Page 1

OPERATING AND MAINTENANCE MANUAL FOR

STEAM FIRED WATER HEATER

ELECTRIC HEATER COMPANY

BASE MODEL “ ST and STH ”

Page 2

HUBBELL ELECTRIC HEATER COMPANY

P.O. BOX 288

STRATFORD, CT 06615

PHONE: (203) 378-2659

FAX: (203) 378-3593

INTERNET: http://www.hubbellheaters.com/

-- IMPORTANT --

Always reference the full model number and serial number when calling the factory.

WARNING / CAUTION

1. Tank is to be completely filled with water and all air is to be vented before energizing.

2. Due to the rigors of transportation, all connections should be checked for tightness before heater

is placed in operation.

3. Safety relief valve must be installed in tapping provided.

4. KEEP AWAY FROM LIVE ELECTRICAL CIRCUITS.

Do not perform any maintenance, make any adjustments, or replace any components inside the

control panel with the high voltage power supply turned on. Under certain circumstances,

dangerous potentials may exist even when the power supply is off. To avoid casualties, always

turn the power supply safety switch to off, turn the charge or ground the circuit before

performing any maintenance or adjustment procedure.

5. Generalized instructions and procedures cannot anticipate all situations. For this reason, only

qualified installers should perform the installation. A qualified installer is a person who has

licensed training and a working knowledge of the applicable codes regulation, tools, equipment,

and methods necessary for safe installation of a steam fired water heater. If questions regarding

installation arise, check with your local plumbing and electrical inspectors for proper

procedures and codes. If you cannot obtain the required information, contact the company.

