Huba 619 Service Manual

HUBA-REGISTERED TRADE MARK

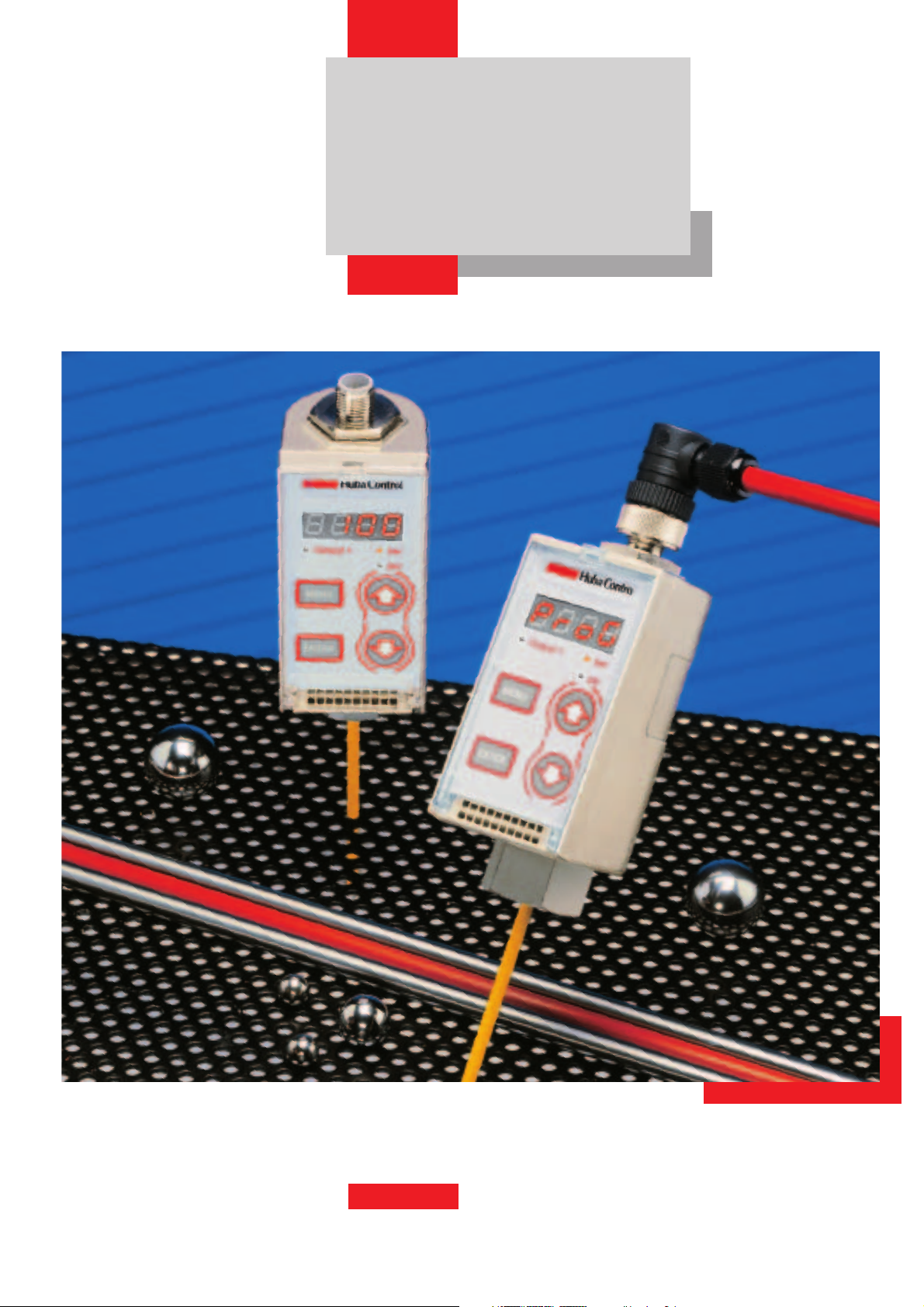

619

Pressure transmitter and

electronic pressure switch

programmable

Relative –1 to 600 bar

EDITION 02/2002

Huba Control

FOR FINE PRESSURE AND FLOW MEASUREMENT

Accuracy

Analogue output:

