Hubbel LTC3 Installation Instructions

IMPORTANT SAFETY INFORMATION. READ AND FOLLOW ALL SAFETY INSTRUCTIONS. Follow label information

and instructions concerning Wet or Damp Locations, installation near combustible materials, insulation, building materials,

n areas subject to combustible vapors or gases. Before wiring to power supply and

All servicing or relamping must be performed by

d to avoid potential electric shock or other potential hazard.

Product must be mounted in locations and at heights and in a manner consistent with its intended use, and in

quipment not recommended by

the manufacturer or installed contrary to instructions may cause an unsafe condition. Do not block light emanating from

, screens or

Part No...........................................93122660

Series

ensure that

d

with

Pull the

while

spring

ull the reflector/light engine

holding the cylinder

queeze two

spring together and insert ends into two

Insert the reflector/light engine

assembly

draw reflector

should be taken when installing reflector

into cylinder as springs will snap into place and

engine assemblies are supplied

to all light

engine components and future upgrades. (For

compatible replacement, refer to label on

reflector/light engine assembly.)

and proper lamping. Do not install i

during servicing or relamping, turn off power at fuse or circuit breaker.

qualified service personnel. Product must be grounde

compliance with the National Electrical Code and local codes. The use of accessory e

product in whole or part, as this may cause an unsafe condition. Do not allow items such as drapes, curtains

the like to come into contact with the product or to block light from the product, as this may cause an unsafe condition.

Page 1 of 44

INSTALLATION INSTRUCTIONS

LTC3/4/6RD/SQD CYLINDER PowerHUBB

CAUTION: DO NOT ATTEMPT TO MODIFY OR REWIRE FACTORY-INSTALLED WIRING ON THE

FIXTURE. SAFETY AND PROPER OPERATION OF THE FIXTURE DEPEND ON THE INTEGRITY OF

THE WIRING.

