Page 1

OPERATING AND MAINTENANCE

MANUAL FOR

ELECTRIC BOOSTER HEATER

ELECTRIC HEATER COMPANY

BASE MODEL “ J ”

ASME ANSI/NSF5

2010 Edition

Page 2

2

HUBBELL

ELECTRIC HEATER COMPANY

45 SEYMOUR STREET

P.O. BOX 288

STRATFORD, CT 06615

PHONE: (203) 378-2659

FAX: (203) 378-3593

INTERNET: http://www.hubbellheaters.com

-- IMPORTANT --

Always reference the full model number and serial number when calling the factory.

WARNING / CAUTION

1. Tank is to be completely filled with water and all air is to be vented before energizing.

2. Due to the rigors of transportation, all connections should be checked for tightness before

heater is placed in operation.

3. Safety relief valve must be installed in tapping provided.

4. The refractory material used in heating elements may absorb some moisture during

transit, periods of storage, or when subjected to a humid environment. This moisture

absorption results in a cold insulation resistance of less than twenty (20) megohm s. If this

heater has been subjected to the above condition, each heating element must be checked

for insulation resistance before energizing. Contact the factory for a replacement element.

5. KEEP AWAY FROM LIVE ELECTRICAL CIRCUITS.

Do not perform any maintenance, make any adjustments, or replace any components

inside the control panel with the high voltage power supply turned on. Under certain

circumstances, dangerous potentials may exist even when the power supply is off. To

avoid casualties, always turn the power supply safety switch to off, turn the charge or

ground the circuit before performing any maintenance or adjustment procedure.

6. The unit is designed to operate at pressure not more than 150 psi.

7. Generalized instructions and procedures cannot anticipate all situations. For this reason,

only qualified installers should perform the installations. A qualified installer is a person

who has licensed training and a working knowledge of the applicable codes, tools,

equipment, and methods necessary for safe installation of an electric resistance water

heater. If questions regarding installation arise, check your local plumbing and electrical

inspectors for proper procedures and codes. If you cannot obtain the required

information, contact the company.

8. Water Quality Requirements – Recommended water hardness is 4 to 6 grains of

hardness per gallon (GPG). Water hardness above 6 GPG should be treated by a water

conditioner (water softener or in-line treatment). Water hardness below 4 GPG also

requires treatment to reduce potential corrosion. Excessive GPG will result in higher

operating and maintenance costs and will reduce product longevity. Chlorides must

not exceed 50 parts per million (ppm). Excessive chlorides will result in metallic

corrosion and will reduce product longevity. Water treatment has been shown to

reduce costs associated with de-liming the booster as well as reducing metallic

corrosion. Product failure caused by these conditions is not covered under warranty.

See warranty for complete details.

9. This water heater is not intended for space heating applications.

10. The water heater is factory set at 185°F for booster water heating applications. This

results in the possibility of a scalding water injury. A full thickness skin burn can

occur in less than one second of exposure to water at this temperature.

Page 3

3

TABLE OF CONTENTS

SECTION TITLE PAGE No.

I GENERAL DESCRIPTION AND CONSTRUCTION 4

II INSTALLATION AND START-UP 9

III SCHEDULED MAINTENANCE AND OPERATION 24

IV TROUBLESHOOTING 26

V SERVICING AND REPLACEMENT OF PARTS 32

VI SERVICE PARTS LIST 35

VII TORQUE VALUES 37

VIII WARRANTY INFORMATION 38

Page 4

SECTION I - GENERAL DESCRIPTION AND CONSTRUCTION

GENERAL DESCRIPTION

This book describes a packaged electric booster heater that is typically used to provide 180°F

sanitizing rinse water. The complete assembly consists of the storage tank, immersion electric

heating element(s), electronic control module, safety relief valve, magnetic contactor(s), and

any other required electrical operating control. Optional equipment may be supplied with your

unit. Please consult the product packing list for details specific to your assembly. The unit is

factory assembled, insulated, jacketed, wired, tested, and ready for electrical and plumbing

service connections.

CAPACITY

Model

Storage

Capacity

(gallons)

kW

40°F

Rise

(GPH)

70°F

Rise

(GPH)

Model

Storage

Capacity

(gallons)

kW

40°F

Rise

(GPH)

70°F

Rise

(GPH)

J32.9 3 2.9 30 17 J161 16 1 10 5

J35.7 3 5.7 58 33 J161.5 16 1.5 15 8

J39.9 3 9.9 101 58 J162 16 2 20 11

J310.4 3 10.4 107 61 J163 16 3 30 17

J311.4 3 11.4 117 67 J164 16 4 41 23

J411 4 11.4 117 67 J166 16 6 62 35

J415 4 15 154 88 J167 16 7 72 41

J427 4 27 277 158 J169 16 9 92 53

J61 6 1 10 5 J1612 16 12 123 70

J61.5 6 1.5 15 8 J1613 16 13.5 138 79

J62 6 2 20 11 J1615 16 15 154 88

J63 6 3 30 17 J1618 16 18 185 105

J64 6 4 41 23 J1624 16 24 246 141

J65 6 5 51 29 J1627 16 27 277 158

J66 6 6 62 35 J1630 16 30 308 176

J67 6 7 72 41 J1636 16 36 369 211

J69 6 9 92 53 J1639 16 39 400 228

J610 6 10.5 108 62 J1640 16 40.5 415 237

J612 6 12 123 70 J1645 16 45 461 264

J613 6 13.5 138 79 J1654 16 54 554 316

J615 6 15 154 88 J1658 16 58.5 600 343

J618 6 18 185 105 J1664 16 64 656 375

J624 6 24 246 141 J1666 16 66 677 387

J627 6 27 277 158 J1668 16 68 697 398

J630 6 30 308 176 J1679 16 79 810 463

J636 6 36 369 211 J1681 16 81 830 474

J639 6 39 400 228 J1685 16 85 871 498

J640 6 40.5 415 237 J1686 16 86 882 504

J645 6 45 461 264 J1688 16 88 902 515

J654 6 54 554 316 J1690 16 90 923 527

J658 6 58.5 600 343

4

Page 5

5

Page 6

6

Page 7

CONSTRUCTION

TANK

The storage tank is designed, manufactured, and stamped in accordance with ASME section

VIII Division 1. The tank is constructed of type 304L stainless steel for maximum tank

longevity and fabricated by all welded construction and is designed for a maximum allowable

working pressure of 150 psi (225 psi TP).

TANK CONNECTIONS

The heater is supplied with separate connections for the cold/warm inlet and the hot water

outlet. Water entering the warm water inlet and leaving through the hot water outlet is evenly

circulated by means of a diffuser within the tank. A ¾-inch FNPT connection is provided for

mounting a combination safety temperature and pressure relief valve. An overflow line should

be utilized from the relief valve outlet to a floor drain. See drawing for locations and sizes.

HEATING ELEMENT

The water heater is supplied with an electric

immersion heating element assembly(s), composed

of copper sheathed elements that are fitted into a

brass 1½-12UNF screw plug with 1-7/8” hex. Each

assembly is threaded into the tank and sealed with an o-ring gasket. See drawing for voltage and

power ratings. Note that the J3 model element is a 1” NPS thread with a 1 ½” hex.

MAGNETIC CONTACTOR

The definite purpose magnetic contactor(s) is a heavy-duty resistive

load type. The contactor supplies power to the heating element(s)

based on the resistive load (non-inductive) of the heater only when

the relay on the control board is closed, thereby pulling in the

contacts until the desired temperature is reached. At this point, the

contacts will drop out, which in turn disconnects power from the

elements. Units with two contactors will turn on and off in stages.

CONTROL BOARD AND DISPLAY

The control board supplies all the

necessary function for heater operation.

These include control temperature, hilimit cut-out, low water detection, and

leak detection.

LOW VOLTAGE CONTROL TRANSFORMER

A control circuit transformer is supplied with all models rated

greater than 240-volts. This component is used to step down the

primary power supply (600, 480, 440, 415, 380, or 277) to 208/240volts for safety when working with control circuits.

POWER CIRCUIT BREAKERS

When required by code, a magnetic power circuit breaker is

supplied for circuit overload protection. The circuit breaker can

be reset in the event of a current overload.

OUTER SHELL, INSULATION, AND SUPPORTS

The tank is encapsulated in high efficiency foam insulation meeting the requirements for UL 94

HF-1 rating. The protective shell is constructed of type 304 brushed stainless steel. NSF

approved adjustable plastic legs are provided for support. Plastic legs for the J3 and J4 models

are optional.

DIAL TEMPERATURE AND PRESSURE GAUGE

A combination temperature (30°-240° F / 0°-120°C) and pressure (0–200

psi / 0-1400 kPa) gauge with 3-inch dial is supplied with the unit for in-line

installation (shipped loose). The connection is ½” NPT with a 2” long

sensing probe. Dial temperature and pressure gauges for the J3 and J4

models are optional.

7

Page 8

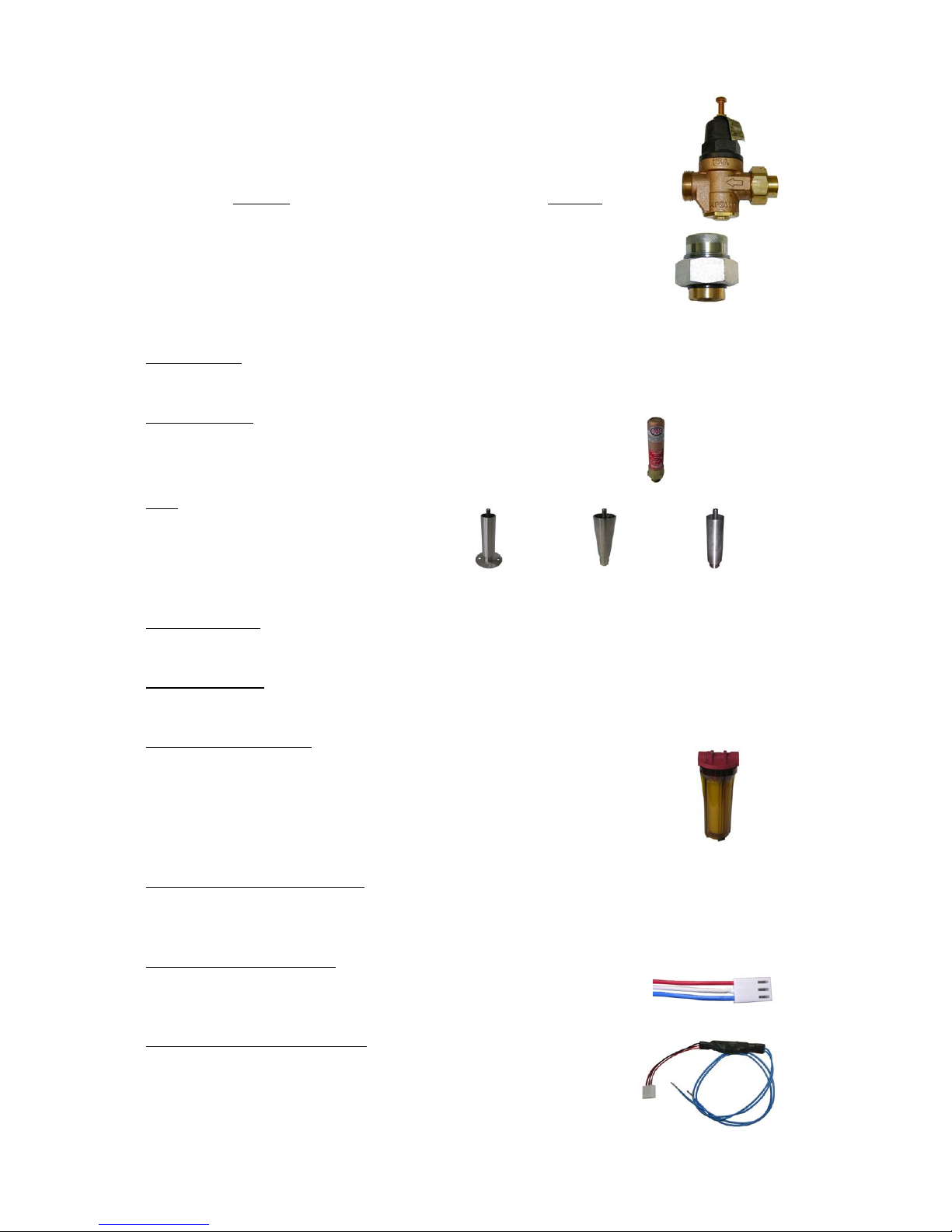

PRESSURE REDUCING VALVE

A bronze pressure reducing valve with built-in bypass is supplied with the

unit. This valve is shipped separately for in-line installation. The ¾” NPT

valve is adjustable from 25-psi to 75-psi. The inlet connection is supplied with

a ¾” union by sweat connection. The outlet connection is ¾” female NPT.

