Hubbell GAI-TRONICS 277-700, GAI-TRONICS 210-702, GAI-TRONICS 247-700, GAI-TRONICS 257-700, GAI-TRONICS 227-700 User Manual

Page 1

Pub. 42004-519C

G A I - T R O N I C S®

A H U B B E L L C O M P A N Y

Rugged VoIP Autodial Handset Telephones

T A B L E O F C O N T E N T S

GAI-TRONICS 3030 KUTZTOWN RD. READING, PA 19605 USA

610-777-1374 ◼ 800-492-1212 ◼ Fax: 610-796-5954

VISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Confidentiality Notice .....................................................................................................................1

Product Overview ............................................................................................................................1

Features and Functions .......................................................................................................................... 2

System Requirements and Limitations ................................................................................................. 2

Tips for VoIP Subscribers ...................................................................................................................... 2

Operation .........................................................................................................................................2

Place a Call .............................................................................................................................................. 2

Receive a Call .......................................................................................................................................... 3

Handset Receiver Volume Control ........................................................................................................ 3

Monitor and Report Telephone Status .................................................................................................. 3

Status Indication ..................................................................................................................................... 3

Power .................................................................................................................................................... 3

Heartbeat ............................................................................................................................................... 3

EACT .................................................................................................................................................... 3

Installation ......................................................................................................................................4

Safety Guidelines ..................................................................................................................................... 4

Security Hardware .................................................................................................................................. 4

Conduit Installation Details (Applicable to Models 247-700 and 257-700) ........................................ 4

Models 210-702, 210-702BH, and 210-702BHAC................................................................................. 5

Model 227-700 ......................................................................................................................................... 7

Model 247-700 ......................................................................................................................................... 9

Model 257-700 ....................................................................................................................................... 11

Model 277-700 ....................................................................................................................................... 13

Models 277-702BH and 277-702BHAC ............................................................................................... 15

Flush-mount Installation ..................................................................................................................... 15

Surface-Mount Installation ................................................................................................................. 17

Field Wiring ..................................................................................................................................17

Recommended Cabling ......................................................................................................................... 17

Power ...................................................................................................................................................... 18

Power-Over-Ethernet .......................................................................................................................... 18

Local Power ........................................................................................................................................ 18

Ground (For Models 210-702BH/-702BHAC, 227-700/-702BH/-702BHAC Only) ......................... 19

Network .................................................................................................................................................. 19

Page 2

Table of Contents Pub. 42004-519C

GAI-TRONICS 3030 KUTZTOWN RD. READING, PA 19605 USA

610-777-1374 ◼ 800-492-1212 ◼ Fax: 610-796-5954

VISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Auxiliary I/O.......................................................................................................................................... 19

Inputs................................................................................................................................................... 19

Outputs ................................................................................................................................................ 20

Programming ................................................................................................................................20

VoIP PCBA Setup ................................................................................................................................. 20

VoIP PCBA Initial Network Configuration ....................................................................................... 20

VoIP Telephone Input Contact Configuration ................................................................................... 21

VoIP Telephone Output Contact Configuration ................................................................................ 21

Maximum (Handset Receiver) Level Remote Control ...................................................................... 21

Maintenance ..................................................................................................................................21

General Information ............................................................................................................................. 21

Preventive Maintenance for Model 277-700/-702BH/-702BHAC ..................................................... 21

Cleaning .............................................................................................................................................. 21

Prevention ........................................................................................................................................... 22

Service .................................................................................................................................................... 22

Troubleshooting .................................................................................................................................... 22

Replacement Parts and Accessories .............................................................................................23

Specifications ................................................................................................................................24

Power ...................................................................................................................................................... 24

Network .................................................................................................................................................. 24

Handset Audio ....................................................................................................................................... 24

Inputs ..................................................................................................................................................... 25

Outputs .................................................................................................................................................. 25

Indicators ............................................................................................................................................... 25

Mechanical ............................................................................................................................................. 25

Approvals .......................................................................................................................................26

Page 3

Pub. 42004-519C

G A I - T R ON I C S®

A H U B B E L L C O M P A NY

Rugged VoIP Autodial Handset Telephones

GAI-TRONICS 3030 KUTZTOWN RD. READING, PA 19605 USA

610-777-1374 ◼ 800-492-1212 ◼ Fax: 610-796-5954

VISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Confidentiality Notice

This manual is provided solely as an installation, operation, and maintenance guide and contains sensitive

business and technical information that is confidential and proprietary to GAI-Tronics. GAI-Tronics

retains all intellectual property and other rights in or to the information contained herein, and such

information may only be used in connection with the operation of your GAI-Tronics product or system.

This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any third

party.

Product Overview

GAI-Tronics’ VoIP Autodial Handset Telephones are designed for connection to a 10/100 BaseT Ethernet

network. These telephones operate from Power-over-Ethernet (PoE) or an external power source. These

VoIP telephones provide direct point-to-point communications between personnel throughout a facility

over an existing LAN.

The following VoIP Telephones are detailed in this manual:

Table 1. Model Chart

Model

Description

210-702

Corridor VoIP Autodial Telephone with 29-inch armored cord handset.

210-702BH

Behavioral Health VoIP Autodial Telephone with 12-inch armored cord

handset.

210-702BHAC

Behavioral Health VoIP Autodial Telephone with 15-inch armored cord

handset.

227-700

Tough VoIP Autodial Telephone, weather and vandal resistant sand-cast

aluminum enclosure with a spring-loaded door and 15-inch armored cord handset.

247-700

Rugged Indoor VoIP Autodial Telephone, engineered plastic enclosure and

handset with Hytrel® coiled cord (6-foot extended).

257-700

Rugged Weatherproof VoIP Autodial Telephone, weatherproof, engineered

plastic enclosure with door and handset with Hytrel® coiled cord (6-foot

extended).

277-700

Flush-panel VoIP Autodial Telephone, heavy-gauge brushed stainless steel front

panel with 29-inch armored cord handset.

277-702BH

Flush-panel VoIP Behavioral Health Autodial Telephone, heavy-gauge

brushed stainless steel front panel with 12-inch armored cord handset.