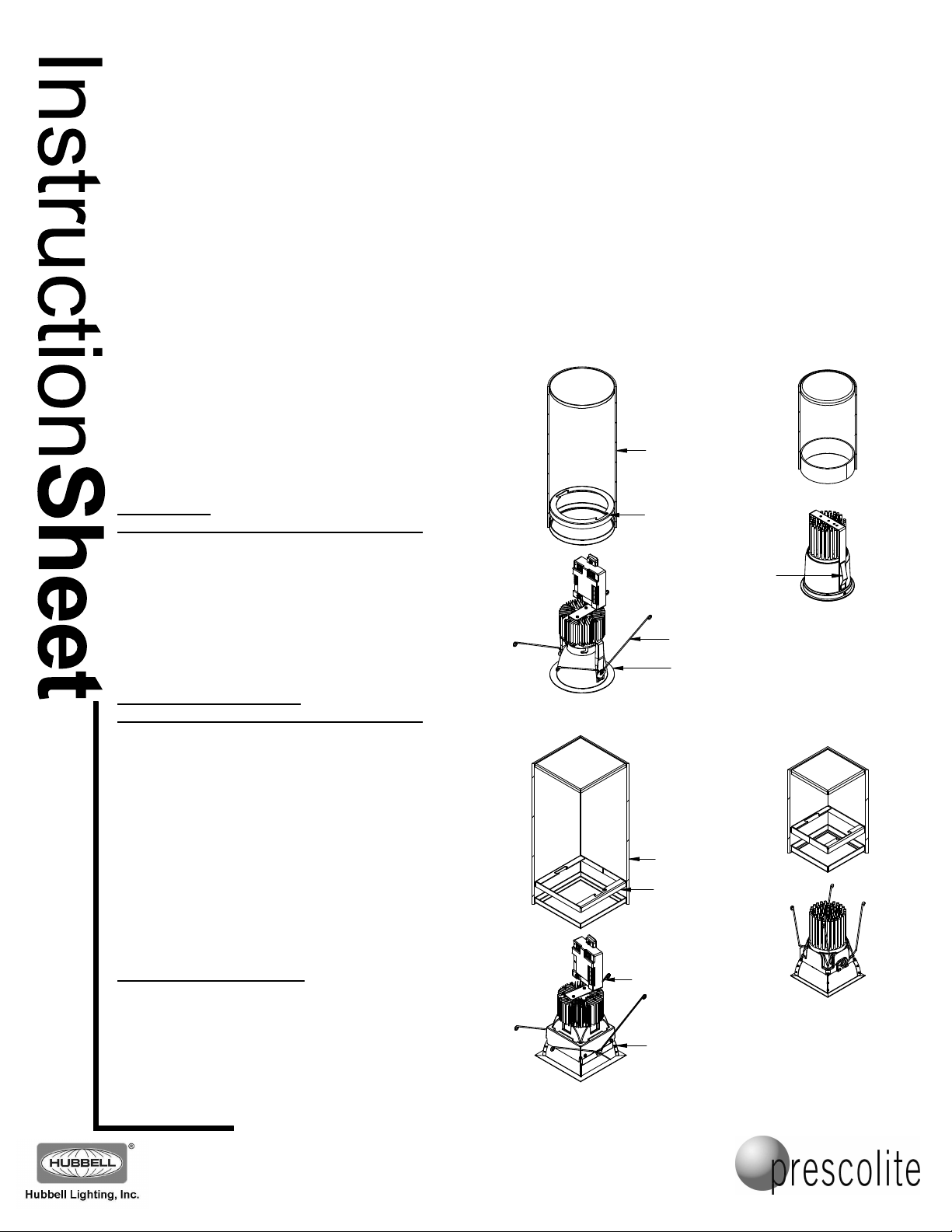

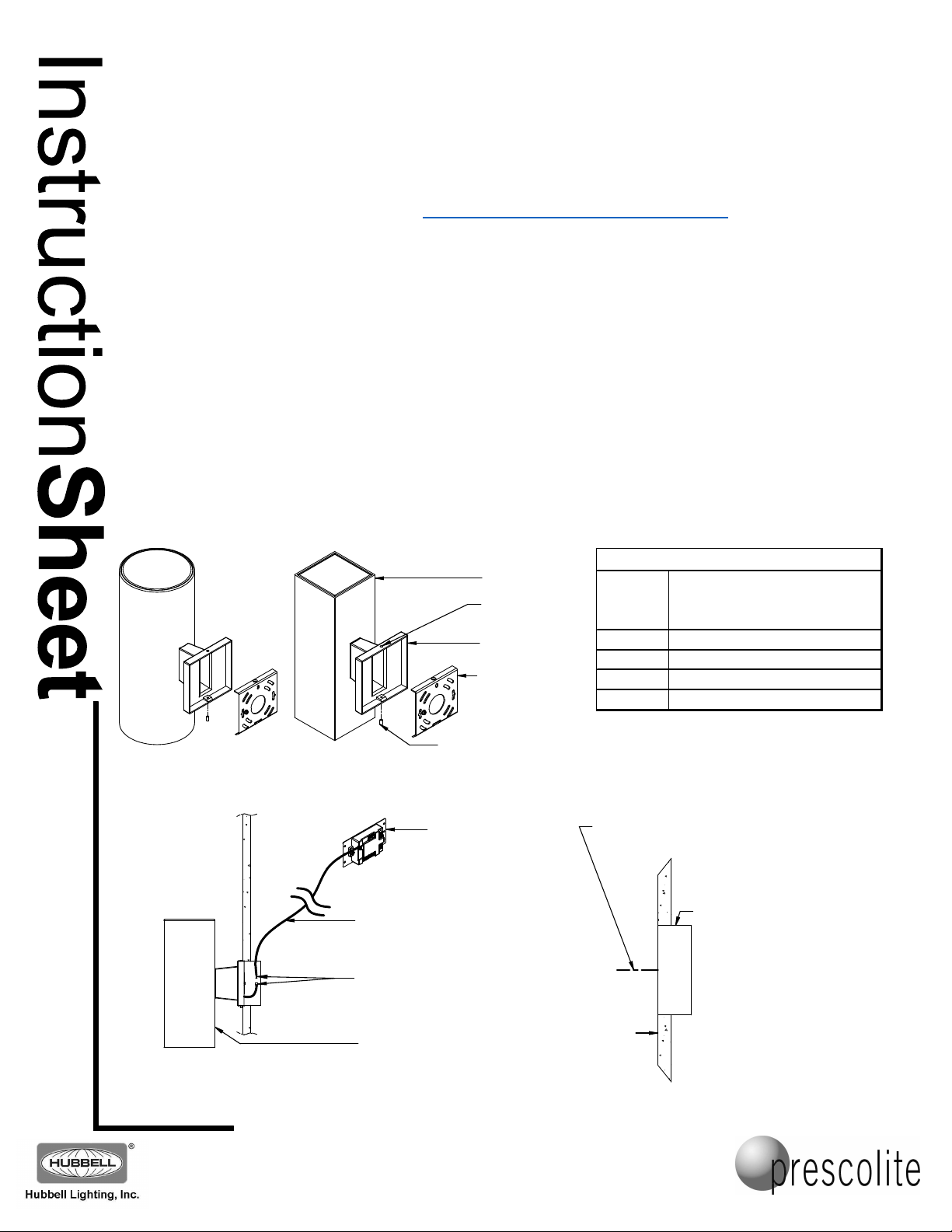

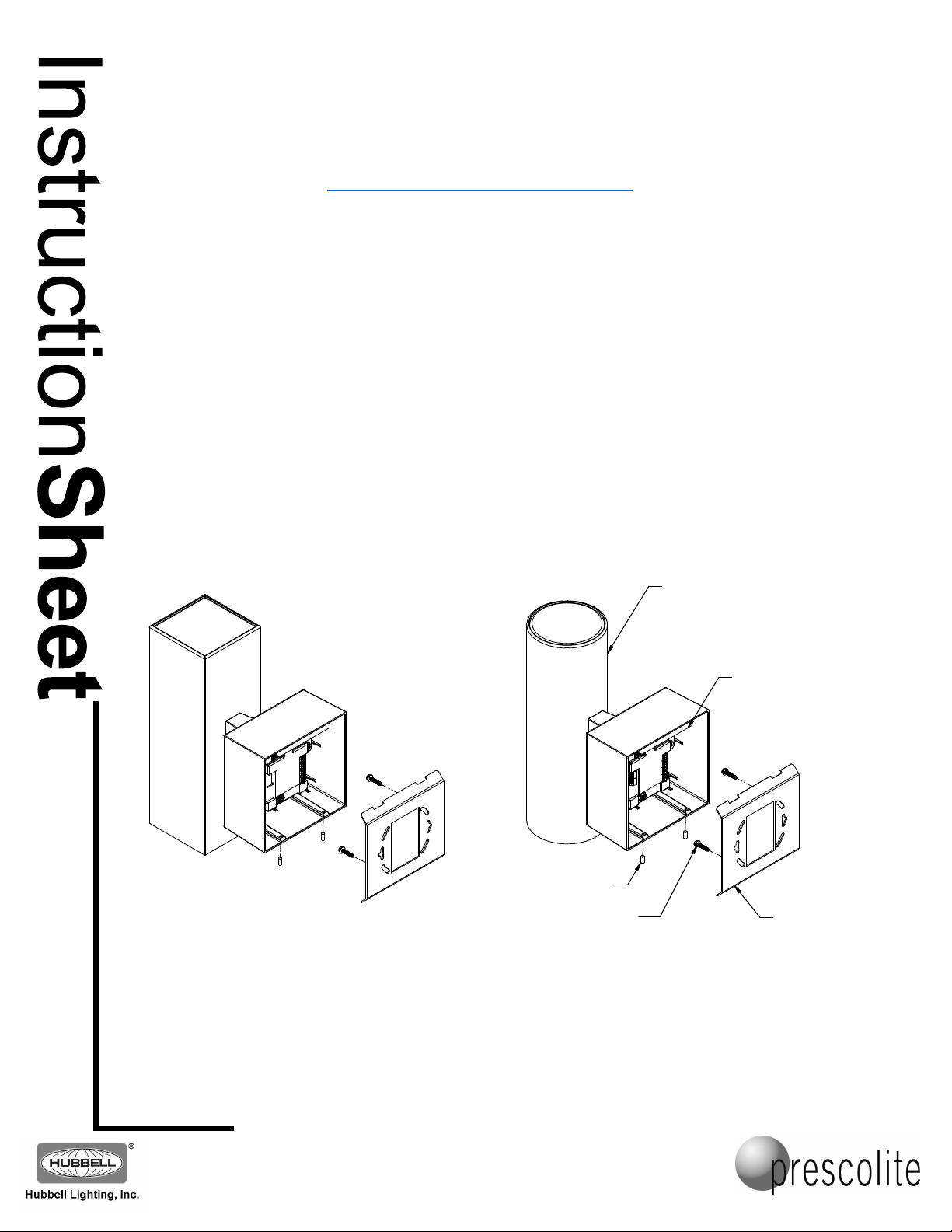

PRIOR TO MOUNTING: LTCRD/SQD

Cylinders are shipped with the reflector/Light

Engine assembly pre-installed. Always

the reflector/light engine assembly is fully secure

cylinder and has not loosened during shipping.

Refer fig 1.1 to 1.3

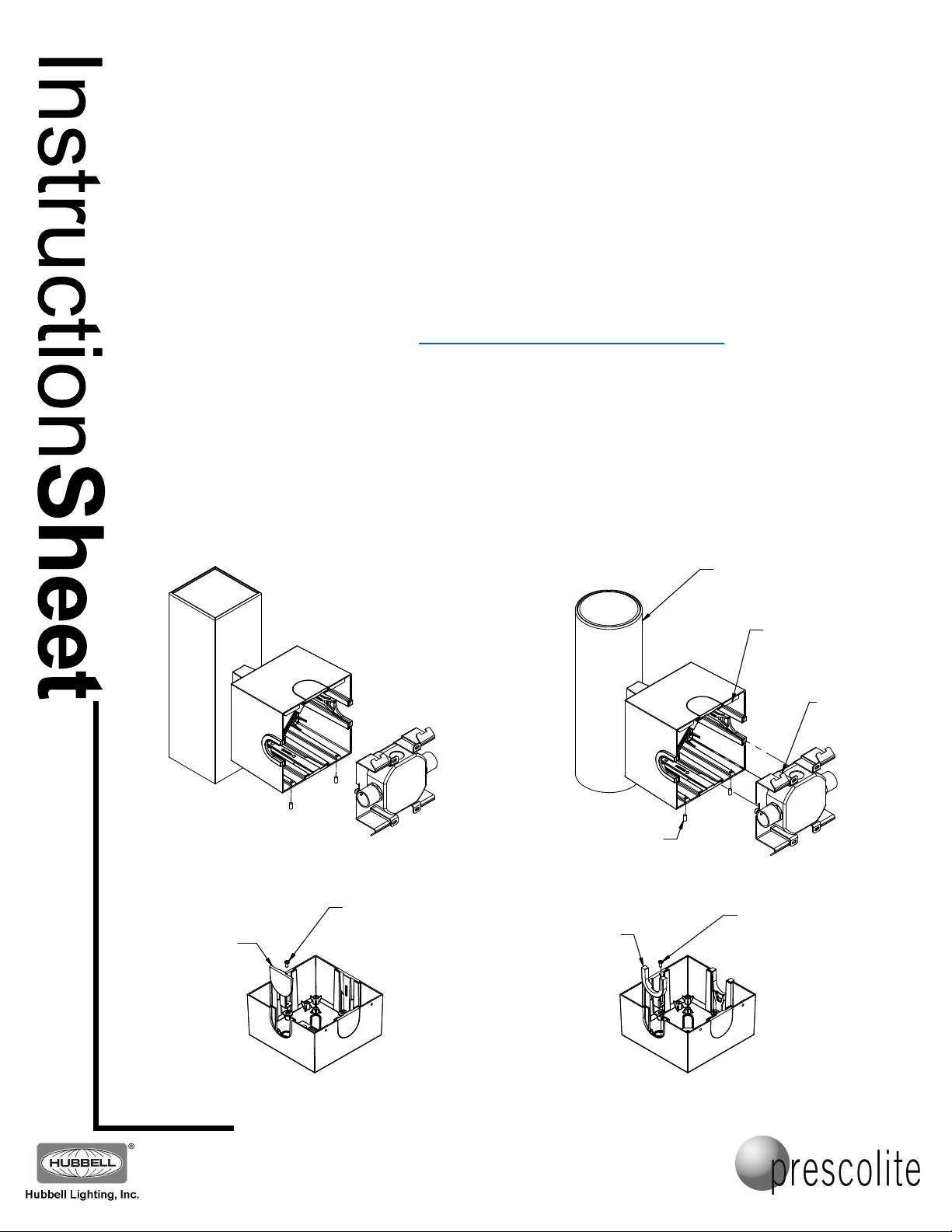

TO REMOVE

REFLECTOR/LIGHT ENGINE ASSEMBLY:

1. For LTC4/6RD & LTC3/4/6SQD,

reflector/light engine assembly downwards

holding the cylinder firmly, when the torsion

is visible squeeze it to remove completely.

2. For LTC3RD, P

assembly downwards while

firmly, until the knee spring bend is completely out.

TO INSTALL/REINSTALL

REFLECTOR/LIGHT ENGINE ASSEMBLY:

1. For LTC4/6RD & LTC3/4/6SQD, S

torsion

brackets.

2. For LTC3RD,

assembly gently into the cylinder.

NOTE: Push the reflector/light engine

up towards cylinder until springs

firmly against the cylinder.

!! Caution

LTC4/6RD

CYLINDER

BRACKET

KNEE

BEND SPRING

LTC3RD

TORSION SPRING

REFLECTOR/LIGHT ENGINE

ASSEMBLY

FIG 1.1

CYLINDER

BRACKET

www.prescolite.com • Prescolite Toll Free Technical Support

1.888.PRS.4TEC

• Hours: 8am - 5pm ET

fingers can be pinched!!

TO REPLACE/UPGRADE:

TORSION SPRING

All reflector/light

with quick connects for easy access

REFLECTOR/LIGHT ENGINE

ASSEMBLY

LTC4/6SQD

FIG 1.2

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.

