Page 1

SIZE 2, 3, 4, 5, 6, & 6A

SPECIFICATIONS

4220

Hubbell Industrial Controls, Inc.

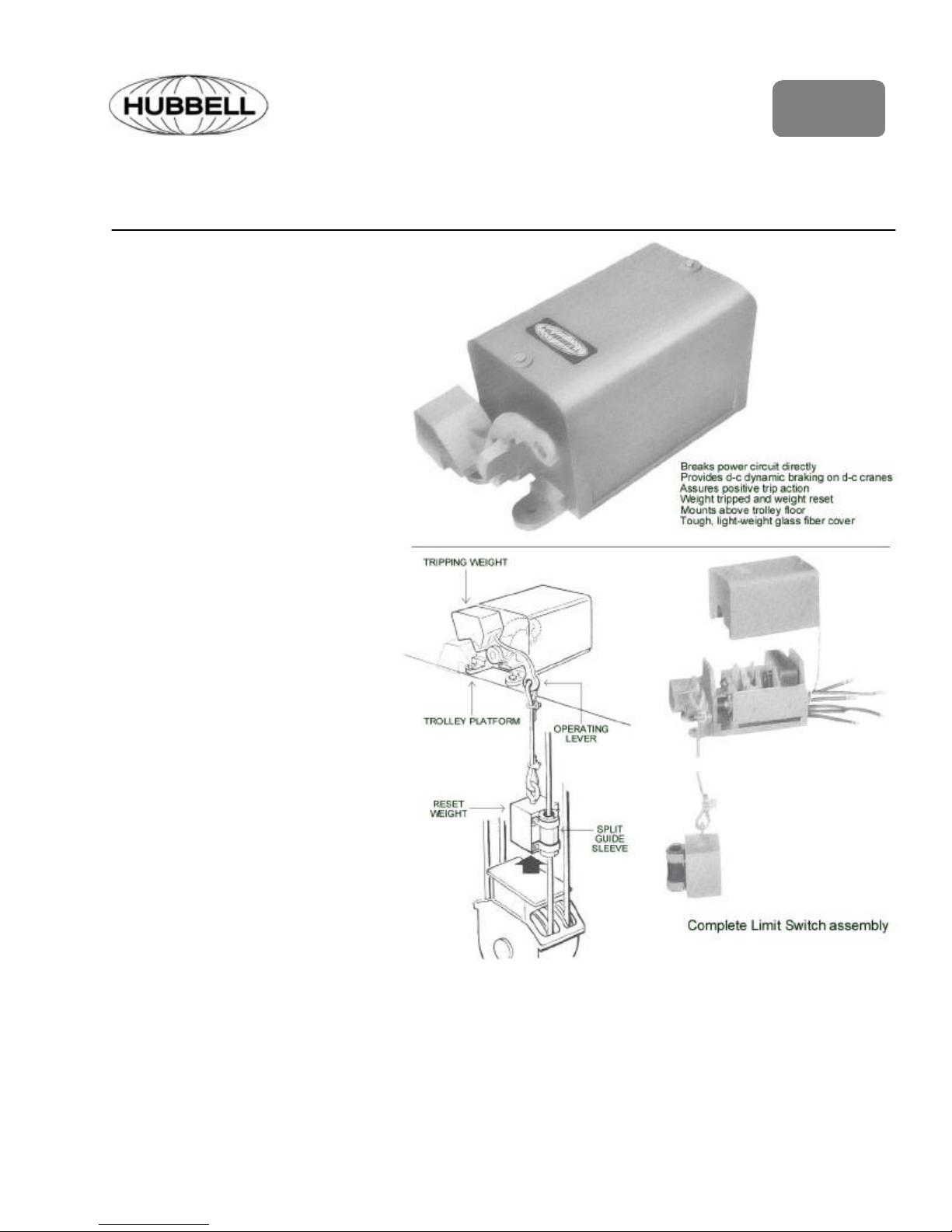

EUCLID™ AC & DC POWER LIMIT SWITCHES

General Information

D-C Limit Switches are devices

that are used to interrupt the main

power circuit, setting up a dynamic

braking circuit that quickly stops

hook travel with a minimum of drift.

