Page 1

INSTALLATION, OPERATION &

MAINTENANCE DATA SHEET

ENCLOSED AND GASKETED LIGHTING FIXTURES FOR

MB SERIES HID BALLAST TANKS

CLASS I, ZONE 2

EXNR APPLICATIONS. REFER TO NAMEPLATE FOR

CLASSIFIED LOCATION INFORMATION.

MB SERIES HID BALLAST TANKS

CAUTION:

Before installing, make sure you are compliant with area classications, failure to do so may result in bodily injury,

death and property damage. Do not attempt installation until you are familiar with the following procedures. All

installation must comply with the applicable Electrical Code.

Make sure that the circuit is de-energized before starting installation or maintenance.

Verify that the installation is grounded. Failure to ground will create electrical shock hazards, which can cause

serious injury and or death.

IMPORTANT:

Before installing, check the xture nameplate to be sure you have the correct xture. Verify that there is

ground continuity in the electrical system. Refer to the xture nameplate for specic supply wire temperature

rating.

Technical information, advice and recommendations contained in these documents is based upon information

that Killark believes to be reliable. All the information and advice contained in these documents is intended for

use only by persons having been trained and possessing the requisite skill and know-how and to be used by

such persons only at their own discretion and risk. The nature of these instructions is informative only and does

not cover all of the details, variations or combinations in which this equipment may be used, its storage, delivery,

installation, check out, safe operation and maintenance. Since conditions of use of the product are outside of the

care, custody and control of Killark, the purchaser should determine the suitability of the product for his intended

use, and assumes all risk and liability whatsoever in connection therewith.

3940 Dr. Martin Luther King Drive

St. Louis, MO 63113

P/N 00912239 FORM NO. K1199 R02/08 ECO-I-004-08

Page 1 of 3

Page 2

WARNING - Turn OFF the supplying circuit before

starting installation.

NOTE: All installations must comply with applicable

local and / or National Electrical Code.