2

Page 3

TABLE OF CONTENTS

SECTION TITLE PAGE #

I GENERAL DESCRIPTION AND CONSTRUCTION 9

II INSTALLATION AND OPERATION 13

III SCHEDULED MAINTENANCE AND SERVICING 18

IV ADJUSTMENT OF TEMPERATURE REGULATORS 25

V TROUBLESHOOTING 28

VI MISCELLANEOUS CHARTS AND FORMULAS 30

3

Page 4

4

Page 5

5

Page 6

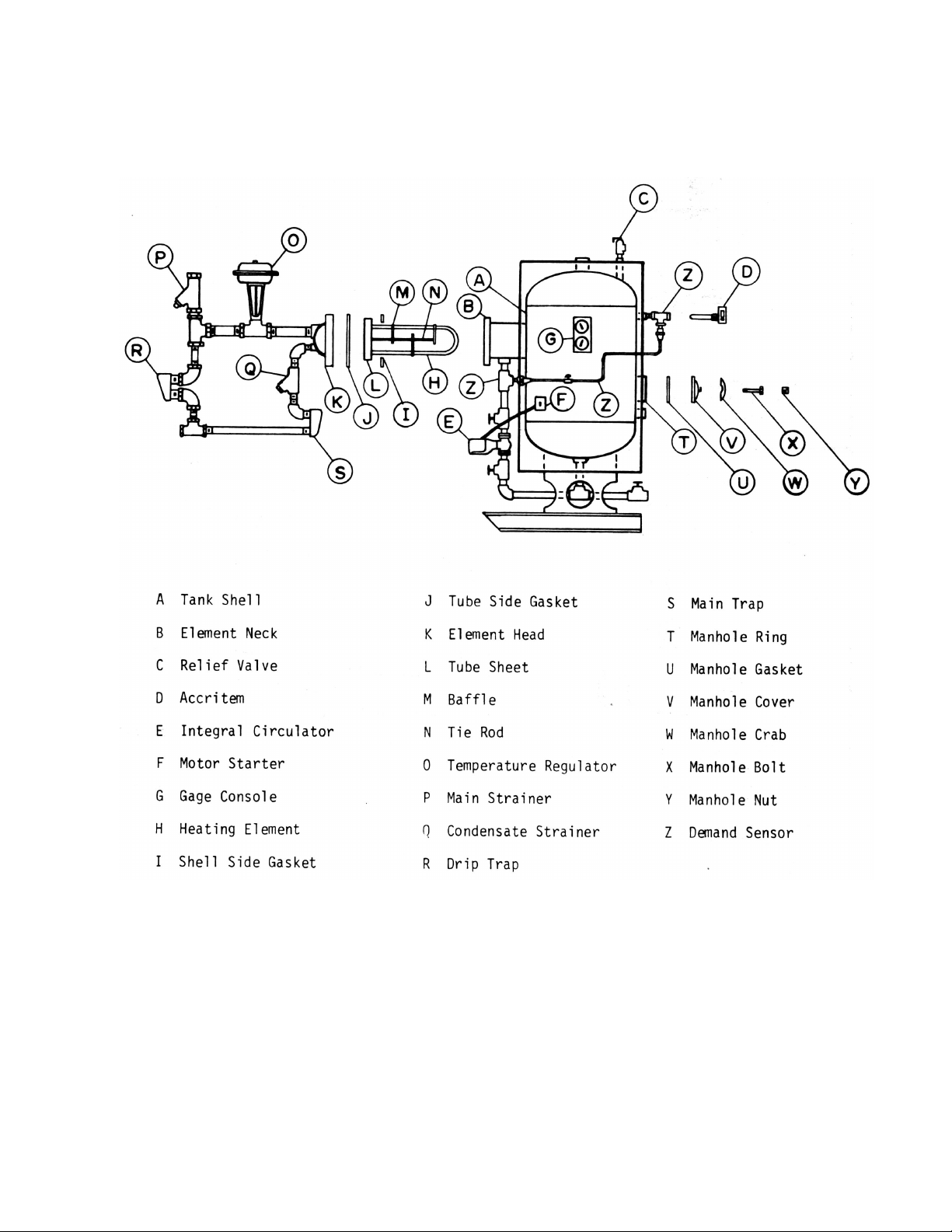

NOMENCLATURE FOR PARTS

6

Page 7

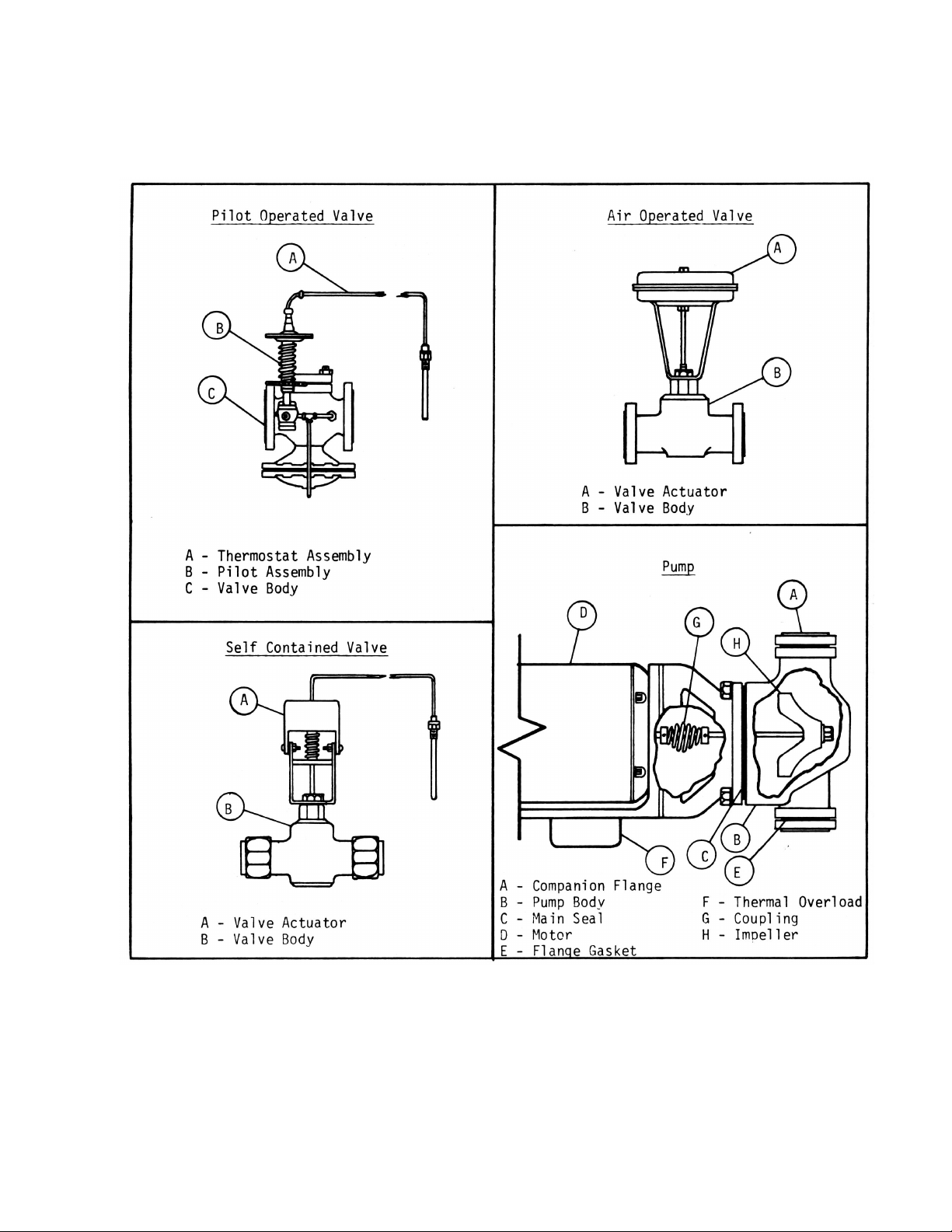

NOMENCLATURE FOR ACCESSORY PARTS

7

Page 8

8

Page 9

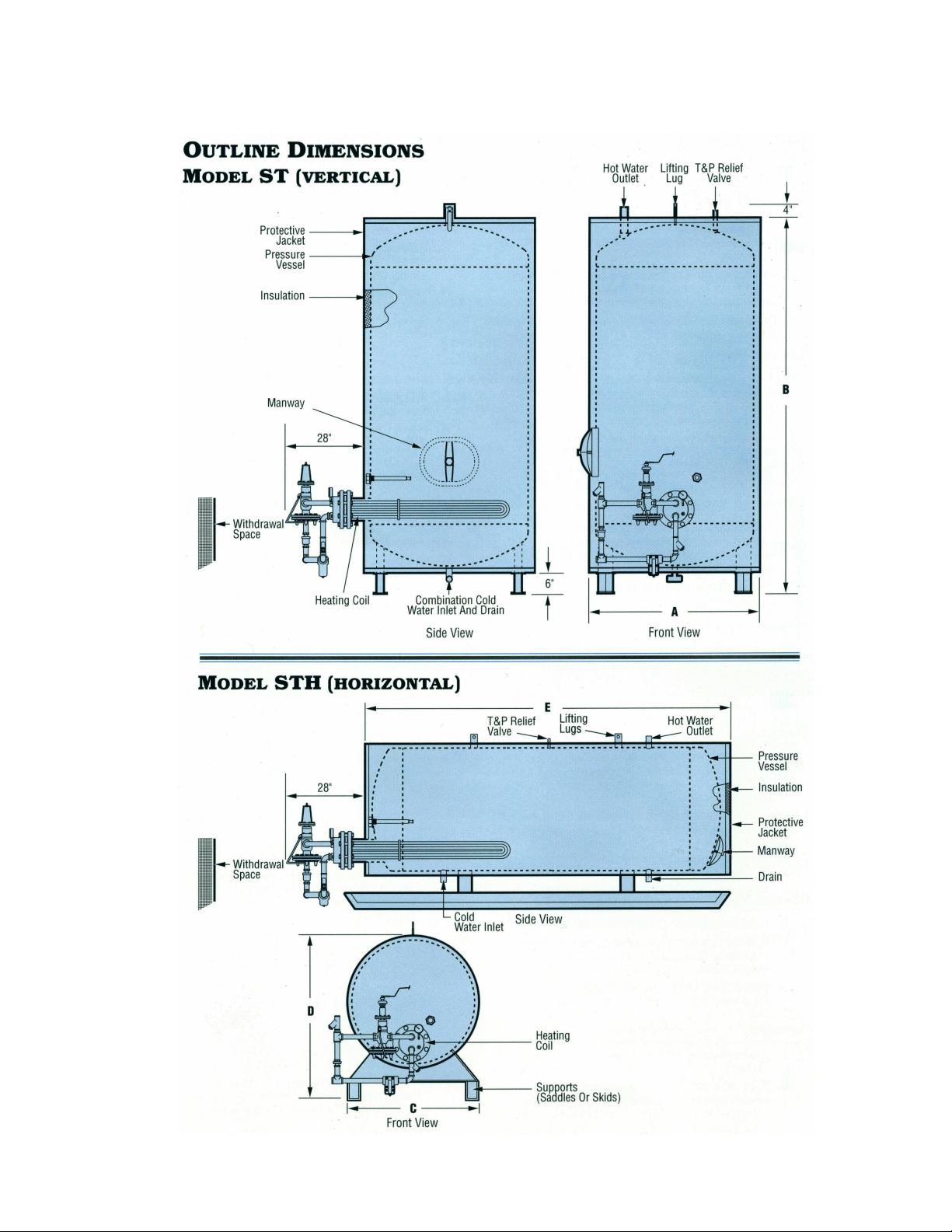

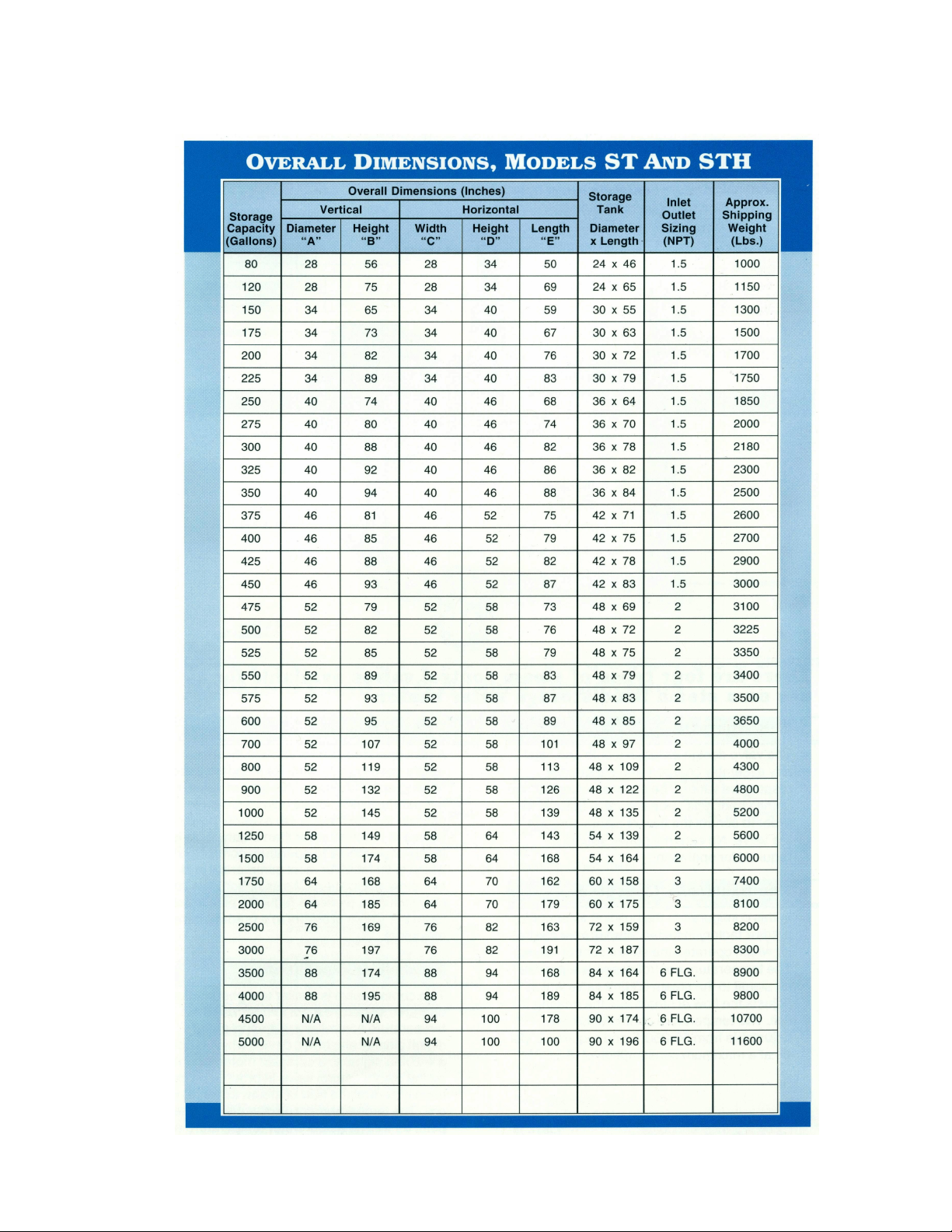

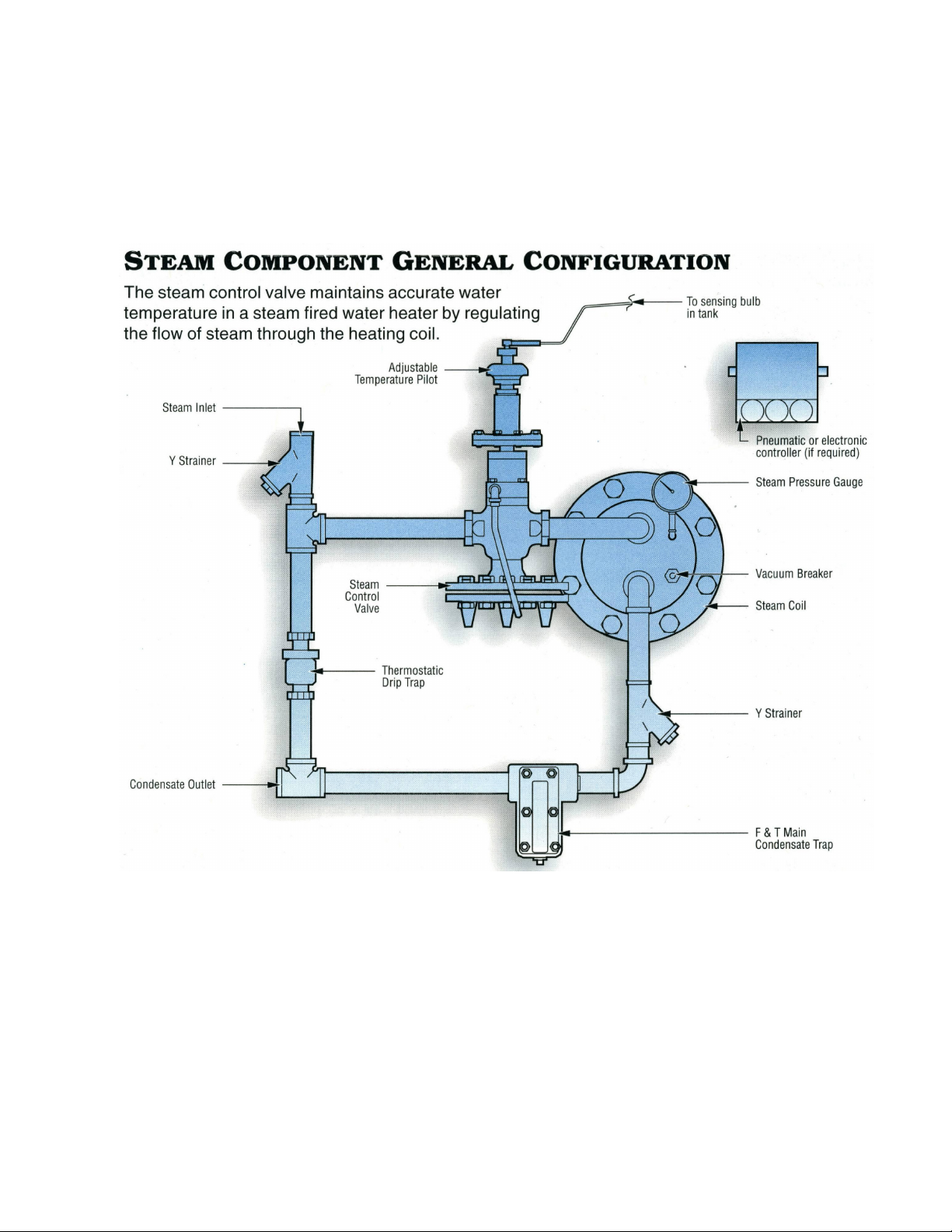

SECTION I - GENERAL DESCRIPTION AND CONSTRUCTION

GENERAL DESCRIPTION

This book describes a packaged steam powered water heater that is a stationary, self-contained unit.

The complete assembly on a standard unit consists of the storage tank, immersion heating coil, steam

regulator, steam drip trap, condensate trap, steam strainer, condensate strainer, vacuum breaker, and

an ASME rated combination temperature and pressure safety relief valve. Optional equipment may

