Page 1

®

HUBBELL CABLETRAK

Installation Instructions

NOTICE: READ INSTRUCTIONS BEFORE INSTALLING THIS DEVICE

1. GENERAL INFORMA TION

CABLETRAK

®

components require no special tools for installation or servicing. Y ou will only need a 1/4" (6 mm) wide flat tip screwdriver approxi-

mately 6" (15 cm) long.

While most travel should be along the primary axis, CABLETRAK

®

can also provide travel along a secondary axis, see fig. 1-1 through 1-3. This

feature makes it ideal for use on robots and other machines. CAUTION: Travel along third axis will damage track.

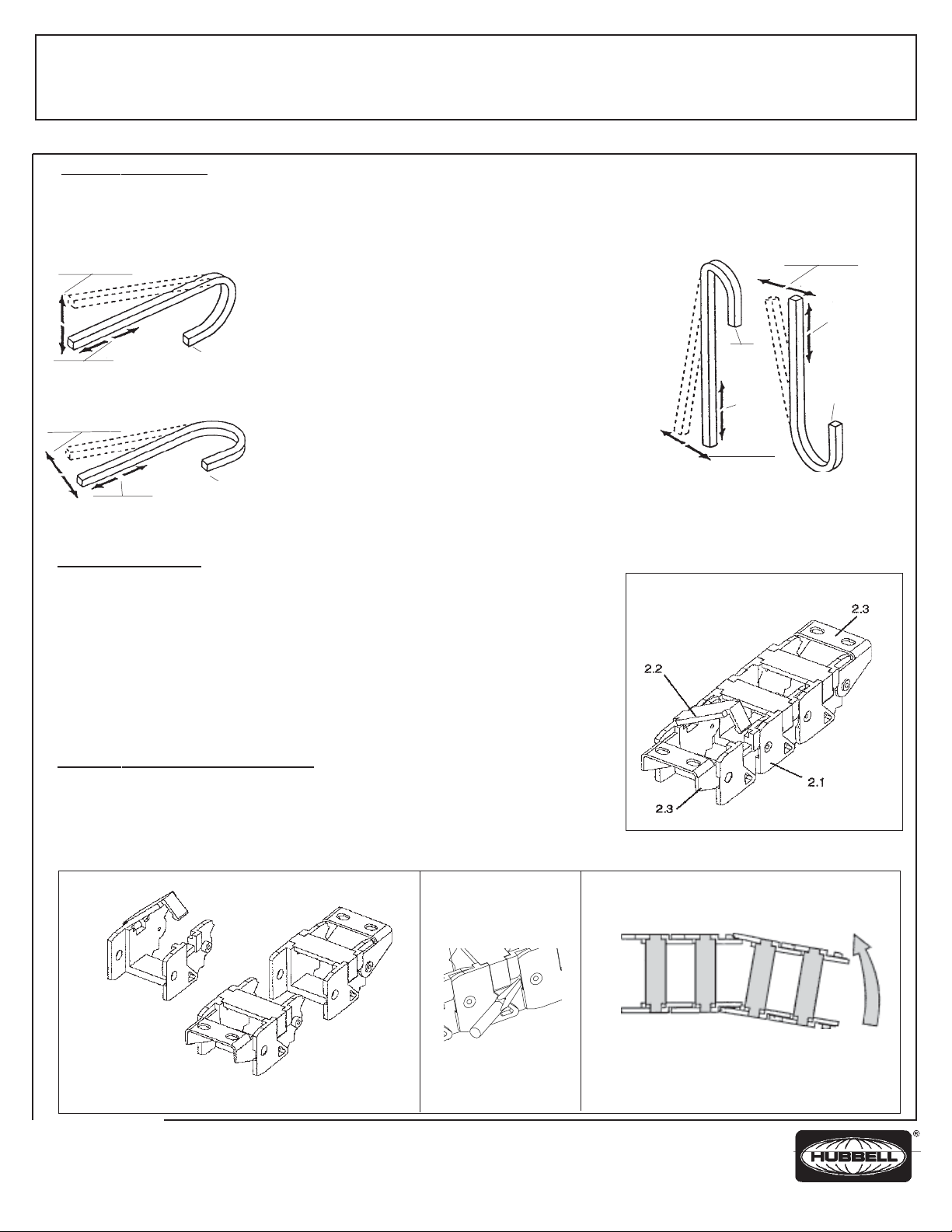

SECONDARY AXIS

Fig. 1-1

Usual “upright” mounting position provides

travel along both horizontal (primary) and

vertical (secondary) axes.

