Hubbell JTX011-2S, JTX008-2RS, JTX011-3R, JTX011-3T3, JTX012-2RS Installation, Operation And Maintenance Manual

...Page 1

INSTALLATION, OPERATION, AND

MAINTENANCE MANUAL FOR

THE HUBBELL MODEL JTX / JHX

TANKLESS BOOSTER HEATER

ELECTRIC HEATER COMPANY

* The Hubbell Model JTX is designed for use with conveyor and flight type dish

machines. This product is not intended for use with door style dish machines.

Edition 2012A

Page 2

2

HUBBELL

ELECTRIC HEATER COMPANY

P.O. BOX 288

STRATFORD, CT 06615-0288

PHONE: (203) 378-2659

FAX: (203) 378-3593

INTERNET: http://www.hubbellheaters.com

Important Safety Information

1. You must read and follow all instructions. Serious bodily injury or death could occur

if you ignore this warning.

2. All circuit breakers and/or disconnect switches servicing the heater must be turned off

when installing, uninstalling, or repairing this booster heater.

3. The Hubbell Tankless Booster Heater must be grounded.

4. The unit must be installed by a licensed electrician and plumber.

5. The unit must be wired in accordance with the current version of the National

Electrical Code (US) or Canadian Electric Code (Canada).

6. This installation must comply with all national, state, and local plumbing and

electrical codes.

7. When the heater is not within sight of the electrical circuit breakers, an additional

local means of disconnection of all ungrounded conductors must be provided that is

within sight of the appliance or a circuit breaker lockout must be used. (Ref. NEC

422.31)

8. Water Quality Requirements – Recommended water hardness is 4 to 6 grains of

hardness per gallon (GPG). Water hardness above 6 GPG should be treated by a

water conditioner (water softener or in-line treatment). Water hardness below 4 GPG

also requires treatment to reduce potential corrosion. Excessive GPG will result in

higher operating and maintenance costs and will reduce product longevity. Chlorides

must not exceed 50 parts per million (ppm). Excessive chlorides will result in

metallic corrosion and will reduce product longevity. Water treatment has been

shown to reduce costs associated with de-liming the booster as well as reducing

metallic corrosion. Product failure caused by these conditions is not covered under

warranty. See warranty for complete details.

9. The booster heater is factory set at 185°F for booster water heating applications. This

results in the possibility of a scalding water injury. A full thickness skin burn can

occur in less than one second of exposure to water at this temperature.

10. *Disclaimer: The Hubbell Model JTX is designed for use with conveyor and flight

type dish machines. This product is not intended for use with door style dish

machines.

Page 3

3

TABLE OF CONTENTS

SECTION TITLE PAGE No.

I TANKLESS BOOSTER HEATER OPERATING PRINCIPLE 4

II GENERAL DESCRIPTION AND CONSTRUCTION 5

III INSTALLATION 9

IV OPERATION AND MAINTENANCE 23

V TROUBLESHOOTING 29

VI SERVICING & REPLACEMENT OF PARTS 36

VII PARTS LIST 40

VIII WARRANTY 41

Page 4

4

SECTION I – TANKLESS BOOSTER HEATER OPERATING PRINCIPLE

How the Hubbell Tankless Booster Heater Works:

For the most part, operating the new tankless booster heater is very similar to using any

traditional booster heater system. However, it is very important that all of the set-up

procedures and operating instructions are carefully read to ensure maximum performance

and energy savings from the new water heater.

The Hubbell Tankless Booster Heater does not store hot water like a conventional tank-type

booster heater. It contains high powered heating elements that are capable of heating water

instantly on-demand as needed. As soon as there is a hot water demand, a sophisticated flow

sensor within the heater recognizes the demand and initiates the heating process. This

sensor measures the water flow rate while two other sensors measure the incoming and

outgoing water temperature. This information is transmitted continually to the

microprocessor controller which determines the precise amount of power to send to the

heating elements to heat the water to the desired temperature. The Hubbell tankless booster

heater only uses as much power as is needed to meet the demand by fully modulating the

heating elements from 0 to 100%.

It is important to keep in mind that all tankless booster heaters are subject to a maximum

flow rate. If this flow rate is exceeded, the heater will not be capable of fully heating water.

The amount of water that can be heated by the tankless booster heater at any given time will

depend on the model selected and the incoming water temperature. See the charts in Section

II to determine the maximum flow rates.

Moreover, since a tankless booster heater eliminates the ongoing thermal losses caused by

storing hot water in a tank, there will be a significant energy savings compared to a

conventional tank type booster heater.

*Disclaimer: The Hubbell Model JTX is designed for use with conveyor and flight type

dish machines. This product is not intended for use with door style dish machines.

Page 5

5

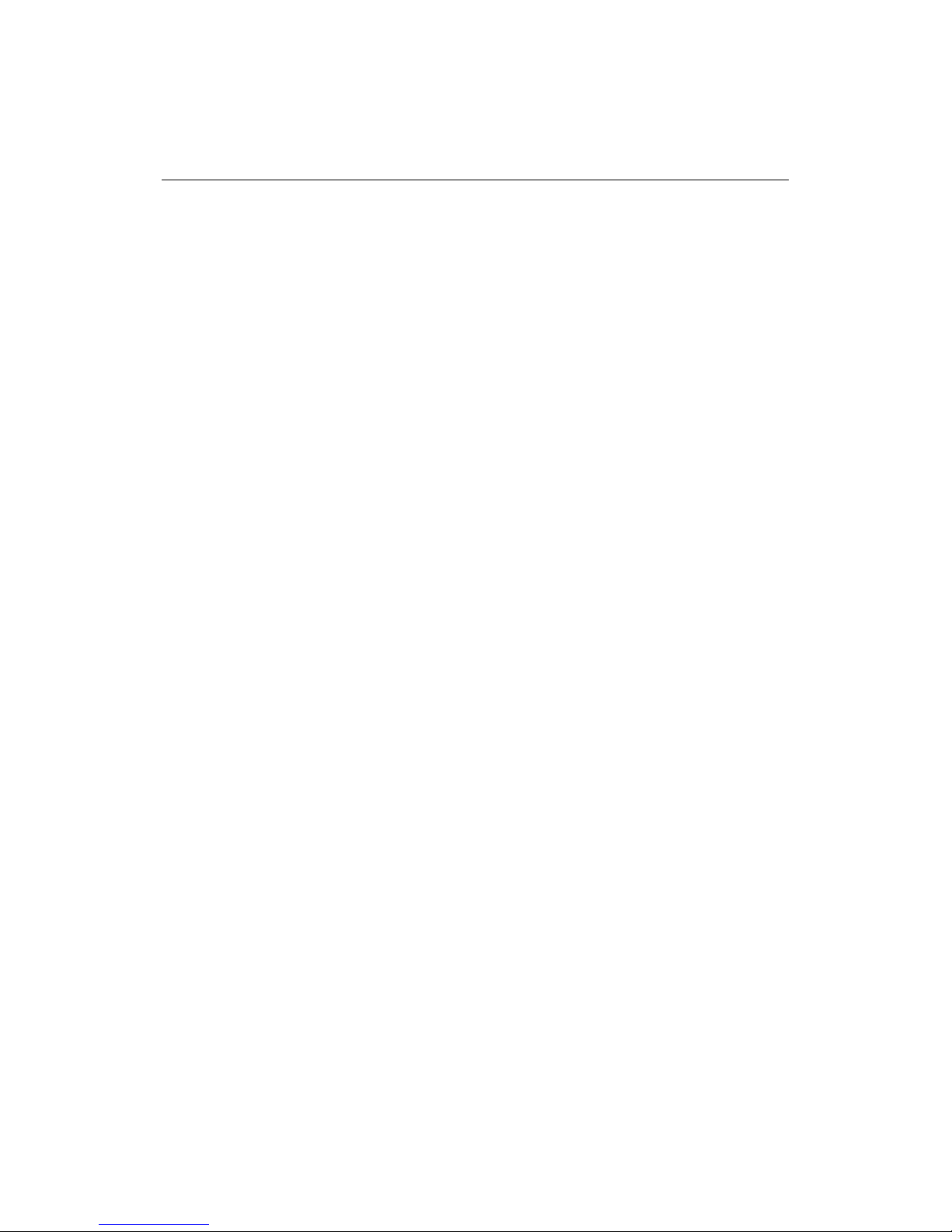

Heating Elements

Heating Chamber Hi-Limit Switches

Inlet Thermistor

Outlet Thermistor

Element Switching

Devices (Triacs)

Temperature

Controller

LED Digital Display

(with buttons)

Power Distribution Block

Ground Lug

Hot Water

Outlet

Warm

Water Inlet

Drain

Flow Meter

Magnetic

Contactor

Transformer

Control Fuse

SECTION II – GENERAL DESCRIPTION AND CONSTRUCTION

Technical Specifications Common to All Models:

Materials: Copper Exchanger /

Stainless Steel Casing

Plumbing

Connection:

Low

Flow

¾” Copper Sweat

Energy

Efficiency:

98%

High

Flow

1” Copper Sweat

Voltage: 208-600 Volts Operating Range: 5 – 150 psi

Frequency: 50 / 60 Hz Protection: Thermal Auto Reset

Product Overview:

Notes:

1. Power distribution blocks are only installed on single phase models.

2. Magnetic contactors are only installed on 3-phase models.

3. Transformers are only installed on 3-phase models over 240 volts.

4. 2-Element models will have a plug in the lowest element chamber and have only two hilimit switches and triacs installed.

Typical 2/3-Element Model

Page 6

6

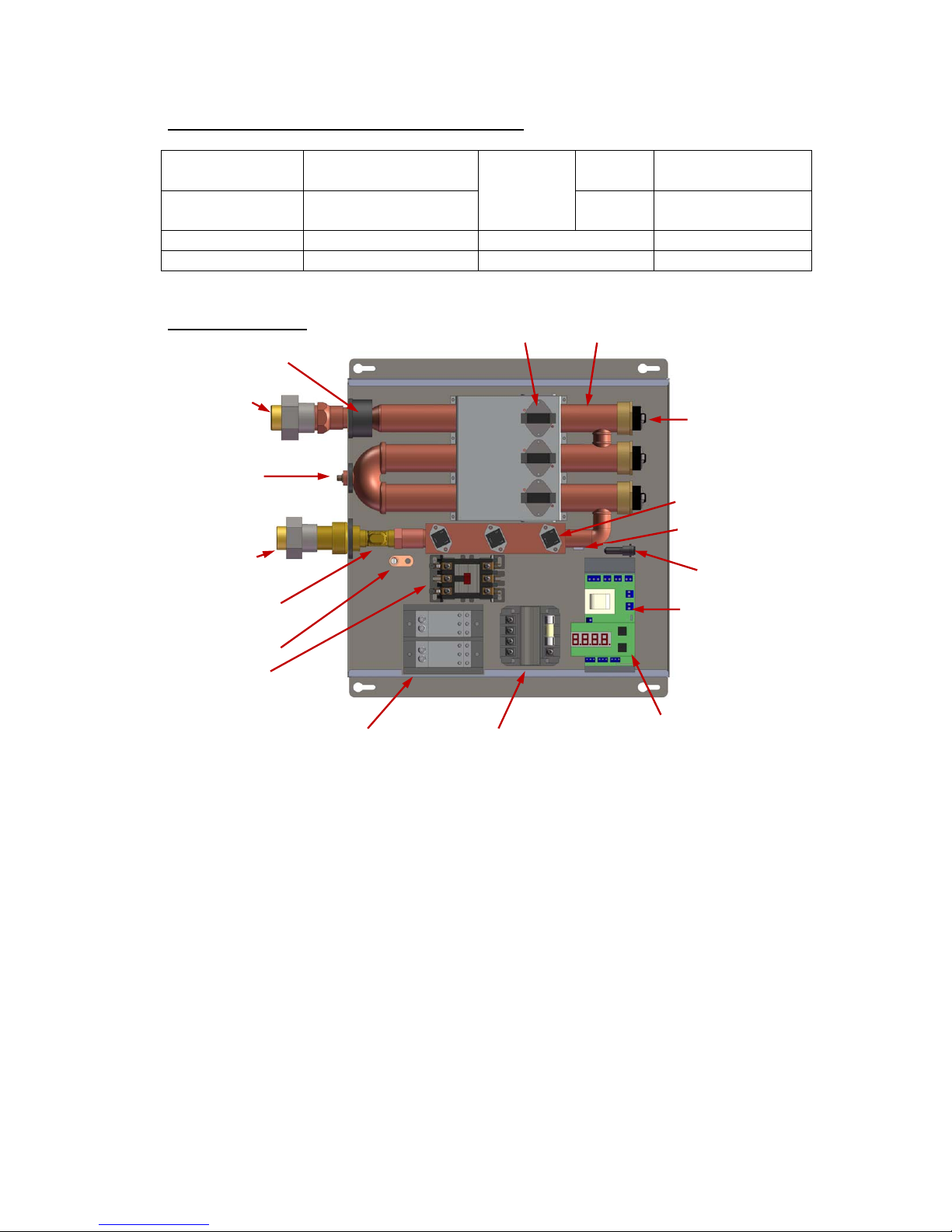

Heating Elements

Inlet Thermistor

(beneath triac

plate)

Outlet Thermistor

Element Switching

Devices (Triacs)

Temperature

Controller

LED Digital Display

(with buttons)

Magnetic Contactor

Ground Lug

Hot Water

Outlet

Warm

Water Inlet

Drains

Flow Meter

Hi-Limit Switches

Heating Chamber

Transformer

Power

Distribution

Bl

ock

Control Fuse

Notes:

1. Power distribution blocks are only installed on single phase models and 3-phase models

that require two magnetic contactors. Single phase models use a 2-pole power

distribution block.

