Page 1

INSTALLATION and MAINTENANCE INSTRUCTIONS

S-32 DIRECT DRIVE ELECTRIC CABLE REELS

All units are provided with right hand rotation unless otherwise

specified. This means that cable is pulled off spool top left or

bottom right (spool rotates clockwise to wind cable) when

viewing spring end of reel. See diagram on parts page.

Clock-type springs provide power for automatic cable take-up.

Spring must be pretensioned at time of installation to

insure that tension is applied to cable at all times. Atension

adjustment spanner wrench is provided with each reel.

WARNING

Some reels with large or multiple springs are equipped with a

ratcheted adjustment wrench. Follow separate instructions

for its use. Failure to use ratcheted wrench, on reels so

equipped, could result in serious personal injury.

WARNING

Do not attempt to relieve spring tension using spanner

wrench. Doing so may result in personal injury.

INSTALLATION

1. Insure that machinery to be serviced by reel is at position

closest to reel.

2. Securely mount reel in desired position using 3/8"(M10)

bolts. Be sure spool is aligned with cable run.

3. Position optional cable guide, if reel is so equipped.

See CABLE INSTALLATION DRAWING.

4. Unspool cable from reel, without allowing spool to rotate, so

that desired length of cable extends from reel. Do not pull

cable directly off reel as this will apply tension to the spring

and may cause overtensioning when the reel is put into

service. Connect free end of cable to junction box on

machine or adjust cable stop

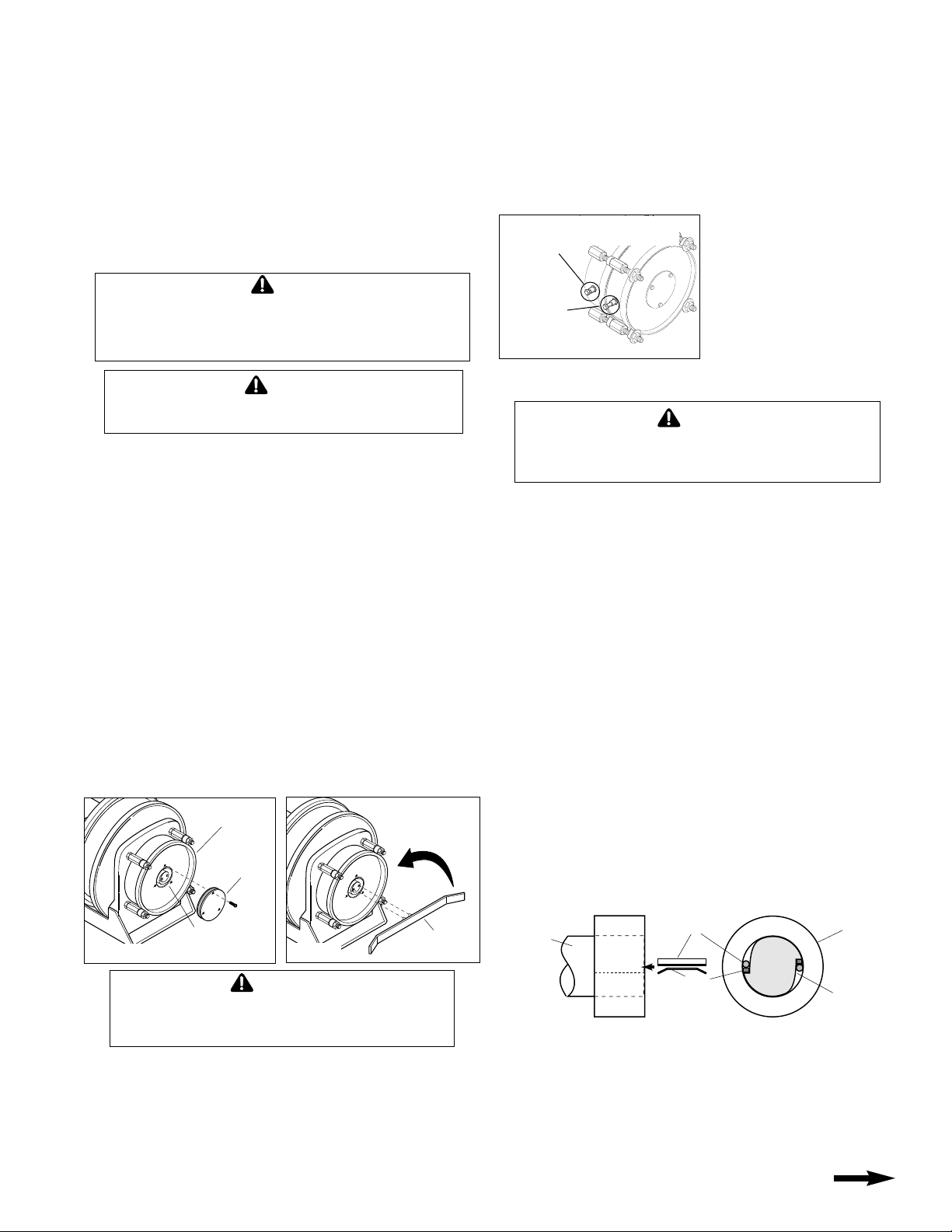

5. Remove cover plate on spring housing to expose

shaft and spring hub. (See Figure 1).

6. Insert spanner wrench into holes in spring hub (Fig 2).

Rotate wrench counterclockwise (for standard rotation).

Number of 360

number on serial plate.

O

turns should match last digit in model

If model number includes an “R”,

reel is reverse rotation and wrench must be rotated

clockwise.

Figure 1

(See EXPLANATION on parts list page.)

SPRING

HOUSING

SPRING

HUB

COVER

PLATE

Figure 2

COUNTER-

CLOCKWISE

FOR STANDARD

ROTATION

SPANNER

WRENCH

CAUTION

Do not exceed number of turns indicated on serial plate.

Over-tensioning can cause a broken spring,

sheared shaft or other damage.

NOTE: If reel is equipped with ratcheted adjustment

wrench, follow instructions on separate sheet.

NOTE: On reels containing more than one spring, the hubs

are connected at the factory. Therefore, by tightening the

outer spring, the inside spring(s) will be tightened.

7. Remove collector cover and connect individual supply

conductors to collector terminals. See ELECTRICAL

CONNECTIONS diagram, on parts page.

MAINTENANCE

Periodically: A. Use compressed air to clean collector

assembly and inside of collector housing. Inspect collector

