Hubbell Prime Installation, Operation And Maintenance Manual

INSTALLATION, OPERATION, AND

MAINTENANCE MANUAL FOR

CONDENSING GAS

STORAGE WATER HEATER

BASE MODEL “PRIME”

2

Table&of&Contents&

1.0 INTRODUCTION ................................................................................................................................. 4

Operating Principle ................................................................................................................................ 4

Safety Information and Precautions ...................................................................................................... 4

Outline Dimensions ............................................................................................................................... 8

Electrical .............................................................................................................................................. 10

Gas ....................................................................................................................................................... 10

2.0 INSTALLATION ...................................................................................................................................... 11

Installation Safety Notes ...................................................................................................................... 11

Installer Responsibilities .......................................................................................................... 12

Water Heater Placement ...................................................................................................................... 12

Ventilation ........................................................................................................................................... 12

Removing an Existing Water Heater from Common Venting System .................................... 13

Direct Vent Installation ........................................................................................................... 13

Combustion Air-inlet Contamination ...................................................................................... 14

Water Heater Vent/Air Piping ................................................................................................. 14

Vent and Air-inlet Pipe Length Determination ....................................................................... 15

Termination– Direct Vent Installation ..................................................................................... 16

Venting Rules and Guidelines: ................................................................................................ 20

Flammable Solvents and Plastic Piping ................................................................................... 23

Mandatory Pre-commissioning Procedure for Plastic Venting (PVC or CPVC) .................... 23

Condensate Drain ................................................................................................................................ 24

Gas Installation .................................................................................................................................... 25

Gas Valve and Burner Set-up .................................................................................................. 27

Water Piping Installation ..................................................................................................................... 30

Space Heating Application .................................................................................................................. 31

Filling the Water Heater .......................................................................................................... 32

Electrical Installation ........................................................................................................................... 32

Final Checks ........................................................................................................................................ 32

Lighting the Water Heater ................................................................................................................... 33

Initial Start-Up ......................................................................................................................... 33

Turning Off the Water Heater ................................................................................................. 34

Turning On the Water Heater .................................................................................................. 34

3.0 CONTROLLER OPERATION ................................................................................................................. 34

LCD Display ........................................................................................................................................ 34

Button Layout ...................................................................................................................................... 35

Temperature Adjustments via Status Overview .................................................................................. 36

Showing Errors on the Status Overview .............................................................................................. 37

User Menu ........................................................................................................................................... 37

Installer Menu ...................................................................................................................................... 38

Warnings .............................................................................................................................................. 39

4.0 SCHEDULED MAINTENANCE ............................................................................................................. 40

Freezing ............................................................................................................................................... 40

Manual Inspection ............................................................................................................................... 40

5.0 TROUBLESHOOTING ............................................................................................................................ 41

Controller Error Messages and Procedures ......................................................................................... 42

Lockout Codes ......................................................................................................................... 42

Blocking Errors ........................................................................................................................ 43

6.0 MAINTENANCE & SERVICING ........................................................................................................... 44

3

Surface Temperature Hi-Limit Cutout Switch .................................................................................... 44

Removing the Condensate Outlet ........................................................................................................ 44

Removing the Fan Assembly ............................................................................................................... 44

Heat Exchanger .................................................................................................................................... 44

Relief Valve ......................................................................................................................................... 45

Heating Element (If Equipped) ............................................................................................................ 45

7.0 REPLACEMENT OF PARTS ................................................................................................................... 47

WARRANTY .................................................................................................................................................. 49

List of Figures .................................................................................................................................................. 49

List of Tables ................................................................................................................................................... 51

1.0 INTRODUCTION

Operating Principle

The Hubbell Condensing Gas Water Heater is a Category IV water heater — a water heater that operates

with a positive vent static pressure and with a vent gas temperature that may cause excessive condensate

production in the vent. The unit uses combusted gas to transfer heat from the air to water. In comparison,

traditional electric water heaters use resistive heating elements to directly heat the water. A benefit of a gas

water heater is that gas heaters are less expensive to operate than electric resistance heaters.

This water heater utilizes the natural principles of combustion and fluid dynamics to achieve heat transfer.

Natural gas is a combustible substance, and when exposed to flames will combust. This causes the bonds

within the molecules to break, releasing the energy contained in these bonds. This energy becomes heat energy

and is how the water contained within the tank becomes hot.

After the gas has combusted, it will produce hot carbon dioxide and water vapor. These substances will

transfer heat through the stainless steel condensing unit tubing to the water contained within the tank, resulting

in hot water.

HUBBELL HEATER COMPANY

45 SEYMOUR STREET

P.O. BOX 288

STRATFORD, CT 06615

PHONE: (203) 378-2659

FAX: (203) 378-3593

INTERNET: http://www.hubbellheaters.com

-- IMPORTANT --

Always reference the full model number and serial number when calling the factory.

Safety Information and Precautions

Please read the following safety information before proceeding:

DANGER: Indicates a hazardous situation which, if not avoided, will result in serious injury or death.

WARNING: Indicates a hazardous situation which, if not avoided, could result in serious injury or death.