The set screw located at the top of the diaphragm adjusts the pressure, turn

clockwise to decrease

the pressure and counter-clockwise to increase the

pressure. Pressure reducing valves for the J3 and J4 models are optional.

DIELECTRIC UNIONS

Dielectric unions are provided for the inlet and outlet nipples to isolate stray

ground currents to reduce the possibility of galvanic corrosion. (Optional on

the J3 and J4 Models).

OPTIONAL EQUIPMENT

Slide Brackets

8

Available for the J6 Model only, these brackets allow for mounting the booster heater under a

counter. See slide bracket diagram on page 9 for details.

Shock Absorber

The optional shock absorber can be installed between the booster

and the dishwasher to reduce the harmful pressures resulting from

quick closing dishwasher solenoid valves.

Legs

In lieu of the standard black plastic legs,

optional adjustable legs are available in

stainless steel, die-cast nickel plated, and

floor mount stainless steel. All optional

legs are adjustable height type. Floor Mount Nickel Plated Stainless Steel

Security Package

For prison and other secure facilities a tamper resistant package is available. All external screws

are spader type requiring a spader wrench for removal.

Alternate Voltage

Other voltages are available, including 277V single-phase, and 380V, 415V, and 440V threephase. Consult the factory for details.

Water Treatment System

The optional water treatment system provides superior mineral scale

prevention and corrosion control by feeding a special blend of scale

control compounds into the warm water stream before the heater. The

in-line system includes a clear cartridge housing to allow an operator to

view the cartridge and determine when it needs replacement without the

need to open the system.

XB1 Low Temperature Interlock

An optional in-line control board with separate manual setpoint (range: 165°F – 194°F)

monitors the temperature of the water through the P65 probe and will trip a SPDT relay for

customers’ remote applications.

Remote Alarm Plug Adapter

An optional plug adapter is available to provide a remote fault alarm

signal through the J4 connector on the control board. See page 12 for

installation details.

24-Volt Heater Interlock Adapter

An optional plug adapter is available to interlock the heater via a 24-volt

signal through the J1 connector on the control board. The 24-volt heater

interlock adapter is supplied standard on the J3 model. See page 13 for

installation details. (Only available with r23 or later software).

Page 9

Protective Shrouds (J6 and J16 only)

An optional durable protective plastic shroud is

available to prevent damage to the booster due to

water intrusion. The cover fits snugly over the

entire booster and can be easily removed for

cleaning and service.

SECTION II – INSTALLATION AND START-UP

WARNING / CAUTION

• DO NOT TURN ON THE ELECTRIC POWER SUPPLY to this equipment until

heater is completely filled with water and all air has been released. If the heater is

NOT filled with water when the power is turned on, the heating elements will burn

out.

• For protection against excessive pressures and temperatures, local codes require the

installation of a temperature-and-pressure (T&P) relief valve certified by a nationally

recognized laboratory that maintains periodic inspection of production of listed

equipment of materials, as meeting the requirements for Relief Valves and Automatic

Gas Shutoff for Hot Water Supply Systems. ANSI Z21.22-1971. THE CUSTOMER

IS RESPONSIBLE TO PROTECT PROPERTY AND PERSONNEL FROM HARM

WHEN THE VALVE FUNCTIONS.

• All water heaters have a risk of leakage at some unpredictable time. IT IS THE

CUSTOMER'S RESPONSIBILITY TO PROVIDE A CATCH PAN OR OTHER

ADEQUATE MEANS, SO THAT THE RESULTANT FLOW OF WATER WILL

NOT DAMAGE FURNISHINGS OR PROPERTY.

• Installation or service of this unit requires ability equal to that of a licensed tradesman

in the field.

• The installation must conform to these instructions and any local authority having

jurisdiction. Grounding and electrical wiring connected to the unit must also conform

to the latest version of the National Electric Code NFPA-70.

WATER HEATER PLACEMENT

NOTE: For most effective operation, install the booster heater as close as possible to the

dishwasher. If the distance between the booster and the dishwasher exceeds NSF

requirements, recirculation methods must be employed.

1. Place the heater on a solid, level foundation in a clean, dry location as near as possible

to the dish washing machine.

2. The water heater should be protected from freezing and waterlines insulated to reduce

energy and water waste.

3. Leave a minimum of 18” clearance for element withdrawal and control access.

4. Do not install in an area where flammable liquids or combustible vapors are present.

SLIDE BRACKETS FOR

HANGING SUPPORT

MOUNTING

1. Weld slide rails to

bottom of dishtable.

Spacing should be 17”

for J6 models up to

18kW and 22” for J6

models 24 to 58.5kW.

J16 models are not

designed for use with

slide brackets.

9

Page 10

2. Attach slide bracket angles to heater with #8 sheet metal screws. It will be necessary

to drill 1/8” holes into heater jacket for screw pilot holes.

3. Slide heater onto slide rails under dishtable.

PIPING INSTALLATION – See Diagrams

NOTES:

• No check valve may be installed in the supply line to the booster.

• All shut-off valves must be gate or ball valves – not globe valves.

• To minimize heat loss and maximize efficiency, hot water piping should be insulated.

• Teflon tape should be used on all NPT threaded pipe connections.

1. Install the factory supplied dielectric unions on the inlet and outlet piping.

2. Connect the cold/warm water inlet and hot water outlet to the appropriate connections

as shown; refer to the specifications for location and sizes.

IMPORTANT – Be certain to connect the outlet piping to the final rinse and not to the

wash tank.

IMPORTANT (applies to J6 Models only) – Do not turn the entering warm water or

exiting hot water nipples from their factory installed positions. The internal diffusers

are aligned at the factory and turning the nipple will change the diffuser position and

affect performance. Hubbell recommends that the inlet and outlet pipes are insulated

to prevent excessive heat loss.

IMPORTANT (applies to J6 Models only) – Do not apply heat directly to the entering

warm water or exiting hot water nipples. If sweat connections are to be used, sweat

tubing to the adapter before threading the adapter to the nipple on the heater. Any heat

applied to the heater nipple will damage the internal plastic diffuser and affect

performance.

3. Install water pressure regulator in the entering cold/warm water inlet line and adjust to

the pressure recommended by the dishwasher manufacturer. WHEN A STANDARD

PRESSURE REGULATOR IS USED, (other than that purchased with the booster), it

acts as a check valve and it is possible that thermal expansion will cause the relief

valve to drip or occasionally blow off a small amount of water. To overcome this

condition, it is recommended that a 3/8” by-pass arrangement with a horizontal check

valve be installed around the pressure regulator. This will prevent annoyance caused

by the relief valve dripping or blowing off. The pressure reducing valve is adjustable

from 25 to 75 psi. The set screw located at the top of the diaphragm adjusts the pressure,

turn clockwise

to increase the pressure and counter-clockwise to decrease the pressure.

4. Install the factory supplied in-line pressure and temperature gauge in the entering

cold/warm water line. NOTE: The temperature sensing element must be in the water

stream.

5. Install the combination temperature and pressure safety relief valve in the tapping

provided. Note that this is required by law for safety considerations.

Install into provided tapping Manual Release Lever

Temperature Probe

Outlet to floor drain

Temperature and Pressure Relief Valve

6. Install a relief valve overflow pipe to a nearby floor drain.

NOTE: Relief valve discharge piping limitations:

a. Termination to be plain end (no threads)

b. Maximum 30-feet

10

Page 11

c. Maximum four (4) elbows

d. No reduction in line size

e. No valve of any type to be installed between the relief valve and tank or in the

drain line

f. Termination to be 6-inches above the drain

7. A shock absorber is recommended in the hot water outlet line to soften the water

hammer caused by automatic dishwasher solenoid valves.

8. If supplied, install the optional second dial temperature and pressure gauge in the

outlet line. The temperature sensing element must be in the hot water stream and the

gauge must be mounted upright.

FILLING THE HEATER

1. Open the valve to the cold water inlet and allow the heater and piping system to

completely fill, as indicated by a steady flow of water through the dishwasher rinse

nozzles.

NOTE: Flush the tank at full flow for 10 minutes prior to putting into service.

ELECTRICAL INSTALLATION

1. Enter the base through the factory cut KO’s with properly sized feeder leads, See

Wiring Chart. Single-phase installations require two (2) leads. All Hubbell 3-phase

heaters are intended for use with a 3-wire delta system plus ground. No neutral is

required. For a 4-wire plus ground system, install 3 legs of power plus the ground and

terminate the neutral leg.

2. Install these power leads into the box lugs on the power distribution block or magnetic

contactor, as required.

3. Connect incoming ground wire to ground lug supplied.

4. Check for proper grounding. Check for AC millivolts (mV) between the ground

connection at the booster and the inlet piping past the dielectric union (on the building

side, not the booster side). There should be zero potential/millivolts (mV). If not

zero, then the piping should be re-grounded.

5. All other electrical connections are made at the factory; therefore, no other electrical

connections are necessary.

6. Check all connections, including factory connections, for tightness.

OPTIONAL XB1 LOW TEMPERATURE INTERLOCK

1. If desired, the XB1 can be used as an alarm relay or a temperature interlock at a

setpoint other than the water temperature setpoint on the booster heater.

2. If the XB1 is not factory installed, mount the XB1 to the control panel, plug the P65

probe into the XB1, and plug the XB1 into the T1000 control board.

11

Page 12

3. To set the XB1 setpoint, turn the potentiometer clockwise for a higher setpoint and

counter-clockwise for a lower setpoint. The range is adjustable between 150°F and

180°F.

4. Make connections as required to the relay terminal block. When the temperature drops

below the XB1 setpoint the relay is open between Normally Open (NO) and Common

(C) and the LED will flash green. When the temperature is above the XB1 setpoint the

relay is closed between NO and C and the LED will be solid green. Use NO and C for

low temperature interlock or high temperature alarm. Use Normally Closed (NC) and C

for low temperature alarm. A red LED indicates an error.

