Page 1

INSTALLATION, OPERATION &

MAINTENANCE DATA SHEET

GO113 N34, GO114 N34, GOL113 & GO1114

ROTARY OPERATORS FOR POTENTIOMETERS,

FOR CLASS I, GROUPS B, C & D, CLASS II, GROUPS E, F &

G AND CLASS III HAZARDOUS LOCATIONS AND TYPE 3, 4

& 4X ENCLOSURES

GO113 N34, GO114 N34, GOL113 & GO1114

ROTARY OPERATORS FOR

POTENTIOMETER

CAUTION:

Before installing, make sure you are compliant with area classications, failure to do so may result in bodily injury,

death and property damage. Do not attempt installation until you are familiar with the following procedures. All

installation must comply with the applicable Electrical Code.

Make sure that the circuit is de-energized before starting installation or maintenance.

Verify that the installation is grounded. Failure to ground will create electrical shock hazards, which can cause

serious injury and or death.

Technical information, advice and recommendations contained in these documents is based upon information

that Killark believes to be reliable. All the information and advice contained in these documents is intended for

use only by persons having been trained and possessing the requisite skill and know-how and to be used by

such persons only at their own discretion and risk. The nature of these instructions is informative only and does

not cover all of the details, variations or combinations in which this equipment may be used, its storage, delivery,

installation, check out, safe operation and maintenance. Since conditions of use of the product are outside of the

care, custody and control of Killark, the purchaser should determine the suitability of the product for his intended

use, and assumes all risk and liability whatsoever in connection therewith.

3940 Dr. Martin Luther King Drive

St. Louis, MO 63113

P/N 00911740 FORM NO. K1081 R11/08 ECO-3-045-08

Page 1 of 3

Page 2

These operators will accept standard rotary

electrical devices with 1/4” diameter shafts,

such as potentiometers, and are designed

for enclosures that meet the requirements of

Article 500 of the National Electrical Code.

GO 113 N34 & GO 114 N34 devices are

designed for mounting in enclosures with

walls up to 1-1/2” thick. GOL113 & GOL114

devices are designed for mounting in

enclosures with walls up to 2-1/2” thick.

1. DIRECTIONS FOR INSTALLATION

WARNING: Be sure to turn OFF the supplying circuit

before beginning installation.

1. Using the installation drawings below as a

guide, drill and tap a ¾ -14NPSM-2B hole in the

enclosure cover / wall. The hole must be located

so that a at area is available to tighten the locknut

on the inside of the cover, and enough room is

allowed for mounting the dial assembly on the

outside. In addition, the inside cover surface must

be perpendicular to the threaded hole and smooth

in order to properly seat the sealing locknut. For

Group B locations, a minimum of 7 full threads

engagement is required and for Group C & D

locations, a minimum of 5 full threads is required.

For proper electrical clearance, these devices

should be mounted on 2-1/2” centers and 1-3/4”

from any vertical wall.

2. Remove the knob and dial and thread the

remainder of the assembly through the hole from

the inside of the cover until the end of the threaded

body is ush with the cover face.

3. Orient the assembly as desired, and tighten the

sealing locknut to secure it. (The assembly may be

staked in place, if desired).

4. (For GO113 N34 & GOL113) Position the dial plate

at the end of the body, drill the dial plate in the

enclosure cover / wall with a #47 drill, 3/1 6” to 1/4”

deep, and fasten the dial plate with the #2-56 selflapping screws provided. Attach the control knob

and secure it with its setscrews (you will need a

5/64” Allen wrench).

(4A) (For GO114 N34 & GOL114) Refer to the

drilling template and an Allen wrench which are

included to complete this installation.

3940 Dr. Martin Luther King Drive

St. Louis, MO 63113

P/N 00911740 FORM NO. K1081 R11/08 ECO-3-045-08

Page 2 of 3

Page 3

5. When installing the potentiometer or device,

secure it to the ex coupling with the setscrews

provided.

6. Wire the system, secure the enclosure and turn

ON the circuit to test the system.

NOTE: All installations must comply with

applicable local and/or National Electrical Code.

