Huawei UPS5000-E-400 kVA, UPS5000-E-480 kVA, UPS5000-E-360 kVA, UPS5000-E-440 kVA User Manual

Page 1

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power

Modules)

Issue

07

Date

2020-01-10

HUAWEI TECHNOLOGIES CO., LTD.

Page 2

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

i

Copyright © Huawei Technologies Co., Ltd. 2020 . All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees

or representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address:

Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website:

https://e.huawei.com

Page 3

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

About This Document

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

ii

Purpose

Symbol

Description

Indicates a hazard with a high level of risk which, if not

avoided, will result in death or serious injury.

Indicates a hazard with a medium level of risk which, if

not avoided, could result in death or serious injury.

Indicates a hazard with a low level of risk which, if not

avoided, could result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in equipment damage, data loss,

performance deterioration, or unanticipated results.

NOTICE is used to address practices not related to

personal injury.

This document describes the UPS5000-E-(360 kVA-480 kVA) in terms of its features,

performance, working principles, appearance as well as instructions for installation, and

operation and maintenance (O&M).

Intended Audience

This document is intended for:

About This Document

Sales engineers

Technical support engineers

System engineers

Hardware installation engineers

Commissioning engineers

Data configuration engineers

Maintenance engineers

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Page 4

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

About This Document

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

iii

Symbol

Description

Supplements the important information in the main text.

NOTE is used to address information not related to

personal injury, equipment damage, and environment

deterioration.

Change History

Changes between document issues are cumulative. The latest document issue contains all the

changes made in earlier issues.

Issue 07 (2020-01-10)

Added SNMP descriptions to the sections about site configuration.

Added the SNMP V1 and V2 protocol description.

Updated the safety information.

Issue 06 (2017-11-17)

Updated the section "Battery Electrical specifications".

Issue 05 (2017-10-09)

Updated the recommended cable data.

Issue 04 (2017-02-22)

Updated the voltage data of the monitoring interface card and the content of routine

maintenance.

Issue 03 (2016-01-20)

Updated the maximum voltage and current which the monitoring interface card can support,

optimized the dual bus scenario, and updated the routine maintenance.

Issue 02 (2015-08-20)

Deleted V100R001 from the version information.

Issue 01 (2015-04-02)

This is the first release.

Page 5

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

Contents

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

iv

Contents

About This Document ............................................................................................................... ii

1 Safety Information ................................................................................................................... 1

1.1 General Safety ....................................................................................................................................................... 1

1.2 Personnel Requirements ........................................................................................................................................ 4

1.3 Electrical Safety .................................................................................................................................................... 4

1.4 Installation Environment Requirements .................................................................................................................. 6

1.5 Mechanical Safety ................................................................................................................................................. 7

1.6 Device Running Safety .........................................................................................................................................10

1.7 Battery Safety ....................................................................................................................................................... 11

1.8 Others ..................................................................................................................................................................14

2 Overview ................................................................................................................................. 15

2.1 Model Description ................................................................................................................................................15

2.2 Working Principle ................................ ................................................................................................ .................15

2.2.1 Conceptual Diagram ..........................................................................................................................................15

2.2.2 Working Modes .................................................................................................................................................16

2.2.2.1 Normal Mode .................................................................................................................................................16

2.2.2.2 Bypass Mode ..................................................................................................................................................17

2.2.2.3 Battery Mode ..................................................................................................................................................18

2.2.2.4 Maintenance Bypass Mode .............................................................................................................................19

2.2.2.5 ECO Mode .....................................................................................................................................................20

2.3 Product Description ................................ .............................................................................................................. 22

2.3.1 Appearance ........................................................................................................................................................22

2.3.2 Product Structure ............................................................................................................................................... 23

2.4 Control Module ....................................................................................................................................................24

2.4.1 Overview ...........................................................................................................................................................24

2.4.2 ECM .................................................................................................................................................................25

2.4.3 Dry contact card ................................................................................................................................................27

2.4.4 (Optional) Backfeed Protection Card ..................................................................................................................29

2.4.5 (Optional) Dry Contact Extended Card ...............................................................................................................29

2.4.6 Monitoring Interface Card ..................................................................................................................................29

2.5 MDU....................................................................................................................................................................34

2.6 Typical configurations ..........................................................................................................................................36

Page 6

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

Contents

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

v

2.6.1 Single UPS ........................................................................................................................................................36

2.6.2 Parallel System ..................................................................................................................................................36

2.6.3 Dual-Bus System ............................................................................................................................................... 37

2.7 Optional Components ...........................................................................................................................................38

3 Installation .............................................................................................................................. 40

3.1 Installation Preparations .......................................................................................................................................40

3.1.1 Site ....................................................................................................................................................................40

3.1.2 Tools and Instruments ................................................................ ........................................................................42

3.1.3 Power Cables .....................................................................................................................................................44

3.1.4 Unpacking and Checking ................................................................................................ ...................................47

3.1.5 (Optional) Splitting the Power Cabinet and Bypass Cabinet ................................................................................50

3.1.6 Optional) Combining the Power Cabinet and Bypass Cabinet .............................................................................59

3.2 Single UPS Installation .........................................................................................................................................60

3.2.1 Installing a UPS .................................................................................................................................................60

3.2.2 Installing Antiseismic Kits .................................................................................................................................65

3.2.3 Installing an IP21 Component ............................................................................................................................67

3.2.4 (Optional) Installing an Ambient Temperature and Humidity Sensor ...................................................................68

3.2.5 Installing Batteries .............................................................................................................................................68

3.2.6 (Optional) Installing Fuses .................................................................................................................................70

3.2.7 Routing Cables ..................................................................................................................................................73

3.2.7.1 Top Cable Routing ................................................................ ..........................................................................73

3.2.7.2 Bottom Cable Routing ....................................................................................................................................75

3.2.8 Connecting Ground Cables ................................................................................................................................79

3.2.9 Connecting AC Input Power Cables ...................................................................................................................80

3.2.9.1 Single Mains ...................................................................................................................................................80

3.2.9.2 Dual Mains ................................................................ .....................................................................................81

3.2.10 Connecting AC Output Power Cables ...............................................................................................................85

3.2.11 Connecting Battery Cables ...............................................................................................................................85

3.2.12 Remote EPO ....................................................................................................................................................87

3.2.13 Connecting Communications Cables ................................................................................................................88

3.3 Parallel System Installation ................................................................ ...................................................................88

3.3.1 Connecting Power Cables ..................................................................................................................................88

3.3.2 Connecting Signal Cables ..................................................................................................................................92

3.4 Installation Verification .........................................................................................................................................94

4 User Interface .......................................................................................................................... 97

4.1 LCD Interface ......................................................................................................................................................97

4.1.1 LCD ..................................................................................................................................................................97

4.1.2 LCD Menu ........................................................................................................................................................98

4.1.2.1 Menu Hierarchy ..............................................................................................................................................98

4.1.2.2 Initial Startup ..................................................................................................................................................99

4.1.2.3 Main Menu ................................................................ .....................................................................................99

Page 7

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

Contents

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

vi

4.1.3 System Info Screen .......................................................................................................................................... 101

4.1.3.1 Module Data Screen ...................................................................................................................................... 101

4.1.3.2 Runn Info Screen ................................................................ .......................................................................... 102

4.1.3.3 Alarms Screen............................................................................................................................................... 107

4.1.3.4 Settings Screen ............................................................................................................................................. 109

4.1.3.5 Maintenance ................................................................................................................................................. 132

4.1.3.6 About Screen ................................................................................................................................................ 136

4.1.4 System Status Screen ....................................................................................................................................... 137

4.1.5 Common Functions Screen .............................................................................................................................. 137

4.2 WebUI ................................................................................................................................................................ 138

4.2.1 Login............................................................................................................................................................... 138

4.2.2 Monitoring Page .............................................................................................................................................. 140

4.2.2.1 Active Alarms Page ....................................................................................................................................... 141

4.2.2.2 Real-time Data Page ..................................................................................................................................... 142

4.2.2.3 Param. Settings Page ..................................................................................................................................... 142

4.2.2.4 Comm. Config. Page ..................................................................................................................................... 143

4.2.2.5 Control Page ................................................................................................................................................. 143

4.2.3 Query Page ...................................................................................................................................................... 144

4.2.3.1 Historical Alarms Page ................................................................................................................................ .. 144

4.2.3.2 Logs Page ..................................................................................................................................................... 144

4.2.4 Config. Page .................................................................................................................................................... 145

4.2.5 Maint. Page ................................................................ ..................................................................................... 147

5 Operations ............................................................................................................................. 150

5.1 Single UPS Operations ....................................................................................................................................... 150

5.1.1 Powering On and Starting the UPS ................................................................................................................... 150

5.1.2 Shutting Down and Powering Off the UPS ....................................................................................................... 161

5.1.3 Starting the UPS in Battery Mode .................................................................................................................... 164

5.1.4 Transferring to Bypass Mode ........................................................................................................................... 165

5.1.5 Setting ECO Mode........................................................................................................................................... 166

5.1.6 Testing Batteries .............................................................................................................................................. 168

5.1.6.1 Forced Equalized Charging Test .................................................................................................................... 168

5.1.6.2 Shallow Discharge Test ................................................................................................................................. 168

5.1.6.3 Capacity Test ................................................................................................................................................ 170

5.1.6.4 Test Data Download ...................................................................................................................................... 171

5.1.7 Transferring to Maintenance Bypass Mode ....................................................................................................... 172

5.1.8 Transferring from Maintenance Bypass Mode to Normal Mode ........................................................................ 173

5.1.9 Performing EPO .............................................................................................................................................. 174

5.1.10 Clearing the EPO State .................................................................................................................................. 175

5.2 Setting Hibernation Mode ................................................................................................................................... 175

5.2.1 LCD ................................................................................................................................................................ 176

5.2.2 WebUI ............................................................................................................................................................. 177

Page 8

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

Contents

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

vii

5.3 Setting Intelligent Power Mode ........................................................................................................................... 178

5.3.1 LCD ................................................................................................................................................................ 178

5.3.2 WebUI ............................................................................................................................................................. 183

5.3.3 Reused Scenario .............................................................................................................................................. 187

5.3.4 ATS Scenario ................................................................................................................................................... 188

5.4 Parallel System Operations ................................................................................................................................. 189

6 Routine Maintenance ........................................................................................................... 190

6.1 UPS Maintenance ................................................................................................ ............................................... 190

6.1.1 Monthly Maintenance ...................................................................................................................................... 190

6.1.2 Quarterly Maintenance..................................................................................................................................... 191

6.1.3 Annual Maintenance ........................................................................................................................................ 191

6.2 Battery Maintenance ........................................................................................................................................... 192

6.2.1 Precautions for Battery Maintenance ................................................................................................................ 193

6.2.2 Monthly Maintenance ...................................................................................................................................... 193

6.2.3 Quarterly Maintenance..................................................................................................................................... 194

6.2.4 Annual Maintenance ........................................................................................................................................ 195

7 Troubleshooting ................................................................................................................... 196

8 Technical Specifications ...................................................................................................... 198

8.1 hysical Characteristics ........................................................................................................................................ 198

8.2 Environment Features ......................................................................................................................................... 198

8.3 Safety Regulations and EMC ................................ .............................................................................................. 199

8.4 Mains Input Electrical Specifications .................................................................................................................. 199

8.5 Bypass Input Electrical Specifications ................................................................................................................. 200

8.6 Battery Electrical specifications .......................................................................................................................... 200

8.7 Output Electrical Specifications .......................................................................................................................... 201

8.8 System Electrical Specifications ......................................................................................................................... 201

A Menu Hierarchy .................................................................................................................. 202

A.1 Menus on the LCD ............................................................................................................................................ 202

A.2 Menus on the WebUI ......................................................................................................................................... 204

B Alarm List ............................................................................................................................. 220

C Acronyms and Abbreviations ............................................................................................ 229

Page 9

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

1

1.1 General Safety

Statement

Before installing, operating, and maintaining the equipment, read this document and observe

all the safety instructions on the equipment and in this document.

