Huawei UPS5000-A-300KTTL, UPS5000-A-200K-FT, UPS5000-A-200K-ST, UPS5000-A Series, UPS5000-A-300K-FT User Manual

...Page 1

UPS5000-A-(200 kVA-800 kVA)

User Manual

Issue

03

Date

2019-02-15

HUAWEI TECHNOLOGIES CO., LTD.

Page 2

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

i

Copyright © Huawei Technologies Co., Ltd. 2019. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address:

Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website:

http://e.huawei.com

Page 3

UPS5000-A-(200 kVA-800 kVA)

User Manual

About This Document

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

ii

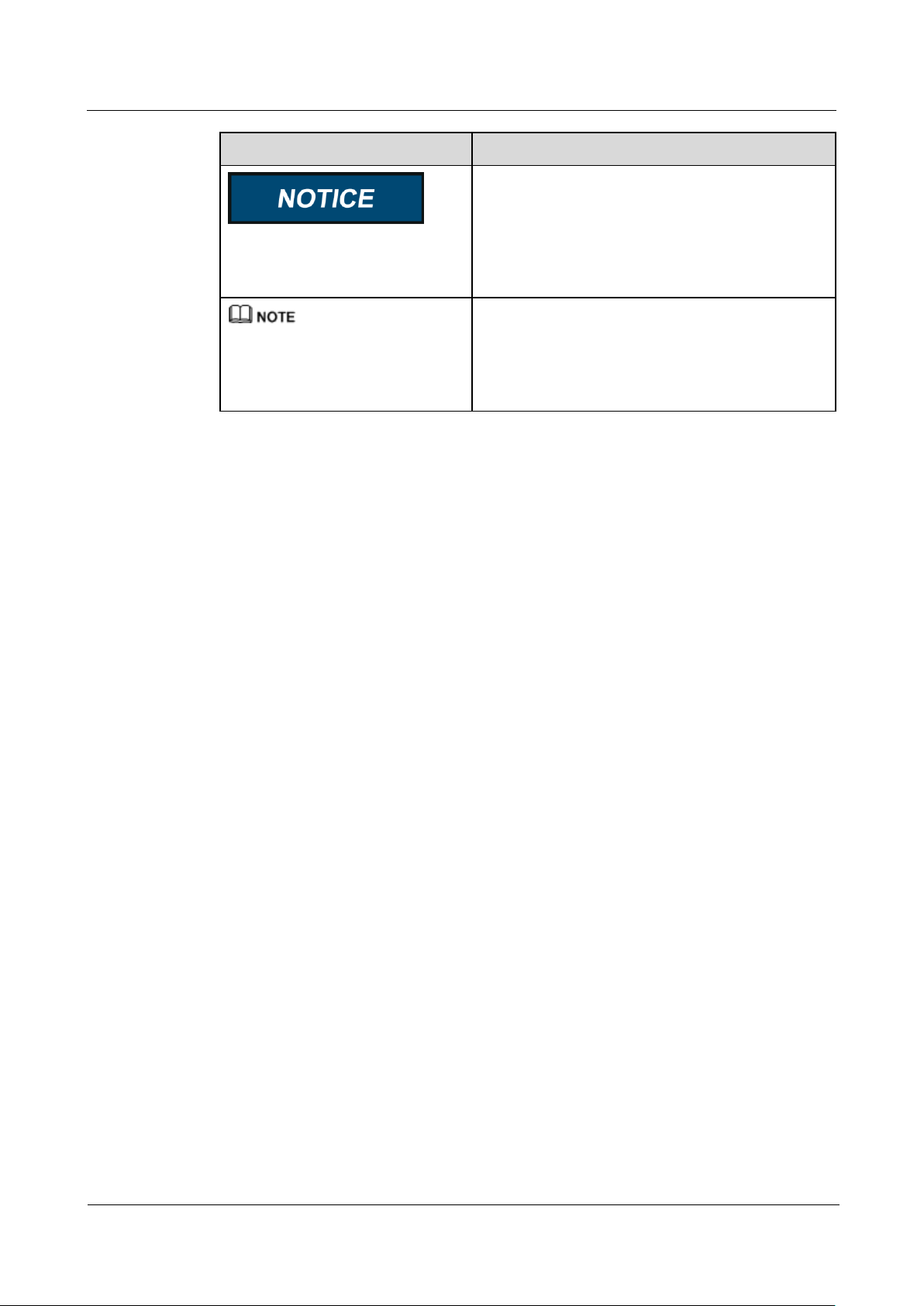

Purpose

Symbol

Description

Indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

This document describes the UPS5000-A-(200 kVA–800 kVA) in terms of its features,

performance specifications, working principles, appearance as well as instructions for

installation, and operation and maintenance (O&M). UPS is short for uninterruptible power

system.

Intended Audience

About This Document

This document is intended for:

Sales engineers

Technical support engineers

System engineers

Hardware installation engineers

Commissioning engineers

Data configuration engineers

Maintenance engineers

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Page 4

UPS5000-A-(200 kVA-800 kVA)

User Manual

About This Document

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

iii

Symbol

Description

Indicates a potentially hazardous situation which, if

not avoided, could result in equipment damage, data

loss, performance deterioration, or unanticipated

results.

NOTICE is used to address practices not related to

personal injury.

Calls attention to important information, best

practices and tips.

NOTE is used to address information not related to

personal injury, equipment damage, and

environment deterioration.

Change History

Changes between document issues are cumulative. The latest document issue contains all the

changes made in earlier issues.

Issue 03 (2019-02-15)

Added the isolation protection model.

Issue 02 (2018-11-30)

Update some MDU screenshots.

Issue 01 (2018-03-05)

This issue is the first official release.

Page 5

UPS5000-A-(200 kVA-800 kVA)

User Manual

Contents

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

iv

Contents

About This Document .................................................................................................................... ii

1 Safety Precautions ......................................................................................................................... 1

1.1 General Safety .............................................................................................................................................................. 1

1.2 Electrical Safety ............................................................................................................................................................ 3

1.3 Operating Environment................................................................................................................................................. 6

1.4 Battery Safety ............................................................................................................................................................... 6

1.5 Mechanical Safety ........................................................................................................................................................ 8

1.6 Laying Out Cables ........................................................................................................................................................ 9

1.7 Information About Foreign Objects near UPS Equipment Installation ....................................................................... 10

2 Overview ....................................................................................................................................... 12

2.1 Model Description ...................................................................................................................................................... 12

2.2 Working Principles...................................................................................................................................................... 14

2.2.1 Conceptual Diagram ................................................................................................................................................ 14

2.2.2 Working Modes ........................................................................................................................................................ 15

2.2.2.1 Normal Mode ........................................................................................................................................................ 15

2.2.2.2 Bypass Mode ........................................................................................................................................................ 16

2.2.2.3 Battery Mode ........................................................................................................................................................ 16

2.2.2.4 Maintenance Bypass Mode ................................................................................................................................... 17

2.2.2.5 ECO Mode ............................................................................................................................................................ 17

2.3 Product Introduction ................................................................................................................................................... 19

2.3.1 Product Appearance (200K, 300K) ................................................................................................ .......................... 19

2.3.2 Product Appearance (300K-FT, 400K, 500K, 600K, 800K) .................................................................................... 20

2.3.3 Product Structure (200K, 300K) .............................................................................................................................. 23

2.3.4 Product Structure (300K-FT, 400K, 500K, 600K, 800K) ........................................................................................ 26

2.4 Control Unit ................................................................................................................................................................ 32

2.4.1 Overview ................................................................................................................................................................. 32

2.4.2 ECM......................................................................................................................................................................... 32

2.4.3 Dry contact card ....................................................................................................................................................... 33

2.4.4 Monitoring interface card ........................................................................................................................................ 35

2.5 MDU ........................................................................................................................................................................... 40

2.6 Typical configurations ................................................................................................................................................ 43

2.6.1 Single UPS ............................................................................................................................................................... 43

Page 6

UPS5000-A-(200 kVA-800 kVA)

User Manual

Contents

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

v

2.6.2 Parallel System ........................................................................................................................................................ 43

2.6.3 Dual-Bus System ..................................................................................................................................................... 44

2.7 Optional Components (200K, 300K) ................................................................................................ .......................... 45

2.8 Optional Components (300K-FT, 400K, 500K, 600K, 800K) .................................................................................... 48

3 Installation.................................................................................................................................... 51

3.1 Installation Preparations ............................................................................................................................................. 51

3.1.1 Site ........................................................................................................................................................................... 51

3.1.1.1 UPS Weight and Dimensions (200K, 300K) ......................................................................................................... 51

3.1.1.2 UPS Weight and Dimensions (300K-FT, 400K, 500K, 600K, 800K) ................................................................... 52

3.1.1.3 Installation Environment ....................................................................................................................................... 56

3.1.1.4 Installation Clearances .......................................................................................................................................... 56

3.1.2 Tools and Instruments .............................................................................................................................................. 57

3.1.3 Preparing Power Cables (200K, 300K) ................................................................................................................... 59

3.1.4 Preparing Power Cables (300K-FT, 400K, 500K, 600K, 800K) ............................................................................. 62

3.1.5 Unpacking (200K, 300K) ........................................................................................................................................ 66

3.1.6 Unpacking (300K-FT, 400K, 500K, 600K, 800K) .................................................................................................. 67

3.1.7 (Optional) Splitting the Power Cabinet and Bypass Cabinet (300K-FT, 400K, 500K, 600K) ................................. 68

3.1.8 (Optional) Combining the Power Cabinet and Bypass Cabinet (300K-FT, 400K, 500K, 600K) ............................ 75

3.2 Single UPS Installation ............................................................................................................................................... 76

3.2.1 Installing UPS Cabinets (200K, 300K) .................................................................................................................... 76

3.2.2 Installing UPS Cabinets (300K-FT, 400K, 500K, 600K, 800K) .............................................................................. 81

3.2.2.1 Installing the UPS on the Floor ............................................................................................................................. 81

3.2.2.2 Installing the UPS on Channel Steel ..................................................................................................................... 84

3.2.3 Installing UPS Cabinets (800K)................................................................ ............................................................... 85

3.2.3.1 Installing the UPS on the Floor ............................................................................................................................. 85

3.2.3.2 Installing the UPS on Channel Steel ..................................................................................................................... 95

