Page 1

Hubbell Industrial Controls, Inc.

EUCLID™ PBP PENDANT

PUSHBUTTON STATIONS

ASSEMBLY AND PARTS INFORMATION

INSTRUCTIONS

2020

Publication No. 132

January 1985

Repl.: January 1984

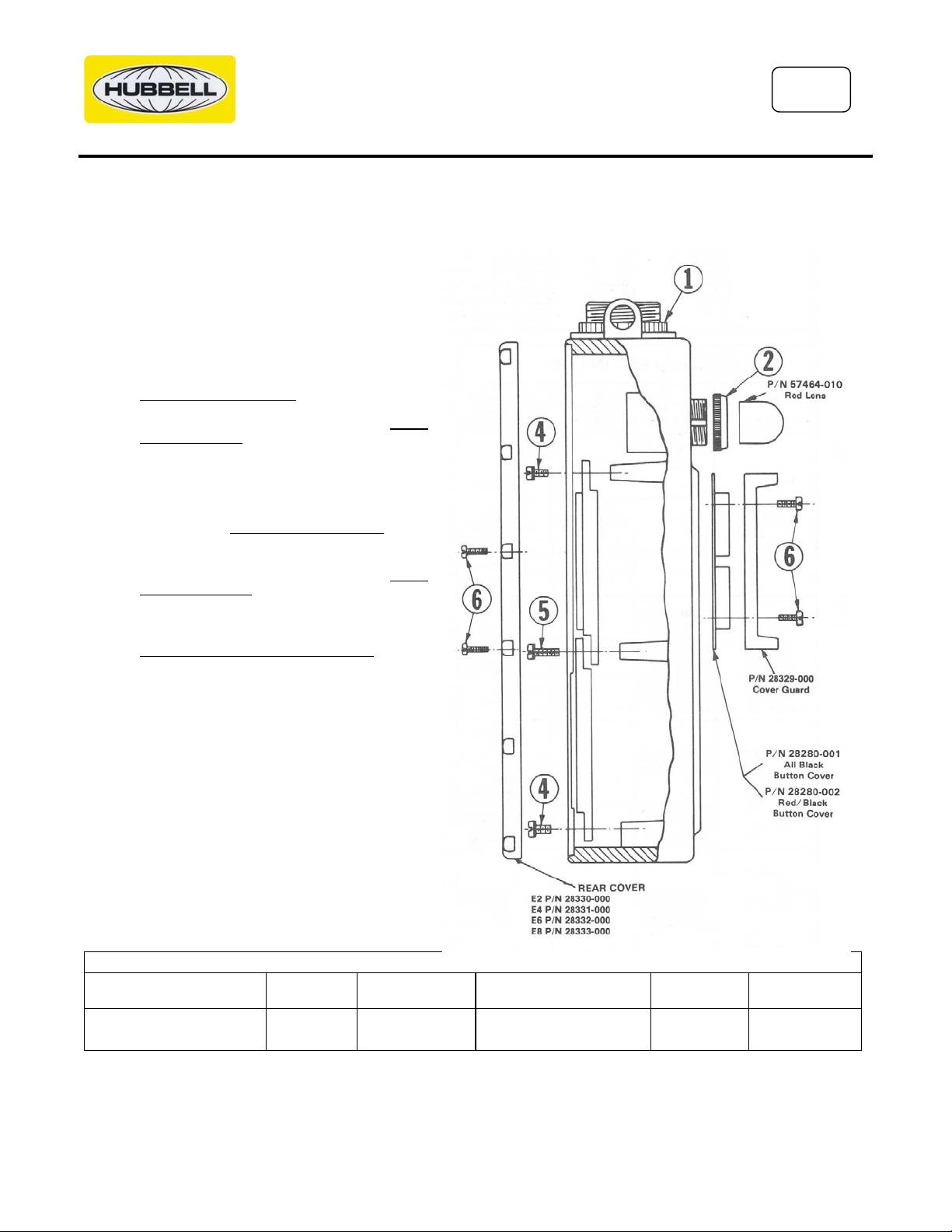

Step #1 Position hanger bracket (Item 1) as required and

Step #2 Pilot light assembly (Item 2) if used -- push out plug

Step #3 *Install button assembly (not Pictorially shown).

Step #4 *Install terminal board with button assembly working

Step #5 *Use 8-32 x 5/8" (P/N 47661-100) "sems" screws

Step #6 Use 8-32 x 1/2" (P/N 47243-059) pan head screws

tighten locking nut 1/3 turn past finger tight.