277-702BHAC

Flush-panel VoIP Behavioral Health Autodial Telephone, heavy-gauge

brushed stainless steel front panel with 15-inch armored cord handset.

Page 4

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 2 of 26

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Features and Functions

The VoIP Telephones covered in this manual include the following features:

• SIP compatible (RFC3261)

• weather and/or vandal-resistant

• real-time alarm reporting via email, syslog, or TMA software

• PoE (Power-over-Ethernet) compatible

• configurable via web page, serial link or download

• four auxiliary inputs, two volt-free contact outputs

System Requirements and Limitations

These VoIP telephones require Power-over-Ethernet (PoE) or a local 24–48 V dc power source for

operation. Two VoIP telephones can be connected in a peer-to-peer configuration without the need for a

LAN. A 10/100 BaseT Ethernet network with a SIP (Session Initiation Protocol) server is required for

systems containing three or more VoIP telephones. Conferences are limited by the customer’s LAN

media capabilities and the services available at each end point.

Tips for VoIP Subscribers

The following points should be addressed for new and existing subscriptions to an interconnected VoIP

service provider:

• Provide accurate physical address information to the VoIP service provider to ensure that emergency

services can quickly be dispatched to the location.

• Be familiar with the VoIP service provider’s procedures for updating the address and promptly update

address information in the event of a change.

• Have a clear understanding of any limitations of the local 911 service.

• Be aware that VoIP telephone services may not work if the power is out or the Internet connection is

down. Consider installing a backup power supply, maintaining a traditional telephone line, or having

a wireless telephone as a backup.

• For questions about interconnected VoIP and 911, or VoIP in general, see

http://www.fcc.gov/cgb/consumerfacts/voip.html.

Operation

Place a Call

To place a call:

1. Lift the handset from the cradle to take the telephone off-hook.

The programmed number is automatically dialed after approximately one second.

2. Control the handset receiver volume by pressing the volume control pushbutton.

3. The call is terminated by placing handset back in the cradle, the receiving caller hangs up, the defined

timeout of the call duration is exceeded, or via the SIP server.

Page 5

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 3 of 26

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Receive a Call

The VoIP telephone’s ringer sounds when called until the handset is removed from the cradle (taken offhook) and a conversation can take place.

Handset Receiver Volume Control

A push-button switch is provided on the front panel for adjustment of the handset receiver volume. When

pressed, it decreases the volume gain from 20 dB to 12 dB, to 0 dB, and back up to 20 dB of the original

signal. After the end of each call the signal gain is automatically set to 20 dB.

Monitor and Report Telephone Status

Each telephone can recognize and generate several hardware and configuration fault condition alarms.

There are three methods to transmit this information to a remote site:

• syslog output over TCP

• SMTP mail message

• TMA (Telephone Management Application) software (purchased separately)

Available alarms are:

• handset integrity loop (if applicable)

• configuration error

• cold reset (power cycle)

• warm reset (internal command)

• key hook (off hook status, if applicable)

• register fail

• audio path test (speaker/microphone test)

Status Indication

Power

The power LED located on the VoIP PCBA illuminates when power is applied to the telephone (see

Figure 18).

Heartbeat

The heartbeat LED located on the VoIP PCBA will flash once network communication is established (see

Figure 18).

EACT

The EACT LED located on the VoIP PCBA turns ON when VoIP PCBA is connected to an Ethernet

device and flashes when data is being transmitted (see Figure 18).

Page 6

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 4 of 26

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Installation

WARNING

—This product can contain hazardous voltages. Always remove power to this

station and any associated equipment before beginning any installation.

CAUTION

—Do not install this equipment in areas other than those indicated on the approval

listing in the Approvals section of this manual. Such installation may cause a

safety hazard and consequent injury or property damage.

Install equipment without modification and according to all applicable local and national electrical codes.

Consult the National Electrical Code (NFPA 70), Canadian Standards Association (CSA 22.1), and local

codes for specific requirements regarding your installation. Class 2 circuit wiring must be performed in

accordance with NEC.

Safety Guidelines

When installing any GAI-Tronics equipment, please adhere to the following guidelines to ensure the

safety of all personnel:

• Do not install wiring during a lightning storm.

• Electrostatic Discharge (ESD) Protection: GAI-Tronics’ VoIP telephones may have an earth

ground terminal provision. Connect this terminal to ground in accordance with all local safety

regulations and the NEC (National Electrical Code). Grounding must be ensured for safe and stable

communications. Do not use long and coiled ground wires. Trim ground wires to the required

length. Use a star configuration whenever possible. Please note proper grounding does not eliminate

the need for lightning protection for the telephone or the telephone system. A Cat5 data line lightning

surge protector is recommended for telephones subject to any electrostatic discharge (e.g. lightning).

• Do not install jacks in wet locations unless the jack is specifically designed for wet locations.

Security Hardware

Models 210-702BH/-702BHAC, 227-700, and 277-702BH/-702BHAC are vandal-resistant. The front

enclosure or panel of these telephones is attached to its mounting plate or enclosure with security screws.

A GAI-Tronics Model 233-001 Security Screwdriver or Torx T-25 security head tip (sold separately) is

required to install the security screws. Models 247-700 and 257-700 Telephones’ front panels are

attached with standard Phillips head screws.