LED

Relay

Terminal Block

12

Temperature Adjustment Potentiometer

FOR REMOTE ON/OFF CONTROL

To remotely control the On / Off

operation of the heater, it is

recommended that a DPST

switch or relay (by others) be

used to break both power legs

(white and black wires)

connected to the top two

terminals of the J5 connector on

the control board. See diagram

at right.

Use a NC (Normally Closed)

relay to turn the booster ON

when energizing the relay coil

or to turn the booster OFF whe

de-energizing the relay coil.

n

Use a NO (Normally Open) relay to turn the booster OFF when energizing the relay coil or

to turn the booster ON when de-energizing the relay coil.

OPTIONAL REMOTE ALARM CONTACTS

1. If desired, the control board can be wired to a remote alarm to indicate a reset fault

condition. These fault conditions include over-temperature, no probe, and low water

(when the configuration is set to manual reset).

2. This alarm can be wired to the J4 connector on the control board as shown below. To

facilitate this installation, an optional adapter, Hubbell P/N PLUG ADAPTER J4, can

be purchased to provide wire connections.

J4 Connector

Note: Rating (resistive)

Max. Switching Power:

60W, 62.5VA

Max. Switching Voltage:

220VDC, 250VAC

Max. Switching Current: 2A

Max. Carr

y

ing Current: 3A

PLUG ADAPTER J4

Wiring by

Customer

Remote Relay by Customer

1

2

3

4

Controller J5 Connector

Red Wire to

Contactor #2

Wiring from Contactor,

Power Distribution Block,

or Transformer

Yellow Wire to

Contactor #1

Note: Rating (resistive):

Max.: 5A @ 120VAC

5A @ 24VDC

(NO)

(NC)

Page 13

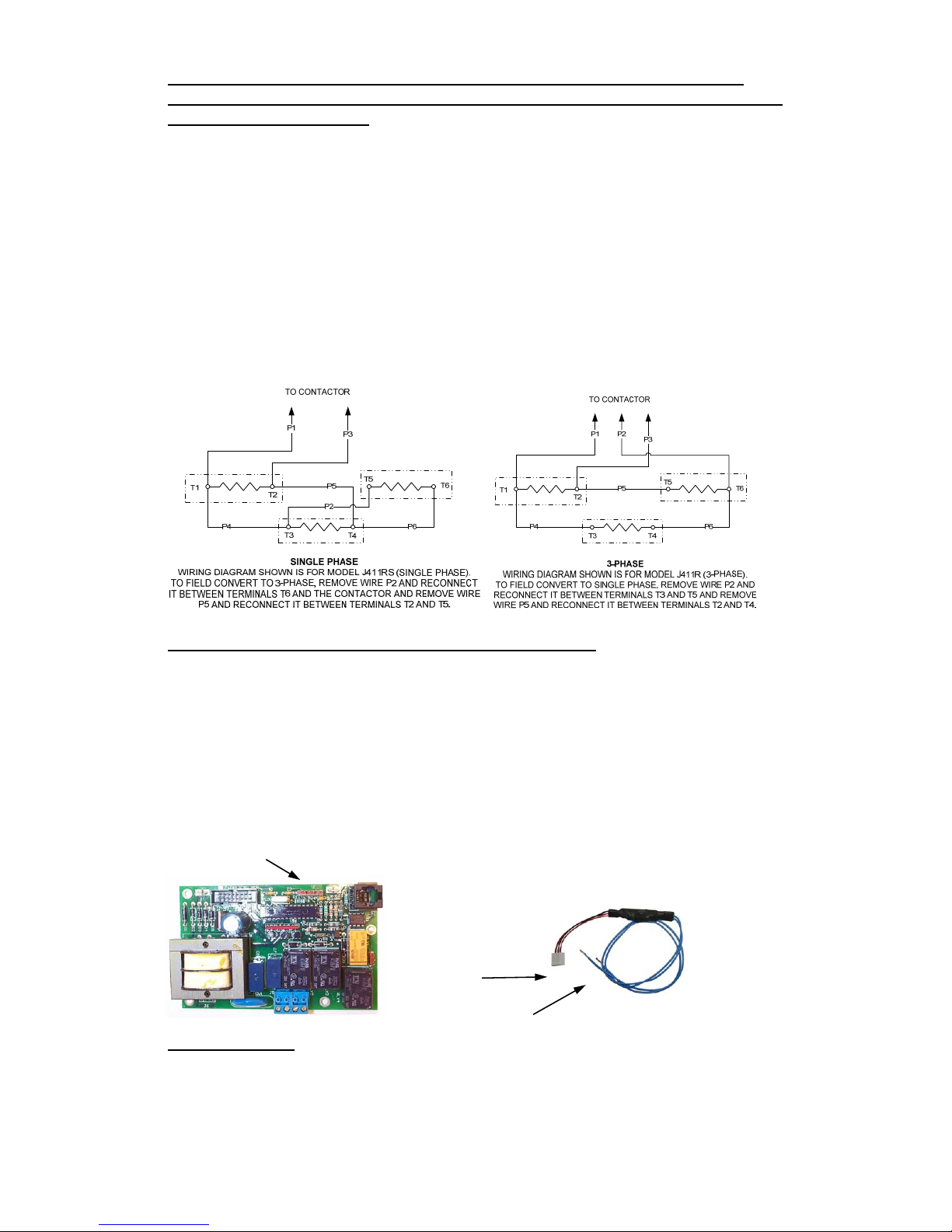

OPTIONAL FIELD CONVERSION FROM SINGLE TO THREE PHASE OR

THREE TO SINGLE PHASE (J6 and J16 models in 6, 7, and 9 kW and 208 and 240

volts and J411 models only)

1. For J6 and J16 models:

a. Find the appropriate diagram for the unit to be converted in the following chart

titled “Wiring Chart”.

b. Re-wire the unit according to the diagram.

NOTE: The wire to be used for internal wiring must conform to SEW-2 or

PTFE (200°C) and must match the wire size currently in use. Contact the

factory for assistance, if required.

c. Contact the factory for correct labels. The factory will need the serial number

for proper identification.

2. For J411 models:

a. Re-wire the unit to desired configuration as indicated below.

Single-Phase 3-Phase

OPTIONAL 24-VOLT HEATER INTERLOCK ADAPTER

1. If desired, the heater can be wired to operate only when supplied with a 24-volt signal

through the heater interlock adapter. When no 24-volt signal is supplied through the

heater interlock adapter the heater is interlocked and will not energize. When

interlocked the display will show “HLd”. The heater will resume normal operation

when a 24-volt signal is re-applied through the heater interlock adapter.

2. To utilize this feature, plug the 24-volt heater interlock adapter into terminal J1 of the

control board and verify that the configuration is set to “Hon”, see the controller

operation section for further detail. The signal can be either AC or DC. However, if a

DC signal is utilized and the interlock feature does not operate, switch the two 24-volt

supply wires at the heater interlock adapter.

J1

13

To J1

To 24-Volt Signal

FINAL CHECKS

1. Check all connections for tightness.

2. Ensure that all the above steps are completed.

3. Remove the protective outer plastic covering from the sheet metal shell.

4. After the water is heated for the first time, monitor the water temperature as described

in Section III, Annual Inspection.

Page 14

J6 and J16 Wiring Chart

kW Volt Ph

Unit

Amp

Draw

Branch

Amp

Draw

Phase-

Phase

Resistance

(Ohms)

Min.

Feed

Breaker

or Fuse

Size

Internal

Power

Wire

Size

Element

Jumper

Wire

Size

Copper

Power Feed

Wire Size

Conduit

Size

Diagram

1 120 1 8.3 8.3 14.4 15 12 N/A 14 ½" 1(NT)

1.5 120 1 12.5 12.5 9.6 20 12 N/A 14 ½" 1(NT)

2 120 1 16.7 16.7 7.2 25 12 N/A 12 ½" 1(NT)

3 120 1 25.0 25.0 4.8 35 12 12 10 ½" 1(NT)

208 1 19.2 19.2 10.8 25 12 N/A 10 ½" 1(NT)

240 1 16.7 16.7 14.4 25 12 N/A 12 ½" 1(NT)

380 1 10.7 10.7 36.1 15 12 N/A 12 ½" 1(WT)

480 1 8.3 8.3 57.6 15 12 N/A 14 ½" 1(WT)

208 1 24.0 24.0 8.7 30 12 N/A 10 ½" 1(NT)

240 1 20.8 20.8 11.5 30 12 N/A 10 ½" 1(NT)

380 1 13.2 13.2 28.9 20 12 N/A 12 ½" 1(WT)

480 1 10.4 10.4 46.1 15 12 N/A 14 ½" 1(WT)

208 1 28.8 28.8 7.2 40 12 12 8 ½" 4

208 3 16.7 16.7 14.4 25 12 12 10 ½" 10(NT)

240 1 25.0 25.0 9.6 35 12 12 8 ½" 4

240 3 14.4 14.4 19.2 20 12 12 12 ½" 10(NT)

380 3 8.6 8.6 48.1 15 12 12 14 ½" 10(WT)

480 3 7.2 7.2 76.8 10 12 12 14 ½" 10(WT)

600 3 6.0 6.0 114.8 10 12 12 14 ½" 14

208 1 32.5 32.5 6.4 45 12 12 8 ½" 4

208 3 18.7 18.7 12.4 25 12 12 10 ½" 10(NT)

240 1 30.5 30.5 8.2 40 12 12 8 ½" 4

240 3 17.6 17.6 16.5 25 12 12 10 ½" 10(NT)

380 3 10.0 10.0 41.3 15 12 12 12 ½" 10(WT)

480 3 8.4 8.4 65.8 15 12 12 14 ½" 10(WT)

600 3 6.8 6.8 102.0 10 12 12 14 ½" 14

208 1 43.3 43.3 4.8 55 10 12 6 ¾" 4

208 3 25.0 25.0 9.6 35 10 12 8 ½" 10(NT)

240 1 37.5 37.5 6.4 50 10 12 8 ½" 4

240 3 21.7 21.7 12.8 30 10 12 10 ½" 10(NT)

380 3 14.3 14.3 32.1 20 12 12 12 ½" 10(WT)

480 3 10.8 10.8 51.2 15 12 12 14 ½" 10(WT)

600 3 9.1 9.1 76.5 15 12 12 14 ½" 14

208 1 48.8 48.8 4.3 65 8 10 6 ¾" 4

208 3 29.1 29.1 8.2 40 12 12 8 ½" 10(NT)

240 1 43.8 43.8 5.5 55 10 12 6 ¾" 4

240 3 25.3 25.3 11.0 35 12 12 8 ½" 10(NT)

380 3 17.1 17.1 27.5 25 12 12 10 ½" 10(WT)

480 3 12.6 12.6 43.9 20 12 12 12 ½" 10(WT)

600 3 10.2 10.2 68.1 15 12 12 14 ½" 14

208 1 57.7 57.7 3.6 75 8 10 4 1" 4

208 3 33.3 33.3 7.2 45 12 12 8 ½" 10(NT)

240 1 50.0 50.0 4.8 65 8 10 6 ¾" 4

240 3 28.9 28.9 9.6 40 12 12 8 ½" 10(NT)

380 3 18.6 18.6 24.1 25 12 12 10 ½" 10(WT)

480 3 14.4 14.4 38.4 20 12 12 12 ½" 10(WT)

600 3 11.3 11.3 61.2 15 12 12 14 ½" 14

208 1 64.9 64.9 3.2 85 8 10 4 1" 4

208 3 37.5 37.5 6.4 50 10 12 8 ½" 10(NT)

240 1 56.3 56.3 4.3 75 8 10 4 1" 4

240 3 32.5 32.5 8.5 45 12 12 8 ½" 10(NT)

380 3 21.4 21.4 21.4 30 12 12 10 ½" 10(WT)

480 3 16.2 16.2 34.1 25 12 12 12 ½" 10(WT)

600 3 13.6 13.6 51.0 20 12 12 12 ½" 14

4

5

6

7

9

10.5

12

13.5

14

Page 15

J6 and J16 Wiring Chart (cont.)

kW Volt Ph

Unit

Amp

Draw

Branch

Amp

Draw

Phase-

Phase

Resistance

(Ohms)

Min.