Total of linearity, hysteresis and

repeatability ≤ 0.6% fs

Zero point rest voltage < 200 mV

Digital output:

Accuracy of switching point

adjustments ≤ 0.6% fs

Housing material

Case: Nickel-plated Zinc pressure

die-casting

Key protection: PC with lettering

In contact with the media:

Ceramic / Stainless Steel (1.4305)

Sealing material: Viton

Temperature influences

Media and ambient

temperature –20 °C … + 80°C

TC zero point < 0.1% fs

TC sensitivity < 0.03% fs

Mechanical rating

Resistant to vibration

5 g (25 … 200 Hz)

35 g (60 … 2000 Hz)

according to IEC 68-2-6

Shock proof

50 g according to IEC 68-2-27

Pressure connection

Inside thread G 1/4

Weight

610 grams

Installation arrangement

Unrestricted

Protection class

IP 67

Power supply

17 … 33 VDC

Diagnostic function

Manual operation with keyboard:

Test of sensor circuit and of ceramic

cell as well as memorizing of pressure peak.

Version with diagnostic input

(shunt-cal): (feed-back with 50% fs

signal 12mA or 5 V

Technical overview

The µP-regulated, programmable

pressure transmitter type 619 has a

robust industry design. Parameters

can easily be programmed with

three different configuration menus.

All systems are equipped with a

diagnostic function. Pressure is

measured by a high resistante ceramic element. Normed analogueand / or open collector outputs are

available depending on the version

chosen.

Outputs

0 – 10 V

4 – 20 mA

Open-collector switching output for

max. 200 mA, programmable NPN

or PNP,

Contact NO or contact NC

Short circuit proof, and protected

against polarity reversal. Each

connection against other with max.

+/– supply voltage.

Load

0 – 10 V > 10 kOhm

4 – 20 mA < 500 Ohm

Current consumption

typ. 50 mA, max. 200 mA

Electrical connection

M 12, Snap-C compatible,

4 contact pins

Admission

Displays

7 Segment LED, 4 digits for the

indication of

• pressure measuring values

• programming codes

• parameter values

• reaction time

Point-LED for state indication of

switching points

Point-LED for indication of programmed measuring unit

Programming

All settings can made in unpressurized state or during the operation.

Ex works with standard setting. The

diagnostic function is active in all

menus.

Menus: «PROG» Configuration of

different system functions, input of

switching point, diagnostic function

«USER» Input of switching point

«READ» Reading of all configurationand input parameters

Display: Pressure unit in bar/psi or

MPa/psi. Reaction time elegible in

steps 1% fs (slow), 0.5% fs (normal) or

10 ms (fast).

Analogue output: Response time

adjustable of 5 … 500 ms, output

characteristic line adjustable of

75 … 125% fs

Digital output: Measuring range

rising pressure 8 … 100% fs

falling pressure 5 … 97% fs

P or N-switching, open-closecontact, rise-delay time eligible

Rise-delay time 0 – 50 s

Switch off delay time 0 – 50 s

Response time 5 … 500 ms

The distinct advantages

• Robust industry design

• High over pressure

• 4-digit LED display

• Sensitive operation keys

• Ergonomic design

• Diagnostic function

• Front cover

EDITION 02/2002

Kind of pressure

Relative pressure

Overload

–1 … 250 bar

4 x measuring range full scale (fs)

–1 … 400 bar

3 x measuring range full scale (fs)

–1 … 600 bar

2 x measuring range full scale (fs)

Rupture pressure

6 x measuring range full scale (fs),

max. 1800 bar

Loading...

Loading...