Huawei UPS5000-A-30 kVA, UPS5000-A-40 kVA, UPS5000-A-80 kVA User Manual

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

Issue

11

Date

2018-12-10

HUAWEI TECHNOLOGIES CO., LTD.

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

i

Copyright © Huawei Technologies Co., Ltd. 2018. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address:

Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website:

http://e.huawei.com

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

About This Document

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

ii

Purpose

Symbol

Description

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

This document describes the high-frequency tower-mounted UPS5000-A-30 kVA & 40 kVA

& 80 kVA in terms of features, appearance, structure, working principle, technical

specifications, installation, operation, and maintenance. UPS is short for uninterruptible

power system. Unless otherwise specified, UPS refers to all the models described in this

document.

Intended Audience

About This Document

This document is intended for:

Sales engineers

Technical support engineers

System engineers

Hardware installation engineers

Commissioning engineers

Data configuration engineers

Maintenance engineers

Symbol Conventions

The symbols that may be found in this document are defined as follows.

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

About This Document

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

iii

Symbol

Description

Indicates a potentially hazardous situation which, if not

avoided, could result in equipment damage, data loss,

performance deterioration, or unanticipated results.

NOTICE is used to address practices not related to

personal injury.

Calls attention to important information, best practices

and tips.

NOTE is used to address information not related to

personal injury, equipment damage, and environment

deterioration.

Change History

Changes between document issues are cumulative. The latest document issue contains all the

changes made in earlier issues.

Issue 11(2018-12-10)

Update some MDU screenshots.

Issue 10 (2018-04-18)

This issue is the tenth official release, which incorporates the following change:

Updated the model specifications.

Issue 09 (2018-01-03)

This issue is the ninth official release, which incorporates the following changes:

Updated the output electrical specifications and typical configuration.

Updated the Monitoring screen image.

Issue 08 (2017-06-09)

This issue is the eighth official release, which incorporates the following changes:

Updated the Monitoring screen image.

Issue 07 (2016-12-03)

This issue is the seventh official release, which incorporates the following changes:

Updated the UPS front space reservation in section 3.1.1 "Site".

Added the section 3.2.7.1 "UPS Cable Connection Reference".

Added checking for foreign matters in section 3.4 "Installation Verification".

Added the section 5.1.5 "Setting ECO Mode" and the section 5.1.6 "Testing Batteries".

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

About This Document

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

iv

Updated the section 6 "Routine Maintenance".

Added the specifications of the internal circuit breaker in the section 8 "Technical

Specifications".

Issue 06 (2015-06-26)

This issue is the sixth official release, which incorporates the following changes:

Updated the Monitoring screen image.

Issue 05 (2014-09-26)

This issue is the fifth official release, which incorporates the following changes:

Added the features of four parallel systems and the battery monitoring unit (BMU).

Issue 04 (2014-07-16)

This issue is the fourth official release, which incorporates the following changes:

Updated section 1 Precautions.

Issue 03 (2014-01-20)

This issue is the third official release, which incorporates the following changes:

Updated section 1 Precautions.

Updated the secured installation for the UPS5000-A-60 kVA/80 kVA/120 kVA in section

3.2.2.

Updated section 7 Troubleshooting Alarm List.

Issue 02 (2013-11-18)

This is the second official release, which incorporates the following changes:

Added figures of OT and DT terminals for the UPS5000-A and tables that list their

specifications in section 3.1.3.

Issue 01(2013-11-05)

This is the first release.

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

Contents

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

v

Contents

About This Document .................................................................................................................... ii

1 Safety Precautions ......................................................................................................................... 1

1.1 General Safety .............................................................................................................................................................. 1

1.2 Electrical Safety ............................................................................................................................................................ 3

1.3 Operating Environment................................................................................................................................................. 6

1.4 Battery Safety ............................................................................................................................................................... 6

1.5 Mechanical Safety ........................................................................................................................................................ 8

1.6 Laying Out Cables ........................................................................................................................................................ 9

1.7 Information About Foreign Objects near UPS Equipment Installation ....................................................................... 10

2 Overview ....................................................................................................................................... 12

2.1 Model Description ...................................................................................................................................................... 12

2.2 Working Principles...................................................................................................................................................... 12

2.2.1 Conceptual Diagram ................................................................................................................................................ 12

2.2.2 Working Modes ........................................................................................................................................................ 13

2.2.2.1 Normal Mode ........................................................................................................................................................ 13

2.2.2.2 Bypass Mode ........................................................................................................................................................ 14

2.2.2.3 Battery Mode ........................................................................................................................................................ 14

2.2.2.4 Maintenance Bypass Mode ................................................................................................................................... 15

2.2.2.5 ECO Mode ............................................................................................................................................................ 15

2.3 Product Description .................................................................................................................................................... 17

2.3.1 Appearance .............................................................................................................................................................. 17

2.3.2 Product Structure ..................................................................................................................................................... 18

2.3.2.1 30 kVA/40 kVA UPS ............................................................................................................................................. 18

2.3.2.2 80kVA UPS ................................ ................................................................ ........................................................... 22

2.3.3 Control Port ............................................................................................................................................................. 23

2.4 Typical configurations ................................................................................................................................................ 27

2.4.1 Single UPS ............................................................................................................................................................... 28

2.4.2 Parallel System ........................................................................................................................................................ 28

2.4.3 Dual-Bus System ..................................................................................................................................................... 29

2.5 Optional Components ................................................................................................................................................. 30

3 Installation.................................................................................................................................... 32

3.1 Installation Preparations ............................................................................................................................................. 32

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

Contents

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

vi

3.1.1 Site ........................................................................................................................................................................... 32

3.1.2 Tools and Instruments .............................................................................................................................................. 35

3.1.3 Power Cables ........................................................................................................................................................... 37

3.1.4 Unpacking and Checking ......................................................................................................................................... 42

3.1.4.1 30 kVA/40 kVA UPS ............................................................................................................................................. 43

3.1.4.2 80 kVA UPS .......................................................................................................................................................... 44

3.2 Installing a Single UPS ............................................................................................................................................... 48

3.2.1 Installing the UPS5000-A-30 kVA/40 kVA ............................................................................................................. 48

3.2.2 Installing the UPS5000-A-80 kVA .......................................................................................................................... 59

3.2.3 (Optional) Installing Antiseismic Kits ..................................................................................................................... 71

3.2.4 (Optional) Installing a Battery Monitoring Unit ...................................................................................................... 72

3.2.5 Installing Batteries ................................................................................................................................................... 74

3.2.6 UPS Cable Connection Reference ........................................................................................................................... 75

3.2.7 Routing Cables......................................................................................................................................................... 76

3.2.7.1 Cable Routes ......................................................................................................................................................... 76

3.2.7.2 Connecting Ground Cables ................................................................................................................................... 78

3.2.7.3 Connecting AC Input Power Cables ..................................................................................................................... 80

3.2.7.4 Connecting AC Output Power Cables ................................................................................................................... 84

3.2.7.5 Connecting Battery Cables ................................................................................................................................... 85

3.2.8 Remote EPO ............................................................................................................................................................ 87

3.2.9 Connecting Communications Cables ....................................................................................................................... 88

3.3 Installing a Parallel System ......................................................................................................................................... 88

3.3.1 Connecting Power Cables ........................................................................................................................................ 88

3.3.2 Connecting Signal Cables ........................................................................................................................................ 92

3.4 Installation Verification ............................................................................................................................................... 94

4 LCD and WebUI .......................................................................................................................... 99

4.1 MDU ........................................................................................................................................................................... 99

4.2 LCD ................................................................ ................................ ................................................................ .......... 101

4.2.1 Overview ............................................................................................................................................................... 101

4.2.2 Status Screen .......................................................................................................................................................... 102

4.2.3 Alarms .................................................................................................................................................................... 105

4.2.4 Settings Screen....................................................................................................................................................... 106

4.2.5 Control ................................................................................................................................................................... 120

4.2.6 About Screen .......................................................................................................................................................... 122

4.3 WebUI ....................................................................................................................................................................... 122

4.3.1 Login ...................................................................................................................................................................... 122

4.3.2 Monitoring Page .................................................................................................................................................... 124

4.3.2.1 Parameter Settings .............................................................................................................................................. 125

4.3.2.2 Communications Settings ................................................................................................................................... 132

4.3.2.3 Control ................................................................................................................................................................ 132

4.3.3 Query Page ............................................................................................................................................................ 133

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

Contents

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

vii

4.3.3.1 Historical Alarms Page ....................................................................................................................................... 133

4.3.3.2 Logs Page ........................................................................................................................................................... 133

4.3.4 Config. Page .......................................................................................................................................................... 134

4.3.4.1 User Management ............................................................................................................................................... 134

4.3.4.2 Site Config. ......................................................................................................................................................... 134

4.3.4.3 RCCMD .............................................................................................................................................................. 136

4.3.4.4 Managing the UPS by Using the NMS Complying with RFC1628 Standard ..................................................... 145

4.3.5 Protecting the Server by Using the RCCMD Software .......................................................................................... 146

4.3.5.1 Introduction to the Software ............................................................................................................................... 146

4.3.5.2 RCCMD Event Shutdown and Message Sending ............................................................................................... 147

4.3.5.3 UPS Alive Check Function ................................................................................................................................. 148

5 Operations .................................................................................................................................. 151

5.1 Powering On and Starting the UPS ........................................................................................................................... 151

5.2 Shutting Down and Powering Off the UPS .............................................................................................................. 155

5.3 Starting the UPS in Battery Mode ............................................................................................................................ 156

5.4 Transferring to Bypass Mode .................................................................................................................................... 157

