Page 1

INSTALLATION and MAINTENANCE INSTRUCTIONS

TMR SERIES ELECTRIC CABLE REELS

DESCRIPTION

The TMR series reel is designed to automatically lift and

retrieve electric cable. The reel incorporates a rotating hollow

shaft with spool mounted outboard on one end and collector

assembly on the opposite end. The main shaft, rotating on

two flange block bearings, is driven by an electric torque motor

through a chain drive. The torque motor has an electronically

released break holding the spool stationary when the reel is

not in use.

INSTALLATION

1. Thoroughly inspect reel upon receipt for damage that may

have been caused in shipping.

2. Mount reel with the main shaft horizontal and level and

with the spool centerline in line with the cable tray. Mount

at recommended height so that proper distance from the

center of the spool to the cable tray is maintained.

CAUTION

Exceeding designed lift distance may lead

to poor cable spooling and

erratic operation because the electric motor

will have insufficient torque.

3. Remove collector cover. Connect conduit to line entrance

of collector housing and connect wires to brushes of

collector assembly. Brush terminals are number coded.

Be careful that incoming wires do not put strain on brush

terminals and cause brush misalignment. Replace

collector cover.

4. Connect motor to electric line of proper specification as

stamped on motor nameplate. Refer to wiring diagram

(below, in terminal box or on name plates. 3-lead

polyphase and 2-lead single phase do not require

diagram). Provide suitable overload protection based on

full load ampere rating shown on nameplate as

recommended by control manufacturer. Protect wiring circuit

with proper fuses selected according to local codes.

OPERA TION

The reel is activated when power is supplied to the torque

motor through the main starting control of the equipment.

Care should be taken to see that all electrical connections are

made before power is turned on to the collector ring and

torque motor. All nuts and bolts should be checked to see that

they are tight. Check to make sure collector ring brushes are

aligned on rings.

MAINTENANCE

GENERAL LUBRICATION: All bearings provided with grease

fittings are lubricated at the factory before shipment. They

should be regreased periodically depending on the running

time of the reel, more often if used in dusty conditions. Parts

with bearing assemblies not provided with grease fittings are

equipped with sealed bearings and do not require lubrication.

CHAIN CASE: Every three months, remove cover from chain

case, check chain tension, and lubricate chain using a lithium

based heavy duty chain lubricant.

TORQUE MOTOR GEAR REDUCER: See section 5.2.2 of

the enclosed brake motor operation instructions for grease

lubrication. This gear reducer is filled with grease when used

with 600 RPM torque motor.

TORQUE MOTOR: Reel is equipped with a Demag torque

motor. See enclosed brake motor operation instructions.