Fig. 1-2

PRIMARY

AXIS

SECONDARY AXIS

FIXED

END

Flat “lying down” position provides travel

PRIMARY AXIS

FIXED END

along two horizontal axes. In this application, CABLETRAK

in tray; consult factory.

®

must be supported

Fig. 1-3

Extended vertical travel can be achieved by mounting

CABLETRAK® in one of the positions shown above. Note that

travel along one horizontal axis is still possible.

2.

PART IDENTIFICATION (See Fig. 2)

2.1 Link Frame - U-shaped body with a wide ribbed beam molded integrally with the side plates

having holes and accurate slots or holes and pins.

FIG. 2

2.2 Retaining Bar - Removable ribbed bar located at top (open end) of the link frame and held

in place by a hook at one end and a clip at the other end. The bars are factory installed, so

the link compartment may be accessed from one side of the CABLETRAK

when removed, they can be flipped end for end so access is at the other side of the

CABLETRAK

CABLETRAK

®

. This is a unique feature to help ease compartment access of an installed

®

. NOTE: Removable retaining bars not available on model types HCT10114

®

only. However,

and HCT10219.

2.3 Mounting Brackets - Plated steel brackets are secured at both ends of the CABLETRAK

®

for a strong, reliable assembly. The brackets can be pivoted 90° for face type mounting or

inverted.

3. REMOVAL AND ASSEMBLY PROCEDURE

Determine the link(s) to be removed and simply insert the blade of a 1/4" (6 mm) wide flat tip screwdriver

between the side-walls and gently pry apart until the outer wall pulls free from the link. See Figure 3-2.

Carefully repeat the same at the opposite side of the joint and pull links apart.

To assemble, match locking posts on link frame side walls, with slots in link frame side walls and

snap into place. See Figure 3-3. NOTE: When adding links, be sure to install them in the same

orientation as the existing CABLETRAK

®

(i.e. all retaining bars on same surface).

FIXED

END

PRIMARY

AXIS

SECONDARY

AXIS

SECONDARY AXIS

PRIMARY

AXIS

FIXED END

Fig. 3-1 Fig. 3-2 Fig. 3-3

Individual Links may be removed

using a small screwdriver .

PD1465 (P AGE 1) Rev. 10/98

SNAP

Page 2

4. CABLETRAK® INSTALLATION

The CABLETRAK

while working with the CABLETRAK

Lay the CABLETRAK

®

carrier system will require a level, rigid support for proper operation. Ambient temperature range of +50°F to +90°F is recommended

®

on a fiat surface with the flexing radius facing upward (See Figure 4-1). Locate the clip end of the retaining bars; largest

®

.

protrusion on bar which utilizes the entire notch area in link side-wall. Release the bar clip gently with 1/4" (6 mm) wide flat tip screwdriver by a

twisting motion beneath the end of the clip in the lower notch area until it “snaps” free and the bar swings upward. CAUTION: Too much leverage

could break-off the clip; so pry up only enough to release it from the catch.

®

Lay the cables/hoses in the CABLETRAK

bars for access at either side of CABLETRAK

compartment, allowing sufficient length at each end for connections (See Figure 4-2). Reinstall the retaining

®

as follows:

Hold the bar vertically. Carefully insert the hook end into the upper area of the notch in the link side-wall. Swing the bar down and center the clip end

over the notch in the opposite link side-wall. Gently apply an increasing downward force until the clip “snaps” into place (see Figure 4-3). DO NOT

hammer with fist or other instrument as they may damage the bar. The top of the link side-walls and the ret aining bar should be flush.

Secure the fixed end mounting brackets to the rigid support. Locate and drill the mounting holes using the brackets as a template if desirable. Fasten

the movable end mounting brackets to the machine arm in direct (plum) alignment with the fixed end brackets.

Complete all cable/hose terminations. NOTE: The cables/hoses must not be twisted and shall be free of kinks or other irregularities. The basic rule for

the maximum allowable cable/hose area utilized within the CABLETRAK

per diameter to allow for dimensional tolerances of the cables/hoses and to insure freedom of movement to prevent erratic CABLETRAK

®

compartment for uniform arrangements is 20 percent clearance or greater

®

operation

and premature cable/hose failure.