CAUTION: Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE: Indicates a hazardous situation which, if not avoided, could result in property damage.

Hazards and Definitions

5

WARNING: If the information in these instructions is not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

• Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

• This water heater does not have a pilot. It is equipped with an ignition device which automatically

lights the burner. Do not try to light the burner by hand.

• BEFORE operating, smell around the water heater area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will settle on the floor. What to do if you smell gas:

o Do not try to light any appliance.

o Do not touch any electric switch.

o Do not use any phone in your building.

o Immediately call your gas supplier from a neighbor’s phone and follow the gas supplier’s

instructions.

o If you cannot reach your gas supplier, call the fire department.

• Use only your hand to push in or turn the gas control knob. Never use tools. If the knob will not push

in or turn by hand, don’t try to repair it; call a certified service technician. Force or attempted repair

may result in a fire or explosion.

• Do not use this water heater if any part has been under water. Immediately call a qualified service

technician to inspect the water heater and to replace any part of the control system and any gas

control which has been underwater.

WARNING: Void Warranty - This Water heater must be filled with water whenever the burner is on or it

will damage the unit and void the warranty. Failure to follow these instructions may result in serious injury

or death.

6

• Water temperature over 125°F can cause severe burns instantly or death from

scalds.

• Children, disabled and elderly are at the highest risk of being scalded.

• See instruction manual before setting temperature at the water heater.

• Feel water before bathing or showering.

• Temperature limiting valves are available, see manual.

The temperature of the water in the heater is regulated by an adjustable, automatic,

temperature control which uses surface mounted thermistors located behind the

jacket. These automatic controls are set at the factory to maintain a water

temperature of 120°F. Although these controls are designed to industry standards,

they can fail to control temperature properly without any notice, and therefore should be tested periodically

for your protection.

To perform the test: Turn on the hot water faucet and measure the maximum temperature with an accurate

thermometer. If the temperature is above the safe limits for your circumstances call a service technician to

adjust or replace the control.

DANGER: IF YOU DISCOVER EXTREME HOT WATER COMING FROM THE FAUCET,

IMMEDIATELY SHUT OFF THE ELECTRICITY AND GAS AT THE MAIN SWITCH AND CALL

COMPETENT SERVICE PERSONNEL. ANY OVERHEATED WATER HEATER IS A POTENTIAL

HAZARD TO LIFE AND PROPERTY. DO NOT OPERATE UNTIL THE SOURCE OF THE PROBLEM

HAS BEEN DETERMINED AND ELIMINATED.

WARNING: Corrosion of the flue ways and vent system may occur if air for combustion contains certain

chemical vapors. This can result in failure and risk of suffocation.

WARNING: Attic and/or exhaust fans operating in conjunction with a water heater can result in carbon

monoxide poisoning and death.

*Operating these fans can produce a negative draft in the area of the water heater and prevent the products

of combustion from exhausting through the chimney or vent pipe. The venting of the water heater should be

inspected by a qualified service technician at the time of installation and periodically thereafter to ensure a

down-draft condition does not exist. Do not obstruct the flow of combustion and ventilating air.

WARNING: Generally, after two weeks or more of non-use, hydrogen gas can be produced in a hot water

system. Hydrogen gas is extremely flammable. To reduce risk of injury caused by this hydrogen, it is

recommended to run the hot water faucet for several minutes at the kitchen sink before using any electrical

appliance connected to the hot water system. If hydrogen is present, typically there will be an unusual noise

similar to air escaping through the pipes. There should be no smoking or open flame near the faucet at the

time it is open.

NOTICE: Should overheating occur or the gas supply fails to shut off, turn off the manual gas control valve

to the appliance.

7

IN THE STATE OF MASSACHUSETTS ONLY

(Check up to date local codes and regulations for other jurisdictions)

(a) For all horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole

or in part for residential purposes, including those owned and operated by the Commonwealth and where the side

wall exhaust vent termination is less than seven (7) feet above finished grade in the area of the venting, including but

not limited to decks and porches, the following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS At the time of installation of the side wall

horizontal vented gas fueled equipment, the installing plumber or gas fitter shall observe that a hard wired carbon

monoxide detector with an alarm and battery back-up is installed on the floor level where the gas equipment is to be

installed and on each additional level of the dwelling, building or structure served by the equipment. It shall be the

responsibility of the property owner to secure the services of qualified licensed professionals for the installation of

hard wired carbon monoxide detectors. a. In the event that the side wall horizontally vented gas fueled equipment is

installed in a crawl space or an attic, the hard wired carbon monoxide detector with alarm and battery back-up may

be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision cannot be met at the time of completion of installation, the

owner shall have a period of 30 days to comply with the above requirements; provided, however, that during said 30

day period a battery operated carbon monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS Each carbon monoxide detector as required in accordance

with the above provisions shall comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE A metal or plastic identification plate shall be permanently mounted to the exterior of the building

at a minimum height of eight (8) feet above grade directly in line with the exhaust vent terminal for the horizontally

vented gas fueled heating water heater or equipment. The sign shall read, in print size no less than one-half (1/2) inch

in size, “GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”

(plate included with water heater).