5.5 Setting ECO Mode .................................................................................................................................................... 157

5.6 Testing Batteries ....................................................................................................................................................... 158

5.6.1 Forced Equalized Charging Test ............................................................................................................................ 158

5.6.2 Shallow Discharge Test .......................................................................................................................................... 159

5.6.3 Capacity Test.......................................................................................................................................................... 161

5.6.4 Test Data Download ............................................................................................................................................... 162

5.7 Transferring to Maintenance Bypass Mode .............................................................................................................. 162

5.8 Transferring from Maintenance Bypass Mode to Normal Mode .............................................................................. 165

5.9 Performing EPO........................................................................................................................................................ 166

5.10 Clearing the EPO State ........................................................................................................................................... 167

6 Routine Maintenance ............................................................................................................... 169

6.1 UPS Maintenance ..................................................................................................................................................... 169

6.1.1 Monthly Maintenance ............................................................................................................................................ 169

6.1.2 Quarterly Maintenance .......................................................................................................................................... 170

6.1.3 Annual Maintenance .............................................................................................................................................. 170

6.2 Battery Maintenance ................................................................................................................................................. 171

6.2.1 Precautions for Battery Maintenance ..................................................................................................................... 172

6.2.2 Monthly Maintenance ............................................................................................................................................ 172

6.2.3 Quarterly Maintenance .......................................................................................................................................... 173

6.2.4 Annual Maintenance .............................................................................................................................................. 174

7 Troubleshooting ........................................................................................................................ 175

8 Technical Specifications .......................................................................................................... 178

8.1 Physical Specifications ............................................................................................................................................. 178

8.2 Internal Switch Parameters ....................................................................................................................................... 178

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

Contents

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

viii

8.3 Environmental Specifications ................................................................................................................................... 178

8.4 Safety Regulations and EMC .................................................................................................................................... 179

8.5 Mains Input Electrical Specifications ....................................................................................................................... 179

8.6 Bypass Input Electrical Specifications ................................................................ ................................ ...................... 180

8.7 Battery Specifications ............................................................................................................................................... 180

8.8 Output Electrical Specifications ............................................................................................................................... 181

8.9 System Electrical Specifications ............................................................................................................................... 181

A Menu Hierarchy ....................................................................................................................... 182

A.1 LCD Menus ............................................................................................................................................................. 182

A.2 Menus on the WebUI ............................................................................................................................................... 183

B Alarm List................................................................................................................................... 186

C Acronyms and Abbreviations ................................................................................................ 200

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

1 Safety Precautions

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

1

1.1 General Safety

This section describes safety precautions to consider before installing, maintaining, and

operating the UPS.

1 Safety Precautions

Declaration

To minimize the risk of personal injury and damage to equipment, read and follow all the

precautions in this document before performing any operation. The "DANGER",

"WARNING", "CAUTION", and "NOTICE" statements in this document are only

supplemental and do not represent all the safety instructions.

Only trained and qualified personnel are allowed to install, operate, and maintain Huawei

equipment.

Follow the precautions and special safety instructions provided by Huawei when operating

Huawei products. Huawei will not be liable for any consequences that are caused due to

violations regarding general safety regulations and equipment design, production, and usage

safety standards.

Huawei does not take responsibilities for the following situations:

Operation under severe environments that are not specified in this document.

Installation or use in environments that are not specified in related international

standards.

Unauthorized product changes and software code modification.

Operations not complying with the operation instructions and safety precautions in this

document.

Damage caused by extreme natural environments.

Damage caused by using batteries provided by Huawei for non-Huawei UPSs.

Damage caused by using batteries not provided by Huawei.

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

1 Safety Precautions

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

2

Power Grid Requirements

A standard UPS can connect to a three-phase, five-wire (L1, L2, L3, N, PE) TT, TN-C, TN-S,

and TN-C-S AC power distribution system (IEC60364-1).

Local Laws and Regulations

Equipment operations must comply with local laws and regulations. The safety instructions in

this document are only supplemental to local safety regulations.

Personal Requirements

Only Huawei engineers or engineers certified by Huawei are allowed to perform UPS

commissioning and maintenance. Otherwise, human injury or equipment damage may occur,

and any resulting UPS faults will be beyond warranty scope.

Personnel who plan to install or maintain Huawei equipment must receive thorough training,

understand all necessary safety precautions, and master the correct operation methods.

Trained and qualified personnel, or personnel certified or authorized by Huawei are:

Allowed to install, operate, and maintain the equipment.

Allowed to remove safety facilities and inspect the equipment.

Allowed to replace or change the devices or components (including software).

Operation personnel must report faults or errors that might cause serious safety issues to

related owners.

This product should be installed and used according to the installation and technical,

specification requirements found in this manual. Otherwise, the product may be damaged,

and the resulting product exceptions or component damage will be beyond the warranty

scope.

Grounding Requirements

Devices to be grounded (excluding the energy storage unit) must meet the following

requirements:

When installing a device, install the ground cable first. When removing a device, remove

the ground cable at the very end.

Do not damage the ground conductor.

Do not operate devices if the ground conductor is not installed. Before operating a device,

check the electrical connection of the device to ensure that it is securely grounded.

Personal Safety

Do not operate the product, or handle cables, during thunderstorms.

To avoid electric shocks, do not connect safety extra-low voltage (SELV) circuits to

telecommunication network voltage (TNV) circuits.

Before operating a device, wear electrostatic discharge (ESD) clothes, ESD gloves, and

an ESD wrist strap. Remove any conductors (such as jewelry or watches) before the

operation to avoid electric shocks or burns.

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

1 Safety Precautions

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

3

Device Safety

In the case of fire, leave the building or the equipment room immediately, and turn on the

fire alarm bell or make an emergency call. Never enter the building on fire in any case.

If the cabinet provides an ESD jack, wear an ESD wrist strap and insert the ground

terminal of the ESD wrist strap into the jack.

Ensure all switches are turned to OFF during device installation.

Power on the UPS only after authorized engineers arrive at the site.

If a C2 UPS is used in residential areas, additional measures must be taken to prevent

radio frequency interferences.

If the UPS is used for life-supporting medical apparatus and facilities such as lifts where

adequate care has to be taken to ensure personal safety, discuss with the manufacturer in

advance about the applicability, settings, management, and maintenance of the UPS,

which require special considerations during design.

Before operation, ensure that the device is firmly anchored to the floor or other solid

objects, such as a wall or an installation rack.

Ensure ventilation vents are unblocked while the system is operating.

Before powering on the device, ensure that all the screws inside it are securely tightened

and will not fall off during operation.

After the installation, remove packing materials from the equipment area.

Replace danger signs that have worn out or are unreadable.

A UPS can be used to serve resistive-capacitive loads, resistive loads, and

micro-inductive loads. It is recommended that a UPS not be used for pure capacitive

loads, pure inductive loads, and half-wave rectification loads. It does not apply to energy

feedback loads.

Do not alter the UPS internal structure or installation procedure unless consent from the

manufacturer is given.

Never use water to clean electrical components inside or outside the UPS.

Do not drill holes into a cabinet.

1.2 Electrical Safety

High Voltage

The high voltage power supply provides power for the device operation. Direct or indirect

contact with high voltage power sources may result in fatal injury.

Non-standard or incorrect high voltage operations may result in fire and electric shocks.

The personnel who install the AC facility must be qualified to perform high voltage and

AC operations.

When selecting, connecting, and routing power cables, ensure compliance with local

laws and regulations.

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

1 Safety Precautions

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

4

When operating the AC power supply facility, ensure compliance with local laws and

regulations.

Before connecting cables to the UPS, ensure that the input power and mains power

distribution switches and output power distribution switch are turned off.

Use only dedicated tools during high voltage and AC operations.

If the operation is performed in a damp environment, ensure that the device is dry. When

water is found in the rack or the rack is damp, switch off the power supply immediately.

High Leakage Current

Ground a device before powering it on. Otherwise, personal injury or device damage may

occur.

If a "high leakage current" tag is attached to the panel of the device, ground the protective

ground terminal on the device enclosure before connecting the AC power supply to

prevent electric shocks.

The UPS can generate high leakage currents. Using a circuit breaker that has the leakage

current protection function is not recommended.

Power Cable

Fuse

Do not install or remove power cables when the device is on. Transient contact between the

core of the power cable and the conductor may generate electric arcs or sparks, which may

cause fire or damage eyesight.

Before moving or reconnecting the UPS, disconnect the mains and batteries, open the

output power distribution switch, and wait a period of at least 5 minutes after the UPS

completely powers off. Otherwise, electric shocks may occur.

Before installing or removing the power cable, open the power switch.

Before connecting a power cable, check that its label is correct.

If a fuse needs replacing, ensure the new fuse is of the same type and specifications so that the

system runs safely.

Backfeed Protection Dry Contact

The UPS can be configured with a backfeed protection dry contact to work with an external

automatic circuit breaker, preventing the voltage from flowing back to input terminals over

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

1 Safety Precautions

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

5

static bypass circuits. If device installation and maintenance personnel do not need to use

backfeed protection, paste labels on the external bypass input circuit breakers informing that

the circuit is connected to the UPS. Disconnect the device from the UPS before performing

operations on the circuit.