assembly for brush wear and pitted slip rings.

B. Inspect cable for wear and check mounting bolts and

“IN” with 2/3

cable off reel–

SPRING OK

BROKEN SPRING

INDICATORS

other hardware for tightness.

C.Check for broken springs

by pulling about 2/3 cable off

reel and observing “Broken

“OUT” with 2/3

cable off reel–

SPRING

BROKEN

Figure 3

Spring Indicators” on sides of

spring canisters. See Fig. 3.

NOTE: Bearings and springs

are prelubricated and require

no periodic maintenance.

SPRING REPLACEMENT

WARNING

Do not attempt to remove spring from its housing. Clock-

type springs can be dangerous to handle. Removal of

spring from housing could result in personal injury.

The unique SAFETYCHANGE® spring motor consists of a

spring and hub sealed within a housing. Areplacement spring

is supplied sealed in its housing and the old unit should be discarded completely.

1. Turn off all electric power.

2. Disconnect cable from machine junction box.

3. Wind all cable onto reel to relieve all spring tension.

4. Remove inspection cover from face of spring housing.

5. Rotate spool clockwise and observe inner shaft. Shaft

should rotate clockwise and hub (with spring attached)

should remain stationary.

NOTE: Do not attempt to remove spring if resistance

is met or hub tends to rotate with shaft.

Continue to rotate spool and strike end of shaft with a rubber

mallet until shaft rotates freely and hub remains stationary.

6. Remove (4) nuts which secure spring motor(s) to frame.

7. Slide spring motor(s) off shaft and discard.

NOTE: On multi-spring reels, be sure to remove and save

dowel pins which connect one spring hub with another. Also

remove snap rings on shaft between spring housings.

8. Install replacement spring motor(s), pawls and pawl springs.

NOTE: Pawl springs must be located between the pawls

and the deepest section of the shaft grooves. Make sure

that pawls and pawl springs are inserted flush with ends of

shaft and hub or they may rub against inspection cover.

SPOOL

SHAFT

SIDE VIEW

PAWL

SPRING

Install

against flat

END VIEW

9. Tighten nuts (and extension bolts) securing spring

housing(s) to reel frame.

10. Connect free end of cable to junction box on machine or

adjust cord stop so that desired length of cord extends from reel.

11. Tension spring with spanner wrench. Refer to

INSTALLATION section.

12. Replace inspection cover.

CONTINUED ON BACK PAGE

SPRING

HUB

(Spring not

shown)

SHAFT

GROOVE

Page 2

1

2

3

4

5

6

7

8

9

10

11

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

1

2

3

1

3

1

1

1

11

11

11

11

7

20

14

20

19

15

15

11

12

11

12

11

12

11

12

8

8

TO DETERMINE ROTATION OF REEL

STANDARD REVERSE

ROTATION ROTATION

Cable is payed out and retracted as shown

when viewing reel from spring motor side.