CAUTION: Premature cable/hose failure can result in hazards to personnel. Check to ensure that the cable/hoses are suitable for the intended

application at the minimum bend radius of the CABLETRAK

Operate the machine slowly throughout the total travel stroke to insure the CABLETRAK

Adjust cable/hose tension to help prevent twisting and premature wear. They must lay within the loop section of the CABLETRAK

condition — not pulled tight against the trak retaining bars — and follow a straight path through the entire length of the CABLETRAK

hoses at both ends of the CABLETRAK

®

, near the mounting brackets to prevent any movement relative to the CABLETRAK®. Do not terminate cable/

®

. Check cable/hoses periodically for excessive wear or damage.

®

is running true and the travel limits are not exceeded.

®

in a relaxed

®

. Secure the cable/

hoses or make electrical connections inside of the CABLETRAK®. Do not install incompatible products in the same length of CABLETRAK®. (e.g.

hydraulic hoses with current-carrying cables).

®

NOTE: For extended runs, a cable retaining tray to guide and support the lower CABLETRAK

section is recommended. The maximum unsupported

travel distance is 9 ft. (2.75 m) without sag and 13.5 ft. (4.1 m) with sag.

5.

MAINTENANCE INSTRUCTIONS

No lubrication is required. T o clean the CABLETRAK

®

, periodically wash-down with water (do not allow to freeze) or blow dirt and debris away with

air pressure.

®

Periodically inspect for cable/hose wear, CABLETRAK

wear and breakage, mounting brackets secureness and cable/hose terminations.

Unlock Tab... Fig. 4-1 Access Cables/Hoses... Fig. 4-2 Lock Tab... Fig. 4-3

Locking tab securely holds retaining bar in

position but unlocks easily with a screwdriver

using a twisting motion.

Easy access is important, especially for

preassembled cable/hose sets involving large

O.D. plugs, receptacles, and couplings.

To lock the Retaining Bars, engage the pivot

and push the locking tab securely into place.

PD1465 (PAGE 2) Rev. 10/98

Page 3

®

CABLETRAK

Directives de montage

AVIS - LIRE CES DIRECTIVES AVANT DE RÉALISER LE MONTAGE

1. RENSEIGNEMENTS GÉNÉRAUX

Le CABLETRAK

Bien que tous les déplacements devraient être dans l’axe primaire, CABLETRAK

1-1 à 1-3. Cette possibilité le rend utile pour l’usage sur des robots et autres machines. ATTENTION –

endommagera le dispositif.

AXE SECONDAIRE

®

se monte et s’entretient sans outils spéciaux. Il suffit d’un tournevis à tête plate de 6 mm de largeur et de 15 cm de longueur.

DE HUBBELL

®

peut aussi se déplacer le long d’un axe secondaire. Voir les figures

Le déplacement le long du troisième axe

AXE SECONDAIRE

Fig. 1-1

Le montage habituel «droit» permet le

déplacement dans l’axe horizontal (primaire)

et dans l’axe vertical (secondaire).

Fig. 1-2

Le montage «couché» permet le

déplacement dans deux axes horizontaux.

Dans ce cas, la chenille CABLETRAK

doit être supportée par un chemin de

câble. Consulter l’usine.

®

AXE

PRIMAIRE

AXE SECONDAIRE

AXE PRIMAIRE

EXTRÉMITÉ

FIXE

EXTRÉMITÉ

FIXE

2. IDENTIFICATION DES COMPOSANTS (voir fig. 2)

2.1 Chenille – Ensemble de maillons en forme de U avec un renfort large moulé intégralement

dans les côtés, contenant des perforations et des encoches précises ainsi que des chevilles.

2.2 Barrette de retenue – Barrette nervurée amovible située sur la face supérieure de la chenille

(côté ouvert) et maintenue en place par un crochet à une extrémité et par un ergot à l’autre. Les

barrettes étant montées en usine, l’accès à l’intérieur de la chenille n’est possible que par un côté

du CABLETRAK

pour permettre l’accès de l’autre côté du CABLETRAK

facilite l’accès à l’intérieur d’un CABLETRAK

®

. Cependant, une fois enlevées, elles peuvent être tournées bout pour bout

®

®

. Ceci est une caractéristique unique qui

déjà installé. REMARQUE - Les barrettes de

retenue amovibles ne sont pas disponibles avec les modèles de types HCT10114 et HCT

10219.

