Hubbell GX200, GX250, G250P, GX200P Installation & Operation Manual

WATER HEATERS SINCE 1920

Intuitive · Reliable · Efficient

INSTALLATION &

OPERATION MANUAL

Hubbell Model

GX200 / GX200P

GX250 / G250P

(nergy 6tar and 64$40D &erti¿ed

/oZ 12[

on 0odels *; / *;3

To avoid product damage, personal injury, or even

possible death, carefully read, understand, and

follow all the instructions in the Installation and

the Operation manuals before installing this

product. Improper installation, adjustment, alteration, or

maintenance can cause injury, loss of life, and/or property

damage. This water heater should be installed and serviced

by a qualified technician. The lack of proper service can

result in a dangerous condition.

This manual contains safety information, installation instructions,

and maintenance procedures. It must be left with the homeowner

or placed near the water heater in a noncombustible place. The

homeowner should retain this manual for future reference.

WARNING

If the information in these instructions is not followed

exactly, a fire or explosion could result causing

property damage, personal injury, or death.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

!

Do not try to light any appliance.

!

Do not touch any electrical switch; do not use

any phone in your building.

!

Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

!

If you cannot reach your gas supplier, call the

fire department.

— Installation and service must be performed by

a qualified installer, service agency, or the gas

supplier.

AVERTISSEMENT

Assurez-vous de bien suivre les instructions données

dans cette notice pour réduire au minimum le

risque d’incendie ou d’explosion ou pour éviter tout

dommage matériel, toute blessure ou la mort.

— Ne pas entreposer ni utiliser d’essence ou

ni d’autres vapeurs ou liquides inflammables

à proximité de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ

"

Ne pas tenter d’allumer d’appareil.

"

Ne touchez à aucun interrupteur; ne pas vous

servir des téléphones se trouvant dans

le bâtiment.

"

Appelez immédiatement votre fournisseur de gaz

depuis un voisin. Suivez les instructions

du fournisseur.

"

Si vous ne pouvez rejoindre le fournisseur,

appelez le service des incendies.

— L’installation et l’entretien doivent être assurés

par un installateur ou un service d’entretien

qualifié ou par le fournisseur de gaz.

Due to Hubbell’s policy of continuous product

improvement and technology, the design and/or technical

speci¿cations are subMect to change Zithout notice

Serial Number: ___________________________________

Date of Installation: ___ / ___ / ______

TABLE OF CONTENTS

Table of Contents

TABLE OF CONTENTS. . . . . . . . . . . . . . . . . . . . . 3

ITEMS SHIPPED WITH WATER HEATER . . . . . . 4

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Icon Nomenclature . . . . . . . . . . . . . . . . . . . . . . 6

Personal Protection . . . . . . . . . . . . . . . . . . . . . . . . . 6

Prohibited Actions. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hazard Avoidance . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation and Installation Warnings . . . . . . . . . . . . . . 6

TECHNICAL SPECIFICATIONS . . . . . . . . . . . . .10

SPECIFICATIONS (NOMENCLATURE) . . . . . . .12

DIMENSIONAL SPECIFICATIONS . . . . . . . . . . .13

QUICK REFERENCE INSTALLATION GUIDE . .14

PREPARATION BEFORE INSTALLATION. . . . . 16

Selecting an Installation Site . . . . . . . . . . . . . . . . . . . 16

High Elevation Installations . . . . . . . . . . . . . . . . . . 17

Water Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

WALL MOUNTING. . . . . . . . . . . . . . . . . . . . . . . .19

Mounting Block Installation Method. . . . . . . . . . . . . . 19

Plywood Installation Method . . . . . . . . . . . . . . . . . . . 19

ADJUSTING THE CO2LEVEL. . . . . . . . . . . . . . .39

Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Display Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Setting the Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Adjusting the Water Temperature . . . . . . . . . . . . . . . 44

Customer Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Domestic Heating Mode. . . . . . . . . . . . . . . . . . . . . 45

Programming ON/OFF Run Times. . . . . . . . . . . . . 45

WATER HEATER PROGRAMMING SECTION. . 45

Recirculation Setup . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Cascading (Daisy Chain). . . . . . . . . . . . . . . . . . . . . . 47

Technician Screens . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Pressure Booster (pump models only . . . . . . . . . . 48

Fast Start Selection . . . . . . . . . . . . . . . . . . . . . . . . 48

Flow Booster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Blower Ramp Selection . . . . . . . . . . . . . . . . . . . . . 49

Flow Control Selection . . . . . . . . . . . . . . . . . . . . . . 50

Fuel Type Selection . . . . . . . . . . . . . . . . . . . . . . . . 50

Blower Override . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Diagnostic Code and Error Log Selection . . . . . . . 51

Diagnostic Code and Error Log Selection . . . . . . . 52

Adjusting CO2 Levels Selection . . . . . . . . . . . . . . . 52

Commercial Heating Selection. . . . . . . . . . . . . . . . 52

GAS CONNECTION. . . . . . . . . . . . . . . . . . . . . . .20

GAS PIPE SIZING TABLES . . . . . . . . . . . . . . . .21

Gas Pipe Sizing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Natural Gas Pipe Sizing . . . . . . . . . . . . . . . . . . . . . 21

LP Gas Pipe Sizing . . . . . . . . . . . . . . . . . . . . . . . . 21

COMBUSTION (FRESH) AIR INLET EXHAUST

OUTLET CONNECTIONS . . . . . . . . . . . . . . . . . .22

VENTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Combustion (All) Air From the Outdoors . . . . . . . . 24

Outdoor Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Two Openings or Ducts. . . . . . . . . . . . . . . . . . . . 24

Size of Openings. . . . . . . . . . . . . . . . . . . . . . . . . 24

Attic Combustion Air . . . . . . . . . . . . . . . . . . . . . . 24

Under-fl oor Combustion Air. . . . . . . . . . . . . . . . . 24

Opening Requirements . . . . . . . . . . . . . . . . . . . . 24

Combustion (All) Air From Inside the Building . . . . 26

Required Volume. . . . . . . . . . . . . . . . . . . . . . . . . 26

Confi ned Space. . . . . . . . . . . . . . . . . . . . . . . . . . 26

Unusually Tight Construction . . . . . . . . . . . . . . . 26

Power Vent Installation Examples . . . . . . . . . . . . . 26

INSTAL HOT WATER LINES. . . . . . . . . . . . . . . . 27

INSTAL COLD WATER LINES . . . . . . . . . . . . . .28

INSTALL CONDENSATE DRAIN . . . . . . . . . . . .29

CONNECT ELECTRICAL POWER / INITIAL

STARTUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

MULTIPLE UNITS . . . . . . . . . . . . . . . . . . . . . . . . 31

MEASURING GAS PRESSURE . . . . . . . . . . . . .36

PROPANE (LPG) CONVERSION . . . . . . . . . . . . 37

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . 53

Cleaning the Inlet Water Y-Strainer . . . . . . . . . . . . . . 54

Draining the Water Heater. . . . . . . . . . . . . . . . . . . . . 54

Filling the Water Heater. . . . . . . . . . . . . . . . . . . . . . . 55

TROUBLESHOOTING CHART . . . . . . . . . . . . . .55

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . .57

COMMERCIAL OPTIONS . . . . . . . . . . . . . . . . . .58

Commercial Option #1 . . . . . . . . . . . . . . . . . . . . . . 59

Commercial Option #2 . . . . . . . . . . . . . . . . . . . . . . 59

Commercial Option #3 . . . . . . . . . . . . . . . . . . . . . . 59

Commercial Option #4 . . . . . . . . . . . . . . . . . . . . . . 59

Commercial Option #5 . . . . . . . . . . . . . . . . . . . . . . 59

Commercial Option #6 . . . . . . . . . . . . . . . . . . . . . . 59

OPERATIONAL DIAGRAM . . . . . . . . . . . . . . . . .59

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Effective Start Date . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Heat Exchanger Coil . . . . . . . . . . . . . . . . . . . . . . . . . 61

All other Parts and Components . . . . . . . . . . . . . . . . 61

Labor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Shipping Costs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Defi nition of Potable Water . . . . . . . . . . . . . . . . . . . . 61

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Not Covered by this Warranty . . . . . . . . . . . . . . . . . . 62

Warranty Limitations . . . . . . . . . . . . . . . . . . . . . . . . . 62

How to Make a Claim . . . . . . . . . . . . . . . . . . . . . . . . 62

Requirements for the State of Massachusetts . . . . . 63

Notice Before Installation . . . . . . . . . . . . . . . . . . . . 63

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

3

ITEMS SHIPPED WITH WATER HEATER

The following items are shipped with the water heater;

upper mounting bracket (1), condensate

Operator’s manual (3), communication cable (4),

(5), and tee fitting (6).

hose (2),

O-rings

IMPORTANT

Condensate drain hose(2) has zip ties to keep

loop. Do not undo or cut these zip ties

4

WARNING

To avoid product damage, personal injury, or even

possible death, carefully read, understand, and

follow all the instructions in the Installation and

Operation manual and on the water heater before

installation, operation, or service.

Hubbell cannot anticipate every circumstance that might

involve a potential hazard and our warnings are, therefore, not

all-inclusive. Proper installation, operation, and service is your

responsibility.

You must be satisfied that the operation and settings of the

water heater are safe for you and for others.

Pour éviter un dommage au produit, une blessure personnelle

ou même la mort, lire avec soin, comprendre et suivre toutes

les instructions dans le manuel d'installation et de fonctionnement et sur le chauffe-eau avant l'installation, le fonctionnement ou l'entretien.

Hubbell ne peut pas prévoir toutes les circonstances qui

pourraient impliquer un danger potentiel et par conséquent,

nos avertissements ne comprennent pas tout. L'installation, le

fonctionnement et l'entretien correct sont votre

responsabilité.

Vous devez être certain que le fonctionnement et les réglages

du chauffe-eau sont sécuritaires pour vous et pour les autres.

IGT-LBL-0001-01

SAFETY

Hazards are identifi ed by the “Safety Alert Symbol”

and followed by a signal word such as “DANGER”,

“WARNING”, or “CAUTION”.

DANGER

Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury. This signal word is limited to

the most extreme situations.

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

Safety Alert Symbols

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey

all safety messages that follow this symbol to

avoid possible injury or death.

This manual contains DANGERS, SAFETY

INSTRUCTIONS, CAUTIONS, IMPORTANT NOTICES,

and NOTES which must be followed to prevent the

possibility of improper service, damage to the equipment,

personal injury, or death. The following key words call the

readers’ attention to potential hazards.

NOTICE

Indicates that equipment or property damage can result if

instructions are not followed.

SAFETY

INSTRUCTIONS

Safety instructions (or equivalent) signs indicate specific safetyrelated instructions or procedures.