3.2.4 Installing Batteries ................................................................................................................................................... 96

3.2.5 Installing Optional Components .............................................................................................................................. 97

3.2.5.1 Installing Antiseismic Kits (200K, 300K) ............................................................................................................. 97

3.2.5.2 Installing an IP21 Component ............................................................................................................................ 100

3.2.5.3 Connecting an Ambient T/H Sensor ................................................................................................................... 101

3.2.5.4 Connecting the BCB Box ................................................................................................................................... 101

3.2.5.5 Installing a Battery Grounding Failure Detector (200K, 300K) ......................................................................... 101

3.2.5.6 Installing a Battery Grounding Failure Detector (300K-FT, 400K, 500K, 600K, 800K) ................................... 105

3.2.5.7 Connecting the iBAT .......................................................................................................................................... 106

3.2.6 UPS Cable Connection Reference ......................................................................................................................... 107

3.2.7 Routing Cables (UPS5000-A-200K-ST) ............................................................................................................... 108

3.2.7.1 Routing Cables from the Top .............................................................................................................................. 108

3.2.7.2 Routing Cables from the Bottom ........................................................................................................................ 115

3.2.8 Routing Cables (UPS5000-A-200K-FT) ............................................................................................................... 121

3.2.8.1 Routing Cables from the Top .............................................................................................................................. 121

Page 7

UPS5000-A-(200 kVA-800 kVA)

User Manual

Contents

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

vi

3.2.8.2 Routing Cables from the Bottom ........................................................................................................................ 128

3.2.9 Routing Cables (UPS5000-A-200K-FT, Isolation Protection)............................................................................... 137

3.2.10 Routing Cables (UPS5000-A-300KTTL) ............................................................................................................ 142

3.2.11 Routing Cables (UPS5000-A-300K-STT) ........................................................................................................... 149

3.2.12 Routing Cables (UPS5000-A-300K-STT, Isolation Protection) .......................................................................... 155

3.2.13 Routing Cables (300K-FT, 400K, 500K, 600K) .................................................................................................. 159

3.2.13.1 Top Cable Routing ............................................................................................................................................ 160

3.2.13.2 Bottom Cable Routing ...................................................................................................................................... 173

3.2.14 Routing Cables (800K) ........................................................................................................................................ 181

3.2.14.1 Top Cable Routing ............................................................................................................................................ 181

3.2.14.2 Bottom Cable Routing ...................................................................................................................................... 189

3.2.15 Remote EPO ........................................................................................................................................................ 197

3.2.16 Connecting Communications Cables ................................................................................................................... 198

3.3 Parallel System Installation ...................................................................................................................................... 198

3.3.1 Installing the UPSs ................................................................................................................................................ 198

3.3.2 Connecting Power Cables (200K, 300K) ............................................................................................................... 201

3.3.3 Connecting Signal Cables (200K, 300K) ............................................................................................................... 204

3.3.4 Connecting Power Cables (300K-FT, 400K, 500K, 600K, 800K) ......................................................................... 206

3.3.5 Connecting Signal Cables (300K-FT, 400K, 500K, 600K, 800K) ......................................................................... 212

3.4 Installing a Lock ....................................................................................................................................................... 214

3.5 Installation Verification ............................................................................................................................................. 215

4 User Interface ............................................................................................................................. 220

4.1 LCD Interface ........................................................................................................................................................... 220

4.1.1 Main Menu ............................................................................................................................................................ 220

4.1.2 System Info Screen ................................................................................................................................ ................ 221

4.1.2.1 Running .............................................................................................................................................................. 222

4.1.2.2 Alarms Screen ..................................................................................................................................................... 225

4.1.2.3 Settings ............................................................................................................................................................... 227

4.1.2.4 Maintenance ........................................................................................................................................................ 247

4.1.2.5 About Screen ....................................................................................................................................................... 251

4.1.3 System Status ................................ ................................................................ ......................................................... 251

4.1.4 Common Functions ................................ ................................................................ ................................ ................ 252

4.2 WebUI ....................................................................................................................................................................... 252

4.2.1 Login ...................................................................................................................................................................... 252

4.2.2 Monitoring ............................................................................................................................................................. 254

4.2.2.1 Parameter Settings .............................................................................................................................................. 255

4.2.2.2 Communication Settings ..................................................................................................................................... 263

4.2.2.3 Control ................................................................................................................................................................ 263

4.2.3 Query ..................................................................................................................................................................... 263

4.2.3.1 Historical Alarms ................................................................................................................................................ 263

4.2.3.2 Logs .................................................................................................................................................................... 264

Page 8

UPS5000-A-(200 kVA-800 kVA)

User Manual

Contents

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

vii

4.2.4 Config. Page .......................................................................................................................................................... 264

4.2.4.1 User Management ............................................................................................................................................... 264

4.2.4.2 Site Config. ......................................................................................................................................................... 265

4.2.4.3 RCCMD .............................................................................................................................................................. 267

4.2.4.4 Managing the UPS by Using the NMS Complying with RFC1628 Standard ..................................................... 276

4.2.5 Protecting the Server by Using the RCCMD Software .......................................................................................... 277

4.2.5.1 Introduction to the Software ............................................................................................................................... 277

4.2.5.2 RCCMD Event Shutdown and Message Sending ............................................................................................... 278

4.2.5.3 UPS Alive Check Function ................................................................................................................................. 279

5 Operations .................................................................................................................................. 282

5.1 Powering On and Starting the UPS ........................................................................................................................... 282

5.1.1 Powering On the UPS ............................................................................................................................................ 282

5.1.2 Starting the Inverter ............................................................................................................................................... 282

5.1.2.1 Initial Startup ...................................................................................................................................................... 283

5.1.2.2 Non-initial Startup .............................................................................................................................................. 289

5.1.3 Powering On Loads ............................................................................................................................................... 291

5.1.4 (Optional) Setting Parameters for the BCB Box .................................................................................................... 292

5.2 Shutting Down and Powering Off the UPS .............................................................................................................. 292

5.3 Starting the UPS in Battery Mode ............................................................................................................................ 294

5.4 Transferring to Bypass Mode .................................................................................................................................... 294

5.5 Setting ECO Mode .................................................................................................................................................... 295

5.6 Testing Batteries ....................................................................................................................................................... 296

5.6.1 Forced Equalized Charging Test ............................................................................................................................ 296

5.6.2 Shallow Discharge Test .......................................................................................................................................... 297

5.6.3 Capacity Test.......................................................................................................................................................... 298

5.6.4 Test Data Download ............................................................................................................................................... 299

5.7 Transferring to Maintenance Bypass Mode (200K, 300K) ....................................................................................... 300

5.8 Transferring to Maintenance Bypass (300K-FT, 400K, 500K, 600K, 800K) ........................................................... 304

5.9 Transferring from Maintenance Bypass Mode to Normal Mode .............................................................................. 306

5.10 Performing EPO...................................................................................................................................................... 306

5.11 Clearing the EPO State ........................................................................................................................................... 307

5.12 Exporting Data ........................................................................................................................................................ 307

6 Routine Maintenance ............................................................................................................... 309

6.1 UPS Maintenance ..................................................................................................................................................... 309

6.1.1 Monthly Maintenance ............................................................................................................................................ 309

6.1.2 Quarterly Maintenance .......................................................................................................................................... 310

6.1.3 Annual Maintenance .............................................................................................................................................. 310

6.2 Battery Maintenance ................................................................................................................................................. 311

6.2.1 Precautions for Battery Maintenance ..................................................................................................................... 312

6.2.2 Monthly Maintenance ............................................................................................................................................ 312

6.2.3 Quarterly Maintenance .......................................................................................................................................... 313

Page 9

UPS5000-A-(200 kVA-800 kVA)

User Manual

Contents

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

viii

6.2.4 Annual Maintenance .............................................................................................................................................. 314

7 Troubleshooting ........................................................................................................................ 315

8 Technical Specifications .......................................................................................................... 318

8.1 Physical Parameters .................................................................................................................................................. 318

8.2 Internal Switch Parameters ....................................................................................................................................... 318

8.3 Environment Parameters ........................................................................................................................................... 319

8.4 Safety Regulations and EMC .................................................................................................................................... 319

8.5 Mains Input Electrical Specifications ....................................................................................................................... 320

8.6 Bypass Input Electrical Specifications ................................................................ ................................ ...................... 320

8.7 Battery Specifications ............................................................................................................................................... 321

8.8 Output Electrical Specifications ............................................................................................................................... 321

8.9 System Electrical Specifications ............................................................................................................................... 322

9 Menu Hierarchy......................................................................................................................... 323

9.1 Menus on the LCD .................................................................................................................................................... 323

9.2 Menus on the WebUI ................................ ................................................................ ................................ ................ 325

10 Alarm List ................................................................................................................................. 328

A Acronyms and Abbreviations ................................................................................................ 342

Page 10

UPS5000-A-(200 kVA-800 kVA)

User Manual

1 Safety Precautions

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

1

1.1 General Safety

This section describes safety precautions to consider before installing, maintaining, and

operating the UPS.

1 Safety Precautions

Declaration

To minimize the risk of personal injury and damage to equipment, read and follow all the

precautions in this document before performing any operation. The "DANGER",

"WARNING", "CAUTION", and "NOTICE" statements in this document are only

supplemental and do not represent all the safety instructions.

Only trained and qualified personnel are allowed to install, operate, and maintain Huawei

equipment.

Follow the precautions and special safety instructions provided by Huawei when operating

Huawei products. Huawei will not be liable for any consequences that are caused due to

violations regarding general safety regulations and equipment design, production, and usage

safety standards.

Huawei does not take responsibilities for the following situations:

Operation under severe environments that are not specified in this document.

Installation or use in environments that are not specified in related international

standards.

Unauthorized product changes and software code modification.

Operations not complying with the operation instructions and safety precautions in this

document.

Damage caused by extreme natural environments.

Damage caused by using batteries provided by Huawei for non-Huawei UPSs.

Damage caused by using batteries not provided by Huawei.

Page 11

UPS5000-A-(200 kVA-800 kVA)

User Manual

1 Safety Precautions

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

2

Power Grid Requirements

A standard UPS can connect to a three-phase, five-wire (L1, L2, L3, N, PE) TT, TN-C, TN-S,

and TN-C-S AC power distribution system (IEC60364-1).