be supplied with your unit. Please consult the product drawing for details specific to your assembly.

The unit is factory assembled, insulated, jacketed, primed, painted, piped, tested, and ready for

service connections.

CONSTRUCTION

TANK

Standard Tank Construction:

The standard storage tank is constructed of all welded carbon steel, designed and built in accordance

with ASME Section VIII and stamped, certified, and registered with the National Board of Boiler and

Pressure Vessel Inspectors. It is internally lined with specially formulated Hydrastone cement to a 5/8inch minimum thickness for superior protection and tank longevity.

Optional Tank Linings:

1. Phenolic – An epoxy coating applied in two coats to a total thickness of 10-12 mils. Typically

used in process applications using low conductivity deionized (DI), distilled, or food grade

water.

2. Copper – A 3lb./sq. ft. copper sheet approximately 0.0646-inches thick covers all interior

surfaces. All copper sheet seams are factory tested to ensure long lasting protection of the steel

vessel.

3. Flame-Spray Copper – Molten copper is sprayed on the interior surfaces to a thickness of 5-6

mils. The copper bonds to the steel, and an additional overcoat of Phenolic lining is applied on

the copper to seal all pores.

4. Galvanizing – The steel pressure vessel is pickled and hot dipped in molten zinc to create a

barrier which internally and externally protects the steel vessel for cold and hot water storage.

Optional Non-Ferrous Tank Materials:

1. Copper-Silicon – A copper-silicon alloy offers tremendous tank longevity due to its ability to

withstand the cycling effects induced from changes in water temperature and pressure. This

material is suitable for storage of hot potable water in a variety of commercial and industrial

applications.

2. 90/10 Copper-Nickel – A 90% copper and 10% nickel alloy similar to copper-silicon, but with

added strength and corrosion resistance. Typically used in applications with corrosive

environments (salt water) or critical applications.