NOTE: Contains additional information important

to a procedure.

IMPORTANT

Indicates that equipment or property damage can

result if instructions are not followed.

NOTE: Provides additional information that is

helpful for installation or operation of the water

heater.

5

Safety Icon Nomenclature

Icons signal a type of hazard and warn of personal

protection issues, prohibited actions, and hazard

avoidance.

SAFETY

Slipping injury

Tripping injury

Personal Protection

Read the manual

Eye protection

High water temperature

Fill water tank before connecting to electrical

power

Disconnect power

Connect power

Close gas valve

Open gas valve

Wait fi ve minutes

5

Use two people when lifting heavy objects

Prohibited Actions

No open fl ame

Use proper tools

Do not use if submerged under water

No liquid around electrical component

Fire hazard

Explosion hazard

Provide proper ventilation

Operation and Installation Warnings

To avoid serious injury or death, read, understand and

follow all the precautions listed here.

DANGER

Vapors from flammable liquids will explode and can

cause a fire, resulting in personal injury or death. The

water heater has a burner that can come on at any

liquids around the water heater.

for safe operation. Inspect the exterior exhaust gas outlet port and

fresh air inlet port on a regular basis to ensure they are functioning

properly.

the exhaust gases with a fully functional and calibrated flue gas

analyzer.

time and ignite vapors. DO NOT use or store flammable

Improper venting can cause a build-up of carbon monoxide.

Breathing carbon monoxide can result in brain damage or

death. DO NOT operate the water heater unless it is properly

vented to the outside and has an adequate fresh air supply

A concentration of carbon monoxide as small as 0.04% (400

parts per million) in the air can be fatal. When making high

fire

low fire adjustments, CO levels must be monitored

or

using a flue

than 400 ppm is exceeded at any time during operation.

Adjusting the “low fire offset” or the “main flow restrictor” in

small increments can result in a significant increase in CO

concentration. To avoid serious injury or death, DO NOT

make any adjustments to the gas valve without monitoring

gas

analyzer

such that a CO level of no more

Hazard Avoidance

Disconnect power electrical hazard

Electrocution or shock hazard

Hot liquid, burn hazard

Hot surface

Lifting hazard

Pressurized liquid

Safety alert symbol

WARNING

The Hubbell water heater must be installed by a licensed plumber,

licensed gas fitter, and/or professional service technician. Improper

installation and/or operation can cause a potentially hazardous

situation, which, if not avoided, could result in serious injury or

death, and will void the warranty.

Proper care is your responsibility. Carefully read and

understand the Operation Information in this manual before

operating the Hubbell water heater.

Make sure you know the location of the gas shut-off valve

and how to operate it. Immediately close the gas shut-off

valve if the water heater is subjected to fire, overheating,

flood, physical damage, or any other damaging condition that

might affect the operation of the unit. Have the water heater checked

by a qualified technician before resuming operation.

6

WARNING

Do not power up the unit unless the gas and water supply

valves are fully opened. Make sure the fresh air intake port

and exhaust gas port are open and functional.

DO NOT attempt to install, service, or repair this water heater

yourself. There are no serviceable parts which can be

changed by the owner. Contact a qualified technician if your

water heater needs repair or maintenance. Ask your gas

supplier

restrict or block the flow in or out of the

is repaired by a qualified technician.

is being used by other persons.

for a list of qualified service providers.

Keep the area around the water heater clean and free of all

materials that can burn. DO NOT store or place gasoline, oils,

spray paint, or other flammable products near the water heater.

DO NOT use spray paint, hair spray, or any other flammable

spray near the water heater or near the exterior fresh air inlet

port. DO NOT place any items in or around the exterior

exhaust gas outlet port and/or fresh air inlet port that could

vent system.

DO NOT store or place newspapers, laundry, or other

combustible items near the water heater or the exterior

exhaust gas outlet and/or fresh air inlet port.

The owner should inspect the system monthly for damage,

water stains, signs of rust, corrosion, and exhaust vent and

air intake blockage. If inspection of the unit shows signs of

damage, the water heater should be shut off until the

DO NOT allow children to operate this unit. DO NOT use this

unit if it does not appear to be operating correctly.

A qualified technician should service and inspect the water

heater annually.

The water heater temperature is factory set to 120°F (49°C).

To avoid scalding, always check the temperature of the hot

water before bathing, showering, washing, etc. DO NOT

adjust the water temperature while the Hubbell water heater

SAFETY

problem

IMPORTANT

Do not use the water heater if any part has

been under water. Immediately call a qualified service

technician and have the unit inspected. Replace any

components that have been under water.

The Hubbell water heater is equipped with a three prong plug. It

should only be plugged directly into a properly grounded three

prong receptacle. DO NOT remove the ground prong from the plug.

DO NOT alter or modify the water heater or water heater controls.

This can be dangerous and will void the warranty.

7

SAFETY

Always read and follow all warnings on water heater safety

decals and in the manual. If the Installation and Operation manual

is missing, go to our website at: www.hubbellheaters.com or

contact Hubbell (203-378-2659) for a replacement.

DANGER

Use this water heater at your own risk. The outlet

temperature of the Hubbell water heater is factory

preset to 120°F (49°C). The temperature can only be

changed by using the control panel on the front of the

water heater.

particular faucet, temperature limiting valves can be installed

by your service professional.

Hot water temperature over 125°F (52°C) can

cause severe burns instantly or death from

scalding. Children, disabled, and elderly are at

the highest risk of being scalded. Do not leave

children or the inf rm unsupervised. Check

temperature of hot water before taking a shower

or bath. To control water temperature to a

WARNING

Do not store or use gasoline or other

f ammable vapors and liquids in the

vicinity of this or any other appliance.

Flammable vapors can ignite and

cause serious damage or injury.

This water heater is factory preset for NATURAL GAS.

For propane conversion, refer to the manual.

Connecting the water heater to any other gas supply can result

in property damage, serious injury, and even death.

Suitable for water (potable) heating and

space heating. The water heater MUST NOT be

connected to any heating system or components previously

used with a nonpotable water heating appliance.

Do not use toxic chemicals, such as used for boiler

treatment, in potable water space heating systems.

This appliance must be installed in accordance with

local codes or, in the absence of local codes, the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 or the

CSA B149.1, Natural Gas and Propane Installation Code.

A pressure relief valve complying with the Standard for

Relief Valves for Hot Water Supply Systems, ANSI Z21.22

or CAN1-4.4 Temperature, Pressure, Temperature and Pressure

Relief Valves and Vacuum Relief Valves must be installed in a

proper outlet port of water heater at the time of installation

according to local codes.

No valve is to be placed between the relief valve and the

water heater.

The discharge from the temperature/pressure relief valve

should be directed to the ground or into a drain system

which will prevent a burn hazard or property damage. The

piping must not have a reducing coupling or other restriction

in the discharge line. The discharge line must be installed to

allow complete drainage of both the valve and line.

If the system requires water for space heating at

temperatures higher than required for other uses, a

mixing valve must be installed to temper the water for those

other uses in order to reduce scald hazard potential.

The pressure relief valve must not be removed or

plugged.

Hubbell

www.hubbellheaters.com

Pressure Relief Valve

Phone: 203-378-2659

IGT-LBL-0002-01

FOR YOUR SAFETY READ BEFORE OPERATING

DANGER

If you do not follow these instructions exactly, a f re or explosion

may result, causing property damage, personal injury, or loss of life.

A. This water heater does not have a pilot. It is

equipped with an ignition device which automatically

lights the burner. Do not try to light burner manually.

B.

settle on the f oor.

C.

service technician. Force or attempted repair may result in a

f re or explosion.

D.

system and any gas control which has been under water.

If water heater is not operating, follow these instructions. This

appliance is equipped with an ignition device which automatically lights the burner. Do not try to light the burner manually.

1.

2.

3.

4.

5.

6.

7.

8.

If water heater will not operate, follow instructions “To Turn Off

Gas To Water Heater” and call your service technician or gas

supplier.

1. Turn OFF electrical power to water heater.

2. Turn manual gas shut-off valve to OFF position.

BEFORE OPERATING, smell all around the water

heater area for gas. Be sure to smell next to the

f oor because some gas is heavier than air and will

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the f re or police

department.

Use only your hand to turn manual gas shut-off valve.

Never use tools. If manual gas shut-off valve will not

turn by hand, don’t try to repair it, call a qualif ed

Do not use this water heater if any part has been under

water. Immediately call a qualif ed service technician

to inspect water heater and replace any part of control

OPERATING INSTRUCTIONS

STOP! Read the safety information above on this

label.

Never use water heater unless it is completely f lled

with water.

Turn OFF electrical power supply to the water heater.

Turn gas shut-off valve clockwise to “OFF” position.

Do not force.

Wait f ve (5) minutes to clear out any gas. If you then

smell gas, STOP! Follow step “B” above on this

5

label. If you don’t smell gas, go to next step.

Turn manual gas shut-off valve to “ON” position.

Turn ON electrical power to unit.

Wait until default temperature (120°) is displayed.

Set desired water temperature. Turn on hot water

faucet.

TO TURN OFF GAS TO WATER HEATER

8

SAFETY

Toujours lire et suivre tous les avertissements sur les

décalcomanies de sécurité sur le chauffe-eau et dans le

manuel. Si le manuel d'installation et de fonctionnement

n'est pas disponible, visiter le www.hubbellheaters.com ou

contacter Hubbell (203) 378-2659 pour un remplacement.

DANGER

Utiliser ce chauffe-eau à vos propres risques. La température

de sortie du chauffe-eau Hubbell est réglée en usine à 49 °C

(120 °F). La température peut être modifiée seulement en

utilisant le panneau de commande à l'avant du chauffe-eau.

Une température d'eau chaude de plus de 52 °C

(125 °F) peut causer des brûlures sévères instantanément ou la mort par ébouillantage. Les enfants,

les personnes handicapées et les personnes âgées

sont les plus à risque d'être ébouillantées. Ne pas

laisser les enfants ou les infirmes sans supervision.

Vérifier la température de l'eau chaude avant de

prendre une douche ou un bain. Des vannes régulatrices de

température peuvent être installées par votre professionnel

d'entretien afin de contrôler la température de l'eau sur un robinet en

particulier.

AVERTISSEMENT

Ne pas entreposer ou utiliser de gazoline

ou autres vapeurs ou liquides

inflammables à proximité de cet appareil

Vapeurs inflammables

Ce chauffe-eau est préréglé en usine pour le GAZ

NATUREL. Pour la conversion au propane, se référer au

manuel. Connecter le chauffe-au à toute autre alimentation

en gaz peut causer un dommage à la propriété, une blessure

sérieuse et même la mort.