1 Safety Information

The "NOTICE", "CAUTION", "WARNING", and "DANGER" statements in this document

do not cover all the safety instructions. They are only supplements to the safety instructions.

Huawei will not be liable for any consequence caused by the violation of general safety

requirements or design, production, and usage safety standards.

Ensure that the equipment is used in environments that meet its design specifications.

Otherwise, the equipment may become faulty, and the resulting equipment malfunction,

component damage, personal injuries, or property damage are not covered under the warranty.

Follow local laws and regulations when installing, operating, or maintaining the equipment.

The safety instructions in this document are only supplements to local laws and regulations.

Huawei will not be liable for any consequences of the following circumstances:

Operation beyond the conditions specified in this document

Installation or use in environments which are not specified in relevant international or

national standards

Unauthorized modifications to the product or software code or removal of the product

Failure to follow the operation instructions and safety precautions on the product and in

this document

Equipment damage due to force majeure, such as earthquakes, fire, and storms

Damage caused during transportation by the customer

Storage conditions that do not meet the requirements specified in this document

General Requirements

Do not install, use, or operate outdoor equipment and cables (including but not limited to

moving equipment, operating equipment and cables, inserting connectors to or removing

connectors from signal ports connected to outdoor facilities, working at heights, and

performing outdoor installation) in harsh weather conditions such as lightning, rain,

snow, and level 6 or stronger wind.

Page 10

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

2

Before installing, operating, or maintaining the equipment, remove any conductive

objects such as watches or metal jewelry like bracelets, bangles, and rings to avoid

electric shock.

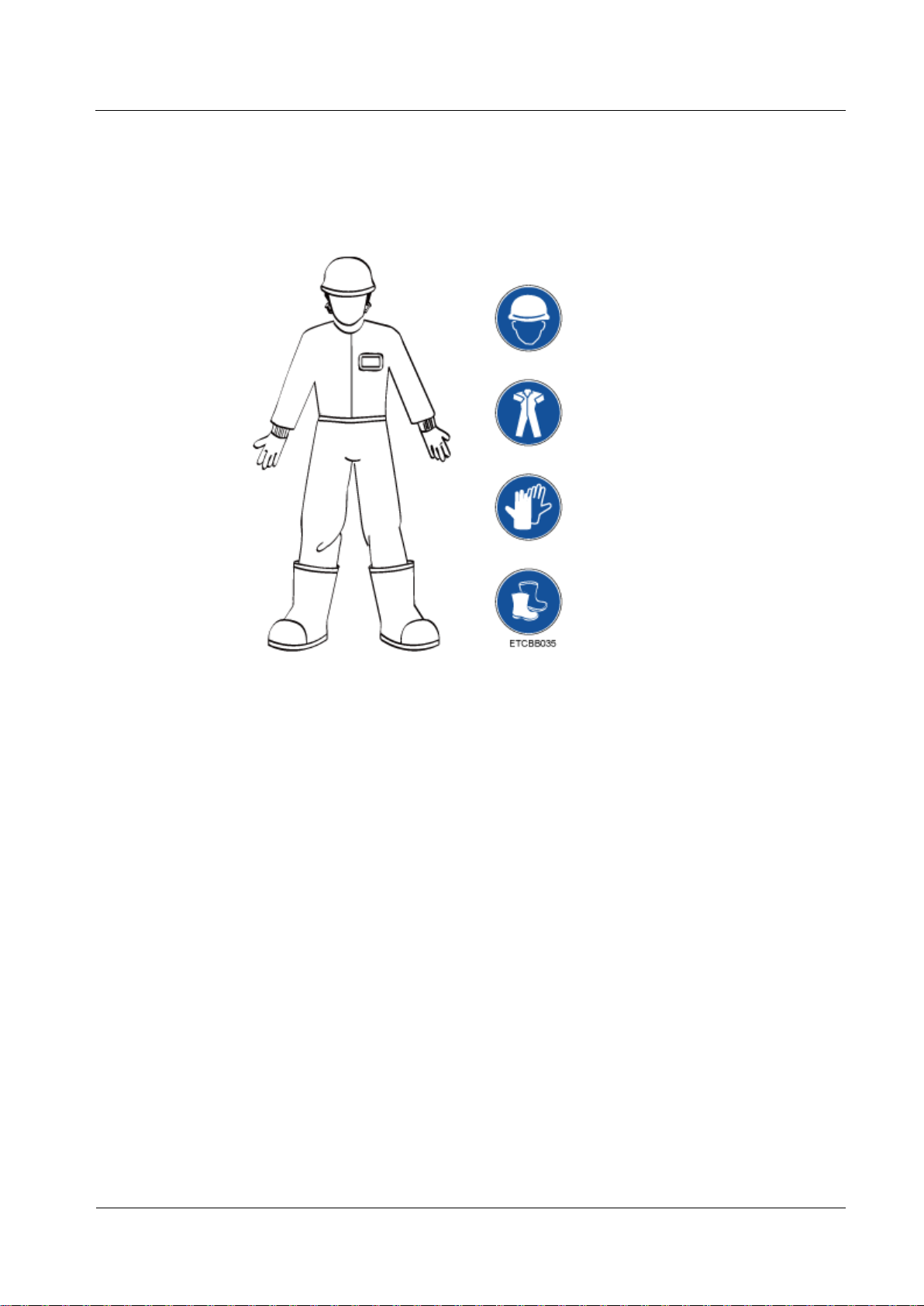

When installing, operating, or maintaining the equipment, wear dedicated protective

gears such as insulation gloves, goggles, and safety clothing, helmet, and shoes, as

shown in the following figure.

Follow the specified procedures for installation, operation, and maintenance.

Before handling a conductor surface or terminal, measure the contact point voltage and

ensure that there is no risk of electric shock.

After installing the equipment, remove idle packing materials such as cartons, foam,

plastics, and cable ties from the equipment area.

In the case of a fire, immediately leave the building or the equipment area, and turn on

the fire alarm bell or make an emergency call. Do not enter the building on fire in any

case.

Do not stop using protective devices. Pay attention to the warnings, cautions, and related

precautionary measures in this document and on the equipment. Promptly replace

warning labels that have worn out.

Keep irrelevant people away from the equipment. Only operators are allowed to access

the equipment.

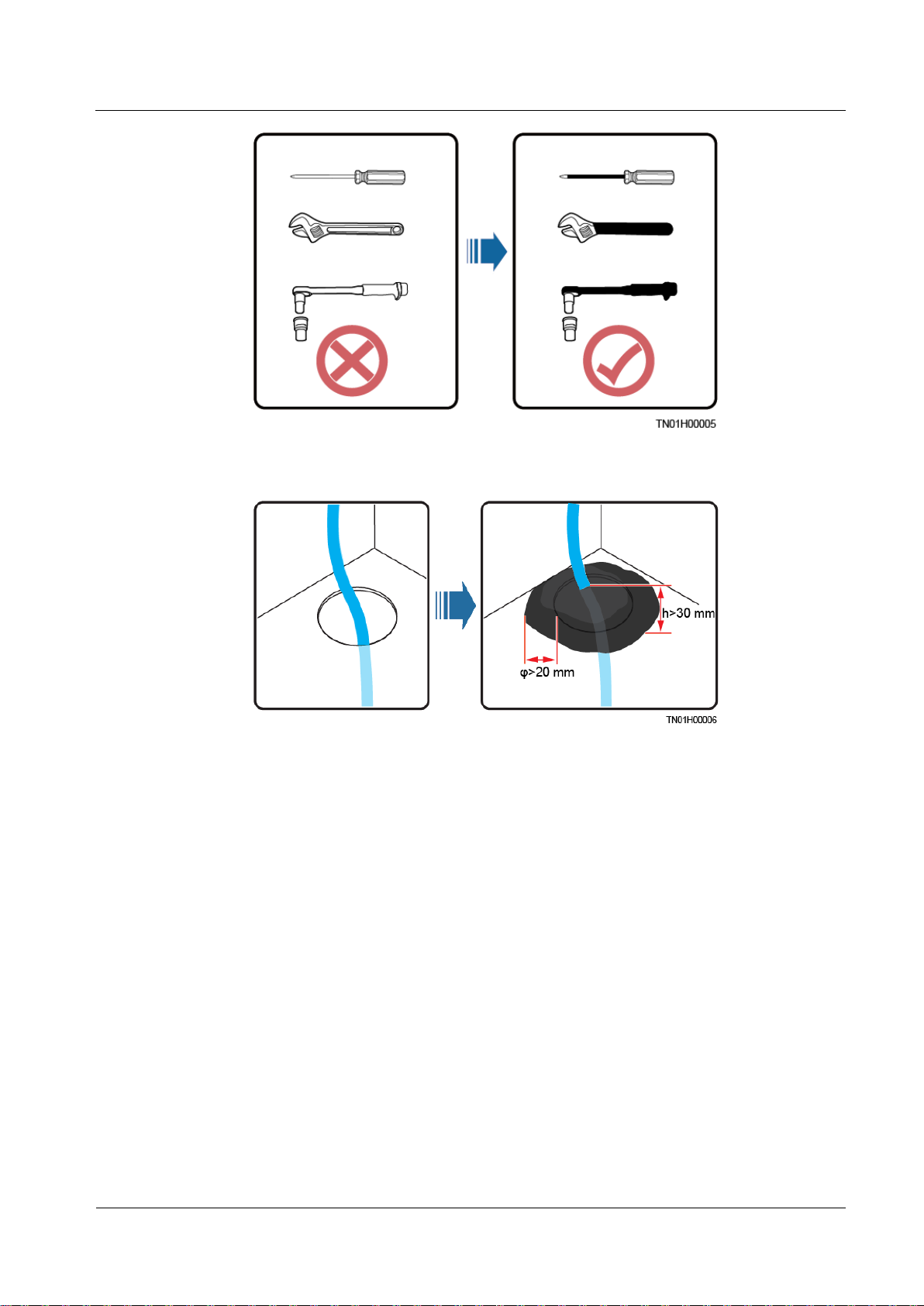

Use insulated tools or tools with insulated handles, as shown in the following figure.

Page 11

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

3

All cable holes should be sealed. Seal the used cable holes with firestop putty. Seal the

unused cable holes with the caps delivered with the cabinet. The following figure shows

the criteria for correct sealing with firestop putty.

Personal Safety

Do not scrawl, damage, or block any warning label on the equipment.

Tighten the screws using tools when installing the equipment.

Do not work with power on during installation.

Repaint any paint scratches caused during equipment transportation or installation in a

timely manner. Equipment with scratches cannot be exposed to an outdoor environment

for a long period of time.

Before operations, ensure that the equipment is firmly secured to the floor or other solid

objects, such as a wall or an installation rack.

Do not use water to clean electrical components inside or outside of a cabinet.

Do not change the structure or installation sequence of equipment without permission.

Do not touch a running fan with your fingers, components, screws, tools, or boards

before the fan is powered off or stops running.

If there is a probability of personal injury or equipment damage during operations on the

equipment, immediately stop the operations, report the case to the supervisor, and take

feasible protective measures.

To avoid electric shock, do not connect safety extra-low voltage (SELV) circuits to

telecommunication network voltage (TNV) circuits.

Page 12

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

4

Do not power on the equipment before it is installed or confirmed by professionals.

1.2 Personnel Requirements

Personnel who plan to install or maintain Huawei equipment must receive thorough

training, understand all necessary safety precautions, and be able to correctly perform all

operations.

Only qualified professionals or trained personnel are allowed to install, operate, and

maintain the equipment.

Only qualified professionals are allowed to remove safety facilities and inspect the

equipment.

Personnel who will operate the equipment, including operators, trained personnel, and

professionals, should possess the local national required qualifications in special

operations such as high-voltage operations, working at heights, and operations of special

equipment.