ILLUSTRATED PARTS LIST

S-32 DIRECT DRIVE ELECTRIC CABLE REELS

ELECTRICAL CONNECTIONS

LEADWIRE INPUT FIXED END

(CUSTOMER SUPPLIED)

BRUSH TERMINAL

CONNECTIONS

1

1

SLIP–RINGS

432

32

SLIP-RING

LEADWIRES ARE

NUMBER TAGGED

SLIP-RING LEAD TO

MOVING CABLE

CONNECTIONS

SLIP–RING

COVER

SLIP–RING ENCLOSURE

•

600 VOLTAC. 250 VOLT DC. WATERTIGHT, DUSTTIGHT.

•

DO NOT EXCEED AMPERAGE RATING OF CABLE OR SLIP RING.

• NUMBER OF CIRCUITS MAY VARY FROM TWO (MINIMUM) TO 36 (MAXIMUM). FOUR CIRCUITS SHOWN.

4

FRAME

SCREW

COLLAR

SET

Always specify SERIAL NUMBER &

MODEL NUMBER when ordering parts.

CABLE LEADWIRES

MOVING END

CABLE

WATER–TIGHT

CABLE GRIP

SPOOL

REEL

MAINSHAFT

NOTE:

Wire size, wire connectors, connection

sequence, and connection methods must comply

with National Electrical code and Local Electrical

ordinances. If in doubt, contact a local electrical

contractor or electrical inspector.

COLOR SEQUENCE FOR TYPE SO CABLE

THREE CONDUCTOR CABLE

# 1 – BLACK

# 2 – WHITE

# 3 – GREEN (ground)

FOUR THRU TWELVE CONDUCTOR CABLE

# 1 – BLACK

# 2 – WHITE

# 3 – RED

# 4 – GREEN (ground)

# 5 – ORANGE

# 6 – BLUE

# 7 – WHITE W/ BLACK TRACER

# 8 – RED W/ BLACK TRACER

# 9 – GREEN W/ BLACK TRACER

#10 – ORANGE W/ BLACK TRACER

#11 – BLUE W/ BLACK TRACER

#12 – BLACK W/ WHITE TRACER

Page 3

S-32 DIRECT DRIVE ELECTRIC CABLE REEL REPLACEMENT PARTS LIST

NOTE: Applicable mounting hardware included with each kit.

ITEM KIT NO. DESCRIPTION QTY.

1 041033 Frame Assembly 1

2 041034 Discs (Set of two) 1

3 041035 Main Shaft Assembly 1

(Includes drive pin and retaining rings)

4 012402 Bearing Kit–2" Bore 1

(Includes housing and gasket)

5 012401 Bearing Kit–1.75" Bore 1

(Includes housing and gasket)

6 012456 Drive Stud Kit 1

7 012209 Stub Shaft, Std. Rot. (801) 1

7 01220901 Stub Shaft, Rev. Rot. (801) 1

7 012210 Stub Shaft, Std. Rot. (802) 1

7 01221001 Stub Shaft, Rev. Rot. (802) 1

7 012211 Stub Shaft, Std. Rot. (803) 1

7 01221101 Stub Shaft, Rev. Rot. (803) 1

7 012212 Stub Shaft, Std. Rot. (804) 1

7 01221201 Stub Shaft, Rev. Rot. (804) 1

7 012213 Stub Shaft, Std. Rotation (1001) 1

7 01221301 Stub Shaft, Rev. Rotation (1001) 1

7 012214 Stub Shaft, Std. Rotation (1002) 1

7 01221401 Stub Shaft, Rev. Rotation (1002) 1

7 012371 Stub Shaft, Std. Rotation (1003) 1

7 01237101 Stub Shaft, Rev. Rotation (1003) 1

7 014619 Stub Shaft, Std. Rotation (1004) 1

7 01461901 Stub Shaft, Rev. Rotation (1004) 1

8 012418 Wrapper Kit–7" Wide, 8" to 14" Dia. 1

(Includes 4 wrapper sections)

8 012419 Wrapper Kit–7" Wide, 15" to 20"Dia. 1

(Includes 8 wrapper sections)

9 012444 Cable Clamp Kit .38–.74 Dia. Cable 1

(U-bolt with lockwashers and hex nuts)

