Page 1

Installation, Operation and

Maintenance Manual

VERSA-TECH® I & VERSA-TECH® LT

Single-Phase Recloser

for Distribution Systems

!

DANGER

Electric Shock Hazard. All parts of recloser are energized.

Contact with in service recloser will cause death or severe injury.

Before contacting or servicing the equipment, or working on the electrical system, isolate and

ground the recloser from the electrical system. Verify recloser is de-energized by testing with

properly rated hot sticks and/or rubber gloves and volt meter.

8100 Churchill Avenue

Leeds, Alabama 35094

(205) 699-0840

www.hubbellpowersystems.com

NOTE: Hubbell has a policy of continuous product improvement.

We reserve the right to change design and specifications

without notice. ©Copyright 2015 Hubbell Incorporated

PSP8620311

Rev. E

IMPORTANT!

Keep this manual readily

available for future reference.

1

Page 2

Warnings

!

DANGER

Electrical equipment contains hazardous voltages. Contact with these hazards will cause death, severe personal

injury or damage equipment.

Only qualified personnel shall install, operate and maintain this equipment.

Always properly ground equipment and lock out electric power (de-energize) before maintenance. Using non-specified/unauthorized parts or

components to repair equipment, or tampering with safety devices/systems

will result in dangerous conditions which can cause death, severe personal

injury or damage to equipment. Take note of and follow all safety instructions

contained in this installation, operation and maintenance manual.

IMPORTANT

These installation, operation and maintenance instructions do not claim to cover all details or variations in

equipment. Nor do they provide for all possible conditions encountered while installing, operating or maintaining this equipment. If further information is desired or needed to address any particular installation, operation

or maintenance problem not covered in this document, contact your authorized factory representative.

The information in this document does not relieve the user from exercising good judgment in selecting equipment for suitability of application. Nor does it relieve the user from using sound practices in installation, operation and maintenance of the equipment purchased.

Note: Because Hubbell has a policy of continuous product improvement, we reserve the right to change design and specications without notice. Should a conict arise between the general information in this document and the contents of drawings or supplementary material, or both, the latter shall take precedence.

QUALIFIED PERSON

For the purpose of this manual, a qualied person is:

(a) familiar with the installation, construction or operation of the subject equipment and the hazards

involved with its installation, operation and maintenance.

(b) trained to de-energize, clear, ground, and tag circuits and equipment in accordance with established

safety practices.

(c) trained in the proper care and use of protective equipment such as rubber gloves, hard hat, safety

glasses or face shields, ash clothing, etc., in accordance with established utility safety practices.

(d) trained to render rst aid.

SUMMARY

The information in this document does not claim to cover all details or variations in equipment, nor to provide

for every possible contingency encountered with installation, operation, or maintenance. Should further information be needed or problems arise that are not covered suciently, contact your factory representative.

The contents of this document are not part of, nor do they modify, any prior or existing agreement, commit-

ment or relationship. Hubbell Power Systems, Inc. terms and conditions of sale constitute the entire obligation of Hubbell Power Systems, Inc. The warranty in the terms and conditions of sale is the sole warranty of

Hubbell Power Systems, Inc. Any statements in this document do not create new warranties or modify any

existing warranty.

2

PSP8620311

Rev. E

Page 3

Contents

Section Subject Page No.

1 — Overview

Safety Information

Ratings and Specications

Duty Cycle

Installation Alternatives

Catalog Number Matrix

Dimensions - Pole/Structure Mount

Dimensions - Crossarm Mount

2 — Installation Requirements

User Supplied Requirements

Hardware Torque Specications

3 — Receiving and Handling

Inspection

Unpacking

Components

Storage

4 — Installation

Installing NR Hookstick Adapter

Installation Options

Installation Preparation

Pole/Structure Surface Mounting

Crossarm Mounting

Connections

Place Recloser in Service

5 — Recloser Operation

Overview

Automatic Operation

Operations Counter

Non-Reclosing Lever/Hot Line Tag

Manual Operating Handle

Lockout Beacon

6 — Control Programming

Overview

Customer Supplied Requirements

Software Installation

Connecting Recloser to PC

To Establish Communications

Connecting Local Radio

Section Subject Page No.

5

Connecting to WiFi

Remote Radio Power

Radio Operation

Windows XP Local Radio Drivers Installation

Windows 7 Local Radio Drivers Installation

Windows 8 Local Radio Drivers Installation Guide

Versa-Tech Programmer Settings Tab

Connecting to a Recloser

9

Programming Settings

Minimum Trip Value

Non-Reclose /Hot Line Tag

10

Operations to Lockout

Manual Closing Delay Time

Sequence Coordination

Time-Current Curve Selection

Time-Current Curve Modiers

11

Minimum Response Time

Reclose Time

Reset Time

Cold Load Time

Cold Load Pickup

Record Manual Close

Time Stamp

Serial Number

17

Buttons Functions and General Form Controls

Real Time Monitoring

Events and Data Log

Time and Security

Scratchpad

Firmware Upgrade

7 — Testing

19

High-Potential Withstand Test

Minimum-Trip Current Test

Sequence of Operation Test

8 — Maintenance

9 — Trouble Shooting

Return Kit Packaging Instructions

42

44

46

47

PSP8620311

Rev. E

3

Page 4

Contents

Tables & Figures....................................................Page Number

Table 1-1 Duty Cycle ................................................................................. 6

Table 1-2 Recloser Catalog Number Matrix............................................... 6

Table 2-1 Hardware Torque Specifications ............................................... 9

Table 9-1 Trouble Shooting Guide............................................................ 46

Figure 1-1 Pole/Structure Face Mounting .................................................6

Figure 1-2 Crossarm Mounting .................................................................6

Figure 3-1 Components............................................................................10

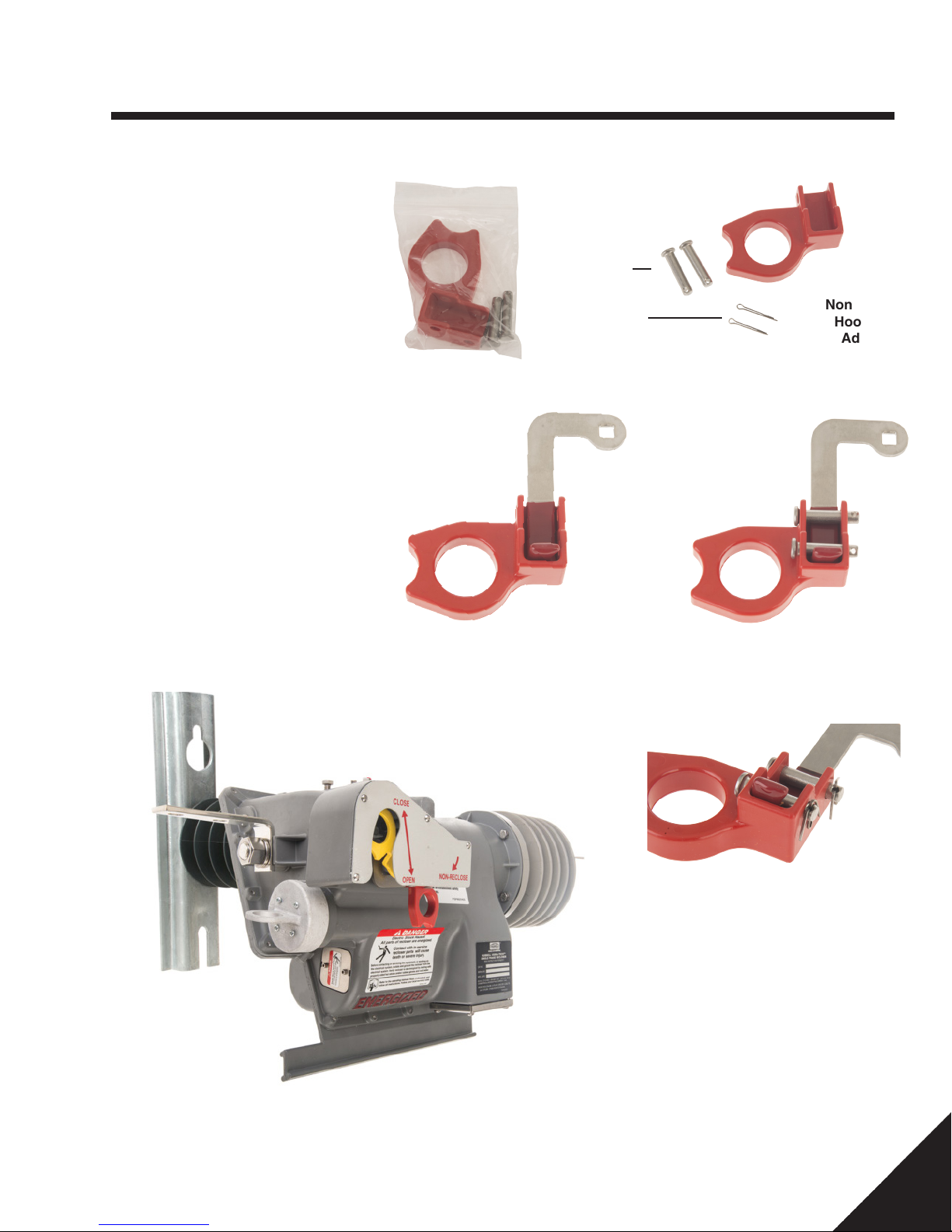

Figure 4-1 Packaged NR Hookstick Adapter Kit........................................11

Figure 4-2 NR Hookstick Adapter Kit Components................................... 11

Figure 4-3 NR Hookstick Adapter Positioning for Assembling...................11

Figure 4-4 Clevis Pin Insertion for NR Hookstick Adapter......................... 11

Figure 4-5 Cotter Pin Insertion for NR Hookstick Adapter......................... 11

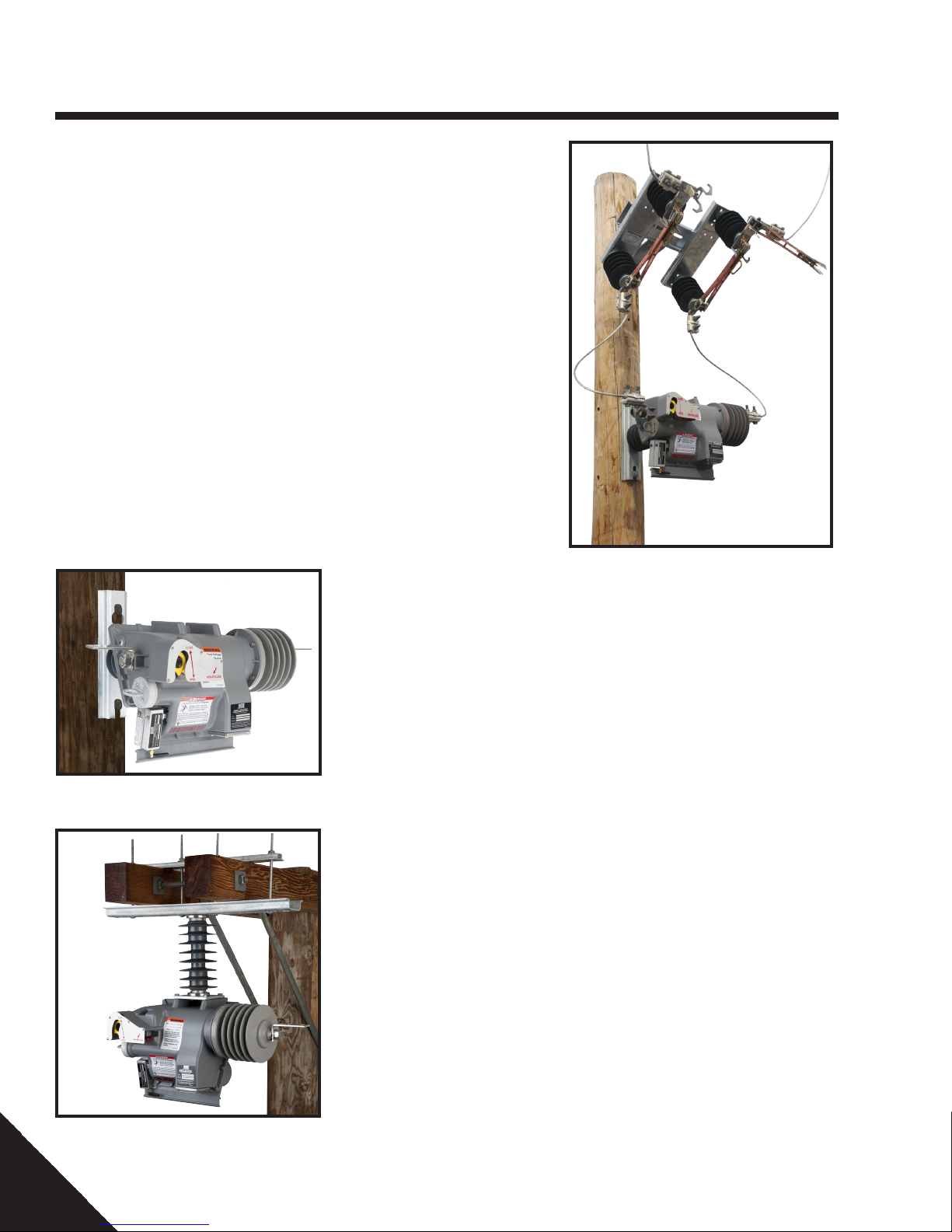

Figure 4-6 Pole/Structure Face Mounting .................................................12