Feed

Breaker

or Fuse

Size

Internal

Power

Wire

Size

Element

Jumper

Wire

Size

Copper

Power Feed

Wire Size

Conduit

Size

Diagram

208 1 72.1 72.1 2.9 95 6 8 3 1" 4 (DB)

208 3 41.6 41.6 5.8 55 10 12 6 ¾" 10(NT)

240 1 62.5 62.5 3.8 80 8 10 4 1" 4

240 3 36.1 36.1 7.7 50 10 12 8 ½" 10(NT)

380 3 22.9 22.9 19.3 30 12 12 8 ½" 10(WT)

480 3 18.0 18.0 30.7 25 12 12 10 ½" 10(WT)

600 3 14.7 14.7 47.1 20 12 12 12 ½" 14

208 1 86.5 86.5 2.4 110 6 8 2 1" 4 (DB)

208 3 50.0 50.0 4.8 65 8 10 6 ¾" 10(NT)

240 1 75.0 75.0 3.2 95 6 8 3 1" 4 (DB)

240 3 43.3 43.3 6.4 55 10 12 6 ¾" 10(NT)

380 3 27.9 27.9 16.0 35 12 12 8 ½" 10(WT)

480 3 21.7 21.7 25.6 30 12 12 10 ½" 10(WT)

600 3 18.1 18.1 38.3 25 12 12 12 ½" 14

208 1 115.4 38.5 1.8 145 10 12 1/0 1¼" 3A

208 3 66.6 66.6 3.6 85 8 10 4 1" 13(NT)

240 1 100.0 33.3 2.4 130 12 12 1 1¼" 3A

240 3 57.7 57.7 4.8 75 8 10 4 1" 13(NT)

380 3 37.1 37.1 12.0 50 10 12 6 ¾" 13(WT)

480 3 28.9 28.9 19.2 40 12 12 8 ½" 13(WT)

600 3 22.6 22.6 30.6 30 12 12 10 ½" 15

208 1 130.0 43.3 1.6 165 10 12 2/0 1½" 6A

208 3 74.9 37.5 3.2 95 10 12 3 1" 12(NCB)

240 1 112.5 37.5 2.1 145 10 12 1/0 1¼" 3A

240 3 65.0 65.0 4.3 85 8 10 4 1" 13(NT)

380 3 42.9 42.9 10.7 55 10 12 6 ¾" 13(WT)

480 3 32.5 32.5 17.1 45 12 12 8 ½" 13(WT)

600 3 27.2 27.2 25.5 35 12 12 8 ½" 15

208 1 144.2 48.1 1.4 185 8 10 3/0 1½" 6A

208 3 83.3 41.6 2.9 105 10 12 2 1" 12(NCB)

240 1 125.0 41.7 1.9 160 10 12 2/0 1½" 6A

240 3 72.2 36.1 3.8 95 10 12 3 1" 12(NCB)

380 3 45.7 45.7 9.6 60 10 12 4 1" 13(WT)

480 3 36.1 36.1 15.4 50 10 12 8 ½" 13(WT)

600 3 29.4 29.4 23.6 40 12 12 8 ½" 15

208 1 173.1 57.7 1.2 220 8 10 4/0 2" 6A

208 3 99.9 50.0 2.4 125 8 10 1 1¼" 12(NCB)

240 1 150.0 50.0 1.6 190 8 10 3/0 1½" 6A

240 3 86.6 43.3 3.2 110 10 12 2 1" 12(NCB)

380 3 55.7 55.7 8.0 70 8 10 3 1" 13(WT)

480 3 43.3 43.3 12.8 55 10 12 6 ¾" 13(WT)

600 3 36.2 36.2 19.1 50 10 12 8 ½" 15

208 1 187.5 62.5 1.1 235 8 10 250 2" 6A

208 3 108.3 54.1 2.2 140 8 10 1/0 1¼" 12(NCB)

240 1 162.5 54.2 1.5 205 8 10 4/0 1½" 6A

240 3 93.8 46.9 3.0 120 10 12 1 1" 12(NCB)

380 3 60.8 60.8 7.4 80 8 10 3 1" 13(WT)

480 3 46.9 46.9 11.8 60 8 10 6 ¾" 13(WT)

600 3 36.2 36.2 19.1 50 10 12 8 ¾" 15

15

18

24

27

30

36

39

15

Page 16

J6 and J16 Wiring Chart (cont.)

kW Volt Ph

Unit

Amp

Draw

Branch

Amp

Draw

Phase-

Phase

Resistance

(Ohms)

Min.

Feed

Breaker

or Fuse

Size

Internal

Power

Wire

Size

Element

Jumper

Wire

Size

Copper

Power Feed

Wire Size

Conduit

Size

Diagram

208 1 195.0 65.0 1.1 245 8 10 250 2" 6A

208 3 112.6 56.3 2.1 145 8 10 1/0 1¼" 12(NCB)

240 1 168.8 56.3 1.4 215 8 10 250 1½" 6A

240 3 97.4 48.7 2.8 125 10 12 1 1" 12(NCB)

380 3 60.8 60.8 7.1 80 8 10 3 1" 13(WT)

480 3 48.7 48.7 11.4 65 8 10 4 ¾" 13(WT)

600 3 36.2 36.2 19.1 50 10 12 8 ¾" 15

208 3 119.1 59.5 1.9 150 8 10 2/0 1¼" 12(NCB)

240 1 187.5 62.5 1.3 235 8 10 250 2" 6A

240 3 108.3 54.1 2.6 140 8 10 1/0 1¼" 12(NCB)

380 3 68.6 34.3 6.4 90 12 12 2 1" 12(WT)

480 3 54.1 54.1 10.2 70 8 10 4 ¾" 13(WT)

600 3 42.2 42.2 16.4 55 10 12 6 ¾" 15

208 3 149.9 74.9 1.6 190 6 8 3/0 1½" 12

240 3 129.9 65.0 2.1 165 8 10 2/0 1½" 12

380 3 80.0 40.0 5.3 100 10 12 1 1" 12(WT)

480 3 65.0 65.0 8.5 85 8 10 4 1" 13(WT)

600 3 54.3 54.3 12.8 70 8 10 4 1" 15

208 3 159.9 79.9 1.5 200 6 8 4/0 1½" 12

240 3 140.7 70.4 2.0 180 6 8 2/0 1½" 12

380 3 91.4 45.7 4.9 115 10 12 1 1" 12(WT)

480 3 70.4 35.2 7.9 90 12 12 3 1" 12(WT)

600 3 54.3 54.3 12.3 70 8 10 4 1" 15

64 208 3 178.6 59.5 1.4 225 8 10 4/0 1½" 17

66 600 3 63.4 63.4 10.9 80 8 10 4 ¾" 18

240 3 162.4 54.1 1.7 205 8 10 4/0 1½" 17

380 3 102.8 34.3 4.2 130 12 12 1/0 1¼" 16(WT)

480 3 81.2 27.1 6.8 105 12 12 2 1" 16(WT)

79 380 3 120.0 40.0 3.7 150 10 12 2/0 1¼" 16(WT)

208 3 224.8 74.9 1.1 285 6 8 300 2" 17

240 3 194.9 65.0 1.4 245 8 10 250 2" 17

480 3 105.5 35.2 5.7 135 12 12 1 1" 16(WT)

85 600 3 81.5 81.5 8.5 105 6 8 2 1" 18

86 208 3 239.8 79.9 1.0 300 6 8 350 2" 17

240 3 211.1 70.4 1.3 265 6 8 300 2" 17

480 3 105.5 35.2 5.2 135 12 12 1/0 1¼" 16(WT)

90 380 3 137.1 45.7 3.2 175 10 12 2/0 1½" 16(CBWT)

88

58.5

40.5

45

54

68

81

J6 and J16 Wiring Chart Notes:

1. Power feed wire sizing is based on using 75°C Cu THHN wire with feeder branch

protection rated at 125%.

2. Internal wire sizing is based on using 200°C SEW-2 or PTFE wiring in a raceway

with an ambient temperature up to 60°C.

3. For information on 277V, 415V, or 440V models reference the supplied drawing

or contact the factory.

4. Normal phase-to-phase resistance tolerance is ±5%.

5. 380, 480, and 600-volt phase-to-phase resistance values are shown with the transformer

disconnected.

6. For 575V models, multiply the kW rating of the 600V model by a de-rating factor of 0.92

to get the actual rating for 575V.

7. For models manufactured prior to June 24, 2005, that utilize wiring diagrams 3, 5, 6,

7(NT), 7(WT), or 11 please contact the factory for wiring diagrams.

16

Page 17

J3 Wiring Chart

kW Volt Ph

Unit

Amp

Draw

Phase-

Phase

Resistance

(Ohms)

Min.

Feed

Breaker

or Fuse

Size

Internal

Power

Wire

Size

Element

Jumper

Wire

Size

Copper

Power Feed

Wire Size

Conduit

Size

Diagram

2.9 120 1 23.8 5.0 30 12 12 10 ½" 4

5.7 120 1 47.5 2.5 60 10 12 6 ¾" 4

208 1 47.6 4.4 60 10 12 6 ¾" 4

208 3 27.5 8.7 35 12 12 8 ½" 10 (NT)

208 1 51.9 4.2 65 10 12 6 ¾" 4

208 3 28.8 8.3 40 12 12 8 ½" 10 (NT)

240 1 47.5 5.1 60 10 12 6 ¾" 4

240 3 27.4 10.1 35 12 12 8 ½" 10 (NT)

277 1 41.2 6.7 55 10 12 6 ¾" 4 (WT)

380 3 16.8 25.3 25 12 12 12 ½" 14

415 3 15.9 30.2 20 12 12 12 ½" 14

480 3 13.7 40.4 20 12 12 14 ½" 14

600 3 11.0 63.2 15 12 12 14 ½" 14

9.9

10.4

11.4

J3 Wiring Chart Notes:

1. Power feed wire sizing is based on using 75°C Cu THHN wire with feeder branch

protection rated at 125%.

2. Internal wire sizing is based on using 200°C SEW-2 or PTFE wiring in a raceway

with an ambient temperature up to 60°C.

