Huba 692 Service Manual

692

Differential pressure transmitter

0 … 0.1 – 25 bar

2

E

Technical overview

The differential pressure transmitter of type

series 692 with proven, unique ceramic

technology, features adjusted and amplified

sensor signals which are available as

standardised voltage or current outputs.

Various application-specific pressure and

electrical connections and housing materials

suitable for different media can be provided.

Medium

Liquids and neutral gases

Pressure ranges

0 … 0.1 – 25 bar

Tolerable overload on one side

See order code selection table

System pressure

25 bar on

differential pressure range <

6bar

50 bar on

differential pressure range >

10 bar

Rupture pressure

1.5 x system pressure

Setting range

(Only adjustable versions)

Zero point and full scale ±10% fs

Materials in contact with the medium

Pressure connection:

Stainless steel 1.4305 / AISI 303, PVDF,

CuZn vni

Diaphragm: Ceramic Al

2O3

(96%)

Sealing material: FPM, EPDM, NBR, MVQ

Case material

Stainless steel 1.4305 / AISI 303

Temperature

Medium and ambient –15 … +85 °C

Storage –40 … +85 °C

Output Power supply

3-wire

0 … 5 VDC 11 … 33 VDC

24 VAC ±15%

0 …10 VDC 18 … 33 VDC

24 VAC ±15%

2-wire

4 … 20 mA 11 … 33 VDC

Load

3-wire > 10 kOhm

2-wire <

[Ohm]

supply voltage – 11 V

0.02 A

Current consumption

At nominal pressure

3-wire < 5 mA

2-wire < 20 mA

Dynamic response

Suitable for static and dynamic measurements

Response time < 5 ms

Load cycle < 50 Hz

Electrical connection

Connector DIN EN 175301-803-A

Round connector DIN EN 60130-9

Cable 1.5 m

Polarity reversal protection

Short circuit proof and protected against

polarity reversal. Each connection is

protected against crossover up to max.

supply voltage.

Protection standard

IP 65

Pressure connections

Pressure-tube tip Ø 4 mm / 6 mm

Screw fitting Ø 6 mm / 8 mm

Outside thread 7/16-20 UNF, G1/8

Inside thread 1/8-27 NPT, G1/8

Installation arrangement

Unrestricted

Mounting

Mounting bracket

Tests / Admissions

CE conformity

Weight

Approx. 430 g

Packaging

Single packaging

in cardboard, accessories included

The distinct advantages

• Very low temperature sensitivity

• High resistance to extreme temperatures

• No mechanical creepage

• Modular system and choice of materials

to suit individual applications

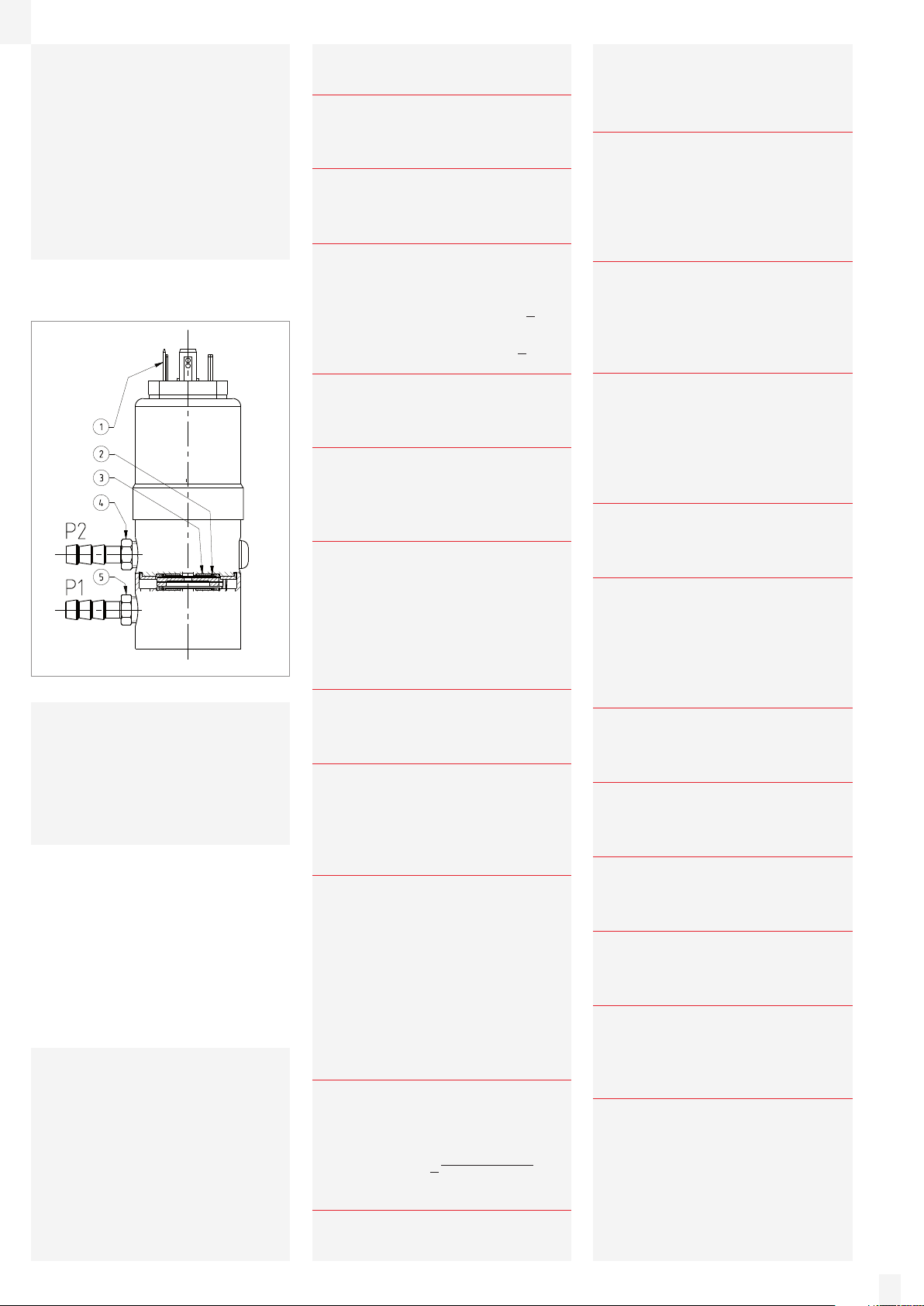

Legend to cross-section drawing

1 Electrical connection

2 Seals

3 Ceramic element

4 P2 Pressure connection (lower pressure)

5 P1 Pressure connection (higher pressure)

692 / EDITION 11/2007, Technical data subject to change.

Loading...

Loading...