Convient pour le chauffage de l'eau (potable) et le chauffage

des locaux. Le chauffe-eau NE DOIT PAS être connecté à un

système de chauffage ou à des composants utilisés pour un

appareil de chauffage d'eau non potable.

Ne pas utiliser de produits chimiques toxiques, comme

ceux utilisés pour le traitement de chaudière, dans des

systèmes de chauffage de locaux et d'eau potable.

Cet appareil doit être installé conformément aux codes

locaux, ou , en l'absence de codes locaux, selon le National

Fuel Gas Code, ANSI Z223.1/NFPA 54 ou le Code

d'installation du gaz naturel et du propane, CSA B149.1.

Une soupape de surpression conforme à la norme Relief

Valves for Hot Water Supply Systems, ANSI Z21.22 ou

CAN1-4.4 Temperature, Pressure, Temperature and

Pressure Relief Valves and Vacuum Relief Valves doit être

installée dans le bon port de sortie du chauffe-eau au moment de

l'installation conformément aux codes locaux.

Aucune vanne ne doit être placée entre la soupape de

surpression et le chauffe-eau.

La décharge de la soupape de température/surpression

devrait être dirigée vers le sol ou dans un système de drain

qui empêchera un risque de brûlure ou un dommage à la

propriété. La tuyauterie ne doit contenir aucun raccord réducteur

ou autre restriction dans la ligne de décharge. La ligne de

décharge doit être installée afin de permettre un drainage complet

de la vanne et de la ligne.

Si le système exige de l'eau pour le chauffage de locaux à

des températures plus élevées que celles pour d'autres

usages, une vanne de mélange doit être installée pour

tempérer l'eau pour ces autres usages afin de réduire la possibilité de blessure par ébouillantage.

La soupape de surpression ne doit pas être retirée ou

bouchée.

Hubbell

www.hubbellheaters.com

ou autre. Les vapeurs inflammables

peuvent s'enflammer et causer un

dommage sérieux ou une blessure.

Soupape de surpression

Téléphone: 203-378-2659

GT-LBL-0003-01

POUR VOTRE SÉCURITÉ, LIRE AVANT D'UTILISER

DANGER

Si vous ne suivez pas ces instructions exactement, un incendie ou

une explosion pourrait résulter causant des dommages à la

propriété, une blessure personnelle ou une perte de vie.

Ce chauffe-eau n'a pas de pilote. Il est muni d'un

A.

B.

Ne pas essayer d'allumer aucun appareil•

• Ne toucher aucun interrupteur électrique; n'utiliser aucun

•

•

C.

D.

Si le chauffe-eau ne fonctionne pas, suivre ces instructions. Cet

appareil est muni d'un dispositif d'allumage qui allume automatiquement le brûleur. Ne pas essayer d'allumer le brûleur manuellement.

1.

2.

3.

4.

5.

6.

7.

8.

Si le chauffe-eau ne fonctionne pas, suivre les instructions

« Pour arrêter l'alimentation en gaz au chauffe-eau » et appeler

votre technicien d'entretien ou votre fournisseur de gaz.

1. METTRE HORS FONCTION l'alimentation électrique au chauffe-eau.

2. Tourner la vanne d'arrêt manuelle du gaz à la position d'arrêt (OFF).

dispositif d'allumage qui allume automatiquement

le brûleur. Ne pas essayer d'allumer le brûleur

manuellement.

AVANT D'UTILISER, sentir tout autour du chauffe-eau

pour détecter une odeur de gaz. S'assurer de sentir

près du plancher parce que certains gaz sont plus

lourds que l'air et retombent sur le plancher.

QUE FAIRE SI VOUS SENTEZ DU GAZ

téléphone dans votre édifice.

Appeler immédiatement votre fournisseur de gaz à partir du

téléphone d'un voisin. Suivre les instructions du fournisseur de gaz.

Si vous ne pouvez pas rejoindre votre fournisseur de gaz, appeler

le service d'incendie ou de police.

Utiliser seulement votre main pour tourner la vanne

d'arrêt manuelle du gaz. Ne jamais utiliser d'outils. Si la

vanne d'arrêt manuelle du gaz ne peut pas être tournée

à la main, ne pas essayer de la réparer, appeler un

technicien d'entretien qualifié. Une réparation forcée ou tentée

pourrait causer un incendie ou une explosion.

Ne pas utiliser ce chauffe-eau si une partie de celui-ci a

été sous l'eau. Appeler immédiatement un technicien

d'entretien qualifié pour inspecter le chauffe-eau et

remplacer toute partie du système de commande et

toute commande de gaz qui a été sous l'eau.

INSTRUCTIONS DE FONCTIONNEMENT

ARRÊTEZ! Lire les renseignements de sécurité

ci-dessus sur cette étiquette.

Ne jamais utiliser le chauffe-eau à moins qu'il soit

entièrement rempli d'eau.

METTRE HORS FONCTION l'alimentation électrique au

chauffe-eau.

Tourner la vanne d'arrêt manuelle du gaz dans le sens

des aiguilles d'une montre à la position d'arrêt (OFF).

Ne pas forcer.

Attendre cinq (5) minutes pour laisser le gaz s'évaporer.

Si vous sentez du gaz, ARRÊTEZ! Suivre l'étape « B »

ci-dessus sur cette étiquette. Si vous ne sentez pas de

5

gaz, passer à l'étape suivante.

Tourner la vanne d'arrêt manuelle du gaz à la position

de fonctionnement (ON).

METTRE EN FONCTION l'alimentation électrique à

l'appareil

Attendre jusqu'à ce que la température

par défaut (120°) soit affichée. Régler la température

désirée pour l'eau. Ouvrir le robinet d'eau chaude.

POUR ARRÊTER L'ALIMENTATION

EN GAZ AU CHAUFFE-EAU

g

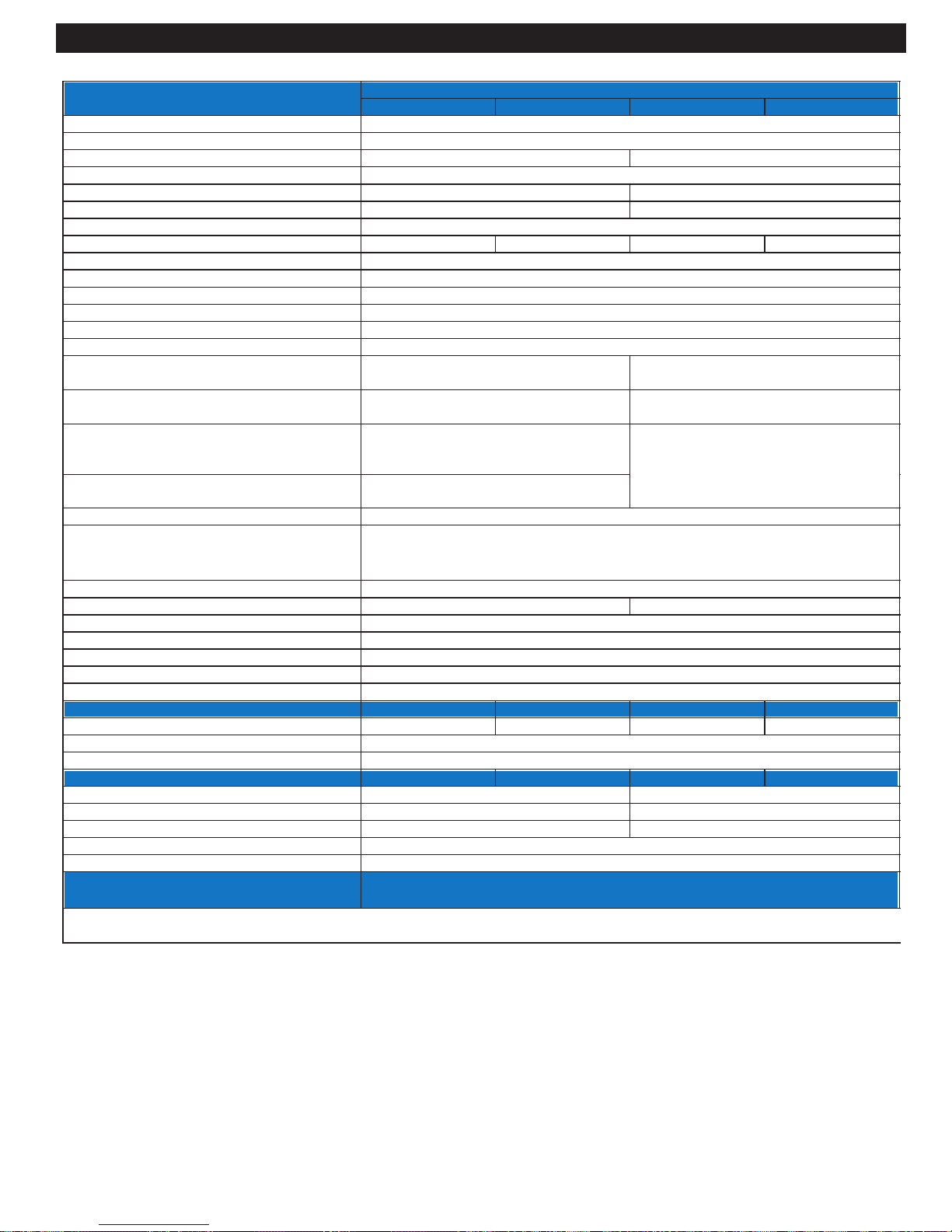

TECHNICAL SPECIFICATIONS

Parameters

Type

Fuel

GX200 GX200P GX250 GX250P

Indoor, Wall hung, Fully Condensing

Preset for NG / LP Convertible

Models

Minimum / Maximum Input (Btu/h)

Combustion Efficiency

98%

Thermal Efficiency

Energy Factor

Dimensions H x W x D (inches)

Water Inlet / Outlet Connection

Gas Inlet Connection

Minmum Flow Rate

Ignition

Venting Type

Venting Materials

Max 3” Vent Length - Single Pipe / Power Vent

Max 3” Vent Length - Two pipe / Direct Vent

Max 2” Vent Length - Single Pipe / Power Vent

(2” not allowed at elevations above 4,000 ft)

Max 2” Vent Length - Two Pipe / Direct Vent (2”

not allowed at elevations above 4,000 ft)

Common Venting

No minimum flow rate for "P" models / 0.6 GPM

Direct Vent (2 pipe - intake & exhaust), Power vent (1 pipe - exhaust only)

Sch. 40 PVC, Sch. 40 CPVC, Polypropylene, Stainless Steel

200 ft, deduct 5 ft per 90° elbow 130 ft, deduct 5 ft per 90° elbow

100 ft, deduct 5 ft per 90° elbow 65 ft, deduct 5 ft per 90° elbow

26 ft, deduct 5 ft per 90° elbow

21 ft, deduct 5 ft per 90° elbow

25.9 x 17.5 x 14.2 (3.7 cu. ft)

3/4" NPT

3/4" NPT

Electronic Spark Ignition

Yes

Flame Rod, Thermal Fuse, Overheat Prevention Device, Fan Speed Monitor, Flue

Safety

Temperature Monitor, Blocked Vent Detector, Water Leak Detector, Water Shut-Off

Valve, 2X10A Fuse, Dual Flame Sensing

Water Pressure Min / Max (PSI)

NG/LP- Minimum Static Gas Pressure 1/2"

NG/LP- Minimum Static Gas Pressure 3/4"

NG/LP - Maximum Static Gas Pressure

Gas Pressure for Adjustments

Electrical

Power Consumption

Features

5" (non-corrugated, black iron) 6" (non-corrugated, black iron)

2.5" (non-corrugated, black iron)

500W (Max 4.2 Amps), 8W (Standby)

GX200 GX200P GX250 GX250P

30 / 150

14”

8" for NG, 11" for LP

120V AC, 60 Hz

Recirculation / Tank Loading No-Pump Built-In Pump No-Pump Built-In Pump

Cascading

Heat Exchanger

Performance

Hot Water Capacity (35F Rise)

Hot Water Capacity (45F Rise)

Hot Water Capacity (77F Rise)

GX200 GX200P GX250 GX250P

10.8

8.4

5.0

Domestic Mode Temp. Settings

Commercial Mode Temp. Settings

Warranty (with recirculation)

Note: 1Due to Hubbell's Policy of continuous product improvements, design, and technical specifications are subject to change

2

Energy Star and Low NOx are applicable to GX200 and GX200P models.