(P/N 28338) from rear. Insert light assembly. Insert

pilot light legend plate. Install locking ring.

Align keying tabs and holes and press push button

assembly into terminal boards. Tighten hold down

screws. (Not used on MS2 & MS5). AVOID

OVERTIGTENING

from top to bottom. Use 8-32 x 1/2" (P/N 47661-

098) "sems" screws (Item 4) where single thickness

terminal board is fastened. Observe "Top" marking

on each board. AVOID OVERTIGHTENING

(Item 5) where two terminal boards overlap. AVOID

OVERTIGHTENING

(Item 6) to install button guards and back cover.

CAUTION: DO NOT OVERTIGHTEN THESE

SCREWS. Recommended torque is 10 in. lbs. To

12 in. lbs. Maximum. A slight rubber bulging is

allowed.

* Where direct wired push buttons are used,

Steps #3, #4, & #5 do not apply.

DESCRIPTION

Pilot Light 120v 60 Hz AC

Pilot Light 240v 60 Hz AC

CATALOG

NUMBER

PL1

PL2

PILOT LIGHTS

LAMP

PART NO.

57465-015

57465-015

DESCRIPTION

Pilot Light 120V DC

Pilot Light 240v DC

CATALOG

NUMBER

PL3

PL4

LAMP

PART NO.

57465-043

57465-007

Page 2

ENCLOSURE DIMENSIONS

MOTION A

1*

2 Buttons

2

4 Buttons

7-

13-

3

6 Buttons

4

8 Buttons

22-

18" 5-

APPROX. WT.

ASSEMBLED

7

/8"2-

11

/16"4-

5

/16"7 lbs. E8

1

/2 lbs. E2

1

/2 lbs. E4

1

/2 lbs. E6

CATALOG NO.

* Pilot light is not available on 1 motion enclosure

CONTACT

INTERRUPTING

RATINGS

MULTI-SPEED

SINGLE BREAK

A.C.

35% PF

D.C.

IND

SINGLE SPEED

DOUBLE BREAK

A.C.

35% PF

D.C.

IND.

120v

240v6A3A

125v

250v

.4A

.2A

120v

240v6A3A

125v

250v

1.1A

.55A

SINGLE SPEED INSERT

SYMBOL PLUG-IN*

MOMENTARY

N.O.

--

-- MAINTAINED DWS

MOMENTARY

N.O. & N.C.

MAINTAINED

N.O. & N.C.

MAINTAINED

MOMENTARY

LIFT/DROP

MOMENTARY

MAINTAINED

MOMEMTARY

START-STOP

RESET-STOP

MOMENTARY

STOP-START

STOP-RESET

DESCRIPTION

MOMENTARY

DIRECT

WIRED**

-- PG1

N.O.

-- PG2

-- PG3

-- PG4 †

-- PG5 †

-- PG6 •

-- PG7 •

CAT.

NO.

DW1

TYPICAL

APPLI-

CATIONS

Crane control:

trolley, bridge

& hoist, etc.

Start-Stop

functions

Interlocking,

crane control

Auxiliary

functions

Magnet

control

Used as a

toggle switch

and for startstop functions

Start-stop onoff functions

Stop-start offon functions

MULTI-SPEED INSERT

DESCRIPTION

SYMBOL PLUG-IN*

USED TO A

MAXIMUM

OF THREE

SPEED

POINTS

USED TO A

MAXIMUM

OF FIVE

SPEED

POINTS

CAT.

NO.

MS2

MS5

TYPICAL

APPLI-

CATION

For

multi-

speed

func-

tions

For

multi-

speed

func-

tions

† PG4 and PG5 inserts have one button maintained and one button momentary.

* Terminal Base Cat. TB2 required for each plug-in insert PG1, PG2, PG3, PG4, PG5,

PG6, PG7 and MS2. Terminal Base TB5 required for MS5 insert.

**Terminal Base not required with direct wired unit.

• "Power On-Off" buttons recommended to comply with provisions of NEMA ICS 3-442.15

Hubbell Industrial Controls, Inc.

A subsidiary of Hubbell Incorporated

4301 Cheyenne Dr., Archdale, NC. 27262

Telephone (336) 434-2800 • FAX (336) 434-2803

http://www.hubbell-icd.com

Sales@hubbell-icd.com

Loading...

Loading...