9 012445 Cable Clamp Kit .75–1.11 Dia. Cable 1

9 012446 Cable Clamp Kit 1.12–1.50 Dia. Cable 1

10 012459 Cable Connector .38–.50 Cable Dia. 1

10 012460 Cable Connector .50–.62 Cable Dia. 1

10 012461 Cable Connector .62–.75 Cable Dia. 1

10 012462 Cable Connector .75–.88 Cable Dia. 1

10 012463 Cable Connector .88–1.00 Cable Dia. 1

10 012464 Cable Connector 1.00–1.12 Cable Dia. 1

10 012465 Cable Connector 1.12–1.25 Cable Dia. 1

10 012466 Cable Connector 1.25–1.38 Cable Dia. 1

10 012467 Cable Connector 1.38–1.50 Cable Dia. 1

11 017049 Spring Motor Kit, Std. Rot.–80 ar

(Includes pawl, pawl springs, cover, gaskets, and snap ring)

11 017050 Spring Motor Kit, Rev. Rot.–80 ar

11 017051 Spring Motor Kit, Std. Rot.–100 ar

11 017052 Spring Motor Kit, Rev. Rot.–100 ar

12 012426 Pawl Kit (80 Springs) ar

(Includes 2 pawls and springs)

12 012427 Pawl Kit (100 Springs) ar

13 012091 Spool Lock Kit 1

ITEM KIT NO. DESCRIPTION QTY.

14 032805 Ratchet Wrench Kit (80 Springs) 1

14 032804 Ratchet Wrench KIt (100 Springs) 1

15 017054 Extension Bolts (80 Springs) ar

15 017055 Extension Bolts (100 Springs) ar

16 016182 Carriage Bolt, .50–13 x 1.5 ar

17 021291 Lockwasher, .56 Med., Z.P. ar

18 100959 Hex Nut, .50–13, Z.P. ar

19 101211 Flat Washer, .50 ar

20 P06-03 ESNA Lock Nut, .50–13, Z.P. ar

21 021762 Hub Lock Pins (100 Springs) ar

21 021761 Hub Lock Pins (All Other Springs) ar

22 012457 Button Plug 1

23 012285 Collector Assembly, 2 Pole, 35 Amp 1

23 012286 Collector Assembly, 3 Pole, 35 Amp 1

23 012287 Collector Assembly, 4 Pole, 35 Amp 1

23 012288 Collector Assembly, 6 Pole, 35 Amp 1

23 012289 Collector Assembly, 8 Pole, 35 Amp 1

23 012290 Collector Assembly, 10 Pole, 35 Amp 1

23 012291 Collector Assembly, 12 Pole, 35 Amp 1

23 012292 Collector Assembly, 14 Pole, 35 Amp 1

23 012293 Collector Assembly, 16 Pole, 35 Amp 1

23 012294 Collector Assembly, 20 Pole, 35 Amp 1

23 012295 Collector Assembly, 24 Pole, 35 Amp 1

23 012296 Collector Assembly, 30 Pole, 35 Amp 1

23 012297 Collector Assembly, 36 Pole, 35 Amp 1

23 012298 Collector Assembly, 2 Pole, 75 Amp 1

23 012299 Collector Assembly, 3 Pole, 75 Amp 1

23 012300 Collector Assembly, 4 Pole, 75 Amp 1

23 012376 Collector Assembly, 6 Pole, 75 Amp 1

23 012377 Collector Assembly, 8 Pole, 75 Amp 1

23 037194 Collector Assembly, 2 Pole, 125 Amp 1

23 037294 Collector Assembly, 3 Pole, 125 Amp 1

23 037295 Collector Assembly, 4 Pole, 125 Amp 1

23 012304 Collector Assembly, 2 Pole, 200 Amp 1

23 012381 Collector Assembly, 3 Pole, 200 Amp 1

23 012382 Collector Assembly, 4 Pole, 200 Amp 1

23 012383 Collector Assembly, 6 Pole, 200 Amp 1

23 012384 Collector Assembly, 8 Pole, 200 Amp 1

24 012440 Brush Kit (35 Amp) ar

24 012441 Brush Kit (75 Amp) ar

24 012443 Brush Kit (125 Amp/200 Amp) ar

25 012409 Collector Cover Kit (8" long) 1

25 012410 Collector Cover Kit (10.5" long) 1

25 012411 Collector Cover Kit (13" long) 1

25 012412 Collector Cover Kit (15.5" long) 1

25 012413 Collector Cover Kit (20.5" long) 1

25 012414 Collector Cover Kit (28.5" long) 1

26 012458 Seal Ring (only) 1

27 Snap Ring 1

(Includes mounting bolts)

(4 bolts per kit–less hardware)

(Each kit includes 4 brushes and 4 fingers)

(Includes seal ring)

Please consult factory for optional accessories: roller guides, ratchet lock, limit

switch, hoop guides, spool lock, and swivel base.