9

Page 10

3. Stainless Steel – Stainless steel (type 304, 316, or 316L) is well suited for high purity

applications requiring a corrosion resistant tank with minimal leaching of impurities into the

water. Well suited for process, RO, and DI water systems in the pharmaceutical, food, and

electronic industries.

TANK CONNECTIONS

The heater is supplied with separate cold water and hot water connections. A connection is provided for

mounting a combination safety temperature and pressure relief valve. An overflow line should be

utilized from the relief valve outlet to a floor drain. See drawing for locations and sizes.

OUTER SHELL, INSULATION, AND SUPPORTS

The tank is encapsulated in 2-inches of high-density fiberglass insulation. The protective shell is

constructed of galvaneel and is coated with a durable silver hammertone finish. The entire vessel is

supported on heavy-duty integrally welded steel supports for sturdy floor mounting.

STEAM HEATING COIL

The water heater is supplied with a high quality factory installed 2-pass U-tube heating coil constructed

from 20-gauge ¾-inch O.D. single wall copper tubing designed for a maximum working pressure of

150 psi. The tubing is installed in a heavy-duty fabricated steel head with threaded NPT steam and

condensate connections. Each assembly is fastened to a corresponding tank flange using a gasket and

hex head steel bolts and nuts. Specialized heating coil construction may be included. These options

include: double wall tubing with a leak detection port, or special materials (stainless steel, 90/10

copper-nickel, other) for the tubes and/or head. See drawing for complete details.

10

Page 11

STEAM OPERATING CONTROLS

The steam operating controls are factory selected, sized, piped, and tested to ensure reliable

operation. Steam controls can be shipped loose, upon request, for in the field installation by others.

All steam components are factory plumbed with schedule 40 black iron pipe and ready for steam and

condensate connections. A cast iron ‘Y’ strainer with 20 mesh screen protects the steam controls and

coil from dirt and debris in the steam supply.

Traps

Two traps should be utilized in the immediate steam piping system of the water heater. The first trap in

the system is a drip trap that is designed to collect condensate from the main steam line before entering

the steam regulator. Additionally, a main condensate trap should be located in the condensate line after

the steam coil. This trap ensures that the steam remains in the coil and releases its energy before exiting

the coil and traveling down the condensate line. There are various types of traps available. The

following may be included in your water heater package:

1. Drip Trap

a. Thermostatic (Standard)

b. Cast Iron Float and Thermostatic type

c. Cast Steel Float and Thermostatic type

2. Main Trap

a. Cast Iron Float and Thermostatic type (Standard)

b. Cast Steel Float and Thermostatic type

c. Bucket

Steam Control Valves

1. Pilot Operated (Standard) – A high quality cast iron pilot operated steam control valve

comes with the standard unit. It is the most widely used type of valve for water heating

applications. In this type of valve, a temperature pilot device utilizes steam to operate the

main valve. No external power source is required other than steam. This highly dependable

temperature control system is suitable for most commercial and industrial applications.

2. Self Operating – This valve design includes a bulb and capillary assembly charged with a

thermally responsive vapor. The expansion / contraction of the vapor acts upon the valve

bellows in order to control the flow of steam through the valve. No external power is required

for operation.

3. Pneumatically Operated – In this configuration the building air supply feeds a factory

installed temperature controller that operates the steam control valve. The temperature

controller sends a precise air signal to the steam control valve which adjusts the flow of

steam into the heating coil. The temperature controller is fully adjustable from 50° - 250 ° F

and requires 20 psi air at a maximum consumption of 0.5 SCFM.

4. Electronically Operated – This control valve is similar to a pneumatically operated system,

except in this case the temperature controller is a sophisticated digital display electronic

device which outputs a 4-20 ma signal to a compact motor mounted on the steam control

valve in order to proportionally control the flow of steam to the heating coil. The temperature

controller displays set point as well as actual water temperature and is available with an

RS485 communications port for remote control.

11

Page 12

OPTIONS

The following optional features may be included in your water heater. Reference the drawing

specific to your heater for further details.

Single Solenoid Safety System

A single solenoid safety system closes the steam supply to the control valve should the temperature

in the tank reach the high limit set point. This option requires 120-volt, 5-amp electrical service.

Double Solenoid Safety System

A double solenoid safety system dumps over heated water in the storage tank to drain in addition to

closing the steam supply to the control valve. This option requires 120-volt, 5-amp electrical service.

Anticipator Control System

The anticipator control system forces incoming cold water over the control valve sensing bulb in

order to begin heating water immediately.

Skid Mounting

Optionally, the unit may be mounted on heavy duty all welded I-beams.

Circulating Pump Package

An intra-tank circulation pump package with On/Off switch to continuously circulate water within the

tank and thereby reduce stratification may be installed. An all bronze circulator pump.

Dial Temperature and Pressure Gauge

A combination temperature (70° - 250° F) and pressure (0 – 200 psi) gauge with 2½-inch dial may be

factory installed in the tank.

12

Page 13

SECTION II – INSTALLATION AND OPERATION

WARNING / CAUTION

DO NOT TURN ON THE STEAM SUPPLY to this unit until heater is completely filled with water

and all air has been released. If the heater is NOT filled with water when the steam supply is turned

on, damage to the heating coil may result.

For protection against excessive pressures and temperatures, local codes require the installation of a

temperature-and-pressure (T&P) relief valve certified by a nationally recognized laboratory that

maintains periodic inspection of production of listed equipment of materials, as meeting the

requirements for Relief Valves and Automatic Gas Shutoff for Hot Water Supply Systems. ANSI

Z21.22-1971. THE CUSTOMER IS RESPONSIBLE TO PROTECT PROPERTY AND

PERSONNEL FROM HARM WHEN THE VALVE FUNCTIONS.

All water heaters have a risk of leakage at some unpredictable time. IT IS THE CUSTOMER'S

RESPONSIBILITY TO PROVIDE A CATCH PAN OR OTHER ADEQUATE MEANS, SO THAT

THE RESULTANT FLOW OF WATER WILL NOT DAMAGE PROPERTY.

