the LRN (O) button to enter linking / unlinking

mode.

The LRN (O) LED starts toggling red / green indicating that

linking / unlinking mode is active. In addition, the connected

load will toggle between 10% and 90%.

Once activated, this mode stays temporary active to provide

© 2016 Hubbell Control Solutions • www.hubbell-automation.com Page 3

It is possible to congure the minimum output voltage

(MinVoltageLevel) of the LED Controller via its button interface.

This level is typically set to avoid ickering and will be the mini-

mum level the load starts at when it is switched on. It will not be

possible to dim the output below this value.

Use the following steps to congure this minimum dimming

value:

Page 4

wiSTAR™ Dimming Control Module • Installation Guide

1. Press and hold the DIM (I) button.

The load will start dimming up and down.

2. Release the button when the desired minimum output volt-

age (dimming value) is reached.

3. Shortly press DIM (I) and LRN (O) button simultaneously to

store this value.

Double click (<0.7s) on “I” button: Light is switched ON immediately at MaxVoltageLevel (default 10.0V).

Short click (<0.7s) or double click (<0.7s) on “O” button (Bottom

button marked on switch or “O” symbol on back of switch): The light is

switched OFF, the current dimming value is stored.

Press and hold “I” or “O” button: Light is brightened or dimmed

until button is released or MinVoltageLevel / MaxVoltageLevel is

5) Operating Modes

The LED Controller supports the following operation modes

based on different types of connected devices:

Mode

Switches only

Occupancy

sensors only

Occupancy

sensors and

switches

Additional

light level

sensor

Additional

central

controller

Additional

demand

response

controller

Behavior of the different components is described in detail

subsequently.

A wide range of conguration parameters can be modied using

the remote commissioning tool Navigan Wireless Commissioner

(WIS-NWC-USB). These congurable parameters are marked

as italic in the following chapter.

Default Action Title 24

Compliance

Manual DIM or ON/OFF No

Auto ON/ Auto OFF (default Auto

OFF after 15 minutes)

Manual DIM or ON, Auto OFF

Can be congured to Auto ON / Auto

OFF via remote commissioning.

(default Auto OFF after 15 minutes)

Continuous dimming based on 5

supporting points or two level

dimming

Dimming via central controller

overriding sensor and switch input

During a demand response event

output will be reduced to the value

specied in the command.

After the demand response time out

the system will switch back to the

previous state.

No

Yes

Yes

Yes

Yes

reached.

Ramp up (RockerSwitchRampUpSpeed) and down (RockerSwitchRampDownSpeed) speeds for rocker operation are

congurable (default 20% per second).

Light can be automatically switched OFF automatically in ab-

sence of an occupancy sensor after time-out of RockerSwitchAutoOffTimer. This feature can be disabled by setting RockerSwitchAutoOffTimer = 0.

This feature is automatically disabled if an occupancy sensor is

present. In this case, automatic switch OFF of the light will be

performed based on the input from the occupancy sensor as

described below.

Occupancy Sensors Only

If at least one sensor detects motion, light is set to OccAutoOn-

Level (default 100%). If none of the sensors detects motion,

light is set to OccAutoOffLevel (default 0%), after OccAutoOffTimer (default 15min) has elapsed.

Ramp up (SensorRampUpSpeed) and ramp down (SensorRampDownSpeed) speeds are congurable (default 20% per

second).

Occupancy Sensors and Switches

Light can be switched ON / OFF manually, function as described

above. Once OccAutoOffTimer (default 15min) has elapsed the

light will be set to OccAutoOffLevel (default 0%).

Light will be automatically turned back ON at the last state, if

occupancy is detected within the OccGraceTimer period (default

45s) after an occupancy sensor Auto OFF event.

The system can also be congured (OccAutoOn) to automati-

6) Functional Behavior

cally switch ON the light. In this case if occupancy is detected

and light is off, the light is switched to OccAutoOnLevel.

0-10V Interface

The minimum output voltage is MinVoltageLevel (default 2.0V);

the maximum output voltage is MaxVoltageLevel (default

The period from switching OFF the light by a rocker until it can

be turned on again by occupancy sensor input can be set using

OccOverrideTimer (default 15 minutes).

10.0V). Dimming below MinVoltageLevel or above MaxVoltage-

Level is not possible.