2. Magnetic contactors are only installed on 3-phase models. One or two magnetic

contactors may be installed as required.

3. Transformers are only installed on 3-phase models over 240 volts.

Typical 6-Element Model

Page 7

7

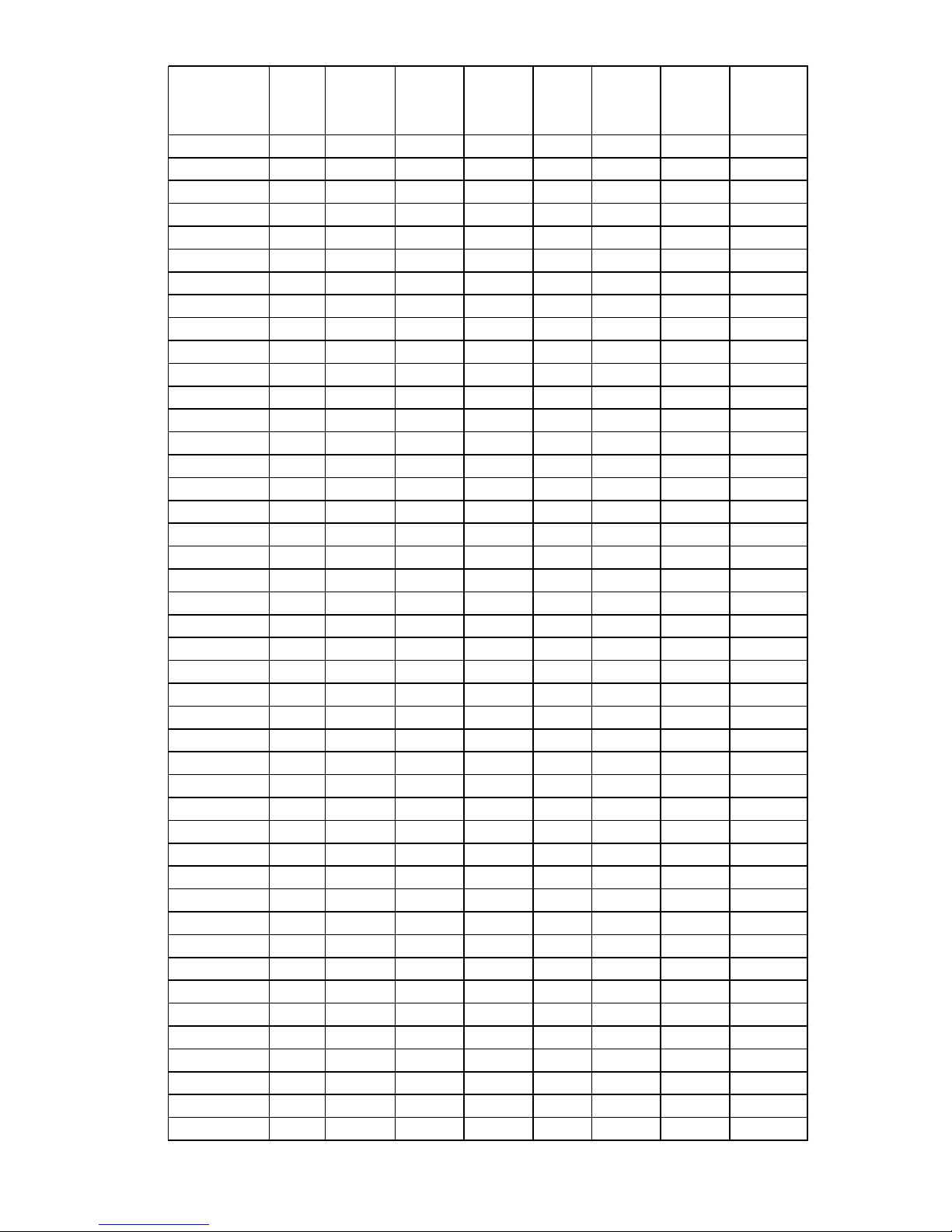

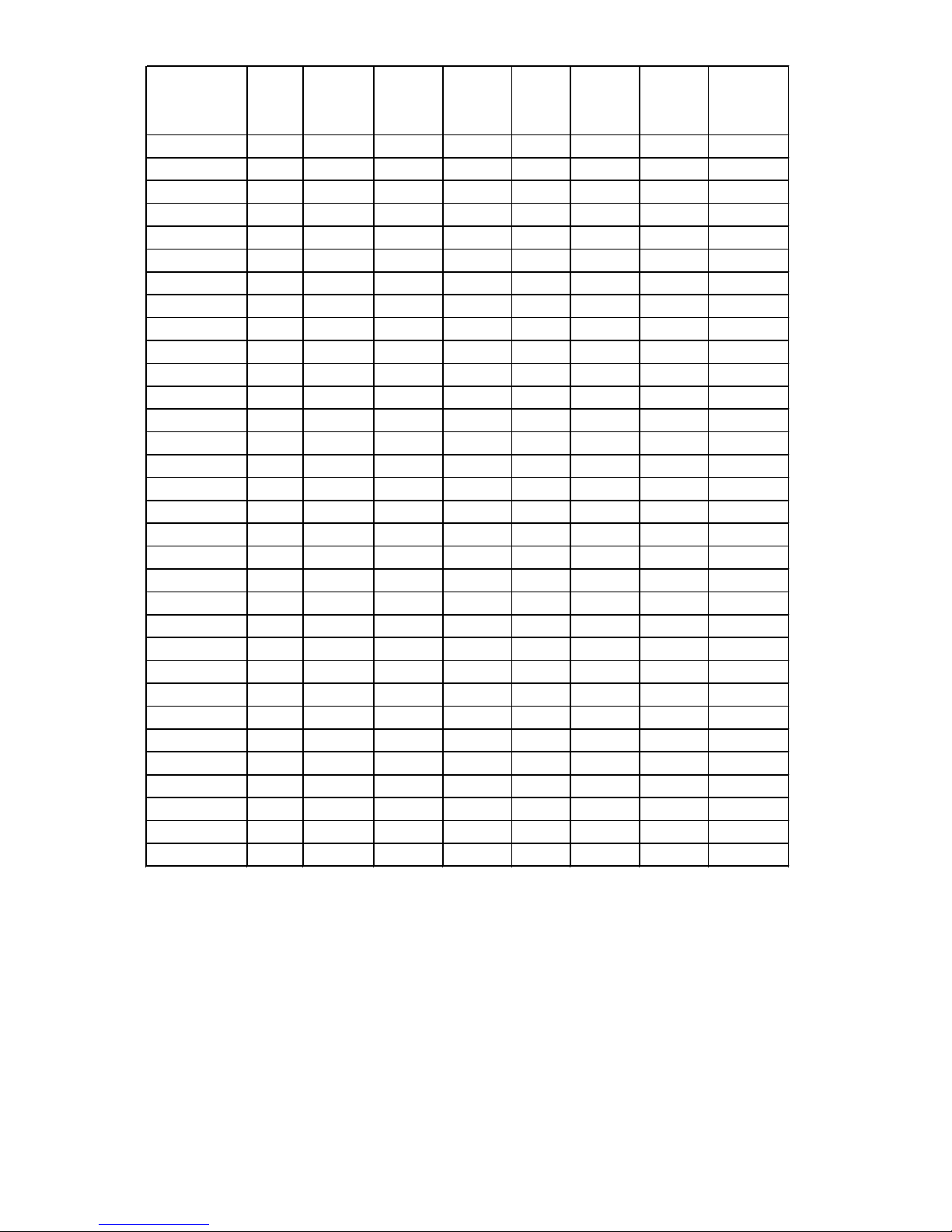

Tankless Booster Heater Maximum Flow Rates:

5°F 10°F 20°F 30°F 40°F 50°F 60°F 70°F 80°F 100°F 120°F 140°F

8

10.9 5.5 2.7 1.8 1.4 1.1 0.9 0.8 0.7 0.5 0.5 0.4

11

15.0 7.5 3.8 2.5 1.9 1.5 1.3 1.1 0.9 0.8 0.6 0.5

12

16.4 8.2 4.1 2.7 2.1 1.6 1.4 1.2 1.0 0.8 0.7 0.6

13

17.8 8.9 4.4 3.0 2.2 1.8 1.5 1.3 1.1 0.9 0.7 0.6

14

19.1 9.6 4.8 3.2 2.4 1.9 1.6 1.4 1.2 1.0 0.8 0.7

15

20.5 10.3 5.1 3.4 2.6 2.1 1.7 1.5 1.3 1.0 0.9 0.7

16

21.9 10.9 5.5 3.6 2.7 2.2 1.8 1.6 1.4 1.1 0.9 0.8

18

24.6 12.3 6.2 4.1 3.1 2.5 2.1 1.8 1.5 1.2 1.0 0.9

20

27.3 13.7 6.8 4.6 3.4 2.7 2.3 2.0 1.7 1.4 1.1 1.0

21

28.7 14.4 7.2 4.8 3.6 2.9 2.4 2.1 1.8 1.4 1.2 1.0

24

32.8 16.4 8.2 5.5 4.1 3.3 2.7 2.3 2.1 1.6 1.4 1.2

25

34.2 17.1 8.5 5.7 4.3 3.4 2.8 2.4 2.1 1.7 1.4 1.2

27

36.9 18.5 9.2 6.2 4.6 3.7 3.1 2.6 2.3 1.8 1.5 1.3

30

20.5 10.3 6.8 5.1 4.1 3.4 2.9 2.6 2.1 1.7 1.5

31

21.2 10.6 7.1 5.3 4.2 3.5 3.0 2.6 2.1 1.8 1.5

33

22.6 11.3 7.5 5.6 4.5 3.8 3.2 2.8 2.3 1.9 1.6

36

24.6 12.3 8.2 6.2 4.9 4.1 3.5 3.1 2.5 2.1 1.8

40

27.3 13.7 9.1 6.8 5.5 4.6 3.9 3.4 2.7 2.3 2.0

42

28.7 14.4 9.6 7.2 5.7 4.8 4.1 3.6 2.9 2.4 2.1

48

32.8 16.4 10.9 8.2 6.6 5.5 4.7 4.1 3.3 2.7 2.3

50

34.2 17.1 11.4 8.5 6.8 5.7 4.9 4.3 3.4 2.8 2.4

54

36.9 18.5 12.3 9.2 7.4 6.2 5.3 4.6 3.7 3.1 2.6

Maximum Flow Rate (GPM) at Tem

p

erature Rise (°FΔT)

Power (kW)

1. Shaded values indicate that a High Flow (JHX) unit is required.

2. Blank values indicate that the flow rate will exceed the flow capability of the flow meter.

3. For alternate power (kW) values, the maximum flow rate can be calculated using the

formulas on the following page.