Professionals: personnel who are trained or experienced in equipment operations and are

clear of the sources and degree of various potential hazards in equipment installation,

operation, maintenance

Trained personnel: personnel who are technically trained, have required experience, are

aware of possible hazards on themselves in certain operations, and are able to take

protective measures to minimize the hazards on themselves and other people

Operators: operation personnel who may come in contact with the equipment, except

trained personnel and professionals

Only professionals or authorized personnel are allowed to replace the equipment or

components (including software).

1.3 Electrical Safety

Grounding

For the equipment that needs to be grounded, install the ground cable first when

installing the equipment and remove the ground cable last when removing the

equipment.

Do not damage the ground conductor.

Do not operate the equipment in the absence of a properly installed ground conductor.

Ensure that the equipment is connected permanently to the protective ground. Before

operating the equipment, check its electrical connection to ensure that it is securely

grounded.

General Requirements

Use dedicated insulated tools when performing high-voltage operations.

AC and DC Power

Page 13

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

5

Cabling

Do not connect or disconnect power cables with power on. Transient contact between the core

of the power cable and the conductor will generate electric arcs or sparks, which may cause

fire or personal injury.

If a "high electricity leakage" tag is attached on the equipment, ground the protective

ground terminal on the equipment enclosure before connecting the AC power supply;

otherwise, electric shock as a result of electricity leakage may occur.

Before installing or removing a power cable, turn off the power switch.

Before connecting a power cable, check that the label on the power cable is correct.

If the equipment has multiple inputs, disconnect all the inputs before operating the

equipment.

A circuit breaker equipped with a residual current device (RCD) is not recommended.

A damaged power cable must be replaced by the manufacturer, service agent, or

professionals to avoid risks.

High voltage operations and installation of AC-powered facilities must be performed by

qualified personnel.

When routing cables, ensure that a distance of at least 30 mm exists between the cables

and heat-generating components or areas. This prevents damage to the insulation layer of

the cables.

Do not route cables behind the air intake and exhaust vents of the equipment.

Ensure that cables meet the VW-1 flame spread rating requirements.

Bind cables of the same type together. When routing cables of different types, ensure that

they are at least 30 mm away from each other.

If an AC input power cable is connected to the cabinet from the top, bend the cable in a

U shape outside the cabinet and then route it into the cabinet.

When the temperature is low, violent impact or vibration may damage the plastic cable

sheathing. To ensure safety, comply with the following requirements:

Cables can be laid or installed only when the temperature is higher than 0°C. Handle

cables with caution, especially at a low temperature.

Cables stored at subzero temperatures must be stored at room temperature for at least 24

hours before they are laid out.

Do not perform any improper operations, for example, dropping cables directly from a

vehicle.

When selecting, connecting, and routing cables, follow local safety regulations and rules.

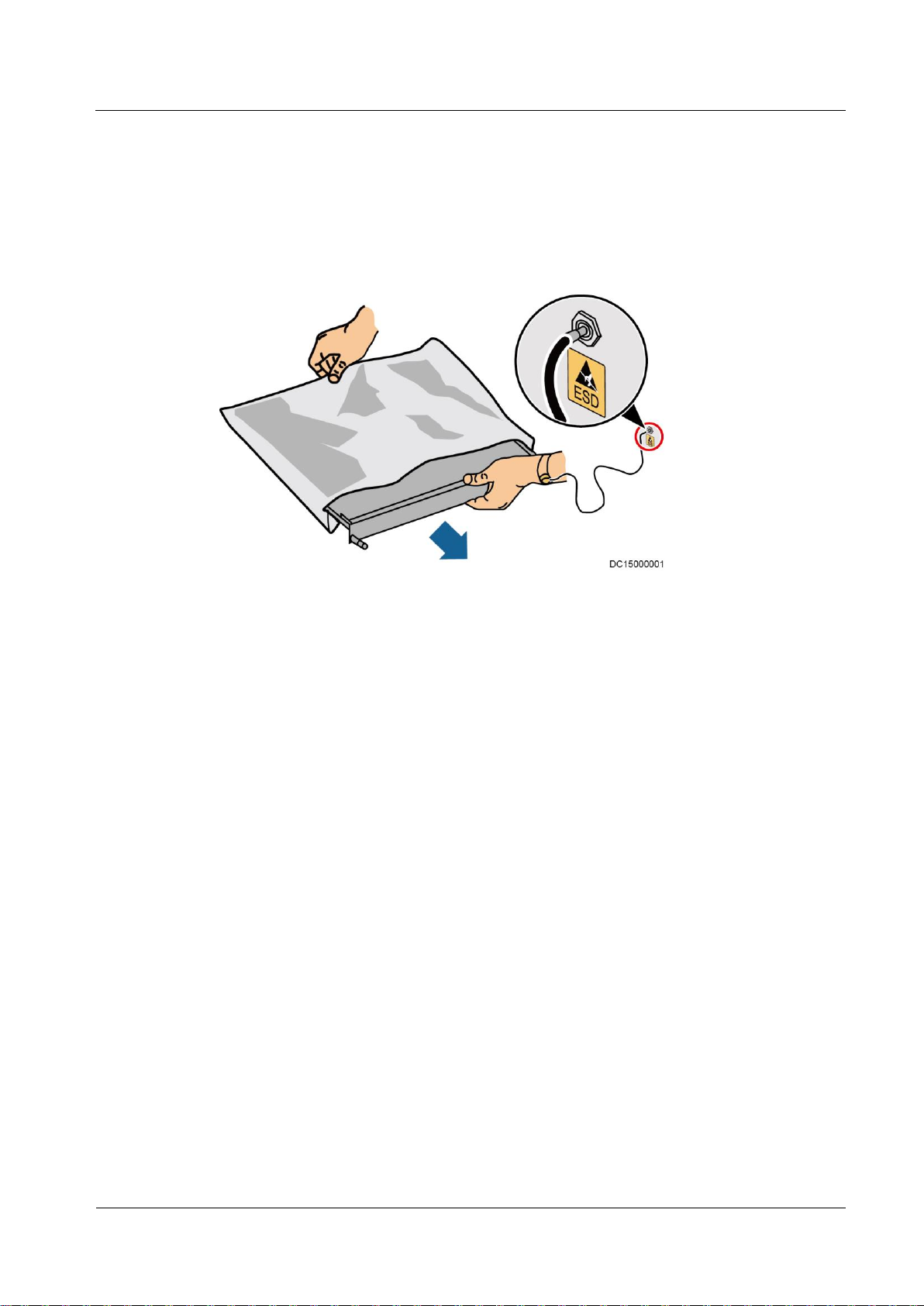

ESD

The static electricity generated by human bodies may damage the electrostatic-sensitive

components on boards, for example, the large-scale integrated (LSI) circuits.

Page 14

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

6

Wear ESD gloves or a well-grounded ESD wrist strap when touching the device or

handling boards or application-specific integrated circuits (ASICs).

When holding a board, hold its edge without touching any components. Do not touch the

components with your bare hands.

Package boards with ESD packaging materials before storing or transporting them.

Figure 1-1 Wearing an ESD wrist strap

Neutral-Ground Voltage

It is recommended that the three-phase loads be equalized and the neutral-ground voltage be

kept at less than 2 V to meet power distribution requirements.

1.4 Installation Environment Requirements

To prevent fire due to high temperature, ensure that the ventilation vents or heat

dissipation system are not blocked when the equipment is running.

Install the equipment in an area far away from liquids. Do not install it under areas prone

to condensation, such as under water pipes and air exhaust vents, or areas prone to water

leakage, such as air conditioner vents, ventilation vents, or feeder windows of the

equipment room. Ensure that no liquid enters the equipment to prevent faults or short

circuits.

If any liquid is detected inside the equipment, immediately disconnect the power supply

and contact the administrator.

Do not expose the equipment to flammable or explosive gas or smoke. Do not perform

any operation on the equipment in such environments.

Ensure that the equipment room provides good heat insulation, and the walls and floor

are dampproof.

Install a rat guard at the door of the equipment room.

Page 15

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

7

Installation at Heights

Working at heights refers to operations that are performed at least 2 meters above the

ground.

Do not work at heights if the steel pipes are wet or other potential danger exists. After the

preceding conditions no longer exist, the safety director and relevant technical personnel

need to check the involved equipment. Operators can begin working only after obtaining

consent.

When working at heights, comply with local relevant laws and regulations.

Only trained and qualified personnel are allowed to work at heights.

Before working at heights, check the climbing tools and safety gears such as safety

helmets, safety belts, ladders, springboards, scaffolding, and lifting equipment. If they do

not meet the requirements, take corrective measures or disallow working at heights.

Wear personal protective equipment such as the safety helmet and safety belt or waist

rope and fasten it to a solid structure. Do not mount it on an insecure moveable object or

metal object with sharp edges. Make sure that the hooks will not slide off.

Set a restricted area and eye-catching signs for working at heights to warn away

irrelevant personnel.

Carry the operation machinery and tools properly to prevent them from falling off and

causing injuries.

Personnel involving working at heights are not allowed to throw objects from the height

to the ground, or vice versa. Objects should be transported by tough slings, hanging

baskets, highline trolleys, or cranes.

Ensure that guard rails and warning signs are set at the edges and openings of the area

involving working at heights to prevent falls.

Do not pile up scaffolding, springboards, or other sundries on the ground under the area

involving working at heights. Do not allow people to stay or pass under the area

involving working at heights.

Inspect the scaffolding, springboards, and workbenches used for working at heights in

advance to ensure that their structures are solid and not overloaded.

Any violations must be promptly pointed out by the site manager or safety supervisor

and the involved personnel should be prompted for correction. Personnel who fail to stop

violations will be forbidden from working.

1.5 Mechanical Safety

Hoisting Devices

Do not walk under hoisted objects.

Only trained and qualified personnel should perform hoisting operations.

Check that hoisting tools are available and in good condition.

Before hoisting objects, ensure that hoisting tools are firmly secured onto a load-bearing

object or wall.