Local Laws and Regulations

Equipment operations must comply with local laws and regulations. The safety instructions in

this document are only supplemental to local safety regulations.

Personal Requirements

Only Huawei engineers or engineers certified by Huawei are allowed to perform UPS

commissioning and maintenance. Otherwise, human injury or equipment damage may occur,

and any resulting UPS faults will be beyond warranty scope.

Personnel who plan to install or maintain Huawei equipment must receive thorough training,

understand all necessary safety precautions, and master the correct operation methods.

Trained and qualified personnel, or personnel certified or authorized by Huawei are:

Allowed to install, operate, and maintain the equipment.

Allowed to remove safety facilities and inspect the equipment.

Allowed to replace or change the devices or components (including software).

Operation personnel must report faults or errors that might cause serious safety issues to

related owners.

This product should be installed and used according to the installation and technical,

specification requirements found in this manual. Otherwise, the product may be damaged,

and the resulting product exceptions or component damage will be beyond the warranty

scope.

Grounding Requirements

Devices to be grounded (excluding the energy storage unit) must meet the following

requirements:

When installing a device, install the ground cable first. When removing a device, remove

the ground cable at the very end.

Do not damage the ground conductor.

Do not operate devices if the ground conductor is not installed. Before operating a device,

check the electrical connection of the device to ensure that it is securely grounded.

Personal Safety

Do not operate the product, or handle cables, during thunderstorms.

To avoid electric shocks, do not connect safety extra-low voltage (SELV) circuits to

telecommunication network voltage (TNV) circuits.

Page 12

UPS5000-A-(200 kVA-800 kVA)

User Manual

1 Safety Precautions

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

3

Device Safety

Before operating a device, wear electrostatic discharge (ESD) clothes, ESD gloves, and

an ESD wrist strap. Remove any conductors (such as jewelry or watches) before the

operation to avoid electric shocks or burns.

In the case of fire, leave the building or the equipment room immediately, and turn on the

fire alarm bell or make an emergency call. Never enter the building on fire in any case.

If the cabinet provides an ESD jack, wear an ESD wrist strap and insert the ground

terminal of the ESD wrist strap into the jack.

Ensure all switches are turned to OFF during device installation.

Power on the UPS only after authorized engineers arrive at the site.

If a C2 UPS is used in residential areas, additional measures must be taken to prevent

radio frequency interferences.

If the UPS is used for life-supporting medical apparatus and facilities such as lifts where

adequate care has to be taken to ensure personal safety, discuss with the manufacturer in

advance about the applicability, settings, management, and maintenance of the UPS,

which require special considerations during design.

Before operation, ensure that the device is firmly anchored to the floor or other solid

objects, such as a wall or an installation rack.

Ensure ventilation vents are unblocked while the system is operating.

Before powering on the device, ensure that all the screws inside it are securely tightened

and will not fall off during operation.

After the installation, remove packing materials from the equipment area.

Replace danger signs that have worn out or are unreadable.

A UPS can be used to serve resistive-capacitive loads, resistive loads, and

micro-inductive loads. It is recommended that a UPS not be used for pure capacitive

loads, pure inductive loads, and half-wave rectification loads. It does not apply to energy

feedback loads.

Do not alter the UPS internal structure or installation procedure unless consent from the

manufacturer is given.

Never use water to clean electrical components inside or outside the UPS.

Do not drill holes into a cabinet.

1.2 Electrical Safety

High Voltage

The high voltage power supply provides power for the device operation. Direct or indirect

contact with high voltage power sources may result in fatal injury.

Non-standard or incorrect high voltage operations may result in fire and electric shocks.

The personnel who install the AC facility must be qualified to perform high voltage and

AC operations.

Page 13

UPS5000-A-(200 kVA-800 kVA)

User Manual

1 Safety Precautions

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

4

When selecting, connecting, and routing power cables, ensure compliance with local

laws and regulations.

When operating the AC power supply facility, ensure compliance with local laws and

regulations.

Before connecting cables to the UPS, ensure that the input power and mains power

distribution switches and output power distribution switch are turned off.

Use only dedicated tools during high voltage and AC operations.

If the operation is performed in a damp environment, ensure that the device is dry. When

water is found in the rack or the rack is damp, switch off the power supply immediately.

High Leakage Current

Ground a device before powering it on. Otherwise, personal injury or device damage may

occur.

If a "high leakage current" tag is attached to the panel of the device, ground the protective

ground terminal on the device enclosure before connecting the AC power supply to

prevent electric shocks.

The UPS can generate high leakage currents. Using a circuit breaker that has the leakage

current protection function is not recommended.

Power Cable

Fuse

Do not install or remove power cables when the device is on. Transient contact between the

core of the power cable and the conductor may generate electric arcs or sparks, which may

cause fire or damage eyesight.

Before moving or reconnecting the UPS, disconnect the mains and batteries, open the

output power distribution switch, and wait a period of at least 5 minutes after the UPS

completely powers off. Otherwise, electric shocks may occur.

Before installing or removing the power cable, open the power switch.

Before connecting a power cable, check that its label is correct.

If a fuse needs replacing, ensure the new fuse is of the same type and specifications so that the

system runs safely.

Page 14

UPS5000-A-(200 kVA-800 kVA)

User Manual

1 Safety Precautions

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

5

Backfeed Protection Dry Contact

The UPS can be configured with a backfeed protection dry contact to work with an external

automatic circuit breaker, preventing the voltage from flowing back to input terminals over

static bypass circuits. If device installation and maintenance personnel do not need to use

backfeed protection, paste labels on the external bypass input circuit breakers informing that

the circuit is connected to the UPS. Disconnect the device from the UPS before performing

operations on the circuit.

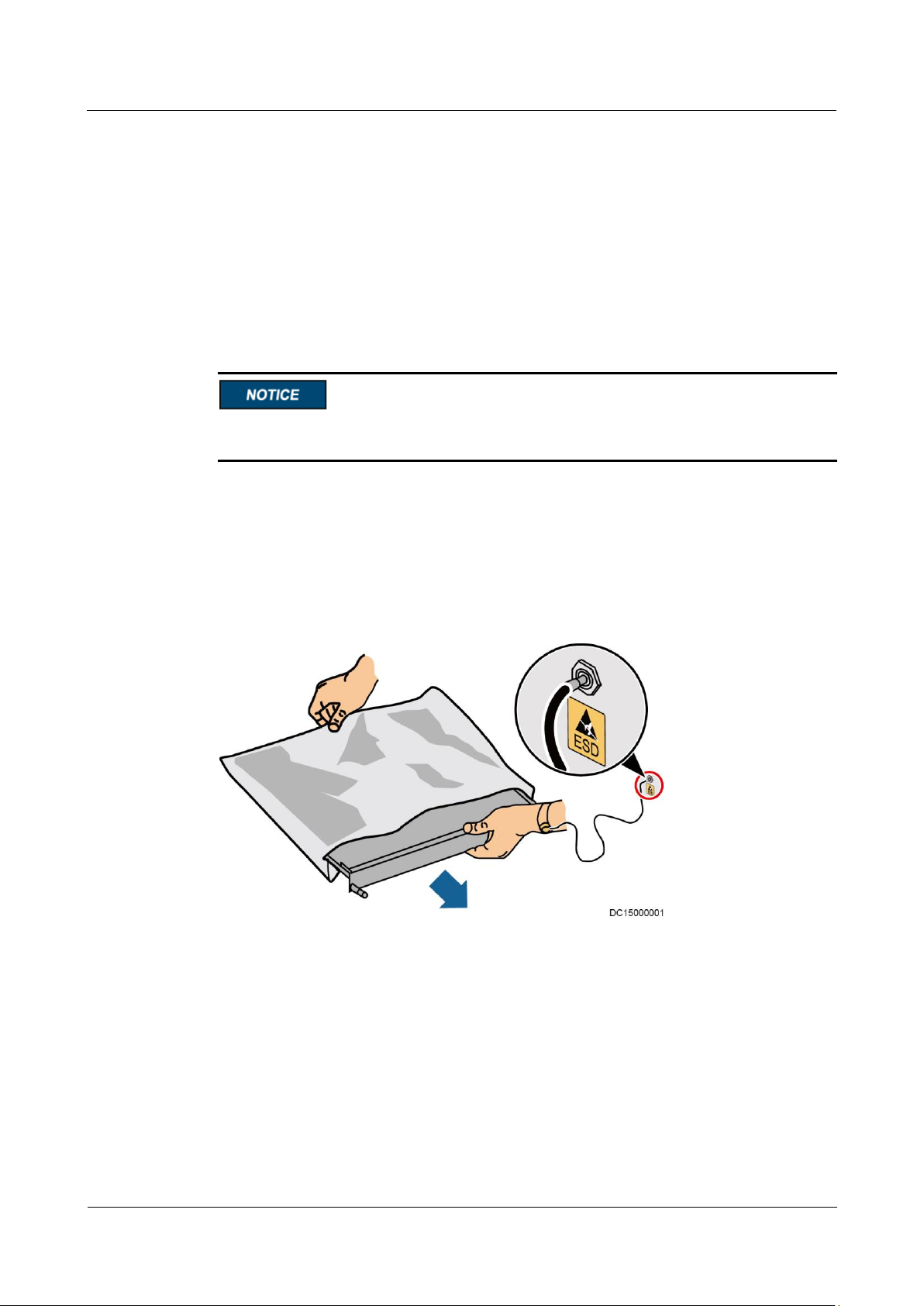

Electrostatic Discharge

Static electricity generated by human bodies may damage the electrostatic-sensitive

components on boards, for example, the large-scale integrated (LSI) circuits.

Wear a pair of ESD gloves or a well-grounded ESD wrist strap when touching the device

or handling boards or application-specific integrated circuits (ASICs).

When holding a board, hold its edge without touching any components, especially chips.

Package boards with ESD packaging materials before storing or transporting them.

Figure 1-1 shows how to wear an ESD wrist strap.

Figure 1-1 Wearing an ESD wrist strap

Liquid Prevention

Do not place the product under areas prone to water leakage, such as near air conditioner

vents, ventilation vents, or feeder windows of the equipment room. Ensure that there is

no condensation inside the product or equipment room. Ensure that no liquid enters the

product. Otherwise, short circuits will occur and may result in serious injury or death.