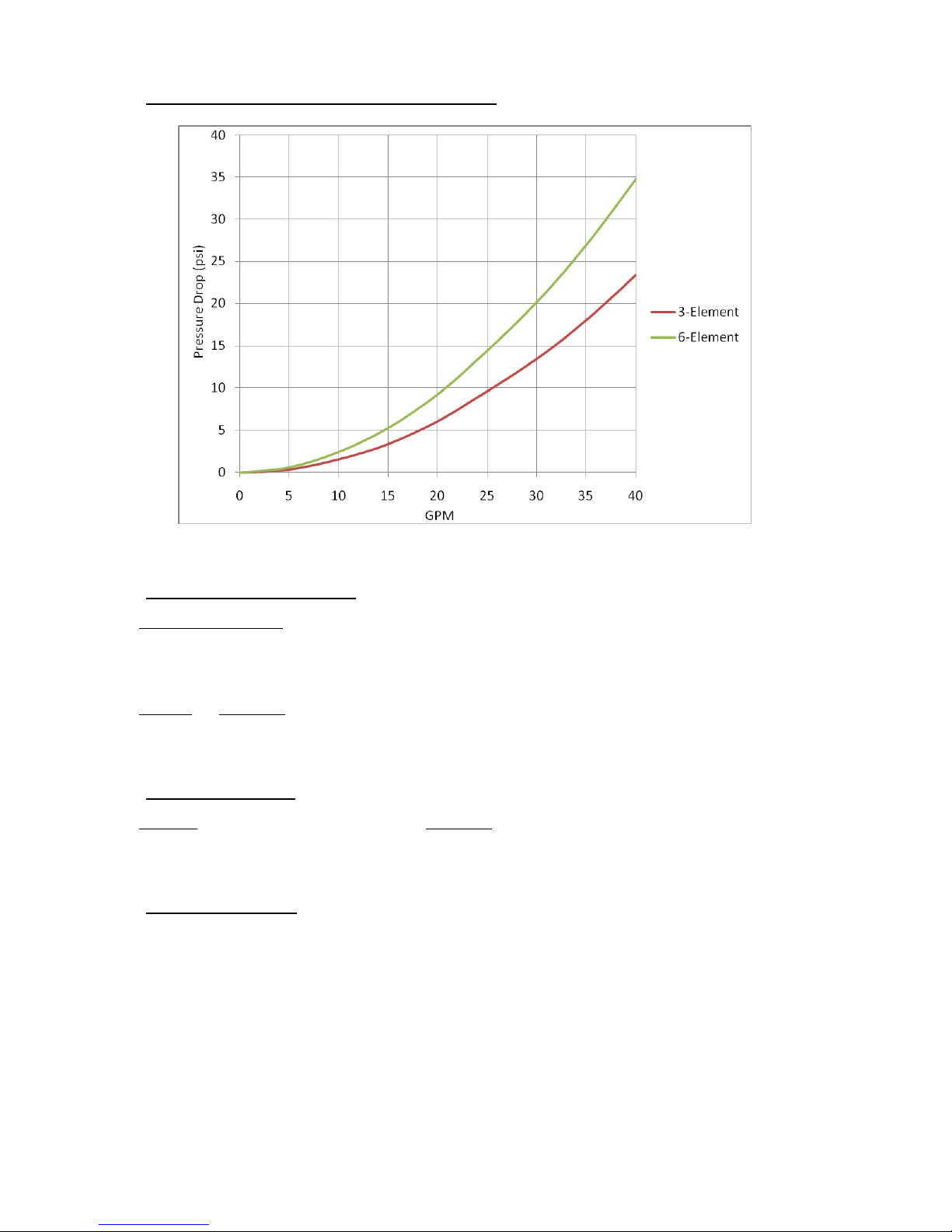

Tankless Low Flow Pressure Drop Chart (JTX):

Page 8

8

Tankless High Flow Pressure Drop Chart (JHX):

Wattage De-rating Formula:

Applied Voltage

2

× Rated Wattage = Actual Wattage

Rated Voltage

2

For example: If installing a 27 kW unit when actual voltage is 212 V,

212

2

=

44,944

= 0.78 × 27,000 W = 21,060 W @ 212 V

240

2

57,600

Amperage Formula:

Watts

= Amps (Single Phase)

Watts

÷1.73 = Amps (3-Phase)

Volts Volts

Flow Rate Formulas:

To determine power (kW) requirement

____GPM × ____ °F ΔT × 0.1465 = ____ kW

To determine temperature rise

____ kW × 6.824 ÷ ____ GPM = ____°F ΔT

To determine flow rate

____ kW × 6.824 ÷ ____ °FΔT = ____ GPM

Page 9

9

SECTION III – INSTALLATION

WARNING: Serious bodily injury or death may occur if the following warnings are

ignored.

•

All circuit breakers and/or disconnect switches servicing this heater must be turned

off before installing, repairing or uninstalling this water heater.

•

Installation of this product is restricted to indoor locations.

•

Installation

MUST

be done by a licensed electrician and licensed plumber.

• *Disclaimer:

The Hubbell Model JTX is designed for use with conveyor and flight

type dish machines. This product is not intended for use with door style dish

machines.

Locating and Mounting Instructions:

The Hubbell tankless booster heater can be installed just about anywhere. Due to the small

size of the water heater, it can be mounted in many small spaces. However, there are some

important guidelines to follow that will ensure that the installation is both safe and

convenient in the event that future servicing is required.

This product is designed to be installed indoors only. The unit may be installed in an

outdoor location as long as it is mounted in a suitable enclosure that protects it from rain,

direct sunlight, debris, and insects. This product should NOT be installed in a location where

it may be subjected to freezing temperatures. If the water inside the tankless booster heater

freezes, it can cause severe and permanent damage that is not covered under the warranty. If

you suspect that the tankless booster heater may have frozen, do not turn on the heater until

it has thawed and it has been inspected for leaks.

When selecting an installation location, give consideration to the existing plumbing

configuration, location of your main electrical panel, and location of the point of use. Try to

choose a location that does not require major plumbing alterations, that is close to the main

electrical panel (this will reduce the amount of wire needed to install), and that is physically

close to the dish machine. By locating the heater close to the dish machine, this will reduce

the amount of time it takes for the hot water to travel from the water heater to the point of

use. Consideration should also be given to future servicing. Do NOT locate the water heater

in a location that is difficult to access. Do NOT install above electrical boxes or junctions.

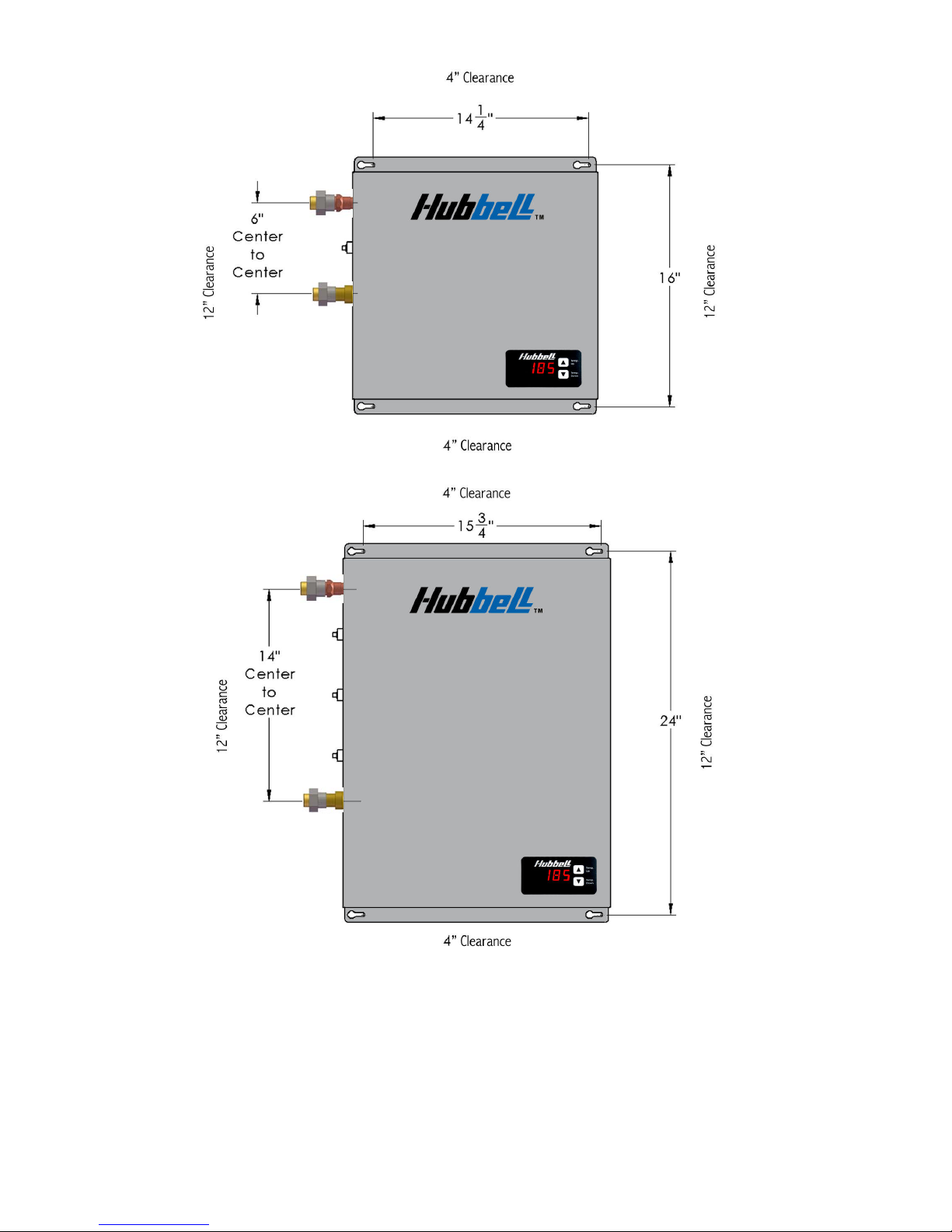

Mounting the unit:

• Leave a minimum of 12” to both sides and 4” on the top and bottom of the unit.

• Mount the booster heater securely to the wall by putting four (4) screws through the

mounting holes.

• Install a ¼” diameter bead of sealing caulk around the entire perimeter of the heater

between the heater back panel and the wall. This prevents any moisture or debris

from accumulating.

Page 10

10

Page 11

11

Plumbing Installation Instructions:

IMPORTANT INFORMATION:

• Ensure all fitting installations comply with local plumbing and building codes.

•

The booster heater does not require a temperature and pressure (T&P) relief valve. A

T&P relief valve may be installed if required by county, city or state plumbing code.

• Installations in the Commonwealth of MASSACHUSETTS and KENTUCKY require

a

T&P

relief valve.

• When connecting to a plumbing system that utilizes Flex or PVC, a

T&P

relief valve

should be used as added safety.

•

Do not connect the unit directly to CPVC pipe. You must use at least three feet of

copper pipe prior to connecting to any CPVC connection.

• WARNING:

Do not solder any pipes with the unit connected to the pipes. Doing so

will damage the flow meter and void your warranty.

•

Before energizing the heater, run water for a minimum of three (3) minutes and

verify that all air has been removed.

•

Installation of an air separator device is recommended for installations where air can

be easily introduced into the water system (i.e. Well water systems, lake pumps, and

other municipal systems).

•

A shut off valve MUST be installed on inlet side of unit. A shut off valve on the

outlet is recommended.