A-C Limit Switches are similar in

construction to D-C Limit Switches.

The difference is in operation. A-C

Limit Switches disconnect two

power lines to the hoist motor

which then is stopped by a magnetic brake.

♦ Positive trigger lock-out

♦ Direct action contact open-

ing and closing

♦ One-piece movable contacts

♦ Exclusive arc transfer action

♦ Sturdy housing

♦ Safety chain on cover

♦ Clearly marked leads

♦ Rugged construction

♦ Oversize ball bearings

November 2010

Repl. June 1994

Application

Euclid A-C and D-C Crane Power

Limit Switches provide dependable

protection against over-hoisting

problems such as damage to the

trolley frame and hoising mechanism. In case of over-travel, these

Limit Switches disconnect the hoist

motor from the line, preventing

further hoist motion.

Operation

For dc operation the Power Limit

Switch is mounted on the trolley

floor of the crane. When the hook

block rises into the danger zone, it

lifts the suspended reset weight.

As the load of the reset weight is

removed from the operating lever,

the tripping weight (an integral part

of the operating lever) operates the

switch. Normally closed power

contacts are opened, normally

open dynamic braking contacts are

closed through a resistor. The

motor armature and series brake

are disconnected from the supply

line. The armature, series field and

braking resistor are connected in

series. RESULT: Setting of the

series holding brake and dynamic

breaking for a quick stop.

Reversing the crane controller lowers the hook to return the Limit

Switch to the “run” position by

means of the suspended reset

weight.

For ac operation, when the Power

Limit Switch is tripped, the shoe

brake is applied and the load is

stopped. The load cannot be

Hoisted when the Limit Switch is

tripped, but Lowering can be performed as usual because the lowering circuit is unaltered.