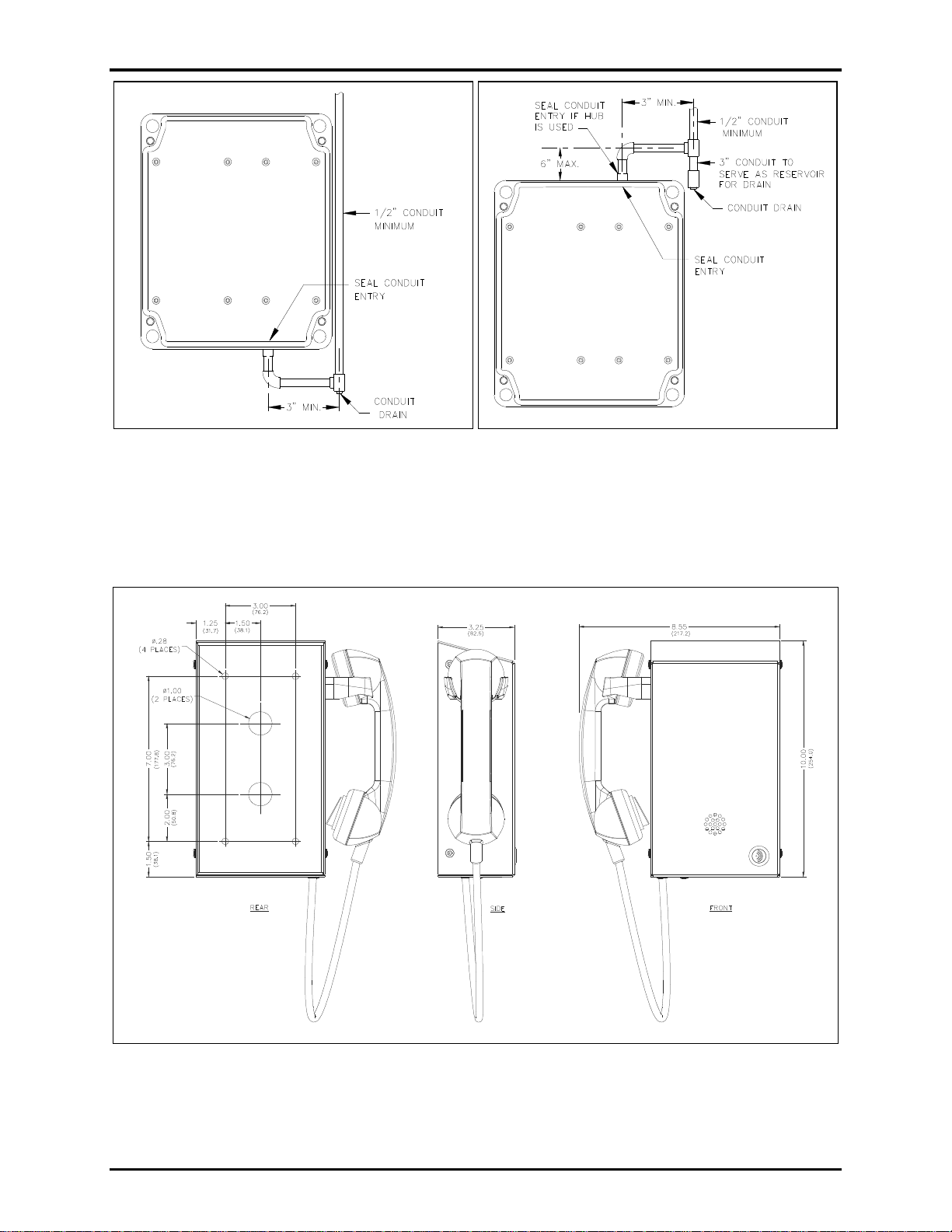

Conduit Installation Details (Applicable to Models 247-700 and 257-

700)

GAI-Tronics recommends installing cabling in conduit to protect against accidental damage and

vandalism. The following points are strongly recommended to prevent moisture from entering the

enclosure:

• Conduit should enter the enclosure from the bottom.

• If entered from the top, the conduit must be internally sealed to prevent moisture ingress.

• Sealed fittings should be installed at all cable entry points.

• Silicone sealant or equivalent must be applied around and inside all conduit entries.

Please refer to Figure 1 and Figure 2.

Page 7

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 5 of 26

Figure 1. Model 247-700 & 257-700—Bottom

entry conduit installation details

Figure 2. Model 247-700 & 257-700—Top entry

conduit installation details—

(NOT RECOMMENDED)

Models 210-702, 210-702BH, and 210-702BHAC

Figure 3. Models 210-702/-702BH/-702BHAC VoIP Autodial Behavioral Telephones Outline and

Mounting Detail

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Page 8

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 6 of 26

1. Use a GAI-Tronics No. 233-001

Security Screwdriver to remove the

four tamper-resistant cover-panel

screws (see Figure 4).

2. Remove the front cover assembly

and set it aside to expose the four

mounting holes on the mounting

panel.

3. Position the rear mounting panel on

the mounting surface and fasten

with four #10-32 screws (customer

supplied).

4. Pull the Ethernet cable through one

of the two holes and install the

cable (see the Network section).

Two 1-inch diameter entry holes

are provided on the mounting panel

for cable entry.

Figure 4. Models 210-702/-702BH/-702BHAC

Front Cover Removal

5. Connect and configure any desired

peripheral devices (see the

Auxiliary I/O section).

6. Perform the initial programming of

the telephone (see the

Programming section).

7. Replace the front cover assembly

and fasten using the four security

screws removed in Step 1. Tighten

the four screws using a GAITronics No. 233-001 Security

Screwdriver.

8. Test the telephone operation by

calling to and from another

telephone.

9. Test the operation of peripheral

equipment.