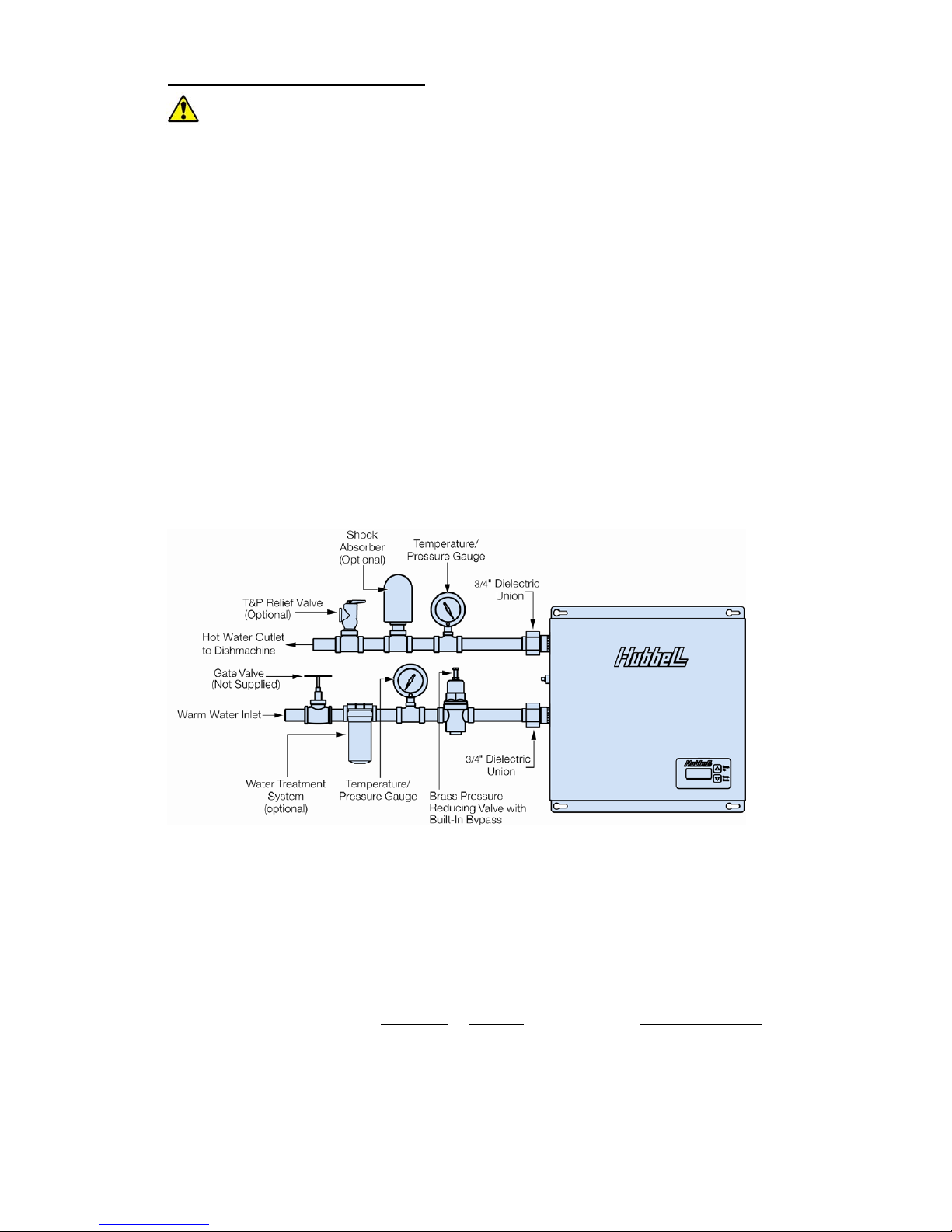

Typical JTX Plumbing Installation:

Piping:

• Remove the sweat end of the dielectric fitting from the unit.

• Sweat the pipe to the dielectric union.

•

Connect the union and pipe assembly to the unit.

IMPORTANT – Be certain to connect the outlet piping to the final rinse and not to the

wash tank.

• Install water pressure regulator in the entering cold/warm water inlet line and adjust to

the pressure recommended by the dishwasher manufacturer. The pressure reducing

valve is adjustable from 25 to 75 psi. The set screw located at the t op of the diaphragm

adjusts the pressure, turn clockwise

to increase the pressure and counter-clockwise to

decrease

the pressure.

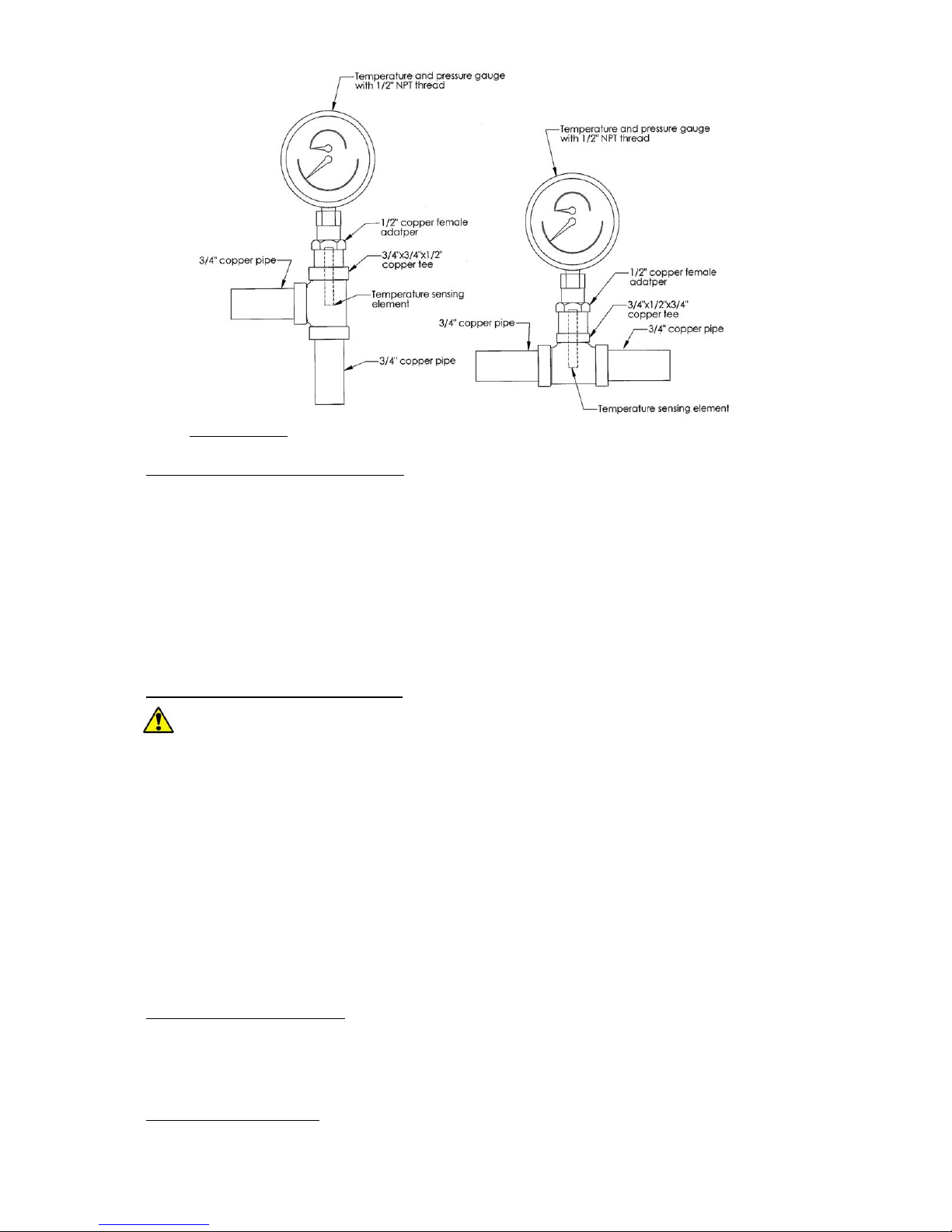

• Install the factory supplied in-line pressure and temperature gauges in the entering

cold/warm and existing hot water lines. NOTE: The temperature sensing element

must be in the water stream as shown below.

• A shock absorber is recommended in the hot water outlet line to soften the water

hammer caused by automatic dishwasher solenoid valves.

Page 12

12

•

Flush the line:

Before connecting the union to the unit, it is extremely important to

flush the lines to eliminate all plumbing paste, residue, or debris in the lines

Checking for Leaks and Purging Air:

• If unit has been wired, verify all circuit breakers supplying power to the unit are

turned off.

• Open all valves supplied by the unit and inspect water connections for leaks.

• With all valves still open, allow the water to run for a minimum of 3 minutes.

Inspect the outlets to ensure all air in the lines has been purged. This process purges

all the air from the water lines and MUST be performed prior to turning on the power

at the unit.

WARNING:

FAILURE TO FOLLOW THIS STEP CAN CAUSE

PERMANENT DAMAGE TO THE HEATING ELEMENTS.

• Close all valves.

Electrical Installation Instructions:

IMPORTANT INFORMATION:

• The unit must be wired in accordance with the current version of the National

Electrical Code (US) or Canadian Electric Code (Canada).

• The unit must have its own independent circuits.

• When the heater is not within sight of the electrical circuit breakers, an additional

local means of disconnection of all ungrounded conductors must be provided that is

within sight of the appliance or a circuit breaker lockout must be used. (Ref. NEC

422.31)

•

Wire entry must be through the electrical KO provided in the bottom of the unit.

• For Canada, per Canadian Electric Code, C22.1-02, the unit must be wired by a single

feed installation with one (1) double-pole circuit breaker.

• For US, the unit may be wired by a single feed installation with one (1) double-pole

circuit breaker or by a multiple feed installation with multiple double-pole circuit

breakers.

Wiring to the booster heater:

•

Connect the power wire from the main panel to the power distribution block or

magnetic contactor as applicable.

•

Connect the main ground wire to t he g ro u nd l ug in th e h eater.

•

Make sure the connections are securely tightened.

Electrical Specifications:

Listed below are the electrical specifications for each tankless booster heater model.

Page 13

13

Model kW

Volts /

Phase Amps

Min.

Breaker

Size

Wire

Size

Conduit

Size

Wiring

Diagram

Element

Amp

Draw

JTX008-2RS 8 208 / 1 38.5 45 8 ¾" 1 19.9

JTX011-3R 11 208 / 3 30.5 35 8 ¾" 3 16.3

JTX011-2S 11 240 / 1 45.8 50 8 ¾" 1 22.9

JTX011-3T3 11 380 / 3 16.7 20 8 ¾" 4 9.9

JTX012-2RS 12 208 / 1 57.7 70 6 ¾" 1 28.9

JTX012-3R 12 208 / 3 33.3 35 8 ¾" 3 19.9

JTX013-3T3 13 380 / 3 19.8 25 8 ¾" 4 11.5

JTX013-3T7 13 415 / 3 18.1 20 8 ¾" 4 10.8

JTX014-2RS 14 208 / 1 67.3 80 4 1" 1 32.5

JTX014-2S 14 240 / 1 58.3 70 6 ¾" 1 29.2

JTX014-3T 14 240 / 3 33.7 40 8 ¾" 3 18.8

JTX015-3T3 15 380 / 3 22.8 25 8 ¾" 4 13.2

JTX016-3RS 16 208 / 1 76.9 90 4 1" 2 25.3

JTX016-3R 16 208 / 3 44.4 50 8 ¾" 3 25.3

JTX016-2S 16 240 / 1 66.7 80 4 1" 1 33.3

JTX016-3T 16 240 / 3 38.5 45 8 ¾" 3 22.9

JTX016-3T7 16 415 / 3 22.3 25 8 ¾" 4 12.6

JTX018-3RS 18 208 / 1 86.5 90 3 1" 2 28.9

JTX018-3R 18 208 / 3 50.0 60 6 ¾" 3 28.9

JTX018-2S 18 240 / 1 75.0 80 4 1" 1 37.5

JTX018-3T3 18 380 / 3 27.3 30 8 ¾" 4 15.7

JTX018-3T7 18 415 / 3 25.0 30 8 ¾" 4 14.4

JTX018-3T4 18 480 / 3 21.7 25 8 ¾" 4 12.5

JTX020-3RS 20 208 / 1 96.2 110 2 1" 2 32.5

JTX020-3R 20 208 / 3 55.5 60 6 ¾" 3 32.5

JTX020-3T3 20 380 / 3 30.4 35 8 ¾" 4 17.7

JTX020-3T7 20 415 / 3 27.8 30 8 ¾" 4 16.2

JTX021-3S 21 240 / 1 87.5 90 3 1" 2 29.2

JTX021-3T 21 240 / 3 50.5 60 6 ¾" 3 29.2

JTX021-3T4 21 480 / 3 25.3 30 8 ¾" 4 14.6

JTX021-3T6 21 600 / 3 20.2 25 8 ¾" 5 20.2

JTX024-6RS 24 208 / 1 115.4 125* 1 2" 6 19.9

JTX024-6R 24 208 / 3 66.6 70 4 1" 7 19.9

JTX024-3S 24 240 / 1 100.0 110 2 1" 2 33.3

JTX024-3T 24 240 / 3 57.7 70 6 ¾" 3 33.3

JTX024-3T7 24 415 / 3 33.4 40 8 ¾" 4 19.3

JTX024-3T4 24 480 / 3 28.9 35 8 ¾" 4 16.7

JTX024-3T6 24 600 / 3 23.1 25 8 ¾" 5 23.1

JTX025-3T3 25 380 / 3 38.0 40 8 ¾" 4 22.2

JTX027-3S 27 240 / 1 112.5 125 1 2" 2 37.5

JTX027-3T 27 240 / 3 65.0 70 4 1" 3 37.5

JTX027-6T3 27 380 / 3 41.0 45 8 ¾" 9 11.5

JTX027-6T7 27 415 / 3 37.6 40 8 ¾" 9 10.8

JTX027-3T4 27 480 / 3 32.5 35 8 ¾" 4 18.8

Page 14

14

Model kW

Volts /

Phase Amps

Min.