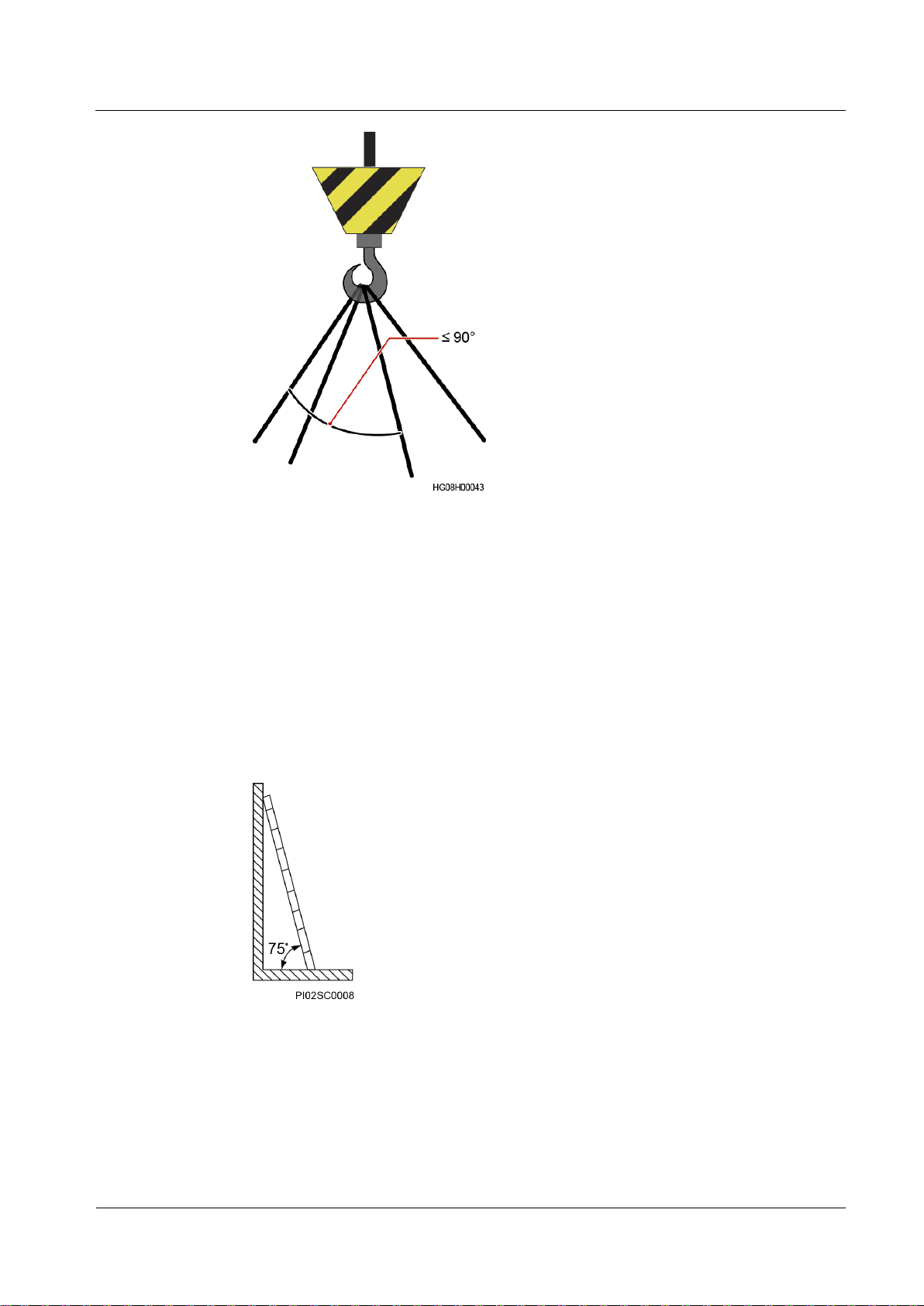

Ensure that the angle formed by two hoisting cables is no more than 90 degrees, as

shown in the following figure.

Page 16

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

8

Do not drag steel ropes and hoisting tools or bump hoisted objects against hard objects

during hoisting.

Using Ladders

Use wooden or fiberglass ladders when you need to perform live working at heights.

When a step ladder is used, ensure that the pull ropes are secured and the ladder is held

firm.

Before using a ladder, check that it is intact and confirm its load bearing capacity. Do not

overload it.

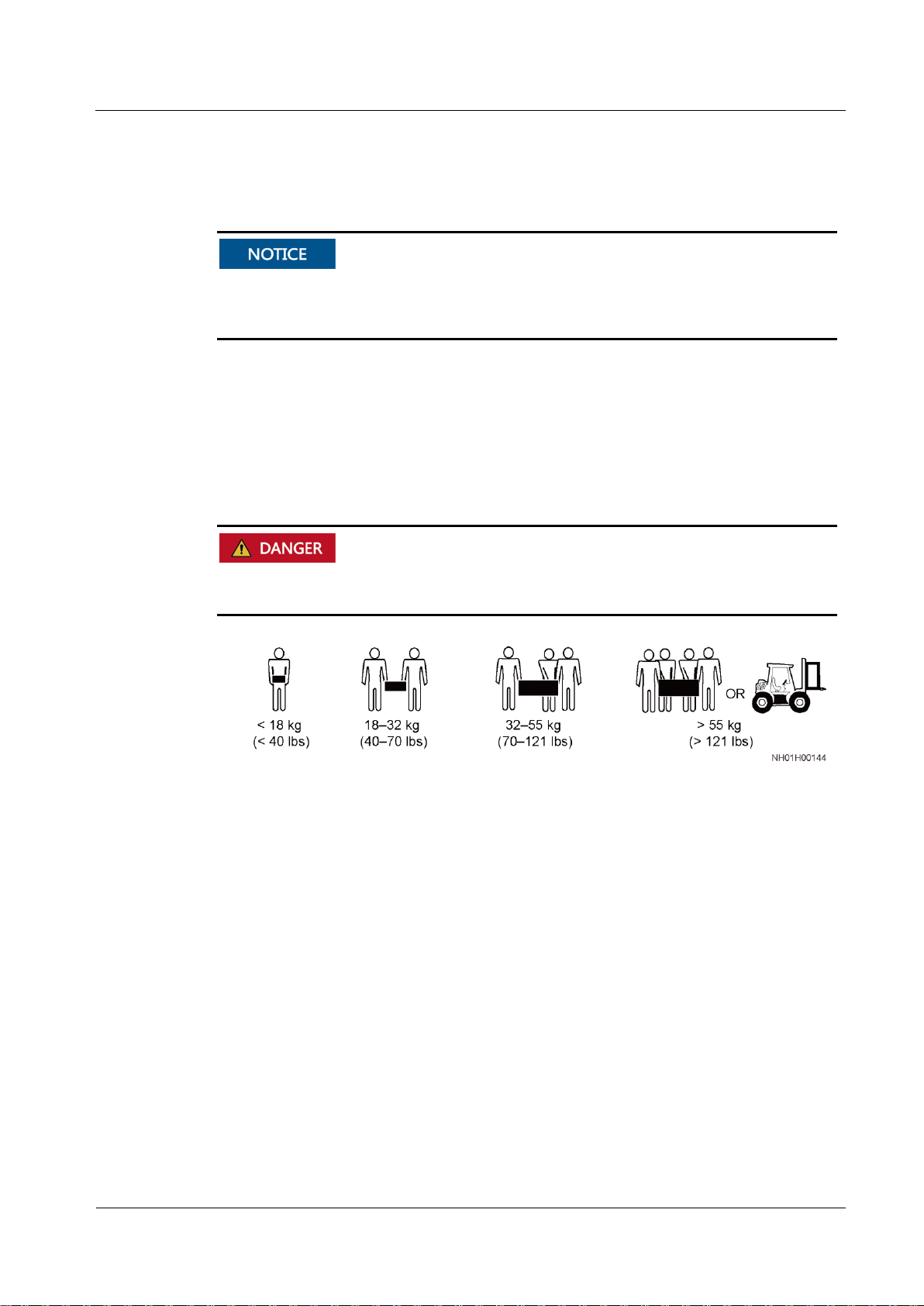

Ensure that the ladder is securely positioned. The recommended angle for a ladder

against the floor is 75 degrees, as shown in the following figure. An angle rule can be

used to measure the angle. Ensure that the wider end of the ladder is at the bottom, or

protective measures have been taken at the bottom to prevent the ladder from sliding.

When climbing a ladder, take the following precautions to reduce risks and ensure

safety:

Keep your body steady.

Do not climb higher than the fourth rung of the ladder from the top.

Ensure that your body's center of gravity does not shift outside the legs of the ladder.

Page 17

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

9

Drilling Holes

When drilling holes into a wall or floor, observe the following safety precautions:

Do not drill holes into the equipment. Doing so may affect the electromagnetic shielding of

the equipment and damage components or cables inside. Metal shavings from drilling may

short-circuit boards inside the equipment.

Obtain the consent from the customer, subcontractor, and Huawei before drilling.

Wear goggles and protective gloves when drilling holes.

When drilling holes, protect the equipment from shavings. After drilling, clean up any

shavings that have accumulated inside or outside the equipment.

Moving Heavy Objects

When removing a heavy or unstable component from a cabinet, be aware of unstable or heavy

objects on the cabinet.

Be cautious to avoid injury when moving heavy objects.

When moving the equipment by hand, wear protective gloves to prevent injuries.

Move or lift the equipment by holding its handles or lower edges. Do not hold the

handles of modules (such as power supply units, fans, and boards) that are installed in

the equipment because they cannot support the weight of the equipment.

Avoid scratching the cabinet surface or damaging cabinet components and cables during

equipment transportation.

When transporting the equipment using a forklift truck, ensure that the forks are properly

positioned to ensure that the equipment does not topple. Before moving the equipment,

secure it to the forklift truck using ropes. When moving the equipment, assign dedicated

personnel to take care of it.

Choose railways, sea, or a road with good condition for transportation to ensure

equipment safety. Avoid tilt or jolt during transportation.

Move a cabinet with caution. Any bumping or falling may damage the equipment.

Page 18

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

10

1.6 Device Running Safety

The UPS is used for commercial and industrial purposes only. It cannot be used as a power

supply for life support devices.

For power supply systems that are critical to significant economic interests or public order,

such as the national computing center, military command system, emergency command

center, railway signal system and control center, civil aviation and air traffic control center,

airport command center, financial clearing center, and transaction center, the Tier 4 or 3 power

architecture specified in TIA-942 must be used. That is, two power supplies must be used to

supply power to loads.

Ensure that the equipment is used in an environment that meets the product design

specifications (including power grid, temperature, and humidity). Otherwise, the equipment

may become faulty, and the resulting equipment malfunction and component damage are not

covered under the warranty.

The UPS operating environment must meet the requirements for the climate indicator,

mechanically active substance indicator, and chemically active substance indicator in ETSI

EN 300 019-1 class 3.6.

After unpacking the UPS, you are advised to power on the UPS as soon as possible. If you

temporarily do not use the UPS, take appropriate measures to prevent moisture, dust, and

foreign matter from entering the UPS.

After unpacking batteries, you are advised to connect the battery supply as soon as

possible. If you temporarily do not use the batteries, store them in a dry and clean

environment. If batteries are stored for more than 90 days, charge them in time. Otherwise,

the battery lifespan may be affected.

Install the UPS in an area far away from liquids. Do not install it under areas prone to

water leakage, such as air conditioner vents, ventilation vents, or feeder windows of the

equipment room. Ensure that no liquid enters the UPS to prevent short circuits. Ensure that

there is no condensation inside the equipment or equipment room.

If any liquid is detected inside the equipment, immediately disconnect the power supply

and contact the administrator.

Do not expose the equipment to flammable or explosive gas or smoke. Do not perform any

operation on the equipment in such environments.

During installation and maintenance, ensure that sundries do not enter the UPS. Otherwise,

equipment damage, load power derating, power failure, and personal injury may occur.

If the valid mains voltage exceeds 320 V AC, the UPS may be damaged.

A UPS can be used to serve resistive-capacitive loads, resistive loads, and micro-inductive

loads. It is recommended that a UPS not be used for pure capacitive loads, pure inductive

loads, and half-wave rectification loads. A UPS does not apply to regeneration loads.

Page 19

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

11

Any operation on any electrical device in an environment that has inflammable air can cause

extreme danger. Strictly obey the operating environmental requirements specified in related

user manuals when using or storing the device.

The UPS can be configured with a backfeed protection dry contact to work with an external

automatic circuit breaker, preventing the voltage from flowing back to input terminals over

static bypass circuits. If the installation and maintenance personnel do not need backfeed

protection, paste labels on external mains and bypass input switches, informing that the UPS

is connected to a backfeed protection card. Disconnect the backfeed protection card from the

UPS before operating the UPS.

Do not use the UPS in the following places:

Environments that are close to flammable or explosive materials, dust, corrosive gases or

dust, conductive or magnetic dust, abnormal vibration, or collision

Rooms or outdoor environments where temperature and humidity are not controlled

(with high temperature, low temperature, moisture, direct sunlight, or heat sources)

Non-confined environments near the ocean (0–3.7 km) and indoor or semi-indoor

environments where the temperature and humidity are not controllable, such as simple

equipment rooms, civil houses, garages, corridors, and direct ventilation cabinets near

the sea; or houses with only roofs, railway station platforms, gymnasiums, and

aquariums

Environments that are conducive for the growth of microorganisms such as fungus or

mildew

Environments where rodents (such as mice) and insects exist

1.7 Battery Safety

Basic Requirements

Before operating batteries, carefully read the safety precautions for battery handling and

master the correct battery connection methods.

Do not expose batteries at high temperatures or around heat-generating devices, such as

sunlight, fire sources, transformers, and heaters. Excessive heat exposure may cause the

batteries to explode.

Do not burn batteries. Otherwise, the batteries may explode.