2.3 Maillons de fixation – Des maillons en acier plaqué sont solidement placés aux extrémités du

CABLETRAK

®

assurant un montage sécuritaire. Ces maillons peuvent être pivotés sur 90º

pour un montage de face ou inversés.

3.

PROCÉDURE DE DÉMONT AGE ET DE MONT AGE

Repérer les maillons à enlever et insérer la lame d’un tournevis à tête plate de 6 mm sous la paroi

du maillon et la soulever par un mouvement léger de torsion jusqu’à ce qu’elle se dégage. Voir la

figure 3-2. Refaire la même chose sur le côté opposé du joint et séparer les maillons.

Pour remonter les maillons, faire coïncider les chevilles sur les parois du maillon avec les encoches

sur les parois du maillon et cliquer en place. Voir la figure 3-3. REMARQUE - Si des maillons sont

ajoutés, s’assurer qu’ils sont orientés dans le même sens que le CABLETRAK

®

existant (toutes

les barrettes de retenue sur le même côté).

AXE

PRIMAIRE

EXTRÉMITÉ

FIXE

AXE

PRIMAIRE

AXE

SECONDAIRE

EXTRÉMITÉ

FIXE

Fig. 1-3

Une course verticale prolongée est réalisable en

montant la chenille CABLETRAK® dans une des

positions montrées ci-dessus. Noter que le déplacement

dans un axe horizontal est encore possible.

FIG. 2

Fig. 3-1 Fig. 3-2 Fig. 3-3

Les maillons individuels peuvent être enlevés

au moyen d’un petit tournevis.

PD1465 (P AGE 3) Rev. 10/98

CLIQUER

Page 4

4. MONTAGE DU CABLETRAK

Le système porteur CABLETRAK

®

®

nécessite un support rigide à niveau pour fonctionner correctement. Une température ambiante située entre 10

ºC et 32 ºC est recommandée.

Déposer la chenille CABLETRAK

®

sur une surface plane avec le rayon de flexion vers le haut (Voir la figure 4-1). Repérer l’extrémité ergot des

barrettes de retenue, la plus grande saillie de la barrette qui utilise complètement l’encoche sur la paroi du maillon. Dégager doucement l’ergot en

introduisant un tournevis à tête plate de 6 mm dans le bas de l’encoche et en appliquant un mouvement de torsion sous l’ergot jusqu’à ce qu’il se

décroche et que la barrette se soulève vers le haut. A TTENTION – Une pression trop forte pourrait casser l’extrémité de la barrette. Appliquer juste la

torsion requise pour dégager l’ergot.

®

Déposer les câbles ou les tuyaux dans le compartiment de la chenille CABLETRAK

permettre leur raccordement. (Voir la figure 4-2). Remettre les barrettes en place pour accéder à l’intérieur du CABLETRAK

en les laissant dépasser suffisamment à chaque extrémité pour

®

d’un côté ou de l’autre

selon les indications suivantes.

T enir la barrette verticalement. Insérer l’extrémité crochet de la barrette dans la partie supérieure de l’encoche dans la paroi du maillon. Pousser la

barrette vers le bas pour centrer l’extrémité ergot sur l’encoche de la paroi opposée du maillon. Appuyer délicatement sur la barrette avec une

force croissante vers le bas jusqu’à ce que l’ergot s’enclenche en place. (Voir la figure 4-3). NE PAS frapper sur la barrette avec le poing ou autre

instrument, ce qui pourrait l’endommager. La barrette de retenue et le dessus de la paroi du maillon doivent être au même niveau.

Assujettir le maillon de fixation de l’extrémité de la chenille sur le support rigide en se servant du maillon comme gabarit pour percer les trous.

Assujettir le maillon de fixation de l’extrémité mobile de la chenille à la machine dans l’axe droit du maillon de l’extrémité fixe.