Figure 4-7 Crossarm Mounting ................................................................ 12

Figure 4-8 Bypass Arrangement .............................................................. 12

Figure 4-9 Program/Installation Tag ........................................................ 13

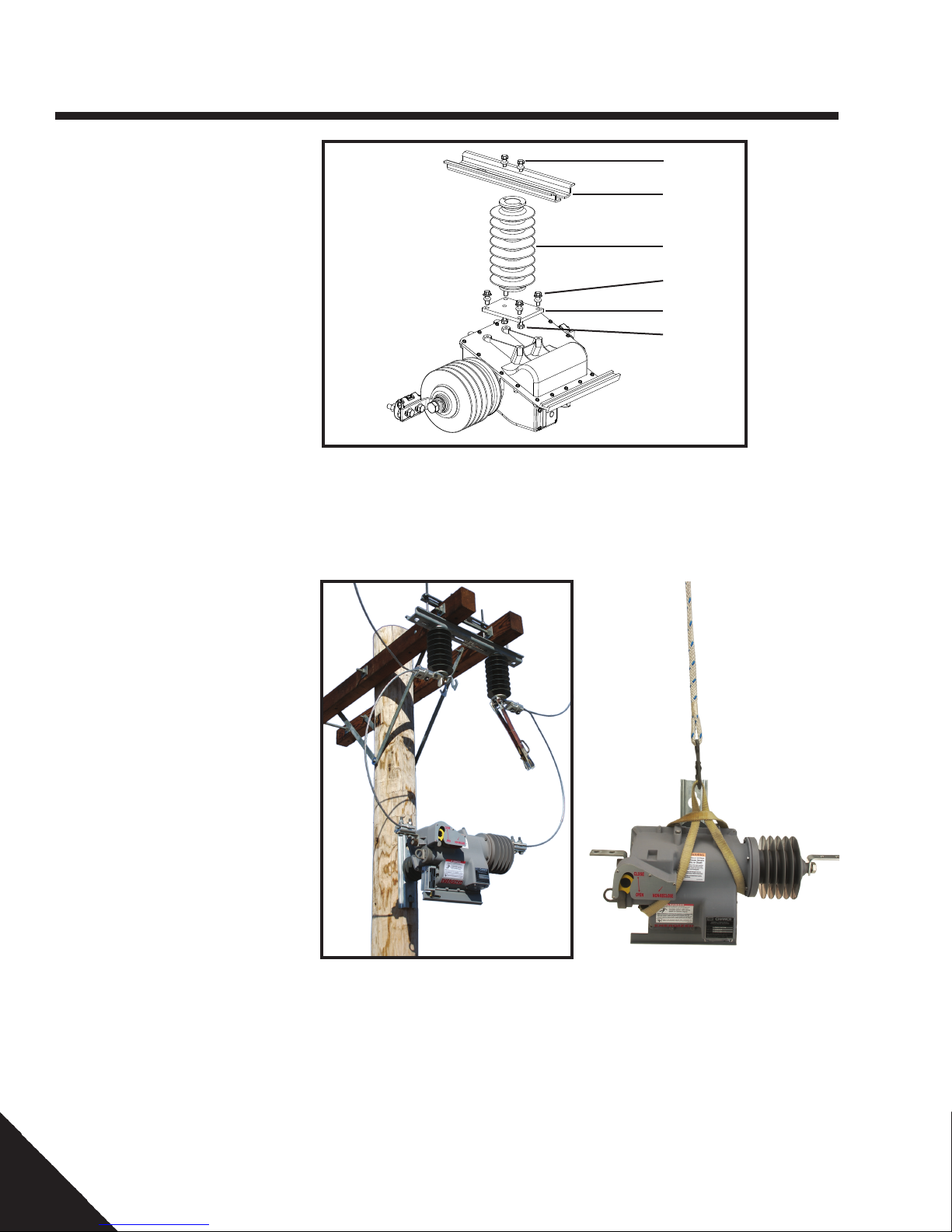

Figure 4-10 Pole/Structure Mount Assembly Detail ................................... 14

Figure 4-11 Pole/Structure Mount Installation ........................................... 14

Figure 4-12 Recloser in Sling ..................................................................... 14

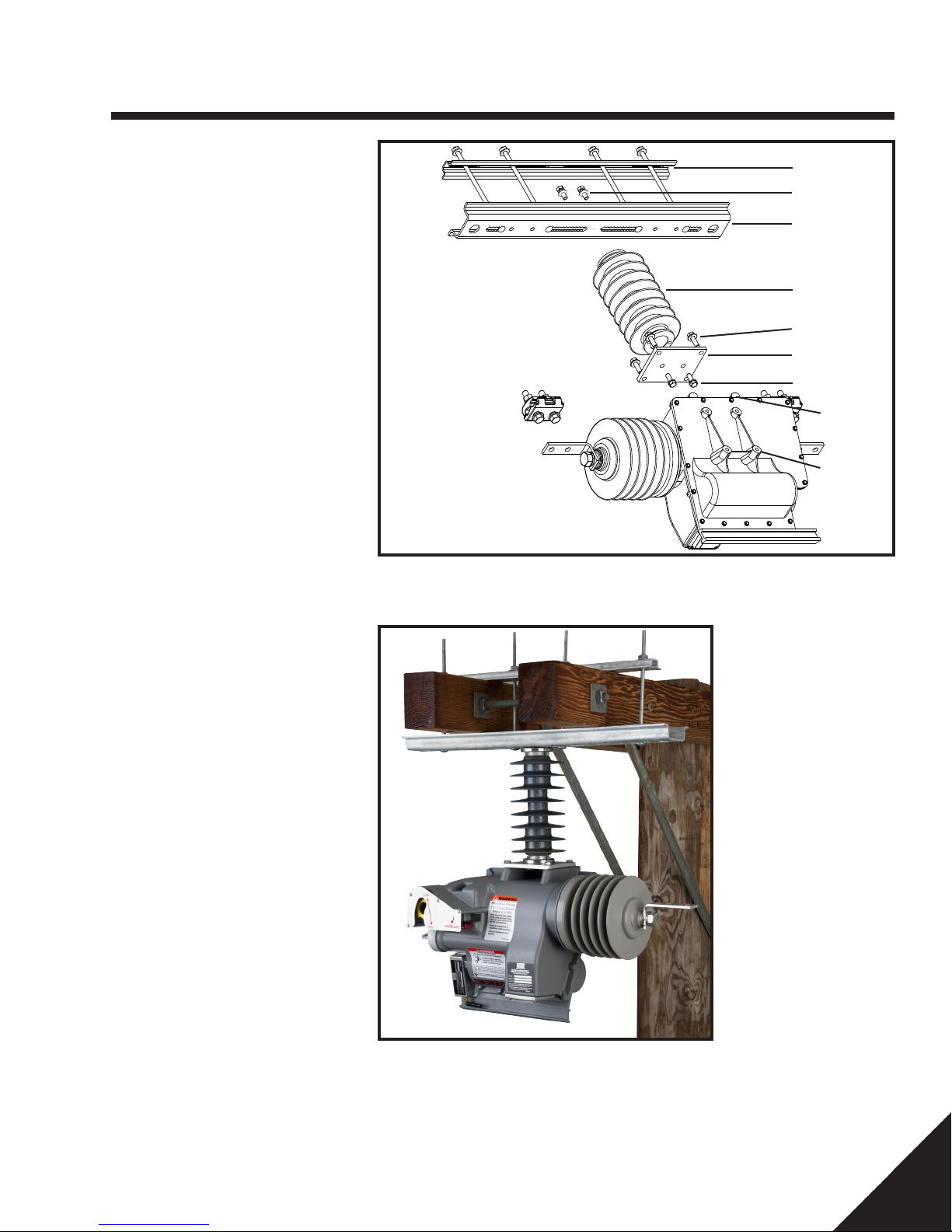

Figure 4-13 Crossarm Assembly Detail ...................................................... 15

Figure 4-14 Crossarm Mount Installation ................................................... 15

Figure 5-1 Feature Position .......................................................................18

Figure 6-1 Connecting Local Radio ...........................................................19

Figure 6-2 Settings Tab of Programmer Software .................................... 27

Figure 6-3 Real Time Monitoring Tab of Programmer Software .............. 36

Figure 6-4 Events and Data Log Tab of Programmer Software ................ 37

Figure 6-5 Sequence Coordination enabled on four operations

and the SC Lockout option Checked ...................................... 38

Figure 6-6 Sequence Coordination enabled on four operations

and the SC Unchecked ........................................................... 38

Figure 6-7 Time and Security Tab ............................................................ 39

Figure 6-8 Scratchpad Tab ....................................................................... 40

Figure 7-1 Recloser attached to high potential test set ........................... 42

Figure 7-2 Recloser attached to high current test set ............................. 43

Figure 8-1 Battery bayonet in the recloser .............................................. 44

Figure 8-2 Battery bayonet partially removed from recloser ................... 44

4

PSP8620311

Rev. E

Page 5

1 — Overview

Safety Information

!

DANGER

All parts of recloser are energized.

Contact with components will cause severe

personal injury, death, or property damage.

Only qualified personnel should work on or

around this equipment after becoming thoroughly familiar with this document and other

publications regarding this equipment.

!

WARNING

!

DANGER

Handle position does not indicate deenergized recloser enclosure controls

or circuit.

Contact with these components will cause severe

personal injury, death, or property damage.

Before contacting or servicing the equipment,

or working on the electrical system, isolate and

ground the recloser from the electrical system.

Verify recloser is de-energized by testing with

properly rated hot sticks and/or rubber gloves

and volt meter.

!

CAUTION

This equipment is not intended to protect human life.

Can cause death, severe personal injury, and/or equipment

damage

Follow all locally approved procedures and safety practices

when installing or operating this equipment.

Introduction

This manual is to guide you through

the programming, installation, opera-

tion and maintenance of the VERSA-

TECH® single-phase recloser. This

manual does not claim to cover

all situations that may arise during

installation. If additional information is needed, contact your factory

representative. Nor does this manual

supersede your company’s established guidelines and practices for

similar equipment. Take note of and

heed all danger, warning and cautions

contained in this document.

Qualied Person

Only qualied trained and competent

personnel that understand proper

safety procedures must select, install

and service this equipment.

Read and understand these instructions before installing, operating or

maintaining this equipment.

This guide is not a substitute for

adequate training and experience

in safety procedures for this type of

equipment.

Signal Words

The signal words “DANGER,” “WARNING”

and “CAUTION” (along with their assigned

symbol) throughout this manual indicate the

degree of hazard the user may encounter.