Figure 5. Models 210-702/-702BH/-702BHAC Internal View

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Page 9

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 7 of 26

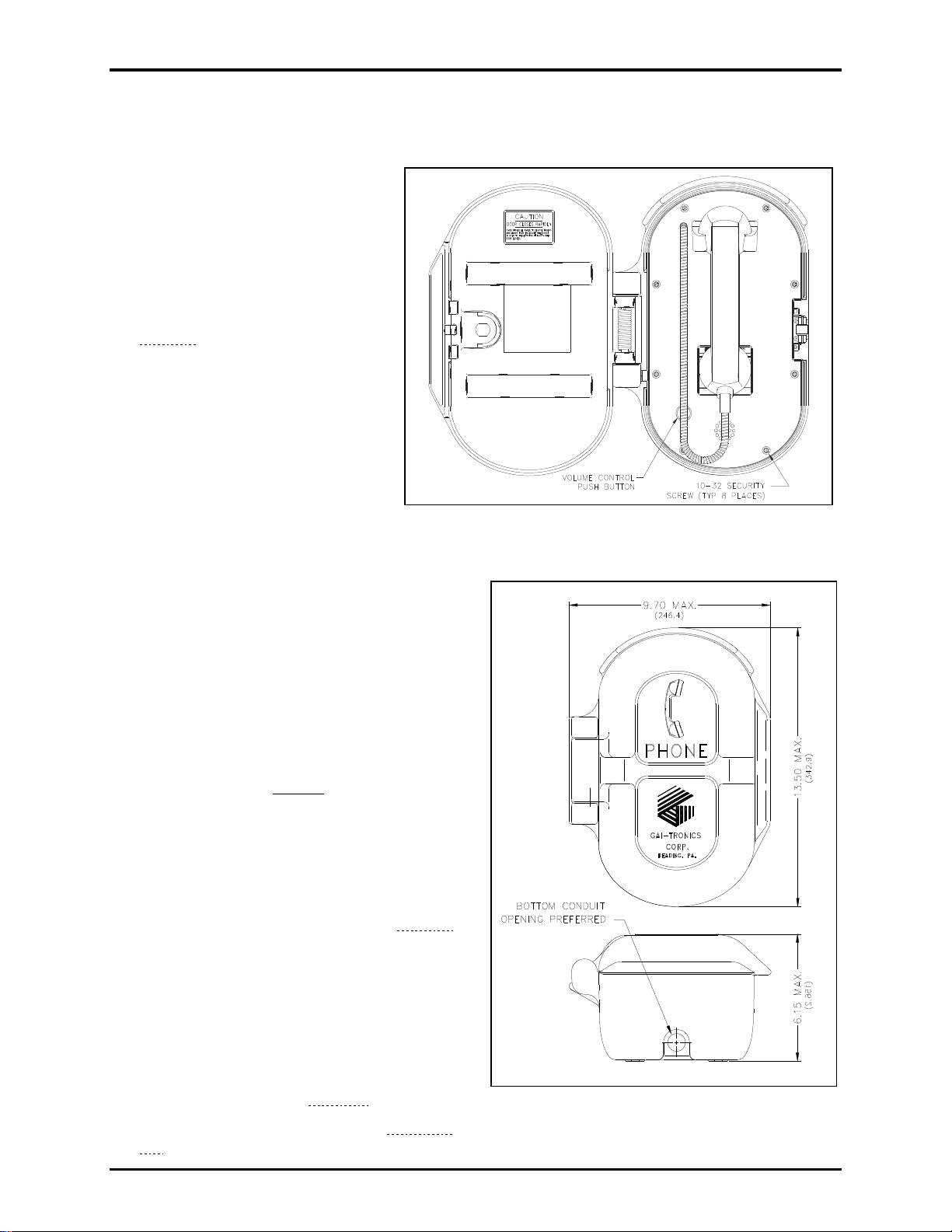

Model 227-700

The mounting and cabling instructions for the Model 227-700 Telephone are as follows:

1. Remove the eight security screws

from the front panel using a GAITronics No. 233-001Security

Screwdriver.

2. Remove the front panel and set it

aside.

3. Determine the hole pattern to use

for mounting the telephone (see

Figure 8).

• Use the 7.875 × 4.0-inch hole

pattern for mounting to a wall

(outside pattern).

• Use the 5.25 × 4.0-inch hole

pattern when using the No.

232-001 Pole Mounting Kit

(inside pattern).

4. Insert (four provided) hole plugs

in the unused mounting holes.

5. Position the enclosure on the

mounting surface and secure it with four

fasteners.

Figure 6. Model 227-700 VoIP Autodial Telephone

with spring loaded door in the open position

• The holes in the telephone enclosure

accept 3/8-inch screws or bolts.

• The Model 232-001 Pole Mounting Kit

includes four 3/8-16 × 1-inch shoulder

bolts with Teflon seal washers.

N

OTE: Use only the round head, hexagon

head, or pan head screws that are

provided. Do not use screws designed

to be countersunk for mounting the

enclosure.

6. Install a conduit fitting in one of the 1/2-inch

NPT conduit entrances located at the top and

bottom of the unit.

The bottom location is preferred (see Figure 7).

7. Insert the conduit into the fitting.

8. Plug the unused access hole with the provided

3/8-inch Allen drive plug.

N

OTE: Use silicone sealant or equivalent

around and inside all conduit entries.

9. Pull the Ethernet cable through the conduit and

install the cable (see the Network section).

10. Connect peripheral devices (see the Auxiliary

I/O section).

Figure 7. Model 227-700 Outline

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Page 10

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 8 of 26

11. Seal the conduit entry point(s).

N

OTE: Use silicone sealant or equivalent around and inside all conduit entries.

12. Perform the initial programming of the telephone (see the Programming section).

13. Verify telephone operation by calling to and from another telephone.

14. Verify the operation of peripheral equipment.

15. Replace the front panel assembly and secure it using the eight front panel security screws.

16. Torque the screws to 10–12 lb⋅in (1.1–1.4 Nm).

Figure 8. Model 227-700 Mounting Detail

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Page 11

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 9 of 26

Model 247-700

The mounting and cabling instructions for

the Model 247-700 Telephone are as

follows:

1. Remove the four screws from the front

panel.

2. Remove the front panel and set it aside.

3. Mount the enclosure to a wall using

either four ¼-20 machine screws with

washers and nuts or four #14 wood

screws of the appropriate length,

depending on the mounting surface.

There are four mounting holes in the

rear enclosure (see Figure 10).

4. Drill a hole for the type of bushing to be

used.

5. Pull the Ethernet cable through the

bushing and install the cable (see the

Network section).

6. Seal the conduit entry point.

Figure 9. Model 247-700 VoIP Autodial Telephone

OTE: Use silicone sealant or equivalent around and inside all cable/conduit entries.

N

7. Connect and configure any desired peripheral devices (see the Auxiliary I/O section).

8. Perform the initial programming of the telephone (see the Programming section).

9. Verify telephone operation by calling to and from another telephone.

10. Test the operation of peripheral equipment.

11. Replace the front panel assembly.

12. Secure the front panel using the four front-panel screws.

13. Torque the screws to 10–12 in∙lb (1.1–1.4 N∙m).

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Page 12

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 10 of 26

Figure 10. Model 247-700 Mounting Detail

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Page 13

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 11 of 26

Model 257-700

The mounting and cabling instructions for

the Model 257-700 Telephone are as

follows:

1. Open the front door and remove the

four outer screws from the mid-section.