If any liquid is detected inside the product, immediately disconnect the power supply and

contact the administrator.

Page 15

UPS5000-A-(200 kVA-800 kVA)

User Manual

1 Safety Precautions

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

6

1.3 Operating Environment

The UPS is used for commercial and industrial purposes only. It cannot be used as a power

supply for life support devices.

The TIER4 or TIER3 power supply architecture specified in TIA942, that is, dual power

supply routes, must be used in the power supply systems that are crucial to major economic

interests or order of public places, such as the national computing center, military command

system, emergency command center, railway signal system and control center, civil aviation

air traffic control center, airport command center, financial clearing center, and transaction

center.

The UPS operating environment must meet the requirements for the climate indicator,

mechanically active substance indicator, and chemically active substance indicator in ETSI

EN 300 019-1 class 3.6.

Do not expose the equipment or perform any operations in an environment with flammable or

explosive gas, or smoke.

Any operation on any electrical device in an environment that has flammable air can cause

extreme danger. Strictly obey the operating environmental requirements specified in related

use manuals when using or storing the device.

Do not use the UPS in the following environments:

Environment containing flammable gases, corrosive gases, abnormal vibrations, and

impacts.

Non-confined environment near the ocean (0–3.7 km) and indoor or semi-indoor

environment where the temperature and humidity are not controllable, such as a simple

equipment room near the ocean, citizen house, garage, corridor, direct ventilation cabinet,

house with only the roof, railway station platform, gymnasium, aquarium, and so on.

1.4 Battery Safety

This section describes precautions for operating batteries.

Before operating batteries, carefully read the safety precautions to ensure correct battery

handling and connection is performed, and personal safety is managed.

Page 16

UPS5000-A-(200 kVA-800 kVA)

User Manual

1 Safety Precautions

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

7

To ensure battery safety and efficient battery management, use the batteries delivered with

the UPS. Huawei shall not be responsible for battery damage caused by using non-Huawei

batteries for Huawei UPSs.

Ensure lead-acid battery handling is in accordance with local regulations.

Incorrect handling of batteries may cause hazards. When operating batteries, avoid

battery short circuits and electrolyte overflow or leakage.

Electrolyte overflow may damage the device by corroding metal parts and circuit boards,

and ultimately damaging the circuit boards.

Short circuits caused by incorrect operations may cause serious injuries due to high

power of batteries.

Do not reversely connect positive and negative battery terminals.

Use batteries of the specified type. Otherwise, the batteries may be damaged.

Check battery connections periodically to ensure that all screws are securely tightened.

Install or store batteries in clean, cool, and dry environments.

Do not decompose, transform, or damage batteries. Otherwise, battery short circuit,

electrolyte leakage, and even personal injury may occur.

Preventative Measures

When installing and maintaining batteries, pay attention to the following points:

Use dedicated insulated tools.

Take measures to protect eyes, such as using eye protection devices.

Avoid skin contact with electrolyte overflow. Wear rubber gloves and protective

clothing.

When handling a battery, ensure that its electrodes always point upward. Do not tilt or

overturn batteries.

Switch off the power supply during installation and maintenance.

Short Circuit

Battery short circuits may cause personal injury. The high transient current generated by a

short circuit may release a surge of power and cause a fire.

To avoid battery short circuits, do not maintain batteries while they are in use.

Harmful Gas

Page 17

UPS5000-A-(200 kVA-800 kVA)

User Manual

1 Safety Precautions

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

8

Do not use unsealed lead-acid batteries. Lead-acid batteries emit flammable gas. Therefore,

place and secure lead-acid batteries horizontally to prevent fire or corrosion.

Store lead-acid batteries in a place with good ventilation, and take fire safety precautions.

Battery Temperature

High temperature may result in battery distortion, damage, and electrolyte overflow.

Install or store batteries far away from fire sources and heating devices such as

transformers. Never burn batteries.

If the battery temperature exceeds 60°C, check the battery for electrolyte overflow. If

electrolyte overflows, handle the leakage immediately.

Electrolyte Leakage

In the case of electrolyte leakage, counteract and absorb the leaking electrolyte immediately.

When moving or handling a battery whose electrolyte leaks, note that the leaking electrolyte

may harm human bodies. If the electrolyte leaks, use the following substances to counteract

and absorb the leaking electrolyte:

Sodium bicarbonate (baking soda): NaHCO3

Sodium carbonate (soda): Na2CO3

When using substances to counteract and absorb electrolytes, strictly follow the guidelines

provided by the battery manufacturer.

If any personnel are exposed to battery electrolyte, wash the exposed area with clean water

immediately and seek medical advice if the situation is serious.

1.5 Mechanical Safety

Moving Sharp Objects

Wear protective gloves when moving sharp objects.

Page 18

UPS5000-A-(200 kVA-800 kVA)

User Manual

1 Safety Precautions

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

9

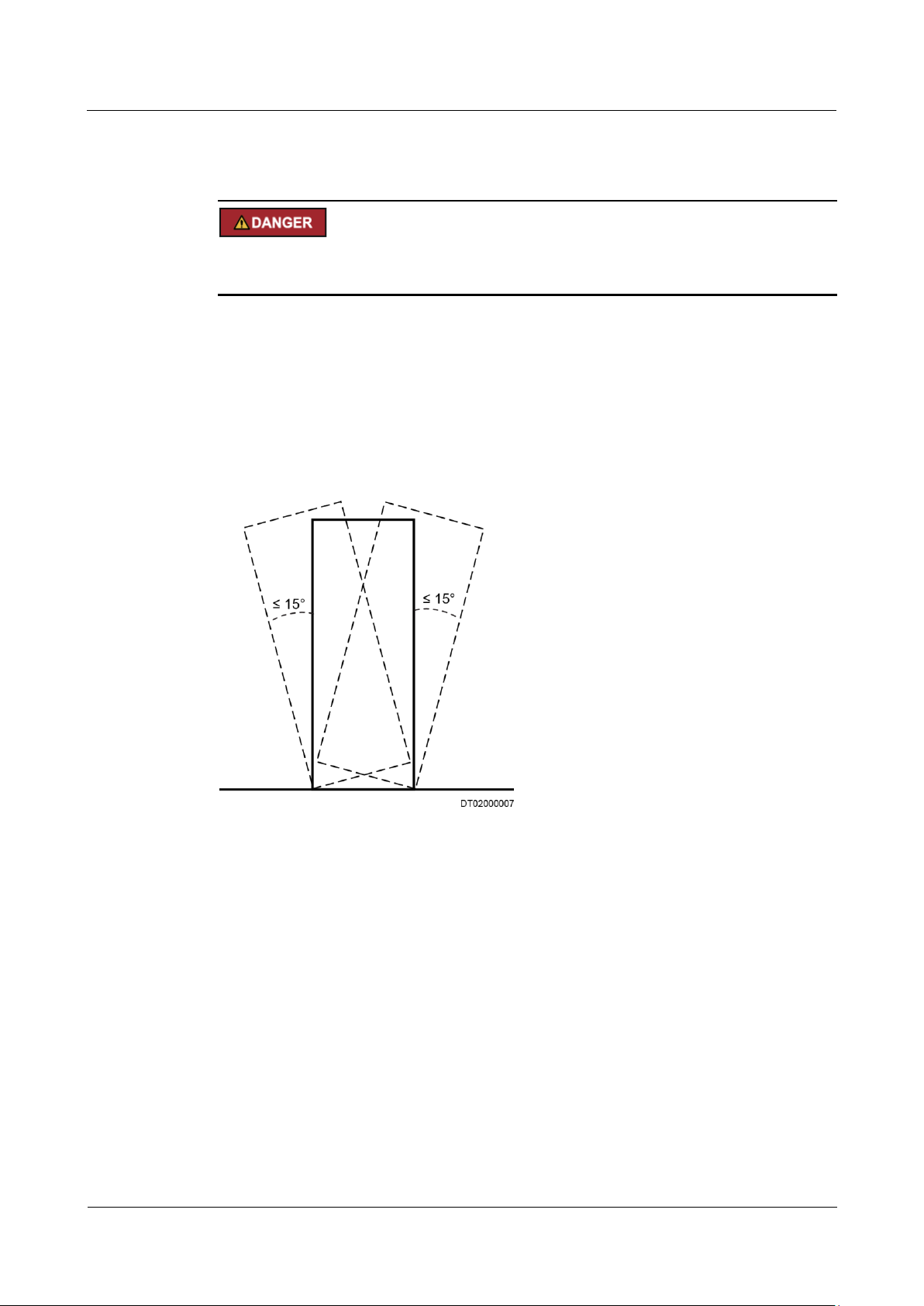

Moving Heavy Objects

Perform operations in accordance with all instructional symbols on the device.

Take caution to avoid injury when moving heavy objects.

When moving or lifting a device, hold the handle or bottom of the device.

When transporting a device using a pallet truck, the forks must be properly positioned to

ensure that the device does not topple. No excessive tilt or jolt is allowed during the

transportation, and the maximum tolerance of the tilting angle during loading and

unloading is 15°. To avoid toppling, secure the device to the pallet truck by using ropes

before moving, and assign persons to watch out the device during movement.

Move the cabinet with caution. Any bumping or falling may damage the device.

