Page 1

IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety precautions

should always be followed including the following:

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

1. Do not use outdoors.

2. Do not mount near heaters or hot surfaces.

3. Equipment should be mounted in locations and at heights where it will not

readily be subjected to tampering by unauthorized personnel.

4. The use of accessory equipment not authorized by the manufacturer may

cause an unsafe condition.

5. Do not use this equipment for other than its intended purpose.

6. Service of this equipment should be performed by qualified service personnel.

Emergency Lighting And Power Equipment For Use In Damp Locations

Damp location listed units are suitable for installation in:

1. Interior locations subject to moderate degrees of moisture, such as some

basements, some barns, some cold-storage warehouses, and the like.

2. Partially protected locations under canopies, marquees, roofed open

porches and the like.

SAVE THESE INSTRUCTIONS

Final Assembly

1. Dress wires neatly to prevent pinching.

4. Energize unit. Charge a minimum of

24 hours prior to testing.

5. Press test switch and hold. Aim lamp

heads for proper light distribution.

2. Align housing slots over

back plate tabs.

3. Pivot housing and

snap closed.

TROUBLE SHOOTING

AC-On Light does not illuminate

• Check AC wiring connections.

Emergency lamps do not work

• Battery is shipped disconnected. Connect

red lead from PC board to positive (+)

battery terminal and

charge before testing.

• Make sure charger board is properly seated.

• Check wiring connections.

MAINTENANCE

Units should be tested and maintained in

accordance with National Electrical Code and

NFPA 101 Life Safety Code requirements. It is

recommended that emergency lighting units be

tested for 30 seconds once a month and for 90

minutes once a year.

RECYCLING INFORMATION

All thermoplastic parts

are recyclable.

All cartons contain recycled

materials. Please recycle.

NOTICE:

Units contain rechargeable lead-acid or

nickel-cadmium batteries which must be

recycled or disposed of properly.

LAMP REPLACEMENT

CAUTION: Allow defective lamp to cool

completely before attempting replacement.

1. Remove plastic lamp lens by prying

carefully with screwdriver at arrow

locations.

2. Pull defective lamp from lighting head

assembly and unplug lamp from socket.

3. Plug replacement lamp into socket and

install lamp into lighting head assembly.

4. Re-install lamp lens.

Wedge-base

incandescent lamp

Lamp lens

2-pin lamp socket

Installation Instructions

CV and

NV Series

Emergency Lighting Units

1300865, 1300866

1300867, 1300868

1300869, 1300909

Hubbell Lighting, Inc. Life Safety Products • www.dual-lite.com • www.cornerstone-lsp.com

Copyright© Hubbell Lighting, Inc., All Rights Reserved • Specifications subject to change without notice.