INSPECTION: Every six months inspect entire reel to see that

all nuts, bolt, screws, and set screws are in place and tight and

that no parts show undue wear. Yearly (more often depending

on duty cycle), check brushes on collector rings. Replace

brushes when worn to the shunt

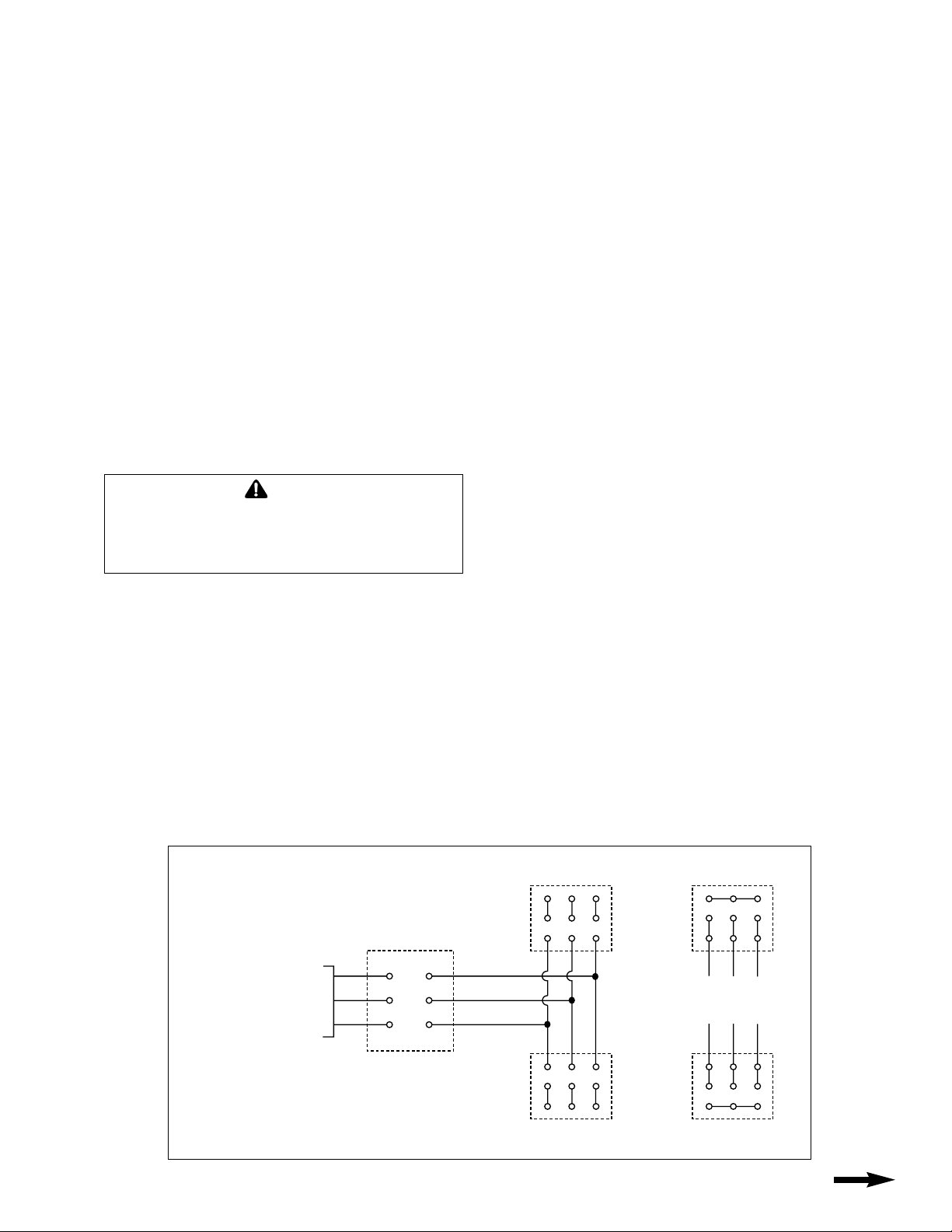

WIRING DIAGRAM

REEL MOTOR

CONTROL PANEL

(Supplied by customer

L3

SUPPLY VOLTAGE

230V or 460V

3 PHASE 60Hz

NOTE: Reel start/stop circuit should be wired into main machine

power master switch (not to machine travel drive motors). Frequent

starting and stopping of torque motor is not recommended.

Torque motor should be wired to wind cable only. Torque motor

compensates for direction change when cable is unwound.

NOTE: Be sure blower motor is also wired up with motor.

T3

L2

T2

L1

T1

TORQUE MOTOR

3/60Hz/460V

456

789

123

T3

T2

T1

123

789

456

BLOWER

3/60Hz/460V

TORQUE MOTOR

3/60Hz/230V

456

789

123

123

789

456

BLOWER

3/60Hz/230V

CONTINUED ON BACK PAGE

Page 2

ILLUSTRATED PARTS LIST

TMR SERIES ELECTRIC CABLE REELS

11

Cable is played out and retracted as shown

when viewing reel from motor side.

19

12

12

TO DETERMINE ROTATION OF REEL

STANDARD ROTATION REVERSE ROTATION

2

7

3

1

8

9

7

8

10

4

12

13

Always specify SERIAL NUMBER &

MODEL NUMBER when ordering parts.