Residential - Heat Exchan

Commercial - Heat Exchanger coil – 6 years, Parts – 5 years, Labor – 1 year

Masterless, 10 units

Expandable, Stainless 316L

100 – 140°F

100 – 185°F

er coil - 15 years, Parts – 5 years, Labor – 1 year

000,052/000,03059,991/000,03

%29%49

A/N39.0

89098909)sbl(thgieW

N/A

13.2

10.3

6.0

10

TECHNICAL SPECIFICATIONS

In order for the water heater to operate properly and

efficiently, the clearances specified in the table below are

required.

Required Mounting Clearances

Location From

Combustibles

Top 6” (15.2 cm) 2” (50.8 cm) 12” (30.4 cm)

2

Back

5/8” (15.8 mm) 5/8” (15.8 mm) 5/8” (15.8 mm)

Sides 1” (25.4 mm) 1/2” (12.7 mm) 5/8” (15.8 mm)

Front 2” (5.1 cm) 2” (5.1 cm) 30” (76.2 cm)

Bottom 12” (30.4 cm) 12” (30.4 cm) 12” (30.4 cm)

1

Service clearances are suggested dimensions to allow for normal

service of the unit.

2

Installing (hanging) the unit with the included brackets automatically

sets this dimension.

CO2 and CO Standards

Description CO2 Range (%) Max. CO Level (ppm)

High Fire 8.8% to 9.1% < 200 ppm

Low Fire 8.6% to 8.9% < 60 ppm

High Fire 8.8% to 9.1% < 200 ppm

Low Fire 8.6% to 8.9% < 60 ppm

From Non-

Combustibles

Natural Gas

LP Gas

Service

Clearance

1

Top Connections

Description Specification

2

Gas Supply Inlet Connection 3/4” Male NPT

Cold Water Inlet Connection

Hot Water Outlet Connection

3/4” Female NPT

3/4” Female NPT

Exhaust Gas Vent 3” O.D. PVC Schedule 40

Fresh Air Intake 3” O.D. PVC Schedule 40

1

Requires a 3” to 2” reducer when using 2” venting pipe.

2

Using sizes other than specified can cause damage to the water

heater and will void the warranty.

Bottom Connections

Description Specification

1

Drain Connection 3/4” Female NPT

Condensate Drain Connection 3/4” Nipple (3/4” flex hose)

Power Supply 120V AC Power Cord

1

Using sizes other than specified can cause damage to the water

heater and will void the warranty.

1

1

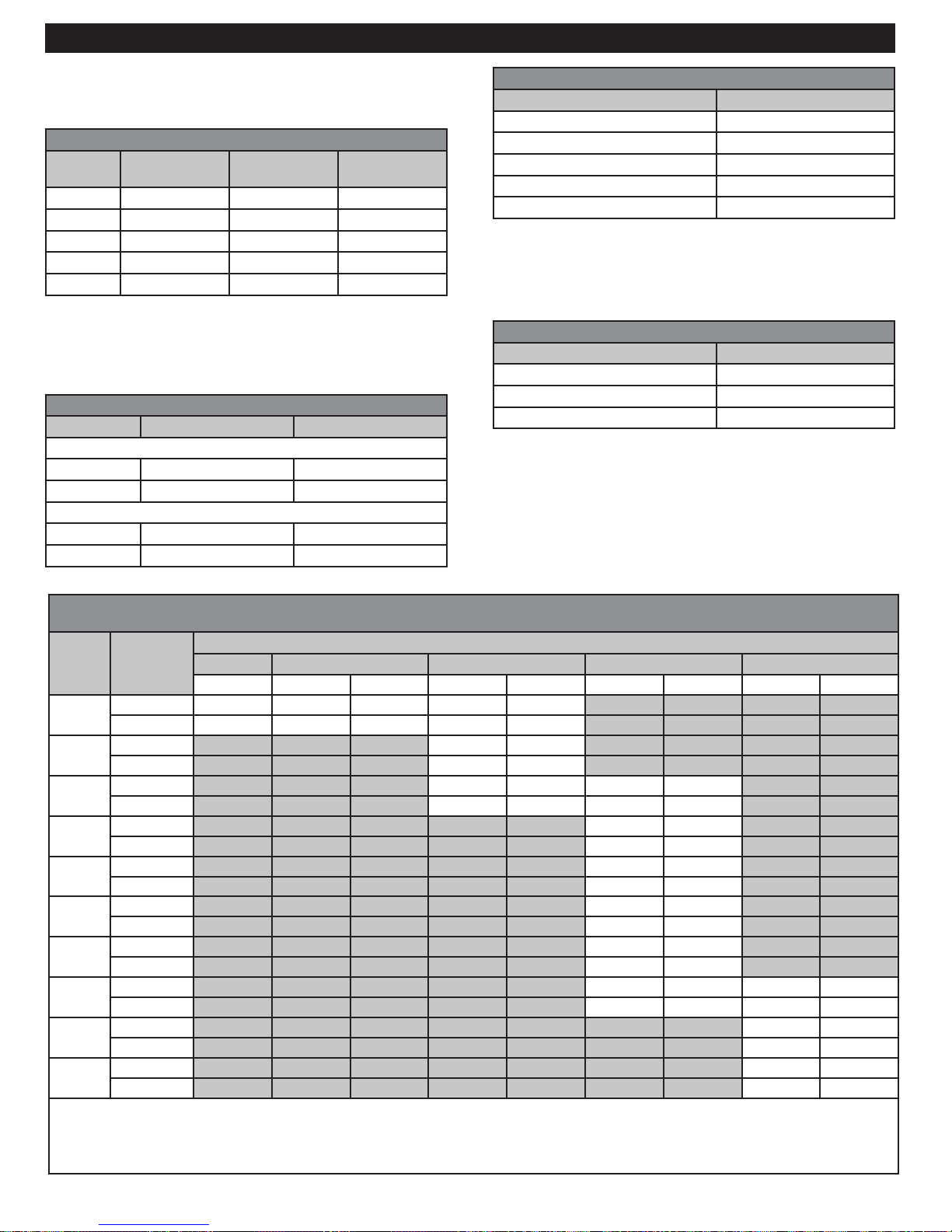

Max Vent Length For Various Duct Sizes And

Number Of Units

Duct Size and Model

Number

of Units

1

2

3

4

5

6

7

8

9

10

Venting

Type

2” 3” 4” 6” 8”

GX200

(P)

GX200

(P)

GX250(P) GX200(P) GX250(P) GX200(P)

GX250

(P)

GX200(P) GX250(P)

1 pipe - PV 26 200 130 200 130

2 pipe - DV 21 100 65 100 65

1 pipe - PV 200 130

2 pipe - DV 100 65

1 pipe - PV 100 30 200 130

2 pipe - DV 50 30 100 65

1 pipe - PV 200 130

2 pipe - DV 100 65

1 pipe - PV 200 130

2 pipe - DV 100 65

1 pipe - PV 200 130

2 pipe - DV 100 65

1 pipe - PV 150 45

2 pipe - DV 75 45

1 pipe - PV 100 30 200 130

2 pipe - DV 50 30 100 65

1 pipe - PV 200 130

2 pipe - DV 100 65

1 pipe - PV 200 130

2 pipe - DV 100 65

PV = Power Vent

DV = Direct Vent

Note: Reduce the maximum equivalent length above by 5 feet per 90° elbow used and by 2 feet per 45° elbow.

Do not exceed the above set limits.

EXHAUST

HOT WATER

OUT

GAS LINE

CHECK

VALVE

TEMPERATURE

AND PRESSURE

VALVE

CHECK

VALVE

INLET

SPECIFICATIONS (NOMENCLATURE)

HOT WATER

TO USAGE

COLD WATER

INLET

GATE VALVE

GAS LINE

WATER TRAP

STRAINER

HOT

WATER

STORAGE

TANK

POINT

CHECK

VALVE

GAS

LINE

COLD WATER

IN

CONTROL

PANEL

WATER HEATER

DRAIN VALVE

IH-01

CONDENSATE

DRAIN

Typical installation of GX200P piped with storage tank.