These symbols and words are defined as:

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

Do not place the recloser in service until all

settings have been programmed and verified.

Failure to comply can result in recloser misoperation,

equipment damage, and personal injury.

Refer to sections 6 and 7 of this manual for control

programming and operation.

!

DANGER

!

WARNING

!

CAUTION

CAUTION

CAUTION used without the safety alert

symbol indicates a potentially hazardous

situation which, if not avoided, may result in

property damage.

Product

The products covered by this manual

are the VERSA-TECH® single-phase

reclosers for medium voltage electrical distribution circuits.

These products are designed for

distribution circuits only at their rated

capacities. They cannot be eld modied for capacities other than what

was shipped with the units.

Function

This product is a single-phase recloser designed to provide a means

for interrupting, sectionalizing and

isolating faults on electrical distribution systems.

PSP8620311

Rev. E

5

Page 6

1 — Overview

Ratings and Specications

VTI VTLT

Rated Maximum Voltage .....................................29.3kV

Rated Continuous Current...................................400A

Fault Make Capacity...............................................8kA

Fault Break Capacity...............................................8kA

Mechanical Operations......................................30,000

3 Second Withstand Current..................................8kA

Transformer Magnetizing Current.........................14A

Cable Charging Current.........................................25A

Line Charging Current..............................................5A

Lightning Impulse Withstand.............................125kV

60Hz, 1-Minute Withstand Voltage.....................60kV

Maximum Terminal Pad Load kg (pounds).......14 (30)

Operating Temperature.......................... -40°C to 60°C

Weight kg (pounds)...........................................21 (46)

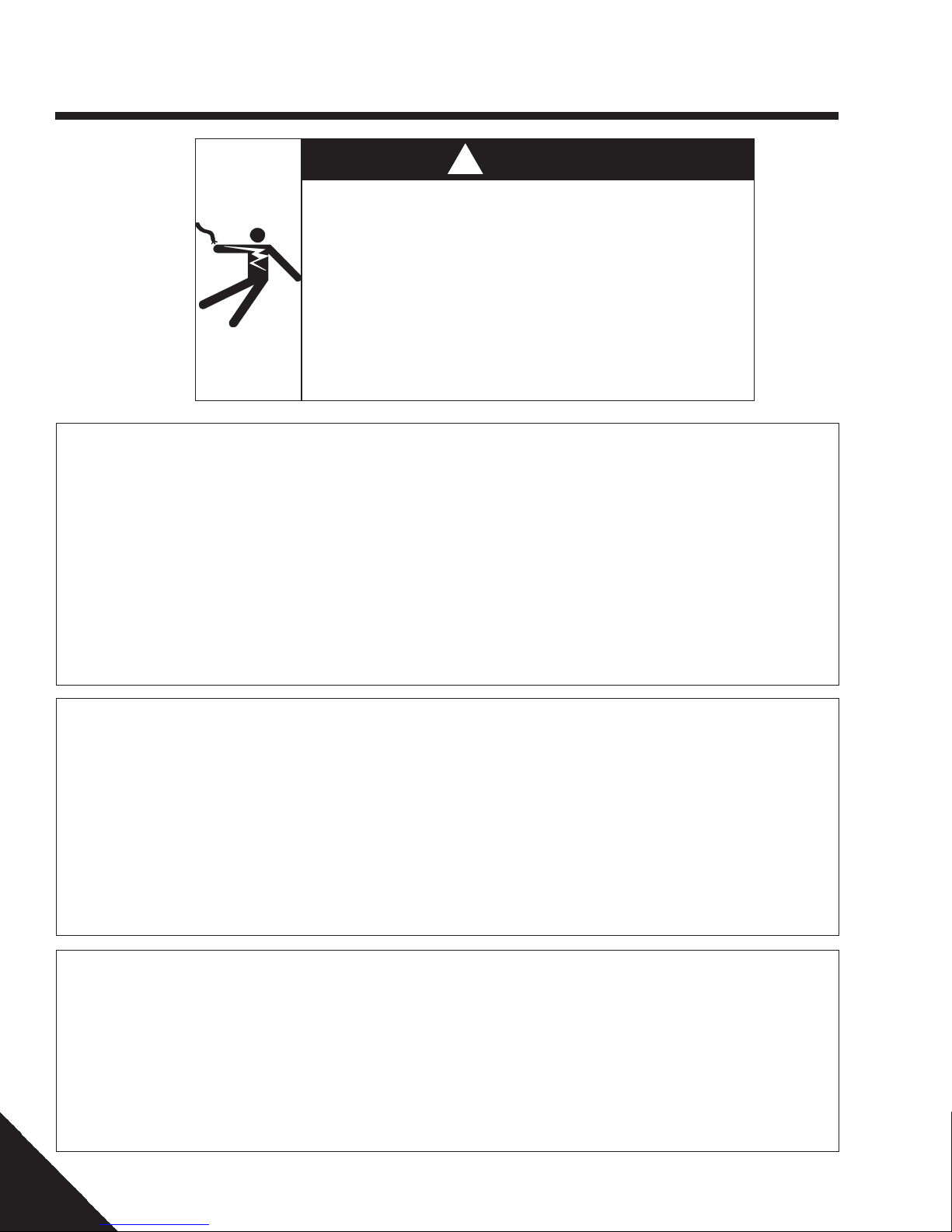

Installation Alternatives

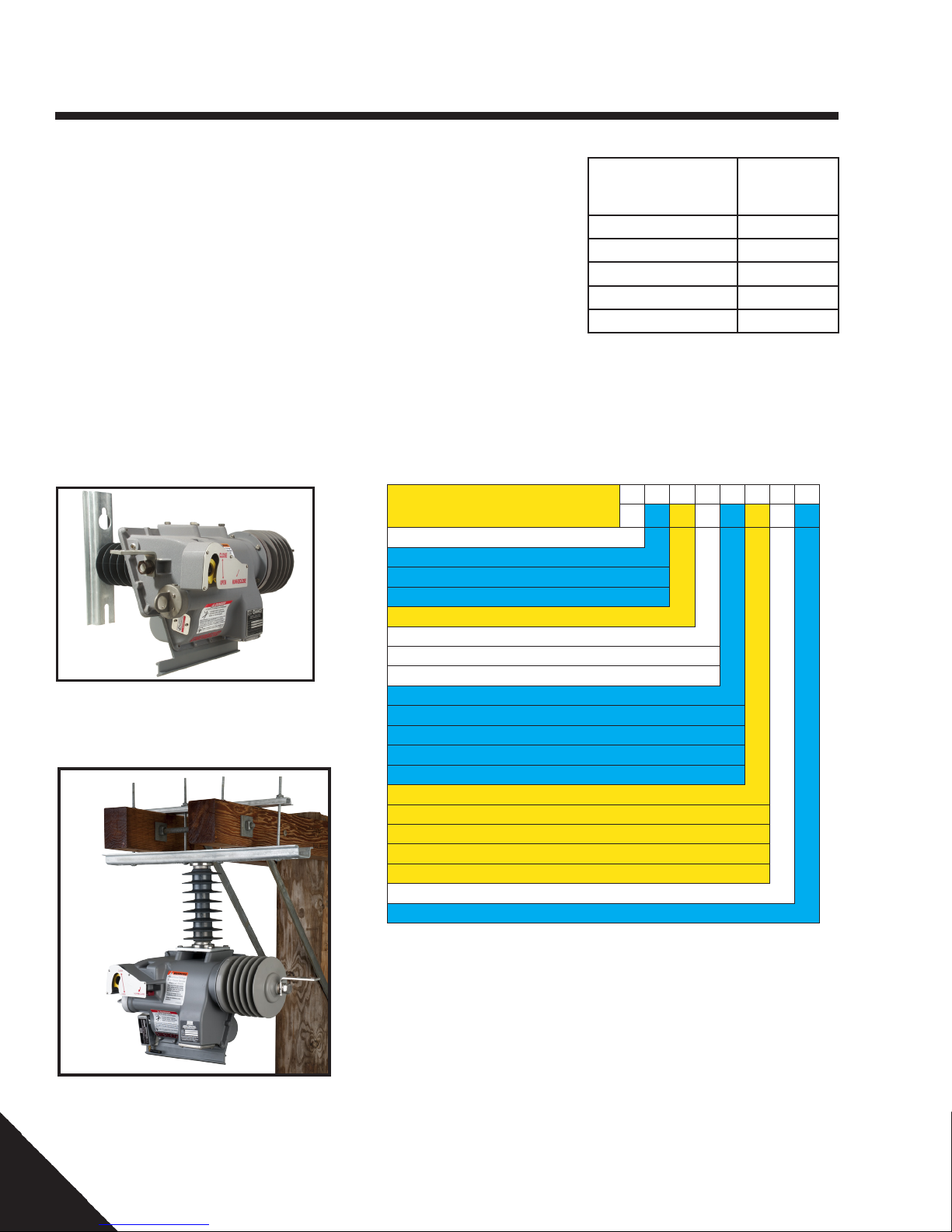

Figure 1-1 Pole/Structure Face

Mounting

Duty Cycle

29.3kV

100A

4kA

4kA

10,000

4kA

14A

25A

5A

125kV

60kV

Percent of 8kA

Maximum Interrupting

Rating (%)

15-20 10000

25 6500

50 1800

75 700

100 400

Table 1-1 Duty Cycle

Number

of

Operations

14 (30)

-40°C to 60°C

21 (46)

Catalog Numbering System

To build your Versa-Tech Recloser, add features

from the matrix to this base number

Catalog No. PSC86

Voltage Rating 27kV 2

Versa-Tech I with FW 3.xx 1

Versa-Tech LT 4

Versa-Tech I with FW 4.xx 5

Minimum Fault Trip 30A 1

Pole/Structure Mount 1

Crossarm Mount 2

Pole with Ground Connector 3

No Connectors 1

PG (Parallel Groove) Clamps (2 total) 2

Captive Hardware 3

Single Tap Lug 4

Double Tap Lug 5

No Radio 1

Standard Performance Remote Digi Radio 2

High Performance SiFLEX Remote Radio 3

WiFi Module 4

XBee Radio 5

Pole Plaques (Additional)

Reserved 1

1 2 3 4 5 6 7 8

2 X 1 X X X X 1

Position

Figure 1-2 Crossarm Mounting

6

The number in Position 7 is the number of pole plaques in addition to the one

included with each recloser (Ex: 3 is 3 more for a total of 4)

NOTE: For more information on the Versa-Tech II Single-Phase Recloser,

please refer to Catalog 10EE on the Hubbell Power Systems website.