To avoid leakage, overheating, fire, or explosions, do not disassemble, alter, or damage

batteries, for example, insert sundries into batteries or immerse batteries in water or other

liquids.

Wear goggles, rubber gloves, and protective clothing to prevent skin contact with

electrolyte in the case of electrolyte overflow. If a battery leaks, protect the skin or eyes

from the leaking liquid. If the skin or eyes come in contact with the leaking liquid, wash

it immediately with clean water and go to the hospital for medical treatment.

Use dedicated insulated tools.

Move batteries in the required direction. Do not place a battery upside down or tilt it.

Page 20

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

12

Keep the battery loop disconnected during installation and maintenance.

Use batteries of specified models. Using batteries of other models may damage the

batteries.

Dispose of waste batteries in accordance with local laws and regulations. Do not dispose

of batteries as household waste. If a battery is disposed of improperly, it may explode.

The site must be equipped with qualified fire extinguishing facilities, such as firefighting

sands and powder fire extinguishers.

To ensure battery safety and battery management accuracy, use batteries provided with the

UPS by Huawei. Huawei is not responsible for any battery faults caused by batteries not

provided by Huawei.

Battery Installation

Before installing batteries, observe the following safety precautions:

Install batteries in a well-ventilated, dry, and cool environment that is far away from heat

sources, flammable materials, moistures, extensive infrared radiation, organic solvents,

and corrosive gases. Take fire prevention measures.

Place and secure batteries horizontally.

Note the polarities when installing batteries. Do not short-circuit the positive and

negative poles of the same battery or battery string. Otherwise, the battery may be shortcircuited.

Check battery connections periodically, ensuring that all bolts are securely tightened.

When installing batteries, do not place installation tools on the batteries.

Battery Short Circuit

Battery short circuits can generate high instantaneous current and release a great amount of

energy, which may cause equipment damage or personal injury.

To avoid battery short-circuit, do not maintain batteries with power on.

Flammable Gas

Page 21

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

13

Lead-acid batteries emit flammable gas when used. Ensure that batteries are kept in a wellventilated area and take preventive measures against fire.

Battery Leakage

Battery overheating causes deformation, damage, and electrolyte spillage.

When the electrolyte overflows, absorb and neutralize the electrolyte immediately. When

moving or handling a battery whose electrolyte leaks, note that the leaking electrolyte may

hurt human bodies.

Do not use unsealed lead-acid batteries.

To prevent fire or corrosion, ensure that flammable gas (such as hydrogen) is properly

exhausted for lead-acid batteries.

Lithium Battery

The safety precautions for lithium batteries are similar to those for lead-acid batteries except

that you also need to note the precautions described in this section.

There is a risk of explosion if a battery is replaced with an incorrect model.

If the battery temperature exceeds 60°C, check for and promptly handle any leakage.

Electrolyte overflow may damage the equipment. It will corrode metal parts and boards,

and ultimately damage the boards.

If the electrolyte overflows, follow the instructions of the battery manufacturer or

neutralize the electrolyte by using sodium bicarbonate (NaHCO3) or sodium carbonate

(Na2CO3).

A battery can be replaced only with a battery of the same or similar model recommended

by the manufacturer.

When handling a lithium battery, do not place it upside down, tilt it, or bump it with

other objects.

Keep the lithium battery loop disconnected during installation and maintenance.

Do not charge a battery when the ambient temperature is below the lower limit of the

operating temperature (charging is forbidden at 0°C). Low-temperature charging may

cause crystallization, which will result in a short circuit inside the battery.

Page 22

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

1 Safety Information

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

14

1.8 Others

Use batteries within the allowed temperature range; otherwise, the battery performance

and safety will be compromised.

Do not throw a lithium battery in fire.

When maintenance is complete, return the waste lithium battery to the maintenance

office.

Exercise caution when manually shutting down the UPS inverter for transferring to

bypass mode, or when adjusting the UPS output voltage level or frequency. Doing so

may affect the power supply to equipment.

Exercise caution when setting battery parameters. Incorrect settings will affect the power

supply and battery lifespan.

Page 23

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

15

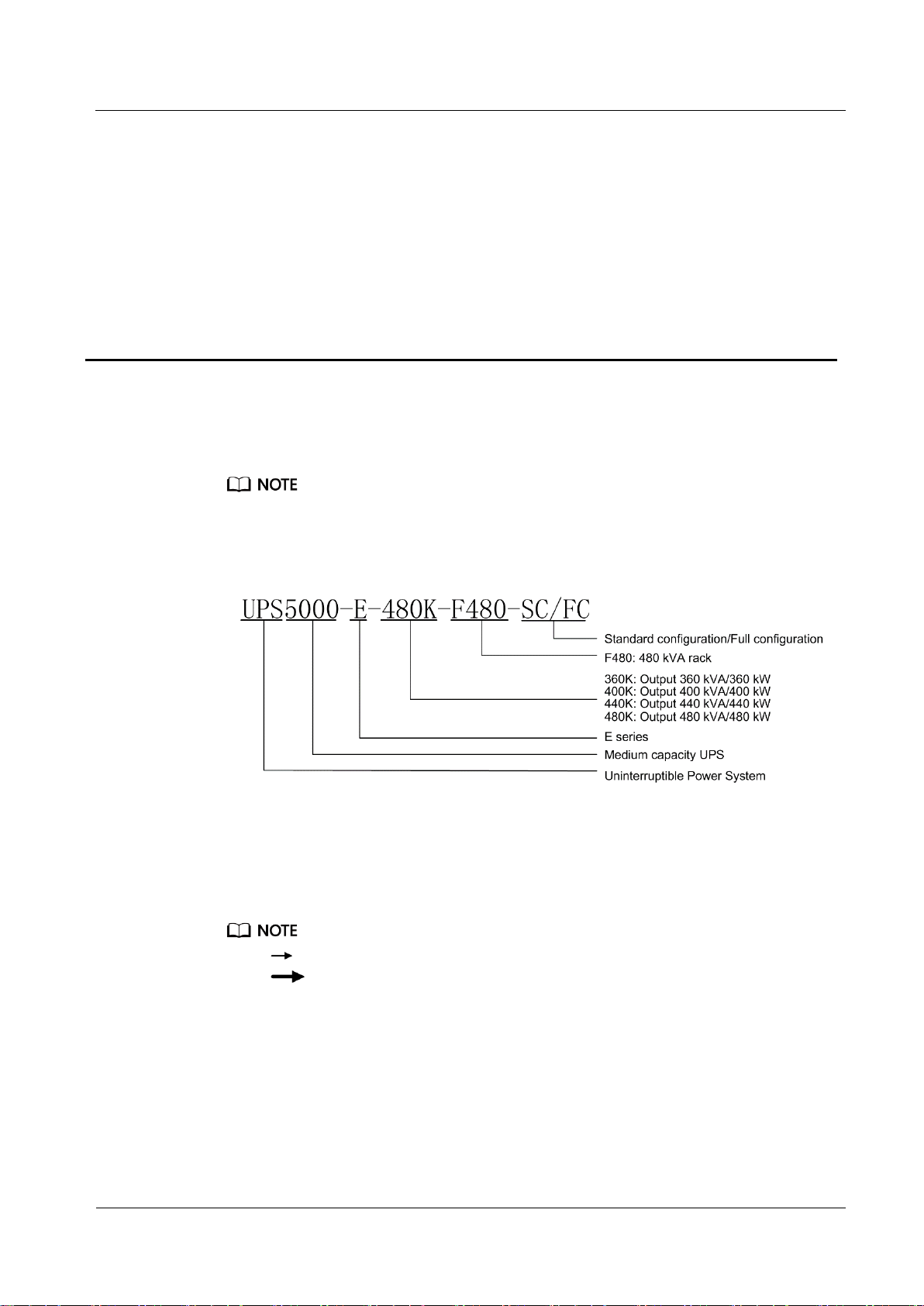

2.1 Model Description

The structural drawings and graphical user interface (GUI) appeared in this document are those of

UPS5000-E-480 kVA.