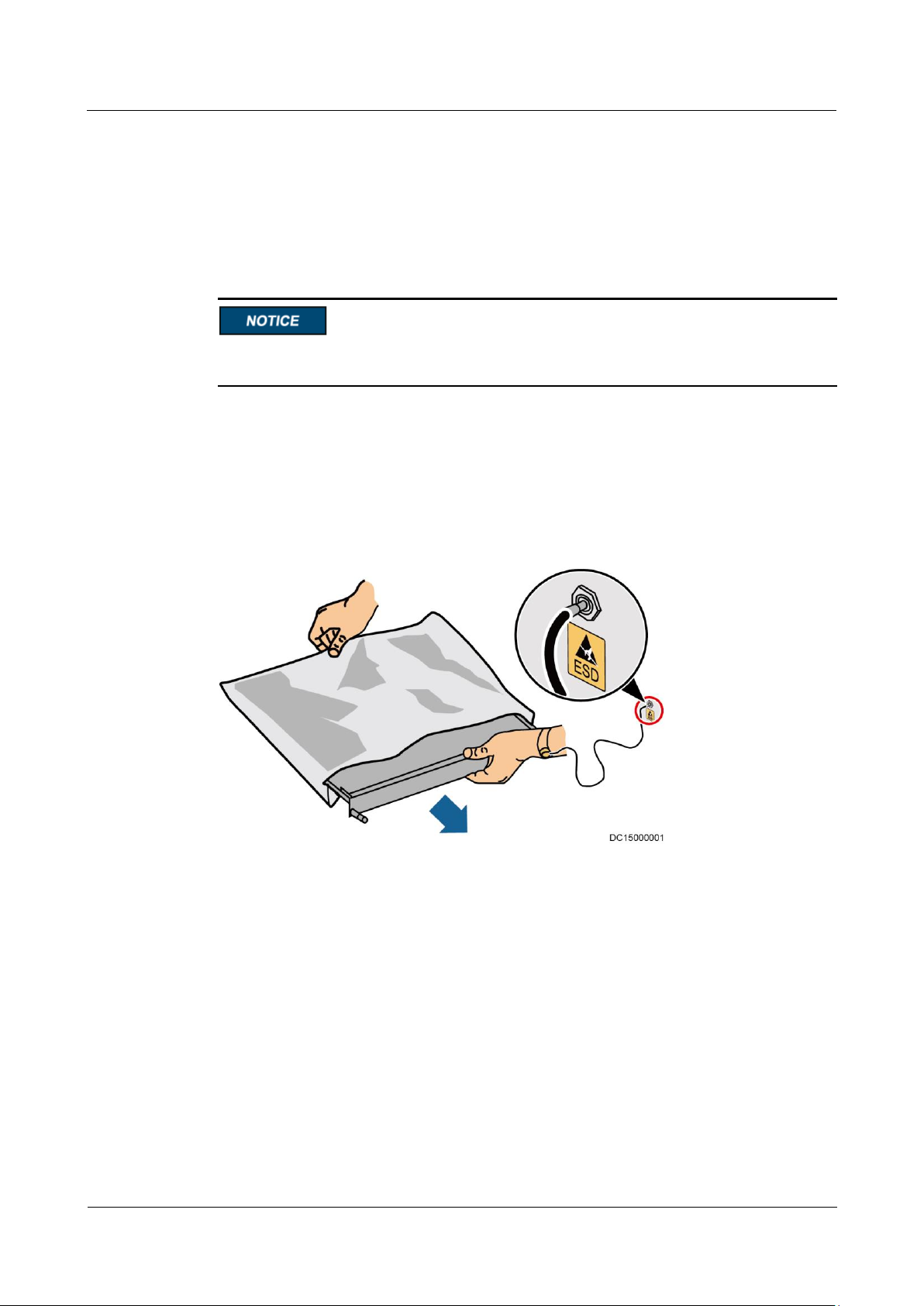

Electrostatic Discharge

Static electricity generated by human bodies may damage the electrostatic-sensitive

components on boards, for example, the large-scale integrated (LSI) circuits.

Wear a pair of ESD gloves or a well-grounded ESD wrist strap when touching the device

or handling boards or application-specific integrated circuits (ASICs).

When holding a board, hold its edge without touching any components, especially chips.

Package boards with ESD packaging materials before storing or transporting them.

Figure 1-1 shows how to wear an ESD wrist strap.

Figure 1-1 Wearing an ESD wrist strap

Liquid Prevention

Do not place the product under areas prone to water leakage, such as near air conditioner

vents, ventilation vents, or feeder windows of the equipment room. Ensure that there is

no condensation inside the product or equipment room. Ensure that no liquid enters the

product. Otherwise, short circuits will occur and may result in serious injury or death.

If any liquid is detected inside the product, immediately disconnect the power supply and

contact the administrator.

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

1 Safety Precautions

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

6

1.3 Operating Environment

The UPS is used for commercial and industrial purposes only. It cannot be used as a power

supply for life support devices.

The TIER4 or TIER3 power supply architecture specified in TIA942, that is, dual power

supply routes, must be used in the power supply systems that are crucial to major economic

interests or order of public places, such as the national computing center, military command

system, emergency command center, railway signal system and control center, civil aviation

air traffic control center, airport command center, financial clearing center, and transaction

center.

The UPS operating environment must meet the requirements for the climate indicator,

mechanically active substance indicator, and chemically active substance indicator in ETSI

EN 300 019-1 class 3.6.

Do not expose the equipment or perform any operations in an environment with flammable or

explosive gas, or smoke.

Any operation on any electrical device in an environment that has flammable air can cause

extreme danger. Strictly obey the operating environmental requirements specified in related

use manuals when using or storing the device.

Do not use the UPS in the following environments:

Environment containing flammable gases, corrosive gases, abnormal vibrations, and

impacts.

Non-confined environment near the ocean (0–3.7 km) and indoor or semi-indoor

environment where the temperature and humidity are not controllable, such as a simple

equipment room near the ocean, citizen house, garage, corridor, direct ventilation cabinet,

house with only the roof, railway station platform, gymnasium, aquarium, and so on.

1.4 Battery Safety

This section describes precautions for operating batteries.

Before operating batteries, carefully read the safety precautions to ensure correct battery

handling and connection is performed, and personal safety is managed.

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

1 Safety Precautions

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

7

To ensure battery safety and efficient battery management, use the batteries delivered with

the UPS. Huawei shall not be responsible for battery damage caused by using non-Huawei

batteries for Huawei UPSs.

Ensure lead-acid battery handling is in accordance with local regulations.

Incorrect handling of batteries may cause hazards. When operating batteries, avoid

battery short circuits and electrolyte overflow or leakage.

Electrolyte overflow may damage the device by corroding metal parts and circuit boards,

and ultimately damaging the circuit boards.

Short circuits caused by incorrect operations may cause serious injuries due to high

power of batteries.

Do not reversely connect positive and negative battery terminals.

Use batteries of the specified type. Otherwise, the batteries may be damaged.

Check battery connections periodically to ensure that all screws are securely tightened.

Install or store batteries in clean, cool, and dry environments.

Do not decompose, transform, or damage batteries. Otherwise, battery short circuit,

electrolyte leakage, and even personal injury may occur.

Preventative Measures

When installing and maintaining batteries, pay attention to the following points:

Use dedicated insulated tools.

Take measures to protect eyes, such as using eye protection devices.

Avoid skin contact with electrolyte overflow. Wear rubber gloves and protective

clothing.

When handling a battery, ensure that its electrodes always point upward. Do not tilt or

overturn batteries.

Switch off the power supply during installation and maintenance.

Short Circuit

Battery short circuits may cause personal injury. The high transient current generated by a

short circuit may release a surge of power and cause a fire.

To avoid battery short circuits, do not maintain batteries while they are in use.

Harmful Gas

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

1 Safety Precautions

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

8

Do not use unsealed lead-acid batteries. Lead-acid batteries emit flammable gas. Therefore,

place and secure lead-acid batteries horizontally to prevent fire or corrosion.

Store lead-acid batteries in a place with good ventilation, and take fire safety precautions.

Battery Temperature

High temperature may result in battery distortion, damage, and electrolyte overflow.

Install or store batteries far away from fire sources and heating devices such as

transformers. Never burn batteries.

If the battery temperature exceeds 60°C, check the battery for electrolyte overflow. If

electrolyte overflows, handle the leakage immediately.

Electrolyte Leakage

In the case of electrolyte leakage, counteract and absorb the leaking electrolyte immediately.

When moving or handling a battery whose electrolyte leaks, note that the leaking electrolyte

may harm human bodies. If the electrolyte leaks, use the following substances to counteract

and absorb the leaking electrolyte:

Sodium bicarbonate (baking soda): NaHCO3

Sodium carbonate (soda): Na2CO3

When using substances to counteract and absorb electrolytes, strictly follow the guidelines

provided by the battery manufacturer.

If any personnel are exposed to battery electrolyte, wash the exposed area with clean water

immediately and seek medical advice if the situation is serious.

1.5 Mechanical Safety

Moving Sharp Objects

Wear protective gloves when moving sharp objects.