Breaker

Size

Wire

Size

(Qty.)

Conduit

Size

Wiring

Diagram

Element

Amp

Draw

JTX027-3T6 27 600 / 3 26.0 30 8 ¾" 5 26.0

JTX030-6T3 30 380 / 3 45.6 50 8 ¾" 9 13.2

JTX031-6RS 31 208 / 1 149.0 175* 2/0 1 ½" 6 25.3

JTX031-6R 31 208 / 3 86.0 90 3 1" 7 25.3

JTX031-6T7 31 415 / 3 43.1 50 8 ¾" 9 12.6

JTX033-6S 33 240 / 1 137.5 150* 1/0 1 ¼" 6 22.9

JTX033-6T 33 240 / 3 79.4 90 4 1" 7 22.9

JTX036-6RS 36 208 / 1 173.1 200* 3(2) 1 ½" 6 28.9

JTX036-6R 36 208 / 3 99.9 110 2 1" 8 28.9

JTX036-6T3 36 380 / 3 54.7 60 6 ¾" 9 15.7

JTX036-6T7 36 415 / 3 50.1 60 6 ¾" 9 14.4

JTX036-6T4 36 480 / 3 43.3 50 8 ¾" 9 12.5

JTX040-6RS 40 208 / 1 192.3 225* 2(2) 2" 6 32.5

JTX040-6R 40 208 / 3 111.0 125 1 2" 8 32.5

JTX040-6T3 40 380 / 3 60.8 70 6 ¾" 9 17.7

JTX040-6T7 40 415 / 3 55.6 60 6 ¾" 9 16.2

JTX042-6S 42 240 / 1 175.0 200* 3(2) 1 ½" 6 29.2

JTX042-6T 42 240 / 3 101.0 110 2 1" 8 29.2

JTX042-6T4 42 480 / 3 50.5 60 6 ¾" 9 14.6

JTX042-6T6 42 600 / 3 40.4 45 8 ¾" 10 40.4

JTX048-6RS 48 208 / 1 230.8 250* 1(2) 2" 6 38.5

JTX048-6R 48 208 / 3 133.2 150* 1/0 1 ¼" 12 38.5

JTX048-6S 48 240 / 1 200.0 225* 2(2) 2" 6 33.3

JTX048-6T 48 240 / 3 115.5 125 1 2" 8 33.3

JTX048-6T7 48 415 / 3 66.8 80 4 1" 9 19.3

JTX048-6T4 48 480 / 3 57.7 70 6 ¾" 9 16.7

JTX048-6T6 48 600 / 3 46.2 50 8 ¾" 10 46.2

JTX050-6T3 50 380 / 3 76.0 80 4 1" 9 22.2

JTX054-6S 54 240 / 1 225.0 250* 1(2) 2" 6 37.5

JTX054-6T 54 240 / 3 129.9 150* 1/0 1 ¼" 12 37.5

JTX054-6T4 54 480 / 3 65.0 70 4 1" 9 18.8

JTX054-6T6 54 600 / 3 52.0 60 6 ¾" 10 52.0

□ Tankless booster heaters are considered a non-continuous load.

□ If a multiple feed installation is used, it is acceptable to install up to two conductors in

one line side port. Additionally, when a power distribution block is supplied,

additional conductors may be installed in an open load side port of the power

distribution block.

□ Wiring sizing listed is for 75°C THHN. 60°C or 90°C wire may be used. Refer to

NEC table 310.16 for sizing.

□ Conductors should be sized to maintain a voltage drop of less than 3% under load.

□ Electrical specifications for the High Flow (JHX) models are the same as listed for the

Low Flow (JTX) models.

□ The Hubbell Model JTX is designed for use with conveyor and flight type dish

machines. This product is not intended for use with door style dish machines.

Page 15

15

□ Where “Min. Breaker Size” is marked with a star (*), these models require a

supplemental protection assembly for installation.

□ For the following models, for installation in Canada per CSA requirements, a single

feed is required sized as follows:

o JTX036-6RS: 3/0

o JTX040-6RS: 4/0

o JTX042-6S: 3/0

o JTX048-6RS: 250

o JTX048-64S: 4/0

o JTX054-6S: 250

Page 16

16

Wiring Diagram 1

Wiring Diagram 2

Page 17

17

Wiring Diagram 3

Wiring Diagram 4

Page 18

18

Triac

Triac

Triac

Flow

Meter

Temperature

Controller

Hi-Limit

Hi-Limit

Hi-Limit

Heating

Element

Heating

Element

Heating

Element

Outlet

Thermistor

Inlet

Thermistor

Magnetic

Contactor

L1 L2 L3

Leak

Detection

Wire

Transformer

Fuse

Wiring Diagram 5

Wiring Diagram 6

Page 19

19

Triac

Triac

Triac

Flow

Meter

Temperature

Controller

Hi-Limit Hi-Limit

Hi-Limit

Heating

Element

Heating

Element

Heating

Element

Outlet

Thermistor

Inlet

Thermistor

Magnetic

Contactor

L1 L2 L3

Hi-Limit

Hi-Limit

Hi-Limit

Heating

Element

Heating

Element

Heating

Element

Triac

Triac

Triac

Leak

Detection

Wire

Fuse

Wiring Diagram 7

Page 20

20

Wiring Diagram 8

Page 21

21

Triac

Triac

Triac

Flow

Meter

Temperature

Controller

Hi-Limit Hi-Limit

Hi-Limit

Heating

Element

Heating

Element

Heating

Element

Outlet

Thermistor

Inlet

Thermistor

Magnetic

Contactor

L1 L2 L3

Hi-Limit

Hi-Limit

Hi-Limit

Heating

Element

Heating

Element

Heating

Element

Triac

Triac

Triac

Leak

Detection

Wire

Transformer

Fuse

Wiring Diagram 9

Page 22

22

Wiring Diagram 10

Page 23

23

Wiring Diagram 12

SECTION IV – OPERATION AND MAINTENANCE

First Use of your Hubbell Tankless Booster Heater:

Once the water supply is on and air has been purged from the system, power the unit on at

the main panel. The unit is now operating automatically. When water flows through the unit,

the heating elements turn on to heat the water to the displayed setpoint temperature. When

the water flow stops, the heating elements turn off.

You can adjust the setpoint upward or downward by pressing the UP or DOWN button.

Displaying Celsius or Fahrenheit degrees and adjusting other settings for the tankless booster

heater can be done via the configuration menu, described below.

Upper Button to

Increase Temperature

Digital Display Lower Button to

Decrease Temperature

Page 24

24

Maintenance:

• The Hubbell Tankless Booster Heater requires no maintenance other than to

periodically check around the outside of the unit for leaks. If a water leak is detected

from your water heater, turn off the water supply at the shut-off valve on the inlet side

of the water heater, turn off the power to the heater at the main electrical panel and

call a service technician or plumber for evaluation and repair.

• When any maintenance is performed on the booster heater or the plumbing system

that may introduce air into the water supply pipes, it is important to turn the power off

to the water heater and purge the air out of the lines before restoring power to the unit.

See Checking for Leaks and Purging Air in Section III.

Temperature Controller User Interface Instructions:

1. The display is always on when power is applied to the unit:

a. To turn the unit OFF, press and hold the DOWN button until display shows

OFF.

b. The controller will preserve all its settings during any power outage or

disconnect.

2. To change setpoint temperature (the temperature is fully adjustable in 1° increments).

a. Press the UP or DOWN button to change the setpoint temperature.

b. Pressing and holding either the UP or DOWN button will fast scroll.

3. Configuration Menu.

a. To enter configuration menu, press and hold the UP and DOWN buttons

simultaneously for 7 seconds. (Note that the display will change during the time

you are holding the buttons. You are in the configuration menu and can release

the buttons when the first character of the display is ‘P’).

b. To scroll through menu items, press the UP or DOWN button.

c. To leave the configuration menu, wait 7 seconds without pushing any buttons.

d. To make a change to a specific configuration menu item, simultaneously press

the UP and DOWN buttons. The menu item setting will now flash indicating it

can be changed.

e. To scroll through menu item settings, press the UP or DOWN key.

f. When the desired setting is displayed, simultaneously press the UP and DOWN

buttons to lock in the selection and return back to the configuration menu.

g. Configuration Menu Items:

i. Power Setting - Sets the total kW rating of booster heater.

1. P###, where ### is adjustable from 001 to 054

(Note that the kW selection should equal the kW

based upon the actual voltage measured to the heater. Please see

the nameplate on the front cover of the heater for a listing of kW

ratings at various voltages).

ii. Temperature Range – Sets the temperature adjustment

range

1. r001, 60° to 140°F (15°-60°C)

2. r002, 32° to 194°F (0°-90°C) (Factory Default)

3. r003, 32° to 104°F (0°-40°C)

iii. Display units – Sets the display units to either Fahrenheit/Gallons or

Celsius/Liters.

1. dEFF, for degrees Fahrenheit and Gallons. (Factory

Default)

2. dECC, for degrees Celsius and Liters.

iv.

Normal Display Mode– Sets the display to show various values.

1. dSP1, to display setpoint tem

perature only. (Factory

Default)

a. setpoint is displayed as ###

Page 25

25

2. dSP2, to display measured inlet temperature intermittently with

setpoint temperature.

a. Inlet temperature is displayed as i###

3. dSP3, to display measured outlet temperature intermittently with

setpoint temperature.

a. Outlet temperature is displayed as o###

4. dSP4, to display measured flow rate intermittently with setpoint

temperature

a. Flow rate is displayed as F##.#, in tenths of a gallon or liter.

5. dSP5, to display inlet temp, outlet temp, flow rate and setpoint all

intermittently.

v. Power Limiting Factor – Sets the % of heater output allowed by the

controller

1. L###, where ### is a percentage from 001 to 100 (Factory Default

100). This feature allows a user to limit the kW rating of the unit

by a specific percentage and effectively lower the total amp draw

of the unit.

vi. Heater Configuration – Sets the controller to perform calculations based

on the heater configuration of the unit.

1. E001, for single-phase one heating element and

all 3-phase units

2. E002, for single-phase two heating elements

3. E003, for single-phase three or six heating elements

4. E004, for single-phase four heating elements

vii. Calibration – Used to calibrate the heater. (For factory use only)

1. CA##, where ## equals the degrees of calibration from -3 to 3.

Default is 0.

viii. Low/High Flow – Sets the unit as either a low flow or

high flow unit.

1. LF, for low flow (Factory Default).

2. HF, for high flow.

ix. Remote Control – Sets the operation of the remote control function (see

Priority and Remote Controls in this section).

1. iPOF, disables the remote control (Factory

Default).