2021 02-19-21

LTC3SQD

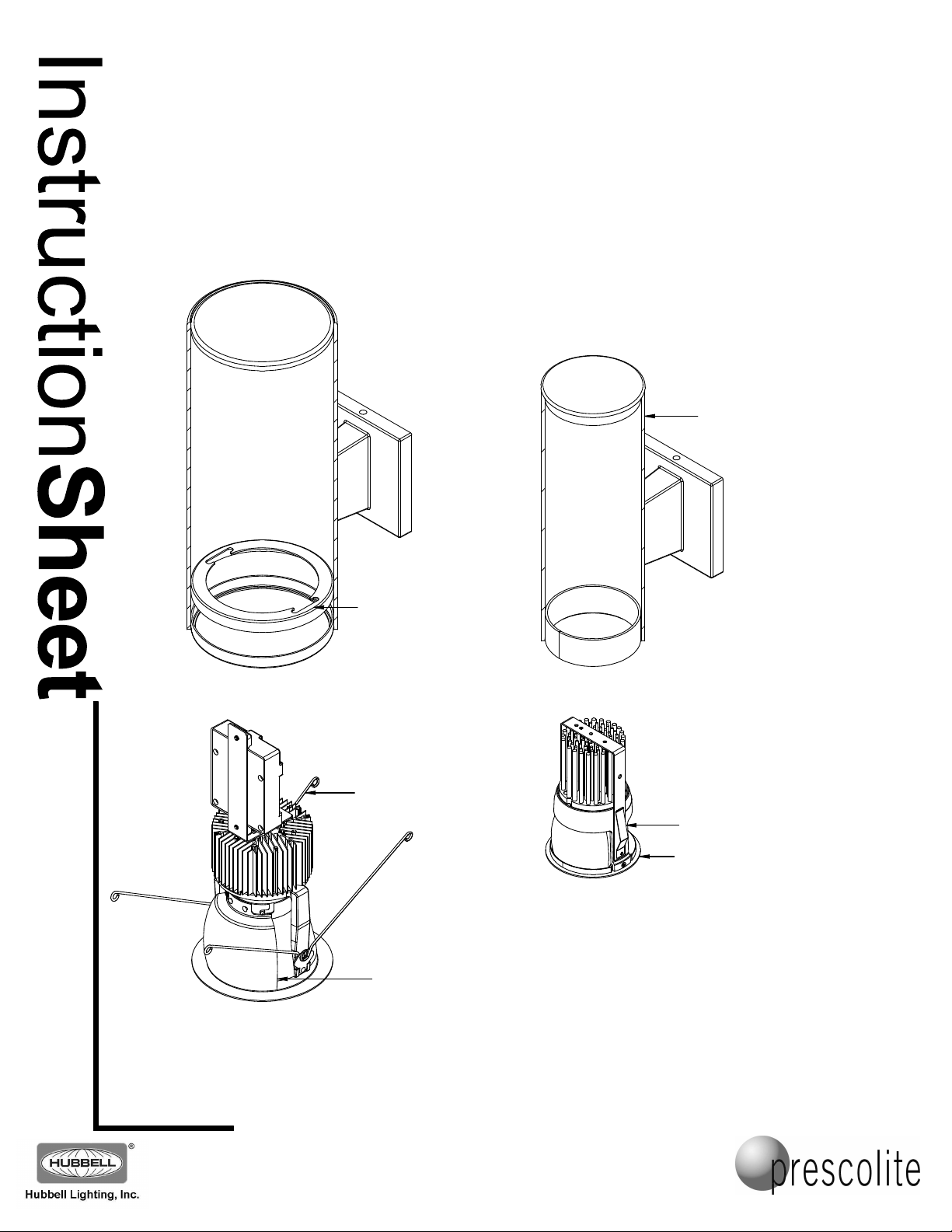

FOR WALL WASH OPTION (WW – FIG 1.3)

Kick reflector

orientation can be changed 180˚ to direct light

in connection

may be necessary to ensure kicker is perpendicular to the wall

The wall wash reflector assembly is pre-installed to aim light toward the wall. (

opposite to wall surface.)

Prior to cylinder installation to wall or ceiling surface, note the orientation of the kick reflector.

If desired, the Wall Wash reflector assembly

away from the wall.

For Surface (S), Pendant Mount (PM) and Cord mount (CM): Slight adjustments

to canopy mounting strap

surface.

Part No...........................................

CYLINDER

93122660

Page 2 of 44

www.prescolite.com • Prescolite Toll Free Technical Support

LTC4/6RW

BRACKET

TORSION SPRING

KICK REFLECTOR

FIG 1.3

LTC3RW

1.888.PRS.4TEC

KNEE BEND SPRING

REFLECTOR/LIGHT ENGINE

ASSEMBLY

• Hours: 8am - 5pm ET

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.2021 02-19-21

Part No...........................................