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

1 Safety Precautions

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

9

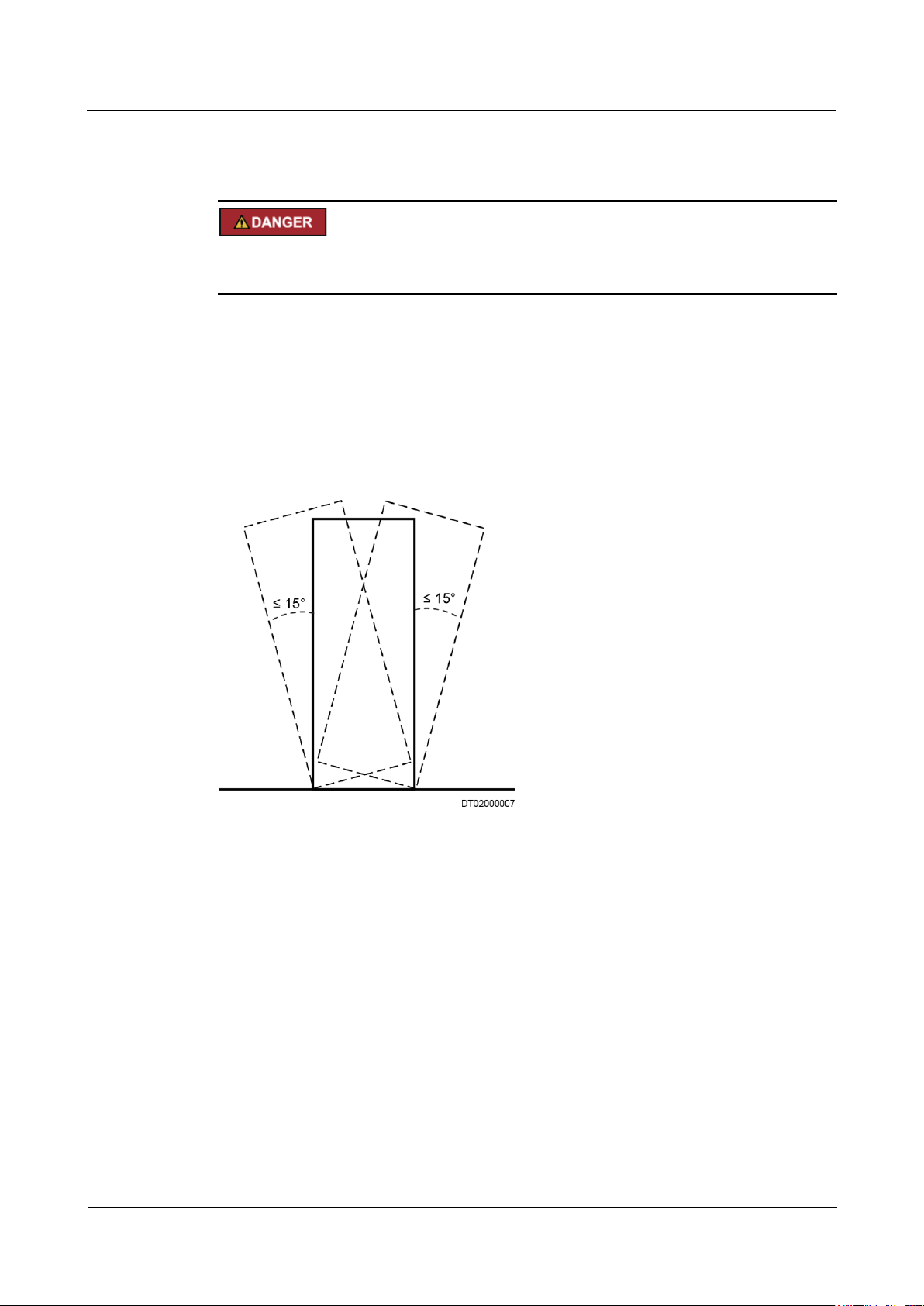

Moving Heavy Objects

Perform operations in accordance with all instructional symbols on the device.

Take caution to avoid injury when moving heavy objects.

When moving or lifting a device, hold the handle or bottom of the device.

When transporting a device using a pallet truck, the forks must be properly positioned to

ensure that the device does not topple. No excessive tilt or jolt is allowed during the

transportation, and the maximum tolerance of the tilting angle during loading and

unloading is 15°. To avoid toppling, secure the device to the pallet truck by using ropes

before moving, and assign persons to watch out the device during movement.

Move the cabinet with caution. Any bumping or falling may damage the device.

Figure 1-2 Tilting angle of a cabinet

Handling Fans

Do not insert fingers or boards into the operating fans until the fans are switched off, and have

stopped running.

1.6 Laying Out Cables

Binding Signal Cables

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

1 Safety Precautions

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

10

Signal cables must be bound separately from strong-current cables and high-voltage cables.

Laying Out Cables

When the temperature is low, a violent strike or vibrations may damage the cable sheathing.

To ensure cable safety, comply with the following requirements:

Cables can be laid, or installed, only when the temperature is higher than 0°C (32°F).

Handle cables with caution, especially at lower temperatures.

Before laying out cables that have been stored in temperatures lower than 0°C (32°F),

move the cables to an environment that is at the requisite ambient temperature. Store

them in this environment for at least 24 hours.

Do not drop the cables directly from the vehicle.

As the insulation layer of a cable may age, or be damaged from high temperatures,

ensure a sufficient distance between cables and the DC busbars, shunts, and fuses.

Cables prepared by the customer should be flame resistant. Cables must not be routed

behind the air exhaust vent of the cabinet. The air exhaust vent should not be blocked by

any object.

Before connecting a cable, ensure that the cable and cable label to be used meet the actual

installation requirements.

1.7 Information About Foreign Objects near UPS Equipment Installation

The purpose of this note is to provide information and warnings about the potential risks of

the operational integrity of an installed UPS. These risks are caused by foreign objects in or

near the UPS modules and relevant auxiliary equipment/components.

These risks are particularly high if conductive materials have entered the UPS modules/units

or the channels in the relevant auxiliary equipment/components.

Potential risks include damage to installed UPS equipment and subsequent power derating

and power failure of loads at critical positions.

Huawei UPS uses the highest safety standard in equipment design to ensure that live parts are

not in contact with the exterior and that no foreign object will enter the equipment during

operation.

However, when the UPS baffle plate and cover are open and the electrical wiring terminals

are exposed by the electrical contractor/installation personnel who are setting up a power line

connection, it is almost impossible to ensure that no foreign object will enter Huawei UPS

during onsite installation.

It is common to have someone working in the same room as the UPS during onsite

installation. Sometimes some people may be working above the UPS and relevant auxiliary

equipment/components.

To avoid serious damage to the onsite operation, property hazards, and personal injury

including fatal injury, it is the responsibility of each equipment manager or construction

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

1 Safety Precautions

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

11

manager to ensure that no foreign object enters the UPS modules/units or relevant auxiliary

equipment/components.

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

2 Overview

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

12

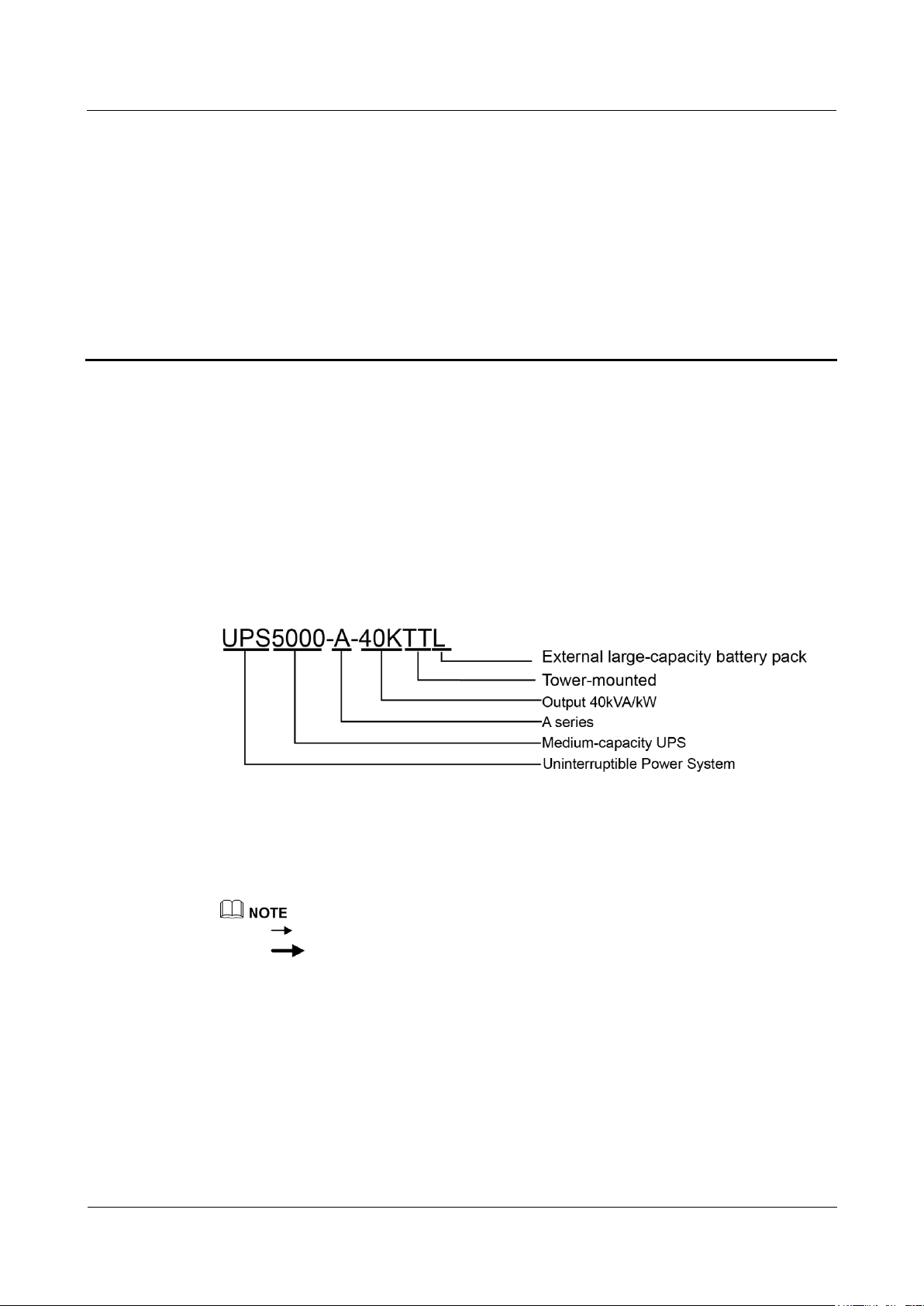

2.1 Model Description

This document describes the following UPS models:

UPS5000-A-30KTTL

UPS5000-A-40KTTL

UPS5000-A-80KTTL

2 Overview

Figure 2-1 Model number

2.2 Working Principles

indicates an input mode.