2. iPHi, 24VDC signal or closed relay connected

to P2 and P3 will allow the heater to operate and loss of 24VDC

signal or open relay connected to P2 and P3 will inhibit the heater

operation.

3. iPLo, 24VDC signal or closed relay connected to P2 and P3 will

inhibit the heater operation and loss of 24VDC signal or open relay

connected to P2 and P3 will allow the heater to operate.

x. Display Lock – Allows the user to lock the heat

er parameters. When the

display is locked the temperature setpoint cannot be changed and

although the configuration menu will still be accessible, no changes can

be made to any parameters, except to change the display lock. With the

display lock on, attempting to change the temperature setpoint will cause

the display to show, Locd.

1. LcOn, to turn the display lock on.

2. LcOF, to turn the display lock off (Factory

Default).

xi. Software Version – Displays the version number of the software

1. Sd##, where ## is the version of the display software.

2. Sb##, where ## is the version of the main board software.

h. After this menu item, the configuration menu cycles back to the first item.

Page 26

26

POINT IS FLASHING

4. Diagnostic Menu Display

a. To display common diagnostic data useful for troubleshooting,

when in normal display mode press and release the UP and

DOWN buttons simultaneously.

b. The display will intermittently display the following values:

flow rate (F##.#), measured inlet temp (i###), measured outlet

temp (o###), setpoint (###).

c. These values and settings will continue to display and scroll

until either the UP or DOWN button is pressed. The display then

returns to normal display mode.

5. Configuration Settings Display

a. To display all configuration settings, when in normal display mode press and

release the UP and DOWN buttons simultaneously twice.

b. The display will scroll through all configuration settings.

c. The display will continue to scroll until either the UP or DOWN button is

pressed and will then return to normal display mode.

6. Power Rate Display

a. The decimal point in the display’s rightmost digit is a visual indicator of how

much power is required to meet the demand. A blinking decimal

point indicates that the triac is being sent a signal to energize and

thus turn the element on. The decimal point light will

blink at a faster rate as the controller is calling for more

heat. When the unit is calling for full power the light is solid.

b. If the amount of power required exceeds the capacity of the heater, then the

entire display will intermittently flash. (Note that the display will only flash

when the display configuration is set to ‘dSP1’.)

7. Cost Calculator – Allows the user to view the amount of power and hot water

consumed and the cost of operation.

a. To display the Cost Calculator values, when in normal display mode press and

release the UP and DOWN buttons simultaneously three times.

b. The display will scroll through the Cost Calculator Values since last reset

i. C###, where ### equals the total cost of operation

ii. ####, where #### equals the total number of kW·Hrs consumed

iii. H0##, where ## equals water usage up to the ten thousands place,

followed by h###, where ### equals water usage up to the hundreds

place. Example: H012, h345 equals 12,345 gallons of water used.

iv. To reset these values to 0, press and hold the UP and DOWN buttons

simultaneously for 5 seconds. When the display shows ‘0000’, the cost

calculator has been reset.

c. To enter a specific cost per kW·Hr value, while displaying the Cost Calculator

values above press and release the UP and DOWN buttons simultaneously.

i. The display shows the cost per kW·Hr as #.### (Factory Default 0.114)

ii. Press the UP or DOWN button to adjust the cost p

er kW·Hr. Holding the

UP or DOWN buttons will fast scroll.

iii. Press the UP and DOWN buttons simultaneously to lock in the cost per

kW·Hr.

iv. Press the UP or DOWN button to return to Cost Calculator values.

v. Press the UP or DOWN button to return to normal display mode.

8. Error Code

a. Err1, indicates a failure of element #1

b. Err2, indicates a failure of element #2

c. Err3, indicates a failure of element #3

d. Err4, indicates a failure of element #4

e. Err5, indicates a failure of the inlet thermistor

Page 27

27

f. Err6, indicates a failure of the outlet thermistor

g. Err7, indicates a failure of the display unit to communicate with the main board

h. LEA H2O, indicates that water has been detected in the case

Remote Display

An optional remote display may be supplied and connected to the TK2000 control board as

shown below.

Priority and Remote Controls:

Optionally, the tankless water heater may be connected to another electrical device (10A

@240VAC max.) that will give priority to the booster heater over that device to ensure that

both do not operate at the same time and/or the tankless booster heater may be wired to a

remote switch, relay, or provided with a 24VDC signal (such as from a building mainte nance

system) to allow the tankless booster heater to be remotely controlled. The diagram and

description below provide details on how connec tions to the tankless booster heater control

board are to be made.

1. Priority Relay (10A@240VAC max.)

a. When the unit is demanding power (calling for heat):

i. The connection between the terminals marked C and NO are closed and

will allow power to pass through.

ii. The connection between the terminals m arked C and NC are open and will

not allow power to pass through.

b. When the unit is not demanding power (not calling for heat):

i. The connection between the terminals marked C and NO are open and will

not allow power to pass through.

ii. The connection between the terminals marked C and NC are closed and

will allow power to pass through.

2. Remote Control

a. When a 24VDC signal (5mA draw max.) is supplied between terminals P1 and

P2, the heater will either operate or be inhibited (displayed as H1d) as determined

by the Remote Control settings as shown above. Loss of 24VDC signal has the

opposite effect.

b. When wired to a volt-free contact (10A max.) between terminal P2 and P3 (output

signal 24VDC@5mA), opening or closing the contact will allow the heater to

either operate or inhibit (displayed as Hld) operation as determined by the Remote

Control settings as shown above.

Page 28

28

TK2000 Control Board Wiring Detail

Power and Triac Wiring

Outlet

Thermistor

Inlet

Thermistor

Leak

Detection

F1 F2 F3

Flow

Meter

Remote

Display

Display

Auxiliary

P1(0VDC) P2(+24VDC) P3

Remote

Control

Priority

Relay

NC

NO

C

Page 29

29

SECTION V – TROUBLESHOOTING

Common Issues:

Symptom Probable Cause Corrective Action

Water reaches setpoint

temperature but does

not last through the

entire dishwasher

cycle.

Low incoming water

temperature.

Incoming water temperature must be

adequate for the booster size. Increase the

incoming water temperature.

Incoming water

temperature is

dropping.

Primary water supply is not adequate to

continually provide correct temperature in

sufficient quantities. Increase the supply of

primary warm water.

Water pressure is too

high.

Higher water pressure uses an excessive

supply of hot water. Verify a pressure

reducing valve is installed a nd adj ust the

water pressure to the dish machine

specifications.

Booster heater may be

undersized.

The booster heater must be properly sized

for the incoming water and rinse

requirements of the dishwasher. If

required, replace with a properly sized unit.

Incorrect voltage. Voltage available at the booster heater

must be correct for unit. Verify voltage on

all phases matches nameplate on the

booster heater.

Gauge(s) not reading

correctly.

Check the temperature of the water with a

thermometer to verify the gauges are

working properly. Replace gauges, if

required.

Temperature setpoint

too low.

Adjust the temperature setpoint.

Water at the

dishwasher is not the

proper temperature.

Booster heater piping to

the dishwasher is not

insulated.

If there is more than 5 linear feet of piping

between the booster heater and the

dishwasher the piping should be wrapped

in insulation or a recirculating system

should be installed.

Bypass valve is open or

allowing water to pass

when closed.

Verify that the bypass valve between the

hot and warm water lines is closed. If

condition continues, replace the bypass

valve.

If none of the above addresses and solves the issue, proceed with the Initial Evaluation.

Page 30

30

Initial Evaluation:

Page 31

31

Advanced Troubleshooting:

WARNING: Serious bodily injury or death may occur if the following warnings are

ignored.

• This following portion of this section is intended for use by a QUALIFIED

ELECTRICIAN.

•

All circuit breakers must be turned off at the main panel before the cover of the unit

is removed.

This troubleshooting section will cover all the points that need to be checked from an

electrical standpoint to ensure that the Hubbell tankless booster heater is working correctly

and to determine which component may need to be replaced.

Tools Required:

• Phillips screwdriver

• Clamp multi-meter able to read voltage and amperage (amperage readings require a

clamp type meter).

• Thermometer

Pre-Operational Procedures:

1. With power to the unit turned ON, verify that the configuration settings are correct in

accordance with the Temperature Controller User Interface Instructions in Section IV.

2. TURN OFF POWER AT THE MAIN PANEL.

3. Remove the cover by unscrewing the screws located on all sides of the unit.

4. Verify that the main power feed is properly connected to the power distribution block

or magnetic contactor, as applicable.

5. Verify all connections are tight.

Check the Power Supply to the Unit:

1. Turn on power to the unit from the main panel.

2. Check the incoming voltage between each phase at the line side of the power

distribution block or magnetic contactor, as applicable.

3. If no voltage is present between all phases, verify that the breakers or disconnect on

the main panel have been turned on.

4. If the breakers are on and there is still no voltage present or if the incorrect voltage or

no voltage is present between any two phases, contact an electrician to troubleshoot

the feed.

5. If all voltage readings are acceptable, proceed to Check the Transformer

.

Check the Transformer:

1. The transformer is utilized on units with supply voltages above 240 volts to supply a

reduced voltage capable of powering the temperature controller.

2. If the display is lit or the unit is not equipped with a transformer (208 and 240 volt

units), proceed to Check the Hi-Limit Thermostats

.

3. Check the voltage on the primary side of the transformer.

4. If there is no voltage present, check the wiring and connections to the primary side of

the transformer from the power distribution block or magnetic contactor, as

applicable.

5. Check the voltage on the secondary side of the transformer.

6. If the secondary voltage does not conform to the table below, replace the transformer.

7. If all voltage readings are acceptable, proceed to Check the Hi-Limit Thermostats

.

Page 32

32

Primary Voltage Secondary Voltage (±5%)

380 207

415 221

440 214

480 234

575 206

600 215

Note: The secondary voltage listed in the transformer is based on the transformer being used

at full capacity. Because there is essentially “no load” on the transformer, the secondary

voltage will be higher than the voltage listed on the transformer. This “regulation” varies

from 8.4% to 12% depending on the primary voltage and the transformer used.

Check the Hi-Limit Thermostats:

1. The unit is supplied with safety hi-limit thermostats mounted on the plate that holds

the heating chamber in place. In single phase units with no contactor, these

thermostats allow the power from one phase of the terminal block to flow to the

heating element. If the hi-limit thermostat fails it will not supply the heating element

with power and therefore the heating element will not turn on and produce heat. In

three-phase units or any unit with a magnetic contactor, the thermostats are wired in

series to a magnetic contactor coil. If any hi-limit thermostat fails it will not supply

power to the contactor coil and therefore no power will be supplied to any heating

elements.

2. For single-phase units, check the voltage between the left-hand metal connection point

of the thermostat and the metal plate. If shrink-wrap is present around the metal

connection point to the hi-limit thermostat, cut back the shrink-wrap with a knife to

expose the metal connection. A voltage reading around 120V should be indicated

since this component is being fed by one leg of the electrical power coming off the

terminal block. Perform this step on the left-hand connection of each hi-limit

thermostat then again on the right-hand connection of each hi-limit thermostat.

3. If there is no voltage at the bottom of any hi-limit thermostat, then check the wiring

and connections between that hi-limit thermostat and the power distribution block.

4. If correct voltage is present at the bottom of the hi-limit thermostat but no voltage is

present at the top of the thermostat, then that hi-limit thermostat needs to be replaced.

5. If correct voltage is present on the top and bottom continue to Check the Thermistor

.

6. For three-phase units, if the magnetic contactor is pulled in, continue to Check the

Thermistor. Otherwise, starting at the left-hand connection of the lowest hi-limit

thermostat, check the voltage between the metal connection point of the thermostat

and the metal plate.

7. A voltage reading around 120V should be indicated. If no voltage is present at this

point, check the wiring and connections to this hi-limit thermostat from the magnetic

contactor or transformer, as applicable.

Page 33

33

8. If correct voltage is present, check the voltage at the right-hand side of the thermostat,

then the left-hand side of the thermostat above and continue this pattern to the

uppermost thermostat.

9. If at any point there is voltage on the left-hand side and there is no voltage on the

right-hand side of the same thermostat, replace that hi-limit thermostat.

10. If at any point there is voltage on the right-hand side of a thermostat and there is no

voltage on the left-hand side of the thermostat above it, check the wiring and

connections.