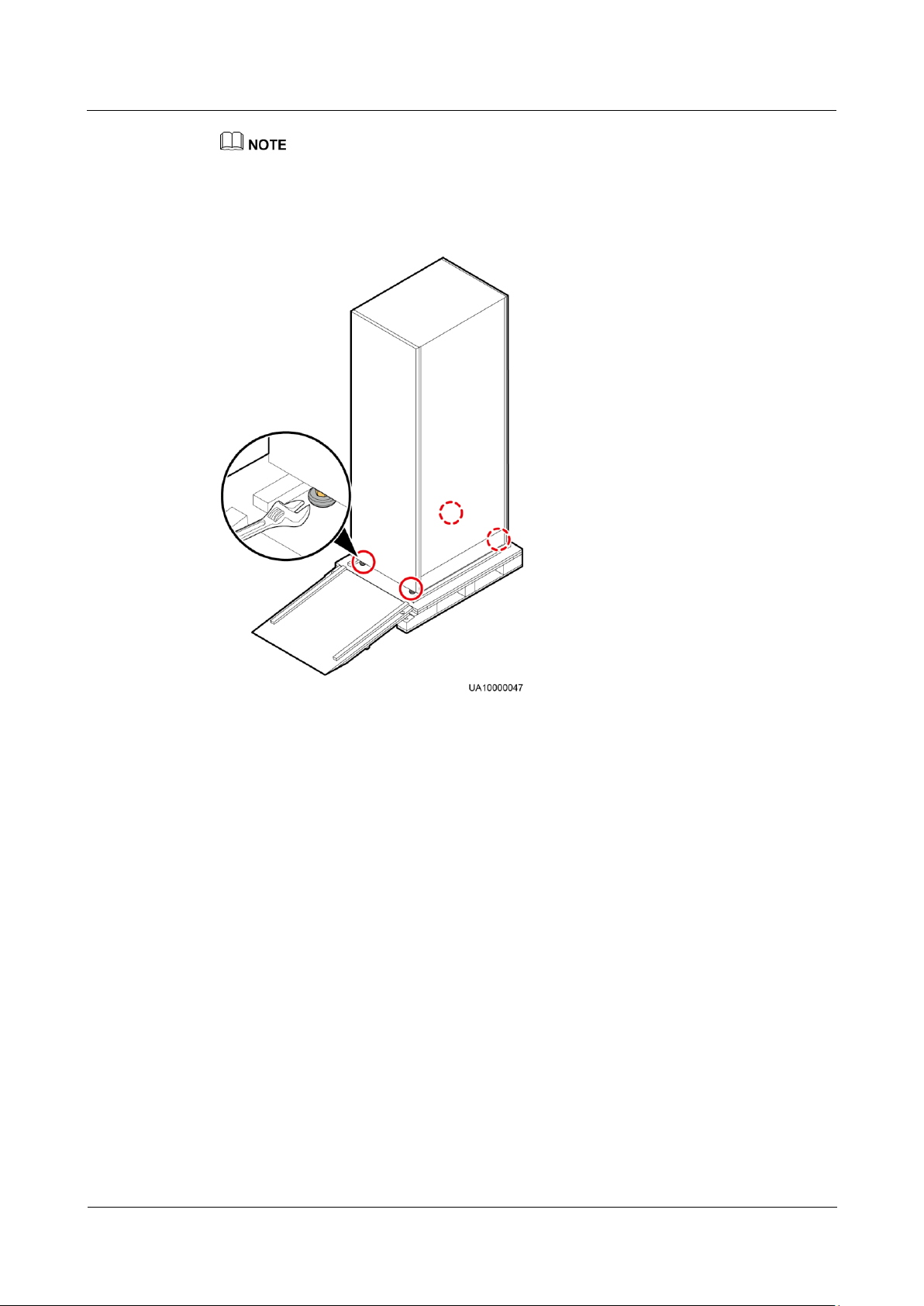

Figure 1-2 Tilting angle of a cabinet

Handling Fans

Do not insert fingers or boards into the operating fans until the fans are switched off, and have

stopped running.

1.6 Laying Out Cables

Binding Signal Cables

Page 19

UPS5000-A-(200 kVA-800 kVA)

User Manual

1 Safety Precautions

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

10

Signal cables must be bound separately from strong-current cables and high-voltage cables.

Laying Out Cables

When the temperature is low, a violent strike or vibrations may damage the cable sheathing.

To ensure cable safety, comply with the following requirements:

Cables can be laid, or installed, only when the temperature is higher than 0°C (32°F).

Handle cables with caution, especially at lower temperatures.

Before laying out cables that have been stored in temperatures lower than 0°C (32°F),

move the cables to an environment that is at the requisite ambient temperature. Store

them in this environment for at least 24 hours.

Do not drop the cables directly from the vehicle.

As the insulation layer of a cable may age, or be damaged from high temperatures,

ensure a sufficient distance between cables and the DC busbars, shunts, and fuses.

Cables prepared by the customer should be flame resistant. Cables must not be routed

behind the air exhaust vent of the cabinet. The air exhaust vent should not be blocked by

any object.

Before connecting a cable, ensure that the cable and cable label to be used meet the actual

installation requirements.

1.7 Information About Foreign Objects near UPS Equipment Installation

The purpose of this note is to provide information and warnings about the potential risks of

the operational integrity of an installed UPS. These risks are caused by foreign objects in or

near the UPS modules and relevant auxiliary equipment/components.

These risks are particularly high if conductive materials have entered the UPS modules/units

or the channels in the relevant auxiliary equipment/components.

Potential risks include damage to installed UPS equipment and subsequent power derating

and power failure of loads at critical positions.

Huawei UPS uses the highest safety standard in equipment design to ensure that live parts are

not in contact with the exterior and that no foreign object will enter the equipment during

operation.

However, when the UPS baffle plate and cover are open and the electrical wiring terminals

are exposed by the electrical contractor/installation personnel who are setting up a power line

connection, it is almost impossible to ensure that no foreign object will enter Huawei UPS

during onsite installation.

It is common to have someone working in the same room as the UPS during onsite

installation. Sometimes some people may be working above the UPS and relevant auxiliary

equipment/components.

To avoid serious damage to the onsite operation, property hazards, and personal injury

including fatal injury, it is the responsibility of each equipment manager or construction

Page 20

UPS5000-A-(200 kVA-800 kVA)

User Manual

1 Safety Precautions

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

11

manager to ensure that no foreign object enters the UPS modules/units or relevant auxiliary

equipment/components.

Page 21

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

12

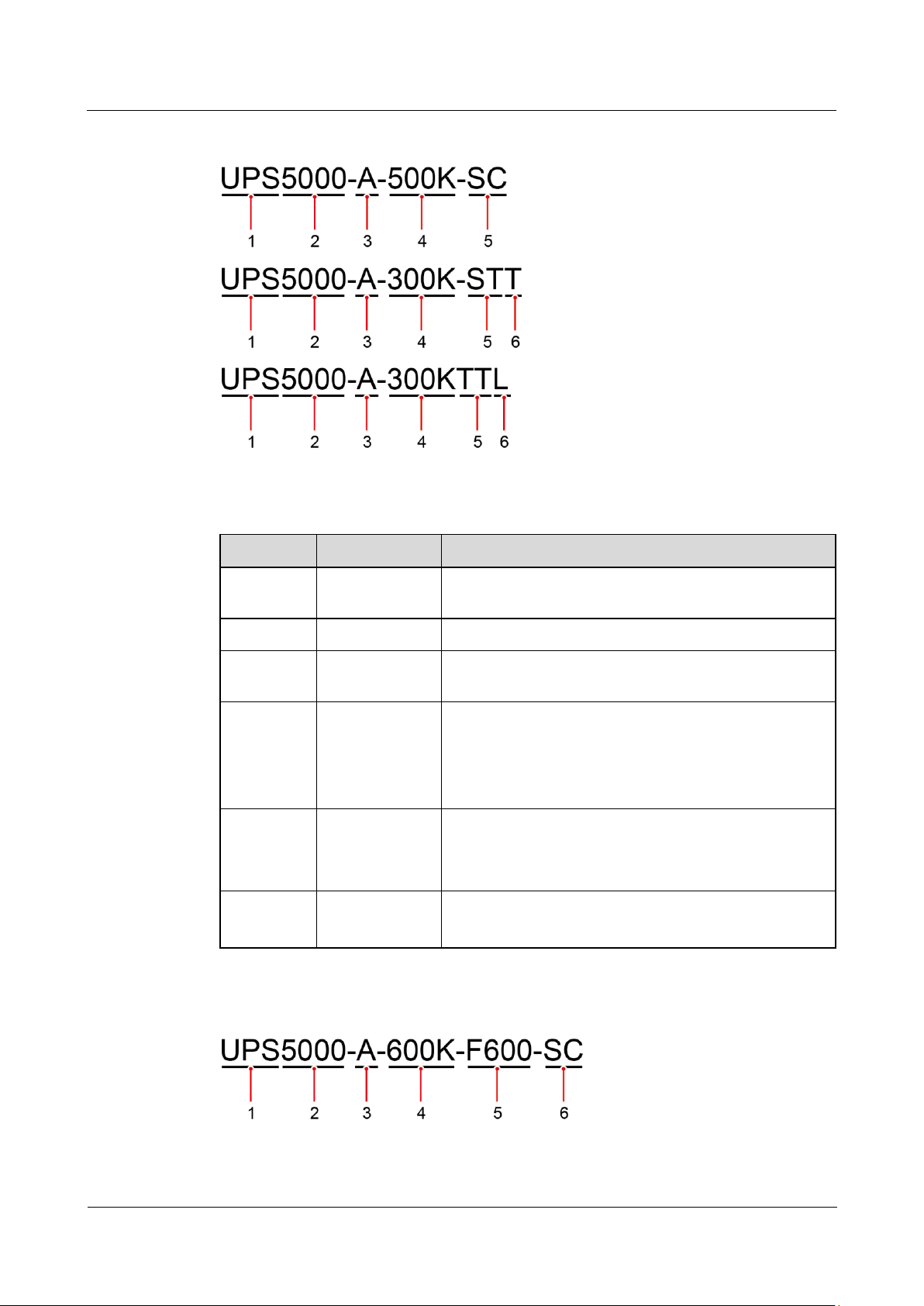

2.1 Model Description

Product Model

Abbreviation in

This Document

Description

UPS5000-A-200K-ST

200K

Top or bottom cable routing

UPS5000-A-200K-FT

Top cable routing, or bottom cable

routing if a cable entry cabinet is

installed

UPS5000-A-300K-STT

300K

Top cable routing

UPS5000-A-300KTTL

Bottom cable routing

UPS5000-A-300K-FT

300K-FT

Top or bottom cable routing

UPS5000-A-400K-SC

400K

UPS5000-A-400K-FC

UPS5000-A-400K-FT

UPS5000-A-500K-SC

500K

UPS5000-A-500K-FC

UPS5000-A-500K-FT

UPS5000-A-600K-F600-SC

600K

UPS5000-A-600K-F600-FC

UPS5000-A-800K-F800-SC

800K

UPS5000-A-800K-F800-FC

Table 2-1 Product model description

2 Overview

Page 22

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

13

Figure 2-1 UPS model number 1

No.