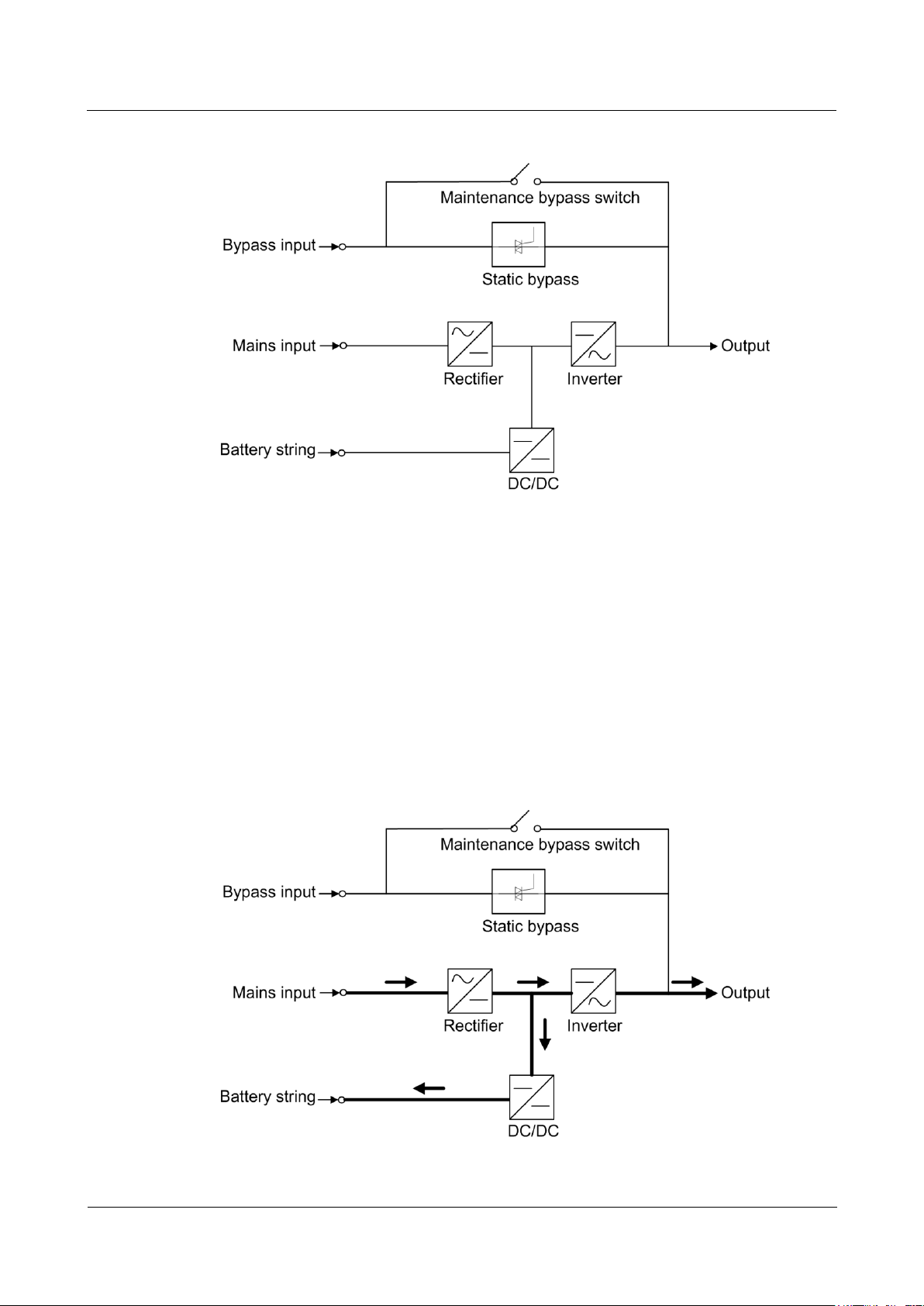

2.2.1 Conceptual Diagram

The UPS5000-A is an online double-conversion UPS that uses digital signal processing (DSP)

technology and features high efficiency and high power density. Figure 2-2 shows a

conceptual diagram for the UPS.

indicates the energy flow direction.

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

2 Overview

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

13

Figure 2-2 UPS conceptual diagram

2.2.2 Working Modes

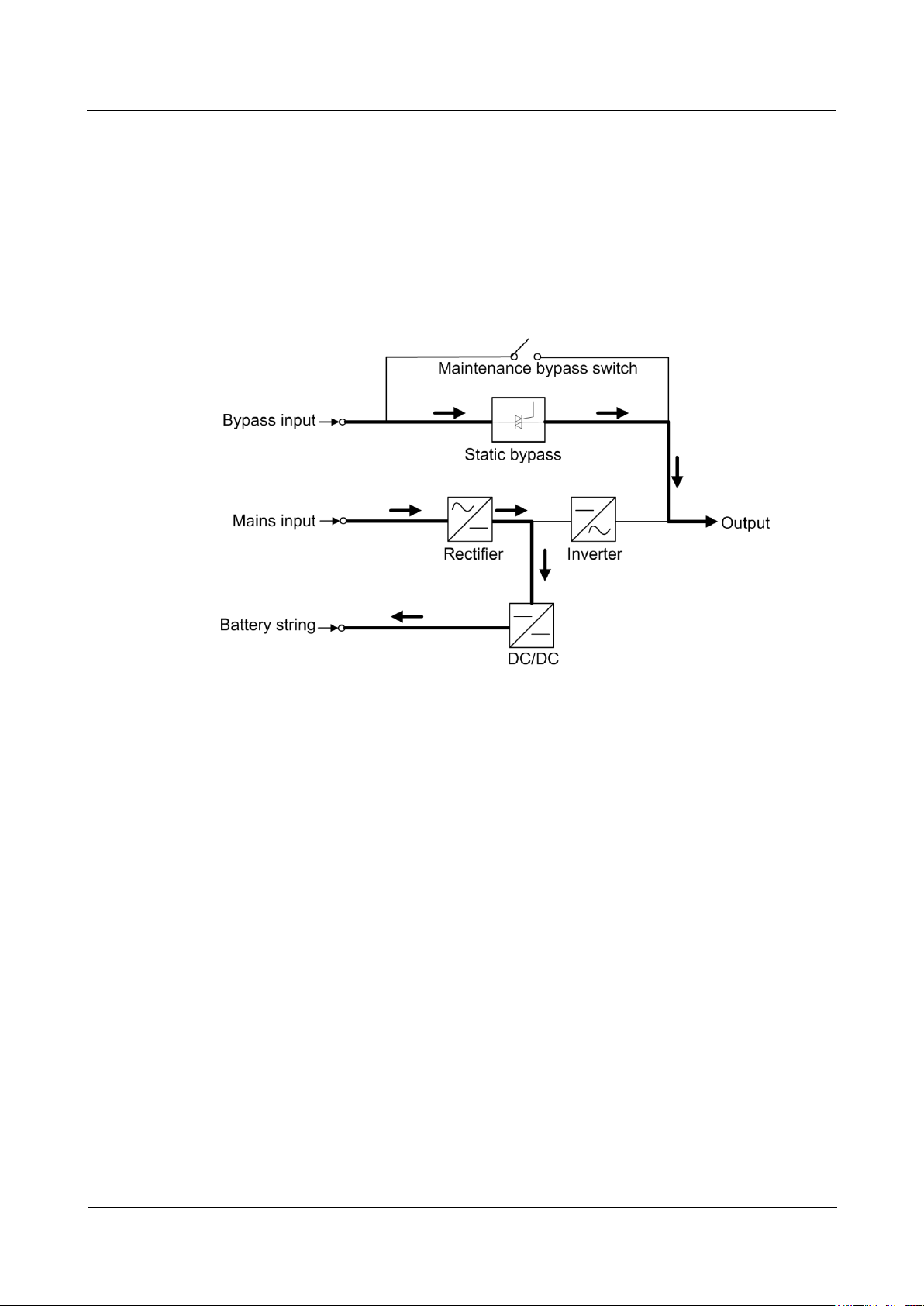

2.2.2.1 Normal Mode

When the UPS works in normal mode, the rectifier converts the AC input voltage into the DC

voltage, which is then raised to the bus voltage by the power factor correction (PFC) circuit.

Then one part of the voltage passes through the DC-DC circuit to charge the battery string,

and the other part is converted by the inverter into AC voltage outputs. The two conversions

ensure high-precision and high-quality output voltages, protecting loads from interferences

such as input harmonics, burrs, and voltage transients. Figure 2-3 shows the conceptual

diagram of the UPS working in normal mode.