4

16

5

6

14

18

15

17

Page 3

TMR SERIES ELECTRIC CABLE REEL REPLACEMENT PARTS LIST

NOTE: Applicable mounting hardware included with each kit.

ITEM KIT NO. DESCRIPTION QTY.

1 021372 Frame Assembly-TMR 1

2 020784 Collector Shaft 1

3 021752 Bearing Kit–2" bore 1

(Includes housing and gasket)

4 012402 Bearing Kit–2" Bore 1

(Includes housing and gasket)

5 105060 Retaining Ring 1

6 021407 Torque Motor-2 1

6 021408 Torque Motor-3 1

6 021409 Torque Motor-5 1

6 021410 Torque Motor-7 1

6 021411 Torque Motor-10 1

6 021412 Torque Motor-14 1

7 021771 Sprocket Kit, Ratio AA 1

(Includes two sprockets and keys)

7 021772 Sprocket Kit, Ratio AB 1

7 021773 Sprocket Kit, Ratio AC 1

7 021774 Sprocket Kit, Ratio AD 1

7 021775 Sprocket Kit, Ratio AE 1

8 021759 Idler Kit 1

(Includes sprocket, shaft, tensioner bar,

locking collar and mounting hardware)

9 021760 Roller Chain Kit 1

(Includes connecting link)

10 021006 Reinforcing Plate 1

11 012459 Cable Connector–.38 to .50 Dia. Cable 1

11 012460 Cable Connector–.50 to .62 Dia. Cable 1

11 012461 Cable Connector–.62 to .75 Dia. Cable 1

11 012462 Cable Connector–.75 to .88 Dia. Cable 1

11 012463 Cable Connector–.88 to 1.00 Dia. Cable 1

11 012464 Cable Connector–1.00 to 1.12 Dia. Cable 1

11 012465 Cable Connector–1.12 to 1.25 Dia. Cable 1

11 012466 Cable Connector–1.25 to 1.38 Dia. Cable 1

11 012467 Cable Connector–1.38 to 1.50 Dia. Cable 1

11 021764 Cable Connector–1.50 to 1.62 Dia. Cable 1

11 021765 Cable Connector–1.62 to 1.75 Dia. Cable 1

12 021763 Chain Cover Kit 1

(Includes cover, gasket and hardware)

13 016337 Collector Entrance Assembly 1

ITEM KIT NO. DESCRIPTION QTY.

14 101652 Pipe Plug 1

15 012285 Collector Assembly, 2 Pole, 35 Amp 1

15 012286 Collector Assembly, 3 Pole, 35 Amp 1

15 012287 Collector Assembly, 4 Pole, 35 Amp 1

15 012288 Collector Assembly, 6 Pole, 35 Amp 1

15 012289 Collector Assembly, 8 Pole, 35 Amp 1

15 012290 Collector Assembly, 10 Pole, 35 Amp 1

15 012291 Collector Assembly, 12 Pole, 35 Amp 1

15 012292 Collector Assembly, 14 Pole, 35 Amp 1

15 012293 Collector Assembly, 16 Pole, 35 Amp 1

15 012294 Collector Assembly, 20 Pole, 35 Amp 1

15 012295 Collector Assembly, 24 Pole, 35 Amp 1

15 012296 Collector Assembly, 30 Pole, 35 Amp 1

15 012297 Collector Assembly, 36 Pole, 35 Amp 1

15 012298 Collector Assembly, 2 Pole, 75 Amp 1

15 012299 Collector Assembly, 3 Pole, 75 Amp 1

15 012300 Collector Assembly, 4 Pole, 75 Amp 1

15 012376 Collector Assembly, 6 Pole, 75 Amp 1

15 012377 Collector Assembly, 8 Pole, 75 Amp 1

15 037194 Collector Assembly, 2 Pole, 125 Amp 1

15 037294 Collector Assembly, 3 Pole, 125 Amp 1

15 037295 Collector Assembly, 4 Pole, 125 Amp 1

15 012304 Collector Assembly, 2 Pole, 200 Amp 1

15 012381 Collector Assembly, 3 Pole, 200 Amp 1

15 012382 Collector Assembly, 4 Pole, 200 Amp 1

15 012383 Collector Assembly, 6 Pole, 200 Amp 1

15 012384 Collector Assembly, 8 Pole, 200 Amp 1

16 012440 Brush Kit (35 Amp) ar

16 012441 Brush Kit (75 Amp) ar

16 012443 Brush Kit (125 Amp/200 Amp) ar

17 012409 Collector Cover Kit (8" long) 1

17 012410 Collector Cover Kit (10.5" long) 1

17 012411 Collector Cover Kit (13" long)

