Huba 694 Service Manual

HUBA-REGISTERED TRADE MARK

694

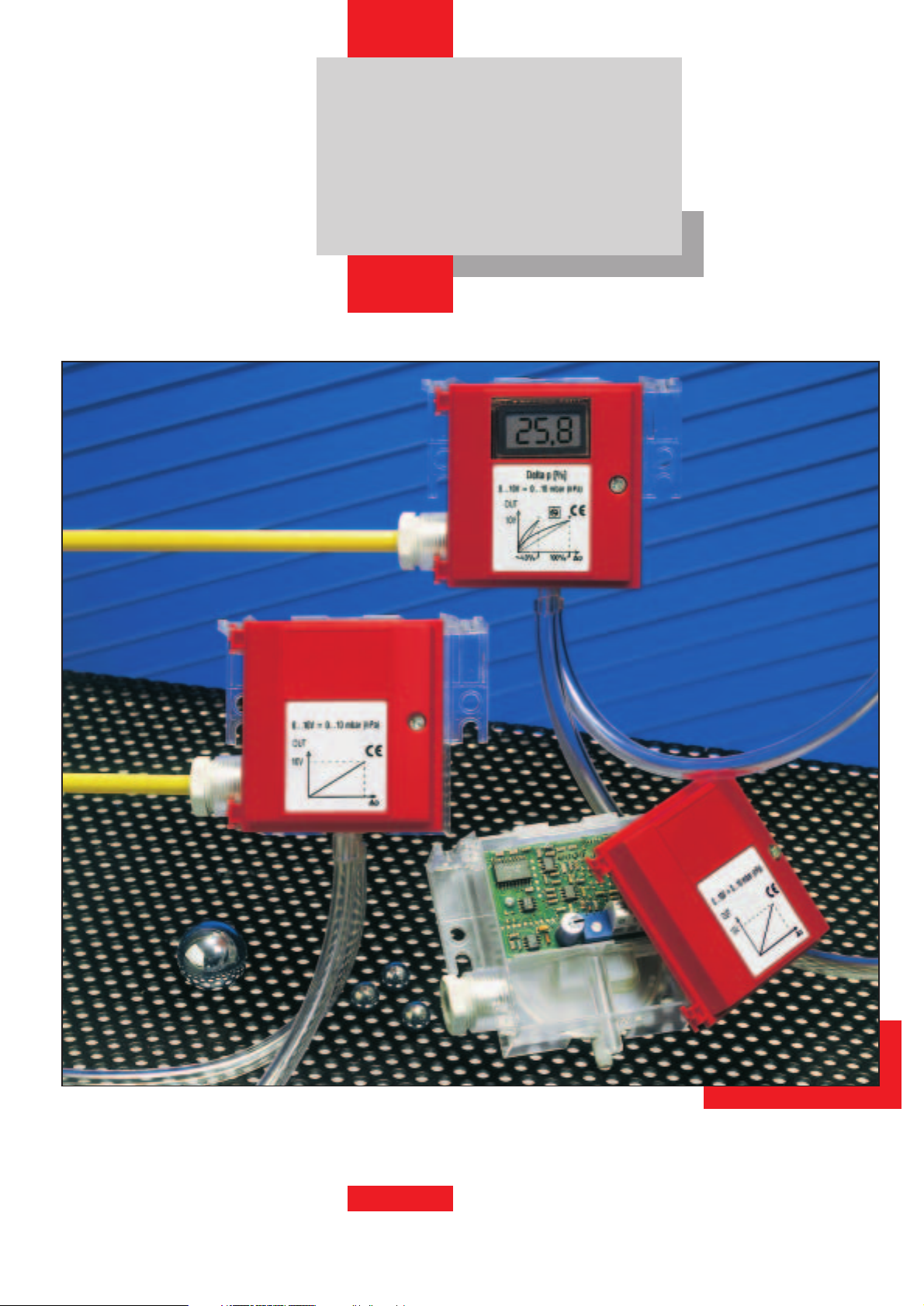

Pressure, vacuum and

differential pressure

transmitter

0 to 50 mbar

Huba Control

FOR FINE PRESSURE AND FLOW MEASUREMENT

EDITION 07/2001

Technical overview

The differential pressure transmitters

of the Type 694 series incorporate

a proved ceramic fulcrum lever technology. They deliver calibrated,

temperature-compensated sensor

signals, available as standard voltage or current outputs. They are ideal for registering low air flow in air

conditioning systems and for the

measurement of fine pressures in environmental, laboratory and cleanroom applications (air and

non-corrosive gases).