2. Carefully pull the enclosure apart until

encountering a slight resistance on the

left side.

3. Pull on the left side of the enclosure

until the hinge plugs pull loose to

separate the front and rear halves.

4. Set the front half of the enclosure aside.

5. Mount the enclosure on the wall using

four ¼-20 machine screws with nuts

and washers or #14 wood screws of the

appropriate length for the mounting

surface.

There are four mounting holes in the

rear enclosure.

6. Drill a hole for the type of bushing to

be used.

Figure 11. Model 257-700 VoIP Autodial Telephone

(Front door open)

7. Reinsert the hinge pins to attach the front half of the enclosure.

8. Insert the Ethernet cable through the gland bushing and install the cable (see the Network section).

NOTE: Conduit may be used in place of the provided gland bushing. If used, the conduit entrance

must be sealed after the cable is installed.

N

OTE: Use silicone sealant or equivalent around and inside all conduit entries.

9. Connect peripheral devices (see the Auxiliary I/O section).

10. Perform the initial programming of the telephone (see the Programming section).

11. Verify telephone operation by calling to and from another telephone.

12. Test the operation of peripheral equipment.

13. Close the mid-section and torque the four screws to 10–12 in⋅lb (1.1–1.4 N∙m).

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Page 14

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 12 of 26

Figure 12. Model 257-700 Mounting Detail

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Page 15

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 13 of 26

Model 277-700

The mounting and cabling instructions for the Model 277-700 Telephone are as follows:

Figure 13. Model 277-700 Outline Drawing

1. Remove the six tamper-resistant screws securing the backbox to the telephone.

2. Flush-mount and GAI-Tronics Model 234 Series Communication Station installations:

Mount the back box to the structure using the appropriate hardware (see Figure 14 for the cutout

dimensions).

Surface-mount installations using a GAI-Tronics 236-00x Series or 238-001 Surface-Mount

Enclosure:

Install the surface-mount enclosure following the instructions included with the enclosure.

The front panel assembly mounts directly to the enclosure (the back box is not required.)

3. Remove a tapered plug from one of the cable entry holes in the back box.

4. Install a cable fitting and pull the cabling into the backbox.

OTE: Installation of a (customer-supplied) surge suppressor on the Ethernet cable and the power

N

line (if used) is recommended when mounting outdoors.

OTE: Use silicone sealant or equivalent around and inside all conduit entries.

N

5. Terminate all wires (see the Field Wiring section).

6. Connect all peripheral devices (see the Auxiliary I/O section).

7. Perform the initial programming of the telephone (see the Programming section).

8. Verify telephone operation by calling to and from another telephone.

9. Test the operation of peripheral equipment.

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Page 16

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 14 of 26

10. Attach the telephone’s front panel to the mounting flanges of the back box using the six supplied

#10-32 security screws and washers.

11. Torque the screws to 10–12 in∙lb (1.1–1.4 N∙m).

Figure 14. Model 277-700 Mounting Detail

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Page 17

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 15 of 26

Models 277-702BH and 277-702BHAC

NOTE: See the cutout and support framing detail for installation planning (see Figure 17).

Figure 15. Models 277-702BH/-702BHAC Behavioral Health Telephone

Flush-mount Installation

1. Remove the four screws securing the dust cover to the back of the telephone and remove the dust

cover.

2. Remove the tapered plug(s) from the cable entry holes and feed all cabling into the dust cover.

3. Terminate all wires (see the Field Wiring section).

4. Connect peripheral I/O devices (see the Auxiliary I/O section).

5. Reinstall the dust cover on the back of the telephone’s front cover and secure it with the four screws

removed in step one.

6. Perform the initial programming of the telephone (see the Programming section).

7. Verify telephone operation by calling to and from another telephone.

8. Test the operation of peripheral equipment.

9. Attach the front panel assembly to the mounting surface using the six supplied #10-32 thread-cutting

security screws.

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Page 18

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 16 of 26

Figure 16. Models 277-702BH/-702BHAC Dust Cover Detail

Figure 17. Models 277-702BH/-702BHAC Cutout and Support Framing Detail

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Page 19

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 17 of 26

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Surface-Mount Installation

NOTE: a GAI-Tronics Model 238-003 stainless-steel surface-mount enclosure (sold separately) is

required for surface mount installations.

1. Remove the four screws securing the dust cover to the back of the telephone and discard the dust

cover.

NOTE: The dust cover included with the Model 277-702BH and 277-702BHAC telephones is not

required for use with the Model 238-003 Surface-Mount Enclosure.

The Model 238-003 Enclosure includes rear and bottom access holes for cable entry. Use the rear

access hole(s) for a completely hidden installation or the bottom access hole(s) for conduit

installation.

2. Pull all cables into the surface-mount enclosure.

3. Terminate all cables to the telephone (see the Field Wiring section).

4. Connect and configure peripheral I/O devices (see the Auxiliary I/O section).

5. Attach the telephone’s front panel to the mounting flanges of the Model 238-003 Surface-Mount

Enclosure.

NOTE: Use the six #10-32 security machine screws supplied with the surface-mount enclosure kit

along with the flat black washers included with the telephone. Do not use the thread-cutting

screws supplied with the telephone in the Model 238-003 enclosure’s tapped holes. A Model

233-001 Security Screwdriver (sold separately) is required for installing the security screws.

Recommended torque is 10–12 in∙lb.

Field Wiring

Install all connections after pulling the field wiring into the rear enclosure (see Table 2 for recommended

conductor sizes and Figure 18 for wiring details).

NOTE: Consult the National Electrical Code (NFPA 70), Canadian Standards Association (CSA 22.1),

and local codes for the specific requirements regarding your installation. Install all equipment

without modification and according to the local and national codes. Class 2 circuit wiring must

be performed in accordance with NEC 725.55.

Recommended Cabling

Table 2. Recommended Cabling

Cable Use

Size and Type

LAN

Cat5 or Cat5e cable with RJ45 connectors

Power

Two-conductor, No. 22 AWG is typical

Inputs

Two-conductor, No. 22 AWG is typical

Output contacts

Two-conductor, No. 18 AWG is typical

Page 20

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 18 of 26

Figure 18. VoIP Telephone PCB Assembly

Power

Power-Over-Ethernet

Connect power to the system as indicated in your PoE equipment manual.