Item

Description

1

Product

category

UPS, short for uninterruptible power system

2

UPS family

5000

3

UPS

subcategory

A

4

Output capacity

200K: The output capacity is 200 kVA.

300K: The output capacity is 300 kVA.

400K: The output capacity is 400 kVA.

500K: The output capacity is 500 kVA.

5

Configuration

type

ST, SC: standard configuration

FT, FC: full configuration

TT: tower-mounted

6

Others T: top cable routing

L: external large-capacity battery pack

Table 2-2 UPS model number description 1

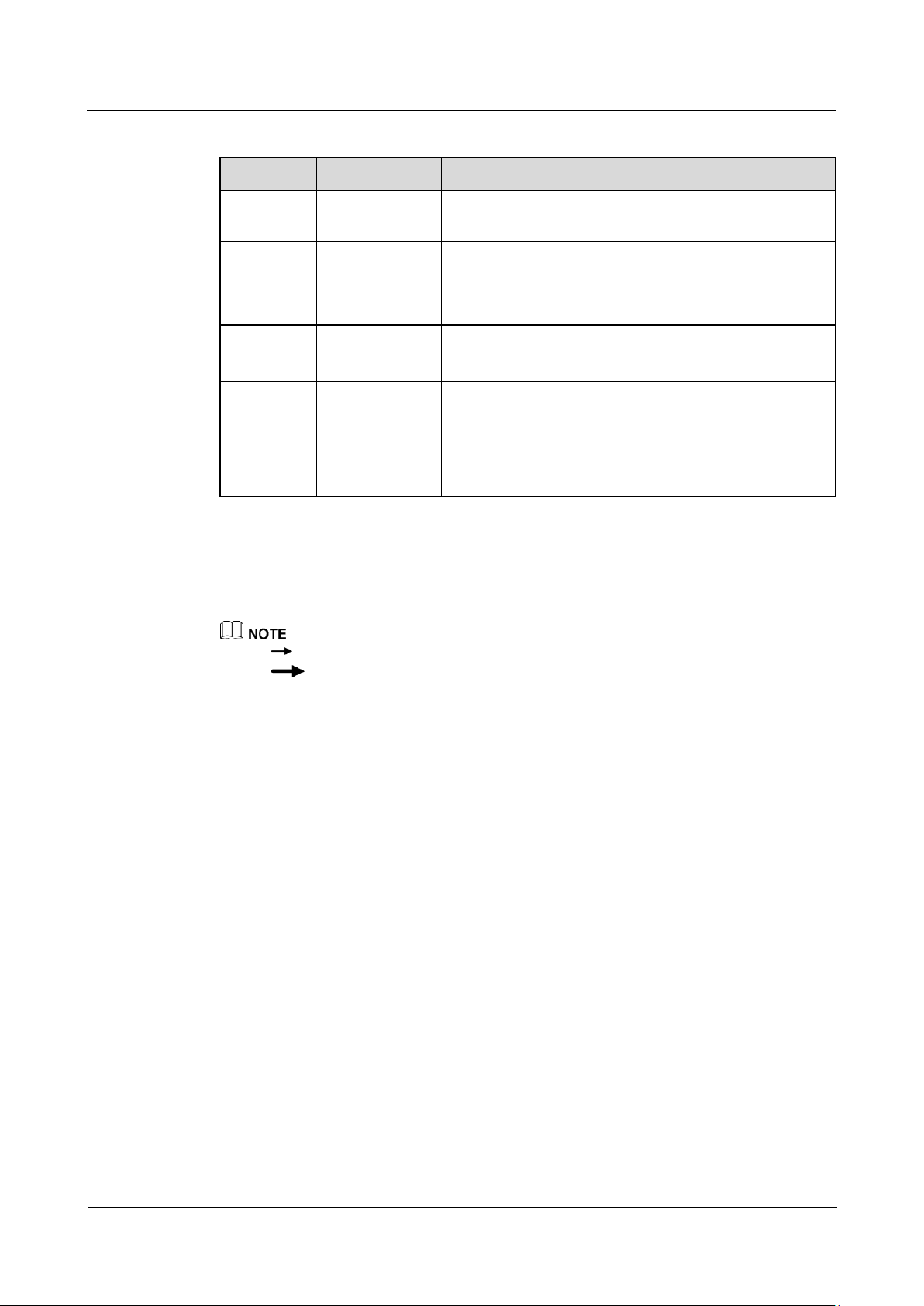

Figure 2-2 UPS model number 2

Page 23

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

14

Table 2-3 UPS model number description 2

No.

Item

Description

1

Product

category

UPS, short for uninterruptible power system

2

UPS family

5000

3

UPS

subcategory

A

4

Output capacity

600K: The output capacity is 600 kVA.

800K: The output capacity is 800 kVA.

5

Rack F600: 600 kVA rack

F800: 800 kVA rack

6

Configuration

type

SC: standard configuration

FC: full configuration

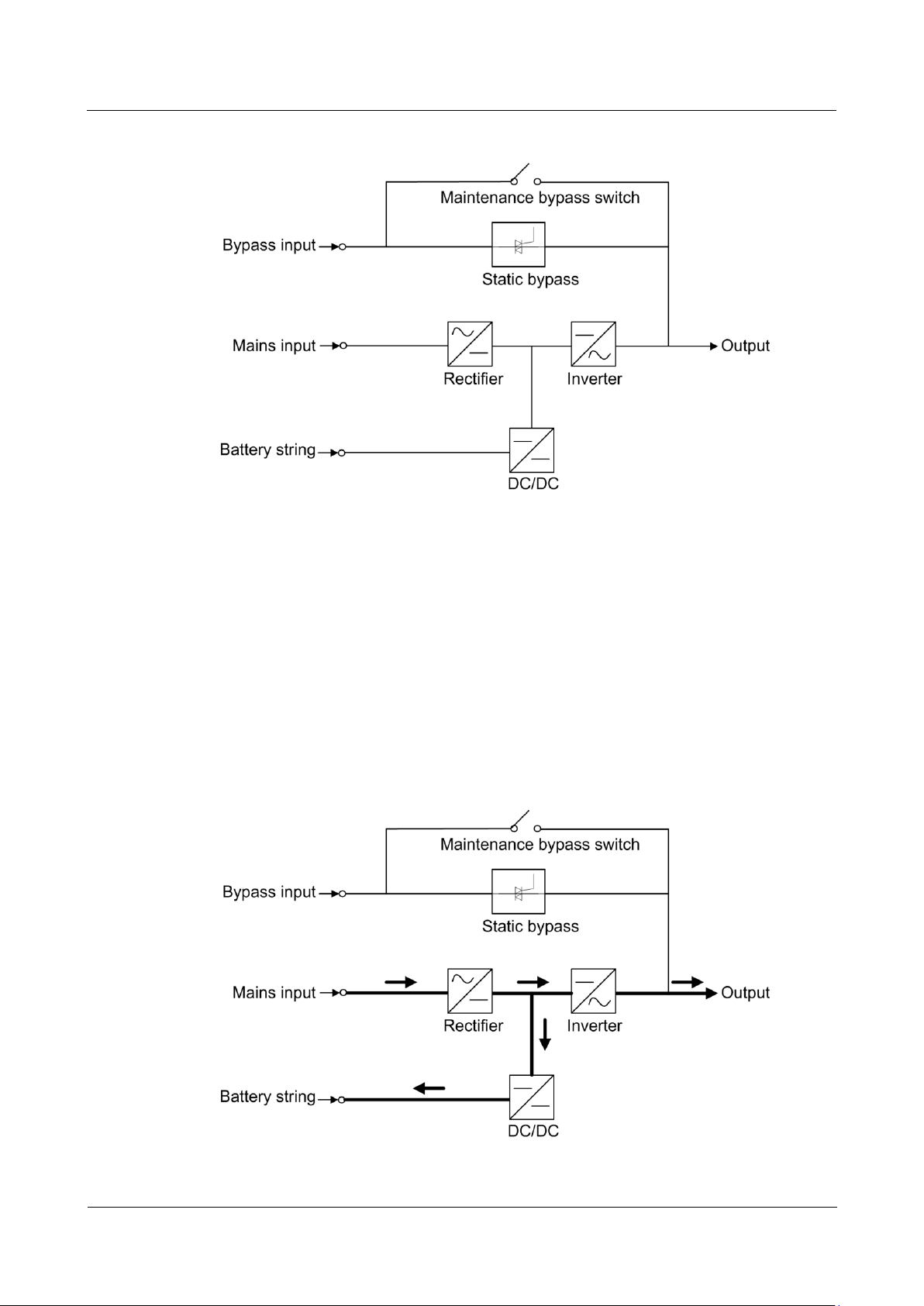

2.2 Working Principles

indicates an input mode.