Pressure ranges

See order code selection table.

Overload

See order code selection table.

Rupture pressure

500 mbar

Accuracy

Linear output:

Zero point < +/- 0.7 % fs

(Type 0 – 1 mbar < +/- 1.0 % fs)

Linearity inclusive

hysteresis < +/- 1.0 % fs

(Type 0 – 1 mbar < +/- 2.0 % fs)

Total of linearity, hysteresis, repeatability and zero point:

from - 50 to + 50 Pa

< ± 3 Pa (3% FS)

Square-root extracted output:

Absolute error

(from 2 ... 100 % pressure)

≤ +/- 0.3 + 1.5

[% of full scale]

Type 0 – 1 mbar:

≤ +/- 0.6 + 1.5

[% of full scale]

Case construction

Fire classification to UL94

Cover: HB

Pressure housing complete: V-2

Diaphragm

Two-component silicone LSR

Temperature influences

Medium and ambient temperature

0 °C to +70 °C

Storage temperature -10 to +70 °C

TC zero point with linear output:

< +/- 0.04 % fs/°C

with root-extracted output:

(from 2 ... 100 % pressure)

< +/- 0.06 in % fs/°C

TC sensitivity

< +/- 0.02 % fs/°C

(linear and root-extracted)

For 1 mbar versions, multiply values

by a factor of 2.5.

Dynamic response / Resolution

Suitable for dynamic measurements.

Response time < 10 ms

Load change < 10 Hz

Resolution:

1 mbar fs version:

< 0.2 % fs

3 to 50 mbar fs versions:

< 0.1 % fs

Pressure connections

Connection pipe

Ø

6.2 mm

Weight

100 grams with display.

90 grams without display.

Installation arrangement

Vertical (factory calibrated),

Pressure connections downwards.

Effect of orientation, see facing

page.

Output signal and power supply

See order code selection table.

Short circuit proof and protected

against polarity reversal. Each

connection against other with max.

+/- supply voltage.

Electromagnetic compatibility: CE

conformity to EC directive 89/336

EEC (EMC) by application of

harmonized standards

IEC 61000-6-3 und EN 61000-6-2.

Load impedance

3-wire cable:

0 ... 10 V > 10 kOhm

0 ... 20 mA < 400 Ohm

4 ... 20 mA < 400 Ohm

2-wire cable:

4 ... 20 mA < Ohm

Current consumption

3-wire cable:

0 ... 10 V < 10 mA

0 ... 20 mA < 30 mA

4 ... 20 mA < 30 mA

2-wire cable: 4 – 20 mA

Electrical connection/Protection standard

Screw terminals for wire and

stranded conductors up to 1.5 mm

2

.

Cable gland with built-in strain

relief Pg 11.

IP 00 without cover

IP 54 with cover

Display

Liquid-cristal, 3 1/2 digit.

Accessories

See order code selection table.

supply voltage – 11 V

0.02 A

The distinct advantages

• Compact construction

• Fast, easy mounting.

Housing incorporates integral

bracket for wall or ceiling mounting.