If unit is painted or insulated on the job site, care should be taken not to paint or insulate over the

A.S.M.E. nameplate. This plate should be accessible and legible at all times to inspectors, and

information from this plate must be used when ordering parts from the factory.

The tank should be fully drained in the event the steam has been turned off and if there is danger of

freezing. If tank is drained and to be left empty for more than 8 hours, at least 2-inches of water should

be left in the bottom of cement lined tanks to prevent lining from drying and cracking.

WATER HEATER PLACEMENT

1. Adequate space should be provided for removal of heating element.

2. Unit should be level to permit proper drainage

PIPING INSTALLATION

NOTE:

galvanic and stray current is the installation of dielectric fittings/unions. The installation of these

fittings is the responsibility of the installing contractor.

The most effective means for preventing deterioration from accelerated corrosion due to

1. All integral components have been properly sized to meet design conditions. Piping to the

unit should be sized to meet the design conditions, as dictated by good engineering practices.

2. Refer to the enclosed drawing for location of piping connection.

13

Page 14

3. Install the combination temperature and pressure safety relief valve in the tapping provided.

Note that this is required by law for safety considerations.

Outlet to floor drain

Install into provided tapping

Manual Release

Lever

Temperature Probe

4. Install a relief valve overflow pipe to a nearby floor drain. CAUTION: No valve of any type

should be installed between the relief valve and tank or in the drain line.

HOOK-UP OF AIR AND WATER OPERATED CONTROLS

1. Most air or water operated valves on Hubbell water heaters are controlled by Powers

Accritem. Occasionally, a Robertshaw Fultrol is furnished which operates identically to the

Powers control except supply and output connections are reversed in location. Controls are

normally mounted on the back side of the tank shell.

14

Page 15

Typical Piping Diagram

ELECTRICAL INSTALLATION

If the unit is furnished with a pilot or self contained control valve, no external source

1.

of power is required for the valve. (See enclosed operation and maintenance manual

for specific valves).

2. If the unit is furnished with an air or electric control valve, see enclosed drawings for

required connections. (See enclosed operation and maintenance manuals for specific

valves).

3. Torque screws per torque chart included in Section VI.

4. All other electrical connections are made at the factory; therefore, no other electrical

connections are necessary.

15

Page 16

FILLING THE HEATER

1. Begin with all steam, condensate, and water valves closed.

2. Open the isolation valves on the integral circulator line ,if supplied.

3. Open cold water valve, fill unit with cold water. Lift lever on relief valve to relieve trapped

air. Release relief valve lever when all traces of air have been vented from the unit. Leave

cold water valve open.

STARTUP

1. Turn pump switch to the “ON” position, if supplied. (Do not operate pump without unit being

2. Set control valve thermostat to approximately 30° F below desired temperature, observe unit,

3. If unit has a safety system, set hi-limit thermostat to desired temperature. (This thermostat

4. Gradually open valve to allow heating medium to enter the heating element. (Boiler water

5. After control valve adjustments have been made and the desired temperature has been

6. Tightening of some gasketed joints may be required after unit has been heated.

7. Never break any joint, gasketed or screwed on unit until the pressure in the unit has been

8. Observe operation of unit for 30-40 minutes after initial start up.

filled with water and isolation valves being opened, as damage to the pump could result).

if unit operates properly gradually raise set point to desired set point.

must be set at a higher temperature than the operating thermostat or the unit will never reach

the desired temperature). Refer to the enclosed piping and wiring drawings.

lines should be vented to eliminate trapped air). Monitor the tank temperature until the

desired temperature is reached. If the temperature regulator shuts off before the desired

temperature is reached, or if over-shoot occurs, adjustment of the temperature regulator will

be required. (Refer to enclosed O&M manuals for your specific control valve).

reached, open the valve on the hot water outlet and the building recirculation line.

reduced to zero and the unit drained.

16

Page 17

SHUTDOWN

1. Close valve to heating medium and air supply valve, if air operated controls are furnished

2. Disconnect all electrical power to unit.

3. Close hot water outlet valve.

4. Close building recirculation inlet valve, and shut down building circulation pump.

5. Close cold water inlet valve.

6. Turn off pump, if supplied.

7. Drain unit by lifting lever on relief valve to vent tank, then slowly open drain valve.

17

Page 18

SECTION III - SCHEDULED MAINTENANCE AND SERVICING

WARNING / CAUTION

Before performing any maintenance procedure, make certain steam supply and electrical power

supply is OFF and cannot accidentally be turned on.

QUARTERLY INSPECTION

1. Monitor thermostat

a. Let water heater completely heat to a designated thermostat setting.

b. After thermostat satisfies (that is, when the thermostat actually clicks off), draw water from

heater.

c. Compare water temperature of drawn water to the temperature setting of the thermostat

when it satisfies. Normal variation between the two points is approximately + 5°F.

d. If these two readings do not coincide within acceptable tolerances and verification has

been made of the accuracy of the temperature-reading gauge, replace the thermostat.

2. Lift test lever on relief valve and let water run through valve for a period of approximately 10

seconds. This will help flush away any sediment that might build up in water passageways.

ANNUAL INSPECTION

1. Units subject to fouling or scaling should be cleaned periodically. A marked increase in

pressure drop and/or reduction in performance usually indicates cleaning is necessary.

2. To clean inside of tubes, remove all heads and covers. (Caution: Do not loosen heads until

you are sure all pressure is off the equipment, and the unit is drained).

3. In cleaning a tube bundle, tubes should not be hammered on. If it is necessary to use scrapers,

care should be taken to insure that the tubes are not damaged.

4. Before it is necessary to apply mechanical means for cleaning, try to clean the unit using the

following methods.

a. Circulate hot fresh water at a reasonable velocity.

b. Try spraying with water hose.

c. Consult with manufacturers of cleaning compounds and chemicals. They will check the

nature of the deposit, recommend the right cleaning compound, and in many cases

provide equipment and personnel for a complete cleaning job.