11. If all voltage readings are good and the contactor is not pulled in, check the wiring and

connections between the right-hand side of the uppermost thermostat and the magnetic

contactor coil.

12. If the wiring and connections are good, replace the magnetic contactor.

Check the Thermistor:

1. The thermistor is a temperature sensing device that changes resistance with changes in

temperature. It is designed to register 150,000Ω at 77°F (25°C).

2. Set the unit to diagnostic mode by pressing and releasing the UP and DOWN buttons

simultaneously.

3. With a thermometer, measure the temperature of the cold water and hot water at a

fixture.

4. Compare the displayed inlet temperature (i###) to the measured cold water

temperature and the displayed outlet temperature (o###) to the measured hot water

temperature. If either of these readings is significantly different, continue with the

next step. Otherwise, proceed to Check the Flow

Meter.

5. At the right hand side of the temperature

controller are two terminal blocks. Disconnect

the wires from the uppermost terminal block

(outlet thermistor). Using the multi-meter probes

with the setting at OHMS or Ω, place one probe

on the end of one wire and the other probe on the

end of the other wire. An ohms reading

consistent with the chart below for the

approximate temperature of the water should be

indicated. NOTE: Alligator clips should be used.

Holding the wires in your hands will give a false

reading. Reconnect the wires.

Thermistor Chart (150,000Ω @ 77°F (25°C))

Temperature, °F (°C)

Ohms, Ω

50 (10.0) 299,516

60 (15.6) 229,905

70 (21.1) 178,244

80 (26.7) 139,501

90 (32.2) 110,157

100 (37.8) 87,723

110 (43.3) 70,418

120 (48.9) 56,957

130 (54.4) 46,402

140 (60.0) 38,062

150 (65.6) 31,425

160 (71.1) 26,106

170 (76.7) 21,816

180 (82.2) 18,333

190 (87.8) 15,489

Outlet

Thermistor

Inlet

Thermistor

Page 34

34

6. Repeat the above step with the lower terminal block (inlet thermistor).

7. If either of these readings is not consistent with the chart (within ±10,000Ω), replace

that thermistor.

8. If all ohms readings are acceptable, proceed to Check the Flow Meter

.

Check the Flow Meter:

1. Set the unit to diagnostic mode by pressing and releasing the UP and DOWN buttons

simultaneously.

2. Turn on the hot water to ensure a good flow rate through the unit.

3. If the flow rate on the display reads ‘F00.0’ then continue with the next step.

Otherwise, proceed to Check the Temperature Controller

.

4. Verify that the wiring from the flow switch is connected to the control board in the

order WHITE/GREEN/BROWN from left to right.

5. With no flow on the unit, using the multi-meter probes with the setting at Volts –

Direct Current, place one probe on the terminal block where the WHITE wire is

connected (F1) and the other probe where the BROWN wire is connected (F3). A

voltage reading in the appropriate range (5V) should be indicated.

6. If the voltage reading is not in the appropriate range (5V), replace the temperature

controller.

7. Turn on the hot water to ensure a good flow rate through the unit and using the multimeter probes with the setting at Volts – Direct Current, place one probe on the

terminal block where the WHITE wire is connected (F1) and the other probe where

the GREEN wire is connected (F2). A voltage reading in the appropriate range (2.5V)

should be indicated.

8. If the voltage reading is not in the appropriate range (2.5V), replace the flow meter.

9. If all voltage readings are acceptable, proceed to Check the Temperature Controller

.

Check the Temperature Controller:

1. At the top of the temperature controller there are 4 sets of terminal blocks. Verify the

wiring is correct as indicated in the wiring diagram specific to the model.

2. Check the voltage between the terminal block where the RED wire is connected (this

will be the leftmost terminal) and the metal heater chamber cover. A voltage reading

in the appropriate range (120V) should be indicated.

3. If no voltage is present, verify that the RED wire in the terminal block is properly

tightened and verify that the opposite end of the RED wire is properly connected to

the power distribution block, magnetic contactor, or transformer, as applicable.

4. Check the voltage between the terminal block where the BLACK wire is connected at

the second terminal from the left and the metal heating chamber cover. A voltage

reading in the appropriate range (120V) should be indicated. Repeat this step for each

of the BLACK wires.

5. If no voltage is present, verify that the BLACK wire in the terminal block is properly

tightened and verify that the opposite end of the BLACK wire is properly connected

to the power distribution block, magnetic contactor, or transformer, as applicable.

6. If voltage is present where both the RED and BLACK wires connect to the terminals

and there is no display, replace the temperature controller.

7. Check the voltage between each additional BLACK wire from left to right and the

metal heating chamber cover. A voltage reading in the appropriate range (one half of

the incoming power voltage, i.e. if the incoming power is 480V, then the reading

should be 240V) should be indicated.

8. If no voltage is present, verify that the BLACK wires in the terminal block are

properly tightened and verify that the opposite ends of the BLACK wires are properly

jumpered to the previous BLACK wire connection terminal or properly connected the

magnetic contactor, as applicable.

9. Turn on the hot water to ensure a good flow rate through the unit and set the

temperature at the highest setting so the unit calls for full power.

Page 35

35

10. Check the voltage between the terminal block where the first YELLOW wire is

connected from left to right and the metal heating chamber cover. A voltage reading in

the appropriate range (one half of the incoming power voltage, i.e. if the incoming

power is 480V, then the reading should be 240V) should be indicated. Repeat this step

for each of the YELLOW wires.

11. If no voltage is present on any one of the YELLOW wires, replace the temperature

controller.

12. If all voltage readings are acceptable, proceed to Check the Triacs (Step 1)

.

Check the Triacs (Step 1):

1. The triacs are the switching mechanism for turning the

heating elements on and off.

2. Turn on the hot water to ensure a good flow rate through

the unit and set the temperature at the highest setting so the

unit calls for full power.

3. Check the voltage between one of the screws where the

RED wire is connected to the top of the heating element

and the screw where the other RED wire is connected to the

top of the heating element. A voltage reading in the

appropriate range (equal to the incoming line voltage)

should be indicated.

4. If no voltage is present on any heating element, the triac connected to that element

should be replaced.

5. If all voltage readings are acceptable, proceed to Check the Heating Elements

.

Check the Heating Elements:

1. To check the heating element the amperage draw from each

heating element must be verified. To do this the unit must be

operating.

2. Turn on the hot water to ensure a good flow rate through the

unit and set the temperature at the highest setting.

3. Using a clamp-on multi-meter, clamp the meter around one

of the RED wires going to the lowest heating element. The

reading should be as indicated (±5%) based on the specific

model listed in the Electrical Specification table in the

Installation section.

4. Repeat for all the heating elements.

5. If any amp reading is not within the range as indicated in the

chart, that heating element should be replaced.

6. If all readings are within range continue to Check the Triacs (Step 2).

Check to Triacs (Step 2):

1. Turn off the flow of hot water.

2. Using a clamp-on multi-meter, clamp the meter around one of the RED wires going to

the lowest heating element (same as in step 3 of Check the Heating Elements

). The

reading should be zero. Repeat for all the heating elements.

3. If any reading is not zero with the hot water turned off, then that triac should be

replaced.

Contact the Factory:

1. If you were unable to determine the problem from the above troubleshooting, please

have the electrician contact the factory.

Page 36

36

SECTION VI – SERVICING & REPLACEMENT OF PARTS

WARNING: Serious bodily injury or death may occur if the following warnings are

ignored.

• This following portion of this section is intended for use by a QUALIFIED

ELECTRICIAN OR PLUMBER.

•

All circuit breakers must be turned off at the main panel before the cover of the unit

is removed.

• When any maintenance is performed on the water heater that may introduce air into

the unit, it is important to purge the air out of the lines before allowing the unit to

power up. See Checking for Leaks and Purging Air in Section III.

Heating Element:

• Disconnect power.

• Shut off cold water inlet and hot water outlet valves.

• Drain unit.

• Remove cover.

• Disconnect the RED power leads from the top of the

element to be replaced.

• Unscrew the element from the heating chamber coupling.

• Install the replacement heating element by screwing it into the

heating chamber coupling.

NOTE: Verify that the o-ring is installed onto the heating

element prior to installation.

• Re-connect the power leads to the element terminals.

• Re-install cover.

• Open the cold water inlet and hot water outlet valves.

• Bleed ai r fr o m t h e u n i t . See Checking for Leaks and Purging

Air in Section III.

• Turn on power.

Hi-Limit Switch:

• Disconnect power.

• Remove cover.

• For single-phase models, disconnect the

leads from the heating element and power

distribution block that connect to the hi-limit switch to be replaced. For three-phase

units, disconnect the wires from the hi-limit switch to be replaced.

NOTE: The replacement hi-limit switch comes with power leads attached. For singlephase units, power leads should not be disconnected from the hi-limit switch. For

three-phase units, disconnect the attached power leads on the replacement piece.

• Remove the two (2) screws securing the hi-limit switch to the heating chamber cover.

• Remove the hi-limit switch.

• Spread a pea sized amount of the conductive thermal paste included with the

replacement kit on the back of the hi-limit switch (the portion to be installed against the

heating chamber tube).

• Install the hi-limit switch to the heating chamber cover with the two (2) screws

previously removed.

• For single-phase units, connect the supplied power leads to the heating element and the

power distribution block. For three-phase units, connect the wires previously

disconnected in the prior step.

• Re-install cover.

• Turn on power.

Page 37

37

Inlet

Thermistor

Inlet Thermistor:

• Disconnect power.

• Remove cover.

• Disconnect inlet thermistor wires from the

controller.

• Cut the tie-wrap securing the inlet thermistor

to the inlet pipe and remove the inlet

thermistor.

• Spread a pea sized amount of the conductive

thermal paste included with the replacement kit on the inlet pipe where

the replacement inlet thermistor is to be installed.

• Secure the inlet thermistor to the inlet pipe with a new tie-wrap.

• Connect the inlet thermistor wires to the controller.

• Re-install cover.

• Turn on power.

Outlet Thermistor:

• Disconnect power.

• Remove cover.

• Disconnect outlet thermistor wires from the

controller.

• Cut the tie-wrap securing the outlet thermistor

insulation.

NOTE: Save the insulation to cover the

replacement outlet thermistor.

• Remove the aluminum tape securing the outlet

thermistor and remove the outlet thermistor.

• Spread a pea sized amount of the conductive thermal paste included with the

replacement kit on the outlet pipe where the replacement outlet thermistor is to be

installed.

• Secure the outlet thermistor to the outlet pipe with a new piece of aluminum tape.

Position the outlet thermistor such that the wires are facing towards the top.

• Secure the outlet thermistor insulation around the outlet

thermistor with a new tie-wrap.

• Connect the outlet thermistor wires to the controller.

• Re-install cover.

• Turn on power.

Temperature Controller:

• Disconnect power.

• Remove cover.

• Mark the wires going to the controller so they can be re-connected in the same places

upon replacement.

• Disconnect all the wires from the controller.

NOTE: The display may need to be removed to access the wires from the flow meter.

The display can be removed by removing the four (4) screws securing the display to the

controller standoffs and then pulling the display from the socket.

• Remove the two (2) screws securing the temperature controller to the controller stand.

• Install the replacement controller with the two (2) screws removed in the last step.

• Re-connect the wires to the temperature controller in the same locations they were

previously disconnected from.

• Re-install cover.

• Turn on power.

Outlet

Thermistor

Inlet

Thermistor

Temperature

Controller

Page 38

38

Triac:

• Disconnect power.

• Remove cover.

• Disconnect the RED wire from the heating element, the

BLACK wire from the power distribution block or

magnetic contactor (as applicable), and the YELLOW

wire from the controller for the triac to be replaced.

NOTE: Replacement triacs come with replacement wires

attached.

• Remove the two (2) nuts securing the triac to the heatsink

and remove the triac.

• Spread a pea sized amount of the conductive thermal paste

included with the replacement kit on the back of the triac to be installed.

• Install the replacement triac to the heatsink with the two (2) nuts removed previously.

• Connect the RED wire to the heating element, the BLACK wire to the power

distribution block or magnetic contactor (as applicable), and the YELLOW wire to the

controller.