as

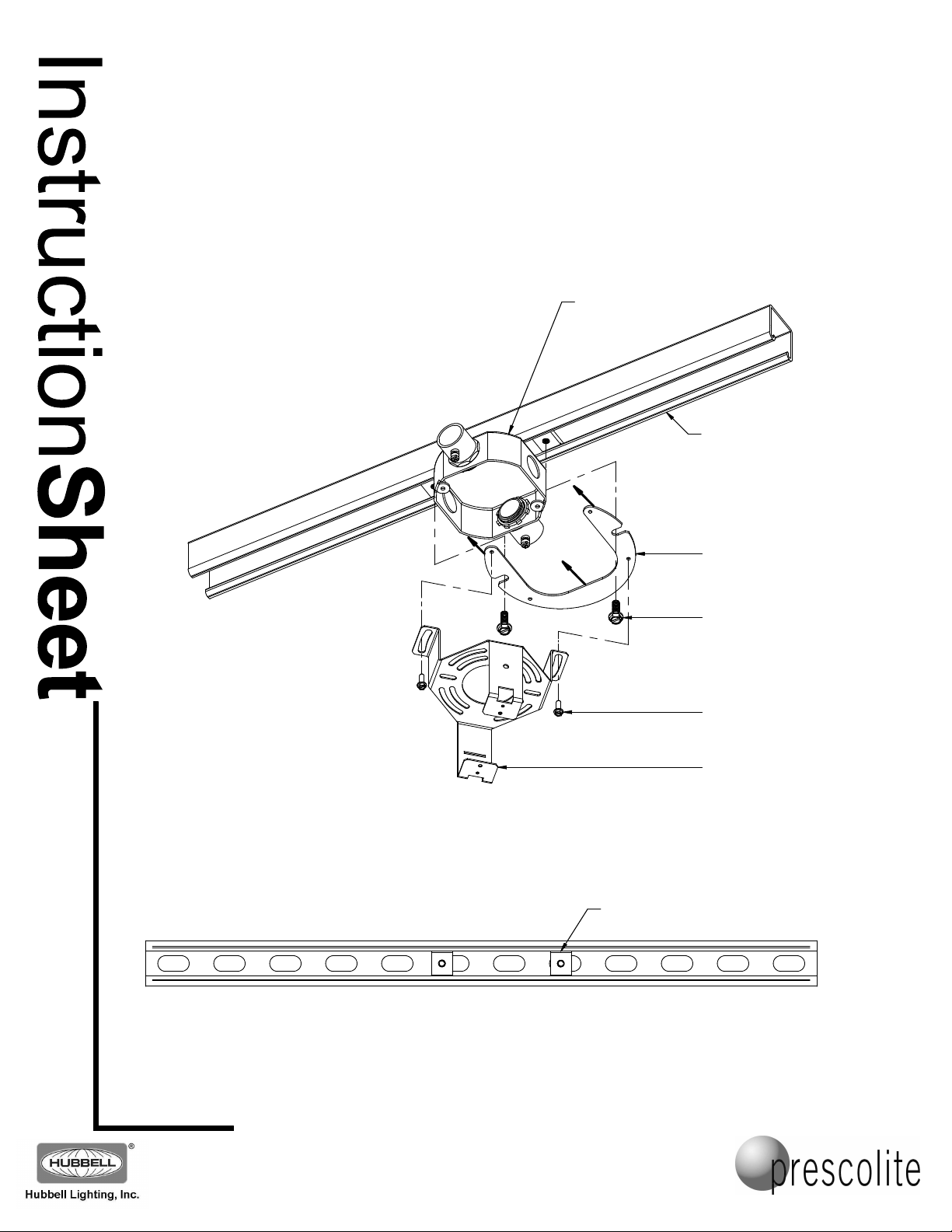

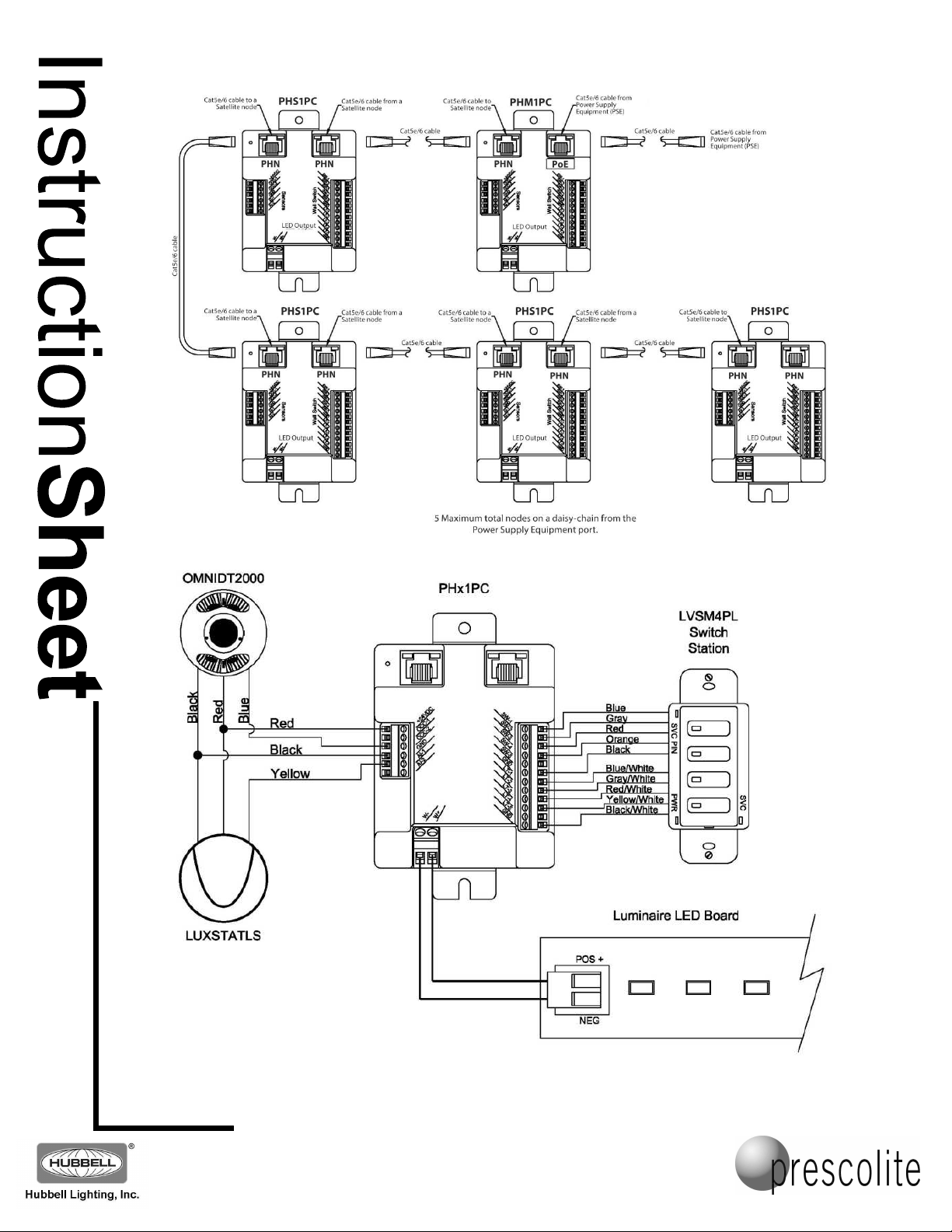

FOR UNISTRUT MOUNTING (P/S/CM ONLY) (CC/PCC VARIANTS – FIG.1.4 & 1.5)

1. Unpack the mounting plate bag from the cylinder carton.

2. Secure the mounting plate to the strut channel using appropriate fasteners (supplied by others)

similar to the channel nut & mounting plate screws (shown below).

NOTE: Outlet box need not be removed (slide-in around box) during mounting plate installation.

3. Unscrew the yoke mounting screws from the mounting plate and secure yoke to the mounting plate

using the same yoke mounting screws (supplied with product).

OUTLET BOX

STRUT CHANNEL

(SUPPLIED BY OTHERS)

93122660

Page 3 of 44

www.prescolite.com • Prescolite Toll Free Technical Support

LTC3/4/6RD/SQD

FIG 1.4

MOUNTING PLATE

(SUPPLIED WITH PRODUCT)

MOUNTING PLATE SCREW

(SUPPLIED BY OTHERS)

YOKE MOUNTING SCREW

(SUPPLIED WITH PRODUCT)

YOKE

STRUT CHANNEL NUT

(SUPPLIED BY OTHERS)

1.888.PRS.4TEC

• Hours: 8am - 5pm ET

FIG 1.5

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.2021 02-19-21

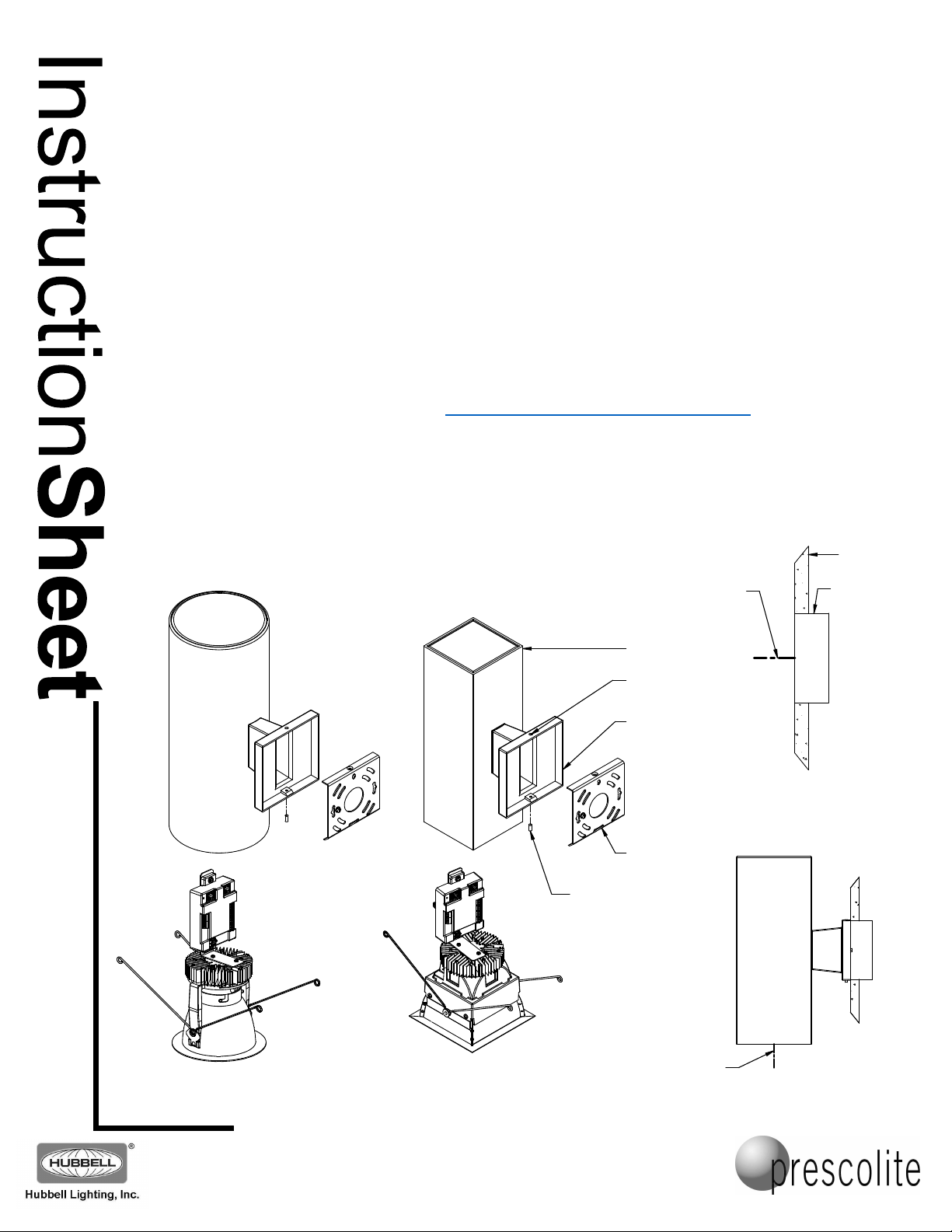

WALL MOUNT (STD – INTEGRAL NODE – FIG 2.1)

POE

Part No...........................................

93122660

Page 4 of 44

1. Remove the Reflector/Light engine assembly from cylinder (Refer page 1 for removal & installation).

Temporarily store the Reflector/Light engine assembly in safe place to avoid scratches and damages

especially on reflector flange surface.

2. Detach mounting plate from wall bracket by loosening set screw.

3. Ensure the CAT5e/6 cable & control wires (if applicable) having 18” – 20” length outside the outlet box

and run them through the mounting plate (Refer Fig 2.2).

4. Secure mounting plate to outlet box using mounting screws supplied with product.

5. Insert the CAT5e/6 cable & wires to the cylinder through the Wall mount bracket.

6. Lower cylinder until it rests against wall. Lock it in place by tightening the set screw on bottom of canopy

housing.

NOTE: Always leave at least 8” – 10” of CAT5e/6 cable & wire length beyond the bottom of the

Cylinder (Refer Fig 2.3).

7. Connect the CAT5e/6 cable & wires in the appropriate jack in Node and install back the reflector/light

engine inside the cylinder, refer FIG 2.1 for orientation of the light engine to have enough room space

for cable & wire (Refer page 1 for installation instruction).

NOTE: Refer to Fig 2.7 for node wiring connections. Refer to page no. 22 for CAT5e/6 Cable

connections. For additional details, visit www.hubbell.com/hubbellcontrolsolutions/en PowerHUBB

Lighting and Control node specification & installation instruction sheets.

NOTE: In compliance with Underwriters Laboratory Standard UL 1570, 1571, or 1572; the use of a

silicone or latex base caulking compound must be used to provide a watertight seal between fixture and

mounting surface to prevent electrical wiring from getting wet.

www.prescolite.com • Prescolite Toll Free Technical Support

CAT5e/6 CABLE/CONTROL WIRES

LENGTH SHOULD BE 18" - 20"

CYLINDER

MOUNTING

PLATE STUD

WALL MOUNT

BRACKET

MOUNTING

PLATE

SET SCREW

WALL

OUTLET

BOX

1.888.PRS.4TEC

FIG 2.2

• Hours: 8am - 5pm ET

CAT5e/6 CABLE & CONTROL WIRES

LTC4/6RD/SQD

LENGTH SHOULD BE MIN. OF 8" - 10"

FIG 2.1

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.2021 02-19-21

FIG 2.3

WALL MOUNT (STD – REMOTE NODE – FIG 2.5)

460

275

180

Part No...........................................