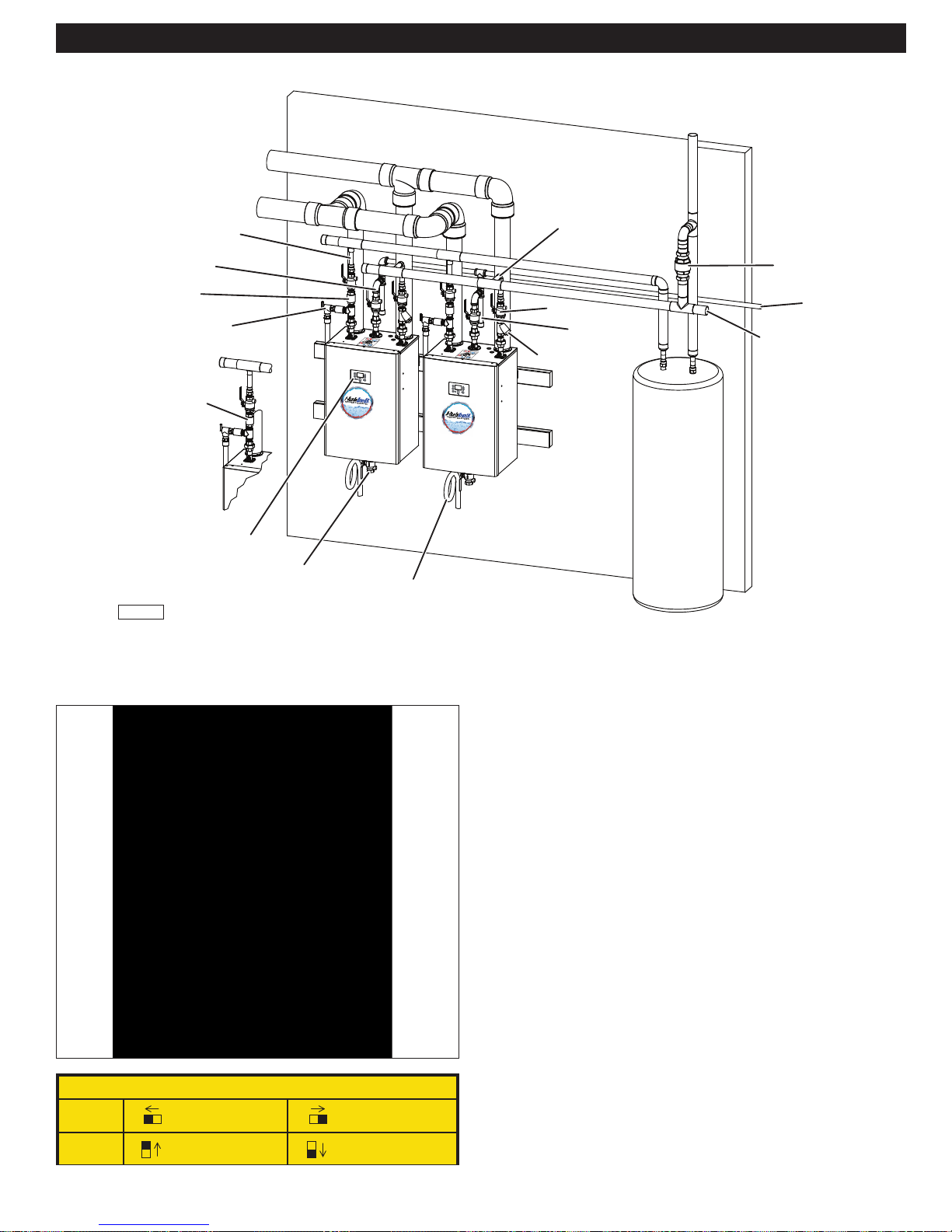

DIP Switch Locations on Control Board

DIP Switch Settings (Réglages des commutateurs DIP)

SW1

SW2

Propane

Cascade Termination ON

(Terminaison en cascade ON)

Natural Gas

(Gaz naturel)

Cascade Termination OFF

(Terminaison en cascade OFF)

12

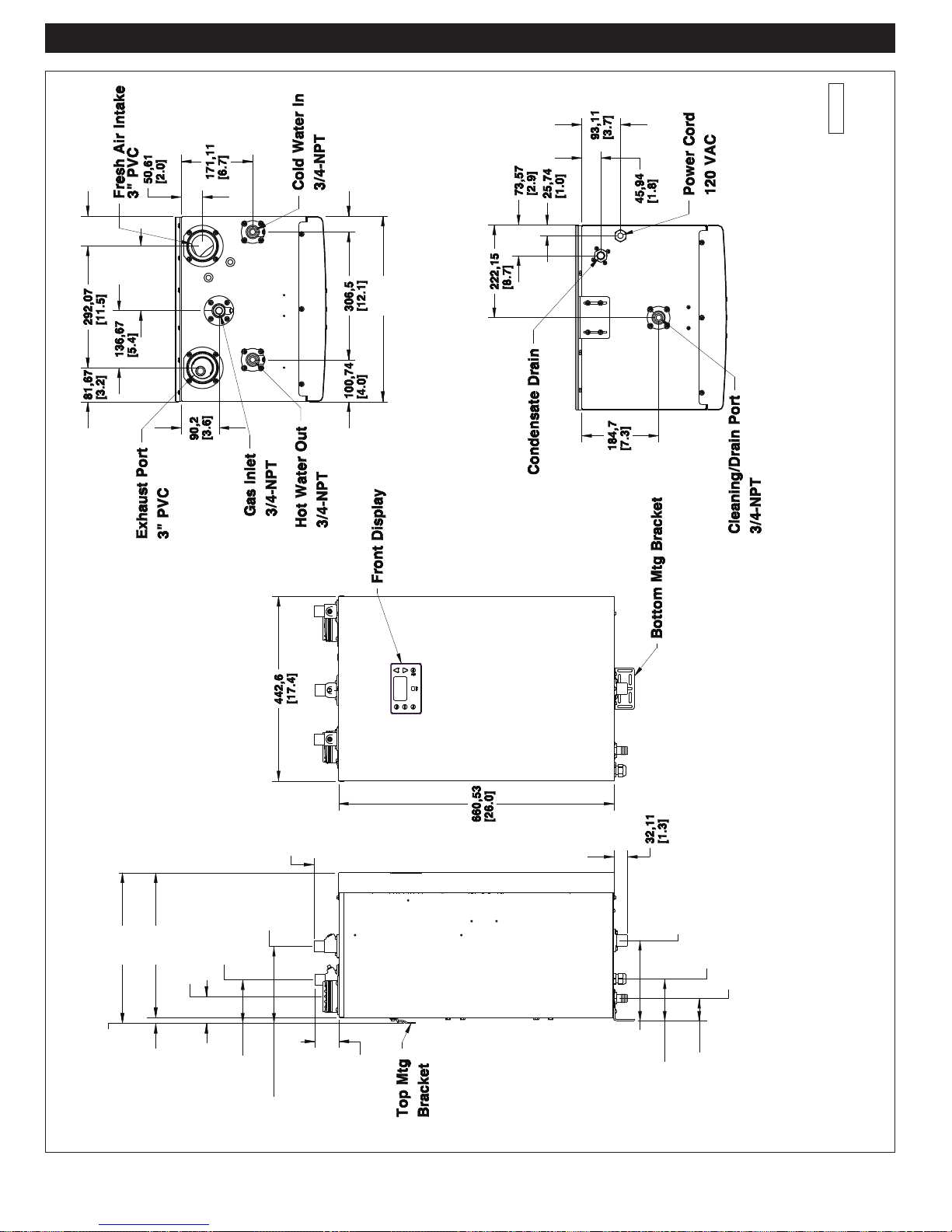

DIMENSIONAL SPECIFICATIONS

Selecting a Location

IH-79

68,86

[2 3/4”]

155,4

[6 1/8”]

35,36

[1 3/8”]

442,6

[17 7/16”]

Top View

Left

Side

Side

Right

Bottom View

361 ,3

[14 1/4”]

Mounting

Wall Surface

347,3

[13 11/16”]

Exhaust Port

14

[9/16”]

3” PVC

64,6

[2 9/16”]

Hot Water

3/4 NPT

Gas Inlet

102,4

[4 1/8”]

Out

3/4 NPT

185,1

[7 5/16”]

59,11

[2 5/16”]

57,79

[2 1/4”]

13

198,7

[7 25/32”]

Drain Port/PRV

107,1

[4 7/32”]

Front View

3/4-NPT

Power Cord

Condensate Drain

59,94

[2 3/8”]