• Re-install cover.

• Turn on power.

Flow Meter:

• Disconnect power.

• Shut off cold water inlet and hot water outlet

valves.

• Drain unit.

• Remove cover.

• Disconnect the flow meter wires from the

controller.

NOTE: The display may need to be removed to

access the wires from the flow meter. The

display can be removed by removing the four (4)

screws securing the display to the controller

standoffs and then pulling the display from the socket.

• Disconnect the cold water supply pipe from the quick-connect fitting. See

Disconnecting a Joint in Section III.

• Unscrew the quick-connect and coupling assembly from the flow meter.

• Unscrew the flow meter from the inlet pipe.

• Screw the replacement flow meter into the inlet pipe.

NOTE: Pipe dope must be used to seal the connection.

• Screw the quick-connect and coupling assembly into the replacement flow meter.

NOTE: Pipe dope must be used to seal the connection

• Re-connect the cold water inlet piping to the quick-connect con n e c t o r . See Installation

of Quick-Connect Fitting in Section III.

• Connect the flow meter wires to the controller. From left to right, WHITE / GREEN /

BROWN.

• Re-install cover.

• Open the cold water inlet and hot water outlet valves

• Bleed ai r fr o m the unit. See Checking for Leaks and Purging Air in Section III.

• Turn on power.

Page 39

39

Magnetic Contactor:

• Disconnect power.

• Remove cover.

• Mark the wires going to the

magnetic contactor so they can be

re-connected in the same places

upon replacement.

• Disconnect all the wires from the

magnetic contactor.

• Remove the two (2) screws

securing the magnetic contactor to

the base.

• Install the replacement magnetic contactor with the two (2) screws removed in the last

step.

• Re-connect the wires to the magnetic contactor in the same locations they were

previously disconnected from.

• Re-install cover.

• Turn on power.

Transformer:

• Disconnect power.

• Remove cover.

• Mark the wires going to the transformer so

they can be re-connected in the same places

upon replacement.

• Disconnect all the wires from the

transformer.

• Remove the two (2) screws securing the

transformer to the base.

• Install the replacement transformer with the

two (2) screws removed in the last step.

• Re-connect the wires to the transformer in the same locations they were previously

disconnected from.

• Re-install cover.

• Turn on power.

Control Flow:

• Disconnect power.

• Remove cover.

• Twist fuse and pull from fuse holder.

• Insert new fuse in holder and twist to lock in place.

• Reinstall cover.

• Turn on power.

Page 40

40

SECTION VII – PARTS LIST

Cate gory Description Hubbell P/N

Plumbing Dielectric Union- 3/4" Sweat x 3/4" FNPT

DIELECTRIC UNION

Dielectric Union- 1" Sweat x 1"FNPT

DIELECTRIC UNION 1"

Heating Chamber: 3 Element, Lo w Flow TK3-FM

Heating Chamber: 3 Element, High Flow TK3-FMHF

Heating Chamber: 6 Element, Lo w Flow TK6-FM

Heating Chamber: 6 Element, High Flow TK6-FMHF

Filter Sc reen for Inlet SCR EEN T K

Bronze Pressure R educing Valve N45BU

Temperature and P ressure Gauge T405

Water Treatment Sys t em (blended pho sphate) HBW-CLEAR

Replacement Cartridge for Water Treatment RSC-10

Elements 4500 Wat ts @ 240 Volts , 8. 5" long N1315-4500

(with O-ring) 5500 Watts @ 240 Volts , 8. 5" long N1315-5500

7000 Watts @ 240 Volts, 12" lo ng N1315-7000

8000 Watts @ 240 Volts, 12" lo ng N1375-8000

9000 Watts @ 240 Volts, 12" lo ng N1375-9000

6000 Watts @ 480 Volts, 12" long N1315-6000T4

7000 Watts @ 480 Volts, 12" long N1315-7000T4

8000 Watts @ 480 Volts, 12" long N1375-8000T4

9000 Watts @ 480 Volts, 12" long N1375-9000T4

7000 Watts @ 440 Volts, 12" long N1315-7000T5

8000 Watts @ 440 Volts, 12" long N1375-8000T5

9000 Watts @ 440 Volts, 12" long N1375-9000T5

7000 Watts @ 346 Volts, 12" long N1315-7000T6

8000 Watts @ 346 Volts, 12" long N1375-8000T6

9000 Watts @ 346 Volts, 12" long N1375-9000T6

8000 Watts @ 208 Volts, 12" long N1375-8000R

Extra O-Ring O RING SGB

Electrical Thermistor (with wire leads) USP9509

Auto Reset Hi-Limit 200°F

(

with wire lead s

)

L93

Temperature Co nt rol Board TK2000

Digital Disp lay TKD2000

Power Distr ib ut io n Block: 3 P ole 16023-3

Power Distr ibut io n Block: 2 P ole 67512

Transf ormer, 50VA, 380V - 185V B050-3351-3

Transf ormer, 50VA, 480V - 208V B050-3299-3

Transf ormer, 50VA, 600V - 195V B050-3350-3

Magnetic Contactor, 40A (R es.), 208/240V Coil C25DNF330B

Magnetic Contactor, 50A (R es.), 208/240V Coil C25DNF340B

Magnetic Contactor, 65A (R es.), 208/240V Coil C25DNF350B

Magnetic Contactor, 75A (R es.), 208/240V C oil C2 5FNF 360B

Magnetic Contactor, 90A (R es.), 208/240V C oil C2 5FNF 375B

Triac , 600V (with wir e leads) TG40E60

Triac , 800V (with wir e leads) TG40E80

Flo w Meter (1/ 2" NP T, 0. 2-8 GPM) TK FLO W BR

Flo w Meter (1" NP T, 0. 5- 40 GPM) VT2511MS HNP000

Control Fuse

LGR-3

Miscellaneous Overlay cover for T KD2000

TANKLESS OVERLAY

Page 41

41

SECTION VIII – WARRANTY

MANUFACTURER’S LIMITED WARRANTY

1. PRODUCT WARRANTY: Hubbell warrants the Hubbell Tankless Booster Heater and

its components as manufactured by Hubbell (the "Product") to be free from defects in

materials and workmanship, under normal use and service for the period of time identified

below beginning from the date of installation, provided that the Product is (i) installed within

sixty (60) days from date of shipment from Hubbell and (ii) installed by a licensed

electrician and plumber (specific proof required) and maintained in accordance with

Hubbell's written instructions.

HEATING CHAMBER: Five (5) years

ELECTRICAL COMPONENTS: One (1) year

REPLACEMENT PARTS: Thirty (30) days

SUCH WARRANTIES DO NOT COVER:

• Product failure caused by liming, sediment buildup, chemical corrosion,

chlorine/chloride corrosion, or freezing.

• Product failure caused by the failure to remove air from system prior to or during

operation.

• Product misuse, tampering or misapplication, accidental damage, improper installation

or the application of improper voltage.

• Costs incurred for shipping, delivery, handling, and/or administrative charges.

• Product failure due to lightening, flood or other natural or manmade calamities.

• Labor charges of any kind.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ANY OTHER

WARRANTY, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR PATENT OR OTHER INTELLECTUAL PROPERTY RIGHT

INFRINGEMENT.

2. LIMITATION OF REMEDIES AND DAMAGES: Hubbell's liability and Buyer's

exclusive remedy hereunder will be limited solely, at Hubbell's option, to repair or

replacement by the Hubbell Service Center with respect to any claim made within the

applicable warranty period referred to above. Without limiting the generality of the

foregoing, all warranty items shall be returned by Buyer, at its sole expense, to the Hubbell

Service Center for replacement or repair. Hubbell reserves the right to accept or reject any

such claim in whole or in part. Hubbell will not accept the return of any product without

prior written approval from Hubbell, and all such approved returns shall be made at Buyer's

sole expense. HUBBELL WILL NOT BE LIABLE, UNDER ANY CIRCUMSTANCES,

FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING BUT NOT

LIMITED TO LABOR COSTS OR LOST PROFITS RESULTING FROM THE USE OF

(OR INABILITY TO USE) THE PRODUCTS OR FROM THE PRODUCTS BEING

INCORPORATED IN OR BECOMING A COMPONENT OF ANY OTHER PRODUCT

OR GOODS.

3. FURTHER LIMITATIONS AND EXCLUSIONS AFFECTING YOUR

WARRANTY: This warranty is void if the product is not installed in accordance with

relevant, local electrical and plumbing codes and in accordance with the installation

instructions specified by the manufacturer. Local codes will override manufacturer’s

instructions at the time of installation and if additional installation parts are required, the

costs will be the responsibility of Buyer. Product nameplate identifying the m

odel and serial

number must be affixed to the unit and legible for the warranty to be exercised. Product

without the nameplate is excluded from warranty consideration. Buyer hereby accepts the

Page 42

42

entire responsibility for ascertaining whether they have sufficient electrical power to operate

our Tankless Water heaters as indicated in our specifications which are readily available at

our website, in our brochures and contained in the shipping box for installers to read before

installation. If Buyer has purchased without first ascertaining the cost for installation or the

necessary power available for operation, Hubbell at its sole and complete discretion may

allow a return and grant a refund less freight and less 30% of the retail price as a restocking

fee. The refund will be conditioned upon a determination by Hubbell after inspection of the

Product being returned (either unopened or in the original shipping box and packing) that the

Product has not been damaged. This request and for this reason only must be made within 30

calendar days of receipt of the Product.

AFTER 30 CALENDAR DAYS FROM DATE OF PURCHASE THERE WILL BE NO

RETURNS WHATSOEVER. BUYER ACCEPTS ALL SALES AS FINAL. ANY

ALTERATION TO THE PRODUCT VOIDS ALL WARRANTIES. HUBBELL IS NOT

RESPONSIBLE FOR ANY OTHER CHARGE OR EXPENSE INCURRED OTHER

THAN THE ORIGINAL PURCHASE PRICE OF THE PRODUCT. Hubbell shall not be

liable for consequential, special, incidental or contingent expenses or damages arising

directly or indirectly from any defect in or use of the Product nor will Hubbell be liable for

any water damage arising directly or indirectly from the use of the Product or from the

failure of or defect in any component part or connecting plumbing. Hubbell and Buyer agree

to these and the above terms in their entirety and accept all sales as final without recourse to

a credit card company and hereby agree that this Manufacturer's Limited Warranty shall be

governed by the laws of the State of Connecticut any and all actions arising from or relating

to this Manufacturer’s Limited Warranty and any aspects of the Product shall be brought in a

court of competent jurisdiction in Fairfield County, Connecticut.

WARRANTY PROCEDURE

4. PARTS REPLACEMENT PROCEDURE (Under Warranty within 1 Year): Have

your licensed electrician determine the exact parts that are defective and require

replacement. Please note that technical support is available for qualified technicians only

(licensed electricians and/or plumbers). Technical support that involves potentially

dangerous electrical conditions is not available to an unqualified person.

When contacting Hubbell, please be sure that the technician has read the “Operation and

Maintenance Manual” and has written down all the data from the Advanced Troubleshooting

Section.

If, at the sole discretion of Hubbell, a component requires repair or replacement under the

terms of this Manufacturer’s Limited Warranty, the part must be purchased and paid for

under our “Bill and Credit” terms and will be shipped via standard ground delivery. All

shipping charges are not included and are the responsibility of the Buyer. If faster shipping

service is desired, the Buyer must select and pay for same.

The replacement part purchased under our “Bill and Credit” terms is purchased via credit

card and upon return of the defective parts Hubbell will determine the cause of failure, and if

under warranty will issue a full credit less shipping charges. The returned part must be

received by Hubbell within thirty (30) days of shipment of the replacement part. Hubbell

will evaluate the returned part within ten (10) days, and if determined to be defective and

covered under terms of this warranty, full credit for the part will be issued.

Return warranty parts to: Hubbell Electric Heater

ATTN: Tankless Warranty

45 Seymour Street

Stratford, CT 06615

Page 43

43

NOTES

Page 44

44

P.O. BOX 288

STRATFORD, CT 06615-0288

PHONE: (203) 378-2659

FAX: (203) 378-3593

INTERNET: http://www.hubbellheaters.com

Loading...

Loading...