4. INSPECTION The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not

approve the installation unless, upon inspection, the inspector observes carbon monoxide detectors and signage

installed in accordance with the provisions of 248 CMR 5.08(2)(a)1 through 4.

(b) EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled “Equipment Not Required To Be Vented” in the most current

edition of NFPA 54 as adopted by the Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate

from the dwelling, building or structure used in whole or in part for residential purposes.

(c) MANUFACTURER REQUIREMENTS – GAS EQUIPMENT VENTING SYSTEM PROVIDED: When the

manufacturer of Product Approved side wall horizontally vented gas equipment provides a venting system design or

venting system components with the equipment, the instructions provided by the manufacturer for installation of the

equipment and the venting system shall include:

1. Detailed instructions for installation of the venting system design or the venting system components; and

2. A complete parts list for the venting system design or venting system.

(d) MANUFACTURER REQUIREMENTS – GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED:

When the manufacturer of a Product Approved side wall horizontally vented gas fueled equipment does not provide

the parts for venting the flue gases, but identifies “special venting systems”, the following requirements shall be

satisfied by the manufacturer:

1. The referenced “special venting system” instructions shall be included with the water heater or equipment

installation instructions; and

2. The “special venting system” shall be Product Approved by the Board, and the instructions for that system shall

include a parts list and detailed installation instructions.

(e) A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled

equipment, all venting instructions, all parts list for venting instructions, and/or all venting design instructions shall

remain with the water heater or equipment at the completion of the installation.

8

Outline Dimensions

Figure 1 - Tank Assembly (55k Btu Unit on top, 110k Unit on bottom)

9

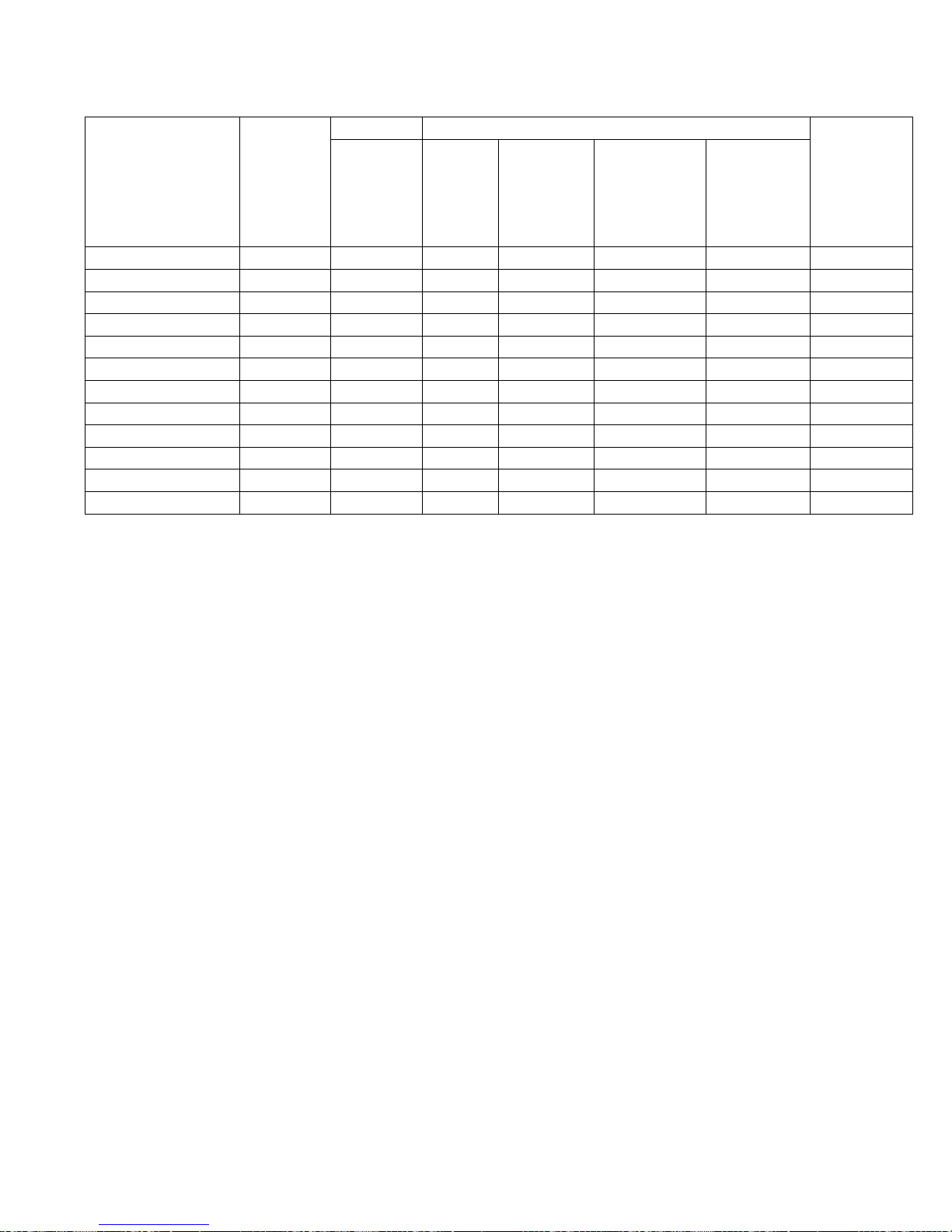

Base Model

Number

Storage

Capacity

(Gallons)

Dimensions (Inches)

Shipping

Weight

(lbs.)