2. OPERATIONAL DATA

The devices used on these operators are electrical

arcing devices. Therefore, the enclosure in which

they are installed must be provided with external

seals, as required by NEC Articles 501-5 &

502-5. In addition, the enclosure must be marked

with a cautionary statement such as, “Caution:

Disconnect this device from the supplying circuit

before entering. Keep assembly tight while circuits

are alive.” This statement must be permanently

visible after the enclosure has been installed.

3. MAINTENANCE DATA

“GO” Series Rotary Operators should be periodically

checked for proper operation. The operator shaft

should be lubricated occasionally if operating

conditions require it.

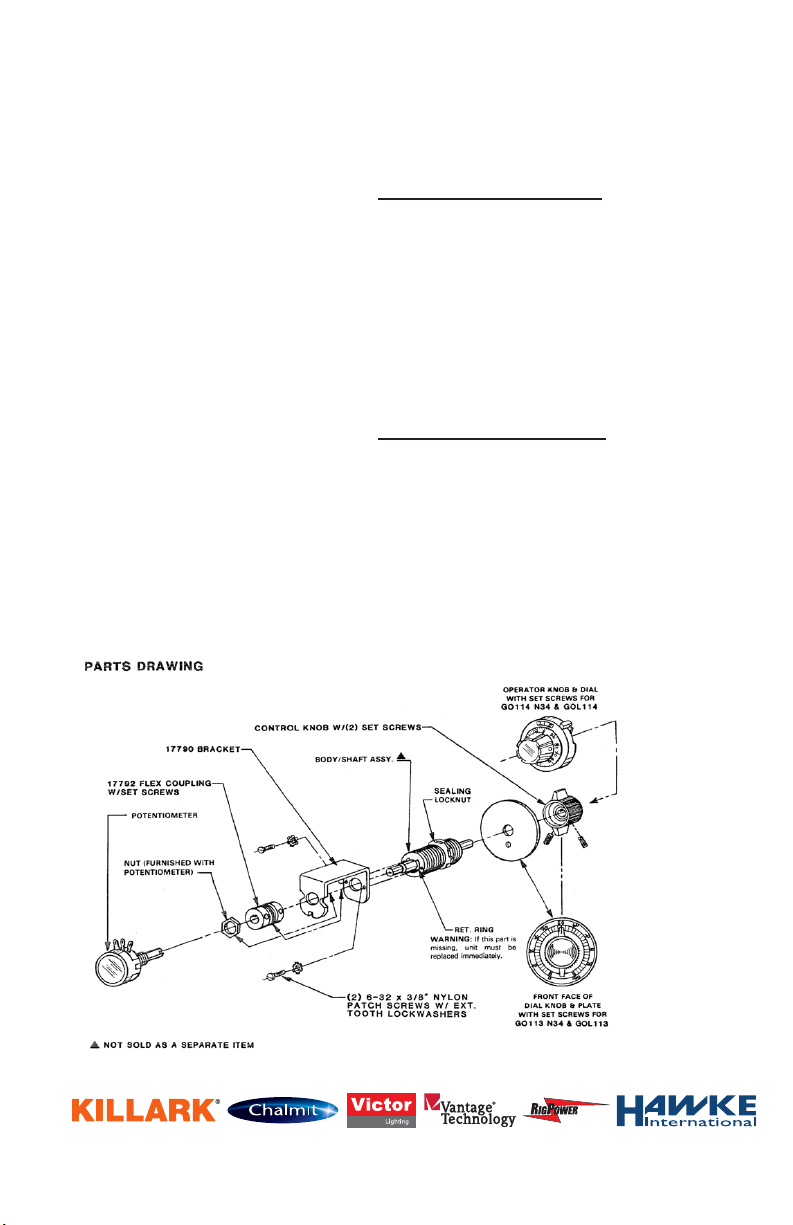

WARNING: The surface between the body and shaft

is a ame path. If excessive play develops between

these parts, the body/shaft assembly must be

replaced at once. Refer to the Parts Drawing on left

and/or to the Killark factory for specic replacement

parts.

REMEMBER TO SAVE ONE OF THESE SHEETS FOR MAINTENANCE PERSONNEL

3940 Dr. Martin Luther King Drive

St. Louis, MO 63113

P/N 00911740 FORM NO. K1081 R11/08 ECO-3-045-08

Page 3 of 3

Loading...

Loading...