Compléter tous les raccordements des câbles ou tuyaux. REMARQUE – Les câbles et tuyaux doivent être exempts de torsion, de noeuds et

d’irrégularités. La règle de base pour déterminer la section d’utilisation optimale à l’intérieur de la chenille CABLETRAK

®

est de laisser un jeu de 20 %

ou plus du diamètre de chaque câble ou tuyau afin d’assurer leur liberté de mouvement et d’empêcher le déplacement erratique du CABLETRAK

ainsi que de prévenir leur défaillance prématurée.

ATTENTION – La défaillance prématurée des câbles ou des tuyaux présente un risque pour le personnel. Examiner les câbles et les tuyaux

périodiquement. S’assurer que les câbles et tuyaux conviennent à l’application et au rayon de courbure minimum de la chenille CABLETRAK

fonctionner la machine lentement sur toute la longueur de sa course afin de s’assurer que le déplacement du CABLETRAK

®

est rectiligne et qu’il ne

®

dépasse pas les fins de course.

Régler la tension des câbles et tuyaux afin de prévenir le tortillement et l’usure prématurée. Ils doivent reposer dans la boucle de la chenille

CABLETRAK

longueur du CABLETRAK

d’empêcher qu’ils se déplacent en relation avec le CABLETRAK

électriques à l’intérieur de la chenille CABLETRAK

®

– sans être tendus et sans s’appuyer sur les barrettes de retenue de la chenille – et suivre une trajectoire rectiligne sur toute la

®

. Assujettir les câbles ou les tuyaux aux deux extrémités du CABLETRAK

®

. Ne pas installer des produits incompatibles dans la même longueur de CABLETRAK

®

. Ne pas établir les raccords de tuyaux ou de câbles ni établir des connexions

®

, près des maillons de fixation, afin

®

(ex.

tuyaux hydrauliques avec câbles électriques).

REMARQUE – Dans le cas de grandes longueurs, il est recommandé d’utiliser un chemin de câble pour supporter la section basse du CABLETRAK

. La longueur de course maximum permise sans support est de 2,75 m sans fléchissement et de 4,1 m avec fléchissement.

5.

DIRECTIVES DE MAINTENANCE

La lubrification n’est pas nécessaire. Pour nettoyer la chenille CABLETRAK

®

, la nettoyer périodiquement avec de l’eau (ne pas laisser geler) ou

utiliser de l’air comprimé pour déloger la saleté et les débris.

Inspecter la chenille CABLETRAK

pas cassés. Vérifier aussi la fixation du CABLETRAK

®

ainsi que les câbles et tuyaux périodiquement pour vérifier leur état d’usure et s’assurer que les maillons ne sont

®

et les raccordements des câbles et des tuyaux.

®

. Faire

®

Lever les barrettes... Fig. 4-1 Acc ès aux câbles /tuyaux. . . Fig. 4-2 Enclencher... Fig. 4-3

L’ergot de verrouillage retient solidement la

barrette de retenue mais se dégage facilement

avec un tournevis en appliquant un mouvement

de torsion.

L’accès facile est important surtout pour les

ensembles câbles-tuyaux comportant des

fiches, des prises ou des accouplements de

grande dimension.

Pour verrouiller les barrettes de retenue,

engager le pivot et appuyer sur l’ergot pour

l’enclencher

PD1465 (P AGE 4) Rev. 10/98

Page 5

®

CABLETRAK

Instrucciones de instalación

AVISO - LEER ANTES DE INSTALAR ESTE DISPOSITIVO

1. INFORMACIÓN GENERAL

Los componentes de CABLETRAK

punta plana de 6 mm de ancho y aproximadamente 15 cm de largo.

Aunque la mayoría de la trayectoria se extienda a lo largo del eje primario, CABLETRAK® también permite el desplazamiento sobre un eje secundario,

ver las figs. 1-1 a 1-3. Esta característica lo convierte en un elemento ideal para ser usado en robots y otras máquinas.

CUIDADO - Desplazarla sobre un tercer eje provocará daños en la canaleta.

EJE SECUNDARIO

®

no requieren herramientas especiales para su instalación o mantenimiento. Sólo se necesita un desarmador de

DE HUBBELL

EJE SECUNDARIO

Fig. 1-1

La posición habitual de fijación «erguida»

permite la trayectoria tanto en el eje

horizontal (primario) como vertical

(secundario).

Fig. 1-2

La posición «acostada» permite la trayectoria sobre dos ejes horizontales. En esta

aplicación, CABLETRAK® debe apoyarse en una bandeja; consultar al fabricante.