Tank

Diameter

“A”

Overall

Depth

“B”

Overall

Height

“C”

Floor to

Relief Valve

“D”

Floor to

Cold

Water

Inlet

“E”

GSE55-C-40SL

40

26

38.625

31.5

25.25

7.75

246

GSE55-C-50SL

50

28

40.625

36

27.5

7.75

286

GSE55-C-65SL

65

26

38.625

46.25

39.375

7.875

294

GSE55-C-80SL

80

26

38.625

57.25

49.875

7.875

351

GSE55-C-100SL

100

26

38.625

67.50

60.375

7.875

409

GSE55-C-120SL

120

28

40.625

67.75

60.375

7.875

438

GSE110-C-40SL

40

26

40.025

31.5

25.25

7.75

286

GSE110-C-50SL

50

28

42.025

36

27.5

7.75

326

GSE110-C-65SL

65

26

40.025

46.25

39.375

7.875

334

GSE110-C-80SL

80

26

40.025

57.25

49.875

7.875

411

GSE110-C-100SL

100

26

40.025

67.50

60.375

7.875

469

GSE110-C-120SL

120

28

42.025

67.75

60.375

7.875

498

Table 1- Model Specific Dimensional Data

10

Electrical

• This water heater has a power cord with a standard 120V three-prong plug.

• Power cord should be plugged directly into a proper 120V wall outlet. Power strips and extension cords

should not be used.

• Maximum amperage draw is .7 amps for single heat exchanger model, 1.4 amps for double heat

exchanger model.

Gas

• The maximum BTU input is 55,000 BTU per hour for single heat exchanger model, 110,000 BTU per

hour for double heat exchanger model.

• The minimum BTU input is 18,000 BTU per hour.

• This water heater has a 1/2 inch female NPT gas fitting.

• See Gas Installation section for more information.

11

2.0 INSTALLATION

WARNING / CAUTION

DO NOT TURN ON THE ELECTRIC POWER SUPPLY to this equipment until heater is completely filled

with water and all air has been released. If the heater is NOT filled with water when the power is turned on,

the heating elements will burn out (if equipped), and can cause damage to gas heat exchanger.

For protection against excessive pressures and temperatures, local codes require the installation of a

temperature-and-pressure (T&P) relief valve certified by a nationally recognized laboratory that maintains

periodic inspection of production of listed equipment of materials, as meeting the requirements for Relief

Valves and Automatic Gas Shutoff for Hot Water Supply Systems, ANSI Z21.22. THE CUSTOMER IS

RESPONSIBLE TO PROTECT PROPERTY AND PERSONNEL FROM HARM WHEN THE VALVE

FUNCTIONS.

All water heaters have a risk of leakage at some unpredictable time. IT IS THE CUSTOMER'S

RESPONSIBILITY TO PROVIDE A CATCH PAN OR OTHER ADEQUATE MEANS, SO THAT THE

RESULTANT FLOW OF WATER WILL NOT DAMAGE FURNISHINGS OR PROPERTY.

Before doing anything, inspect the tank and all parts to assure that no parts are faulty or damaged from

shipping.

Installation Safety Notes

1. Tank is to be completely filled with water and all air is to be vented before energizing. Do not turn on

water heater if cold water supply shut off valve is closed.

2. Due to the rigors of transportation, all connections should be checked for tightness before heater is

placed in operation.

3. Safety relief valve must be installed in the tapping provided.

4. The refractory material used in heating elements may absorb some moisture during transit, periods of

storage, or when subjected to a humid environment. This moisture absorption results in a cold insulation

resistance of less than twenty (20) megohms. If this heater has been subjected to the above condition,

each heating element must be checked for insulation resistance before energizing. A low megohm

condition can be corrected by removing the terminal hardware and baking the element in an oven at

350°F -700°F for several hours or until the proper megohm reading is obtained.

5. KEEP AWAY FROM LIVE ELECTRICAL CIRCUITS.

Do not perform any maintenance, make any adjustments, or replace any components inside the control

panel with the high voltage power supply turned on. Under certain circumstances, dangerous potentials

may exist even when the power supply is off. To avoid casualties, always turn the power supply safety

switch to off, turn the charge or ground the circuit before performing any maintenance or adjustment

procedure.

6. The unit is designed to operate at pressure not more than 150 psi.

7. Generalized instructions and procedures cannot anticipate all situations. For this reason, only qualified

installers should perform the installations. A qualified installer is a person who has licensed training and

a working knowledge of the applicable codes regulation, tools, equipment, and methods necessary for

safe installation of an electric resistance water heater. If questions regarding installation arise, check

your local plumbing and electrical inspectors for proper procedures and codes. If you cannot obtain the

required information, contact the company.