Local Power

When PoE is not available, a separate, isolated 24–48 V dc power supply is required. A removable

terminal block P5 has been provided for connection of local power to the telephone. Connect the positive

conductor to the (+) terminal and the negative conductor to the (−) terminal of P5

18).

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

(see Table 3 and Figure

Page 21

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 19 of 26

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Table 3. 24–48 V dc Power Connection—Terminal Block P5

Pin

Label

Description

1

(+)

Positive

2

(−)

Negative

Ground (For Models 210-702BH/-702BHAC, 227-700/-702BH/-702BHAC Only)

The enclosure must be connected to earth ground. Install a #6 ring lug on the ground conductor and

secure it to the ground terminal located in the rear of the front panel.

NOTE: Not applicable to Models 247-700 and 257-700.

Network

Connect a Cat5 or Cat5e cable with an RJ45 connector between the Local Area Network (LAN) and the

VoIP PCBA.

Auxiliary I/O

Inputs

Four auxiliary inputs have been provided for customer use. Terminations for these inputs are provided on

terminal block P12.

Table 4. Auxiliary Inputs—Terminal Block P12

Pin

Label

Function

1

IN4

Input 4

2

COM

Common

3

IN3

Input 3

4

COM

Common

5

IN2

Input 2

6

COM

Common

7

IN1

Input 1

8

COM

Common

Page 22

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 20 of 26

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Outputs

Two outputs have been provided for customer use. Terminations for these outputs are provided on

connector P10.

Table 5. Output Contacts—Connector P10

Pin

Label

Description

1

C1

Common Output 1

2

NO1

Normally Open Output 1

3

C2

Common Output 2

4

NO2

Normally Open Output 2

Programming

The network configuration must provide VoIP service (using the SIP protocol) between the desired

locations before attempting to configure a GAI-Tronics VoIP telephone.

The general sequence to set up a VoIP telephone is as follows:

VoIP PCBA Setup

1. Connect a PC to the same network as the VoIP telephone.

2. Log into the unit’s web interface.

The unit is factory configured with a static IP address: 192.168.1.2.

3. Enter the user name and password when prompted.

The initial factory settings are:

• USER NAME: user

• PASSWORD: password

4. Change the user name and password upon first login.

This security measure helps to prevent unauthorized changes to the VoIP telephone’s interface

configuration.

VoIP PCBA Initial Network Configuration

Each VoIP PCBA must be set up for the network prior to installation. Assign a local ID, domain, proxy,

and registrar.

Assign a host name Host names provide identification of different VoIP PCBAs on the network.

Test Verify that calls can be made successfully.

Maintain Monitor alarms. Set up auto-updates.

Refer to Pub. 42004-481 for programming instructions for these VoIP devices.

Page 23

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 21 of 26

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

VoIP Telephone Input Contact Configuration

Each VoIP telephone accepts four volt-free inputs (see the Specifications section for the input ratings).

The function of each input is configurable. Inputs can be configured for one of the following modes: On,

Off, or On/Off. The signals can also be inverted between active high (INVERT) or active low

(NORMAL). Activation of these inputs can be configured to update a SYSLOG or generate an email (see

Figure 18 and the Logic Settings section of GTC Pub. 42004-481, VoIP Telephone Configuration Guide

for programming instructions for these inputs).

VoIP Telephone Output Contact Configuration

Each VoIP telephone contains two volt-free output contacts (see the Specifications section for the output

ratings). Both outputs are SPST (single-pole, single-throw) contacts.

The function of each output is configurable. Outputs can be configured for one of the following modes:

On, Off, Pulse, Mute, Ring, Call, Connect, Hook, In Use, Ring Cadence, Ring Out, Page, Registered, or

Emergency. In some modes, the duration of the activation or on/off times can also be set (see Figure 18

and the Logic Settings section of GTC Pub. 42004-481, VoIP Telephone Configuration Guide for

programming instructions for these outputs).

Maximum (Handset Receiver) Level Remote Control

The receiver volume level can be remotely controlled by changing the setting in the configuration file.

Refer to the Handset Volume Setting in the Audio Settings section of Pub. 42004-481, VoIP Telephone

Configuration Guide for programming instructions.

Maintenance

WARNING

—This product can contain hazardous voltages. Always remove power to this

station prior to servicing.

General Information

1. Inspect and replace frayed or cracked wiring.

2. Secure/replace loose wires and terminal lugs.

3. Remove corrosion from terminals.

4. Inspect fuse F1 on the VoIP carrier PCBA.

Preventive Maintenance for Model 277-700/-702BH/-702BHAC

Stainless steel does require maintenance to prevent corrosion from occurring. Different installation

locations may require more regular maintenance than others, depending on the environment and exposure

to airborne contaminants. The following maintenance steps should be performed on a regular basis or

when corrosion is first noticed on your Model 277-700/-702BH/-702BHAC Telephone.

Cleaning

For general cleaning, wipe surface with a cleanser or cleanser and water mixture. Any cleanser that is

safe for glass is usually safe for stainless steel. Wipe dry.

Page 24

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 22 of 26

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

If corrosion or rusting is noticed, remove with a non-abrasive commercial cleanser and water. Rub

stained areas in the same direction as the existing grain. Stubborn stains may be removed with a paste

made from magnesium oxide, ammonia, and water. Wipe clean, water rinse, and dry.

Prevention

Automotive wax provides the best results in preventing corrosion on stainless steel. Simply apply wax,

let dry to a haze, and buff to a shine with a clean dry cloth. This application should protect the telephone

surface for many months as it will allow naturally re-formation of the chromium oxide layer.

DO NOT use steel wool, sandpaper, mineral acids, bleaches, or chlorine cleansers on stainless steel.

Service

Contact a regional service center for an RA# (return authorization number) if the telephone requires

service. Equipment must be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. Repairs or a replacement will be made in accordance with GAI-Tronics’

warranty policy if the equipment is under warranty. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 inside the USA or 610-777-1374 outside the USA for help identifying the Regional

Service Center closest to you.