93122660

Page 5 of 44

1. Secure the supplied remote node assembly in an accessible indoor IP20 location. Maximum wire distance

from node to cylinder must not exceed values shown in Table 2.1. The provided mounting plate may be

removed for alternate methods of directly securing the node (for example, installing within a junction box

or access panel).

2. Connect the CAT5e/6 cable in the appropriate jack in Node.

NOTE: Refer to Fig 2.7 for node wiring connections. Refer to page no. 21 for CAT5e/6 Cable

connections. For additional details, visit www.hubbell.com/hubbellcontrolsolutions/en PowerHUBB POE

Lighting and Control node specification & installation instruction sheets.

3. Connect the 2-conductor low voltage plenum rated cable to the LED terminal of the node.

NOTE: Always leave at least 6” of cable outside the outlet box (Refer Fig 2.6).

4. Detach the mounting plate from the wall bracket by loosening the set screw and run the plenum rated

cable through the mounting plate.

5. Secure mounting plate to outlet box using mounting screws supplied with the product.

6. Make electrical connection using properly sized UL listed wire connectors to connect wires (2 conductors

low voltage plenum rated cable) from junction box & cylinder (Red wire to Red wire, Black wire to Black

wire) and ensure the connection goes inside the junction box.

7. Lower the cylinder until it rests against the wall. Lock it in place by tightening the set screw on the bottom

of the canopy housing.

CAUTION: Don't pinch wires when installing.

NOTE: In compliance with Underwriters Laboratory Standard UL 1570, 1571, or 1572; the use of a

silicone or latex base caulking compound must be used to provide a watertight seal between the fixture

and mounting surface to prevent electrical wiring from getting wet.

www.prescolite.com • Prescolite Toll Free Technical Support

CYLINDER

MOUNTING

PLATE STUD

WALL MOUNT

BRACKET

MOUNTING

PLATE

FIG 2.4

SET SCREW

REMOTE NODE MOUNTING

Lumen

Package

14 TO 18 AWG Wire Size

Max. wire Length*

(in Feet)

06L

10L

15L

20L

140

*Measured from node to LED module

connection (Based on IV drop)

1.888.PRS.4TEC

TABLE 2.1

ALWAYS LEAVE AT LEAST 6"

REMOTE NODE

ASSEMBLY

PLENUM RATED CABLE

OUTSIDE OUTLET BOX

• Hours: 8am - 5pm ET

OUTLET

2-CONDUCTOR LOW

VOLTAGE PLENUM RATED CABLE

(SUPPLIED BY OTHERS)

UL LISTED CONNECTORS

BOX

WALL MOUNT

CYLINDER

LTC3RD/SQD

FIG 2.5

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.2021 02-19-21

WALL

LTC3RD/SQD

FIG 2.6

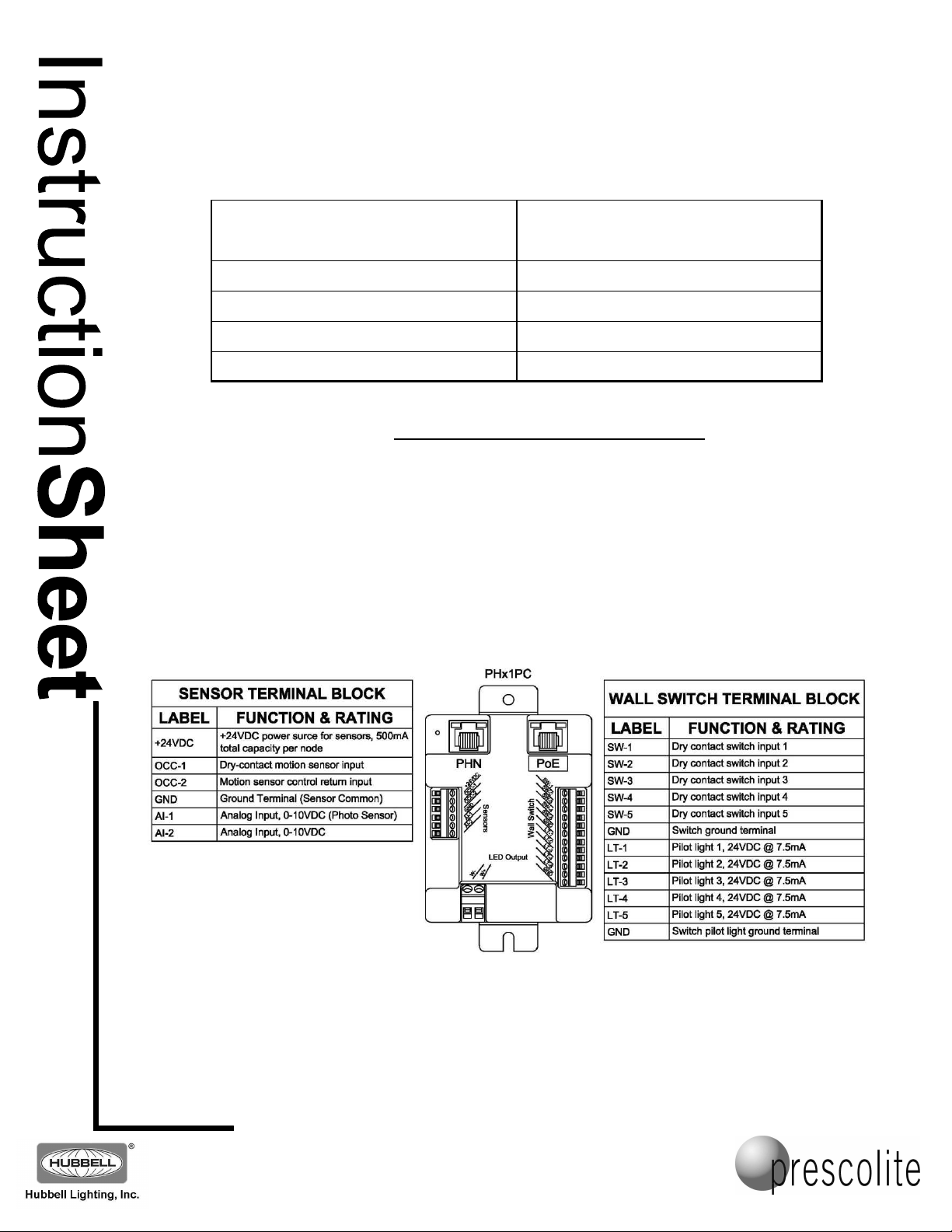

NOTE: Node options -PMC and -

PSC shown. Sensor and Wall Switch terminal blocks are

not present on -PM and -PS

Part No...........................................

93122660

Page 6 of 44

www.prescolite.com • Prescolite Toll Free Technical Support

Prescolite

PowerHUBB Node Option

-PM PHM1P

-PS PHS1P

-PMC PHM1PC

-PSC PHS1PC

For additional details, visit www.hubbell.com/hubbellcontrolsolutions/en PowerHUBB

POE Lighting and Control node specification & installation instruction sheets.

Hubbell Control Solutions

PowerHUBB Node Model #

TABLE 2.2

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.2021 02-19-21

1.888.PRS.4TEC

• Hours: 8am - 5pm ET

Part No...........................................