12

8. In the event of overheating, fire, flood, or physical damage, turn off all power and gas to your water

heater. Do not power the heater until it has been examined by a trained professional.

9. Do not store or use gasoline or other flammable vapors and liquids, such as adhesives or paint thinner,

in the vicinity of this water heater. If such flammable materials must be used near the unit, open nearby

doors and windows to allow for ventilation.

Installer Responsibilities

A qualified installer is a licensed person who has appropriate training and a working knowledge of the applicable codes,

regulations, tools, equipment and methods necessary to install a water heater. The Installer assumes all responsibility for a

safe installation and that it meets the requirements of the water heater instruction manuals, as well as National and local

installation codes. It is also the installer’s responsibility to inform the User/Owner of their obligation with respect to the

description under “User Responsibilities”. Failure to follow this warning could result in fire, serious injury, or death.

Water Heater Placement

1. Place the heater on a solid foundation in a clean, dry location nearest to the point of most

frequent hot water use. If the heater is to be raised off the floor, the entire bottom of the heater

should be supported by a solid surface.

2. The water heater must be installed with a minimum clearance of 12” on top of the water heater,

24” in front of the housing, and 18” to the left of the housing.

3. If the water heater is installed directly on carpeting, a metal or wood panel extending beyond the

full width and depth of the appliance by at least 3 in (76.2 mm) in any direction. If the water

heater is installed in an alcove or closet, the entire floor shall be covered by the panel.

4. Do not install in an area where flammable liquids or combustible vapors are present.

5. The water heater should be protected from freezing and waterlines insulated to reduce energy

and water waste.

6. Locations with warmer ambient air (ex. furnace rooms) are more advantageous as they provide

“free” heat.

7. The water heater will produce exhaust gas which must be piped outdoors, so installation must be

in a location where proper ventilation can be set up. See the following section on venting for proper

installation of ventilation.

NOTICE: If a water heater is installed in a closed water supply system, such as one having a backflow

preventer in the cold water supply line, means shall be provided to control thermal expansion. Contact the

water supplier or local plumbing inspector on how to control this situation.

WARNING: Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance. Failure to follow instructions could result in explosion causing property damage, serious

injury, or death.

Ventilation

The Hubbell Condensing Gas Water Heater is a water heater requiring a “direct venting system” designed for

pressurized venting. The exhaust vent must be piped to the outdoors, using the vent materials and rules

outlined in this section. Under no conditions may this unit vent gases into a masonry chimney unless it is

vacant and utilizes the approved venting material and rules.

NOTE: Common venting or two separate direct vents can be used if you are installing a 110k Btu unit, as this

unit has two separate condensing heat exchangers that need exhaust to be vented outdoors. If this unit is

13

commonly vented, it may only be commonly vented with itself and must satisfy all relating safety codes and

regulations including use of backflow preventers and increasing pipe diameter when additional exhaust lines

connect. It is recommended to increase the pipe diameter to at least 4” PVC if the exhaust lines are combined.

DANGER: Vent and Air-inlet are to be piped separately. This water heater cannot share a common vent or

air-inlet with multiple appliances. Failure to comply will result in serious injury or death.

Removing an Existing Water Heater from Common Venting System

DANGER: Do not install this water heater into a common venting system with any other appliances. Failure

to comply with this warning will cause flue gas spillage and leech carbon monoxide emissions into the

surrounding air resulting in serious injury or death.

WARNING: When an existing water heater is removed from a common venting system, the common venting

system is likely to be too large for proper venting of the remaining appliances connected to it.

Direct Vent Installation

As a direct vent water heater, the combustion air-inlet must also be piped directly to the outdoors using the

methods described in this section and in accordance with the National Fuel Gas Code, ANSI Z223.1 (U.S.),

or CSA B149.1 (Canada) and local requirements.

Figure 2 - Ventilation Connections

WARNING: Make up air requirements for the operation of exhaust fans, kitchen ventilation systems, clothes

dryers, and fireplaces shall be considered in determining the adequacy of a space to provide combustion air

requirements. Failure to ensure adequate make up air to all appliances may result in personal injury or death.

NOTICE: The water heater shall be located so as not to interfere with proper circulation of combustion,

ventilation, and dilution of air.

Single Unit Heater on Left, Double Unit Heater on Right

14

Combustion Air-inlet Contamination

Be careful not to locate the air-inlet termination in an area where contaminants can be drawn in and used for

combustion. When deciding on a location for the vent and combustion air-inlet terminals on an exterior wall,

be sure to allow at least 12 in. between them to prevent drawing in exhaust with the air. These terminals should

also be located at least 1 ft. above grade or average snowfall height (whichever height is greater) to prevent

blockage. Combustion air containing dust, debris, or airborne contaminants will drastically increase the

required maintenance and may cause a corrosive reaction in the heat exchanger, which could result in

premature failure, fire, serious injury, or death. See the following table for a list of areas to avoid when

terminating air-intake piping.