2.2.1 Conceptual Diagram

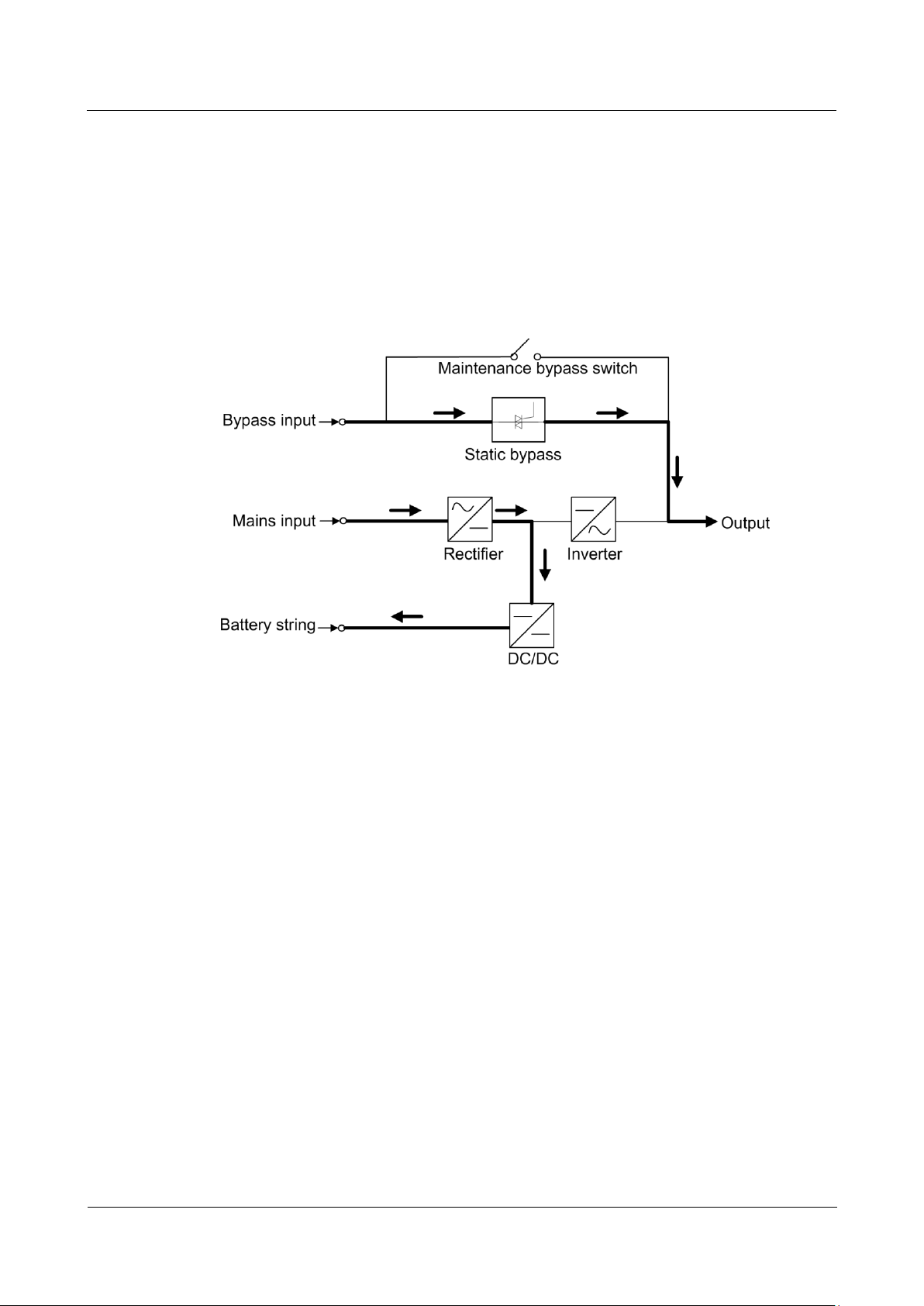

The UPS5000-A is an online double-conversion UPS that uses digital signal processing (DSP)

technology and features high efficiency and high power density. Figure 2-3 shows a

conceptual diagram for the UPS.

indicates the energy flow direction.

Page 24

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

15

Figure 2-3 UPS conceptual diagram

2.2.2 Working Modes

2.2.2.1 Normal Mode

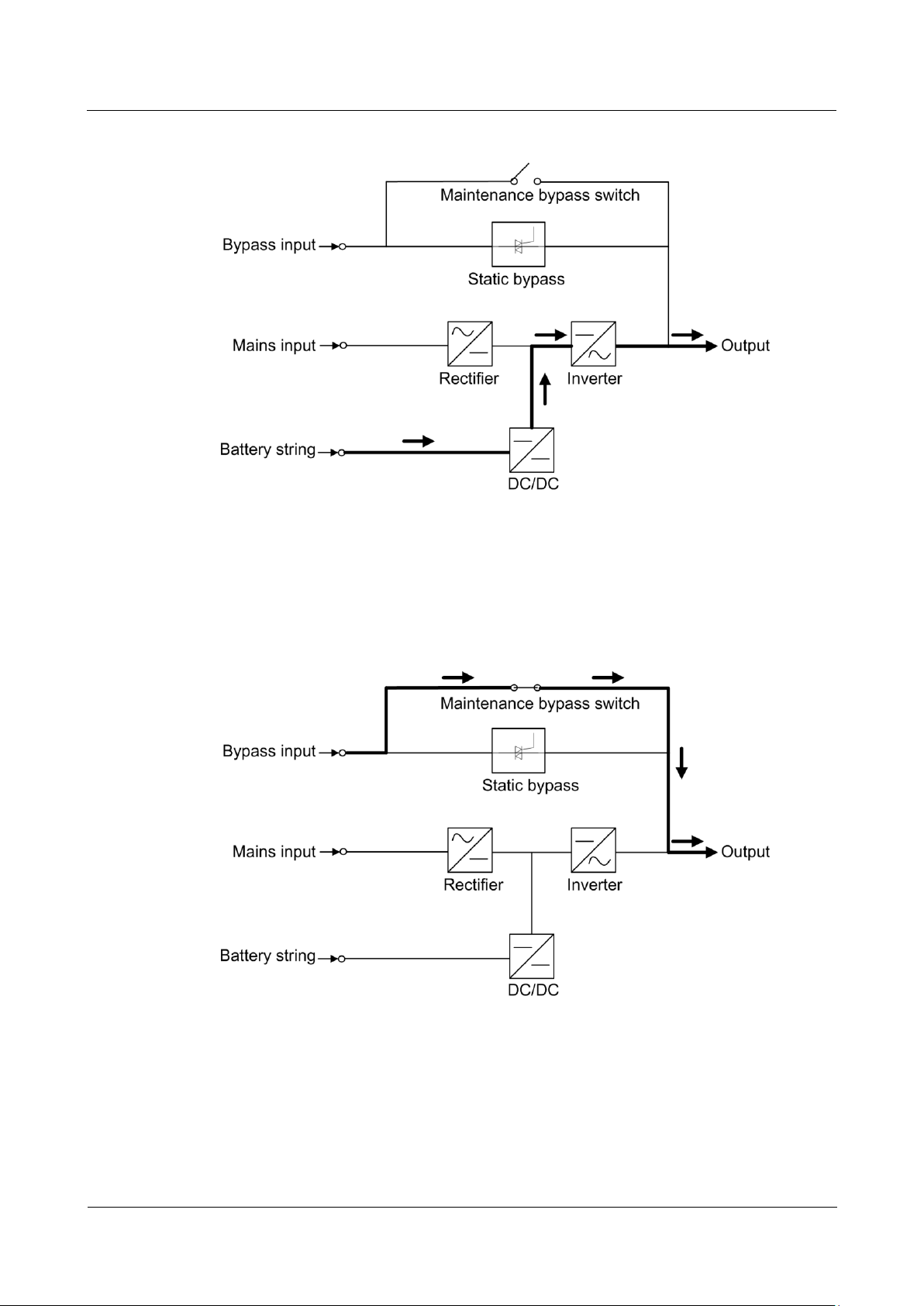

When the UPS works in normal mode, the rectifier converts the AC input voltage into the DC

voltage, which is then raised to the bus voltage by the power factor correction (PFC) circuit.

Then one part of the voltage passes through the DC-DC circuit to charge the battery string,

and the other part is converted by the inverter into AC voltage outputs. The two conversions

ensure high-precision and high-quality output voltages, protecting loads from interferences

such as input harmonics, burrs, and voltage transients. Figure 2-4 shows the conceptual

diagram of the UPS working in normal mode.

Figure 2-4 UPS conceptual diagram in normal mode

Page 25

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

16

2.2.2.2 Bypass Mode

If the inverter does not start or is manually shut down after the UPS is powered on, the bypass

supplies power to loads. The UPS automatically transfers from normal mode to bypass mode

if it detects power unit overtemperature, overload, or other faults that may cause the inverter

to shut down. The bypass power supply is not protected by the UPS which means it may be

affected by mains outage, and incorrect AC voltage or frequency. Figure 2-5 shows a

conceptual diagram of the UPS working in bypass mode.

Figure 2-5 UPS conceptual diagram in bypass mode

2.2.2.3 Battery Mode

If the AC input voltage is not normal, the UPS transfers to battery mode to obtain power from

batteries. The inverter then converts the power into AC outputs. Figure 2-6 shows a

conceptual diagram of the UPS working in battery mode.