3. Normal phase-to-phase resistance tolerance is ±5%.

4. 277, 380,415, 480, and 600-volt phase-to-phase resistance values are shown with the

transformer disconnected.

J4 Wiring Chart

kW Volt Ph

Unit

Amp

Draw

Phase-

Phase

Resistance

(Ohms)

Min.

Feed

Breaker

or Fuse

Size

Internal

Power

Wire

Size

Element

Jumper

Wire

Size

Copper

Power Feed

Wire Size

Conduit

Size

Diagram

208 1 54.1 3.8 70 8 8 4 1" 4

208 3 31.2 7.7 40 8 8 8 ½" 10 (NT)

220 1 57.3 3.8 75 8 8 4 1" 4

220 3 33.1 7.7 45 8 8 8 ½" 10 (NT)

230 1 59.8 3.8 75 8 8 4 1" 4

230 3 34.5 7.7 45 8 8 8 ½" 10 (NT)

240 1 62.5 3.8 80 8 8 4 1" 4

240 3 36.1 7.7 50 8 8 8 ½" 10 (NT)

480 3 18.0 30.7 25 12 12 10 ½" 10 (WT)

208 3 75.0 3.2 95 6 8 3 1" 10 (NT)

240 3 65.0 4.3 85 8 10 4 1" 10 (NT)

480 3 32.5 17.1 45 12 12 8 ½" 10 (WT)

13.8

11.3

12.6

15

27

J4 Wiring Chart Notes:

1. Power feed wire sizing is based on using 75°C Cu THHN wire with feeder branch

protection rated at 125%.

2. Internal wire sizing is based on using 200°C SEW-2 or PTFE wiring in a raceway

with an ambient temperature up to 60°C.

3. Normal phase-to-phase resistance tolerance is ±5%.

4. 480-volt phase-to-phase resistance values are shown with the transformer disconnected.

Page 18

Note: Wiring diagrams 3, 5, 6, 7 (NT), 7 (WT), and 11 are obsolete.

1(WT)

L1

L2

J5

J3

J2

Control, Low Water,

& Hi-Limit Probe

Leak Detection Probe

Control

Module &

Display

1(NT)

L1 L2

J5

J3

J2

Control, Low Water,

& Hi-Limit Probe

Leak Detection

Probe

Control

Module &

Display

J7

J7

L1 L2 L3

J5J3J2

J7

17

Control

Module &

Display

Control, Low

Water, & Hi-Limit

Probe

Leak

Detection

Probe

10(WT)

L1 L3L2

J5

J3

J2

Control, Low Water,

& Hi-Limit Probe

Leak Detection

Probe

Control

Module &

Display

10(NT)

L1 L3L2

J5

J3

J2

Control, Low Water,

& Hi-Limit Probe

Leak

Detection

Probe

Control

Module &

Display

J7

J7

Page 19

6A

L1 L2

J5

J3

J2

Control, Low

Water, & Hi-Limit

Probe

Leak

Detection

Probe

Control

Module &

Display

J7

3A

L1 L2

J5

J3

J2

Control, Low Water,

& Hi-Limit Probe

Leak Detection

Probe

Control

Module &

Display

J7

13 (NT)

L1 L3L2

J5

J3

J2

Control, Low Water,

& Hi-Limit Probe

Leak Detection Probe

Control

Module &

Display

J7

12 (WT)

L1 L2 L3

J5

J3

J2

Control, Low Water,

& Hi-Limit Probe

Leak Detection Probe

Control

Module &

Display

J7

12

L1 L2 L3

J5

J3

J2

Control, Low Water,

& Hi-Limit Probe

Leak

Detection

Probe

Control

Module &

Display

J7

13(WT)

L1 L3L2

J5

J3

J2

Control, Low Water,

& Hi-Limit Probe

Leak

Detection

Probe

Control

Module &

Display

J7

Page 20

20

Page 21

21

Page 22

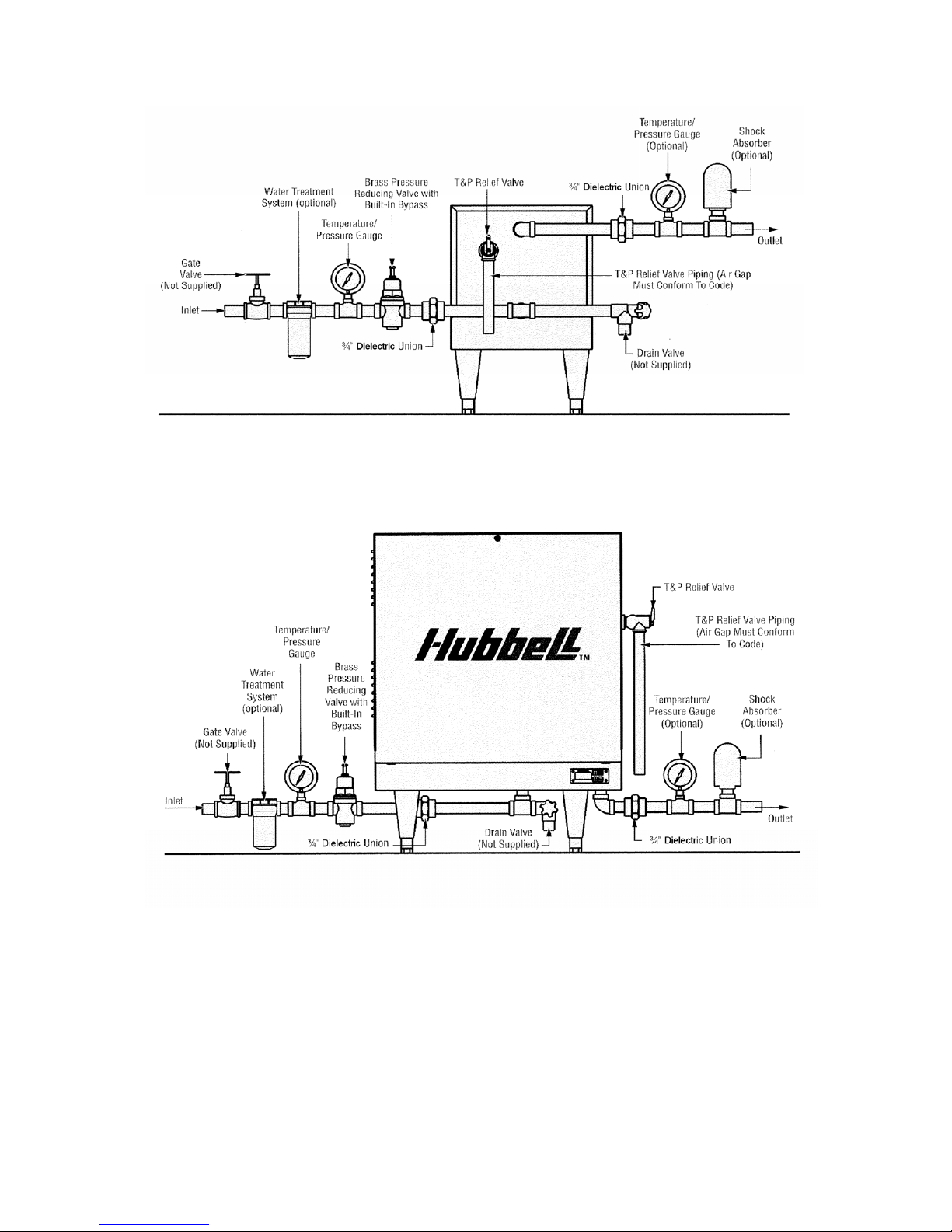

Typical J6 Plumbing Connections

(Rear View)

Typical J16 Plumbing Connections

(Front View)

22

Page 23

Typical J4 Plumbing Connections

(Rear View, shown with optional legs)

Typical J3 Plumbing Connections

(Front View, shown with optional legs)

23

Page 24

24

SECTION III – SCHEDULED MAINTENANCE AND OPERATION

WARNING / CAUTION

Before performing any maintenance procedure, make certain the power supply is turned OFF

and cannot accidentally be turned on.

MAINTENANCE AND OPERATION

The water heater is automatic in its operation. It will maintain a full tank of water at the

temperature setting of the controller. The water heater should not be turned on without first

making sure that the tank is full of water and that all air has been released.

FREEZING

The tank should be fully drained in the event the electricity has been turned off and if there

is danger of freezing.

CONTROLLER OPERATION

NOTE: All controller variables come preset from the factory to include a preset temperature

of 185°F.

1. To turn unit on or off:

a. Press the ON/OFF button on the display module.

b. Note that the controller will resume its last mode of operation if power is

disconnected.

2. To change setpoint temperature (the temperature is fully adjustable from 32° to 194°F

(0°-90°C):

a. Press the UP and DOWN arrows simultaneously to enter setpoint change mode.

b. Press the UP or DOWN button to change the setpoint temperature.

c. Pressing and holding the UP or DOWN button will scroll through the setpoint

temperature.

d. To leave setpoint change mode

i. Wait 5 seconds without pushing any buttons or press the UP and DOWN

buttons simultaneously.

3. To view the number of operational hours (the number of hours when a contactor is

pulled in) and software version:

a. Press the UP and DOWN arrows simultaneously to enter setpoint change mode.

b. Press the ON/OFF button.

c. Display will flash the software version (e.g. R14), HRS, followed by the hours

in thousands of hours, followed by the hours.

i. Example: r14, HrS, 123, 456; indicates software version R1.4 and

123,456 hours.

d. To leave operational hours mode

i. Wait 5 seconds without pushing any buttons or press the UP and DOWN

buttons simultaneously.

4. Configuration Menu. (NOTE: Configuration menu change should only be made by

qualified personnel).

a. To enter the configuration menu, press and hold the UP, DOWN, and ON/OFF

buttons simultaneously for 5 seconds.

b. To scroll through menu settings, press the ON/OFF button.

c. To make a change to a menu setting use either the UP or DOWN arrow.

d. Settings:

i. Relays – sets the number of magnetic contactors used in the heater.

1. r##, where ## is the number of magnetic contactors (01 or 02).

ii. Low water detection – sets the low water detection on or off.

1. LOn, for low water on. (Factory Default)

Page 25

2. LOF, for low water off.

iii. Low water reset – sets the low water reset for either automatic or manual

1. LAU, for low water automatic reset. (Factory Default)

2. LAn, for low water manual reset.

iv. Temperature units – sets the temperature units to either degrees

Fahrenheit or Celsius.

1. DEF, for degrees Fahrenheit. (Factory Default)

2. DEC, for degrees Celsius.

v. Differential – sets the number of degrees below setpoint that the heater

will resume heating after it has achieved setpoint.

1. d##, where ## is the differential in degrees (1 to 20). (Factory set

at 02)

vi. Display – sets the display to either setpoint or actual temperature.

1. dSS, for display setpoint temperature. (Factory Default)

2. dSt, for display actual temperature.

vii. Heater Interlock – sets the heater interlock mode to on or off. (Only

available with r23 or later software).

1. HoF, to disable the 24-volt interlock feature. (Factory Default)

2. Hon, to enable the 24-volt interlock feature.

e. To leave the configuration menu, wait 5 seconds without pushing any buttons or

press the UP and DOWN buttons simultaneously.

5. To reset any high-limit, no probe, or low water (when in manual reset mode) fault

condition, press the RESET button.