PSP8620311

Rev. E

Page 7

1 — Overview

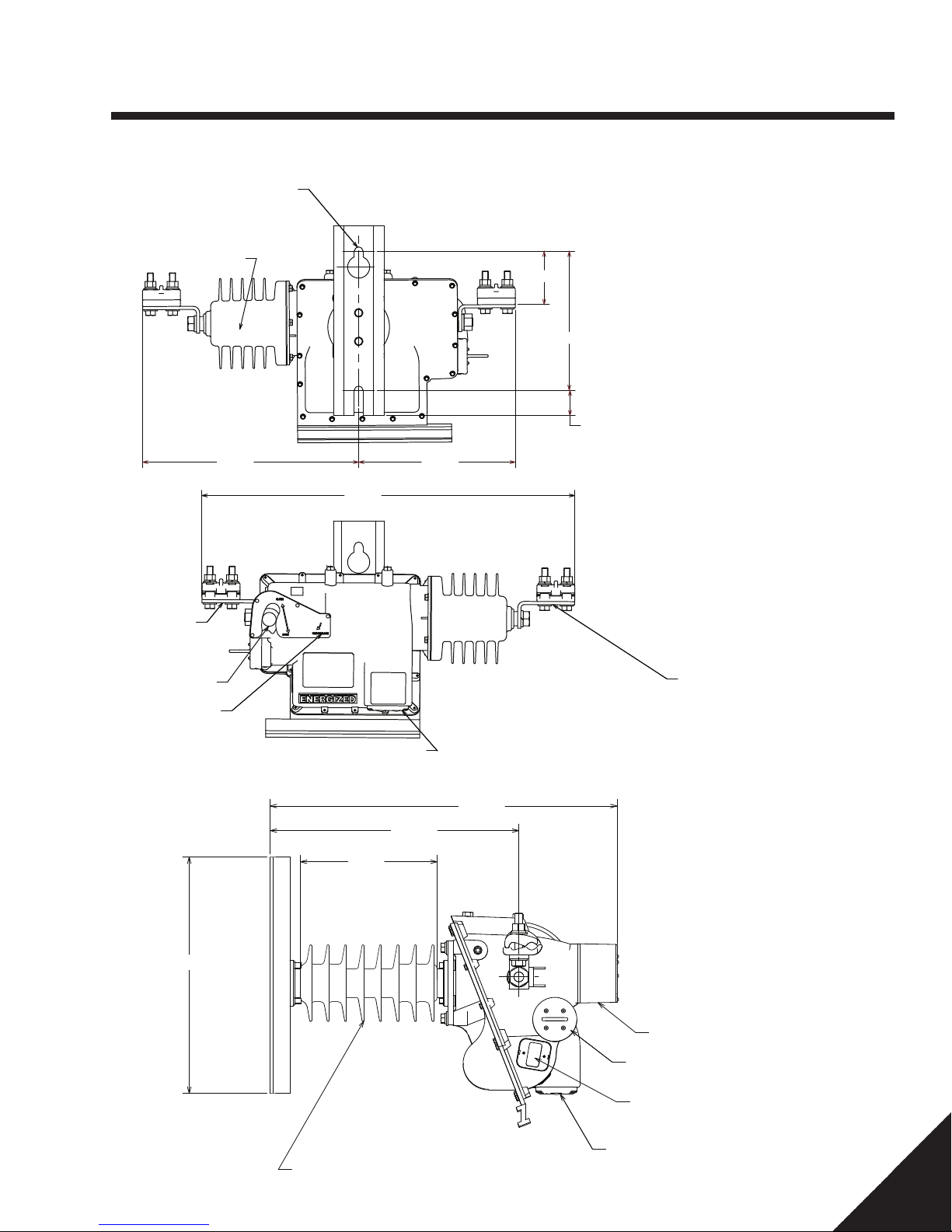

Dimensions - Pole/Structure mounting

MOUNTING HOLES FOR

5/8" (15mm) BOLTS

11" (27.9cm) CENTER

TO CENTER NOMINAL.

VACUUM INTERRUPTER

17.1 12.4

29.5

4.2

Back View

11.0

2.0

2-HOLE NEMA

PAD (STANDARD)

TYPICAL

OPERATING LEVER

NON-RECLOSE

LEVER

15.0

LOCKOUT INDICATOR

BEACON AND COUNTER

8.7

15.8

22.0

Front View

2-HOLE NEMA

PAD (STANDARD)

TYPICAL

Side View

OPERATING LEVER

LEAKAGE DISTANCE - 39.4"

PSP8620311

Rev. E

BATTERY PACK

(HOT STICK REPLACEABLE)

SERIAL PROGRAMMING PORT

LOCKOUT INDICATOR BEACON

AND COUNTER

7

Page 8

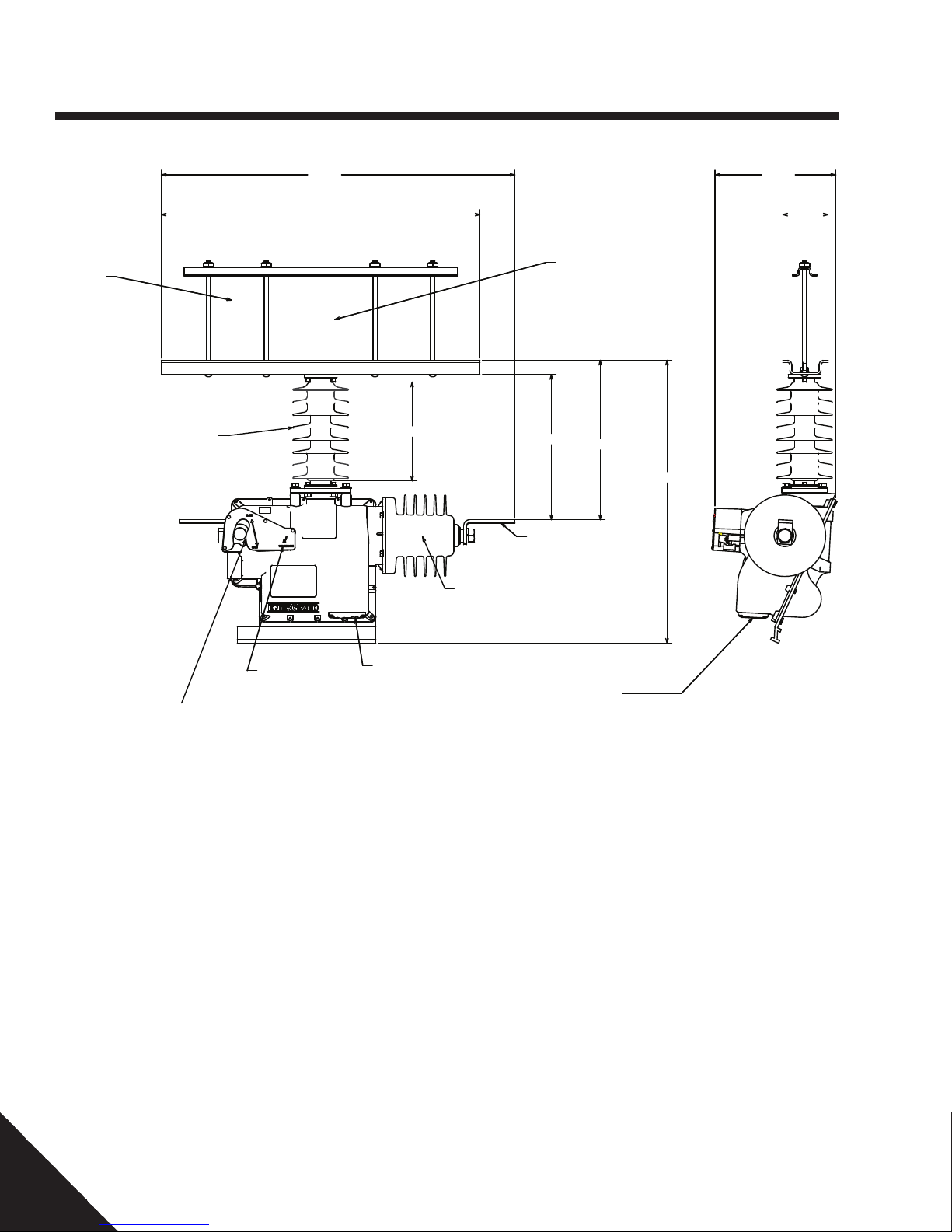

1 — Overview

31.1

10.6

Dimensions - Crossarm mounting

ADJUSTABLE

3" - 9-1/2"

LEAKAGE DISTANCE - 39.4"

OPERATING LEVER

28.0

NON-RECLOSE LEVER

8.7

VACUUM INTERRUPTER

LOCKOUT INDICATOR BEACON

AND COUNTER

ADJUSTABLE

5-1/8" - 10-1/4"

TYPICAL

12.7

2-HOLE NEMA

PAD (STANDARD)

TYPICAL

14.0

LOCKOUT INDICATOR BEACON

AND COUNTER

4.0

24.9

Side ViewFront View

8

PSP8620311

Rev. E

Page 9

2 — Installation Requirements

User Supplied Requirements

The following is required for installation.

Be sure to have these items on hand

before beginning installation.

Safety Equipment (PPE)

• Hard hat

• Steel-toe work boots

• Appropriate eye protection per your

company’s policy

• Other safety equipment as required by

your company’s policies

Hardware

• 5⁄8 inch (16 mm) galvanized thru-bolts

(or equivalent) long enough to pass

through the center of the utility pole,

plus 3 inches (75 mm)

• Curved galvanized washers for the 5⁄8

inch (16 mm) thru-bolts

• Galvanized nuts for 5⁄8 inch (16 mm)

thru-bolts

• Flat galvanized washers for 1⁄2 inch

(12 mm) and 5⁄8 inch (16 mm)) lag

screws

Electrical

• Terminal pad connectors (if not ordered with switch)

• Connector sealing paste (CHANCE ZLN

or equivalent)

• Surge arresters and wire (if needed)

Options

• BP3 By-Pass Switch (for appropriate

Cat. No., see Catalog Section 14B)

• Jumper Wire, 100/400 Amp minimum

capacity (VTLT/VTI)

• M3 Disconnect Switch (for appropriate

Cat. No., see Catalog Section 14B)

Hardware Torque

Specications

It is the installing personnel’s responsibility to be sure all threaded fasteners

are installed with the correct torque. All

user supplied hardware is to be torqued

according to company standards.

Recloser and connector hardware torque

specifications are listed in Table 2-1.

User Supplied Hardware

Item ft-lb N•m Notes

5⁄8 inch (16 mm) thru-bolts N/A N/A Company standards apply

5⁄8 inch (16 mm) lag screws N/A N/A Company standards apply

Terminal connectors N/A N/A Company standards apply

Hubbell Supplied Hardware

Item ft-lb N•m Notes

3/8 inch Crossarm Mount bolts N/A N/A Company standards apply

3/8 inch Insulator Mount bolts 15 20

1/2 inch Terminal bolts 60 81

Table 2-1 Hardware Torque Specications

Hubbell Power Systems, Inc.

Supplied Requirements

All necessary components and hardware

specific to the installation of the VERSATECH® recloser ordered are included.

Carefully check the components and

hardware items against those listed in

Section 3.

Contact your factory representative if any

parts are missing.

PSP8620311

Rev. E

9

Page 10

3 — Receiving & Handling

Inspection

1. Inspect the packaging for obvious

shipping damage.

2. Open and thoroughly inspect the product

for hidden damage.

3. Note any damage on the “Bill of Lading”

prior to accepting the delivery.

4. Check the material nameplate against the

shipping list to ensure the correct material

has been received. In case of shortage

or incorrect material, immediately notify

your factory representative or customer

service.

NOTE: Documentation of visible

shipping damage can determine the

outcome of any damage claim. Notifying

the carrier of concealed damage within

15 days is essential to resolving or

minimizing unsettled claims. Immediately

file your claim and notify your factory

representative.

Unpacking

1. Locate the Hubbell USB Drive that is

enclosed with this manual. The USB

drive should be in the custody of the

personnel who will be responsible for the

programming of the recloser.

1. Carefully remove all items from the

packaging. Exercise caution and do not

drop the unit or strike the skirted end on

anything as this may damage the vacuum

interrupter or mechanism.