Table 2 - Possible Ventilation Contaminants

WARNING: Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance. Failure to follow instructions may result in serious injury or death.

Water Heater Vent/Air Piping

Each water heater is equipped with a (or two, if you have the 110k Btu dual heat exchanger unit) short piece(s)

of approved CPVC vent pipe. Insert one end into the water heater flue outlet adapter and cement the other to

field venting. The CPVC vent pipe should extend fully into the water heater flue outlet adapter and seal with

the O-ring provided. Ensure that the venting system does not apply a load or strain on the water heater flue

outlet adapter. The manufacturer recommends using two elbows to create a swing joint to reduce potential

strain on vent piping and cemented joints.

WARNING: Gasket Seating – Improper seating can cause leakage and eventual failure or the sealing gasket.

Failure to follow these instructions may result in serious injury or death.

WARNING: PVC Exhaust Venting – DO NOT insert PVC pipe directly into the water heater exhaust adapter

as it may not seat in the adapter. Use only the manufacturer supplied PVC pipe. Failure to follow these

instructions may result in gasket failure and/or the dislodging of the exhaust pipe from the water heater

adapter, resulting in property damage, serious injury, or death.

WARNING: Polypropylene or Stainless Steel Venting – When using polypropylene or stainless steel piping,

the appropriate water heater adapters must be used to transition the water heater vent connections to accept

the respective polypropylene or stainless steel venting. Failure to use the correct adapter will result in flue gas

leakage resulting in property damage, serious injury, or death.

15

DANGER: Exhaust venting must be supported to reduce strain on piping joints. Failure to follow these

Pipe

Size

Gas

Length

ft.

Number of Elbows (90’s or 45’s) and Equivalent Feet

1 2 3 4 5 6 7

8

2”

NG

40

30

10

20 - - - - - 3”

NG

100

90

80

70

60

50

40

30

20

instructions may result in damage, serious injury, or death.

NOTICE: In Canada, the first 3 ft (915mm) of vent piping must be readily accessible for inspection.