L/H Side View

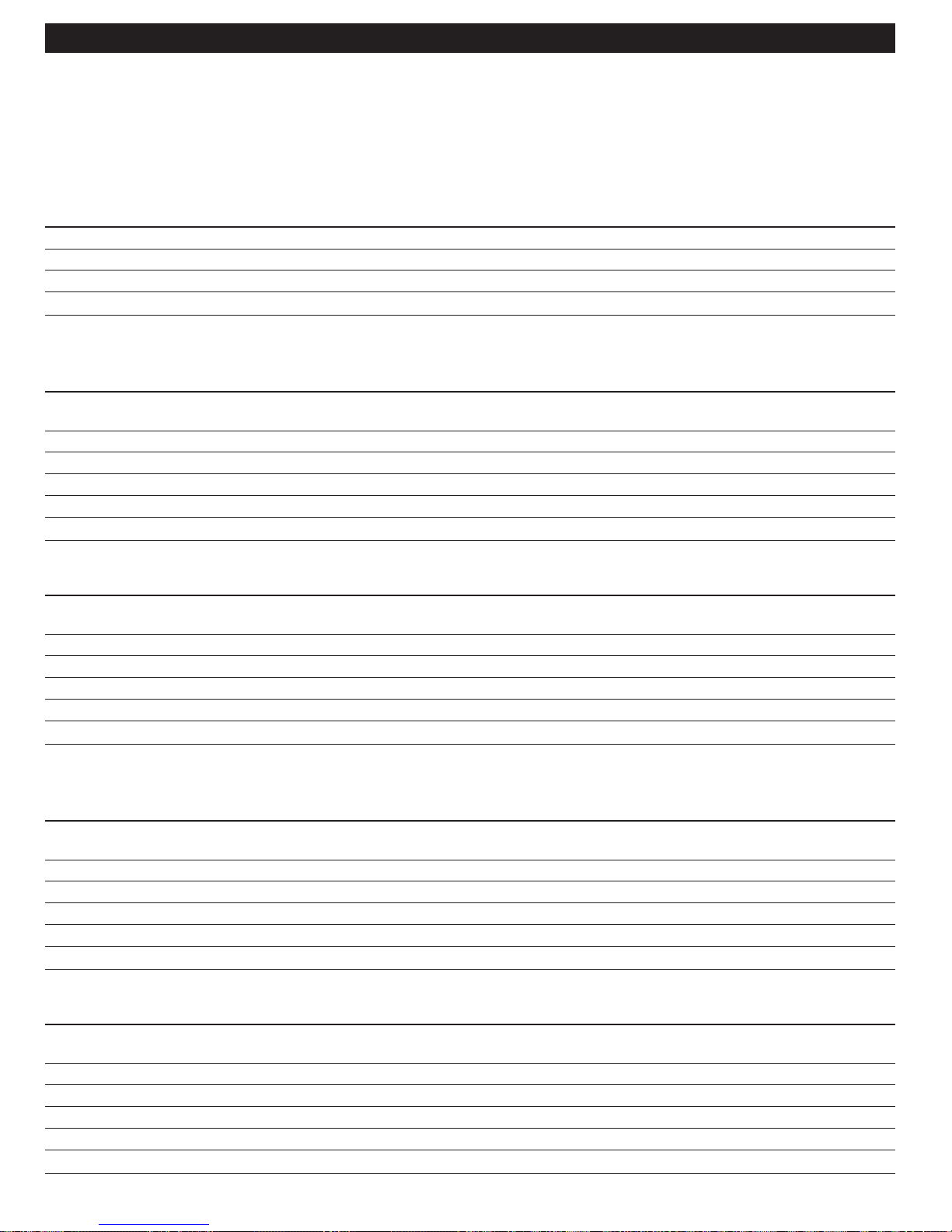

QUICK REFERENCE INSTALLATION GUIDE

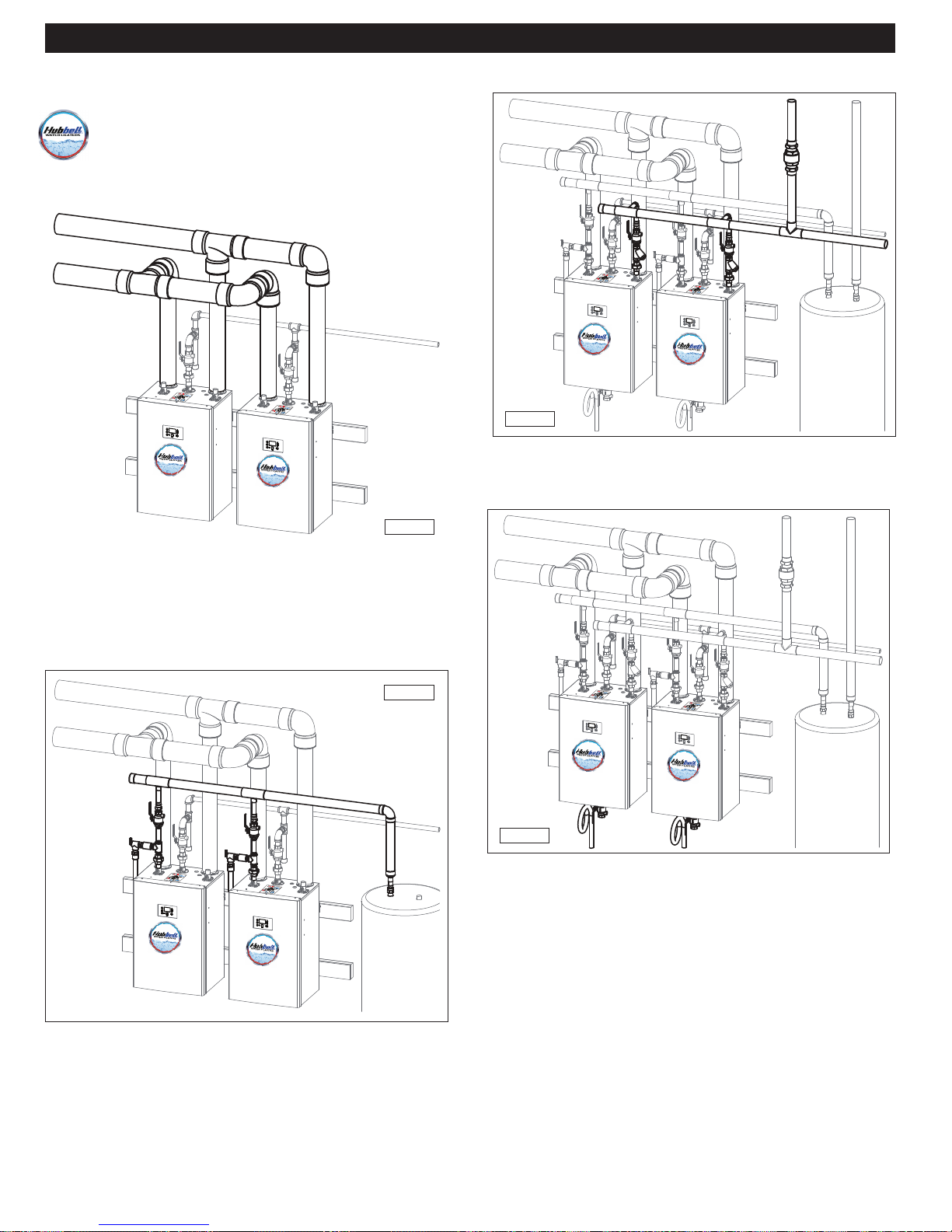

The quick reference illustrations show the installation

of two GX200P water heaters connected together

with a storage tank. Installation of a single unit or

up to five units is basically the same. When

installing multiple units, refer to the Multiple Units

section for additional information.

1. Select a location. Note that the piping can be

confi gured to enter or exit the unit from either the left or

right side, as viewed from the front.

2. Mount the water heater(s) to the wall.

a.

Attach two 2x4 mounting blocks (at least 23” for a

single unit or 46” long for two units) to the wall. The

uppermost mounting boards should be at the

desired height for the top of the unit.

IH-80

e. Hang the unit on the mounting bracket. If multiple

units are installed, the spacing between the units

should be approximately 6”.

IH-81

3. Install the gas lines, as shown in the illustration.

b.

Attach a second mounting block 14” (center to

center) below the upper mounting block.

c. Attach metal mounting bracket(s) to the upper

mounting block approximately 3” on either side

of the center and 1/2” down from the top of the

mounting block.

d.

Adjust and tigthen the bottom bracket to the units so

that the unit to hangs vertically on the wall.

IH-82

a. Temporarily place a short section of 3” schedule

40 PVC pipe on one of the air inlets in order to

judge clearance allowances as the gas piping is

assembled.

b. Due to limited wall clearance, connect the union as

your fi nal step of gas piping.

c. Check for gas leaks at this point in the assembly

process.

14

QUICK REFERENCE INSTALLATION GUIDE

Water Connections

4. Install the combustion air inlet and fl ue gas outlet PVC

piping.

Note: The inlet and outlet pipes from the unit are

3” diameter while the header piping is 4” diameter,

as shown in the illustration. The larger header

piping is required whenever multiple units are

installed.

4"

4"

3"

3"

3"

3"

6. Install and connect the cold water lines.

IH-85

7. Connect and route the condensate trap and drain line

to an appropriate discharge site or drain.

IH-83

5. Install and connect the hot water lines. If an optional

hot water storage tank is required, connect the hot

water lines to this tank. If required, install a pressure

relief valve or a temperature and pressure relief valve.

IH-84

IH-85a

8. Verify gas pressure.

9. Connect the 120 Volt power supply.

10. Test fi re the unit by opening all hot water faucets.

15

Gas Connection

PREPARATION BEFORE INSTALLATION

Selecting an Installation Site

IMPORTANT

When installing this water heater, follow all local

building codes and the current edition of the National

Fuel Gas Code (ANSI Z223.1/NFPA 54) in the USA or

National Gas and Propane Installation Code (CAN/CGA

B149.1) in Canada, when installing this product.

1. Select an interior location for the installation. Each

installation is unique; therefore, take the time to fi nd the

best location for the water heater.

a. Install the water heater near locations that use hot

water, such as bathroom, kitchen, or laundry room

faucets.

b. Select a location that minimizes the length of the

water pipe.

c. If the distances are long or if the faucet or appliance

requires “instant” hot water, we recommend running

a recirculation line back to the water heater from the

furthest fi xture. Insulate the hot water supply and

recirculation lines.

d. Select a location away from foot traffi c and away

from areas where dust, debris, chemical agents, or

other combustible materials could accumulate.

e. Allow suffi cient space for service and maintenance

access to all gas, water, and drain connections.

f. Make sure the location meets all building code

requirements.

IMPORTANT

Reduce the maximum equivalent length by 5 feet

per 90° elbow and by 2 feet per 45° elbow. Intake

and exhaust venting pipes have the same allowable

lengths. Do not exceed these set limits.

EXAMPLE: A 3” vent line or fresh air intake line

(Model GX200) with the six 90 degree elbows

would be limited to a length of 70 feet in a twin

pipe configuration

3. Locate the unit close to a drain and near gas and water

connections.

The water heater produces a signifi cant amount of

condensate during normal operation and should be

located near a suitable drain where damage from

a possible leak will be minimal. Installing the water

heater in a location without a drain will void the

warranty and Hubbell will not be responsible for

any resulting water damages that may occur as a

result. For additional information, refer to the Install

Condensate Drain section.

The water heater should be located in an area where

leakage from the unit or water pipes will not result in

damage to the area around the appliance or to lower

fl oors of the structure. When such locations cannot

be avoided, it is recommended that a suitable drain

pan, adequately drained, be installed under the water

heater. The pan must not restrict combustion air fl ow.

g. Make sure the wall surface the water heater is

mounted onto will support the weight of the unit.

SAFETY

INSTRUCTIONS

The Hubbell .. 200 and GX250 water heaters weigh 90 lbs. The

GX200P and GX250P weigh 98 lbs.

2. Minimize the distance that the exhaust gas vent and

fresh air intake must travel to an exterior wall.

a. The exhaust vent outlet must not be located next to

a walkway, near soffi t vents, crawl space vents, or

other areas where condensate (water vapor) could

cause damage or create a hazard.

b. The fresh air inlet vent must be located at least 12”

from the exhaust vent.

c.

Contaminated or dirty air drawn into the intake

pipe can damage the water heater. The Hubbell

warranty does not cover damage caused by

airborne contaminants.

16

PREPARATION BEFORE INSTALLATION

4. Locate the water heater and all water pipes in an area

where the ambient temperature always remains above

freezing.

NOTICE

In cold climates, if there is a power failure, the unit’s

freeze protection system will not operate, and can

result in water freezing inside the heat exchanger.

To prevent damage to the water heater, turn OFF the gas

supply and inlet

completely drain the unit.

Damage caused by freezing water is not covered by the

Hubbell warranty.

a. When the water heater is connected to an electrical

power supply, it will automatically prevent the water

inside the unit from freezing.

b. The unit’s freeze protection system will not prevent

the water in surrounding pipes from freezing.

water valve. Open the drain valve and

5. Select an appropriate location for the combustion air

and exhaust pipes to exit the house. Use the diagram

and chart on the next page to make this determination.

High Elevation Installations

For operation at elevations above 2,000 feet, Hubbell

model ratings should be reduced by 4% for each 1,000

feet above sea level.

Water Quality

Potable water is defined as drinkable water supplied from

utility or well water in compliance with EPA secondary

maximum contaminant levels (40 CFR part 143.3) as

shown in the table below. If your water contains

contaminants higher than outlined by EPA, then water

treatment is recommended and additional maintainence

may be required. If you suspect that your water is

contaminated in any way or water heater errors occur,

discontinue use of the water heater and contact an

authorized technician or licensed professional.