Page 2

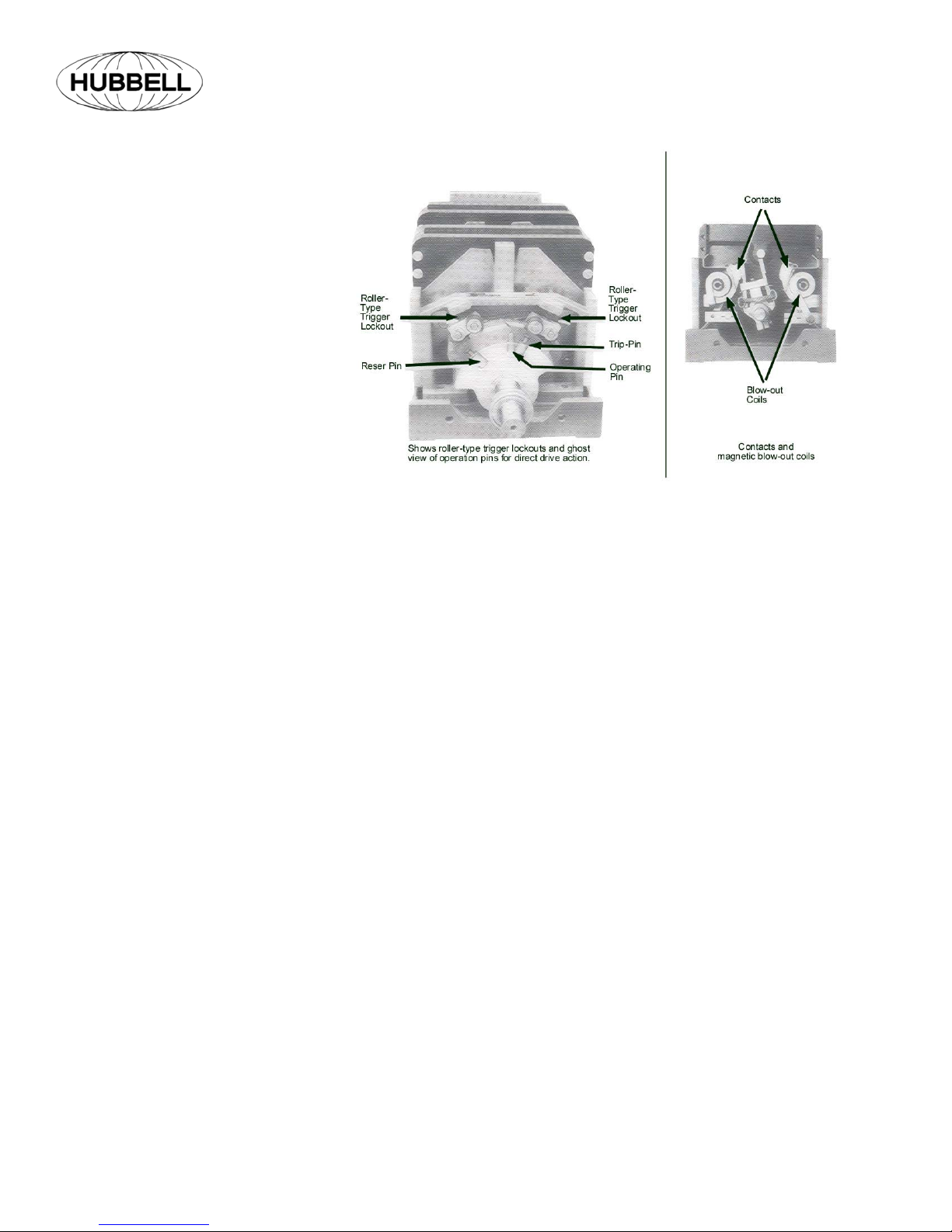

Description

Positive trigger lock-out

Quick make-and-brake contacts, which

directly handle the motor circuit, are

locked in position until tripped. The

roller-type trigger lockouts prevent

positively any operation of the Limit

Switch until the full power of the hightensile, oil-tempered, magnafluxed

spring is available to assure extremely

fast operation for either tripping or resetting. Operation in any intermediate

position of the operating lever is impossible.

Direct contact opening and closing

In the remote possibility of spring failure, the contacts are operated by the

direct drive action of the tripping and

reset weights. In tripping, as the reset

weight causes the trip pin to engage

the operating pin to operate the contacts. In resetting, the reset-pin does

the job.

One piece movable contacts

The low inertia of these contacts practically eliminates any contact bounce.

Exclusive arc transfer system

This arc transfer system combined with

the shape of the arc chamber allows

greater arc interrupting in a smaller

space. The arc is confined to a controlled path for more efficient extinguishing. No destructive burning of the

contacts can occur as the arc is transferred to the rearmost part of the magnetic blowout coil guards and to the

central rod conductor in the arc shield.

A smaller Limit Switch is made possible.

Sturdy Housing

Size 4, 5, 6, & 6A cases are of cast

iron. Size 2 and 3 cases are molded

fiberglass. The cover is of tough glassreinforced polyester resin. It is easily

removed for ready access to the contacts.

Safety chain

The insulated cover is securely fastened to the case by means of a safety

chain to prevent loss when removed

from the case.

Clearly marked leads

Flexible leads for external connections

extend through snug-fitting neoprene

bushings in the back of the cast-iron

case. They are clearly marked to

speed installation.

Rugged Construction

High-quality materials reduce maintenance. All parts are of non-corrosive

materials. Contacts are hard-drawn

copper, except for sizes 3 & 6A which

use silver faced tips. The shaft is

stainless steel. All current-carrying

parts are copper or brass. Contact and

shunt fastening screws are stainless

steel.

Ball Bearings

Four oversize, double-sealed ball

bearings are permanently lubricated to

minimize friction and reduce maintenance.

Early Break Auxiliary (EBA)

The EBA option is available for crane

hoists that are controlled with AC or

DC drives. The EBA contacts (DPDT)

operate prior to the power contacts,

thus providing a signal to turn off the

drive before motor power interruption.

Installation

Euclid™ Type 4220 Crane Power Limit

Switches are easily field installed.

Mount horizontally on top of the trolley

frame of the hoist, with mounting feet

down. Install the split-sleeve suspended weight guide around the deedended cable. A bracket or striker plate

may be attached to the hook block, if

necessary, to lift the suspended weight

when hoising. Steel cable is furnished

for connection the suspended weight to

the operating lever.

D-C Units Only

The operating lever is adaptable for

either right or left-hand operation. Unless otherwise specified, right-hand

operation is furnished. Change in installation for left-hand operation can be

made either at the Factory or in the

field. Terminal markings only are affected. Refer to wiring diagram for

correct connections.