6. Display

a. By default the display will show the setpoint of the booster heater.

b. The decimal points on the display, as shown below, indicate that the controller

is calling for a contactor to pull in.

ANNUAL INSPECTION

1. Monitor water temperature

a. Let water heater completely heat to a designated temperature setting.

b. After controller satisfies (that is, when the magnetic contactor actually clicks

off), draw water from as close as possible heater outlet and measure the

temperature.

c. Compare the water temperature of outlet water to the temperature setting of

the display when it satisfies. Normal variation between the two points is

approximately +

5°F.

d. If these two readings do not coincide within acceptable tolerances and

verification has been made of the accuracy of the temperature-reading gauge,

replace the control board and/or the sensor probe.

2. Lift test lever on relief valve and let water run through valve for a period of

approximately 10 seconds. This will help flush away any sediment that might build up

in water passageways.

3. Inspect element for leakage as follows:

a. Shut off power supply.

25

Page 26

26

b. Remove front cover.

c. Visually inspect around heating element for evidence of leaks.

d. Rub around the heating element with a rag. Check for any evidence of

moisture. If moisture is present or a water drip is observed, follow procedure

outlined in Section V.

CAUTION: The area around the heating element may be hot.

4. Scale and mineral build-up on heating elements is a normal condition. It is

recommended that the heating element be removed for examination and if scaled,

should be cleaned. In an area of known hard or poor water conditions, the elements

may need to be checked more frequently. This will improve the efficiency of the

heater and increase the element life.

NOTE: Failure of the elements due to scale and mineral build-up is not covered under

warranty. See warranty for complete details.

a. Shut off power supply.

b. Drain the tank.

c. Remove front cover.

d. Disconnect the element wiring. It is recommended that one element at a time

is removed to simplify re-wiring.

e. Unscrew element.

f. Lime scale removal

i. Place limed ends of the heating element in a de-limer solution, designed

for potable water applications, and allow lime to dissolve. Do not allow

de-limer to contact heating element terminals.

g. Other scale removal

i. Silicates, sulfates, and aluminates must be rem oved by scraping or other

mechanical means. De-limers will not dissolve these types of scale.

h. Flush the cleaned ends of the elements with clean water.

i. Re-install element with new o-ring.

j. Re-attach element wires.

k. Continue until all heating elements are cleaned.

l. Fill the heater following the filling instructions provided in Section II and check

around the elements for leaks.

m. Re-apply power.

5. Check for loose electrical connections. Tighten as necessary.

SECTION IV – TROUBLESHOOTING

ERROR MESSAGES

1. Err, No, Prb

a. This message will flash when the controller does not detect that the probe is

connected to the control board. To clear this error reinsert the probe connector

and press RESET.

2. Err, too, hot, ### (where ### is the actual temperature of the water.)

a. This message will display if the temperature of the water exceeds the high limit

temperature setpoint. To clear this error, wait until the temperature is below the

operating setpoint and press RESET. Note that the unit will not reset until the

indicated temperature is below 195°F. If this message continually occurs, follow

the troubleshooting flow chart for continuous over-temperature condition.

3. Err, No, H2O

a. This message will display when the water level in the tank has dropped below

the sensor probe. To clear this message, refill the tank. If the low water reset is

set for automatic, the error will clear. If the low water reset is set for manual,

when the tank is full press RESET. Check the heater and the piping for leaks.

Page 27

27

Check for mineral buildup on the probe and clean as required. Check for

continuity between the yellow wire and ground. See diagram 2 on the following

page.

4. Err, H2O, LEA

a. This message displays if the leak detection sensor determines there is water in

the base of the heater shell. To clear this message, remove the water from the

leak detection sensor. Check the unit and piping for leaks.

5. CC

a. This message displays if the display cable is installed into the control board

backwards. To clear this message, remove and correctly install the display cable.

6. 255

a. This message indicates that the probe is likely out of calibration. To clear this

message, it is recommended that the probe be removed and replaced.

7. HLd

a. This message indicates that the 24-volt interlock feature is enabled, there is no

24-volt signal present, and the heater is in standby mode. If it is not the intention

to operate the heater with the 24-volt interlock feature, this feature should be

disabled as shown in the controller operation section. (Only available with r23 or

later software).

CONTACTOR CARE

1. A chattering or humming from the contactor is due to dust or debris on the contact points

that prevents the contactor from making proper contact. The debris can be removed by

utilizing a can of antistatic cleaning and dusting spray (pressurized air) and spraying

through the side of the contactor to remove the debris.

DISPLAY BUTTONS

1. If the display randomly changes or does not respond when the buttons are pressed,

loosen the four (4) screws holding the display to the base, reseat the display in the

center of the opening, and re-tighten the screws.

MISCELLANEOUS

2. If the display flashes when the unit is first turned on or turned on after maintenance,

check that the J5 terminal on the controller is engaging all four pins on the board.

3. Note that before replacing the control board, display, or probe, it is recommended that

the power supply to the booster heater be turned off at the main circuit breaker

disconnect to the booster heater to reset and clear the electronic controller.

CAUTION: Do not use plumber’s tape/Teflon tape/pipe dope when installing the probe.

Tape will prevent the low water detection system from operating properly and will cause

false low water errors. Lubricate O-ring prior to installation.

Page 28

28

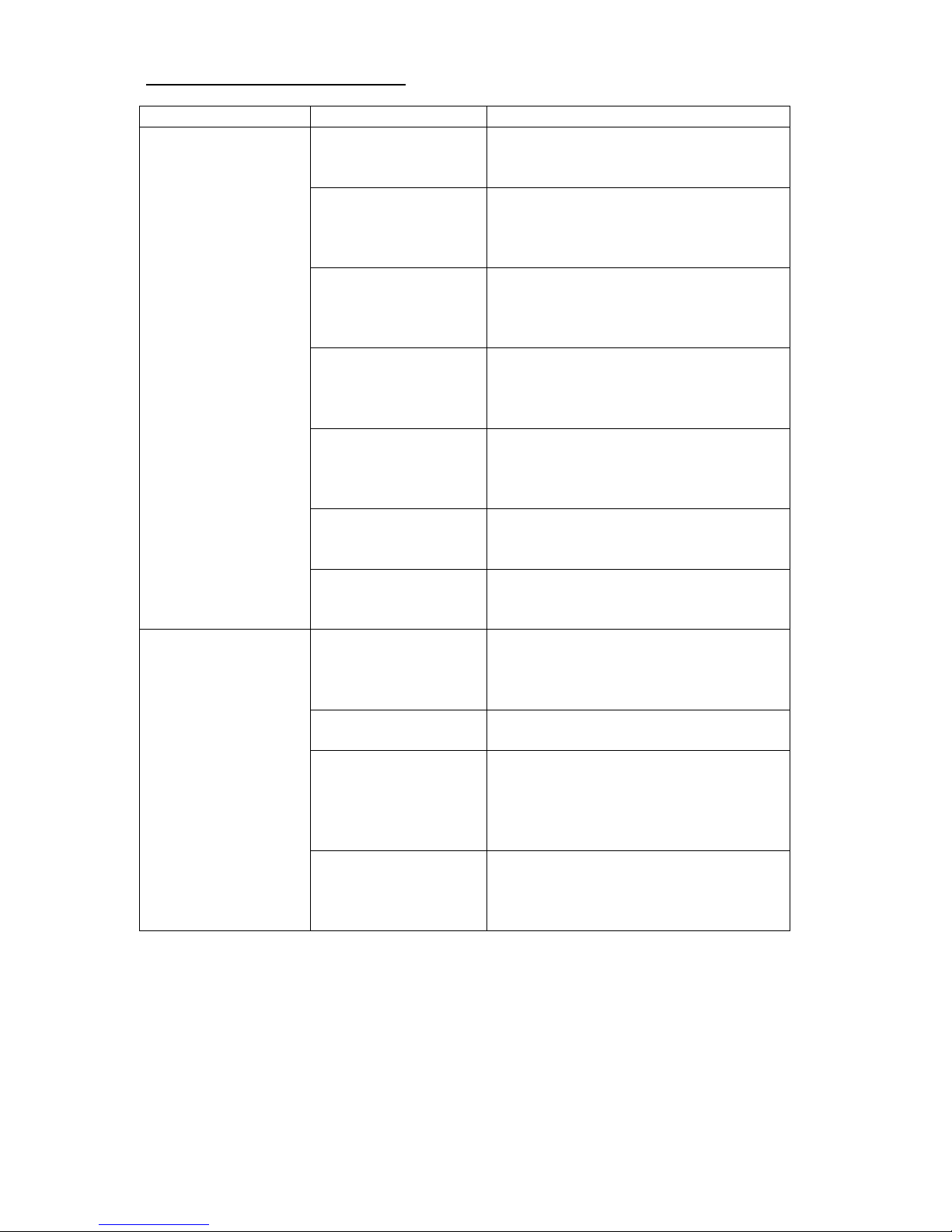

GENERAL TROUBLESHOOTING

Symptom Probable Cause Corrective Action

Water reaches setpoint

temperature but does

not last through the

entire dishwasher

cycle.

Low incoming water

temperature.

Incoming water temperature must be

adequate for the booster size. Increase the

incoming water temperature.

Incoming water

temperature is dropping.

Primary water supply is not adequate to

continually provide correct temperature in

sufficient quantities. Increase the supply of

primary warm water.

Water pressure is too

high.

Higher water pressure uses an excessive

supply of hot water. Verify a pressure

reducing valve is installed and adjust the

water pressure to 20 psi.

Booster heater may be

undersized.

The booster heater must be properly sized

for the incoming water and rinse

requirements of the dishwasher. If required,

replace with a properly sized unit.

Incorrect voltage. Voltage available at the booster heater must

be correct for unit. Verify voltage on all

phases matches nameplate on the booster

heater.

If two magnetic

contactors are utilized,

one is not energizing.

Verify that both magnetic contactors are

operating. If not, see the ‘Magnetic

Contactor Troubleshooting’ section.

One or more elements

are not energizing.

Verify that each element is drawing the

correct amperage. Replace elements as

required.

Water at the

dishwasher is not the

proper temperature.

Gauge(s) not reading

correctly.

Check the temperature of the water with a

thermometer to verify the gauges are

working properly. Replace gauges, if

required.

Temperature setpoint

too low.

Adjust the temperature setpoint.

Booster heater piping to

the dishwasher is not

insulated.

If there is more than 5 linear feet of piping

between the booster heater and the

dishwasher the piping should be wrapped

in insulation or a recirculating system

should be installed.

Bypass valve is open or

allowing water to pass

when closed.

Verify that the bypass valve between the

hot and warm water lines is closed. If

condition continues, replace the bypass

valve.

Page 29

29

Symptom Probable Cause Corrective Action

Temperature and

pressure relief valve

seeps

No pressure reducing

valve or wrong valve

installed causing

excessive pressure in

the unit.

The proper pressure reducing valve with high

pressure bypass must be installed in the inlet

water line to allow for the expansion of water.

Pressure reducing valve

bypass is blocked.

Clean the bypass or install a new valve with a

built-in bypass.

Anti-siphon valve or

check valve installed in

the warm water inlet

line.

Remove the anti-siphon valve or the check

valve to allow for the expansion of the water

or install a back pressure relief valve.