Figure 2-1 Model number

2 Overview

2.2 Working Principle

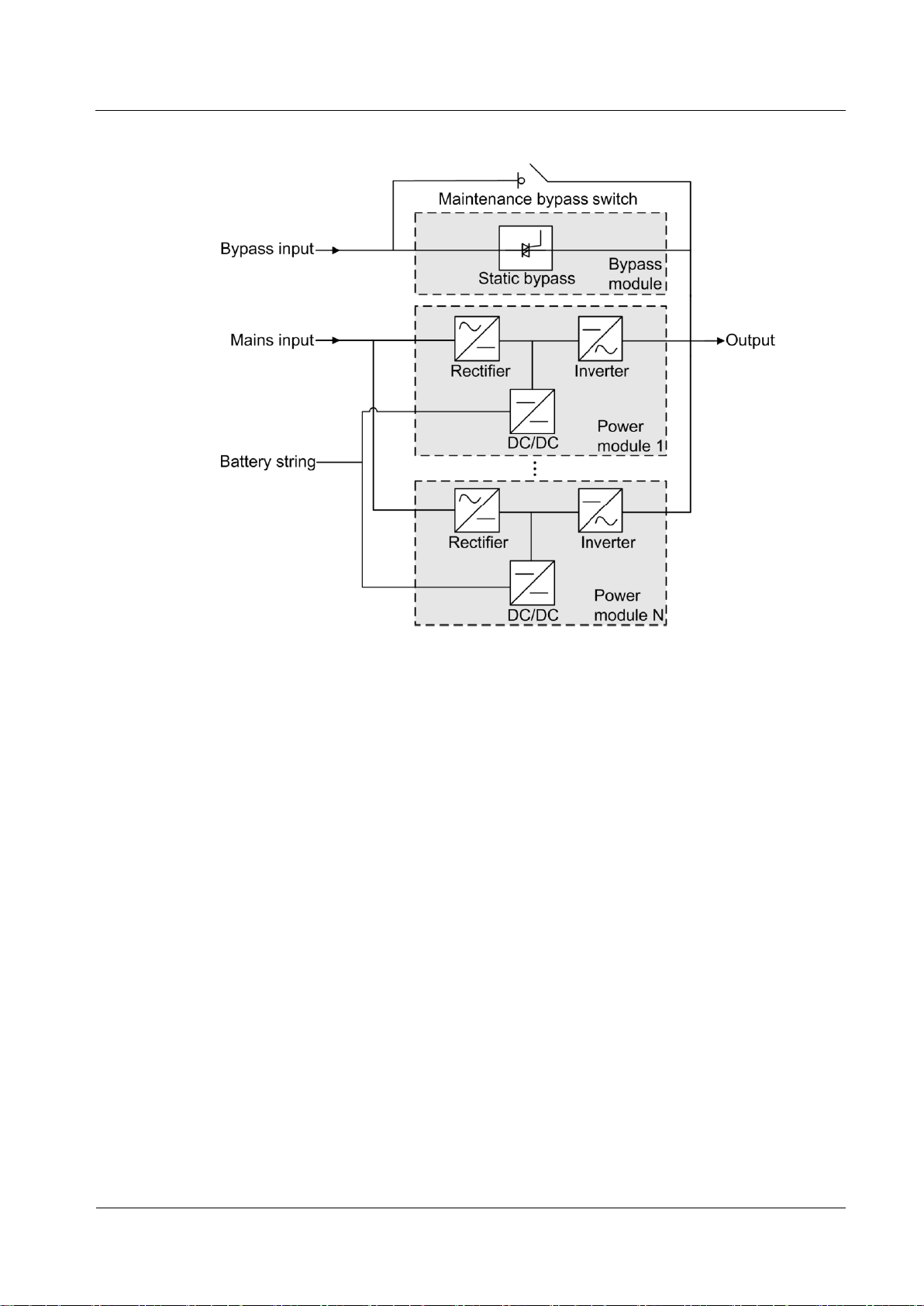

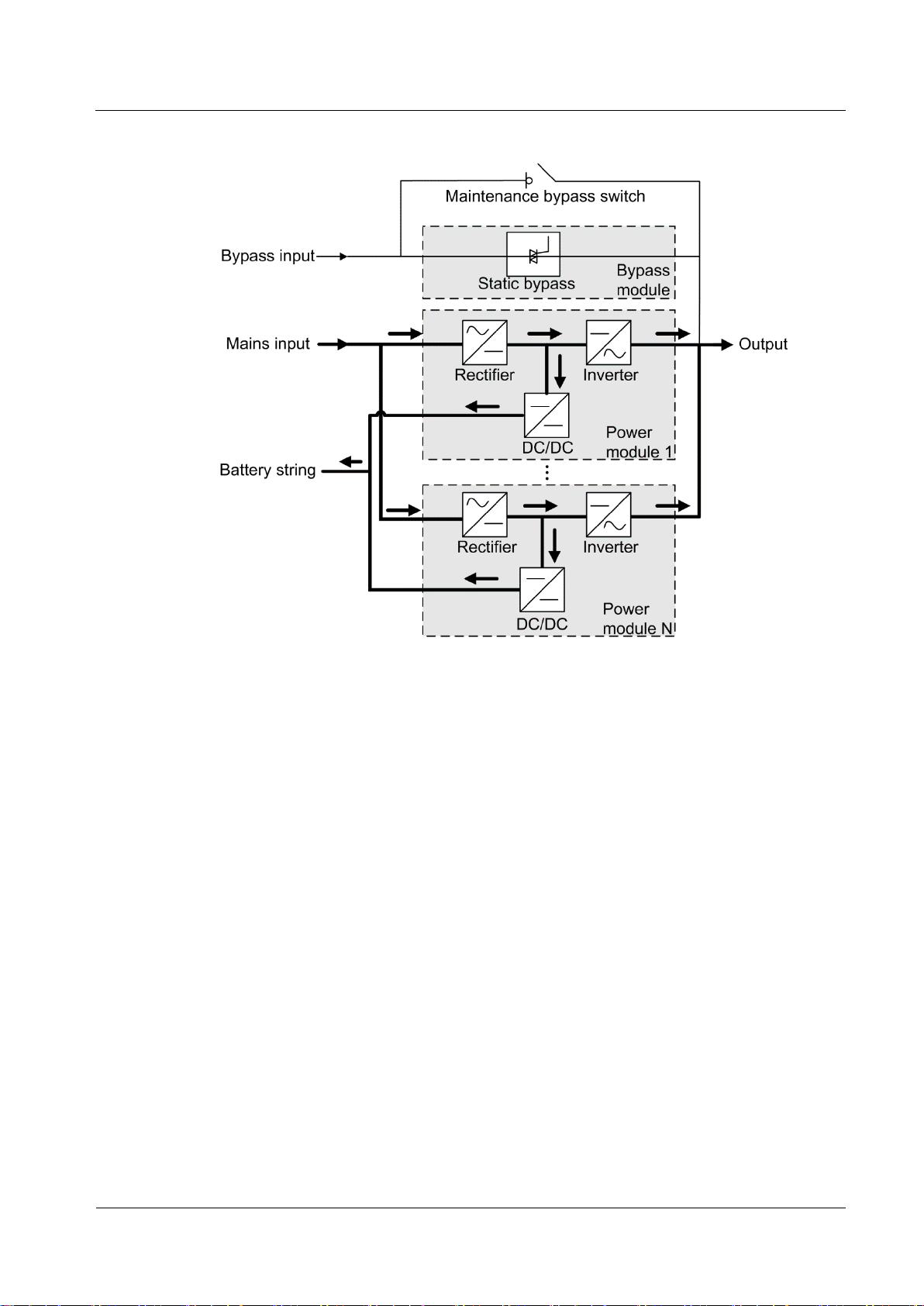

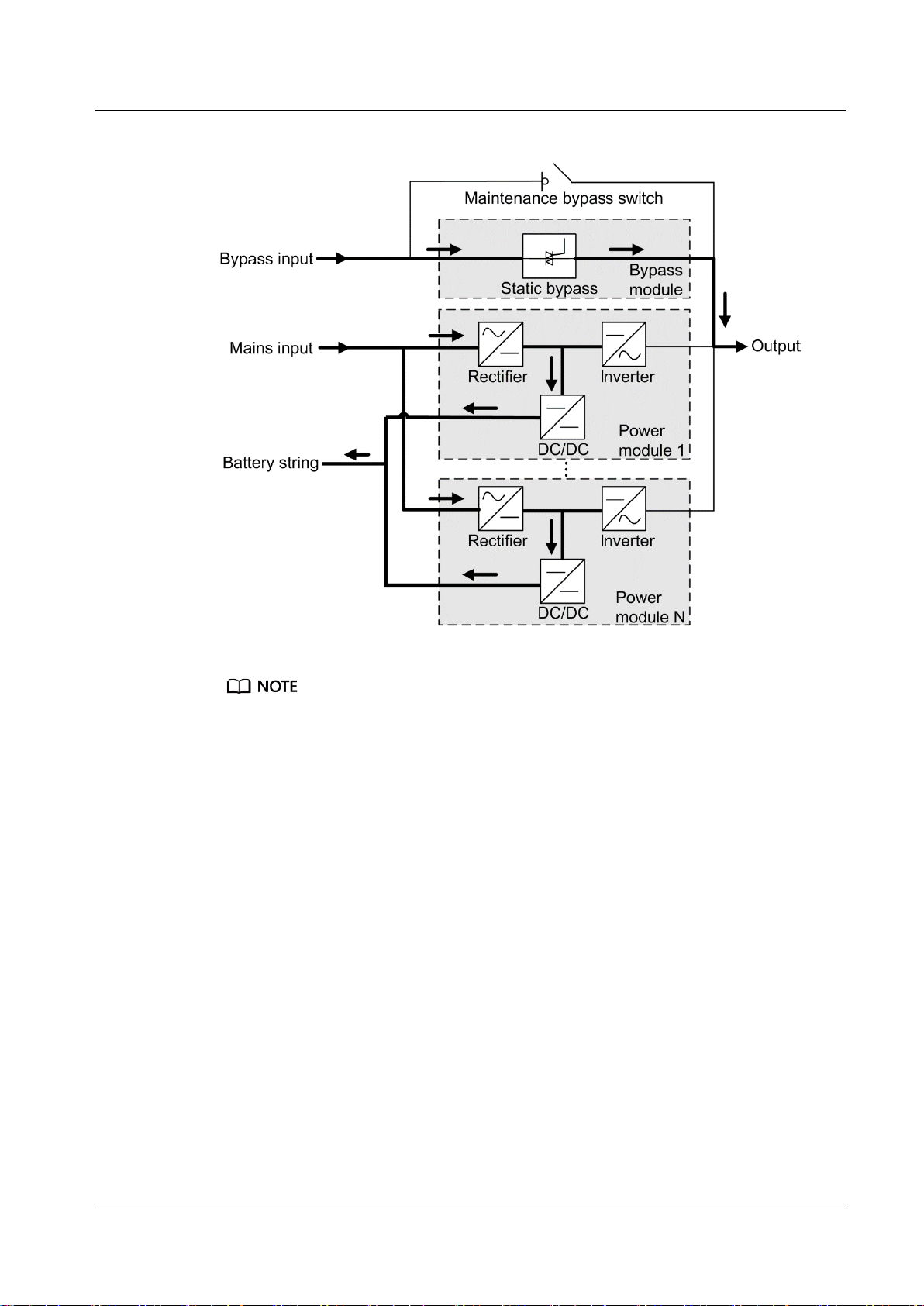

2.2.1 Conceptual Diagram

The UPS5000 is an online product. It uses a modular design, which facilitates maintenance

and capacity expansion. The UPS5000 adopts intelligent control. Its power module consists of

a rectifier, inverter, and DC/DC converter. The UPS5000 converts inputs into pure highquality sine wave outputs by using the high-frequency switching technology.

indicates an input mode.

indicates the energy flow direction.

Page 24

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

16

Figure 2-2 UPS conceptual diagram

2.2.2 Working Modes

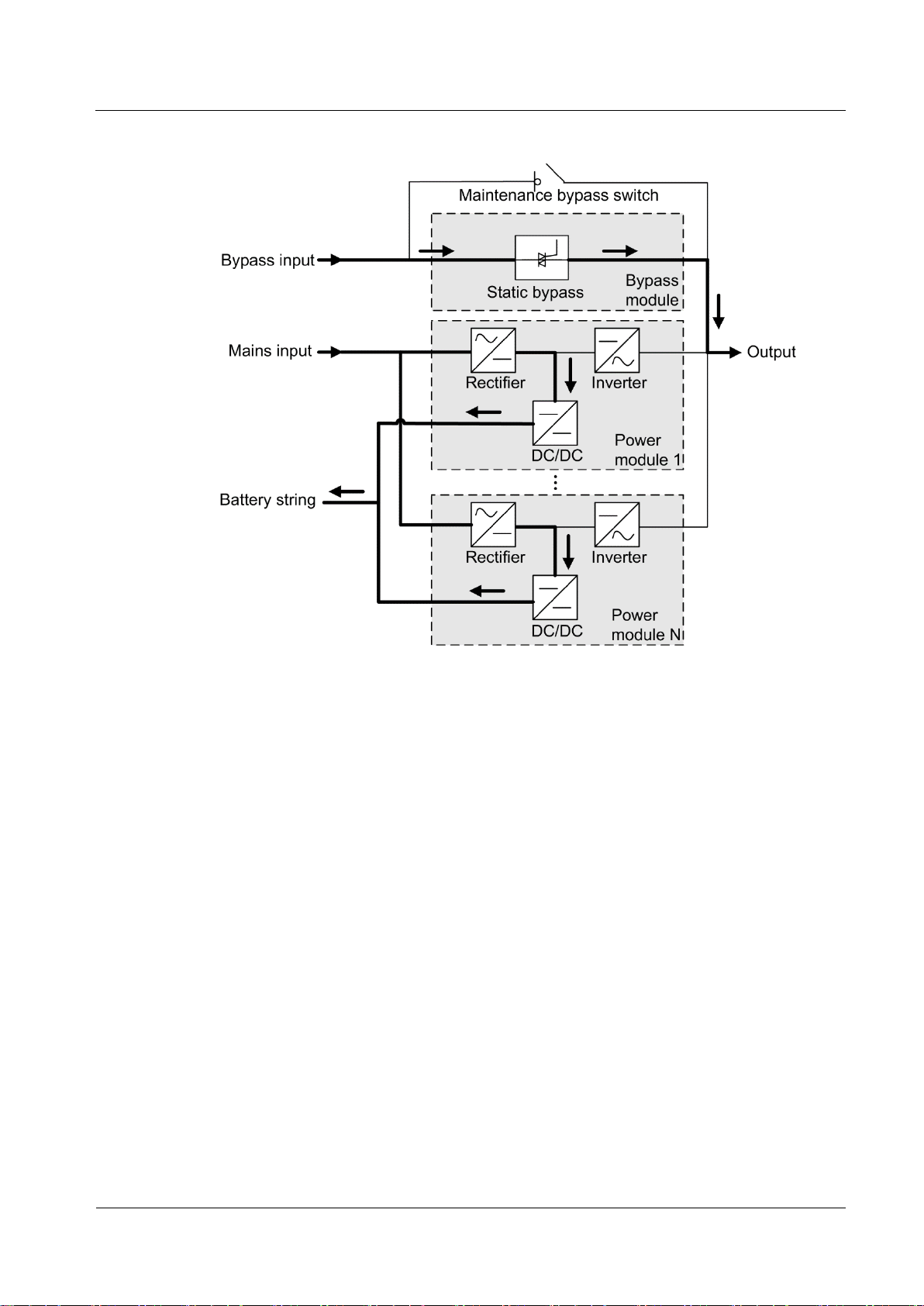

2.2.2.1 Normal Mode

In normal mode, the rectifier converts AC power into DC power, then the inverter converts

DC power into high-precision AC outputs. The conversions protect loads from interference

such as input harmonics, glitches, and voltage transients.