Troubleshooting

Table 6. Troubleshooting Chart

Problem

Possible Solution

Low volume

Increase the volume level in the telephone’s programming configuration.

High volume

Decrease the volume level in the telephone’s programming configuration.

Front panel push

buttons are not

operational

• Verify the push buttons are properly configured.

• Verify power is applied to the unit.

Inputs not operational

• Check the input connections.

• Verify the inputs are properly configured.

Outputs not

operational

• Check the output connections.

• Verify the outputs are properly configured.

Cannot make or

receive calls

• Check the connection of the LAN cable.

• Verify that power is applied to the unit.

• Verify the LAN parameters have been configured properly.

• Verify the telephone has been set up on the network.

No power indication

• Check the power connections.

• If using PoE, check the operation of the PoE equipment.

Page 25

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 23 of 26

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Replacement Parts and Accessories

Table 7. Replacement Parts by Model Number

Part No.

Description

210-702

210-702BH 210-702BHAC 227-700

247-700

257-700

277-700

277-702BH

277-702BHAC

10113-020

Handset Assembly with Armored

Cord, 15-inch

◼

◼

◼

10113-021

Handset Assembly with Armored

Cord, 29-inch

◼

◼

10113-022

Hytrel® Cord Handset Assembly, 6foot

◼

◼

10113-030

Handset Assembly with Armored

Cord, 12-inch

◼ ◼

12512-001

Hookswitch/Assembly Kit (plastic)

◼ ◼ ◼ ◼

◼ ◼

◼

12512-002

Hookswitch/Assembly Kit (metallic)

◼

◼

12516-001

Replacement Mounting Screw Kit

(Phillips, #10-32 × 1 1/8-inch, 10

pack)

◼

◼

12516-002

Replacement Mounting Screw Kit

(Security, #10-32 × ½-inch carbon

screw, 10 pack)

◼

12542-002

Replacement Mounting Screw Kit

(Security, #10-32 × ½-inch machine

screw, 15 pack)

◼ ◼ ◼

◼

12542-003

Replacement Mounting Screw Kit

(Security, #10 × 1 1/4-inch threadcutting screw, 15 pack)

◼

◼

12565-701

VoIP Carrier PCBA Replacement Kit

◼

◼ ◼ ◼ ◼ ◼ ◼ ◼

◼

13707-008

Ringer, Panel-Mount

◼ ◼ ◼

◼

13707-015

Ringer, Panel-Mount

◼

◼

◼

◼

◼

Page 26

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 24 of 26

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Table 8. Available Accessories by Model Number

Part No.

Description

210-702

210-702BH 210-702BHAC 227-700

247-700

257-700

277-700

277-702BH

277-702BHAC

233-001

Model 233-001 Security Screwdriver

◼ ◼ ◼

◼

◼ ◼ ◼

230-001

Pole Mounting Kit, Rugged Phone/RF

Call Box

◼

231-001FS

Pole Mounting Kit for FS/BH Series

Telephones when installed in a No.

238-003 Enclosure

◼

◼

231-002

Pole Mounting Kit for Model 247-700

and for Model 277-700 when installed

in a No. 238-001 Enclosure

◼ ◼

232-001

Pole Mounting Kit, (22x Series)

◼

238-001

Surface-Mount Enclosure, Stainless

Steel, Standard

◼

238-003

Surface-Mount Enclosure, Stainless

Steel, BH Telephones

◼

◼

40419-011

Optional Plug-in Power Supply,

120/240 V ac input, 24 V dc output

◼ ◼ ◼ ◼ ◼ ◼ ◼ ◼ ◼

Specifications

Power

Network power............................................................. Power-over-Ethernet, 802.3af compliant (via RJ45)

Local power requirements .................................................................................................... 24–48 V dc, 6 W

Network

Topology .................................................................................................................... 10/100 BaseT Ethernet

Cabling ............................................................................... Category 5 or Category 5e UTP with RJ45 jacks

Addressing .................................................... Static IP provisioning or DHCP STUN client (NAT traversal)

Call control signaling ...................................................................... SIP (RFC3261 compliant) loose routing

Configuration ............................................................................................................... Embedded web server

Configuration file download

Direct serial connection

Password protection

Handset Audio

Analog microphone gain ........................................................................................................................30 dB

Analog earpiece gain ............................................................................................................. Default: +20 dB

Setting 2: +12 dB

Page 27

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 25 of 26

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Setting 3: 0 dB

Frequency response ........................................................................................................... 250 Hz to 6500 Hz

Frequency response flatness ................................................................................................... 3 dB minimum

THD @ 1 kHz ........................................................................................................................... 1% minimum

Inputs

Push button ............................................................................................................................ Volume control

Configurable inputs (quantity = 4) ............................................................. Internal pull-up 3.3 V dc tolerant

Outputs

Output 1 ..................................................................................................... 8 A @ 30 V ac/dc (resistive load)

Output 2 ..................................................................................................... 8 A @ 30 V ac/dc (resistive load)

Indicators

Internal on VoIP PCBA ............................................................................ Power, Heartbeat, & EACT LEDs

Mechanical

Temperature range

Operating .................................................................................. −4 ºF to +131 ºF (−20 ºC to +55 ºC)

Storage ...................................................................................... −40 ºF to 158 ºF (−40 ºC to +70 ºC)

Relative humidity ............................................................................................... Up to 95%, non-condensing

PCBA (printed circuit board assembly) ..............................................................................Conformal coated

Models 210-702/-702BH/-702BHAC

Enclosure Construction .............................................................. 16-guage (0.060 in) type 304 stainless steel

Dimensions ............................................................ 10.00 H × 5.50 W × 3.27 D in (254 × 139.7 × 83.1 mm)

Handset/cord

210-702 ....................................................................................... G-style with 29-inch armored cord

210-702BH .................................................................................. G-style with 12-inch armored cord

210-700BHAC ............................................................................ G-style with 15-inch armored cord

Weight ...................................................................................................................................... 5.5 lb (2.5 kg)

Model 227-700

Construction

Enclosure ................................................ Thick-walled cast aluminum with protective gray coating

Panel................................................................................................... 0.125-inch brushed aluminum