93122660

Page 7 of 44

www.prescolite.com • Prescolite Toll Free Technical Support

FIG 2.7 PowerHUBB Wiring Diagram and Connections

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.2021 02-19-21

1.888.PRS.4TEC

• Hours: 8am - 5pm ET

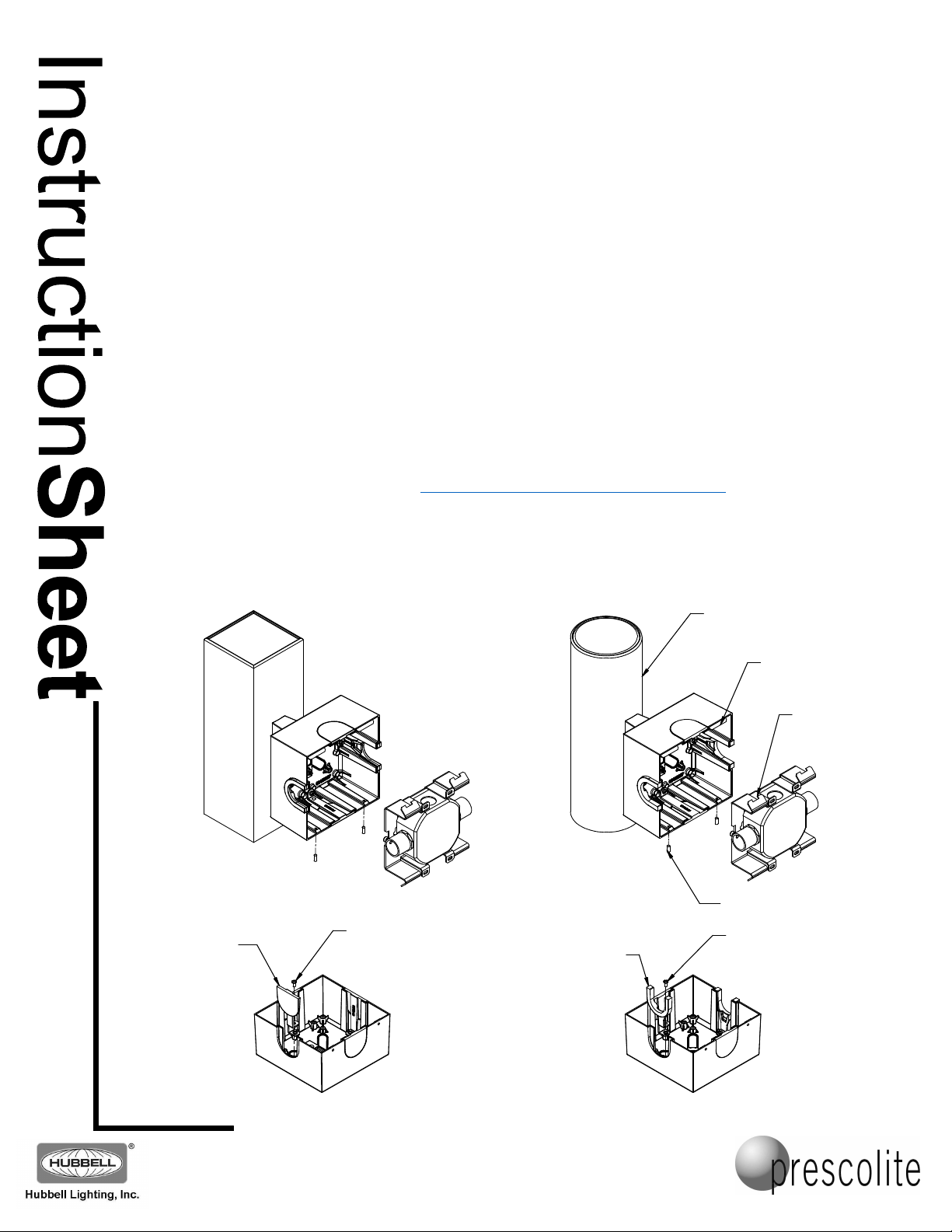

WALL MOUNT (CC VARIANTS – FIG 2.8)

to wall using anchoring hardware

cylinder (Refer page 1 for removal & installation).

safe place to avoid scratches and damages

eassembled with the canopy. Prior to installing

the canopy, configure the canopy with appropriate filler plate/U channel layout in order to satisfy the

e

and reinstall the reflector/light

engine inside the cylinder, refer FIG 2.1 for orientation of the light engine to have enough room space for

the

Prior to tightening set screws, be sure to route the wires accordingly, ensuring that no wires

Part No...........................................

93122660

Page 8 of 44

1. Unpack the mounting bracket from the cylinder carton.

2. Position the wall mounting bracket over the outlet box and secure

(supplied by others). Make sure that the mounting bracket is leveled horizontally.

NOTE: Anchoring hardware to be selected must be rated for 80lbs or greater.

3. Remove the reflector/light engine assembly from the

Temporarily store the Reflector/Light engine assembly in a

especially on the reflector flange surface.

4. The product is equipped with four quantity filler plates pr

respective application making sure to be mindful of conduit feed locations and fixture orientation, whil

doing so.

5. To replace the Filler plates with ‘U’ Channel insert, unscrew the filler plate from the canopy and

replace it with U channel insert and secure it with same screw (FIG 2.9A & 2.9B).

6. Insert the CAT5e/6 cable & wires to the cylinder through the wall arm bracket.

7. Hang fixture on the mounting bracket by positioning the retainer plate over the mounting bracket.

8. Connect the CAT5e/6 cable & wires in the appropriate jack in the node

cable and wires (Refer page 1 for installation instruction).

NOTE: Refer to Fig 2.7 for node wiring connections. Refer to page no. 22 for CAT5e/6 Cable

connections. For additional details, visit www.hubbell.com/hubbellcontrolsolutions/en PowerHUBB POE

Lighting and Control node specification & installation instruction sheets.

9. Lower luminaire until it rests against the wall. Lock it by tightening the set screws at the bottom of

canopy housing.

CAUTION:

are pinched between the outlet box and the mounting bracket (or any other portion of the fixture).

CYLINDER

www.prescolite.com • Prescolite Toll Free Technical Support

FILLER PLATE

(SUPPLIED WITH

PRODUCT)

FIG 2.9A

FILLER PLATE

FIXING SCREW

(SUPPLIED WITH

PRODUCT)

LTC3/4/6RD/SQD

FIG 2.8

U CHANNEL INSERT

(SUPPLIED WITH

PRODUCT)

FIG 2.9B

RETAINER

PLATE

MOUNTING

BRACKET

SET SCREW

FILLER PLATE

FIXING SCREW

(SUPPLIED WITH

PRODUCT)

1.888.PRS.4TEC

• Hours: 8am - 5pm ET

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.2021 02-19-21

WALL MOUNT (PC VARIANTS – FIG 2.10)

canopy

ensuring that no wires

fixture and mounting

Part No...........................................

1. Unpack the mounting plate from the cylinder carton.

2. Secure mounting plate to the outlet box using appropriate mounting screws (supplied with product).

3. Connect the CAT5e/6 cable in the appropriate jack in the node.

NOTE: Refer to Fig 2.7 for node wiring connections. Refer to page no. 21 for CAT5e/6 Cable connections.

For additional details, visit www.hubbell.com/hubbellcontrolsolutions/en PowerHUBB POE Lighting and

Control node specification & installation instruction sheets.

4. Hang fixture on the mounting plate by positioning the retainer plate over the mounting plate.

5. Lower luminaire until it rests against the wall. Lock it by tightening the set screws at the bottom of the

housing.

CAUTION: Prior to tightening the set screws, be sure to route the wires, accordingly,

are pinched between the outlet box and the mounting bracket (or any other portion of the fixture).

NOTE: In compliance with Underwriters Laboratory Standard UL 1570, 1571, or 1572; Silicone or latexbased caulking compound must be used to provide a watertight seal between the

surface to prevent electrical wiring from getting wet.

93122660

Page 9 of 44

www.prescolite.com • Prescolite Toll Free Technical Support

MOUNTING SCREW

LTC3/4/6RD/SQD

FIG 2.10

SET SCREW

(SUPPLIED WITH

PRODUCT)

CYLINDER

RETAINER

PLATE

1.888.PRS.4TEC

• Hours: 8am - 5pm ET

MOUNTING

PLATE

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.2021 02-19-21

WALL MOUNT (PCC VARIANTS – FIG 2.11)

to wall using anchoring hardware

The product is equipped with four quantity filler plates preassembled with the canopy. Prior to installing

y, configure the canopy with appropriate filler plate/U channel layout in order to satisfy the

respective application making sure to be mindful of conduit feed locations and fixture orientation, while

insert, unscrew the filler plate from the canopy and replace it

bottom of

he set screws, be sure to route the wires, accordingly, ensuring that no

Part No...........................................

1. Unpack the mounting bracket from cylinder carton.

2. Position the wall mounting bracket over the outlet box and secure

(supplied by others). Make sure that the mounting bracket is leveled horizontally.

NOTE: Anchoring hardware to be selected must be rated for 80lbs or greater.

3.

the canop

doing so.

4. To replace the Filler plates with ‘U’ Channel

with U channel insert and secure it with same screw (FIG 2.12A & 2.12B).

5. Connect the CAT5e/6 cable in the appropriate jack in the node.

NOTE: Refer to Fig 2.7 for node wiring connections. Refer to page no. 21 for CAT5e/6 Cable

connections. For additional details, visit www.hubbell.com/hubbellcontrolsolutions/en PowerHUBB POE

Lighting and Control node specification & installation instruction sheets.

6. Hang fixture on the mounting bracket by positioning the retainer plates over the mounting bracket.

7. Lower luminaire until it rests against the wall. Lock it in place by tightening the set screws at the

the canopy housing.

CAUTION: Prior to tightening t

wires are pinched between the outlet box and the mounting bracket (or any other portion of the fixture).

93122660

Page 10 of 44

www.prescolite.com • Prescolite Toll Free Technical Support

FILLER PLATE

(SUPPLIED WITH

PRODUCT)

FILLER PLATE

FIXING SCREW

(SUPPLIED WITH

PRODUCT)

LTC3/6RD/SQD

FIG 2.11

U CHANNEL INSERT

(SUPPLIED WITH

SET SCREW

PRODUCT)

CYLINDER

RETAINER

PLATE

MOUNTING

BRACKET

1.888.PRS.4TEC

• Hours: 8am - 5pm ET

FILLER PLATE

FIXING SCREW

(SUPPLIED WITH

PRODUCT)