Figure 2-3 UPS conceptual diagram in normal mode

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

2 Overview

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

14

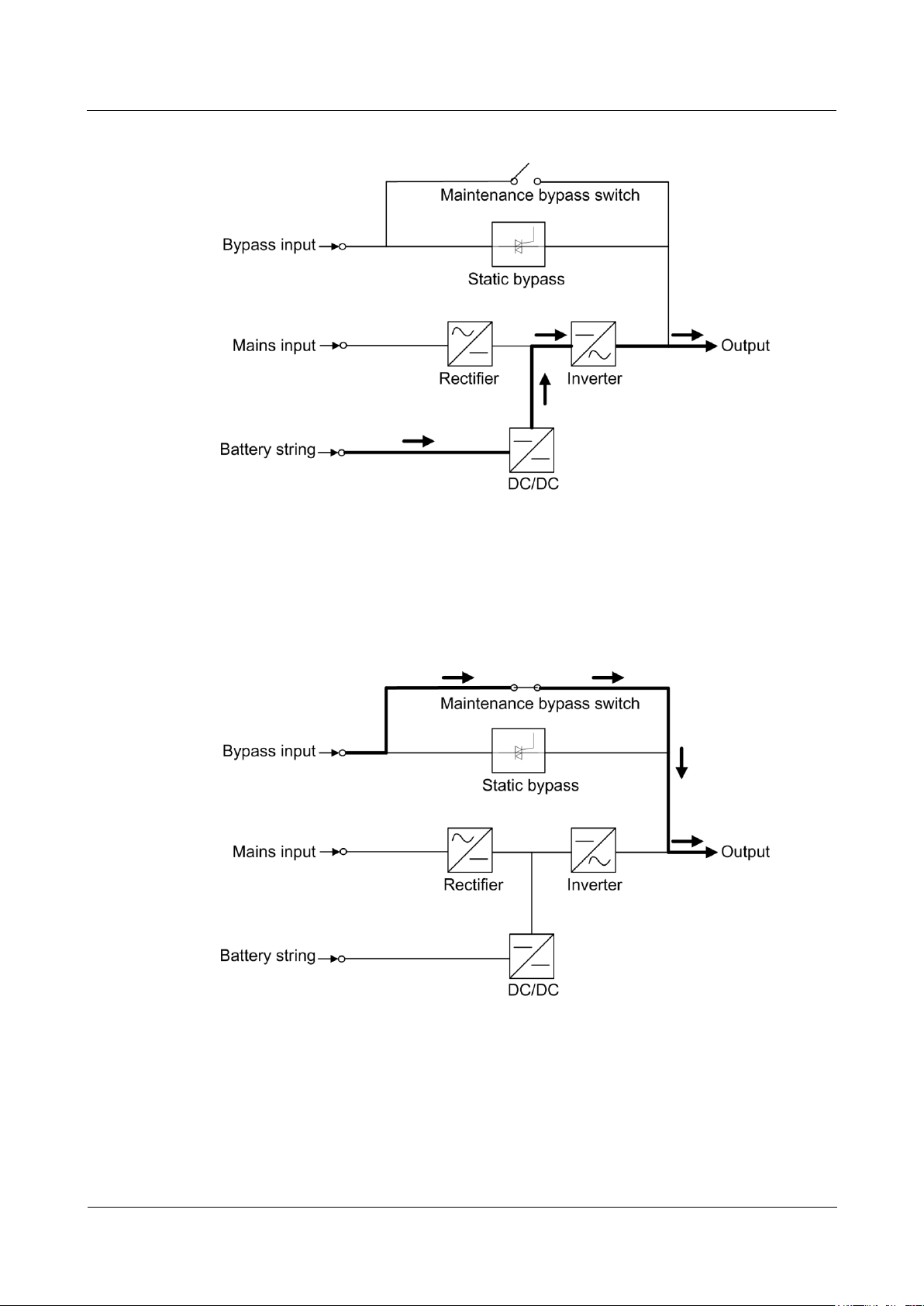

2.2.2.2 Bypass Mode

If the inverter does not start or is manually shut down after the UPS is powered on, the bypass

supplies power to loads. The UPS automatically transfers from normal mode to bypass mode

if it detects power unit overtemperature, overload, or other faults that may cause the inverter

to shut down. The bypass power supply is not protected by the UPS which means it may be

affected by mains outage, and incorrect AC voltage or frequency. Figure 2-4 shows a

conceptual diagram of the UPS working in bypass mode.

Figure 2-4 UPS conceptual diagram in bypass mode

2.2.2.3 Battery Mode

If the AC input voltage is not normal, the UPS transfers to battery mode to obtain power from

batteries. The inverter then converts the power into AC outputs. Figure 2-5 shows a

conceptual diagram of the UPS working in battery mode.

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

2 Overview

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

15

Figure 2-5 UPS conceptual diagram in battery mode

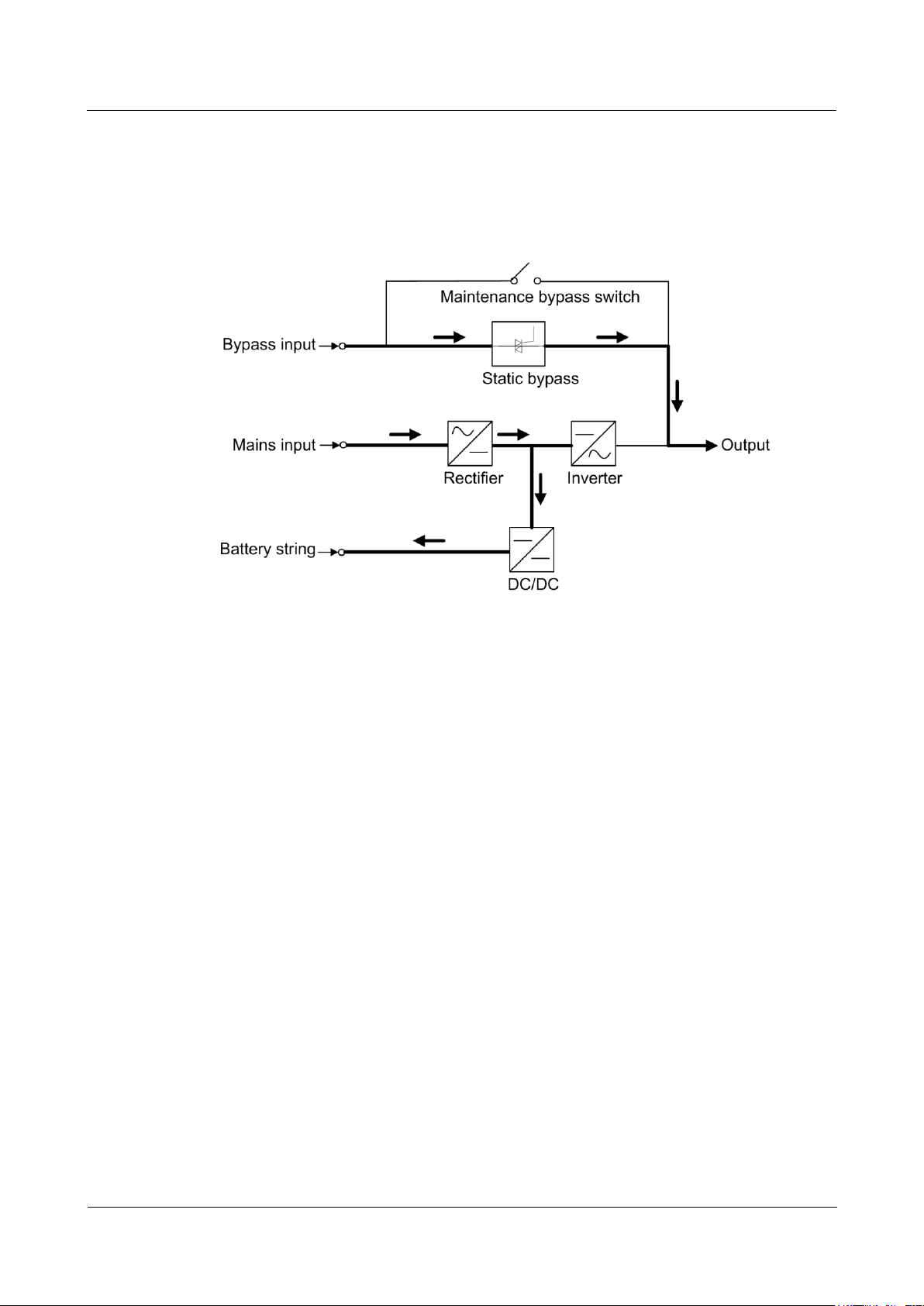

2.2.2.4 Maintenance Bypass Mode

The current flows through the maintenance bypass, instead of the power unit or bypass unit.

UPS maintenance can be performed in this mode.

Figure 2-6 UPS conceptual diagram in maintenance bypass mode

2.2.2.5 ECO Mode

The economy control operation (ECO) mode is an energy-saving mode, which you can

configure on the liquid crystal display (LCD) or web user interface (WebUI). In ECO mode,

when the bypass input voltage is within the ECO voltage range, the bypass combined switch

turns on, and the bypass supplies power. When the bypass input voltage is beyond the ECO

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

2 Overview

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

16

voltage range, the UPS transfers from bypass mode to normal mode. In bypass mode or

normal mode, the rectifier keeps working and charges batteries using a charger. The ECO

mode delivers a higher efficiency. Figure 2-7 shows a conceptual diagram of the UPS working

in ECO mode.