Temperature and

pressure relief valve

opens and/or high

limit temperature

error occurs.

Unit is overheating due

to improper P65 probe

calibration.

See the ‘P65 Probe Troubleshooting’ section.

Unit is overheating due

to the magnetic

contactor staying in the

closed position.

See the ‘Magnetic Contactor Troubleshooting’

section.

Booster heater does

not heat at all.

Main supply circuit

breaker tripped.

Check and/or reset the circuit breaker.

Booster heater circuit

breaker tripped.

If unit is supplied with a circuit breaker, check

and/or reset the circuit breaker.

Booster in high limit. If a high limit error occurs, allow water to cool

and press the reset button. If error continues

see symptom “Temperature and pressure relief

valve opens and/or high limit temperature

error occurs”.

Low water error. Verify that booster heater is full of water. If

error is still present see the ‘P65 Probe

Troubleshooting’ section.

Magnetic contactor

does not energize.

See the ‘Magnetic Contactor Troubleshooting’

section.

No power to control

board (T1000) or

display (TD1000) not

lit.

Reseat the display (TD1000) ribbon cable in

the control board (T1000) connector. If the

display is still not lit, see the ‘Control Board

(T1000) / Display (TD1000) Troubleshooting’

section.

Element Failure Disconnect the wires from each element and

verify that the resistance (ohms) value for each

element is correct. Replace elements as

required.

Page 30

CONTROL BOARD (T1000) / DISPLAY (TD1000) TROUBLESHOOTING

1. Verify proper power supply voltage between each phase (L1 to L2, L2 to L3, and L1 to

L3). The power supply voltage should match the voltage listed on the booster nameplate.

If voltage is incorrect, check main supply wiring or replace unit with proper booster

heater.

2. Check for 208/240VAC between pin 1 (white wire) and pin 2 (black wire) of the J5

connector on the T1000 control board. If no voltage is present, skip to step 4.

3. If 240VAC is present, check for 24VDC between D1 and ground. If 24VDC is present

replace the display (TD1000). If 24VDC is not present replace the control board (T1000).

Ground Wire (J7) Display Cable Leak Detection Wire (J2) Probe Cable (J3)

(D1)

Power Wire (Common, White) Connector (J5)

Power Wire (Black) Wire to #1 Contactor (yellow)

Wire to #2 Contactor (red)

4. If a transformer is installed, verify proper power supply voltage to the primary side of the

transformer and verify approximately 240VAC on the secondary side of the transformer.

If voltage is present of the primary side but not on the secondary side, replace the

transformer.

5. If circuit breakers are installed, verify that the circuit breaker is ON. Verify proper power

supply voltage between each phase (L1 to L2, L2 to L3, and L1 to L3) to the line side of

each circuit breaker and to the load side of each circuit breaker. If voltage is present of

the line side but not on the load side, replace the circuit breaker.

6. Verify that the booster heater is wired according to the proper wiring schematic for the

unit. Correct as required. If unit still does not operate, contact the factory.

MAGNETIC CONTACTOR TROUBLESHOOTING

1. With the unit ON and calling for heat, check for lit decimal points on the display. If the

unit has a single contactor, the first decimal to the right of the display should be lit. If two

decimals are lit, verify that the configuration is set for one contactor. If the unit has two

contactors, verify that two decimals are lit. If only one decimal is lit, verify that the

configuration is set for two contactors. If no decimals are lit, continue to the ‘P65 Probe

Troubleshooting’ section.

2. With the unit ON and calling for heat and one decimal lit, check for 240VAC between

pin 1 (white wire) and pin 4 (yellow wire) of the J5 connector on the T1000 control

board. If no voltage is present, replace the control board (T1000). If voltage is present,

check for voltage across the contactor coil. If voltage is present at the contactor coil,

replace the magnetic contactor. If no voltage is present, verify that the booster heater is

wired according to the proper wiring schematic for the unit.

3. If the unit has two contactors, with the unit ON and calling for heat and two decimals lit,

check for 240VAC between pin 1 (white wire) and pin 3 (red wire) of the J5 connector

30

Page 31

on the T1000 control board. If no voltage is present, replace the control board (T1000). If

voltage is present, check for voltage across the contactor coil. If voltage is present at the

contactor coil, replace the magnetic contactor. If no voltage is present, verify that the

booster heater is wired according to the proper wiring schematic for the unit.

P65 PROBE TROUBLESHOOTING

1. Unplug and reseat the P65 probe wire in the jack on the T1000 control board. Note that

the error message “Err, No, Prb” will be displayed and the reset button must be pressed

to clear the message.

2. If problem persists, unplug the P65 probe from the control board and plug into the RJ45

pigtail (not supplied).

3. If the problem is with temperature control or high limit:

a. Change the configuration to ‘dSt’ to display the actual water temperature.

b. Check the temperature of the water with a thermometer and compare that with the

temperature on the display. If the two temperatures coincide, replace the T1000

control board. If the two temperatures do not coincide, continue to the next step.

c. Unplug the P65 probe from the control board and plug into the RJ45 pigtail (not

supplied). Check the resistance value (ohms) between the blue wire of the pigtail

(#1) and the red wire of the pigtail (#4). Compare the resistance value measure

with the chart below at the measured temperature of the water. If the two values

coincide, replace the T1000 control board. If the two values do not coincide,

replace the P65 sensor

4. If the problem is with low water:

a. Verify that the unit is filled with water.

b. Check for continuity between the yellow wire of the pigtail (#2) and ground. If

continuity exists, replace the T1000 control board. If no continuity exists, replace

the P65 sensor probe.

Thermistor Resistance vs. Temperature

Water Temperature Resistance (±3%)

70°F

11883Ω

80°F

9299Ω

90°F

7334Ω

100°F

5828Ω

110°F

4664Ω

120°F

3758Ω

130°F

3048Ω

140°F

2488Ω

150°F

2043Ω

160°F

1687Ω

170°F

1400Ω

180°F

1169Ω

190°F

980Ω

31

Page 32

SECTION V – SERVICING AND REPLACEMENT OF PARTS

WARNING / CAUTION

Before servicing or replacing any part, make sure to turn the power supply to the unit OFF.

HEATING ELEMENT

1. Disconnect power from unit.

2. Shut off incoming water supply.

3. Attach hose to drain connection.

4. Lift manual release lever on relief valve to let air into system or break union on

outgoing water line.

5. Drain water from tank.

6. Disconnect the wires from the heating element terminals.

7. Unscrew element with a 1-7/8” 6-point socket with no bevel.

O-Ring Groove O-Ring Terminal Connections #220 Buna-N O-Ring

8. Install new #220 Buna-N o-ring gasket and install new heating element. NOTE:

Hubbell recommends lubricating the o-ring with Parker O-Lube prior to installation.

9. Rewire element according to the wiring diagram as shown in the Section II.

10. Fill tank and check around element for any leaks.

32

MAGNETIC CONTACTOR

1. Disconnect power from unit.

2. Disconnect line and load wires to contactor.

3. Disconnect the control circuit wires.

Control Wires

Line Wires

Load Wires

Mounting Screws

4. Loosen holding screws and remove contactor.

5. Replace with new contactor using reverse procedure.

CONTROL BOARD

1. Disconnect power from unit.

2. Disconnect display cable, probe cable (J3), leak detection wire (J2), ground wire (J7),

and terminal block (J5) from the control board. NOTE: The terminal block (J5) is

removable from the control board. Grasp the terminal block on the ends and pull

straight away from the board.

Page 33

Ground Wire (J7) Display Cable Leak Detection Wire (J2) Probe Cable (J3)

Power Wire (Common, White) Connector (J5)

Power Wire (Black) Wire to #1 Contactor (yellow)

Wire to #2 Contactor (red)

3. Remove four (4) screws securing control board to panel.

4. Remove and replace control board.

5. Reconnect wires disconnected in step 2. NOTE: When reconnecting the ribbon cable,

be sure to have the key on the cable align with the slot in the connector.

6. Connect power to unit.

RELIEF VALVE

1. Disconnect power from unit.

2. Shut off incoming water supply.

3. Attach hose to drain connection.

4. Lift manual release lever on relief valve to let air into system or break union on

outgoing water line.

5. Drain water from tank.

6. Disconnect overflow piping.

7. Unscrew relief valve, remove assembly and replace with new one.

8. Connect overflow piping.

9. Turn on incoming water supply and check for leaks.

10. Connect power to unit.

P65 SENSOR PROBE

1. Disconnect power from the unit.

2. Unplug the P65 probe connector from the T1000 control board.

33

Probe connection (J3)

3. Twist the cord and shrink-wrap end of the P65 probe (or cut the shrink-wrap with a

sharp knife) to loosen the P65 sensor assembly from the P65 thermowell.

4. Remove the old P65 sensor assembly by pulling on the cord coming out of the P65

thermowell.

Page 34

34

Note: It is unnecessary to unscrew the

thermowell from the vessel to replace the P65 sensor.

Cord P65 Sensor

Shrink-Wrap Cap

5. Insert the new P65 sensor assembly into the P65 thermowell. Be sure to insert the

sensor until the shrink-wrap cap engages the threads on the end of the thermowell.

Note: The new sensor and cord assembly is push-fit onto the end of the thermowell

threads. Do not twist the new sensor and cord assembly into the thermowell. The

thermal conductive heat transfer paste inside the thermowell is sufficient for

replacement sensors. Adding additional paste is not required.

6. Plug P65 probe connector into the T1000 control board.

7. Turn on power to the unit. If display shows “Err, No, Prb”, press the reset button.

P65 THERMOWELL

1. Follow steps 1-4 for removing the P65 Sensor Probe above.

2. Shut off incoming water supply.

3. Attach hose to drain connection.

4. Lift manual release lever on relief valve to let air into system or break union on

outgoing water line.

5. Drain water from tank.

6. Remove the thermowell from tank using a 13/16” socket.

7. Install new #115 Buna-N o-ring gasket

and install new thermowell. NOTE:

Hubbell recommends lubricating the oring with Parker O-Lube prior to

installation. WARNING: Do not remove

the jam nut.

Thermowell

8. Reinstall or install a replacement P65 sensor

probe in accordance with steps 5 and 6 above.

9. Refill tank.

10. Check for leaks. Retighten as required.

11. Turn on power to the unit.

12. Note that to resume operation the controller will need to be reset by pressing the

‘RESET’ button on the display.

CAUTION: Do not use plumber’s tape/Teflon tape/pipe dope when installing the P65

Thermowell. Tape will prevent the low water detection system from operating properly and

will cause false low water errors. Lubricate O-ring prior to installation.

Tighten probe at the brass hex flats only.