NOTE:

MODEL NUMBER EXPLANATION

SPRING

REEL

FRAME

SERIES

SPRING

SERIES

NO. OF

SPRINGS

NO. OF

POLES

AMPACITY

CORE

DIAMETER

PRETENSION

S 32 80 2 R - 12 3 10 - 1

INDICATES REVERSE ROTATION.

NO LETTER INDICATES STANDARD ROTATION.

TURNS

AMPACITY

CODE

3

7

12

20

AMPS

35

75

125

200

Page 4

CABLE REMOVAL

Use the following procedure to remove worn or damaged cable

from reel prior to installation of new cable.

CAUTION

Failure to relieve all spring tension prior to removing

cable could result in damage to equipment or personal

injury. Follow instructions carefully.

1. Move machine serviced by reel to a position closest to

reel. Springs will still be under pre-tension at this point.

2. Turn off all electric power.

3. Lock spool to prevent turning using either a spool lock

mechanism or by tying off.

4. Disconnect cable from machine junction box.

5. Grip spool by hand and carefully release spool lock or

tie. Slowly unwind remaining tension.

6. Again lock or tie spool to prevent rotation.

7. Remove cable from spool. Loosen U-bolt and water-tight

connector and disconnect conductors from slip ring.

8. Install new cable following instruction at right.

CABLE INSTALLATION

Use the following procedure to replace cable or if reel was

ordered without cable. Refer to CABLE INSTALLATION

REFERENCE DRAWING, below.

1. Unspool new cable from shipping spool and lay out

to eliminate twist.

NOTE: This step is not essential, but will aid in winding

operation of the reel and prolong cable life.

2. Feed one end of the cable through water-tight connector on

the main shaft inside the spool and into the slip ring side.

(See drawing below).

NOTE: This may require that jacket of cable be stripped

to allow conductors to pass through shaft.

3. Connect individual conductors to appropriate rings on

collector using crimp fitting or similar connection method.

4. Tighten water-tight connector and U-bolt provided on

drum wrapper segments. Do not over-tighten.

5. Wind the cable onto the reel spool by hand rotating

spool in direction it turns free of spring tension.

6. Connect free end of cable to machine junction box.

7. Pretension reel and complete installation as

previously described.

COLLECTOR REPLACEMENT

1. Turn off all power to reel.

2. Remove collector cover and gasket.

3. Disconnect electric leads to and from collector.

4. Remove drive stud bolt from bearing housing.

5. Remove button plug from hole in side of housing. Insert

long 1/8” Allen wrench through hole and loosen two set

screws in collector locking collar Set screws are at 90

O

to one another..

NOTE: Older reels may have lock screws which must be

removed to reach set screws holding collector to shaft.

6. Slide collector off shaft.

7. Install new collector by reversing above steps.

CABLE INSTALLATION REFERENCE DRAWING

TERMINATE THIS END TO

MACHINE JUNCTION BOX

ATTACH INDIVIDUAL

CONDUCTORS TO

COLLECTOR LEADS

ATTHIS END

COLLECTOR

COVER

REMOVE

LINE

ENTRANCE

(NPT)

SLIP RING

ASSEMBLY

HUBBELL

BUTTON

PLUG

®

®

A Hubbell Company

INSTALLCABLE

THIS DIRECTION

CABLE

U-BOLT

WATER- TIGHT

CONNECTOR

MAIN SHAFT

POSITION CABLE

GUIDE (OPTIONAL)

SO THAT ROLLER

PLATE FACES CABLE

PAYOFF DIRECTION.

PAYOFF

DIRECTION

SPRING MOTOR

HOOP GUIDE

(OPTIONAL)

SPOOL

GLEASON REEL CORP.

P.O. Box 26 • 600 South Clark St

Mayville, WI 53050–0026

Phone 920–387–4120

Fax 920–387–4189

SPOOL ROTATION DIRECTION

TO WIND CABLE WHEN

VIEWED FROM SPRING SIDE

(STANDARD ROTATION)

PAYOFF

DIRECTION–

OPTIONAL

GUIDE

LOCATION

PRETENSION

HUB

SPRING

MOTOR

PAYOFF

DIRECTION–

OPTIONAL

GUIDE

LOCATION

Printed in USA

Bulletin No. 041103.a

Loading...

Loading...