Page 25

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

17

Figure 2-3 UPS conceptual diagram in normal mode

2.2.2.2 Bypass Mode

The UPS automatically transfers to bypass mode upon detecting power module

overtemperature, overload, or other faults that may cause the inverter to shut down. The

bypass power supply is not protected by the UPS which means it may be affected by mains

outage, and incorrect AC voltage or frequency.

Page 26

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

18

Figure 2-4 UPS conceptual diagram in bypass mode

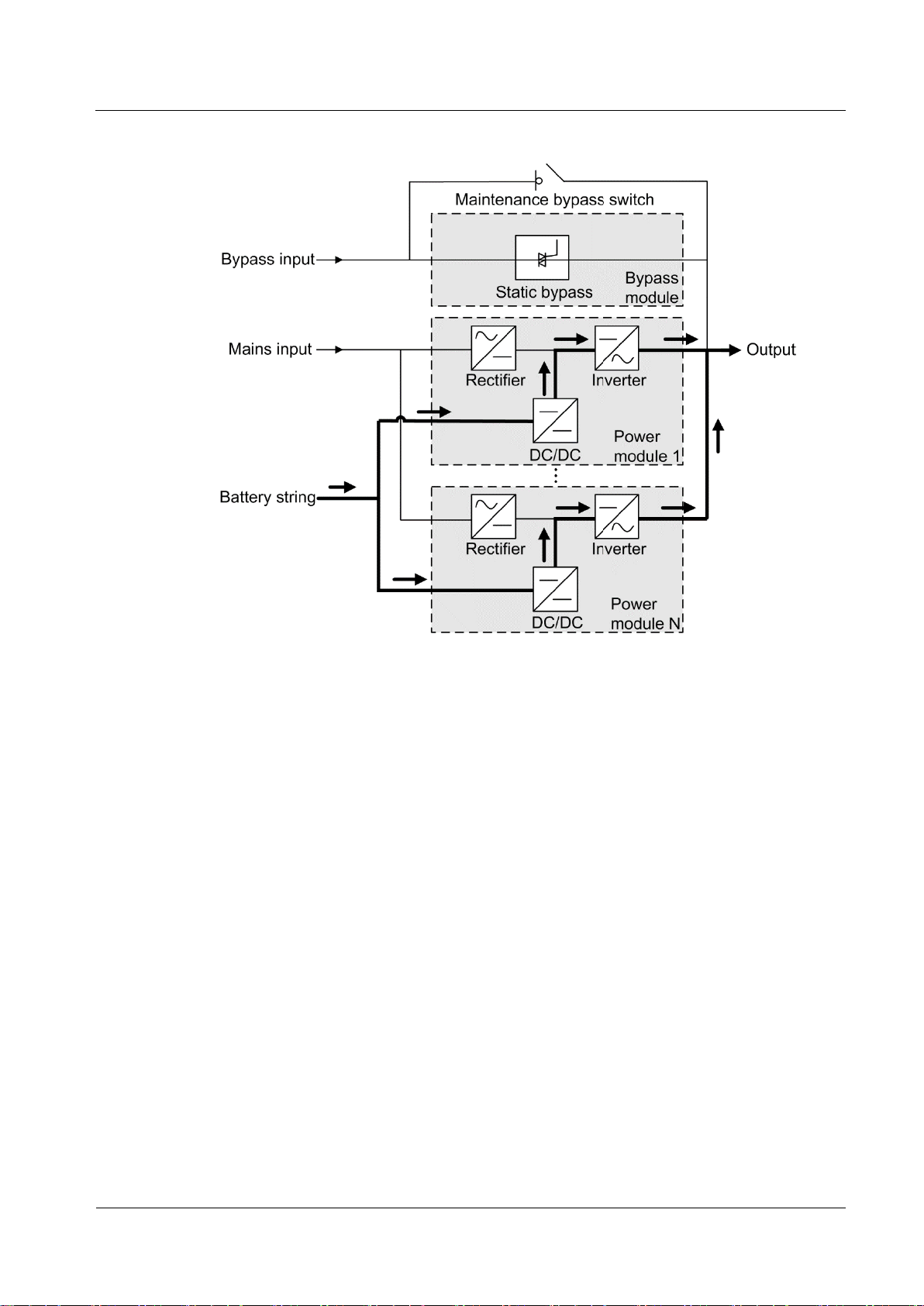

2.2.2.3 Battery Mode

If the mains input is abnormal or the rectifier becomes abnormal, the UPS transfers to battery

mode. The power module obtains DC power from batteries, and the power is converted into

AC output by the inverter.

Page 27

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

19

Figure 2-5 UPS conceptual diagram in battery mode

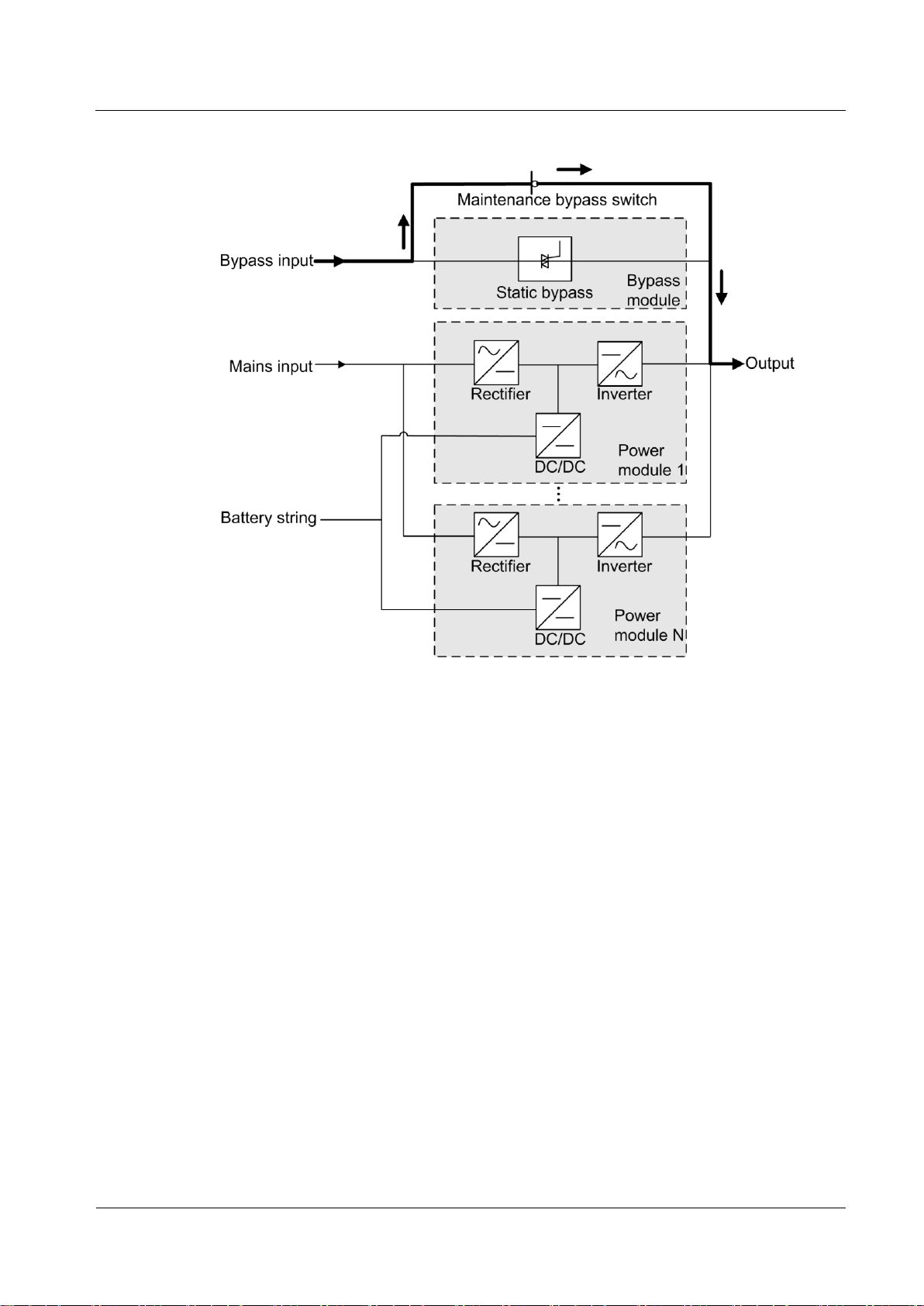

2.2.2.4 Maintenance Bypass Mode

When the UPS works in maintenance bypass mode, the current flows through the

maintenance bypass instead of the power module. You can maintain the circuit inside the

cabinet.

Page 28

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

20

Figure 2-6 UPS conceptual diagram in maintenance bypass mode

2.2.2.5 ECO Mode

The economic control operation (ECO) mode is an economical working mode, which can be

configured on the LCD or web user interface (WebUI). In ECO mode, when the bypass input

is within the ECO voltage and frequency ranges and other ECO power supply conditions are

met, the UPS works in bypass mode and the inverter is in standby state. When the bypass

voltage is outside the ECO voltage range, the UPS transfers from bypass mode to normal

mode. In bypass mode or normal mode, the rectifier keeps working and charges batteries

using a charger. The ECO mode delivers a high efficiency.

Page 29

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

21

Figure 2-7 UPS conceptual diagram in ECO mode

Manual startup is required to ensure that the inverter is in standby state and the power flow has reached

the inverter.

Page 30

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

22

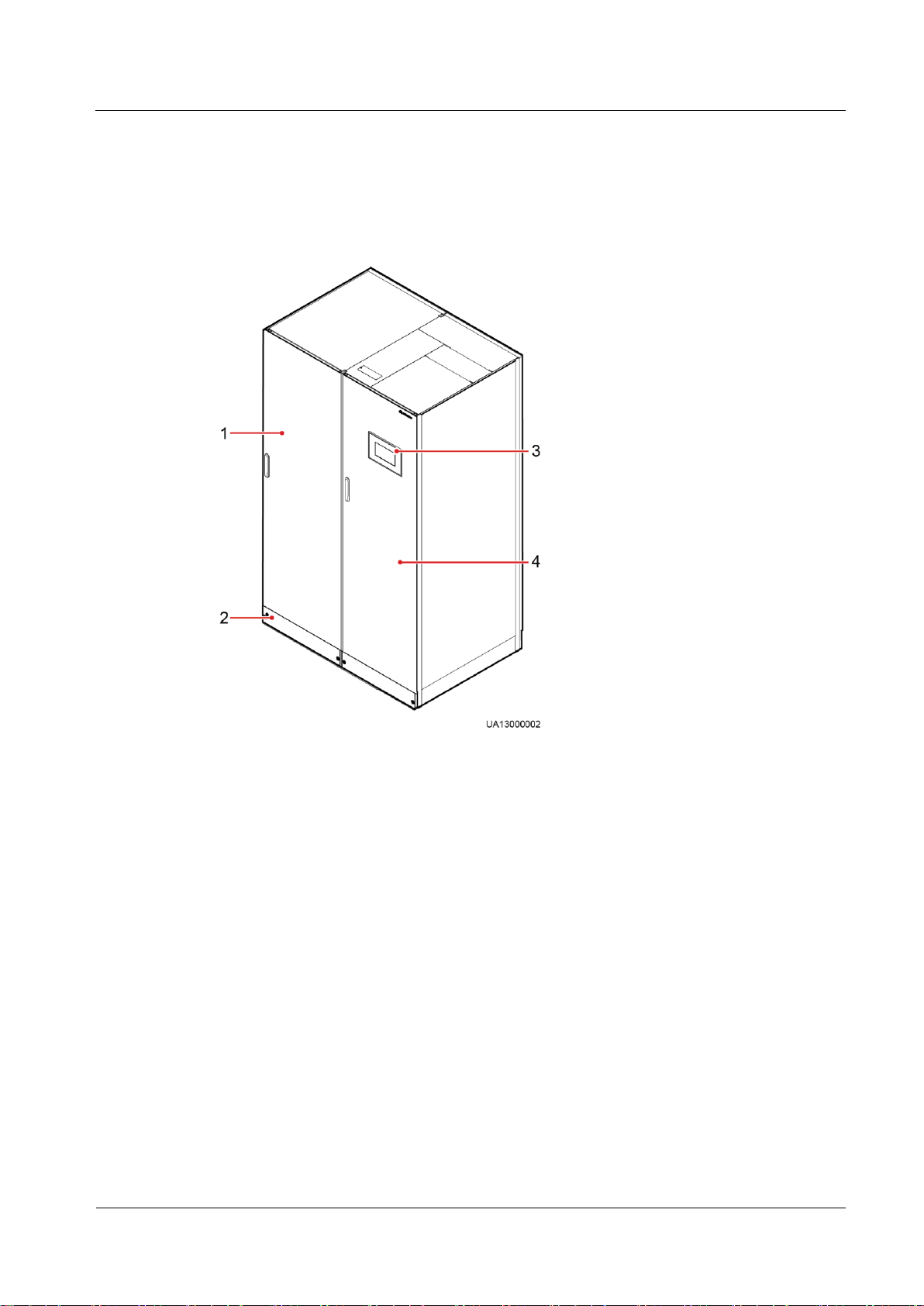

2.3 Product Description

(1) Power

cabinet

(2) Anchor baffle

plates

(3) Monitor display unit

(MDU)