17 012412 Collector Cover Kit (15.5" long) 1

17 012413 Collector Cover Kit (20.5" long) 1

17 012414 Collector Cover Kit (28.5" long) 1

18 012458 Seal Ring (only) 1

19

*

Consult factory for part number of Spool Assembly and related hardware.

Please give model number and serial number to obtain correct Spool Assembly.

(Each kit includes 4 brushes and 4 fingers)

(Includes seal ring)

* Spool Assembly 1

MODEL NUMBER EXPLANATION

(Typical model number)

TMR - 4 12 - XX XX XX - AE - 3

REEL

TYPE

NUMBER

POLES

AMPACITY

CODE*

SPOOL

DIMENSIONS

and TYPE

CHAIN

RATIO

CODE**

MOTOR

SIZE

*SLIP RING

AMPACITY CODE

MAX

CODE AMPS

335

775

12 125

20 200

**CHAIN RATIO

CODE

CHAIN

CODE RATIO

AE 1.0:1

AD 1.5:1

AC 2.0:1

AB 2.5:1

AA 3.0:1

Page 4

CABLE REMOVAL

Use the following procedure to remove worn or damaged cable

from reel prior to installation of new cable.

1. Move machine serviced by reel to a position closest to

reel.

2. Turn off all electric power.

3. Lock spool to prevent turning using either a spool lock

mechanism or by tying off.

4. Disconnect cable from machine junction box.

5. Remove cable from spool. Loosen cable connector (Item 11

on parts list) and disconnect conductors from slip ring.