5. Do not clean tubes by blowing steam through individual tubes.

6. To tighten a loose tube joint, use a suitable roller type tube expander. Do not roll tubes that

are not leaking. If double wall tubes are supplied return to the factory for repairs.

7. If the unit is dismantled for any reason, it should be reassembled using new gaskets.

8. Do not tighten bolts until gaskets are properly seated.

9. Exterior of unit should be cleaned and if necessary repainted.

10. When tightening bolts in the element head, tighten the bolts in a criss-cross pattern. This will

evenly distribute pressure around the flange, and help prevent warping. See diagram below.

18

Page 19

11. Convection packages may be equipped with an integral circulator. This circulator should be

serviced per the enclosed pump O&M manual.

12. The unit as well as all strainers should be blown down regularly to remove any trash, and

sediment that may have accumulated.

13. If unit is supplied with anode rod, it shall be inspected for excessive wear.

14. Packing on valves and regulators should be checked for leaks and repaired or replaced as

necessary.

15. To seal the manhole gasket, first install the cover, crab, new gasket, bolt and nut. Turn the

nut until it is snug against the crab, then turn 1 ½ revolutions. Fill the tank with water and

allow pressure to build up, letting the water pressure seal the gasket. (Some leakage may

19

Page 20

occur at this point, but as the gasket seats, leaking will gradually stop). After leaking has

stopped, turn the nut approximately 1 revolution. At this point there may be some miner

seepage, wait a few minutes to see if this seepage stops. If seepage continues drain the tank,

inspect the manhole ring, and cover for any damage, (repair or replace as required) Repeat

the above procedure using a new gasket.

Never try to seal the cover solely by turning the nut down tight this may cut or crush

the gasket and make sealing impossible.

16. Drain and flush tank as follows. Perform annually or more often , if required. NOTE: Cement

lining is a durable lining that will provide many years of service protecting your steel

pressure vessel from corrosion. The process of cement lining includes an inspection to ensure

that the lining is applied to the correct thickness, covers all appropriate surfaces, and is free

from defects or cracks greater than 3 mm (1/8”) in width. Any deficiencies are repaired at the

factory prior to shipment. However, it is characteristic to find hairline cracks in the cement

lining prior to initial installation. After the vessel is first filled, the water will work its way

into these cracks and begin the corrosion process. At the same time the cement lining

undergoes a “wet curing” process whereby the cement absorbs water and expands. The water

that is absorbed into the lining becomes trapped between the cement lining and the steel tank

and once the cement is fully absorbed with water, the water in contact with the steel tank

becomes deoxygenated which serves to protect the steel vessel. In addition, the cement

leaches minerals and various impurities from the water which fills and “heals” the cracks.

This “healing” together with the “wet curing” and expansion of the cement prevents any

ongoing corrosion. In the unlikely event a crack greater than 3 mm (1/8”) develops, the

cement lining can be easily repaired in the field. For repair procedures please contact Hubbell

a. Shut down unit as described in Section II.

b. Close valve on hot water outlet piping.

c. Open valve on drain piping.

d. Cold water inlet line pressure will be strong enough to flush sediment from the bottom of

the tank out through the drain. Let water run for 3-4 minutes.

e. Clean strainer filter, see below.

f. Close drain valve.

g. Open hot water valve.

h. Re-start unit as described in Section II

.

17. Clean strainer filter. Perform annually or more often , if required.

a. Remove blowoff bushing (E) or cap (F), as required.

b. Remove gasket (B), if required.

c. Remove, clean, and re-install screen (A).

d. Replace gasket (B).

e. Re-install blowoff bushing (E) or cap (F), as required.

20

Page 21

21

Page 22

22 23

Page 23

SINGLE SAFETY SOLENOID SYSTEM (if installed)

Page 24

DOUBLE SAFETY SOLENOID SYSTEM (if installed)

24

Page 25

SECTION IV – ADJUSTMENT OF TEMPERATURE REGULATORS

1. The spring tension on temperature regulators is adjusted at the factory to meet design

conditions. However, design conditions may vary from actual operating conditions and readjustment might be required on this job.

2. Whenever possible, Hubbell uses “fail safe” regulators. This means that if the controlling

medium, such as air or water is lost, the valve will close under it’s own spring tension.

3. ADJUSTMENT OF 2-WAY AIR OR WATER OPERATED VALVES

a. Release all air pressure from the diaphragm.

b. Apply steam pressure to the valve.

c. If at this point, there is pressure on the downstream side of the valve, or if steam can be

heard passing through the valve, valve spring tension needs to be increased.

d. Turn the spring adjustment screw slowly to increase spring tension until the pressure on

the down stream side of the valve has dropped to “0” and there is no sound of flow

through the valve. Do not turn spring adjustment past this point.

If the valve will not open with air on the diaphragm, spring is adjusted too tightly.

(1) Release all air pressure from the valve diaphragm.

(2) Apply steam pressure to the valve.

(3) Loosen tension on the spring until steam begins to seep through the valve.

(4) Slowly, tighten spring tension until flow stops.

(5) Do not turn spring adjustment past this point

4. ADJUSTMENT OF 3-WAY AIR OR WATER OPERATED VALVES

a. Turn thermostat down so that no air pressure is on the valve diaphragm. If unit continues

to heat, valve spring tension needs to be increased.

b. Shut off heating medium.

c. Disconnect stem coupling (A).

d. Lift lower stem (B) and hold against upper valve seat.

e. Turn adjustment screw (C) until there is approximately a 1/16-inch gap between the two

stem halves.

.