Figure 2-7 UPS conceptual diagram in ECO mode

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

2 Overview

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

17

2.3 Product Description

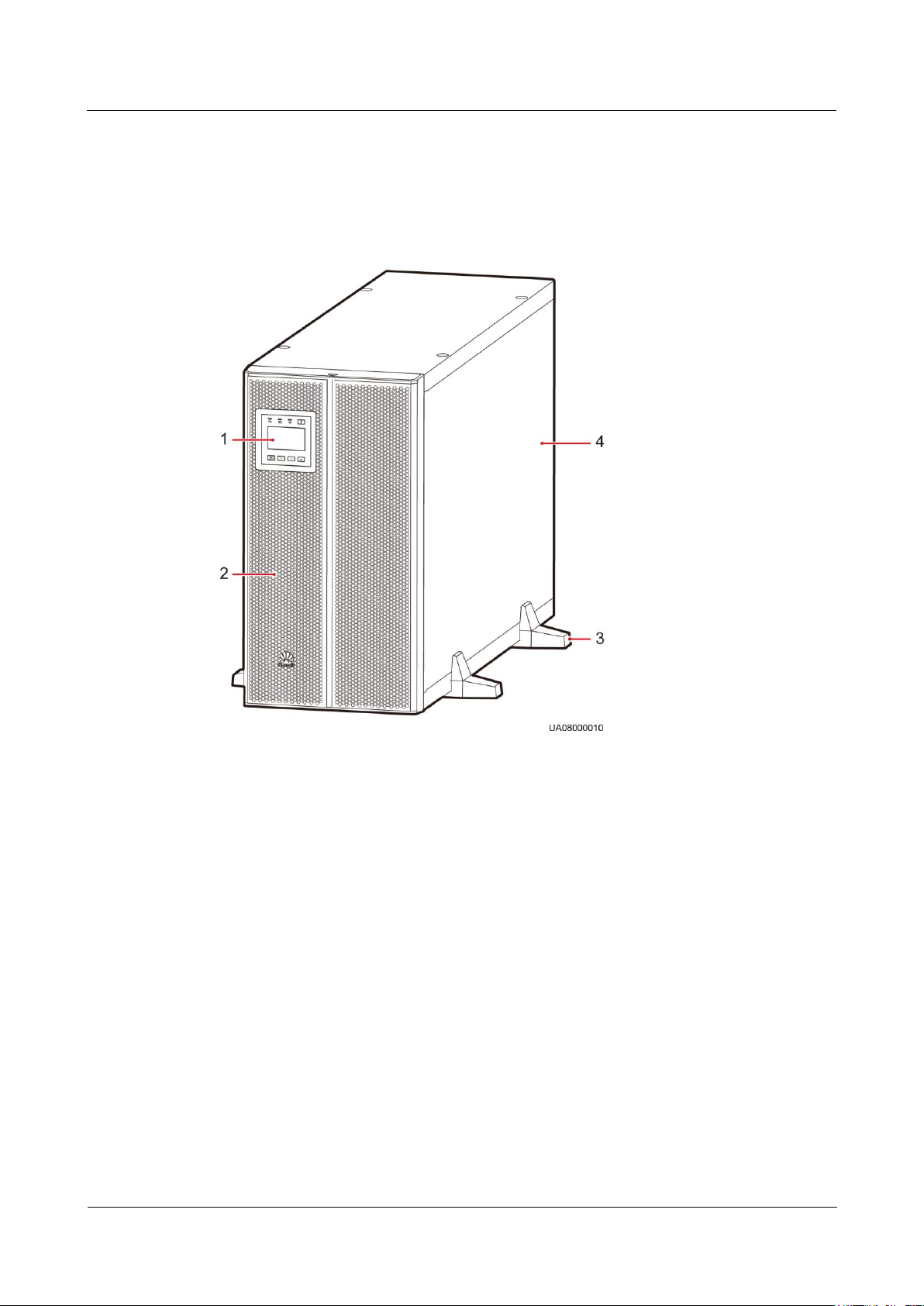

(1) Monitor display unit (MDU)

(2) Front panel

(3) Support base

(4) Chassis

2.3.1 Appearance

Figure 2-8 UPS5000-A-30 kVA/40 kVA

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

2 Overview

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

18

Figure 2-9 UPS5000-A-80 kVA

(1) Front panel 1

(2) MDU

(3) Front panel 2

(4) Leveling foot

(5) Castor

(6) Chassis

2.3.2 Product Structure

2.3.2.1 30 kVA/40 kVA UPS

Figure 2-10 and Figure 2-11 show the architecture of the UPS5000-A-30 kVA/40 kVA. Figure

2-10 shows the UPS with the front panel and the MDU removed.

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

2 Overview

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

19

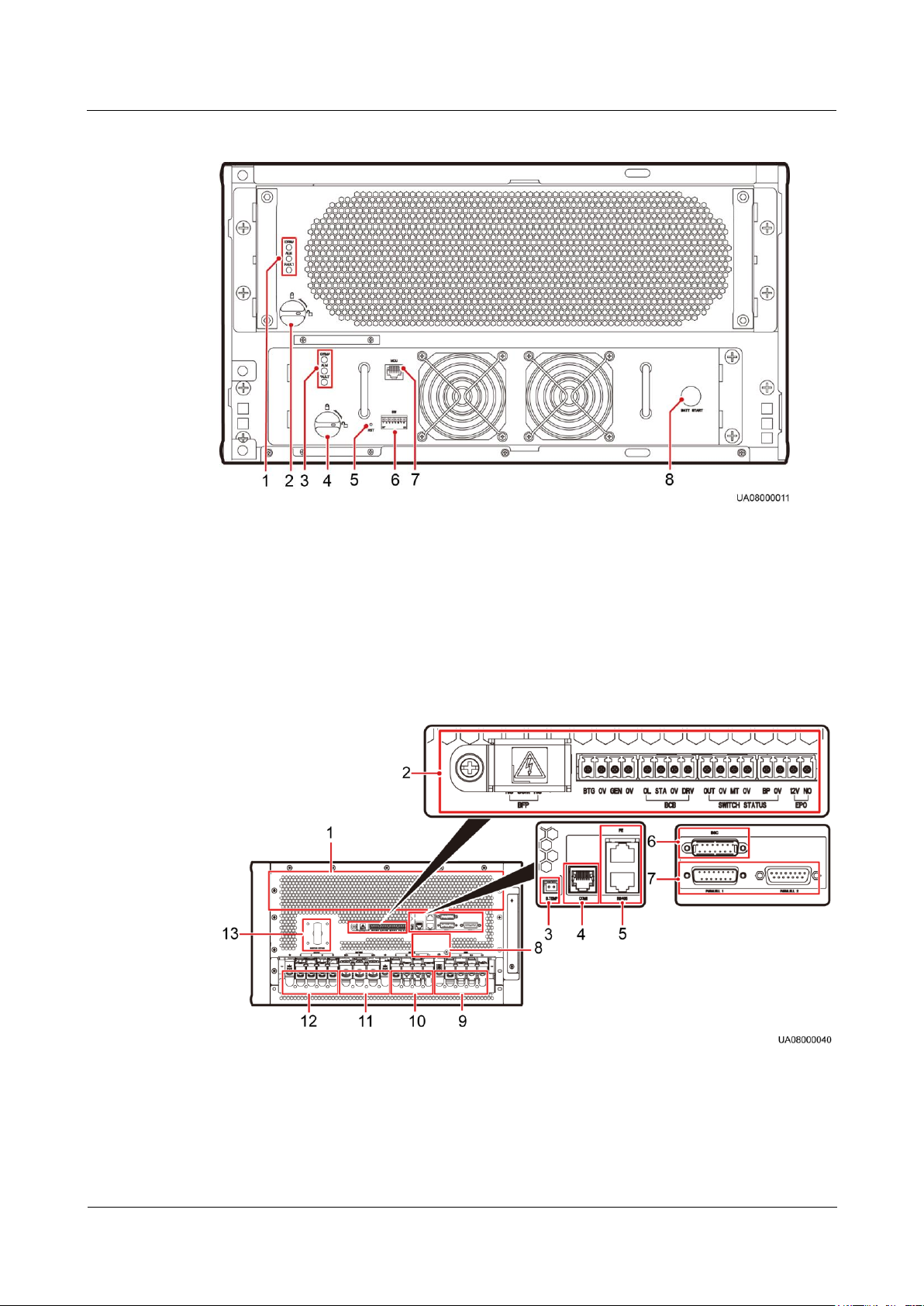

Figure 2-10 UPS5000-A-30 kVA/40 kVA product structure (front view)

(1) Power unit

indicators

(2) Power unit ready

switch

(3) Bypass unit

indicators

(4) Bypass unit

ready switch

(5) MDU reset

button

(6) Dual in-line package

(DIP) switch

(7) MDU port

(8) Cold-start button

(1) Ventilation

panel on the rear

panel

(2) Dry contacts

(3) Battery

temperature sensor

port

(4) Ambient temperature

and humidity sensor port

or battery monitoring unit

(BMU) port

Figure 2-11 UPS5000-A-30 kVA/40 kVA product structure (rear view and enlarged view of

certain parts)

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

2 Overview

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

20

(5) FE port (upper)

and RS485 port

(lower)

(6) BSC port

(7) Parallel ports

(8) Slot for dry contact

card (optional)

(9) UPS mains

input terminals

(under the cover)

(10) UPS bypass

input terminals

(under the cover)

(11) Battery

wiring terminals

(under the cover)

(12) UPS output terminals

(under the cover)