1. DIRECTIONS FOR INSTALLATION

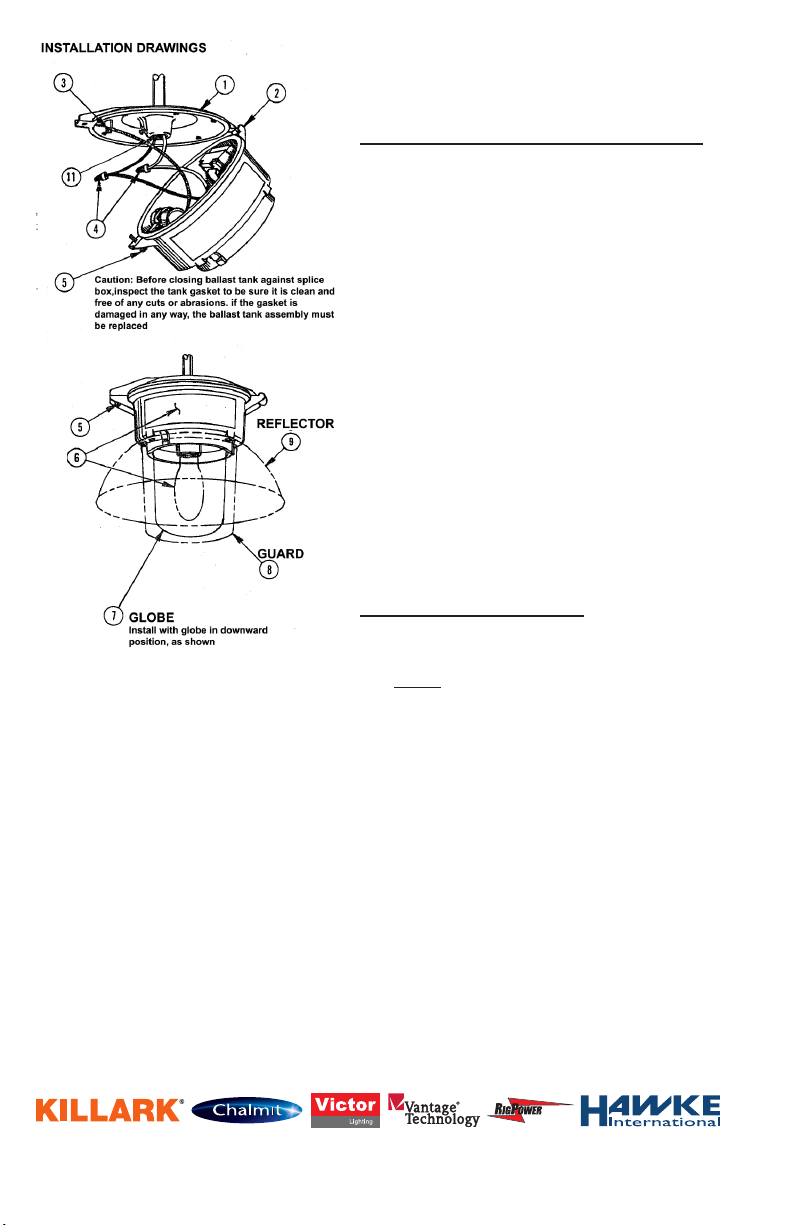

1. Using the installation drawings as a guide, make

sure the splice box is securely installed (Refer to

installation sheet supplied with splice box).

2. Hang the xture on the splice box hinge.

3. Attach the green (ground) lead to the splice box

grounding screw provided.

4. Connect supply wires to appropriate ballast tank

wire leads, using the wirenuts provided.

5. Close the ballast tank against the splice box and

tighten the screw to secure it.

6. Referring to xture nameplate, install the proper

size and type of lamp.

7. Install globe in globe threads. Band wrench

tighten 1/4 turn past hand tight.

8. Install globe guard over lugs on ballast tank, turn

until stopped. Secure by tightening screw.

9. To install reectors, back out (4) screws provided

ballast tank bosses enough to slip the reector

over the screws and twist in place. Tighten

screws to secure the reector.

10. Turn ON the supplying circuit and test the xture.

11. Seal all wire entries with a setting type of silicone

caulking, such as RTV.

2. OPERATIONAL DATA

3940 Dr. Martin Luther King Drive

St. Louis, MO 63113

P/N 00912239 FORM NO. K1199 R02/08 ECO-I-004-08

Operate this xture only at the voltage of your

specic supply circuit.

NOTE: Most HID lamps need 4 to 5 minutes to

reach full lighting output. A power failure or a

large voltage drop will extinguish the arc. The

lamp will restrike after cooling for approximately

5 to 12 minutes (30 to 90 seconds for High

Pressure Sodium).

NOTE: Join or “lap” marks may form

during pouring of molten glass in the globe

manufacturing process. It is not unusual for

these marks to become visible. This is a

common and normal occurrence for large globes

and does not affect performance.

Page 2 of 3

Page 3

3. MAINTENANCE DATA

CAUTION - Disconnect the supplying circuit

before opening xture or removing globe for

relamping. To relamp, remove the globe guard

and globe. Replace lamp with one of the

correct type. Refer to the xture nameplate for

this information.

To maintain maximum light output, this xture

should be cleaned periodically. Maintenance

procedures sometimes require xtures to

be hosed down for good housekeeping. The

supply circuit must be turned OFF and the

xture globe must be allowed to cool to the

ambient room temperature before cleaning.

Only mild, non-abrasive cleaning agents should

be used. The force of water applied by a hose

must not exceed 65 gallons per minute coming

from a 1” diameter hose applied at a distance

of 10 feet. These periodic cleaning procedures

are important to prevent the accumulation of

dust and dirt which will impair the light output of

the xture. The glass globe should be regularly

inspected for scratches and chips and, if

damaged, must be replaced.

HIGH VIBRATION AREAS - Periodic

inspection of globe tightness is required;

recommended every six (6) months.

REMEMBER TO SAVE ONE OF THESE SHEETS FOR MAINTENANCE PERSONNEL.

3940 Dr. Martin Luther King Drive

St. Louis, MO 63113

P/N 00912239 FORM NO. K1199 R02/08 ECO-I-004-08

Page 3 of 3

Loading...

Loading...