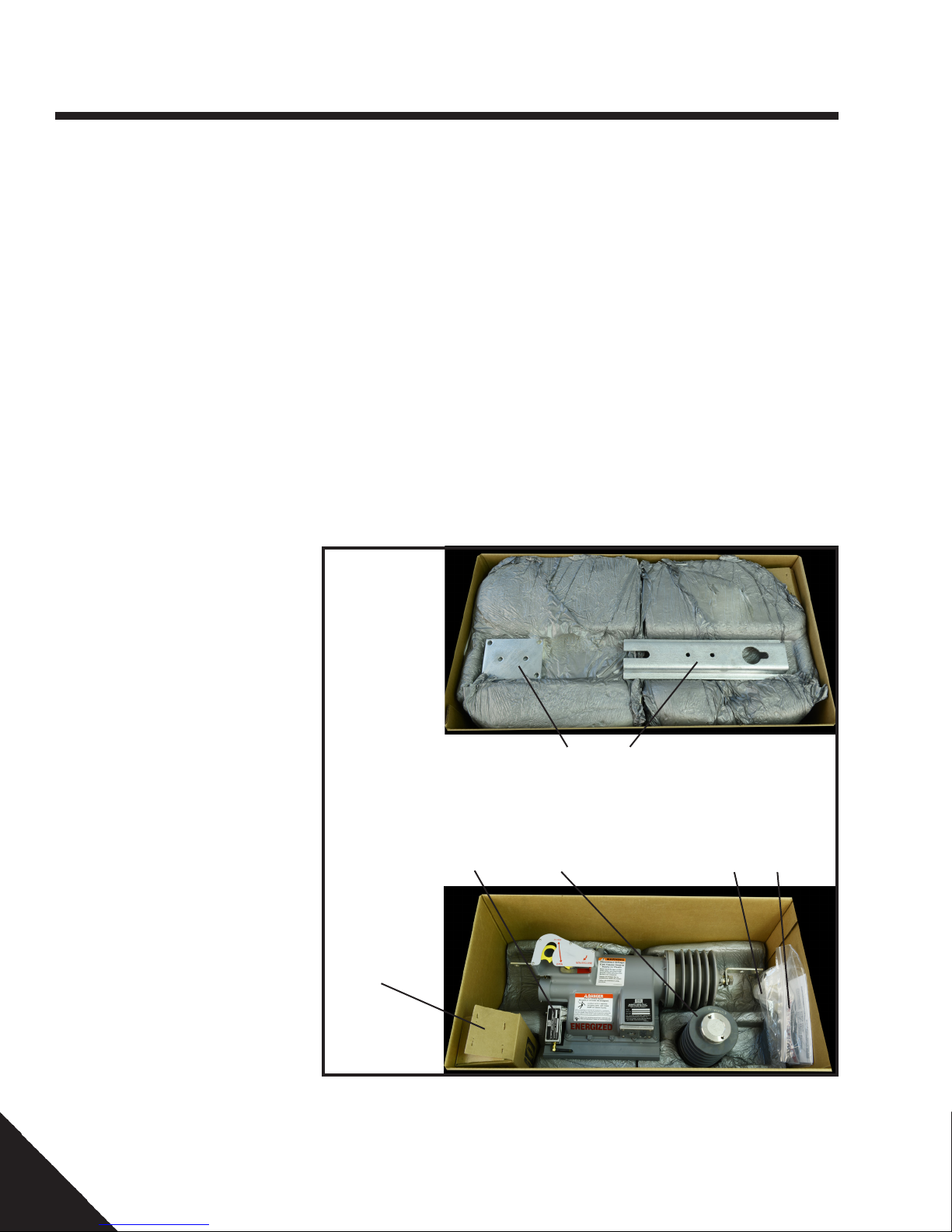

1. Refer to Figure 3-1 to familiarize yourself

with all components.

NOTE: When batteries are removed for

more than seven days, the time stamp

chip will stop keeping time. If time stamp

feature is required, the time stamp can

be reset before placing the recloser in

service. (See Section 7.)

Storage

If the recloser is not going to be put into service

immediately, re-pack all components in the

factory package to minimize storage damage

and to ensure good operating conditions in the

future. Hubbell Power Systems recommends

that the recloser be stored indoors or under

cover, off the ground, not subject to direct sun,

rain or snow.

If the storage area temperature exceeds

100°F, remove the batteries and store in a

cool, dry area.

10

Radio

(optional)

Battery Bayonet

Figure 3-1 Components

Mounting

Brackets

Insulator

Mounting

Fasteners

and

PG Clamps

Instructions,

Flash Drive

and NR

Handle

Adapter Kit.

PSP8620311

Rev. E

Page 11

4 — Installation

Installing the Optional NonReclose Hookstick Adapter

The Non-Reclose (NR) Hookstick

Adapter Kit is an adapter that can

be attached to the NR handle on the

Versa-Tech Recloser to allow for easier

operation with a hookstick. The addition

of the adapter is not mandatory. The

same gentle pull action, as used with

the NR handle, is utilized for operation.

Figure 4-1 shows the NR Hookstick

Adapter Kit as packaged. Figure 4-2

shows the components.

Step 1: Pull the Non Reclose (NR)

handle to the down position.

Step 2: Take the NR Hookstick Adapter

and place it so that the NR handle is

positioned as shown in Figure 4-3.

Figure 4-1

Clevis Pins

Cotter Pins

Non Reclose

Hookstick

Adapter

Figure 4-2

Step 3: Insert the clevis pins through

the holes of the NR Hookstick Adapter as

shown in Figure 4-4.

Figure 4-3 Figure 4-4

Figure 4-5

Step 4: Place the cotter pins though the

holes on the clevis pins. Fold the legs of

each cotter pin as shown in Figure 4-5.

NOTE: The Non Reclose Hookstick

Adapter operation has not been tested

under icing conditions.

PSP8620311

Rev. E

11

Page 12

4 — Installation

Installation Options

VERSA-TECH® single-phase reclosers are designed for outdoor pole or

structure mounting and application on

overhead electrical distribution systems.

The energized recloser is insulated from

the pole/structure by a polymer insulator.

The VERSA-TECH® Single Phase Electronic Recloser is available in two basic

mounting configurations:

1. Pole/Structure mounting (see Fig. 4-1)

2. Crossarm mounting (see Fig. 4-2).

Refer to the catalog number of the unit. The

fourth (4th) character position indicates

the mounting arrangement, e.g., the "1" in

the seventh position of (PSC86)2X11XXX

indicates a Pole/ Structure mounting. A “2” in

this position indicates Crossarm mounting,

e.g., (PSC86)2X12XXX.

Figure 4-8 Bypass Arrangement

Figure 4-6 Pole/Structure Mounting

Hubbell Power Systems recommends the

use of a by-pass switch in parallel with the

recloser. This arrangement allows the unit to

be easily taken out of the circuit for service,

should the need arise. It also allows all

connections to be made without picking up

load current with the jumper connections

(see Fig. 4-3).

LIGHTNING ARRESTERS NOTE:

Hubbell Power Systems recommends

placing appropriately rated lightning

arresters as close as possible on both

the source and load sides of the recloser.

(Refer to Ohio Brass catalog.)

Figure 4-7 Crossarm Mounting

12

PSP8620311

Rev. E

Page 13

4 — Installation

!

WARNING

Follow all appropriate OSHA and company

work rules in the installation of this equipment.

All clearances, cover-up and personal protective equipment must be used. Failure to follow

these instructions may result in damage to

equipment, personal injury or death.

!

CAUTION

The unit must be mounted horizontally as illustrated in this manual. Failure to mount in

this attitude may result in improper operation

of the interrupter.

!

WARNING

Do not store or lay the recloser in mud, snow or

water.

This could contaminate the insulation over the

interrupter leading to electrical flashover at the

system voltage.

A clean, dry storage environment is recommended.

!

CAUTION

Do not place the recloser in service until all settings have been programmed and verified.

Failure to comply can result in recloser

misoperation, equipment damage, and personal

injury.

Refer to sections 6 and 7 of this manual for control

programming and operation.

Installation Preparation

1. Program the unit with the desired

parameters as outlined in Section 6 of

this manual. Record the settings on the

supplied tag and attach the tag to the

operating handle for reference during

installation (Fig. 4-4).

2. Prior to installation, verify vacuum

interrupter integrity by applying 50/60 Hz

40kV AC across the open contacts for 60

seconds. (See Section 7.)

Complete this tag when unit is programmed and tie to the operating handle of the unit.

Hubbell Versa-Tech® Single Phase Recloser

This unit has been programmed to the following settings by: _______________ Date: _____________

Operations to Lockout: 1 2 3 4

Minimum Trip (Amps): ___________ Reset Time (sec): ____________

Min. Response Time (mSec): __________ Cold Load Time: ____________

Sequence Coordination Enabled ❑ Min. Response Enabled for Operation 1 2 3 4

Operation #1: TCC1 TCC2 TCC1 Curve: _____________

Modier: _____________

Operation #2: Reclose Time 1 (sec): ____ Curve: TCC1 TCC2

TCC2 Curve: _____________

Modier: _____________

Operation #3: Reclose Time 2 (sec): ____ Curve: TCC1 TCC2

Operation #4: Reclose Time 3 (sec): ____ Curve: TCC1 TCC2

Location for Installation: _______________________________________________________________

Installed by: ______________________________________________ Date: _____________________

Figure 4-9 – Program/Installation Tag

PSP8620311

Rev. E

13

Page 14

4 — Installation

Pole/Structure Surface

Mounting

1. Refer to Figure 4-5 for assembly detail

and Table 2-1 for torque specifications.

• Assemble the insulator (1) to the

rectangular steel adapter plate (2)

using two 3/8" X 1" bolts and split lock

washers (3) as shown.

• Assemble the mounting bracket (4) to

the opposite end of the insulator (1)

using two 3/8" X 1" bolts, flat washers

and split lock washers (5) as shown.

• Attach the insulator/bracket/adapter

plate to the four threaded bosses on

the flat side of the body of the recloser

as shown. Use four ss 3/8" X 1-1/4"

bolts, flat washers and split lock

washers (6).

NOTE: Do not attach to the 4 threaded

holes on the top of the body. These

attachment holes are used only on the

crossarm mounting arrangement.

2. Determine the mounting location on the

pole. The pole mount uses 2 bolts, 5/8"

diameter on 12" centers.

3. Drill the appropriate holes through the

pole.

5

4

1

6

2

3

Figure 4-10 Pole/Structure Mount Assembly Detail

4. Install the bolt in the top hole.

NOTE: The head of the bolt must be on

the side of the pole where the recloser

will be mounted. Install the nut and

washers on the back side. Leave

approximately 2" of bolt exposed under

the head for the keyhole slot in the

mounting bracket.

5. Using a nylon sling, sling the unit as

shown in Figure 4-7.

CAUTION: Do not use a metal sling or

chain as this may damage the unit.

6. Using suitable means, lift the unit into

position.

CAUTION: Do not allow recloser to

impact or collide with pole or other

objects as it is lifted and installed.

7. Ensure the top bolt engages the small

portion of the “keyhole” slot.

Figure 4-11 Pole/Structure

Mount Installation

Figure 4-12 Recloser in Sling

8. Install the bottom bolt/washers and nut.

9. Tighten the hardware per Table 2-1.

14

PSP8620311

Rev. E

Page 15

4 — Installation

Crossarm Mounting

This configuration is intended for application

to a double crossarm structure.

This is the preferred arrangement if three

units are to be mounted.

1. Remove the four 3/8" X 5/8" bolts from top

mounting flange (8) and use to fill the four

holes on the cover (9).

2. Refer to Figure 4-8 for assembly detail

and Table 2-1 for torque specifications.

• Orient the insulator (1) so the skirts

will shed water towards the rectangular

steel adapter plate (2) and assemble

using two 3/8" X 1" bolts and split lock

washers (3) as shown.

• Assemble the mounting bracket (4)

to the opposite end of the insulator

(1) using two 3/8" X 1" bolts, split lock

washers and flat washers (5) as shown.

• Attach the insulator/bracket/adapter

plate to the four threaded bosses on

the top of the body of the recloser as

shown. Use four ss 3/8" X 1-1/4" bolts,

flat washers and lock washers (6).

3. Using a nylon sling, sling the unit as

shown in Figure 4-7.

7

5

4

1

6

2

3

8

9

Figure 4-13 Crossarm Assembly Detail

CAUTION: Do not use a metal sling or

chain as this may damage the unit.

4. Using suitable means, lift the unit into

position.

5. Install the back plate (7), and four 3/8"

X 7-1/2" carriage bolts/lock washers/

and square nuts. Adjust the bolt

spacing as necessary to fit the crossarm

arrangement.

6. Tighten the hardware per Table 2-1.

NOTE: Make sure the terminal L brackets

(2-hole NEMA pads) are not bent in any

angle. Terminal L bracket nuts, sixteen

screws around the recloser and six screws

around the vacuum interrupter are not to be

removed or re torqued by any means. The

integrity of the contacts is compromised if the

above factory standard torqued hardware is

tampered.