FIG 2.12A

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.2021 02-19-21

FIG 2.12B

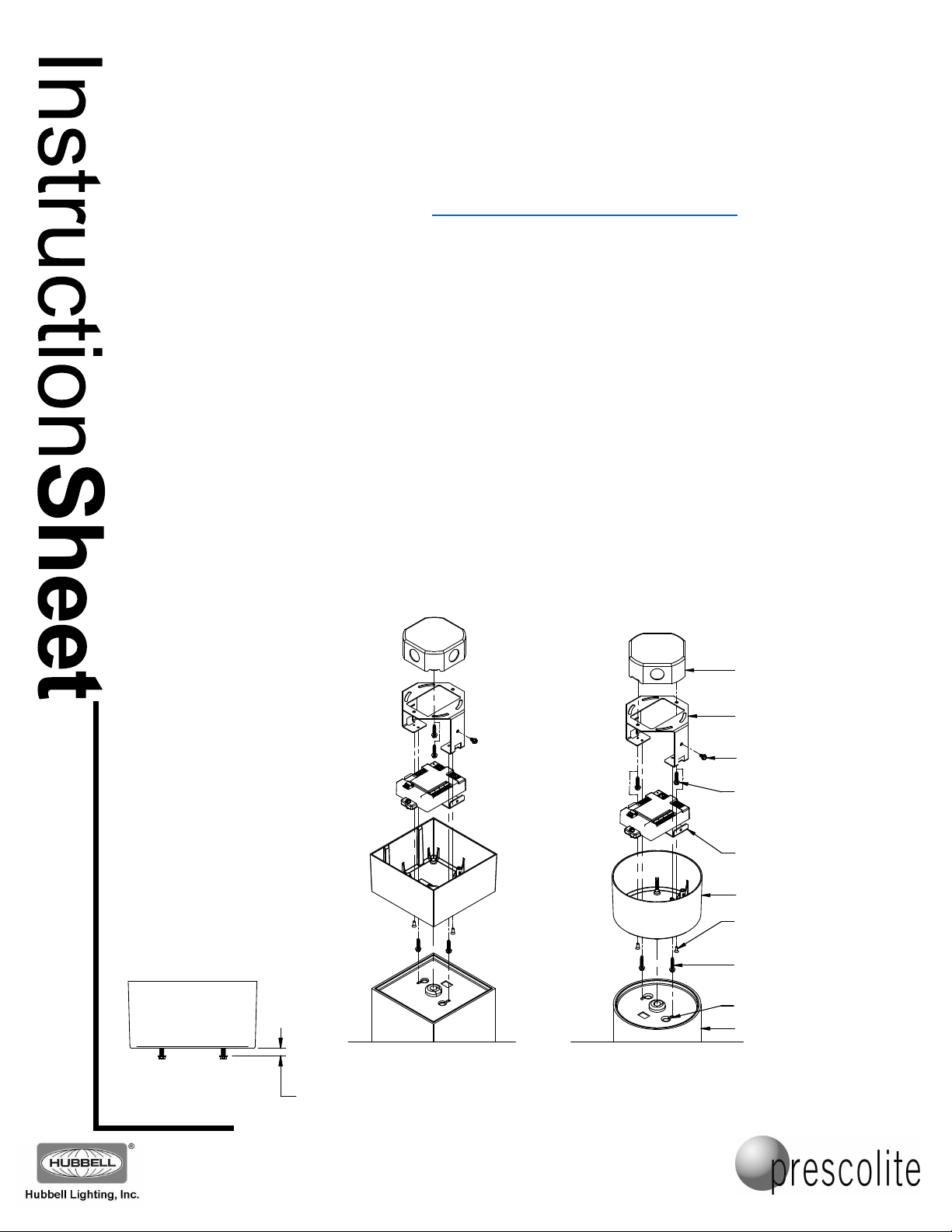

SURFACE MOUNT (STD – REMOTE NODE – FIG 3.1)

to support the

canopy is up against finished

with washer & two quantity

Bottom of junction box flange should be even

ight engine assembly in safe place to avoid

a minimum

Make electrical connection of wires from junction box & cylinder (Red wire to Red wire, Black wire to

For

it inside the cylinder

Part No...........................................

1. Secure ¼-20 threaded rod (Supplied by others) to above ceiling structure adequately

weight of fixture safely, and so enough is hanging down a minimum of 6” height from the finished ceiling.

2. Connect the CAT5e/6 cable & wires in the appropriate jack in node.

NOTE: Refer to Fig 2.7 for node wiring connections. Refer to page no. 20 for CAT5e/6 Cable

connections. For additional details, visit www.hubbell.com/hubbellcontrolsolutions/en PowerHUBB

POE Lighting and Control node specification & installation instruction sheets.

3. Insert remote node assembly and canopy up over threaded rod so that the

ceiling. NOTE: Ceiling cut-out should be 6” in diameter. Secure this assembly

nuts (supplied with product) over the ¼-20 threaded rod.

or recessed within ¼” from drop ceiling (Refer to FIG 3.3).

4. Remove the Reflector/Light engine assembly from cylinder (Refer page 1 for removal & installation) and

disconnect the wiring. Temporarily store the Reflector/L

scratches and damages especially on reflector flange surface.

5. Secure cylinder mounting screws to remote node assembly (Junction box) ensuring to leave

of ½” thread length of the mounting screws below junction box (FIG 3.2).

6.

Black wire) and ensure the connection goes inside the junction box.

7. Install the cylinder by aligning key-slots with cylinder mounting screws and rotate to lock into place.

square cylinders align canopy such that it is parallel with adjacent wall.

8. Reconnect the wiring harness of the reflector/Light engine assembly and install

(Refer page 1 for installation instruction).

CAUTION: Don't pinch wires when installing.

93122660

Page 11 of 44

www.prescolite.com • Prescolite Toll Free Technical Support

Minimum height

is 6 inch

J-BOX

SQUARE CANOPY

WASHER

NUT

LTC3/4/6/RD/SQD

FIG 3.1

ALLOW FOR 1/8" TO 3/8"

LENGTH OF ROD

ROOF CEILING

1/4-20 THREADED ROD

(SUPPLIED BY OTHERS)

NOTE: DO NOT USE

THIS KNOCKOUT

REMOTE NODE ASSY.

DROP CEILING

ROUND CANOPY

1.888.PRS.4TEC

CYLINDER MOUNTING SCREWS

(SUPPLIED WITH PRODUCT)

REFER FIG 3.4

FOR SCREW LOCATION.

CYLINDER

• Hours: 8am - 5pm ET

MOUNTING SCREW MUST

BE SCREWED IN THIS HOLE

SHOULD BE FLUSH OR

FIG 3.2

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.2021 02-19-21

RECESSED WITHIN 1/4"

1/2" THREAD LENGTH

DROP CEILING

FIG 3.3

FIG 3.4

SURFACE MOUNT (PC VARIANTS – FIG 3.5)

assembly

square cylinder,

Use canopy mounting screws to secure the canopy to the yoke and ensure that the mounting screws are

ve a minimum of ½” thread

Remove the Reflector/Light engine assembly from the cylinder (Refer page 1 for removal & installation)

ne assembly in a safe place to avoid

& cylinder (Red wire to Red wire, Black wire to Black

: For Spectra Sync make connections from Red wire to Red wire, Black wire to Black wire, and Blue

then

inside the cylinder

Part No...........................................

1. Unpack the canopy mounting parts bag from the cylinder carton. Detach the canopy and node

from the yoke. Temporarily store the parts & fasteners in a safe place to avoid damages.

2. Secure yoke to outlet box using appropriate mounting screws (supplied with product). For a

yoke adjustment may be needed, if specific orientation is required.

3. Connect the CAT5e/6 cable & wires in the appropriate jack in the node.

NOTE: Refer to Fig 2.7 for node wiring connections. Refer to page no. 20 for CAT5e/6 Cable

connections. For additional details, visit www.hubbell.com/hubbellcontrolsolutions/en PowerHUBB POE

Lighting and Control node specification & installation instruction sheets.

4. Secure the node assembly to the yoke using node assembly mounting screw (supplied with product).

5.

flush with the canopy surface.

6. Secure the cylinder mounting screws to the canopy and yoke, ensuring to lea

length of the mounting screws below the canopy (FIG 3.6).

7.

and disconnect the wiring. Temporarily store the Reflector/Light engi

scratches and damages especially on the reflector flange surface.

8. Make the electrical connection of wires from the node

wire) and ensure all the wire connections goes inside the canopy.

NOTE

Wire to Blue wire.

9. Install the cylinder by aligning the key-slots over the cylinder mounting screws and rotate to lock, and

tighten the screws.

10. Reconnect the wiring harness of the reflector/light engine assembly and install it back

(Refer page 1 for installation instruction).

CAUTION: Do not pinch wires when installing.

93122660

Page 12 of 44

www.prescolite.com • Prescolite Toll Free Technical Support

FIG 3.6

1/2" THREAD LENGTH

LTC3/4/6/RD/SQD

FIG 3.5

OUTLET BOX

YOKE

NODE ASSEMBLY

MOUNTING SCREW

YOKE MOUNTING

SCREW (SUPPLIED

WITH PRODUCT)

NODE ASSEMBLY

CANOPY

CANOPY MOUNTING

SCREW

CYLINDER MOUNTING

SCREW

KEY-SLOT

CYLINDER

1.888.PRS.4TEC

• Hours: 8am - 5pm ET

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.2021 02-19-21

SURFACE MOUNT (PCC VARIANTS – FIG 3.7)

assembly

square cylinder, always

(Refer page 3 for unistrut channel product

preassembled with the canopy. Prior to installing the

order to satisfy the respective

it

Use canopy mounting screws to secure the canopy to the yoke and ensure that the mounting screws are

uring to leave a minimum of ½” thread

Remove the Reflector/Light engine assembly from the cylinder (Refer page 1 for removal & installation)

Reflector/Light engine assembly in a safe place to avoid

& cylinder (Red wire to Red wire, Black wire to Black

: For Spectra Sync make connections from Red wire to Red wire, Black wire to Black wire, and Blue

then

inside the cylinder

Part No...........................................

93122660

Page 13 of 44

1. Unpack the canopy mounting parts bag from the cylinder carton. Detach the canopy and the node

from the yoke. Temporarily store the parts & fasteners in a safe place to avoid damages.

2. Secure yoke to the ceiling using anchoring hardware (supplied by others). For a

ensure the conduit pipe is laid parallel to the adjacent wall

mounting).

NOTE: Anchoring hardware to be selected must be rated for 80lbs or greater.

3. Connect the CAT5e/6 cable & wires in the appropriate jack in the node.

NOTE: Refer to Fig 2.7 for node wiring connections. Refer to page no. 20 for CAT5e/6 Cable

connections. For additional details, visit www.hubbell.com/hubbellcontrolsolutions/en PowerHUBB POE

Lighting and Control node specification & installation instruction sheets.