Level and ramp percentage levels refer to the interval between

MinVoltageLevel (1%) and MaxVoltageLevel (100%). An output

level of 0% equals OFF state.

Light Level Sensor

WIS-IDM supports the integration of a light level sensor in an

open-loop system for daylight harvesting.

The light level sensor adjusts the light level according to incoming ambient light. The light level sensor will not switch ON the

Switches Only

Short click (<0.7s) on “I” button of the rocker switch: Light

comes ON at last dimming value stored before device was

switched off. At rst usage or after a reset, it will be switched to

MinVoltageLevel (default 2.0V).

© 2016 Hubbell Control Solutions • www.hubbell-automation.com Page 4

light by itself; therefore it works only in conjunction with rockers

or occupancy sensors in the system.

The light level sensor should be placed at a position facing the

window or skylight where it is not or only minimally inuenced

by light from the xtures.

Page 5

wiSTAR™ Dimming Control Module • Installation Guide

If a light level sensor is connected, the LED controller will by

default activate daylight harvesting with continuous open loop

dimming according to a user-dened dimming curve based on 5

congurable supporting points.

Each of these 5 supporting points denes the output light level

set by the LED controller for a specic input illumination level

reported by the light sensor.

In order to start dimming based on illumination the light must be

switched ON either via rocker switch or by an occupancy sensor

Auto ON event, depending on system conguration.

After a double click (<0.7s) on the “I” button of the light level

sensor, after brightening or dimming via “I” or “O” button or after

switch ON via occupancy sensor input, light will stay at the set

level until switched OFF manually or by an occupancy Auto OFF

event or until the LlsOverrideTimer (default 15 minutes) elapses.

Users can adapt the output level of the LED controller for the

current illumination level reported by the light level sensor.

This is achieved using a fast triple click (<0.7s) on the “I” button.

Doing so will replace the supporting point matching most closely

the current reported illumination level reported by the light level

sensor with the current light level and the current 0-10V output

level.

Doing that at different daylight levels allows dening the whole

curve. In addition these supporting points can also be cong-

ured by remote commissioning.

The light level sensor can alternatively be used to activate an

automatic switching mode between MaxVoltageLevel and MinVoltageLevel based on light intensity.

This can be achieved by conguring DaylightingMode to 2-level

via remote commissioning.

The thresholds for switching between these levels are dened

by PhotoOnThres (output will be set to MaxVoltageLevel for

reported values below this level) and PhotoOffThres (output will

be set to MinVoltageLevel for reported values above this level).

Repeater Function

The LED controller provides the option to activate a one or

two-level repeater for EnOcean radio telegrams. This function is

only available via remote commissioning.

1-level repeater: If a received telegram is a valid and original

(not yet repeated), the telegram is repeated after a random

delay.

2-level repeater: If a received telegram is valid and original or

repeated once, the telegram is repeated after a random delay.

Note: 2-level repeating function should only be activated if

really needed! Otherwise the system function can be compromised by collisions of telegrams.

be switched off completely. By setting it to 0xFFFF only event

based messages will be sent.

Central Controller

WIS-IDM can also be connected to a central controller (EEP A538-00). It supports the dimming command 0x02 of this EEP.

7) Troubleshooting

Problem Solution Checklist

The device does not

power up

The device does not

control linked load

Cannot link other

devices

The device does not

respond to wire-

less messages or

selected settings

Contains:

902 MHz: FCC: SZV-STM300U

IC: 5713A-STM300U

This device complies with part 15 of the FCC rules and Industry Canada ICES-003.

Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

IMPORTANT! Any changes or modications not expressly approved by the party responsible for

compliance could void the user’s authority to operate this equipment.

• Check the wiring for errors

• Check the circuit breaker

• Use a voltage meter to conrm power

• Click the DIM (I) button to open/close

the

relay manually

• Turn off the power and then restore it

• Check if linking mode can be accessed

• Move closer to the device; it may be out

of range

• Try linking a different device

• Check for environmental conditions that

interfere with RF signals

• Verify the maximum number of devices

has not been exceeded

- 20 switches

- 10 occupancy sensors

- 1 light level sensor

- 1 central controller

- 1 demand response controller

• Check for environment or range issues

• Verify the device is linked

• Check if appropriate devices are linked

according to good system planning

• Extend the antenna to amplify the range:

remove it from the groove in the module,

and straighten it.