6. Install new cable following instruction below.

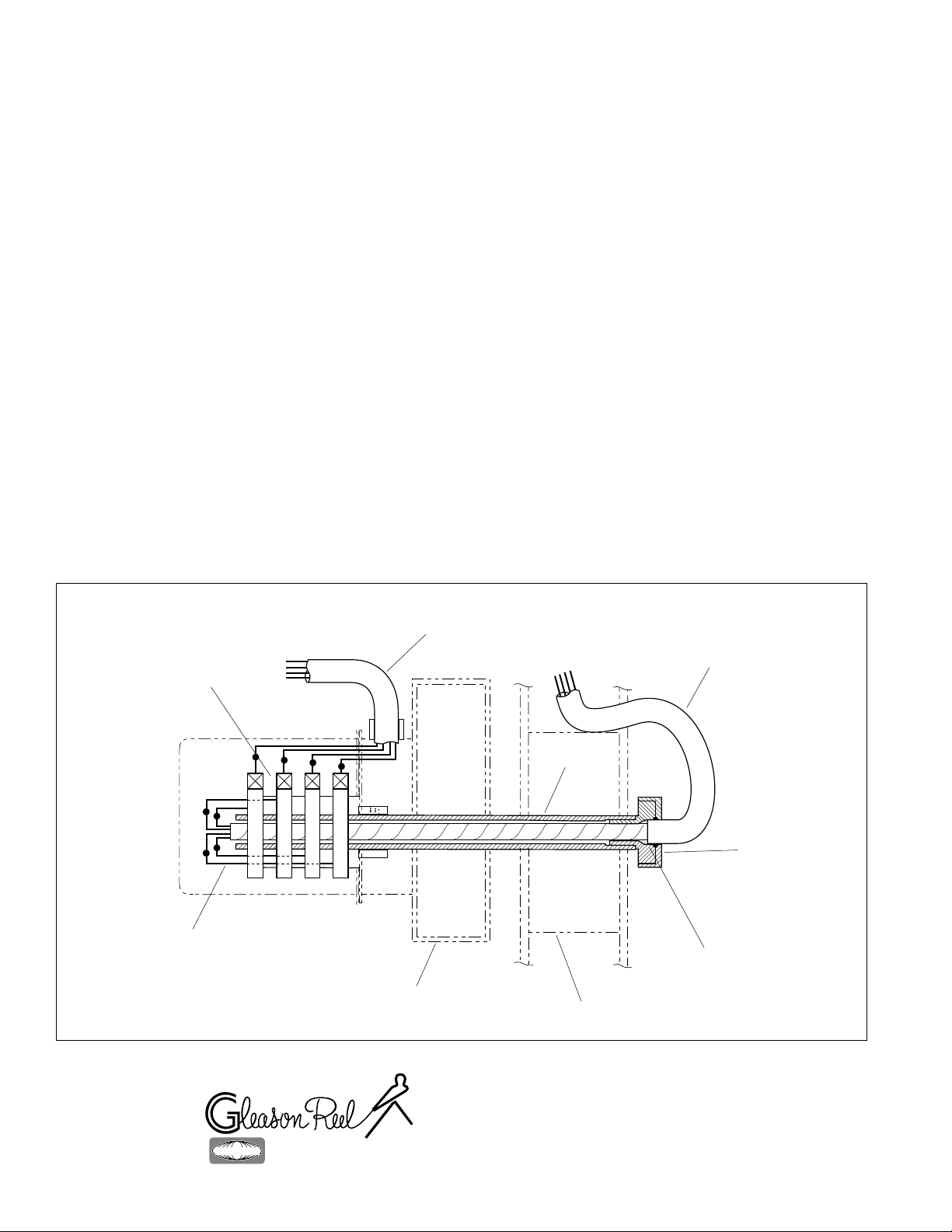

CABLE INSTALLATION

Use the following procedure to replace cable or if reel was

ordered without cable. Refer to CABLE INSTALLATION

REFERENCE DRAWING, below.

1. Unspool new cable from shipping spool and lay out

to eliminate twist.

NOTE: This step is not essential, but will aid in winding

operation of the reel and prolong cable life.

2. Feed one end of the cable through cable connector on

the main shaft inside the spool and into the slip ring side.

(See drawing below).

NOTE: This may require that jacket of cable be stripped

to allow conductors to pass through shaft.

3. Connect individual conductors to appropriate rings on

collector using crimp fitting or similar connection method.

4. Tighten cable connector and U-bolt provided on

drum wrapper segments. Do not over-tighten.

5. Wind the cable onto the reel spool by hand rotating

spool.

6. Connect free end of cable to machine junction box.

COLLECTOR REPLACEMENT

1. Turn off all power to reel.

2. Remove collector cover and gasket.

3. Disconnect electric leads to and from collector.

4. Remove drive stud bolt from bearing housing.

5. Remove plug plug from hole in side of housing. Insert

long 1/8” Allen wrench through hole and loosen two set

screws in collector locking collar Set screws are at 90

to one another..

NOTE: Older reels may have lock screws which must be

removed to reach set screws holding collector to shaft.

6. Slide collector off shaft.

7. Install new collector by reversing above steps.

O

CABLE INSTALLATION REFERENCE DRAWING

Collector

Connect leads

to collector

Frame/Gear Case

Cable

(Input)

Reel

Shaft

Spool

Cable

(Output)

Cable Gland

Thread gland into

shaft. Thread cable

thru gland and shaft.

Tighten gland cover

to secure cable.

NOTE:

Strip cable to inside

of gland. Wrap

leads with electrical

tape thru shaft.

Printed in USA

HUBBELL

®

®

A Hubbell Company

GLEASON REEL CORP.

P.O. Box 26 • 600 South Clark St

Mayville, WI 53050–0026

Phone 920–387–4120

Fax 920–387–4189

Bulletin No. 053151.a

Loading...

Loading...