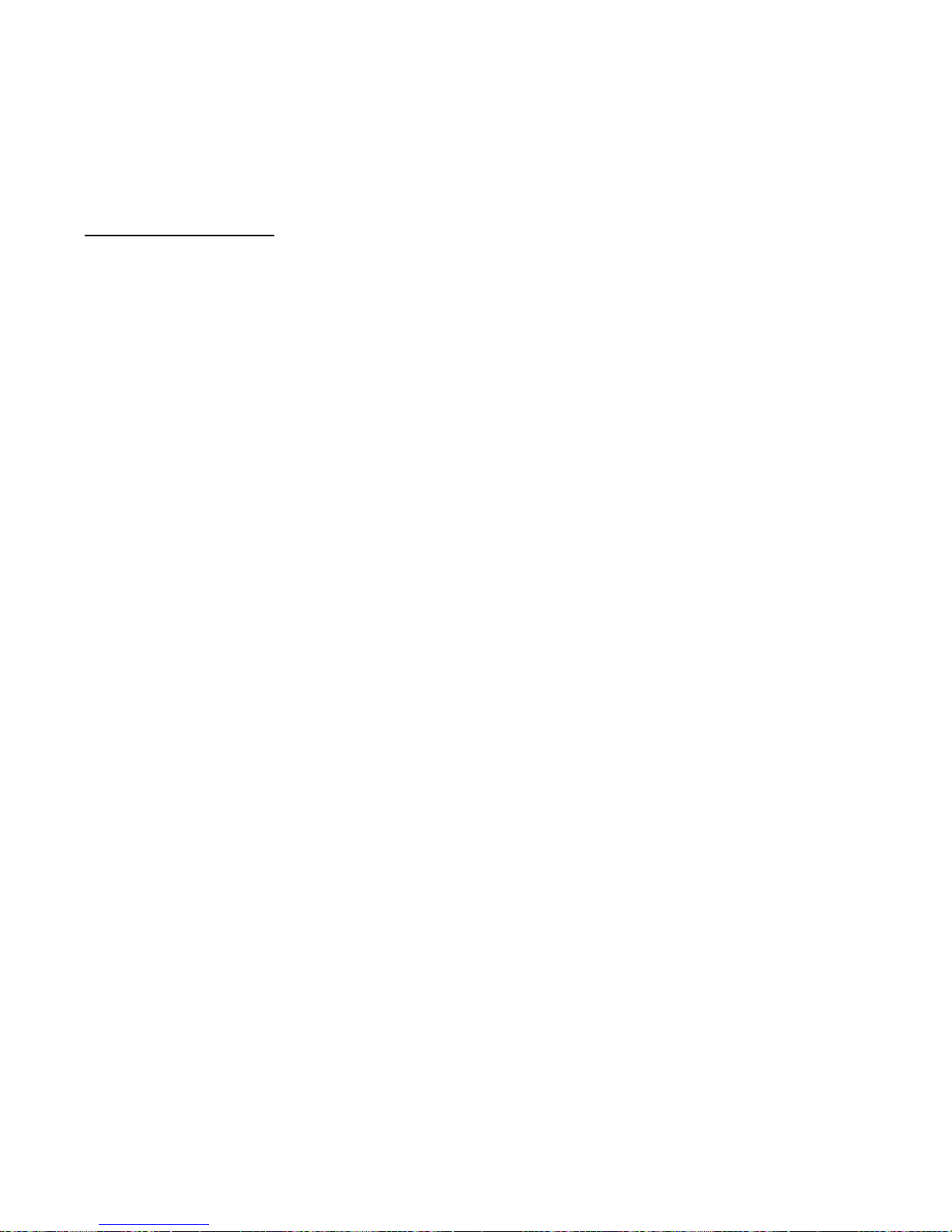

Table 3 - Vent/Air-inlet Pipe Materials

WARNING: All vent and air-inlet-materials installed on gas fired appliances in CAN/US must meet the

standards for the region in which they are installed. Failure to comply may result in fire, serious injury, or

death.

WARNING: The use of cellular core PVC (ASTM F891), cellular core CPVC, or Radel (polyphenol-sulfone)

in the exhaust venting system is prohibited. Failure to follow these instructions may result in property damage,

personal injury, or death.

WARNING: Covering non-metallic vent pipe and fittings with thermal insulation is prohibited. Failure to

follow these instructions may result in property damage, personal injury, or death.

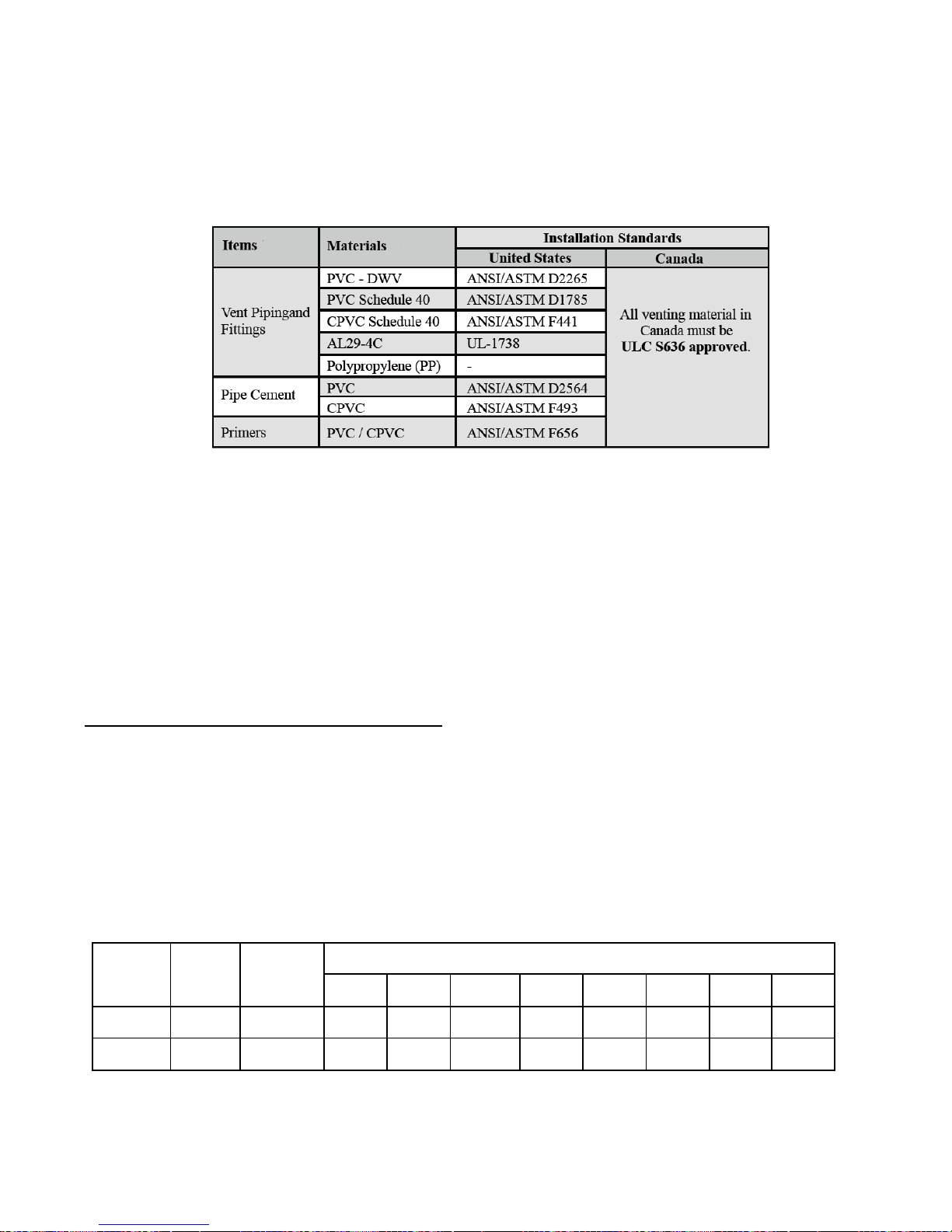

Vent and Air-inlet Pipe Length Determination

Use the provided inlet and outlet adapters to attach duct work to the water heater. When using 3” piping, an

additional adapter is required from 2” to 3”.