4. Secure the node assembly to the yoke using node assembly mounting screw (supplied with product).

5. The product is equipped with four quantity filler plates

canopy, configure the canopy with appropriate filler plate/U channel layout in

application making sure to be mindful of conduit feed locations and fixture orientation, while doing so.

6. To replace the Filler plates with ‘U’ Channel insert, unscrew the filler plate from the canopy and replace

with U channel insert and secure it with same screw (FIG 3.8A, 3.8B).

7.

flush with the canopy surface.

8. Secure the cylinder mounting screws to the canopy and yoke, ens

length of the mounting screws below the canopy (FIG 3.9).

9.

and disconnect the wiring. Temporarily store the

scratches and damages especially on the reflector flange surface.

10. Make the electrical connection of wires from the node

wire) and ensure all the wire connections goes inside the canopy.

NOTE

Wire to Blue wire.

11. Install the cylinder by aligning the key-slots over the cylinder mounting screws and rotate to lock, and

tighten the screws.

12. Reconnect the wiring harness of the reflector/light engine assembly and install it back

(Refer page 1 for installation instruction).

CAUTION: Do not pinch wires when installing.

www.prescolite.com • Prescolite Toll Free Technical Support

FILLER PLATE

(SUPPLIED WITH

PRODUCT)

FILLER PLATE

FIXING SCREW

(SUPPLIED WITH

PRODUCT)

FIG 3.8A

FILLER PLATE

U CHANNEL INSERT

(SUPPLIED WITH

PRODUCT)

FIXING SCREW

(SUPPLIED WITH

PRODUCT)

FIG 3.8B

FIG 3.9

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.2021 02-19-21

1/2" THREAD LENGTH

LTC3/4/6/RD/SQD

FIG 3.7

OUTLET BOX

YOKE

NODE ASSEMBLY

MOUNTING SCREW

NODE ASSEMBLY

CANOPY ASSEMBLY

CANOPY MOUNTING

SCREW

CYLINDER MOUNTING

SCREW

KEY-SLOT

CYLINDER

1.888.PRS.4TEC

• Hours: 8am - 5pm ET

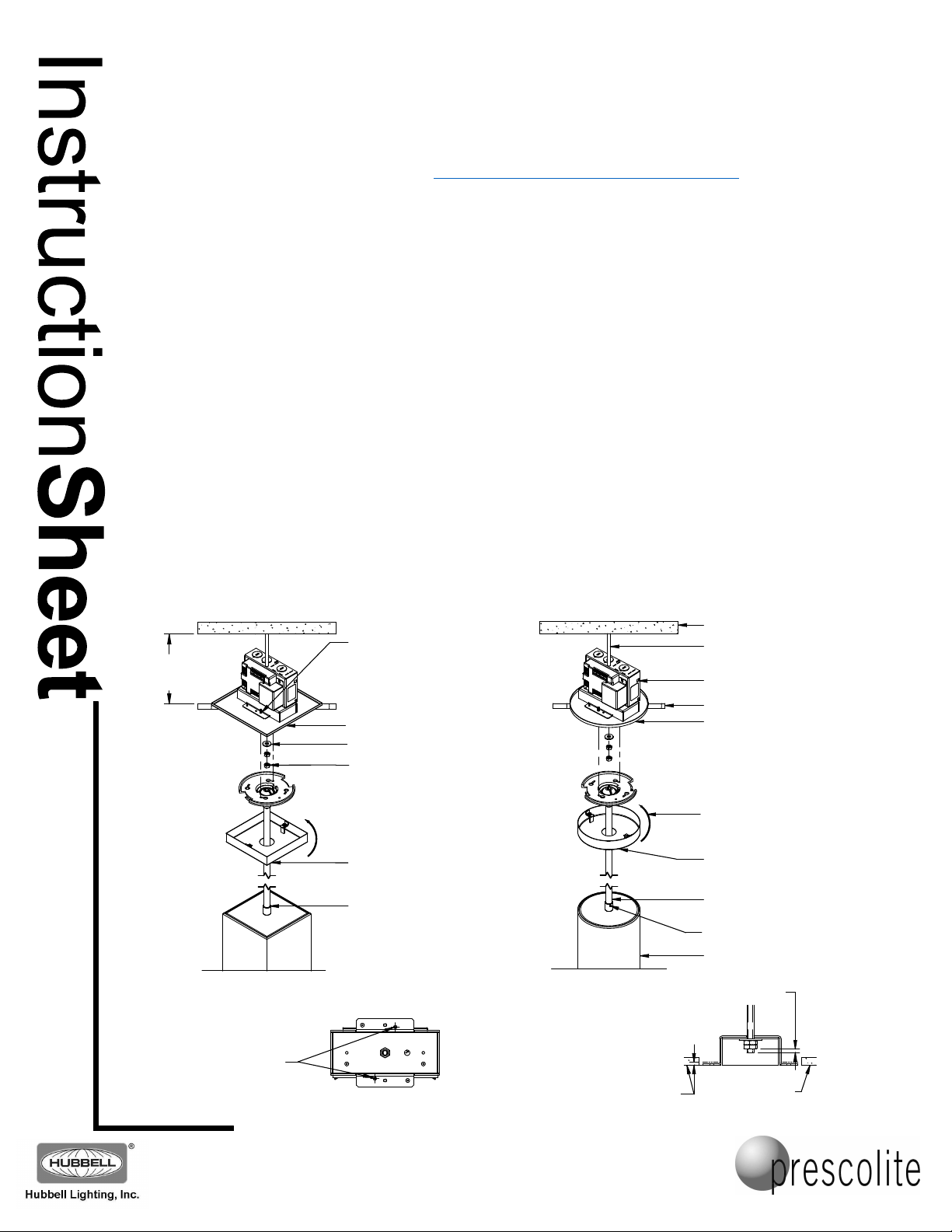

PENDANT MOUNT (STD – REMOTE NODE – FIG 4.1)

) to above ceiling structure adequately to support the

rod so that canopy is up against finished

Secure this assembly with washer & two quantity

20 threaded rod. Bottom of junction box flange should be even

minimum

Ensure that PTFE tape is present around the thread area of the stem for sealing purpose. If it is

to fixture adapter

strip individual wires being used

ion box & cylinder (Red wire to Red wire, Black wire to

box

assembly junction box screws and rotate

Part No...........................................

1. Secure ¼-20 threaded rod (Supplied by others

weight of fixture safely, and so enough is hanging down a minimum of 6” height from the finished ceiling.

2. Connect the CAT5e/6 cable & wires in the appropriate jack in Node.

NOTE: Refer to Fig 2.7 for node wiring connections. Refer to page no. 20 for CAT5e/6 Cable

connections. For additional details, visit www.hubbell.com/hubbellcontrolsolutions/en PowerHUBB

POE Lighting and Control node specification & installation instruction sheets.

3. Insert remote node box assembly and canopy up over threaded

ceiling. NOTE: Ceiling cut-out should be 6” in diameter.

nuts (supplied with product) over the ¼or recessed within ¼” from drop ceiling (Refer to FIG 4.3).

4. Secure cylinder mounting screws to remote node assembly (Junction box) ensuring to leave a

of ½” thread length of the mounting screws below junction box (FIG 3.2 at page 4).

5. Install Canopy Swivel assembly coupling to top of threaded stem and secure with set screw.

NOTE:

missing, make sure to wrap 3 turns of PTFE tape around the stem thread.

6. Feed all fixture wires through bottom of stem and canopy swivel assembly, thread stem

and secure with set screw.

NOTE: Cut any excess wire lengths over 6” above mounting plate and

to 3/8” and re-label the dimming wires for future reference.

7. Make electrical connection of wires from junct

Black wire) and ensure the connection goes inside the junction box.

8. Rotate and slide canopy cover from mounting plate. For square cylinders align remote node

assembly such that it is parallel with adjacent wall.

9. Align appropriate key-slots in mounting plate with Remote node

to lock into place, then tighten the screws.

10. Re-attach the canopy.

CAUTION: Don't pinch wires when installing.

93122660

Page 14 of 44

www.prescolite.com • Prescolite Toll Free Technical Support

Minimum height

is 6 inch

MOUNTING SCREW MUST

BE SCREWED IN THIS HOLE

ONLY FOR LTC3/4/6SQD

MOUNTING PLATE SCREWS

(SUPPLIED WITH PRODUCT)

REFER FIG 4.2

FOR SCREW LOCATION.

SQUARE CANOPY

WASHER

NUT

CANOPY SWIVEL

ASSY (SQUARE)

FIXTURE ADAPTER

LTC3/4/6/RD/SQD

FIG 4.1

FIG 4.2

ALLOW FOR 1/8" TO 3/8"

LENGTH OF ROD

SHOULD BE FLUSH OR

RECESSED WITHIN 1/4"

ROOF CEILING

1/4-20 THREADED ROD

(SUPPLIED BY OTHERS)

REMOTE NODE ASSY.

DROP CEILING

ROUND CANOPY

FOR FIXING, ROTATE

SWIVEL ASSY. THROUGH

THE KEY SLOT

CANOPY SWIVEL

ASSEMBLY (ROUND)

STEM

SET SCREW

CYLINDER

DROP CEILING

FIG 4.3

1.888.PRS.4TEC

• Hours: 8am - 5pm ET

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.2021 02-19-21

Loading...

Loading...