Figure 4-14 Crossarm Mount Installation

PSP8620311

Rev. E

15

Page 16

4 — Installation

Connections

1. Wire brush the jumper conductors and

terminal pads.

2. Apply contact aid, such as CHANCE ZLN

to the contact surfaces. Install the recloser

end of the jumpers. Tighten the terminal

bolts per Table 2-1. if used.

3. Make sure the recloser handle is in the

open position and the contacts are open.

4. Connect the jumpers to the power source.

Tighten the terminal bolts per Table 2-1.

5. The recloser is a bidirectional current

sense device and can be connected

either way to the source or the load side

of the feeder.

NOTE: The unit will not close with the

Non-Reclose handle down if in HLT only

mode.

CAUTION: Avoid applying side loads to

vacuum interrupter end of recloser when

making connections to terminal pads.

Place recloser into service

1. Using appropriately rated hot stick, pull

the red non-reclosing lever to the down

position.

2. Using appropriately rated hot stick, install

the battery pack by inserting; align the

pins in the slots, push and turn clockwise

to lock in place.

3. Ensure all connections are tight and

properly connected.

4. Using an appropriately rated hot stick,

close the unit by pushing the yellow lever

to the extreme up position and release.

You should hear the unit close.

5. Using an appropriately rated hot stick,

open the by-pass switch

6. Push the red non-reclosing lever to the

up position. The unit is now in normal

operating mode.

!

DANGER

Electric Shock Hazard. All parts of recloser are energized.

Contact with in service recloser will cause death or severe injury.

Before contacting or servicing the equipment, or working on the

electrical system, isolate and ground the recloser from the electrical system. Verify recloser is de-energized by testing with properly

rated hot sticks and/or rubber gloves and volt meter.

!

WARNING

Do not ground the recloser.

Grounding the recloser can result in recloser misoperation,

equipment damage and personal injury.

!

WARNING

Open the recloser before making final connections.

Failure to comply can result in an electrical arc which can cause

death, personal injury or equipment damage.

Before making any connections to the power line, pull the red non-reclosing lever down and open the recloser by pulling the yellow handle

to the down position.

!

WARNING

Do not open the by-pass switch while the recloser is open.

Failure to comply can result in an electrical arc which can cause

death, personal injury or equipment damage.

16

PSP8620311

Rev. E

Page 17

5 — Recloser Operation

Overview

The VERSA-TECH® Recloser is a unique

and patented approach to recloser design.

The interrupter, drive mechanism, control,

and housing are raised to the system

potential. The entire assembly is then

insulated from ground using a standard

polymer post insulator. This approach

allows a compact simplified design and also

eliminates the potential for an insulation

breakdown failure.

The fault interruption occurs in the recloser’s

vacuum interrupter. This vacuum interrupter

has state of the art contacts utilizing axial

magnetic fields to interrupt in diffuse mode

for maximum interrupter life. The vacuum

interrupter is supported by an insulating

support housing with bonded epoxy

composite formulation over-molding for

maximum weather resistance.

The drive for the vacuum interrupter is

provided by a mechanism with a magnetic

actuator. The actuator has a rare-earth

neodymium magnet, which provides the

latching and holding force for the vacuum

interrupter in the closed position. A spring

provides the pressure to hold the vacuum

interrupter in the open position. Together

the rare-earth magnet and the spring

arrangement allow the mechanism to be

stable in the open or closed position without

the need for external power. To open the

vacuum interrupter a coil on the magnetic

actuator is pulsed in one direction. To close

the same coil is pulsed in the other direction.

Energy to open and close the recloser is

provided by a set of capacitors.

The control for the recloser is provided by

a microprocessor based electronic circuit.

The control is designed to allow complete

flexibility and user choice of minimum

trip, time-current curves and sequencing

parameters. User access to all parameters

is provided through an RS-232 serial

connection. Current sensing for the control

occurs through a 1000:1 current transformer.

No external transformer power for the

recloser is required. Power for the control

and the mechanism is converted from fault

or load current using two power current

transformers. The open and close capacitors

needed to drive the recloser are charged by

the load or fault current through the power

current transformers. Using this approach

the recloser will continue to open and close

as necessary without the need for external

power or even the hot-stick replaceable

lithium battery pack. The lithium battery

pack provides power to the real time clock,

beacon, the remote radio when current

is less than 10A when the Non-Reclose

handle is engaged (See Recloser Operation

Section) and after lockout or manual open.

Automatic Operation

The VERSA-TECH® Recloser, when in the

closed position, operates automatically per

the programmed user settings.

Operations Counter*

Refer to Figure 5-1 for Counter location.

Operations counter is an electromechanical

counter, which counts open operations

both manual and automatic initiated by the

control.

*Applicable to VTI only. External operations

counter is not present on the VTLT.

Non-Reclosing Lever/Hot

Line Tag

Refer to Figure 5-1 for the location of

the Non-Reclosing Lever (red lever). The

handle is shown in the normal or UP

position. In this position, the recloser will

follow the automatic sequence it has been

programmed for.

Legacy Versa-Tech I Reclosers

(manufactured July 2011 and

earlier):

The Versa-Tech Programmer User Interface

(UI) allows the programming of the NonReclosing (NR) lever to a single

functionality mode only (Non-Reclose

Mode OR Hot Line Tag mode). If the NR

Mode Only is selected when the red lever is

rotated 90 degrees clockwise to the down

position, the recloser will trip using TCC1

and lockout on any current above minimum

trip. If the Hot Line Tag (HLT) Mode Only is

selected when the red lever is rotated 90

degrees clockwise to the down position, the

recloser will trip instantaneously and lockout

on any current above minimum trip.

Versa-Tech Reclosers manufactured

after July 2011 (Versa-Tech I and

Versa-Tech LT):

The Versa-Tech Programmer User Interface

(UI) allows the programming of the NonReclosing (NR) lever to a dual

functionality mode (Non-Reclose/Hot Line

Tag) or a single functionality mode (Hot Line

Tag Only). When the "NonReclose/Hot Line Tag" option is selected,

the recloser will be in a Non-Reclose mode

when the red lever is rotated to the down

position one time. In the NR mode, the

recloser will trip using TCC1 and lockout

on any current above minimum trip. If the

red lever is rotated to the down position

twice within 30 seconds, the recloser will be

placed in Hot Line Tag mode. The Hot Line

Tag Mode is an instantaneous trip mode.

When the "Hot Line Tag Only" option is

selected, the recloser will always be in Hot

Line Tag mode when the red lever is placed

in the down position.

Note for Versa-Tech I Reclosers with

Firmware 4.xx: For Versa-Tech I Reclosers

with firmware version 4.xx, whenthe recloser

locks out on Hot Line Tag, the solenoid can

be closed only after the Hot Line Tag mode

is disabled. This is accomplished by first

rotating the red lever back to its original

position (UP) and then by pushing the

Manual Handle (yellow handle) back to its

UP position. If the Manual Handle is UP prior

to putting the red lever to the UP position,

the Manual Handle must be pulled DOWN

and then pushed to the UP position in order

for the solenoid to close.

All Versa-Tech I and Versa-Tech LT

Reclosers: Hot Line Tag is an instantaneous

trip mode. As long as the capacitors are

fully charged, the Versa-Tech will trip in

1/2 cycle or 8ms while in HLT. Hot Line Tag

takes precedence over Cold Load Time and

Non-Reclose mode. Cold Load Time takes

precedence over Non-Reclose Mode. The

red lever is also used to turn on the remote

radio (Digi/XBee, SiFLEX, or WiFi) when

line current goes below 10A. To turn on

the remote radio, pull the red lever DOWN

and then push it UP within 30 seconds. the

radio will then automatically shut OFF after

10 minutes of communications inactivity to

minimize battery drain. If the red lever is

left in the DOWN position, the radio will be

powered for 60 minutes before automatically

shutting OFF.

PSP8620311

Rev. E

17

Page 18

5 — Recloser Operation

Manual Operating Handle

Refer to Figure 5-1 for Manual Operating Handle location. The manual operating handle is designed to allow manual operation of the

recloser with a hotstick. If the manual handle operating handle is rotated 90 degrees counter-clockwise to the down (open) position the

recloser will open and interrupt the distribution circuit. Pulling the manual handle down anytime will manually pull open the mechanism and

the vacuum interrupter opening the recloser.

Closing the recloser after a manual open or automatic lockout can be done by moving the manual operating handle clockwise 90 degrees

to the up (closed) position. This will activate the electronic control, which will initiate the close sequence. Before the recloser is closed

the close capacitor is charged to the required level from the lithium batteries. When it reaches the necessary charge level, the magnetic

actuator closes the recloser. This process from movement of the handle until the recloser closes may take a few seconds.

Lockout Beacon

Refer to Figure 5-1 for Beacon location. The Lockout Beacon is a unique feature which is designed to aid the utility lineman in identifying

a locked out recloser. This high intensity sunlight visible amber LED will flash once every 3 seconds when the recloser has sequenced to

lockout. The lithium batteries provide the power for the flashing beacon.

Versa-Tech I Reclosers with FW 3.xx and Versa-Tech LT Reclosers:

The beacon will continue to flash every 3 seconds until the lineman closes the recloser or 1 hour has passed. After 1 hour, the flashing

beacon will automatically shut OFF. The beacon is also utilized when the recloser is manually opened. When manually opened, the beacon

will continue to flash until the recloser is closed or 60 seconds has passed.

Versa-Tech I Reclosers with FW 4.xx:

The beacon will continue to flash every 3 seconds until the lineman closes the recloser or 4 hours have passed. After 4 hours, the flashing

beacon will automatically shut OFF. The beacon is also utilized when the recloser is manually opened. When manually opened, the beacon

will continue to flash until the recloser is closed or 4 hours have passed.

Manual Operating Handle

Non-Reclosing

Lever

Lockout Beacon

18

Operations Counter*

Figure 5-1 Feature position

*Applicable to VTI only. External

Operations Counter is not present

on the VTLT.

PSP8620311

Rev. E

Page 19

6 — Control Programming

Overview

The VERSA-TECH® Recloser can be fitted with an

optional radio which will allow settings, diagnostics and

scratchpad to be viewed remotely while the unit is in

service. The radio will also allow settings, timestamp and

scratchpad to be changed while the recloser remains in

service. The remote radio options are Digi/XBee 900MHz,

SiFLEX 900MHz, or Wireless (WiFi) 2.4GHz. The remote

radio is adapted to the serial port on the recloser. In

order to accomplish communication with the Digi/XBee or

SiFLEX remote radios, a separate Digi/XBee or SiFLEX

local radio is needed. The local radio is a USB powered

radio that is attached to the laptop or other personal

computer running the Versa-Tech Programmer User

Interface. Communication with the WiFi remote radio is

accomplished through the Wireless Network on the laptop

or personal computer.

Customer Supplied Requirements

Personal computer with Microsoft® Windows® XP,

Windows® 7 32/64 bit or Windows® 8 operating system,

a USB to RS-232 serial cable if a direct connection is

desired, PC wireless card for connection through the WiFi

remote radio, local Digi/XBee radio with USB Type B serial

cable for connection through the Digi/XBee remote radio,

or local SiFLEX radio with USB Type B serial cable for

connection through the SiFLEX remote radio.

Software Installation

To Establish Communications

If external local radios are required, they must be connected before

launching the programming software. If a WiFi remote radio is

utilized, connection to the wireless network card on the PC must

be established prior to launching the programming software. Once

the programming software is launched, click "Refresh List" on the

User Interface to scan for the reclosers within the range and "Auto

Connect" to connect to the selected detected devices. See Control,

Programming > Connection Section 6 of this manual.

Connecting Local Radio

The local radio is controlled and powered by connecting a USB cable

between the module and a personal computer as shown in Figure

6-1. Communication with the local radio is accomplished through

the recloser programmer software (see section 6) provided with the

recloser.