Snap-on cover with a single screw

• Available with our without LCD

display

• Available with or without rootextracted output

• Attractive price/performance ratio

pFS

p

pFS

p

pFS

p

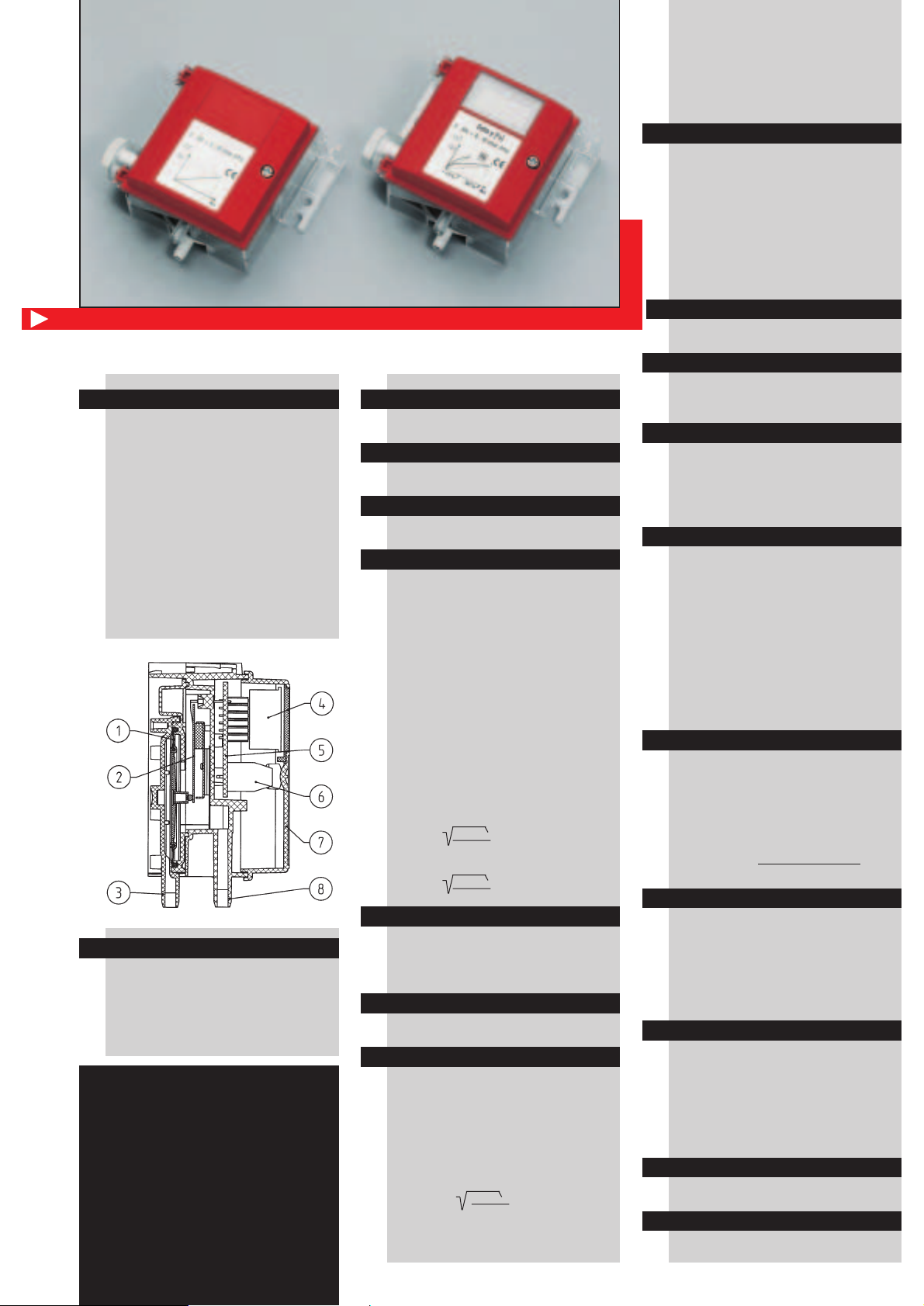

Legend to cross-section drawing

1 Diaphragm 2 Sensor element

3 P1 higher pressure/lower vacuum

4 Display 5 Amplifier electronics

6 Connection terminals 7 Cover

8 P2 lower pressure/higher vacuum

EDITION 07/2001

Loading...

Loading...