Contaminant Maximum Allowable Level

Total Hardness 200 mg/l (12 grains/gallon)

Aluminum 0.05 to 0.2 mg/l

Chloride 250 mg/l

Copper 1.0 mg/l

Iron 0.3 mg/l

Manganese 0.05 mg/l

pH 6.5-8.5

Sulfate 205 mg/l

Total Dissolved Solids (TDS) 500 mg/l

Zinc 205 mg/l

17

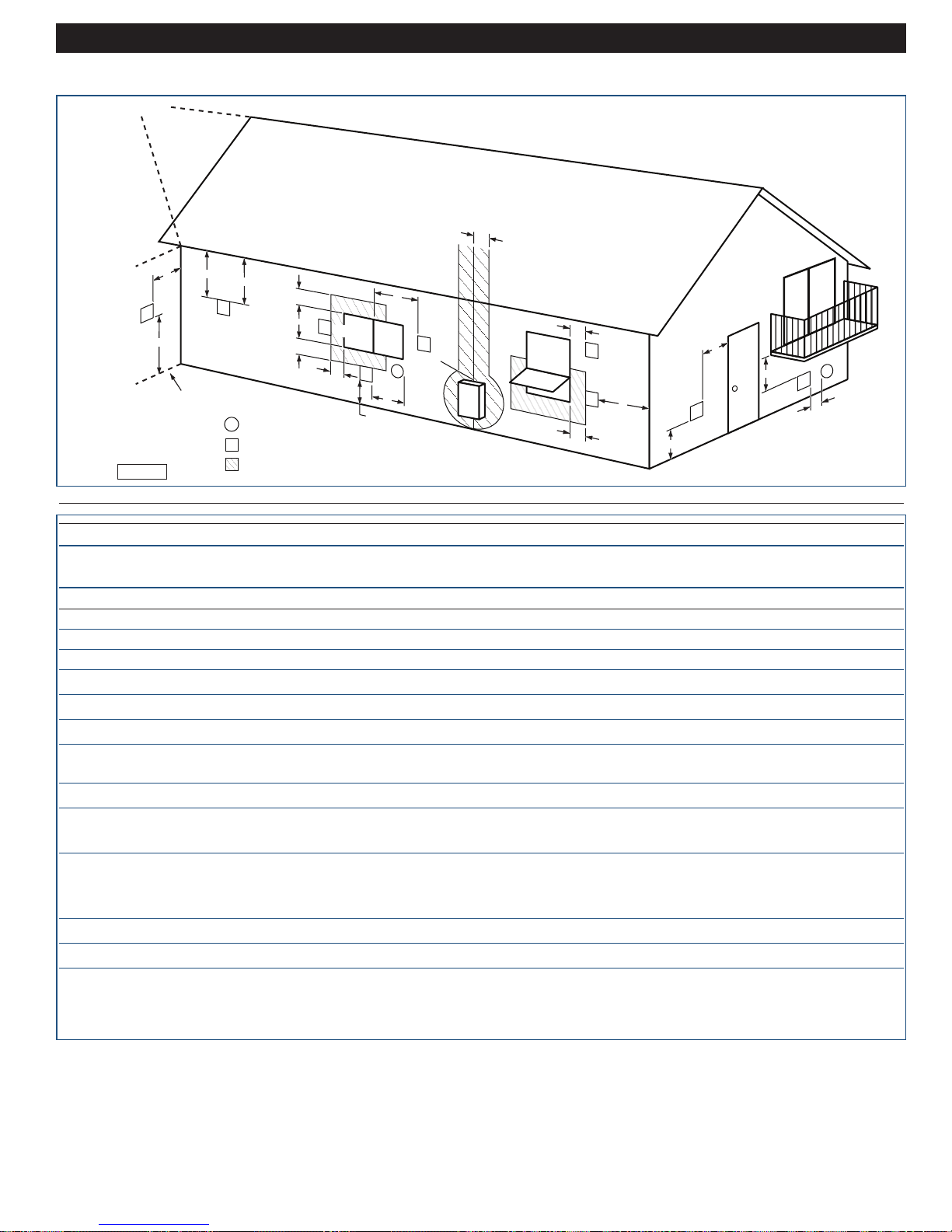

Venting Connections

D

IH-31

V

G

A

Inside Corner

Detail

E

V

Air Inside Inlet

X

V

Vent Terminal

Area Where Terminal is Not Permitted

PREPARATION BEFORE INSTALLATION

H

V

A

Fixed

Closed

J

B

V

I

X

Operable

Fixed

Closed

C

V

V

F

B

L

B

V

Operable

B

B

B

M

V

X

V

K

ANSI Z223.1 / NFPA 54 for USA and CAN/CSA B149.1 for Canada - Venting Requirements

USA Clearance Canada Clearance

Item Description Specification Specification

A Above grade, veranda, porch, deck, or balcony 1 ft 1 ft

B Window or door that may be opened 1 ft** 3 ft

C Permanently closed window * *

D Vertical clearance to a ventilated soffit, eves, or overhang 3 ft*** *

E Unventilated soffit, eves, or overhang 3 ft*** *

F Outside corner * *

G Inside corner * *

H Each side of centerline extended from meter/regulator * 3 ft within a height 15 ft above the

meter/regulator assembly

I Service regulator vent outlet * 3 ft

J Non mechanical air supply inlet or combustion air inlet

to any other appliance 1 ft** 3 ft

K Mechanical air supply inlet 3 ft above if 6 ft

within 10 ft

horizontally

L Above paved sidewalk or paved driveway on public property * 7 ft

M Under veranda, porch, deck, or balcony * 1 ft

*

Not specified in ANSI Z223.1 / NFPA 54 or CAN/CGA-B146.

Use clearances in accordance with local building codes and local gas supplier.

**

4 feet (1.2 m) below or to the side of opening and 1 foot (300 mm) above opening.

*** Hubbell recommendation.

18

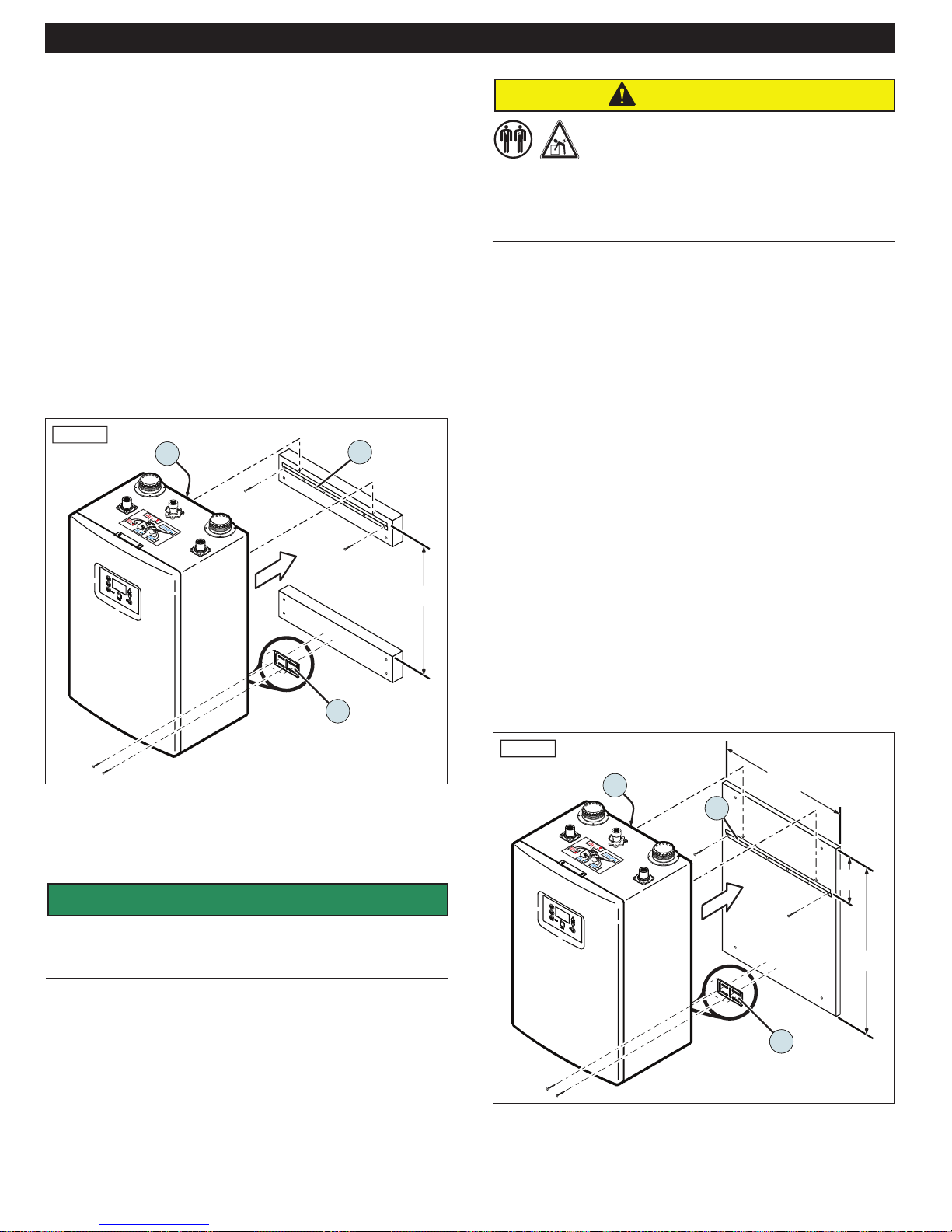

WALL MOUNTING

Secure the unit to the wall using either two wood

mounting blocks or one piece of 3/4” plywood, as

described in this section.

Mounting Block Installation Method

1. Attach two 2x4 or 2x6 mounting blocks (horizontal

framing), at least 18 inches long, to the wall.

a. In wood or steel construction, use adequate wood/

metal screws and secure the mounting blocks with

at least two screws in each vertical wall stud (four

screws total).

b. In concrete block or solid concrete wall construction,

attach the mounting blocks with at least four

masonry screws or suitable masonry wall anchors in

each mounting block.

IH-26

1

2

CAUTION

Lifting Hazard

According to the National Institute for Occupational

Safety and Health, the recommended maximum safe

lifting weight is 51 pounds, with all lifting conditions perfect—

minimal forward reach, steady load close to the body, straight back,

load between knees and shoulders, and good grips. To avoid

personal injury, always use these proper lifting techniques and use

two people to move the water heater which weighs 80 pounds.

3. With assistance, hang the unit on the upper wall

bracket, interlocking bracket (1) on the back of the unit

and wall bracket (2).

4. Install two appropriately sized wood screws in lower

bracket (3) to secure the unit to the wall.

5. Make sure the unit is plumb and level and tighten the

four sheet metal screws on bottom bracket (3). When

properly installed, there should be a 5/8” air space

between the back of the water heater and the mounting

blocks.

21”

3

2. Level upper bracket (2) and attach it to the mounting

block with at least four appropriately sized wood

screws (do not use drywall screws).