(4) Bypass

cabinet

2.3.1 Appearance

Figure 2-8 UPS

Page 31

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

23

2.3.2 Product Structure

(1) Power modules

(2) Control module

(3) Optional card slot

(behind the filler panel)

(4) Power distribution unit (PDU)

covers (four pieces)

(5) Maintenance

bypass switch

(6) Bypass module

Figure 2-9 Product structure (UPS with standard line configurations)

Page 32

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

24

Figure 2-10 Product structure (UPS with full copper bar configurations)

(1) Power modules

(2) Control module

(3) Optional card slot (behind the filler

panel)

(4) Mains input switch

(5) Output switch

(6) Power distribution unit covers (four

pieces)

(7) Maintenance bypass

switch

(8) Bypass input

switch

(9) Bypass module

A UPS in standard configurations has only one switch, that is, the maintenance bypass switch. A UPS in

full configurations has four switches. They are the mains input switch, mains output switch, maintenance

bypass switch, and bypass input switch from the top to the bottom.

2.4 Control Module

2.4.1 Overview

In a standard configuration, the control module consists of two ECMs, one dry contact card,

and one monitoring interface card (from left to right). The four cards are hot swappable. One

Page 33

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

25

subrack is reserved above the dry contact card. A backfeed protection card or dry contact

(1) Ground terminal

(2) Parallel port 1

(3) BSC port

1

(4) Ready switch

on ECM 1

(5) Indicators for ECM 1

(6) Parallel port 2

(7) BSC port

2

(8) Ready switch

on ECM 2

(9) Indicators for ECM 2

(10) Dry contact card

(11) Dry

contacts

(12) MDU port

(13) RS485 port

(14) Fast Ethernet (FE)

port

(15) COM2

port

(16) COM1 port

(17) Battery temperature

sensor port

(18) Optional card

subrack cover

extended card can be inserted into this subrack.

Figure 2-11 Signal panel on the control module

2.4.2 ECM

Appearance

Ports are protected by a security mechanism.

The control module consists of two energy control modules (ECMs) in active/standby mode.

Figure 2-12 ECM

Page 34

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

26

Table 2-1 Ports on the ECM

Silk Screen

Description

PARALLEL

The PARALLEL port transmits parallel signals between racks.

BSC

The BSC port is used in a dual-bus system to synchronize output

frequencies and phases between UPS systems, ensuring that two buses

can switch with each other.

BSC cables are hot-swappable.

Indicator

Color

Status

Description

NORMAL

Green

Steady on

This ECM is the active ECM.

Blinking at

0.5 Hz

This ECM is the standby ECM and it is ready.

Off

This ECM is not ready or the CPLD of this

ECM is being upgraded.

Blinking at

4 Hz

The DSP of the ECM is being upgraded or not

configured.

ALM

Yellow

Steady on

The ECM has a minor alarm, but it does not

need to be replaced.

Off

The ECM has no minor alarm or the DSP of the

ECM is being upgraded.

FAULT

Red

Steady on

The ECM has a critical alarm.

Off

The ECM has no critical alarm or the DSP of the

ECM is being upgraded.

For a single UPS, the parallel cable is not needed.

Table 2-2 Indicator description

Functions

As a control interface for the entire system, the ECM communicates with each module

and provides a bus to communicate with the dry contact card. The ECM ensures

equalized output currents between modules so that load power is equally shared.

Provides module running information for the MDU.

Controls the running of a single UPS5000 and a parallel system, and reports the

UPS5000 status information to other monitoring modules.

The system provides three types of CAN communication: monitoring CAN

communication, intra-rack parallel CAN communication, and inter-rack parallel CAN

communication.

Page 35

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

27

Specifications

Silk Screen

Description

Status

Initial Status

BTG

Port for detecting battery

grounding faults

Connected: battery

grounding fault

Disconnected: no

battery grounding

fault

Disconnected

0V

Port for signal ground

GEN

Port for detecting diesel

generator (D.G.) mode

Connected: D.G.

mode

Disconnected:

non-D.G. mode

Disconnected

0V

Port for signal ground

Figure 2-13 Logical connections for CAN communication

Hot-swappable

1 U high

2.4.3 Dry contact card

Appearance

Figure 2-14 Dry contact card

Table 2-3 Ports on the dry contact card

Page 36

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

28

Silk Screen

Description

Status

Initial Status

BCB_OL

Port for detecting the BCB

box

Grounded: BCB

box connected

Disconnected:

BCB box not

connected

Grounded

BCB_STA

Port for monitoring the

battery switch

Connected: battery

switch ON

Disconnected:

battery switch

OFF

Disconnected

BCB_DRV

Controls battery circuit

breaker trip. When the

voltage is +12 V, the circuit

breaker trips.

0 V: battery switch

not tripped

12 V: battery

switch tripped

0 V

BCB_0V

Port for signal ground

EPO_NO

Emergency power-off (EPO)

port

If the normally open

(NO) port is

connected to the

EPO_12V port, EPO

is triggered.

Disconnected

EPO_12V

+12 V

EPO_NC

EPO port

If the normally closed

(NC) port is

disconnected from the

EPO_12V port, EPO

is triggered.

Connected

EPO_12V

+12 V

SWITCH

STATUS_OUT

Port for monitoring the UPS

output circuit breaker

Connected: circuit

breaker ON

Disconnected:

circuit breaker

OFF

Connected

SWITCH

STATUS_0V

Port for signal ground

SWITCH

STATUS_MT

Port for monitoring the

maintenance circuit breaker

Disconnected:

circuit breaker ON

Connected: circuit

breaker OFF

Disconnected

SWITCH

STATUS_0V

Port for signal ground

SWITCH

STATUS_BP

Port for monitoring the

bypass input circuit breaker

Connected: circuit

breaker ON

Disconnected:

circuit breaker

OFF

Connected

SWITCH

STATUS_0V

Port for signal ground

SPD

Port for monitoring the input

AC surge protective device

(SPD)

Connected: SPD

enabled

Disconnected:

SPD disabled

Connected

0V

Port for signal ground

Page 37

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

29

The dry contact interface card takes effect only after it is set on the monitoring system. Set the

unused dry contact signal to the unused status.

Set the EPO port to NO or NC as required.

When multiple UPSs are paralleled, all dry contact signals to be used need to connect to each UPS.

Single cables require dual-insulated twisted cables. If the length of a power cable is within 25–50 m,

its cross-sectional area must be 0.5 mm2 to 1.5 mm2.

Functions

The dry contact card allows the UPS to detect and manage the switch status of the battery

system (including the external battery switch) and implement remote emergency power-off

(EPO).

Specifications

Hot-swappable

0.5 U high

2.4.4 (Optional) Backfeed Protection Card

Backfeed can cause damage to the UPS, loads, and maintenance personnel. If backfeed

occurs, the backfeed protection card triggers alarm signals, or disconnects the backfeed loop.

The backfeed protection card uses relay contact signals. The signal ports support any power

signals with a voltage of no more than 240 V AC and a current of less than 4 A. For details,

see the UPS5000 Backfeed Protection Card User Manual (03021KQQ).

2.4.5 (Optional) Dry Contact Extended Card

The dry contact extended card provides five signal output ports and five signal input ports.

For details, see the UPS5000 Dry Contact Extended Card User Manual (03021RKN).

2.4.6 Monitoring Interface Card

The FE port resembles the RS485 port. Follow the silk screen when connecting

communications cables as, if the RS485 port is mistaken for the FE port during cable

connection, the WebUI cannot be connected and MDU communication fails. Conversely, if

the FE port is mistaken for the RS485 port during cable connection, RS485

communication fails.

Only once being set will dry contact signals take effect. Set unused dry contact signals to

the unused state on the LCD.

In a parallel system, ensure that used dry contacts properly connect to each UPS.

The monitoring interface card provides external ports as well as monitoring and control

functions for the MDU. The ports include the ambient temperature and humidity sensor port,

battery monitoring unit (BMU) port, FE port, battery temperature monitoring port, and

network management port. MDU functions include monitoring of the UPS, allowing users to

Page 38

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

30

set parameters, command delivery, information reports, and UPS key information and

Port

Silk

Screen

Description

DO_1

NO

DO_1 is used to output alarms and indicates critical

alarms by default. It can be set to indicate minor alarms,

bypass mode, battery mode, or low battery voltage.

COM

DO_2

NO

DO_2 is used to output alarms and indicates minor

alarms by default. It can be set to indicate critical

alarms, bypass mode, battery mode, or low battery

voltage.

COM

DO_3

NO

DO_3 is used to output alarms and indicates bypass

mode by default. It can be set to indicate critical alarms,

minor alarms, battery mode, or low battery voltage.

COM

DO_4

NO

DO_4 is used to output alarms and indicates battery

mode by default. It can be set to indicate critical alarms,

minor alarms, bypass mode, or low battery voltage.

When the UPS works in intelligent power mode, DO_4

indicates D.G. control, which cannot be changed.

COM

DB26

MDU

Provides FE, RS485, I2C, and CAN signals.

Battery

temperature

sensor port

B_TEMP

Connects to an indoor battery temperature sensor.

Southbound

COM1

Connects to an ambient temperature and humidity

parameters displayed on the LCD.

Figure 2-15 shows the signal ports on the monitoring interface card.

Figure 2-15 Monitoring interface card

Table 2-4 describes the ports on the monitoring interface card.

DO_1 to DO_4 meet the maximum voltage and current requirements of 30 V DC/1 A or 60 V DC/0.5 A.

Table 2-4 Ports on the monitoring interface card

Page 39

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

31

Port

Silk

Screen

Description

communications

port 1

sensor over two wires.

Southbound

communications

port 2

COM2

Connects to a southbound device, such as a BMU.

Network port

FE

Connects to the network port on a PC.

Northbound

communications

port

RS485

Connects to a northbound network management device

or a third-party network management device over two

wires.

Signal cables must be double-insulated twisted cables. If the cable length is 25–50 m, the crosssectional area must be 0.5–1.5 mm2.

RS485 cables and FE cables must be shielded cables.

Figure 2-16 and Figure 2-17 are recommended wiring methods for DO ports.

Figure 2-16 Wiring method 1

Figure 2-17 Wiring method 2

Figure 2-18 and Table 2-5 describe the COM1 pin definitions.

Page 40

UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

32

Figure 2-18 COM1 pins

Pin

Description

1

GND