(13) Maintenance

bypass switch

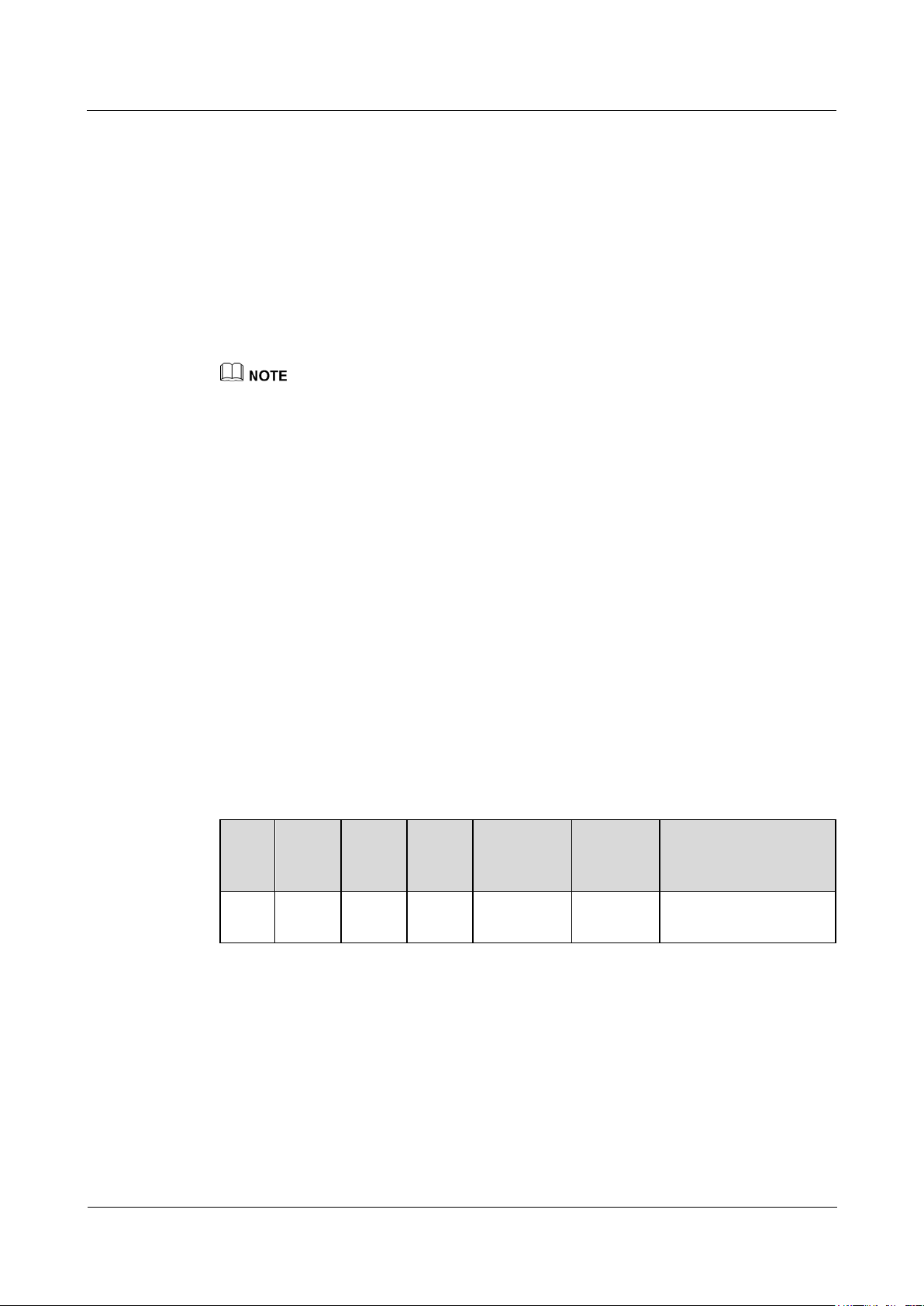

Indicators

DIP

Swit

ch

DIP1

DIP2

DIP3

LCD

Operation

Function

Remarks

Statu

s 1

OFF

OFF

OFF

N/A

Not

defined.

N/A

Connect the BMU by using a 04080298 transfer cable, which is delivered with the BMU.

When no ambient temperature and humidity sensor is installed, connect the BMU to the COM1 port

on the UPS.

When an ambient temperature and humidity sensor is installed, connect the BMU to the

RS485_OUT port on the sensor.

Both the power unit and bypass unit provide the Run indicator, Alarm indicator, and Fault

indicator (from top down).

MDU Reset Button

If the MDU does not work properly, use this button to reset the MDU, without affecting

power supply.

DIP Switch

Typically, three toggle switches are reserved for function settings. Table 2-1 describes the DIP

switch status.

Table 2-1 DIP switch status

UPS5000-A-30 kVA & 40 kVA & 80 kVA

User Manual

2 Overview

Issue 11 (2018-12-10)

Copyright © Huawei Technologies Co., Ltd.

21

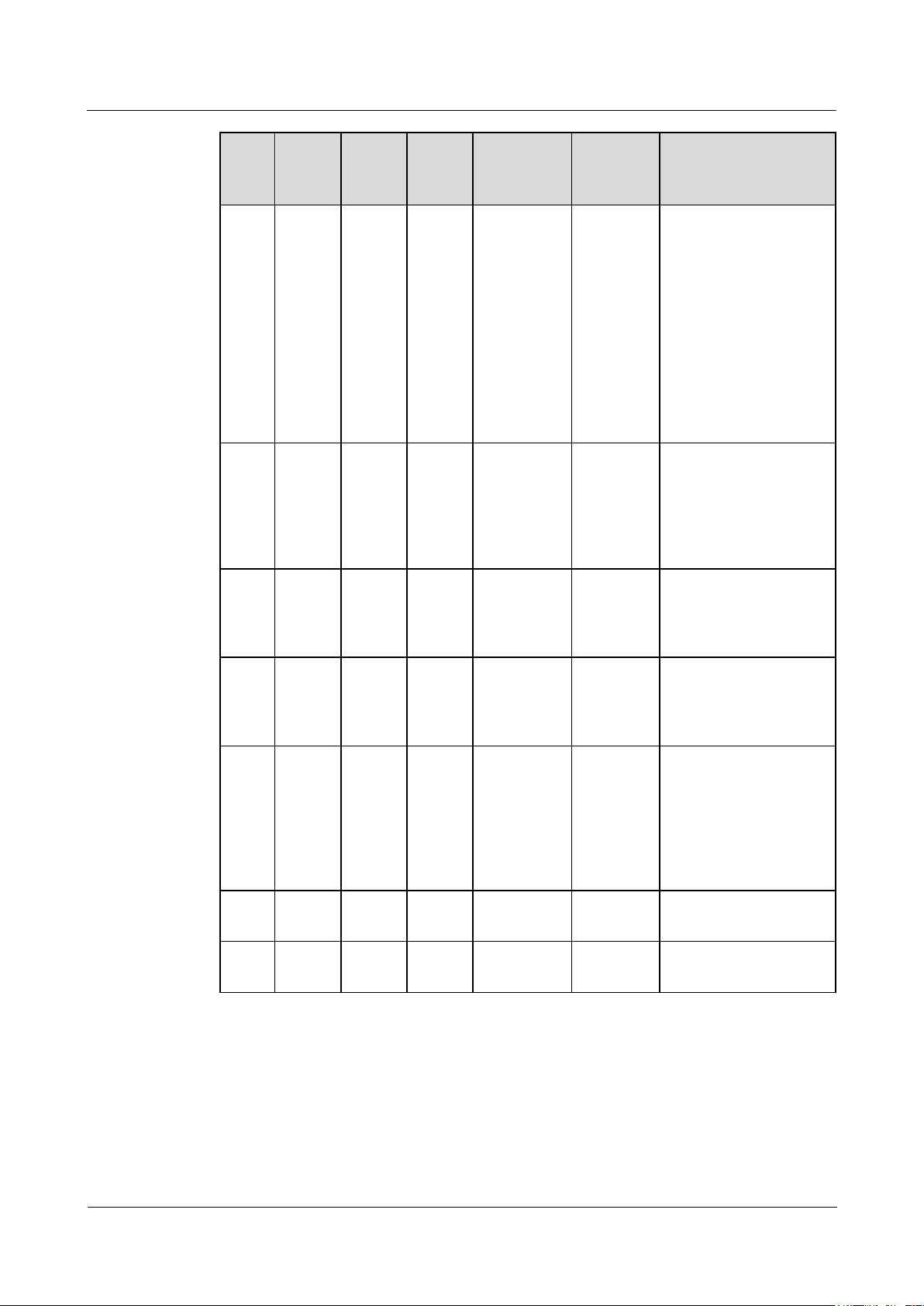

DIP

Swit

ch

DIP1

DIP2

DIP3

LCD

Operation

Function

Remarks

Statu

s 2

ON

ON

OFF

Settings >

Restore

Default

Settings

Restores

factory

defaults.

After clearing system

parameters, battery

parameters, monitoring

parameters, and logs

(operation logs, upgrade

logs, and battery test

and statistics logs), the

MDU does not restart

automatically. The

settings will take effect

after the MDU is

powered on again.

Statu

s 3

ON

OFF

ON

Hold down

the Up and

Down

buttons at

the same

time for 5s.

Restores

the user

name and

password.

After restoring the

preset user name and

password, the MDU

restarts automatically,

without affecting power

supply.

Statu

s 4

ON

OFF

OFF

Control >

Clear

historical

alarms

Clears

historical

alarm

records.

After clearing historical

alarm records, the MDU

restarts automatically.

Statu

s 5

OFF

ON

ON

Control >

Clear

operation

logs

Clears

operation

logs.

After clearing operation

logs, the MDU restarts

automatically.

Statu

s 6

OFF

ON

OFF

Settings >

Advanced

Param. >

Work

mode >

Self-load

mode

Sets

self-load

mode.

After entering self-load

mode subsequent to

inverter startup, the

MDU does not restart

automatically.

Statu

s 7

OFF

OFF

ON

-

Not

defined.

-

Statu

s 8

ON

ON

ON

-

Not

defined.

-

Loading...

Loading...