Resistors For D-C Limit Switches

Euclid™ Type K-exclusive continuous

wound, corrosion resistant, nonbreakable resistors, are specifically

designed for use with Euclid™ Type

4220 Hoist Limit Switches. See Price

List 4220.

Page 2

Page 3

SIZE A B

2 & 3 9-7/8 1-3/4 5-1/2 12-5/8 5-1/2 3-7/8 8-1/16 5-1/8 1-5/8 4-1/2 1/2 5-1/4 5 1-7/16 1-7/16 1-5/8 18 5 3-1/2 13/32 9/16 1/4

4 14-1/16 2-1/4 8-5/8 17-7/8 8-1/8 7-3/8 11-1/4 6-3/4 2-3/8 6-3/4 1-1/2 7-5/8

5 18-3/16 3 12-1/2 21-1/4 11 10-1/4 22-5/16 9-1/2 2-7/8 8-3/4 2-1/4 9-7/8 8-3/8 3

6 & 6a 24-13/16 7-1/2 18-1/4 27-3/4 16-7/8 15 22-5/16 14 3 11-1/2 2-3/4 13-1/2 7-1/4

NOTE: Catalog dimensions are not to be used for construction purposes. Prints will be furnished upon receipt of your order with your request for prints.

C

E

D

F G H J K L M N P R S T U V W X Y

6-

1-3/4 3 2-1/2 21 5-1/2 4 9/16 1/2 3/4

11/16

3-

3-3/4 27 7 5 9/16 5/16 1-1/8

11/16

2-

13/16

2-

3

27 9 6 13/16 7/16 1-1/2

13/16

APPROXIMATE WEIGHT IN POUNDS

PART NUMBER SIZE

4220-71220-001

4220-71221-001

4220-72530-001

4220-72531-001

4220-71240-001

4220-71241-001

4220-71250-001

4220-71251-001

4220-71260-001

4220-71261-001

4220-71260-003

4220-71261-003

2

3

4 70 98 100 128

5 170 210 225 265

6

6a

LIMIT SWITCH WITHOUT CABLE,

FITTINGS AND WEIGHT

LIMIT SWITCH WITH

CABLE, FITTINGS AND WEIGHT

NET BOXED NET BOXED

28 40 50 64

300 360 370 420

Page 3

Page 4

LIMIT SWITCH RESISTORS

FOR USE WITH DYNAMIC LOWERING CRANE HOISTS

250 VOLTS D.C.

DC LIMIT SWITCH RESISTORS

230/250 VDC, ENCLOSED Disc.

FOR USE WITH DYNAMIC LOWERING HOISTS Sch E37

HP

RANGE

5 – 10

11 – 13.5

14 – 26

27 – 33

34 – 45

46 – 65

66 – 100

101 – 135

136 – 200

201 – 265

PART

NUMBER

69453-069

69453-070

69453-071

69453-072

69453-073

69453-074

69453-075

69453-076

69453-077

69453-078

ABCDE

12.75”

15.50”

15.50”

15.50”

15.50”

15.50”

18.25”

21.00”

27.00”

27.00”

13.37”

13.37”

13.37”

13.37”

13.37”

13.37”

13.37”

13.37”

13.62”

13.62”

DIMENSIONS

12.00”

14.75”

14.75”

14.75”

14.75”

14.75”

17.50”

20.25”

20.25”

20.25”

NOTE: Duplex DC Power Limit Switches require two

Sets of L.S. Resistors

11.12”

11.12”

11.12”

11.12”

11.12”

11.12”

11.12”

11.12”

6.00”

6.00”

6.06”

6.06”

6.06”

6.06”

6.06”

6.06”

6.06”

6.06”

9.75”

9.75”

ER-694-2M © 1994

Printed in U.S.A.

Hubbell Industrial Controls, Inc.

A subsidiary of Hubbell Inc.

4301 Cheyenne Dr., Archdale, NC 27263

Telephone (336) 434-2800 • FAX (336) 434-2803

http://www.hubbell-icd.com

sales@hubbell-icd.com

Loading...

Loading...