EJE

PRIMARIO

EJE SECUNDARIO

EJE PRIMARIO

EXTREMO

FIJO

EXTREMO

FIJO

2. IDENTIFICACIÓN DE LAS P ARTES (V er la fig.2)

2.1 Eslabón-marco – elemento en forma de U con una ancha vigueta nervada moldeada

integralmente y placas laterales perforadas con orificios, ranuras y espigas que calzan con

precisión.

2.2 Barra-retén – barra nervada desmontable, situada en la parte superior (extremo abierto) del

eslabón-marco y retenida en su sitio por un gancho en un extremo y una traba en el otro. Las

barras están instaladas en fábrica de modo que sólo se pueda tener acceso al compartimiento

del eslabón por un lado de CABLETRAK

extremo por extremo, para dejar acceso del otro lado de CABLETRAK

exclusiva facilita el acceso al compartimiento de un CABLETRAK

®

. Sin embargo, una vez retiradas, pueden soltarse

®

®

. Esta característica

instalado. NOT A - Barras de

retención desmontables no disponibles con modelos de tipos HCT10114 y HCT10219.

2.3 Ménsulas de fijación – Ménsulas de acero niquelado que se fijan en ambos extremos del

CABLETRAK

®

para asegurar un montaje sólido y fiable. Las ménsulas pueden pivotar 90º

para montarlas de frente o invertirse.

3. PROCEDIMIENTO P ARA DESARMAR Y ARMAR

Determinar el eslabón o eslabones que se desea retirar e insertar simplemente la hoja de un

desarmador de punta plana de 6 mm de ancho entre las paredes laterales, apartándolas

suavemente hasta que la pared externa se desprenda del eslabón. V er la figura 3-2. Repetir la

operación con cuidado en el lado opuesto de la unión y separar los eslabones.

Para armar, hacer coincidir los puntos de traba con las ranuras en las paredes laterales de los

eslabones y calzarlos en su sitio. Ver la figura 3-3. NOTA - Al agregar eslabones, hay que asegurarse

de orientarlos en el mismo sentido que el CABLETRAK

®

existente (es decir, todas las barras de

retención del mismo lado).

EJE

PRIMARIO

EXTREMO

FIJO

EJE

PRIMARIO

EJE

Fig. 1-3

SECUNDARIO

Puede obtenerse una extensa trayectoria

vertical fijando CABLETRAK

EXTREMO

FIJO

®

en una de las

posiciones que se ilustran. Advertir que todavía

es posible la trayectoria en un eje horizontal.

FIG. 2

Fig. 3-1 Fig. 3-2 Fig. 3-3

Desarmar los eslabones utilizando un

pequeño desarmador.

PD1465 (P AGE 5) Rev. 10/98

TRABAR

Page 6

4. INSTALACIÓN DEL CABLETRAK

El sistema de transporte CABLETRAK® requiere un soporte uniforme y rígido para funcionar correctamente. Se recomienda que la temperatura

ambiente sea de +10 ºC a +32 ºC mientras se trabaja con CABLETRAK

Apoyar CABLETRAK

®

sobre una superficie plana con el radio flexible hacia arriba (Ver la figura 4-Ubicar el extremo de traba en las barras-retén; la

®

®

.

saliente más ancha en la barra que utiliza toda la zona de muesca de la pared lateral del eslabón. Desprender suavemente la traba de la barra con un

desarmador de punta plana de 6 mm de ancho aplicando un movimiento de torsión bajo el extremo de la traba en la zona inferior del eslabón hasta que

se suelte, dejando la barra en libertad. CUIDADO - Un movimiento de palanca excesivo podría quebrar la traba; hay que levantar sólo lo suficiente para

destrabarla.

®

T ender los cables/tubos en el compartimiento de CABLETRAK

Reinstalar las barras-retén para dejar acceso por ambos lados de CABLETRAK

, dejando suficiente longitud en cada extremo para las conexiones (ver la figura 4-2).

®

del modo siguiente:

Sostener verticalmente la barra. Insertar con CUIDADO el extremo de gancho en la zona superior de la muesca en la pared lateral del eslabón. Bajar

la barra balanceándola y centrar el extremo de traba sobre la muesca en la pared lateral opuesta del eslabón. Aplicar suavemente una presión

creciente hacia abajo hasta que la traba calce en su sitio (ver la figura 4-3). NO martillar con el puño ni con un instrumento, porque se puede dañar

la barra. La parte superior de las paredes laterales del eslabón y la barra-retén deben quedar al mismo nivel.