Connecting WiFi

The Versa-Tech Recloser uses a 2.4GHz RN171 remote radio to

communicate over WiFi (without the need for a local radio). Wireless

communication is established to the Versa-Tech I (FW 3.xx or 4.xx)

and Versa-Tech LT through the internal wireless card on a PC and

the Versa-Tech Programmer software (UI version 4.50.15 or higher).

Wireless communication with a Versa-Tech I with firmware version

4.xx and Versa-Tech LT can be also be established using the VersaTech Recloser Programmer Version 3.1 iPad app. The WiFi radio has

the capability to communicate up to 100 feet from the recloser.

Recloser programming software must be installed on the

computer proir to use. Installation software is provided

with each recloser on a Hubbell USB drive or is available

on the Hubbell Power Systems website.

Connecting Recloser to PC

The customer supplied DB9 Male/Female serial cable is

used to directly connect the recloser to a PC (hardwired).

Wireless communications can be established utilizing the

appropriate 900MHz remote/local radio combination or

the PC wireless networks/WiFi remote radio combination.

Figure 6-1 Connecting Local Radio

PSP8620311

Rev. E

19

Page 20

6 — Control Programming

Remote Radio Power

When the VERSA-TECH® Recloser is in service with a load current of 10 Amps or more, the attached remote radio is on and powered from

the recloser's internal current transformers. If the recloser is not in service or the load current is less than 10 Amps, the radio is ON only for

10 minutes and must be powered from the recloser internal batteries. To turn on the radio, pull down the Non-Reclosing handle (red lever)

and then push it up. The radio then will automatically shut off after 10 minutes of communications inactivity to minimize battery drain. If the

Non-Reclosing Lever is left in the down position without the ample 10 Amps of load current, wireless communications will time out in 60

minutes.

NOTE: Whenever the remote radio on the recloser is changed or swapped with another remote radio, make sure that the battery is pulled

out of the recloser for at least 60s for the control to completely reset. After the reset, plug in the new remote radio to the DB 9 port of the

recloser followed by the battery pack insertion. This process lets the remote radio get correctly identified by the Versa-Tech Programmer.

Radio Operation

The Digi/XBee and SiFLEX radios communicate with each other on a 900MHz channel which utilizes frequency hopping to minimize

interference from other radio frequency sources. The RF modules are FCC compliant. The communication range is up to 500 feet open air.

The radios use a two-part addressing scheme to help ensure that messages from only authorized sources are passed to a recloser.

First, all VERSA-TECH® Recloser local and remote radios have a unique user transparent address which is transmitted during

communications. The recloser local radio will accept messages only from a remote radio with the same address. This helps prevent other

900MHz radios from making unauthorized communications with VERSA-TECH® Reclosers.

Second, each remote radio is programmed with a unique fixed radio communications address. This address allows users to differentiate

between multiple reclosers all within a 500-foot transmit/receive range. The remote radio will discard any message that does not include

its unique radio communications address. The local radio has provisions through the recloser programmer software (see Section 6) which

permits selecting any recloser's remote radio communications address.

20

PSP8620311

Rev. E

Page 21

6 — Control Programming

Windows XP Local Radio Drivers Installation Guide

Before using the Local Radio for the first

time, the Windows® device drivers will

have to be installed. The following steps

illustrate the process.

1. Download the radio drivers from the

Hubbell Power Systems website. Be sure to

extract the files.

2. Connect the USB plug to USB port on

the radio.

3. Connect the other end of the USB cord

to USB port on the PC/laptop.

4. “Found New Hardware” Wizardshould

start.

5. At the “Can Windows connect to

Windows Update to search for

software?” window, select “No, not at

this time” and click <NEXT>

6. Insert the provided Hubbell USB drive.

Found New Hardware wizard should

automatically continue, if not, click

<NEXT>.

7. Click Finish.

8. “Found New Hardware” Wizard should

start again. This time it is adding the

USB port.

9. Repeat Steps 5 to 7 above.

NOTE: Because Hubbell has a policy of continuous product improvement, we reserve the right to change

design and specications without notice.

PSP8620311

Rev. E

21

Page 22

6 — Control Programming

10. Click NEXT.

11. Click FINISH.

12. Computer should state “New

hardware is installed and ready to use.”

To determine which COM port the local

radio is using, as assigned by your computer, perform these steps:

1. Right click on “My Computer.”

2. Select “Properties.”

3. Select the “Hardware” Tab.

4. Click the “Device Manager” Button.

5. Click the “+” icon next to Ports.

6. In the Ports section it will state “HPS Local

Radio "(COM XX) for the Siflex Local Radio and "Digi PKG-U Serial Port Adapter

"(COMXX) for the Digi Local Radio”. The

“X” is the port number it is using. This

number will be used during programming.

NOTE: Refer to the "VTI Communication

Troubleshooting Guide VT1-APR0013" which

is available on the Hubbell Power Systems

website for more detailed instructions on

installing the local radio drivers.

Before attempting to communicate with

the recloser radios each time, be sure to:

1. Attach antenna to radio unit.

2. Know or determine the COM port the local

radio is using as outlined above.

3. See Recloser Installation, Operationand

Maintenance Manual for programming

software setup and communication with

reclosers through remote radios.

22

PSP8620311

Rev. E

Page 23

6 — Control Programming

Windows 7 Local Radio Drivers Installation Guide

1. Download the radio drivers from the Hubbell Power Systems website. Be sure to

extract the files.

2. Connect the local radio to the computer with the provided USB cable. Windows will

attempt to automatically install drivers using the found hardware wizard.

If this driver installation process does not continue automatically:

3. Open the Device Manager by going to Start Menu>Right click on “Computer”>Select

“Manage”

4. Click on the device manager and locate “HPS Local Radio”

5. Right click on “HPS Local Radio” then select “Update Driver Software”

PSP8620311

Rev. E

23

Page 24

6 — Control Programming

6. Select “Browse my computer for driver software” & select the Windows 7 64 bit drivers

location on the USB drive,. Click Next.

7. Pop-up will say “Cannot verify publisher,” choose “Install anyway”; Driver will be installed.

24

PSP8620311

Rev. E

Page 25

6 — Control Programming

8. Repeat from Step 3 to 7 for an item called “USB Serial Port”; drivers are now installed.

9. After the radio drivers have been correctly double installed the local radio would

appear in the Device Manager under ports (COM & LPT) section as below.

1. Digi PKU-G Serial Adapter(COMXX) for a Digi Local Radio

2. HPS Local Radio(COMXX) for a Siflex High Performance Radio.

NOTE: The installer must run twice. Once to install the radio driver itself and then again to

install the USB Serial Port

NOTE: Refer to the "VTI Communication Troubleshooting Guide VT1-APR0013" which

is available on the Hubbell Power Systems website for more detailed instructions on

installing the local radio drivers.

PSP8620311

Rev. E

25

Page 26

6 — Control Programming

Windows 8 Local Radio Drivers Installation Guide

To download and install the Digi/XBee 9XCite (USB, 232/485 module) local radio drivers

for Windows® 8, please visit the Digi International website.

26

PSP8620311

Rev. E

Page 27

6 — Control Programming

Versa-Tech® Programmer Settings Tab

*

* For Versa-Tech® I: Minimum trip is programmable from 30A-800A.

For Versa-Tech® LT: Minimum trip is programmable from 30A-200A.

PSP8620311

Rev. E

Figure 6-2

27

Page 28

6 — Control Programming

Connection

Communications with the Versa-Tech Recloser can be established

through the below two options.

1. Identify Device

2. Manual Connect

Identify device option scans for all possible reclosers available within

the communication range with respect to the local device connected

and selected on the Versa-Tech Single Phase Programmer. Manual

connect option is used to specifically connect to a recloser whose RF

address is known.

Connecting to a Recloser with a Digi/XBee or SiFLEX Radio

After the drivers have been correctly installed as per the previous

section, communications can be established to the recloser by the

Versa-Tech Single Phase Recloser Programmer using the below two

options.

Identify Device

To establish communications:

1. Connect the local radio link (or RS 232 DB9-F serial cable) to the

USB (or RS 232) port of the computer and with the remote radio

(or RS 232 DB9-M serial cable) plugged into the RS 232 F port

of the recloser.

Manual Connect

To establish communications through Manual Connect:

1. Follow Step 1 - Step 3 from Identify Device section

2. Click Manual Connect option.

3. Select the Manual Connect parameters as per the recloser specifications

and enter the Remote Radio RF address of the recloser as below.

4. Click Connect.

2. Ensure that the +12V battery pack is inserted into the recloser unit

firmly. If the recloser sees a current less than10A, power cycle (pull

the handle down and then push it backup) the NR handle(red) once

to turn the remote radio on for 10 minutes. If the current is more

than 10A the remote radio is always ON.

3. Hit "Refresh List" on the Programmer to populate the local devices

in the communication grid.

4. Now, Check the Local Device(highlighted in blue) in the

communication grid where communication has to initiate and then

click "Identify Device".

5. When the Programmer returns all the available reclosers with

the Remote Radio addresses, select each recloser individually

(highlighted in blue) and connect to the unit by clicking Connect

option on the Programmer.

6. User can change the settings once the communications has been

established. Program the settings by writings the settings to Recloser

with the password provided.

7. To disconnect from the recloser, click Disconnect.

5. Once the communication has been established with the specific recloser

unit, the RXD communication light flashes in green to confirm successful

communication.

6. To disconnect from the recloser, click Disconnect

28

PSP8620311

Rev. E

Page 29

6 — Control Programming

Connecting to a Recloser with WiFi Radio

In order to communicate with the WiFi radio, the Versa-Tech Single

Phase Programmer v4.50.15 or higher will need to be used.

To establish communication:

1. Ensure that the +12V battery pack is inserted into the recloser unit

firmly. If the recloser sees a current less than 10A, power cycle

(pull the handle down and then push it backup) the NR handle

(red) once to turn the remote radio on for 10 minutes. The NR

handle (red) can also be left in the down position to power the

WiFi radio for 60 minutes. If the current is more than 10A the WiFi

radio is always ON.

2. Open up the wireless networks on the PC. Click "Connect" under

the wireless network HPSVT1_SNX where X is the serial number

of the WiFi Remote Radio.

5. Once the WiFi Remote Radio is identified, the "Connect" button

will be enabled. Click "Connect".

6. Once communication has been established with the recloser, the

RXD communication light flashes in green and the "Status" box

will show "Connected".

7. To disconnect from the recloser, click Disconnect.

3. Enter the security key "hubbell1234" when prompted.

4. Highlight the appropriate port and click "Identify Device".

PSP8620311

Rev. E

29

Page 30

6 — Control Programming

Settings Tab

Programming Settings

The Recloser Settings Tab appears when the Recloser

Programmer Software is loaded and opened. See Figure 6-2. At

this point, changes to the settings can be made as required for

the recloser’s particular application. When settings changes are

complete, the “Write Settings To Recloser” button will allow the

settings displayed to be stored in the recloser. Notice that settings

fields that are not identical to what is actually stored in control

memory are displayed in red until they are committed to memory.

From this point forward the recloser will use these new stored

settings. These settings can be checked at any time by clicking the

“Read Settings From Recloser” button.

Minimum Trip Value

The Minimum Trip Value is the minimum current sensed that will

cause the Recloser to trip. This current is programmable from

30A to 800A for Versa-Tech I and 30A to 200A for Versa-Tech

LT in 10A increments. The control will begin counting towards

meeting the selected time current curve when there is a half cycle

of current above this threshold. The current level is measured

by sampling and finding its peak value. The sample frequency

for current measurement is 1.04ms. This gives 16 samples per

60Hz cycle. Sliding window approach is followed to perform

current measurement. Current measurement is on half-cycle

basis. Hence, to assert a fault (current above Min. Trip), at least 8

samples are required.

Non Reclose/Hot Line Tag

Operations to Lockout

The control can be set to 1, 2, 3, or 4 operations before the

recloser goes to lockout.

Manual Closing Delay Time

The time from when the manual handle is activated until the

recloser begins closing the circuit can be programmed from 0 to

30 seconds. The actual delay may be a few seconds longer than

the time programmed.