SAFETY

INSTRUCTIONS

The Hubbell water heaters weigh 90 to 100 lbs (40.8 to 45.4 kg) and

must be securely attached to the wall. Mounting hardware is

included and should be used to mount the unit.

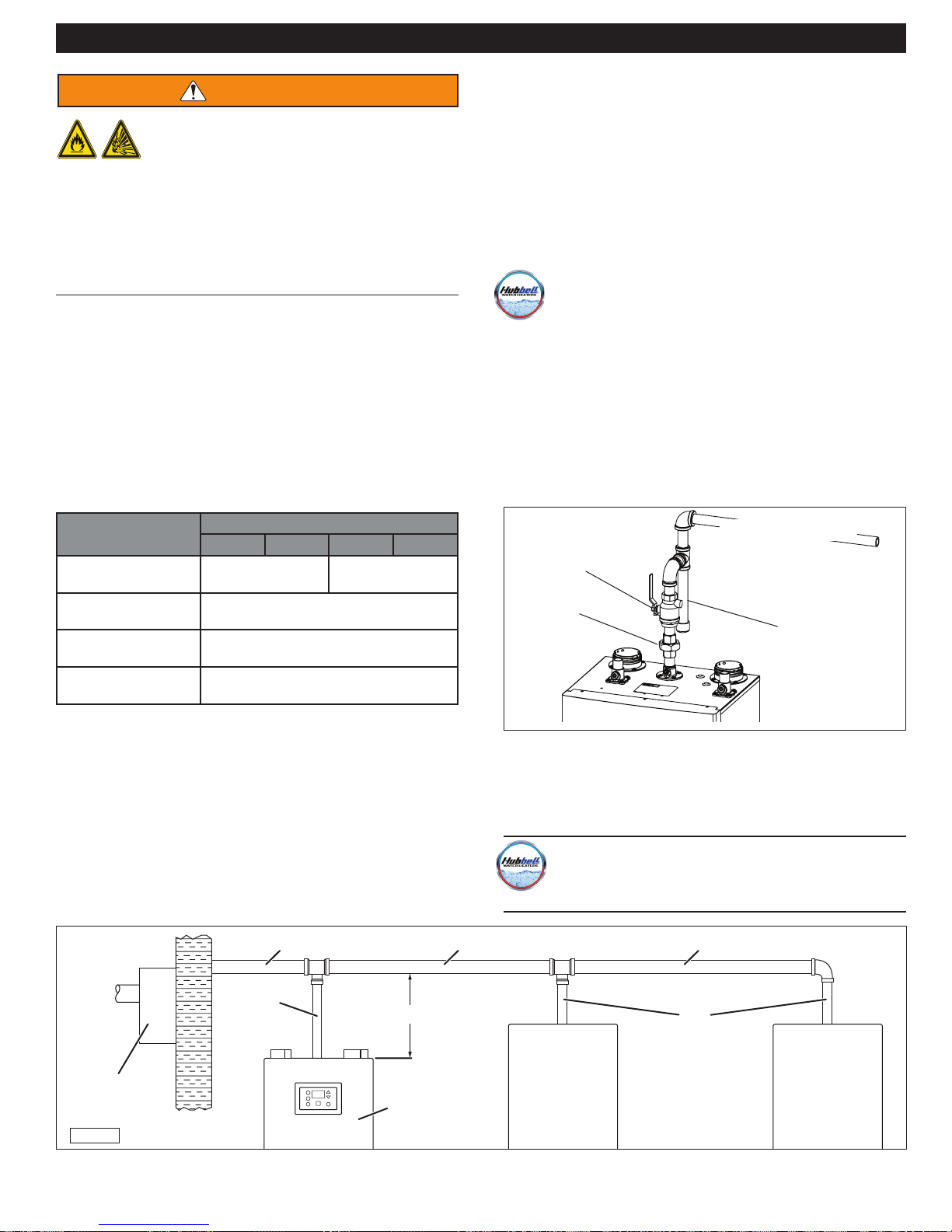

Plywood Installation Method

1. Mount a piece of 3/4” plywood (at least 32” high x 20”

wide) to the wall.

a. In wood or steel construction, use adequate wood/

metal screws and secure the plywood with at least

two screws in each vertical wall stud.

b. In concrete block or solid concrete wall construction,

attach the plywood with at least four masonry

screws or suitable masonry wall anchors.

IH-27

1

20”

2

8”

32”

3

2. Follow Steps 2 through 5 in the above procedure to

complete the installation.

19

GAS CONNECTION

WARNING

FIRE AND/OR EXPLOSION HAZARD

To avoid serious injury or even death, the gas line

installation and the gas line inlet pressure test

must be done by a licensed professional.

Always match the water heater with the type of gas supplied to the

unit (natural gas or LP gas). The water heater is factory preset for

natural gas.

Make sure the gas line pressures are within normal limits. Pressures

outside normal limits can result in poor performance and hazardous

operating conditions.

1.

Determine if the Hubbell water heater will use natural

gas (factory preset) or LP (propane) gas.

a. To convert the unit to propane, refer to the Propane

(LPG) Conversion section in this manual.

b. Make sure your gas supply matches the rating decal

located on the side of the water heater.

2. Make sure the gas pressure meets the requirements

for the unit, as shown in the tables.

b. Measure the length of the gas supply line from the

gas meter to the water heater or other appliances

requiring gas.

c. Use the Gas Pipe Sizing tables in this manual or

refer to the gas line manufacturers sizing information

to determine the correct diameter for the supply pipe.

d. The diameter of the gas lines, shown in the

illustration, will vary according to the specifi c

installation requirements.

NOTE: Always clean the inside of the gas line of

any dirt or debris before connecting the piping to

the unit.

4. Install a gas union connection with a short piece of 3/4”

NPT pipe.

5. Following local building codes, install a manual shut-off

valve.

6.

Connect the manual shut-off valve to the gas supply

line. Also install a dirt pocket drip leg off of the main

supply line, as shown.

Models

Parameters

NG/LP- Minimum Static

Gas Pressure (1/2")

NG/LP- Minimum Static

Gas Pressure (3/4")

NG/LP - Maximum

Static Gas Pressure

Gas Pressure for

Adjustments

3.

Make sure the supply line is correctly sized for the

GX200 GX00P GX250 GX250P

5” (non-corrugated,

black iron)

2.5” (non-corrugated, black iron)

8” for NG, 11” for LP

6” (non-corrugated,

black iron)

14”

maximum output of the water heater model being

installed. The Hubbell water heater should be the

f r st appliance to be connected to the gas supply line.

a. Determine the gas requirement of the water heater(s)

and other appliances requiring gas. The supply line

must be sized according to the COMBINED total

maximum BTUH draw for all the appliances as if they

were all operating at the same time.

1” 1” 1”

Manual

Main Supply Line

Shut-off

Valve

Union

Drip leg

7. Leak test the gas line piping before placing the unit

in operation. Only use approved leak detector liquid

solutions to check for leaks.

IMPORTANT

Do not fire (operate) the water heater until all

connections have been completed and the heat

exchanger is filled with water.

1/2”

Gas

Meter

IH-77

Typical installation when using 1/2” gas line.

Home

Wall

Less then 40’

Hubbell

1/2”

Laundry Stove

20

GAS PIPE SIZING TABLES

Gas Pipe Sizing

This information is for reference only. Refer to gas pipe manufacturer specifications for actual delivery capacity. The DOE

standard for Natural Gas is 1100 BTU/ft3. Contact the local gas supplier for actual BTU/ft3 rating.

1/2” Black Iron Sizing

The following table shows gas supply in cubic feet per hour (CFH) assuming a specific gravity of 0.6 for Natural Gas, 0.585

for propane, pressure drop of 4.6” WC, and 5.0” WC. Contact your gas supplier for BTU/ft3 ratings. Use 1000 BTU/ft3 for

estimates.

Length (Including fittings)

Gas Pipe Size 5 10 15 20 25 30 35 40

Natural Gas 1/2” 571 404 330 286 255 233 216 202

LP 1/2” 578 409 334 289 259 236 219 204

Natural Gas Pipe Sizing

Maximum Natural Gas Delivery Capacity — Length of Black Iron Pipe in Feet

Pipe Cubic Feet per Hour (0.60 Specific gravity, 0.5 WC Pressure Drop)

Size 10 20 30 40 50 60 70 80 90 100 150 200

3/4” 363 249 200 171 152 138 127 118 111 104 84 72

1” 684 470 377 323 286 259 239 222 208 197 158 135

1-1/4” 1404 965 775 663 588 532 490 456 428 404 324 278

1-1/2” 2103 1445 1161 993 880 798 734 683 641 605 486 416

2” 4050 2784 2235 1913 1696 1536 1413 1315 1234 1165 936 801

Maximum Natural Gas Delivery Capacity — Length of Corrugated Stainless Steel Pipe in Feet

Pipe Cubic Feet per Hour (0.60 Specific gravity, 0.5 WC Pressure Drop)

Size 10 20 30 40 50 60 70 80 90 100 150 200

3/4” 206 147 121 105 94 86 80 75 71 67 55 48

1” 383 269 218 188 168 153 141 132 125 118 94 82

1-1/4” 614 418 334 284 251 227 209 194 181 171 137 116

1-1/2” 1261 888 723 625 559 509 471 440 415 393 320 277

2” 2934 2078 1698 1472 1317 1203 1114 1042 983 933 762 661

LP Gas Pipe Sizing

Maximum LP Gas Delivery Capacity — Length of Black Iron Pipe in Feet

Pipe Thousands of BTU/Hour, 0.5 WC Pressure Drop

Size 10 20 30 40 50 60 70 80 90 100 125 150 200

3/4” 567 393 315 267 237 217 196 185 173 162 146 132 112

1” 1071 732 377 323 286 259 239 222 208 197 174 252 213

1-1/4” 2205 1496 775 663 588 532 490 456 428 404 358 511 440

1-1/2” 3307 2299 1161 993 880 798 734 683 641 605 536 787 675

2” 6221 4331 2235 1913 1696 1536 1413 1315 1234 1165 1033 1496 1260

Maximum LP Gas Delivery Capacity — Length of Corrugated Stainless Steel Pipe in Feet

Pipe Thousands of BTU/Hour, 0.5 WC Pressure Drop

Size 10 20 30 40 50 60 70 80 90 100 150 200

3/4” 325 232 191 166 149 136 126 118 112 106 87 76

1” 605 425 344 297 265 241 222 208 197 186 143 129

1-1/4” 971 661 528 449 397 359 330 307 286 270 217 183

1-1/2” 1993 1404 1143 988 884 805 745 696 665 621 506 438

2” 4638 3285 2684 2327 2082 1902 1761 1647 1554 1475 1205 1045

21

Loading...

Loading...