Atornillar las ménsulas de fijación del extremo fijo al soporte rígido. Ubicar y perforar los orificios de fijación usando las ménsulas como plantilla, si es

conveniente. Sujetar las ménsulas de fijación del extremo móvil al brazo de la máquina en alineación directa (a plomo) con las ménsulas del extremo

fijo.

Completar todas las terminaciones. NOT A: Los cables/tubos no deberán retorcerse ni tendrán dobleces u otras irregularidades. La regla básica para

calcular la superficie máxima admisible de cables y tubos utilizados dentro del compartimiento de CABLETRAK

dejar un 20% o más de margen por diámetro previendo las tolerancias en el tamaño de los cables y tubos, y para asegurar la libertad de movimiento

con el fin de evitar el funcionamiento errático de CABLETRAK

®

y el deterioro prematuro de cables y tubos.

®

para arreglos uniformes consiste en

CUIDADO - El deterioro prematuro de cables y tubos puede provocar riesgos al personal. Asegurarse de que los cables y tubos sean apropiados para la instalación prevista, con el radio mínimo de curvatura de CABLETRAK®. V erificar periódicamente si no se ha producido un desgaste

excesivo o daños en los cables y tubos.

Hacer funcionar lentamente la máquina en todo el trayecto para asegurarse de que CABLETRAK

®

marcha bien y de que no se exceden los límites del

recorrido.

Ajustar la tensión de los cables y tubos para evitar que se retuerzan y desgasten prematuramente. Deberán correr flojos dentro de la sección curva

de CABLETRAK

los cables y tubos en ambos extremos de CABLETRAK

dejar el extremo de cables o tubos ni hacer conexiones eléctricas dentro de CABLETRAK

®

- no quedar tirantes contra las barras-retén de la canaleta - y seguir una trayectoria lineal todo a lo largo de CABLETRAK®. Sujetar

®

, cerca de las ménsulas de fijación para evitar todo movimiento relativo a CABLETRAK®. No

®

. No instalar en un mismo tramo de CABLETRAK® productos

incompatibles (p.ej., tubos hidráulicos con cables eléctricos).

NOTA - En trayectorias extensas, se recomienda una bandeja retén de cables para guiar y sostener la sección inferior de CABLETRAK

®

. La distancia

máxima de trayecto sin apoyo es de 2,75 m sin comba y de 4,1 m con comba.

5.

INSTRUCCIONES DE MANTENIMIENTO

No se requiere lubricación. Para limpiar CABLETRAK

®

, lavarlo periódicamente con agua (no permitir que se congele) o soplar la suciedad y los

residuos con aire a presión.

Inspeccionar periódicamente el desgaste de los cables y tubos, el desgaste y roturas en CABLETRAK

®

, la firmeza de las ménsulas de fijación y las

terminaciones de los cables y tubos.

Destrabar... Fig. 4-1 Acceso a los cables/tubos... Fig. 4-2 Trabar... Fig. 4-3

La traba mantiene firme la barra en su lugar,

pero se destraba fácilmente con un desarmador,

aplicando un movimiento de torsión.

Es importante tener fácil acceso,

especialmente para los conjuntos

premontados de cables y tubos que llevan

grandes clavijas, tomacorrientes y

acoplamientos.

HUBBELL DE MEXICO garantiza este producto, de estar

libre de defectos en materiales y mano de obra por un

año a partir de su compra. Hubbell reparará o reemplazará

ei artículo a su juicio en un plazo de 60 días. Esta garantía

no cubre desgastes por uso normai o daños ocasionados

por accidente, mal uso, abuso o neqligencia. El vendedor

no otorga otras garantías y excluye expresarnente daños

incidentales o consecuenciales inherentes a su uso.

HUBBELL DE MEXlCO, S.A. DE C.V.

Av. Coyoacán # 1051 Tel.: (5)575 - 2022

México, D.F. 03100 Fax: (5)559 - 8626

Para trabar las barras-retén, calzar el pivote

y empujar la traba para que quede firme en

su sitio.

PD1465 (P AGE 6) Rev. 10/98

Loading...

Loading...