Status Messages

The LED controller will transmit a status message

(EEP D2-40-00) after change of its output state or after the

StatusMessageTimer has elapsed.

By setting StatusMessageTimer to 0 status messages can

© 2016 Hubbell Control Solutions • www.hubbell-automation.com Page 5

Page 6

wiSTAR™ Dimming Control Module • Installation Guide

8) Remote Commissioning Parameters

The following parameters can be set via remote commissioning,

e.g. using the Navigan tool.

Parameter

System Parameters

MinVoltageLevel

MaxVoltageLevel

0-10VRelayDelay

ModeAfterPowerLoss

StatusMessageTimer

RepeaterFunction

Enable-Debug-

Minimum 0-10V output voltage

level when light is switched ON

Maximum 0-10V output voltage

level when light is switched ON

Delay between switching the relay

on and starting to ramp up the

0-10V output

ModeAfterPowerLoss

(ON/OFF/LAST STATE)

Denes, how often status messages are transmitted (seconds, 0=off,

0xFFFF=only event based)

Denes the repeater level of the

device (OFF/1-Level/2-Level)

Enable or disable debug messages OFF

Messages

EnableLinkChecker

RockerSwitch-

RampUpSpeed

RockerSwitch

Ramp-

Enable or disable link checker

(if a learn telegram from a linked

device is received while in operat-

ing mode, the 0-10V output will

toggle once between 10% and

90%)

Ramp-up speed when change is

triggered by rocker input

Ramp-down speed when change is

triggered by rocker input

DownSpeed

RockerSwitch-

RockerSwitchAutoOffTimer 0 (disabled)

AutoOffTimer

Generic Sensor Parameters (Occupancy and Light Level)

SensorRamp-

UpSpeed

SensorRampDownSpeed

Ramp-up speed when change is

triggered by an occupancy or light

level sensor

Ramp-down speed when change is

triggered by an occupancy or light

level sensor

Description Default/

Notes

2.0V

10.0V

50ms

LAST

STAT E

0xFFFF

OFF

ON

2 0 % / s

0= No ramp

(immediate)

2 0 % / s

0= No ramp

(immediate)

20%/s

0= No ramp

(immediate)

20%/s

0= No ramp

(immediate)

Parameter

OccAutoOn

OccAutoOnLevel

OccOverrideTimer

OccAutoOffTimer

OccAutoOffLevel

OccGraceTimer

DaylightingMode

PhotoOnThres

PhotoOffThres

LEV1…5

OUT1…5

RAMP12, 23,

34, 45

LlsOverrideTimer

Description Default/

Occupancy Sensor Parameters

Denes if a signal from an occupancy sensor automatically

switches on lights (True/False)

Dimming value at which light is

switched on in case of Auto ON

event from occupancy sensor

Time before the occupancy sensor can switch the light back ON

in Auto ON Mode after the user

switched it OFF

Time after which lights will be

switched to OccAutoOffLevel in

case of no motion

Dimming value to which lights will

be dimmed after an occupancy

sensor Auto OFF timer event

If occupancy is detected within the

OccGraceTimer period after an oc-

cupancy Auto OFF event, lights are

turned back ON

Light Level Sensor Parameters

2-level or 5 point continuous daylight dimming

In case of 2-level mode, light is

switched to MaxVoltageLevel if

light level is below PhotoOnThres

In case of 2-level mode, light is

switched to MinVoltageLevel if light

level is above PhotoOffThres

Denes 5 input light levels

for open loop dimming curve

(LEV1<LEV2<...<LEV5)

Denes the LED controller output

values for the corresponding input

light levels

Ramp speeds between light levels

1 and 2, 2 and 3, 3 and 4 , 4 and 5

Time before the light level sensor

can modify the light level set by

user or occupancy sensor input

Notes

FALSE if

at least

one switch

is linked,

otherwise

TRUE

100%

15 min

15 min

0=disabled

0%

45 s

5 point

<200lux

>400lux

100, 200,

400, 600,

800 lux

100, 100%,

60%, 20%,

0%

1%/s

15 min

© 2016 Hubbell Control Solutions • www.hubbell-automation.com Page 6

72-00602

Loading...

Loading...