Dimensions ................................................ 13.50 H × 9.70 W × 6.15 D inches (342.9 × 246.4 × 156.2 mm)

Handset/cord ........................................................... G-style with 19-inch armored cord and internal lanyard

Mounting ........................................................................................................ Eight 0.39-inch diameter holes

Weight .................................................................................................................................. 14.5 lb (6.58 kg)

Model 247-700

Construction ...................................................................................................... Engineered plastic enclosure

Dimensions ......................................................... 9.50 H × 8.00 W × 6.90 D in (241.3 × 203.2 × 175.3 mm)

Handset/cord ........................................................... Hytrel® cord (6-foot) with noise-canceling microphone

Mounting ......................................................................................................... Four 0.28-inch diameter holes

Weight .................................................................................................................................... 4.8 lb (2.18 kg)

Page 28

Pub. 42004-519C

Rugged VoIP Autodial Handset Telephones Page 26 of 26

P:\Standard IOMs - Current Release\42004 Instr. Manuals\42004-519C.docx

10/19

Model 257-700

Construction ...................................................................................................... Engineered plastic enclosure

Dimensions ....................................................... 13.20 H × 9.40 W × 7.40 D in (335.4 × 238.8 × 188.0 mm)

Handset/cord ........................................................... Hytrel® cord (6-foot) with noise-canceling microphone

Mounting ......................................................................................................... Four 0.28-inch diameter holes

Weight .................................................................................................................................. 10.0 lb (4.54 kg)

Model 277-700

Construction

Front Panel .................................................. 14-gauge (0.075-inch) type 304 brushed stainless steel

Back Box ................................................... 16-gauge (0.060 in) steel with black polyurethane finish

Dimensions

Front panel ..................................................................... 12.00 H × 10.00 W in (304.8 × 254.0 mm)

Back box (overall).................................. 10.06 H × 8.43 W × 2.50 D in (255.5 × 214.1 × 63.5 mm)

Handset/cord ........................................................... G-style with 29-inch armored cord and internal lanyard

Cutout for mounting back box ...................................................... 10.13 H × 7.63 W in (257.3 × 193.8 mm)

Weight .................................................................................................................................... 7.0 lb (3.18 kg)

Models 277-702BH/-702BHAC

Construction

Front Panel ...................................................... 14-gauge (0.075 in) type 304 brushed stainless steel

Back Box ................................. 16-gauge (0.060 in) cold rolled steel with black polyurethane finish

Dimensions

Front Panel .......................................................................... 8.50 H ×7.50 W in (215.9 × 190.5 mm)

Back Box (overall) ................................... 7.62 H × 5.62 W × 2.31 D in (193.5 × 142.7 × 58.7 mm)

Handset/cord

277-700BH .................................................................................. G-style with 12-inch armored cord

277-700BHAC ............................................................................ G-style with 15-inch armored cord

Weight (approximate) ................................................................................................................. 5 lb (2.3 kg)

Approvals

Models All:

Compliance to Standard ................................................................................................. FCC CFR 47 Part 15

Models 227, 247, 257, and 277:

Safety of Information Technology Equipment ...................................................................... UL/CSA 60950

Models 227, 257, and 277 only:

Enclosure for Electrical Equipment .................................................................................................. Type 3R

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Depending upon the wiring

and features used on this device, additional precautions may be necessary not to cause harmful interference.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at their own expense.

Page 29

Warranty

Equipment. GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any

GAI-Tronics equipment supplied hereunder shall be free of defects in material and workmanship, shall

comply with the then-current product specifications and product literature, and if applicable, shall be fit

for the purpose specified in the agreed upon quotation or proposal document. If (a) Seller’s goods prove

to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above,

Buyer may return such goods to GAI-Tronics nearest depot repair facility, freight prepaid, at which time

they will be repaired or replaced, at Seller’s option, without charge to Buyer. Repair or replacement shall

be Buyer’s sole and exclusive remedy. The warranty period on any repaired or replacement equipment

shall be the greater of the ninety (90) day repair warranty or one (1) year from the date the original

equipment was shipped. In no event shall GAI-Tronics warranty obligations with respect to equipment

exceed 100% of the total cost of the equipment supplied hereunder. Buyer may also be entitled to the

manufacturer’s warranty on any third-party goods supplied by GAI-Tronics hereunder. The applicability

of any such third-party warranty will be determined by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors,

shall be performed in accordance with the standard of care with which such services are normally

provided in the industry. If the services fail to meet the applicable industry standard, GAI-Tronics will reperform such services at no cost to buyer to correct said deficiency to Company's satisfaction provided

any and all issues are identified prior to the demobilization of the Contractor's personnel from the work

site. Re-performance of services shall be Buyer's sole and exclusive remedy, and in no event shall GAITronics warranty obligations with respect to services exceed 100% of the total cost of the services

provided hereunder.

Warranty Periods. Every claim by Buyer alleging a defect in the goods and/or services provided

hereunder shall be deemed waived unless such claim is made in writing within the applicable warranty

periods as set forth above. Provided, however, that if the defect complained of is latent and not

discoverable within the above warranty periods, every claim arising on account of such latent defect shall

be deemed waived unless it is made in writing within a reasonable time after such latent defect is or

should have been discovered by Buyer.

Limitations / Exclusions. The warranties herein shall not apply to, and GAI-Tronics shall not be

responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent

caused by Buyer’s neglect, failure to follow operational and maintenance procedures provided with the

equipment, or the use of technicians not specifically authorized by GAI-Tronics to maintain or service the

equipment. THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE IN LIEU OF AND

EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER EXPRESS OR IMPLIED BY

OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Return Policy

If the equipment requires service, contact your Regional Service Center for a return authorization number

(RA#). Equipment should be shipped prepaid to GAI-Tronics with a return authorization number and a

purchase order number. If the equipment is under warranty, repairs or a replacement will be made in

accordance with the warranty policy set forth above. Please include a written explanation of all defects to

assist our technicians in their troubleshooting efforts.

Call 800-492-1212 (inside the USA) or 610-777-1374 (outside the USA) for help identifying the

Regional Service Center closest to you.

(Rev. 10/06)

Loading...

Loading...