Page 35

SECTION VI – SERVICE PARTS LIST

Category Description Volts Ohms Hubbell P/N

Accessories Bronze Pressure Reducing Valve N45BU

Plastic Legs (Price each, 4 Req'd.) AP61-4003-C

Nickel Plated Legs (Price each, 4 Req'd.) AE61-4002-C

Stainless steel adjustable legs (Price each) A50-5048-C

Floor Mount Legs S/S (Price each, 4 Req'd.) A50-9939-C

Temp. and Pressure Gauge T405

Dielectirc Union, 3/4" DIELECTRIC UNION

Relief Valve (up to 27 kw) 100XL .75 150LB

Relief Valve (30-58 kw) 40XL-5 .75 150LB

Relief Valve (64-90 kw) 40XL-4 1 150LB

Slide Brackets (J6 models only, 2 per set) J6 SLIDE BRACKET

J6, 3 Element Plastic Protective Shroud (1 to 18 kW) J6-3 SHROUD

J6, 6 Element Plastic Protective Shroud (24 to 58.5 kW) J6-6 SHROUD

J16 Element Plastic Protective Shroud J16 SHROUD

Water Treatment System (blended phosphate) HBW-CLEAR

Replacement cartridge for water treatment RSC-10

Circuit Breakers 60 amp CB 60 AMP

70 amp CB 70 AMP

80 amp CB 80 AMP

90 amp CB 90 AMP

100 amp CB 100 AMP

Contactors 20 Amp Resistive, 15 Amp Indu ctiv e, 208/240 VAC Coil C25DNF315B

40 Amp Resistive, 30 Amp Indu ctive, 208/240 VAC Coil C25DNF330B

50 Amp Resistive, 40 Amp Indu ctive, 208/240 VAC Coil C25DNF340B

65 Amp Resistive, 50 Amp Indu ctive, 208/240 VAC Coil C25DNF350B

75 Amp Resistive, 60 Amp Indu ctive, 208/240 VAC Coil C25FNF360B

90 Amp Resistive, 75 Amp Indu ctive, 208/240 VAC Coil C25FNF375B

Elements

2000 Watts 208 21.6 C1315-2

J4, J6, and J16

4000 Watts 208 10.8 C1315-3

(Note: Each element

5000 Watts 208 8.7 C1315-4

is supplied wi th an

6000 Watts 208 7.2 C1315-5

O-Ring)

6500 Watts 208 6.7 C2315-6

7150 Watts 208 6.1 C2315-7

9000 Watts 208 4.8 C2315-9

9600 Watts 208 4.5 C2315-10

2000 Watts 240 28.8 C1315-11

3000 Watts 240 19.2 C1315-12

3500 Watts 240 16.5 C1315-13

4000 Watts 240 14.4 C1315-14

4500 Watts 240 12.8 C1315-15

5000 Watts 240 11.5 C1315-16

6000 Watts 240 9.6 C1315-17

6500 Watts 240 8.9 C1315-18

6750 Watts 240 8.5 C1315-34

7500 Watts 240 7.7 C2315-19

9000 Watts 240 6.4 C2315-20

9750 Watts 240 5.9 C2315-21

2000 Watts 480 115.2 C1315-22

2333 Watts 480 98.8 C1315-23

3000 Watts 480 76.8 C1315-24

3500 Watts 480 65.8 C1315-25

4000 Watts 480 57.6 C1315-26

4500 Watts 480 51.2 C1315-27

5000 Watts 480 46.1 C1315-28

6000 Watts 480 38.4 C1315-29

6500 Watts 480 35.4 C1315-30

7500 Watts 480 30.7 C1315-31

9000 Watts 480 25.6 C1315-32

9750 Watts 480 23.6 C1315-33

6750 Watts 480 34.1 C1315-35

Extra O Ring (#220 Buna-N) O RING J MODEL

Elements 1900 Watts 120 7.6 SGB-2197

J3 3300 Watts 208 13.1 SGB-2337

(Note: Each element 3460 Watts 208 17.6 SGB-2347

is supplied with an 3200 Watts 220 15.1 SGB-2327V

O-Ring) 3800 Watts 240 15.2 SGB-2387

3800 Watts 277 20.2 SGB-2387V

3800 Watts 346 31.5 SGB-2388V

35

Page 36

SERVICE PARTS LIST (cont.)

Category Description Volts Ohms Hubbell P/N

Misc. Electrical

Control Board T1000

Digital Display Module (with overlay and J16 Extension) TD1000

J16 Ribbon Cable Extension RIBBON CABLE J16

Display Overlay OVERLAY J MODEL

Probe Sensor P65

Probe Thermowell (includes #115 Buna-N O- Ring) P65 WELL

Transformer 480-208V B050-3299-3

Transformer 600-195V B050-3350-3

Transformer 380-185V B050-3351-3

Transformer 480-208V (J3 and J4 only) TRAN 480-208 25VA

Transformer 380-208V (J3 only) TRAN 380-208 25VA

Transformer 277-208V (J3 only) TRAN 277-208 25VA

Transformer 600-208V (J3 only) TRAN 600-208 25VA

Power Distribution Block 175 amp 2 pole 16220-2

Power Distribution Block 175 amp 3 pole 16220-3

Power Distribution Block 310 amp 3 pole 16023-3

Diffuser Assembly with Nipple J6 DIFFUSER

RJ45 Pigtail for P65 Probe Testing P65-RJ45 TESTER

Low Temperature Interlock XB1

24-Volt Interlock Adapter

PLUG ADAPTER J1

Remo

te Alarm Plug Adapter PLUG ADAPTER J4

Wire #18 200C (black,white,red,yellow) Tefzel 750 WIRE #18 200C "COLOR"

Wire #12 200C (blue or red) Tefzel 750 WIRE #12 200C "COLOR"

Wire #10 200C (blue or red) Tefzel 750 WIRE #10 200C "COLOR"

Wire #8 200C (blue or red) Tefzel 750 WIRE #8 200C "COLOR"

Wire #6 200C (black) Tefzel 750 WIRE #6 200C BLACK

Vessel J6 Vessel with 3 Element Openings J6-3 TANK KIT

(includes insualtion J6 Vessel with 6 Element Openings J6-6 TANK KIT

and o-rings) J16 Vessel with 3 Element Openings J16-3 TANK KIT

J16 Vessel with 6 Element Openings J16-6 TANK KIT

J16 Vessel with 9 Element Openings J16-9 TANK KIT

J3 Vessel J3 TANK KIT

J4 Vessel J4 TANK KIT

Stainless Steel J6, 3 Element Base J6-3 BASE

Enclosure Parts J6, 3 Element Top Enclosure J6-3 JACKET

J6, 3 Element Front Cover J6-3 FRONT COVER

J6, 6 Element Base J6-6 BASE

J6, 6 Element Top Enclosure J6-6 JACKET

J6, 6 Element Front Cover J6-6 FRONT COVER

J16 Base J16 BAS E

J16 Top Enclosure J16 JACKET

J16 Front Cover J16 FRONT COVER

J3 Base J3 BASE

J3 Top Enclosure J3 JACKET

J3 Front Cover J3 FRONT COVER

J4 Base J4 BASE

J4 Top Enclosure J4 JACKET

J4 Front Cover J4 FRONT COVER

36

Page 37

37

SECTION VII – TORQUE VALUES

Part P/N Wire Size

Torque

(in•lbs)

Torque

(ft•lbs)

Element to

Tank

All N/A 600 50

Wire to

Element

All All 15 1.25

Probe to Tank All N/A 300 25

Wire to Ground

Lug

KA8C All 25 2.08

KA4C All 45 3.75

Wire to Circuit

Breaker

All

#14-#10 35 2.92

#8 40 3.33

#6-#4 45 3.75

Transformer All All 15 1.25

Wire to Control

Board

All All 3.5 0.29

Wire to

Contactor

C25DNF315B

C25DNF330B

C25DNF340B

C25DNF350B

#14-#12 15 1.25

#10 25 2.08

#8 40 3.33

#6-#4 45 3.75

C25FNF360B

C25FNF375B

#14-#10 40 3.33

#8 45 3.75

#6-#4 50 4.17

Wire to Power

Distribution

Block

16023-3

16023-2

Line All 275 22.92

Load

#14-

#10

20 1.67

#8 25 2.08

#6-#4 35 2.92

63133

63132

Line

#14-#8 50 4.17

#6-2/0 120 10

Load

#14-

#10

20 1.67

#8 25 2.08

#6-#4 35 2.92

Control Board

to Panel

All N/A 10 0.83

Display to Base All N/A 10 0.83

All Other

Components to

Panel

All N/A 20 1.67

Page 38

38

SECTION VIII – WARRANTY INFORMATION

LIMITED WARRANTY

1. PRODUCT WARRANTY. Hubbell warrants the booster heater it manufactures and its

components (the "Product") to be free from defects in materials and workmanship, under

normal use and service for the period of time identified below beginning from the date of

installation, provided that the product is installed within three (3) months of date of shipment

from Hubbell and when the Product is installed and maintained in accordance with Hubbell's

written instructions (see operators manual for details). Owner must establish the Product's

purchase date by means satisfactory to Hubbell in its sole discretion.

TANK and COMPONENTS: One (1) year parts and labor

TANK ONLY: Ten (10) years Non Pro-Rated

REPLACEMENT PARTS: Thirty (30) days parts only, no labor, from date of purchase

SUCH WARRANTIES DO NOT COVER:

• Product failure (including but not limited to the tank and/or heating elements) caused

by liming, sediment buildup, chemical corrosion, chlorine corrosion, or freezing.

• Temperature setting adjustments, pressure reducing valve adjustments, resets, and

plumbing leaks.

• Product misuse, tampering or misapplication, accidental damage, improper installation

or the application of improper voltage.

• Costs incurred for shipping, delivery, handling, and/or administrative charges.

• For the tank warranty after the first year, all labor, shipping, installation costs, and

components (other than the tank) are the responsibility of the owner.

• With respect to labor warranty within the first year, overtime, holiday, weekend or any

other non-standard labor rate.

• Excessive and unreasonable labor rates and/or travel expenses as determined by

Hubbell in its sole discretion.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ANY OTHER

WARRANTY, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR PATENT OR OTHER INTELLECTUAL PROPERTY RIGHT

INFRINGEMENT.

2. LIMITATION OF REMEDIES AND DAMAGES. Hubbell's liability and Buyer's

exclusive remedy hereunder will be limited solely, at Hubbell's option, to repair or

replacement by a Hubbell authorized service agency (other than where Buyer is located

outside of the United States or Canada, in which case Hubbell's liability and Buyer's

exclusive remedy hereunder will be limited solely to replacement of part under warranty)

with respect to any claim made within the applicable warranty period referred to above.

Without limiting the generality of the foregoing, all warranty items shall be returned by

Buyer, at its sole expense, to the nearest Hubbell-authorized service agency or to the Hubbell

factory (45 Seymour Street Stratford, CT 06615) for replacement or repair. Hubbell reserves

the right to accept or reject any such claim in whole or in part. Hubbell will not accept the

return of any product without prior written approval from Hubbell, and all such approved

returns shall be made at Buyer's sole expense. HUBBELL WILL NOT BE LIABLE,

UNDER ANY CIRCUMSTANCES, FOR CONSEQUENTIAL OR INCIDENTAL

DAMAGES, INCLUDING BUT NOT LIMITED TO LABOR COSTS OR LOST PROFITS

RESULTING FROM THE USE OR INABILITY TO USE THE PRODUCTS OR FROM

THE USE OF OR INABILITY TO USE THE PRODUCTS OR FROM THE PRODUCTS

BEING INCORPORATED IN OR BECOMING A COMPONENT OF ANY OTHER

PRODUCT OR GOODS.

Page 39

39

NOTES

Page 40

P.O. BOX 288

STRATFORD, CT 06615-0288

PHONE: (203) 378-2659

FAX: (203) 378-3593

INTERNET: http://www.hubbellheaters.com/

40

Loading...

Loading...