Sequence Coordination

The sequence coordination feature if enabled will prevent

unnecessary operations of the recloser when used in a series

arrangement upstream from other fault interrupting device. If

the recloser senses current above the minimum trip level for a

duration shorter than the programmed control response time,

then the recloser will internally advance its software count by one

without tripping. This action allows an upstream recloser to stay in

proper sequence when faults are cleared by downstream recloser.

False counting is avoided by applying hysteresis to the minimum

trip threshold. The current must increase above the minimum

threshold and then decrease to 87.5%of the trip threshold before

a count is registered. The count is remembered for the reset time.

Versa-Tech I Reclosers with FW 3.xx and VersaTech LT

Reclosers:

The Non-Reclose handle has a dual functionality when the option

‘Non-Reclose/Hot Line Tag’ is selected by the proper radio buttons

on the main "Settings" tab of the user interface. In this mode,

when the red handle is pulled to the down position once (rotate

90° in the clockwise direction) the recloser is placed in the

traditional Non-Reclose mode using whichever curve is selected

to lockout on TCC1 (See Recloser Operation Section). However,

if the red handle is cycled (pull the handle down and up) twice

and the handle is brought back to the down position within 30

seconds, the unit is now placed in Hot Line Tag (HLT) or the

instantaneous trip mode. When the user selects the ‘Hot Line Tag

Only’ option in the Settings, the Non Reclose handle will function

always as HLT when the handle is pulled down( rotated 90° in

the clockwise direction). A unit placed in HLT mode is always

accompanied by a characteristic pulsed strobe of the beacon

serving as a visual indicator confirming the HLT mode. Hot Line

Tag takes precedence over Cold Load time.

Note for Versa-Tech I Reclosers with FW 4.xx:

When the recloser locks out on a HLT mode dropping the Manual

Operating handle (yellow), the unit would be able to close back in

only after the HLT mode is removed meaning that the NonReclose handle (red) has to be manually returned to the normal

position to disable the HLT function and then the Manual

Operating Handle is to be rotated 90° in the anti clockwise

direction for the recloser contacts to close back in.

NOTE: Units manufactured prior to August 2011 will not have the

dual functionality of the Non-Reclose Handle. However, these

units would have dedicated options for the Non-Reclose and Hot

Line Tag modes that can be enabled through the User Interface.

When "Sequence Coordination" box is checked, sequence

coordination is applied to all programmed shots.

Versa-Tech I Reclosers with FW 4.xx:

Sequence coordination is allowed to be made shot specific by

using the software and choosing the TCC curves where the

Sequence Coordination should operate on. This is accomplished

by selecting the check boxes for Sequence Coordination under

the respective TCC curves on the User Interface. Sequence

coordination would be applicable only on the checked TCC curves.

By checking the SC on lockout option, the recloser would trip

on TCC2 for a permanent fault that the unit would see past the

operations to lockout. For example: If the unit has 4 operations to

lockout with the SC Lockout option checked and the unit sees a

permanent fault that didn’t clear after 4 downstream operations

by the downstream devices, the recloser unit would lockout out

on the delayed TCC2 curve which would appear as a 5th actual

operation after recording 4(SC) events in the event log.

However, user can uncheck this option on the User Interface and

the recloser would continue to record all the downstream blinks

or the faults that didn’t engage Versa-Tech TCC curves on the line

as 5(SC) 6(SC) 7(SC) so on. Note that the unit would still lockout

on the delayed curve (TCC2) when the unit sees a permanent

fault which was not cleared by the downstream devices in either

situations. (See Control Programming > Event and Data Logs >

Sequence Coordination Events Logs Section).

30

PSP8620311

Rev. E

Page 31

6 — Control Programming

Time-Current Curve Selection

The control can be set to utilize two different time current curves TCC1 and TCC2. TCC1 and TCC2 can be set separately to use one of 15

different time current curves. See Reference Bulletin TD10005E through TD100034E. Each of the 4 possible operations can be set to use either

TCC1 or TCC2.

Time-Current Curve Modiers

Out of the 15 TCC curves, 11 of the curves come in with modifiers for greater coordination flexibility. By selecting Mod1, Mod2 or Mod3, the shape

of the time-current curve can be modified as shown in Reference Bulletin TD10005E through TD100026E.

Minimum Response Time

Minimum response time is used to achieve coordination between fault interrupting devices where fault levels would cause two devices in series to

both trip. When minimum response is enabled, tripping is inhibited until the minimum response time programmed is less than or equal to the fault

current time. The minimum response time is programmable from 0 to 250 milliseconds in 1 millisecond steps and can be enabled on operation

1, 2, 3, or 4. Minimum response can be enabled to each of the specific time current curves of the counts by checking the Enable Min. Response

option individually under each curve.

Basically, when a minimum response time is entered and the minimum response box is checked, the recloser will not open on the selected

shot until the minimum response time or the TCC time for that shot, whichever one is greater.

Reclose Time

Reclose Time is the amount of time from when the recloser interrupts the over-current until the recloser attempts to close the circuit again. Each of

the three possible reclose intervals is separately programmable from 0.25 to 60 seconds in 0.05 second increments.

Reset Time

Reset time is the amount of time from the last reclose until the present count of operations completed is reset to zero and it is also defined as

the amount of time from the last momentary over current event (current above minimum trip) the recloser sees until the timer expires. When the

recloser goes to lockout, the count is also reset to zero. Reset time is programmable from1 to 240 seconds in 1-second increments.

PSP8620311

Rev. E

31

Page 32

6 — Control Programming

Cold Load Time

During this programmed interval, pick-up

threshold is elevated to Cold Load Pickup

value and the control is placed in one

operation to lockout mode. Over current timing

of TCC2 is used by the control. Cold Load

Pickup is active after the recloser has been

opened manually or has been locked out. Cold

Load Time is not valid while the recloser is

performing it's reclose operations. If no over

current is present during this interval, the

control will reset after cold time expires. Cold

Load Time is programmable from 0 to 300

sec. for VTI (FW 3.xx) and VTLT and 0 to 600

sec. for VTI (SCADA FW 4.xx) in 1 second

increments. Cold load time takes precedence

over the Non-Reclosing lever function.

Cold Load Pick up

NOTE: Cold Load Pick Up is only enabled for

Versa-Tech I Reclosers with FW 4.xx.

The range of the minimum trip can be elevated

by multiplying the minimum trip by the cold

load pick up factor during the Cold Load

Time. The Cold Load Pickup factor ranges

from 1-20 and is programmable in steps of

1.For example: A recloser programmed at a

minimum trip of 50A, cold load time of 100 sec

with the cold load pick up of 2 has a minimum

trip range from 1A-100A during the 100sec

cold load time when the unit has locked out (or

manually opened) and closed back in.

Record Manual Close

When enabled, this feature causes the recloser

to store in the Event History the time and

date of manual closes as well as over-current

operations. When disabled, only over-current

operations are stored.

Time Stamp

The recloser has a built in time stamp circuit

which records the time and date following each

recloser operation. The time stamp on the

recloser can be set in two ways.

1. Every time the User Interface

communicates with the unit, the

Programmer generates a pop up question

to auto sync the host computer's clock

with the real time clock on the recloser.

2. The real time clock can also be set to

the Local or the UTC time zones by

selecting the proper radio button on the

User Interface and writing them to the

recloser by the clicking "Set Recloser

Time zone " under the Time and Security

tab. (See Section Time and Security.)

NOTE: Make sure that the host computer

has accurate time and date before using

the "Set Recloser Timezone " or the Auto

Sync option. The recloser would be able

to keep the time only when the time is

set wirelessly through the radios and

with the provided battery pack inside the

unit. INVALID times would be seen on the

Recloser Time section when times are set

through an RS232 serial connection.

The time stamp utilizes one of 3 power sources

to maintain correct time. When the recloser is

in service internal current transformer power

is used. When the recloser is open or not in

service the main lithium batteries are used. If

both of these power sources are unavailable

the control has a capacitor backup circuit,

which can power the time stamp for up to 7

days.

NOTE: Once the time stamp has been

set, it is important that the lithium battery

bayonet not be removed for more than 7

days. If the time stamp loses power, the

recloser will continue to function correctly,

but the times and dates stored for recloser

operations will be INVALID.

Note for Versa-Tech I Reclosers with FW

4.xx: The lithium battery bayonet should not

be stored in the recloser while the unit is

not in service. FW 4.xx does not incorporate

low power optimization which will result in

decreased battery life. When the recloser is

ready to be put in service, insert the battery

bayonet and connect to the recloser to sync

the time stamp. See Section 8 Maintenance

> Battery Replacement Section for additional

information regarding VTI with firmware 4.xx.

32

PSP8620311

Rev. E

Page 33

6 — Control Programming

Settings Tab

To disconnect

Click the “Disconnect” button. A “Rescan” for newly connected (within range) or different devices can now be performed by clicking the

“Identify Device” button.

Note the status indicators at the top of the form window.

COM: Successful Communications

RXD: Receive (data)

NR: Non Reclose

HLT: Hot Line Tag

S/N – Recloser Serial Number

Local Radio: Present Local Radio Address

Status: The status of the last action is displayed in this window

Recloser Time: Present time programmed into Recloser

For Versa-Tech I Reclosers with FW 4.xx (only):

Open: The bottle status is indicated in Green when the contacts are open.

Close: The bottle status is indicated in Red when the contacts are closed.

NOTE: VTLT and VTI with FW 3.xx and below will not have bottle status indicators.

PSP8620311

Rev. E

33

Page 34

6 — Control Programming

Settings Tab

Serial Number (S/N)

Serial Number of the unit signies the manufacturing date of the unit. It's based on the Julian date

format that includes the last two digits of the year it was manufactured in, day of the year, the nth

recloser manufactured on that day. Ex: S/N:1234567

12 345 67

Year Day nth unit

Dual functionality of the Non Reclose handle for Non-Reclose / Hot Line Tag

available on units manufactured post 7/2011. Example: Valid S/N 1121320

The units manufactured prior 8/2011 would have dedicated NR and HLT options that

can be programmed from the VersaTech Programmer. Example: Valid S/N 0713212

Address of both local and

remote radio must match

for Digi radio use. (at right)

Address of remote and local

SiFlex radios do not have to

match. (at right)

WiFi radios do not have a

local radio address. (at right)

34

PSP8620311

Rev. E

Page 35

6 — Control Programming

Settings Tab

Button Functions General Form

Controls

Read Settings From Recloser

Extracts currently programmed settings values from

the recloser control’s memory.

Write Settings To Recloser

Programs the recloser’s control with currently

displayed settings values "Recloser Settings Profile".

Recloser Settings Prole Load From

Opens a window where previously

stored settings can be retrieved from a known

directory or location. Supported format extension is

.vtp (Versa Tech profile) file.

Save To File

Opens a window where a particular

directory or location can be browsed to and selected

in which to store currently displayed settings values.

Generate Full Recloser report

Generates full report including all settings,

Scratchpad, and fault history

Can be exported as .txt or .xml file.

Identify Device

Identify device performs a scan for all possible

reclosers "within range" with respect to the local

device selected in the communication grid of the User

Interface.

Connect/Disconnect

Establishes or disconnects digital communications,

wireless or hardwired.

PSP8620311

Rev. E

35

Page 36

6 — Control Programming

Real Time Monitoring

*

* For Versa-Tech® I: RMS Current "Now" is 400A Max

For Versa-Tech® LT: RMS Current "Now" is 200A Max

Instantaneous Current Monitoring

The real time monitoring features are automatically updated following a successful connection.

Now: It is the Root Mean Square current (RMS) calculated every one second.

Last hour: It is average of RMS current calculated for every one second and averaged over 3600 sec (1h=60x60) i.e., an hour. The

Last hour average current is updated every 10 sec only for the very first one hour when the recloser sees the current since it would

not see the 3600 entries for times less than one hour.

Peak: It is the mean square current seen for every one second interval which is always compared against the previous mean square

current and the greater of the two is displayed.