25

Page 26

f. Apply air pressure to valve diaphragm so that stem halves are aligned and re-connect

stem halves.

g. If valve will not open with air on the diaphragm, spring tension should be decreased.

h. Adjustment is essentially the same as if spring tension were increased except the

adjustment screw is turned in the opposite direction.

5. ADJUSTMENT OF PILOT OPERATED VALVES

a. Pilot operated valves such as Spence or Spirax/Sarco are not fail safe. These valves have

a liquid or gas filled thermo-static bulb and if this bulb loses its charge, the valve will go

to its full open position and cause overheating of the water heater. This situation should

be considered before attempting to adjust these valves.

b. Spirax/Sarco Valves

adjustment. Set the thermostat at the desired temperature and no further adjustment is

required.

26

are completely pre-set at the factory and there is no spring

Page 27

c. Spence Valves: There is no main spring adjustment on Spence Valves. To set temperature

on the water heater:

(1) Turn pilot spring adjustment “A” clockwise until all tension is off the spring.

(2) Refer to unit start-up section and start unit except for thermostat setting.

(3) Turn spring adjustment “A” counter-clockwise until the wheel is firmly against the

spring.

(4) Continue to turn wheel “A” one 360° turn or until steam begins to pass thru the valve.

(5) Allow unit to heat until the valve closes off.

(6) If unit is not up to temperature at this point, continue to turn adjustment wheel ½ turn,

stop and allow valve to shut off.

(7) Repeat this cycle until unit is up to the desired temperature.

27

Page 28

Symptom Probable Cause Corrective Action / Remedy

Gradual loss of heating

capacity.

SECTION V – TROUBLESHOOTING

(See separate component O&M for additional details.)

Tubes are fouled. Clean tubes per Section III, annual

scheduled maintenance.

Excess silt in bottom of tank. Drain and flush tank per Section III ,

annual scheduled maintenance.

Air or water leak in

temperature control.

Ruptured diaphragm on air

or water operated valve.

Debris in Accritem. Clean Accritem.

Strainers clogged. Clean strainers per Section III, annual

Pump impellor deteriorated. Repair or replace per separate O&M.

Repair or replace per separate O&M.

Repair or replace per separate O&M.

scheduled maintenance.

Overheating.

Immediate loss of heating

capacity.

Temperature regulator has

lost its charge, self contained

valves only.

Ruptured tube(s) in heating

coil.

Temperature regulator needs

adjusting.

Circulator not operating. Repair or replace per separate O&M.

Debris under seat of

temperature control valve.

Capillary tube pinched on

temperature control.

Rib blown out of tube side

gasket.

Capillary tube pinched on

temperature control.

Ruptured diaphragm on

temperature control valve.

Defective steam trap. Repair or replace per separate O&M.

Blockage in condensate line. Clean blockage from condensate line.

Loss of air pressure on

temperature regulator.

Repair or replace per separate O&M.

Remove / replace heating coil.

Adjust temperature regulator per

Section IV.

Repair or replace per separate O&M.

Repair or replace per separate O&M.

Remove heating coil and replace

gasket.

Repair or replace per separate O&M.

Repair or replace per separate O&M.

Check air pressure to temperature

regulator. Verify that it is within

limits. Adjust as necessary.

28

Page 29

High rate of flow beyond

design conditions.

Under sized piping to the

unit.

Water hammer.

* Red symptom indicates that equipment should be shut down immediately and cause of malfunction

corrected before unit is re-started or serious damage may result.

Defective steam trap. Repair or replace per separate O&M.

Undersized condensate lines. Re-pipe condensate line using proper

Insufficient slope on

condensate lines causing

backup.

Consult factory. Excessive vibration.

Re-pipe lines to unit using proper

sized lines.

sized lines.

Increase slope on condensate lines.

29

Page 30

SECTION VI – MISCELLANEOUS CHARTS AND FORMULAS

TORQUE VALUES

BOLT SIZE

4-40

4-48 6.6 5.4 6.1 3.6 6.9 6.7

5-40 7.7 6.3 7.1 4.2 8.1 7.8

5-44 9.4 7.7 8.7 5.1 9.8 9.6

6-32 9.6 7.9 8.9 5.3 10.1 9.8

6-40 12.1 9.9 11.2 6.6 12.7 12.3

8-32 19.8 16.2 18.4 10.8 20.7 20.2

8-36 22.0 18.0 20.4 12.0 23.0 22.4

10-24 22.8 18.6 21.2 13.8 23.8 25.9

10-32 31.7 25.9 29.3 19.2 33.1 34.9

1/4-20 75.2 61.5 68.8 45.6 78.8 85.3

1/4-28 94.0 77.0 87.0 57.0 99.0 106.0

5/16-18 132 107 123 80 138 149

5/16-24 142 116 131 86 147 160

3/8-16 236 192 219 143 247 266

3/8-24 259 212 240 157 271 294

7/16-14 376 317 349 228 393 427

7/16-20 400 327 371 242 418 451

1/2-13 517 422 480 313 542 584

1/2-20 541 443 502 328 565 613

9/16-12 682 558 632 413 713 774

9/16-18 752 615 697 456 787 855

5/8-11 1110 907 1030 715 1160 1330

5/8-18 1244 1016 1154 798 1301 1482

3/4-10 1530 1249 1416 980 1582 1832

3/4-16 1490 1220 1382 958 1558 1790

7/8-9 2328 1905 2140 1495 2430 2775

7/8-14 2318 1895 2130 1490 2420 2755

1-8 3440 2815 3185 2205 3595 4130

1-14 3110 2545 2885 1995 3250 3730

18-8 S/S

IN.-LBS.

5.2 4.3 4.8 2.9 5.5 5.3

BRASS

IN.-LBS.

SILICON

BRONZE

IN.-LBS.

ALUMINUM

2024-T4

IN.-LBS.

316 S/S

IN.-LBS.

MONEL

IN.-LBS.

30

Page 31

METRIC CONVERSIONS

31

Loading...

Loading...