Printed in U.S.A. 0603189 6/05

Page 2

INSTALLATION INSTRUCTIONS

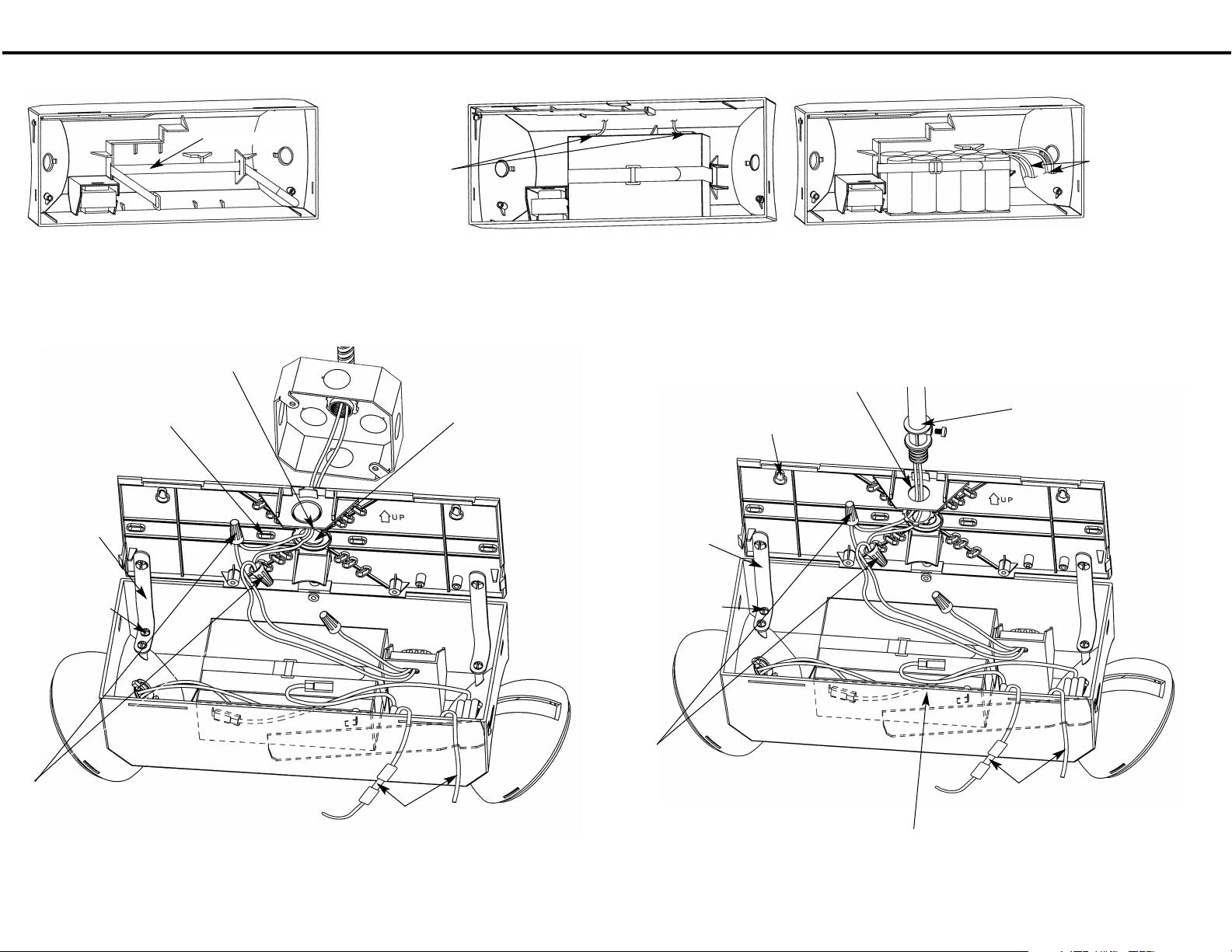

Wall Mount – Back Power Feed

Wall Mount – Surface Wiring (Top Power Feed Only)

1. Remove center

3

/4” KO in back plate.

1

.

Remove both keyhole KO’s in back

plate and mount to wall.

4. Attach unit

housing to

back plate

by plastic

hinge straps

provided.

7. Connect remote lighting load to yellow

and (fused) blue pigtail leads provided

(remote capacity models only).

5. Connect building wires to transformer leads.

• Black and white wires (120V)

(Cap off red wire)

• Red and white wires (277V)

(Cap off black wire)

Security

screw. See

“IMPORTANT”

note below.

3. Feed wires through center

KO and mount back plate to

electrical box.

3

.

Secure conduit

(or surface raceway)

to KO and feed wires.

2. Remove appropriate back plate KO's

for electrical box screws.

2. Remove conduit entry KO at top

flange of back plate.

5. Connect building wires to transformer leads.

• Black and white wires (120V)

(Cap off red wire)

• Red and white wires (277V)

(Cap off black wire)

7. Remove conduit arch KO in the top of

the unit housing.

6. Connect remote lighting load to

yellow and blue (fused) pigtail leads

(remote capacity models only).

4. Attach unit

housing to

back plate

by plastic

hinge straps

provided.

Security

screw. See

“IMPORTANT”

note below.

IMPORTANT: Install security screw if additional protection against tampering is desired. Use pointed tool to remove KO at bottom center of unit chassis. After closing unit, install security screw through bottom KO and tighten.

To complete installation, see Final Assembly instructions on back page.

Battery Installation

Lead-Calcium Battery Models

Nickel-Cadmium Battery Models

On models shipped with battery uninstalled, check that

battery security strap is positioned as shown above.

Battery Security Strap

1) Place battery in housing as shown above in front of security

strap.

2) Fasten by tightening security strap.

Battery Connections:

Connect yellow circuit board

lead to battery negative (–)

terminal.

Note: On factory installed

batteries, yellow battery lead

is shipped connected.

Connect red circuit board

lead to battery positive (+)

terminal.

Battery Connections:

Connect battery harness

leads from circuit board to

corresponding leads from

battery assembly.

1) Remove double-sided tape protective layer on bottom of

battery assembly.

2) Position battery in housing in front of security strap as

shown above and press battery firmly in place.

3) Fasten by tightening security strap.

Loading...

Loading...