Use the table below to determine the maximum pipe length that can be used. The table calculates sweep, 90°

elbows, and 45° elbows at 10 equivalent feet each.

Table 4 - Vent and Air-inlet (Single Heat Exchanger Ventilation)

16

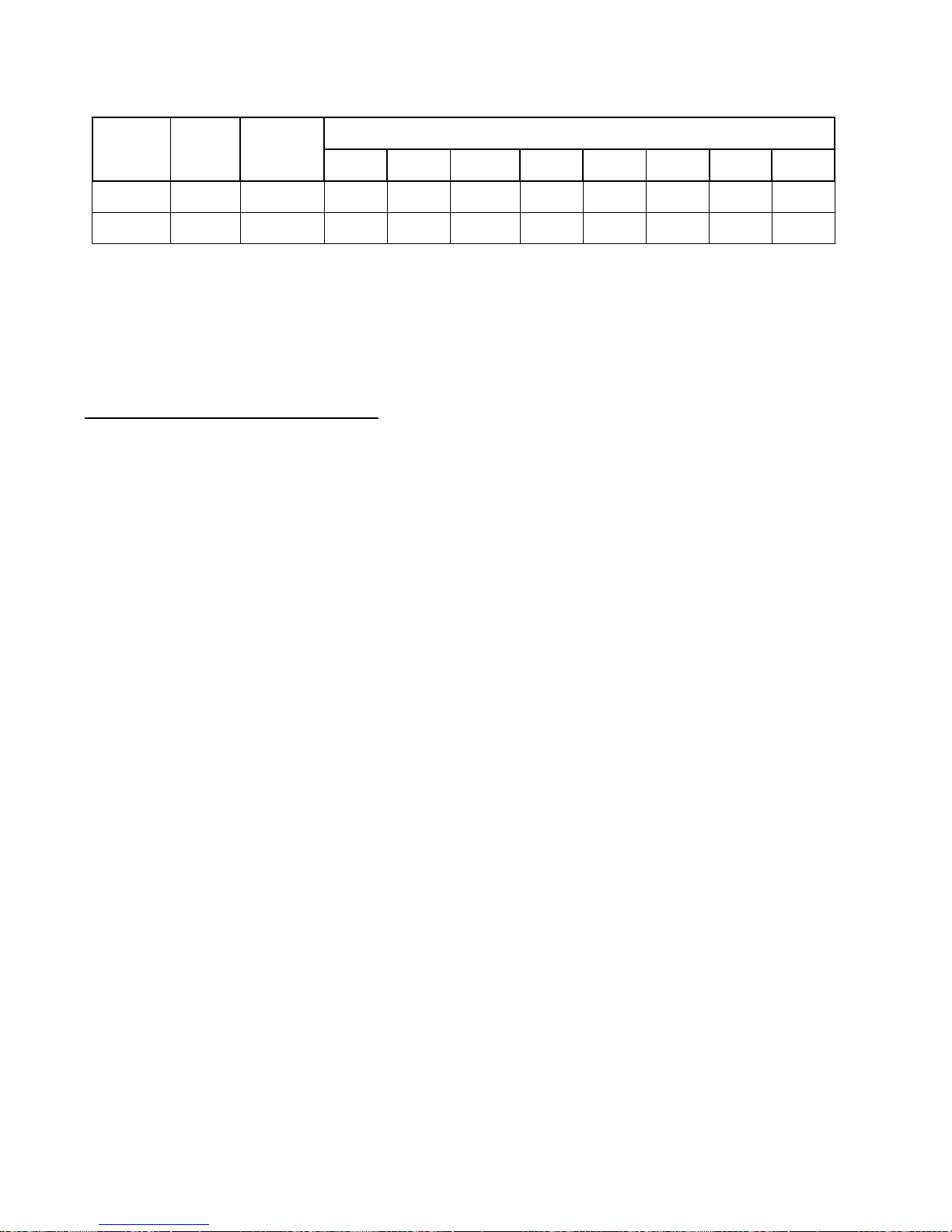

Table 5 - Vent and Air-inlet Pipe Length Determination (Common Vented Double Unit)

Pipe

Size

Gas

Length

ft.

Number of Elbows (90’s or 45’s) and Equivalent Feet

1 2 3 4 5 6 7 8 3”

NG

35

25

15 5 - - - - -

4”

NG

150

140

130

120

110

100

90

80

70

NOTICE: 1 foot of piping minimum required before first elbow.

NOTICE: The length of one vent pipe (air-inlet or exhaust) may not exceed the length of the other vent pipe

by more than 20 equivalent feet.

Termination– Direct Vent Installation

The venting system of this water heater must be terminated using field supplied piping to construct a “TwoPipe” termination.

IMPORTANT: PVC In Canada – Authorities in some jurisdictions may not allow the use of any PVC venting

materials with condensing water heaters; check with the local safety inspector to verify compliance prior to

installing a PVC Vent Kit with a water heater.

Loading...

Loading...