Page 26

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

17

Figure 2-6 UPS conceptual diagram in battery mode

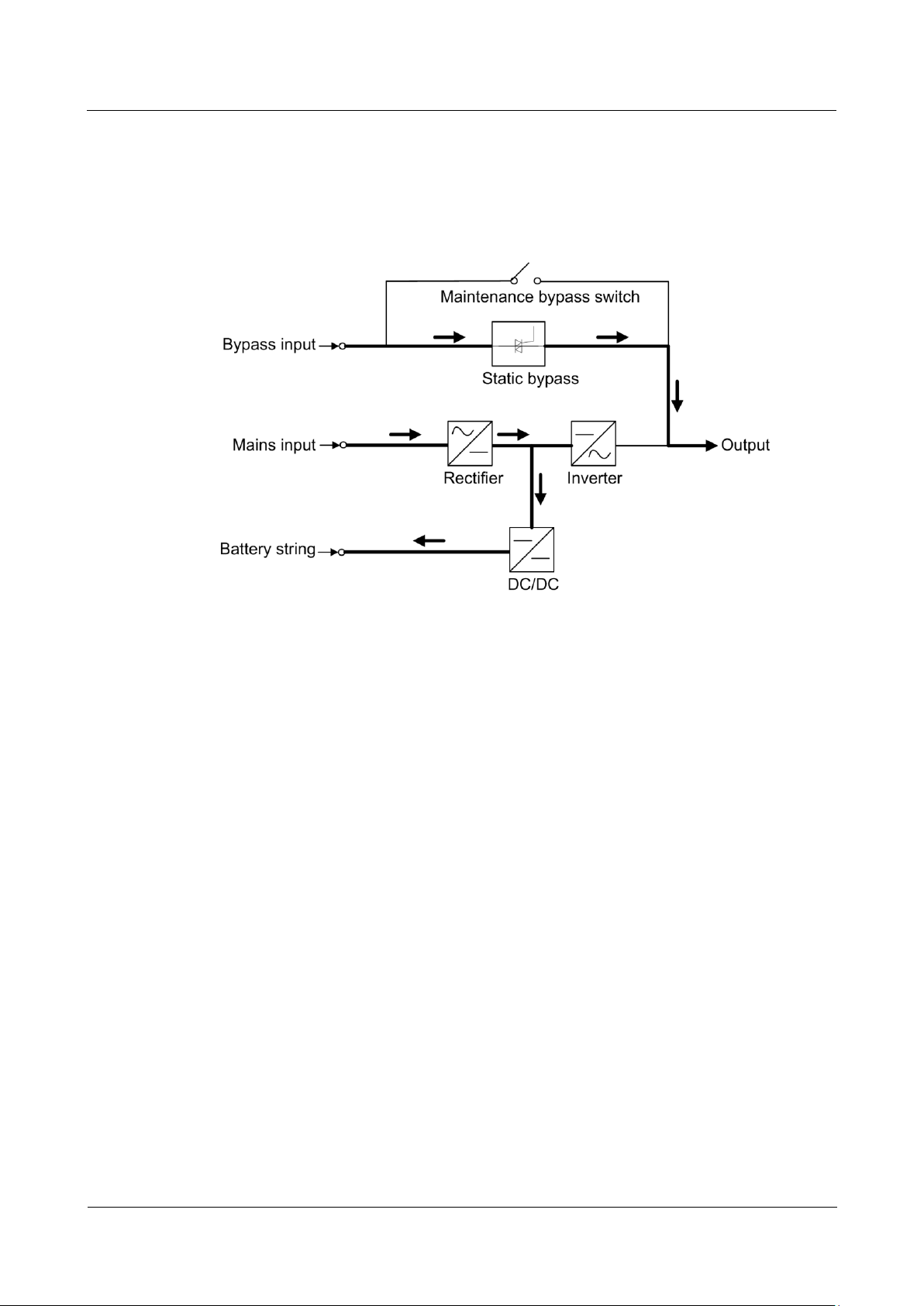

2.2.2.4 Maintenance Bypass Mode

The current flows through the maintenance bypass, instead of the power unit or bypass unit.

UPS maintenance can be performed in this mode.

Figure 2-7 UPS conceptual diagram in maintenance bypass mode

2.2.2.5 ECO Mode

The economy control operation (ECO) mode is an energy-saving mode, which you can

configure on the liquid crystal display (LCD) or web user interface (WebUI). In ECO mode,

when the bypass input voltage is within the ECO voltage range, the bypass combined switch

turns on, and the bypass supplies power. When the bypass input voltage is beyond the ECO

Page 27

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

18

voltage range, the UPS transfers from bypass mode to normal mode. In bypass mode or

normal mode, the rectifier keeps working and charges batteries using a charger. The ECO

mode delivers a higher efficiency. Figure 2-8 shows a conceptual diagram of the UPS working

in ECO mode.

Figure 2-8 UPS conceptual diagram in ECO mode

Page 28

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

19

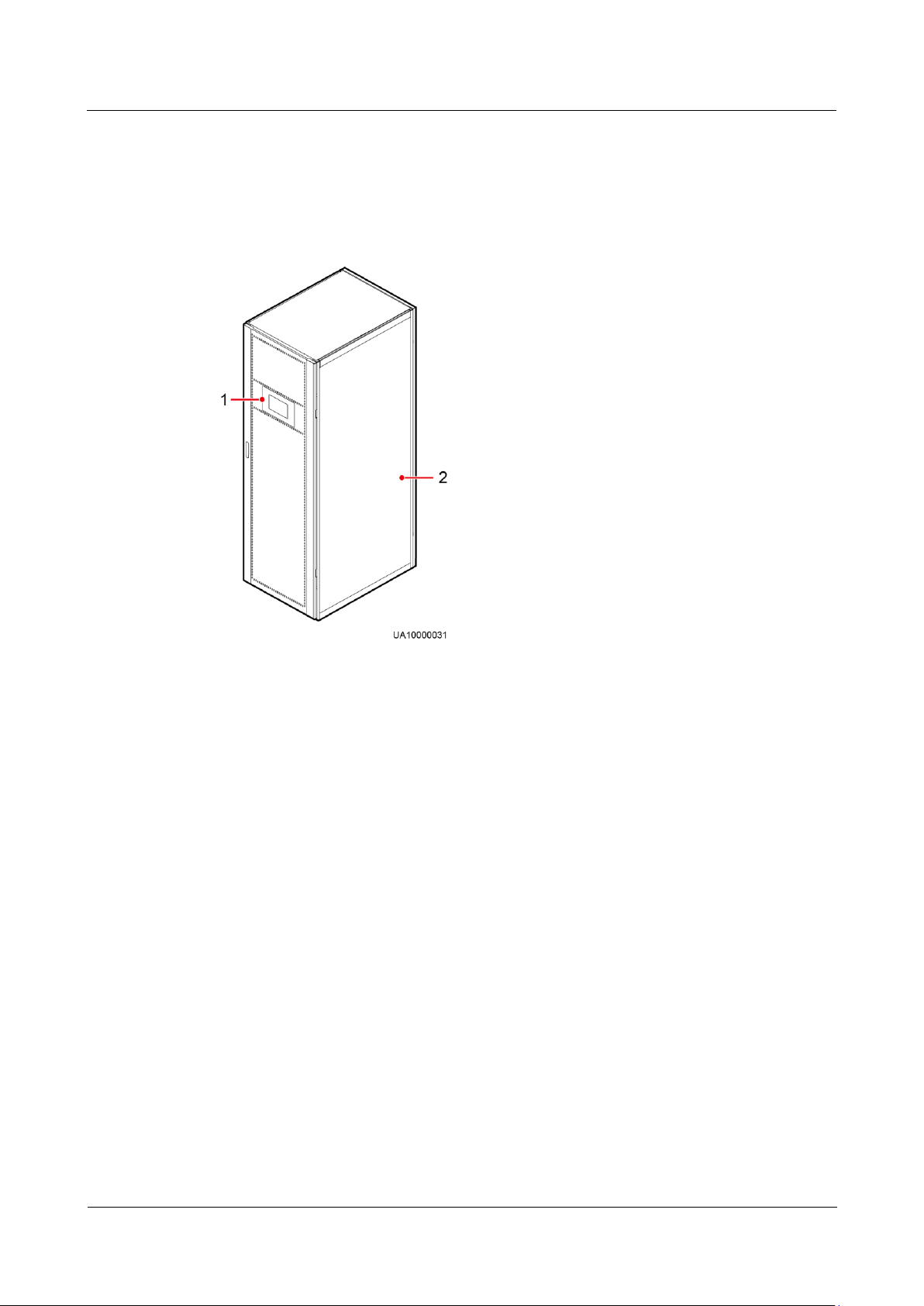

2.3 Product Introduction

(1) Monitor display unit (MDU)

(2) Rack

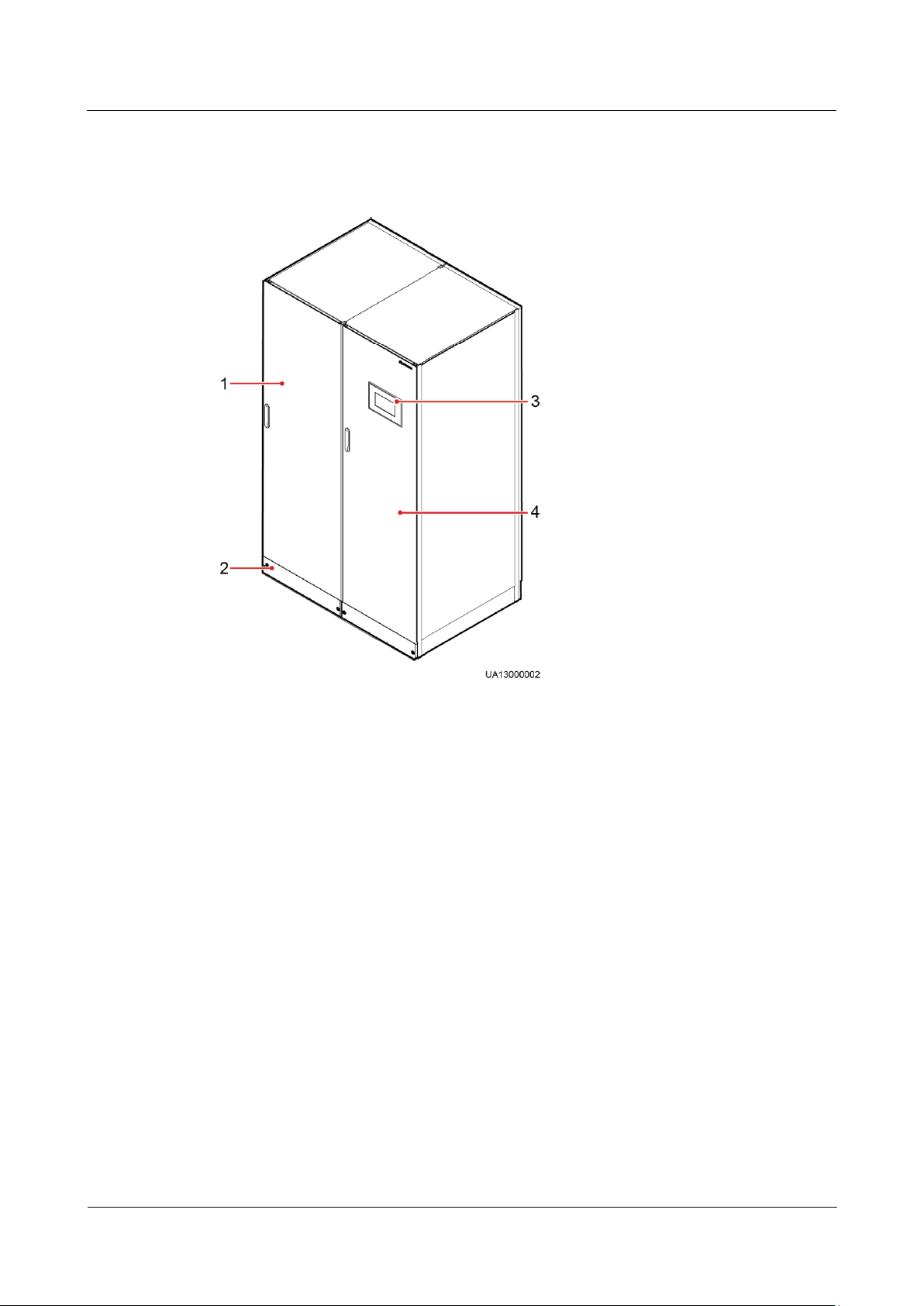

2.3.1 Product Appearance (200K, 300K)

Figure 2-9 UPS appearance (200K, 300K)

Page 29

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

20

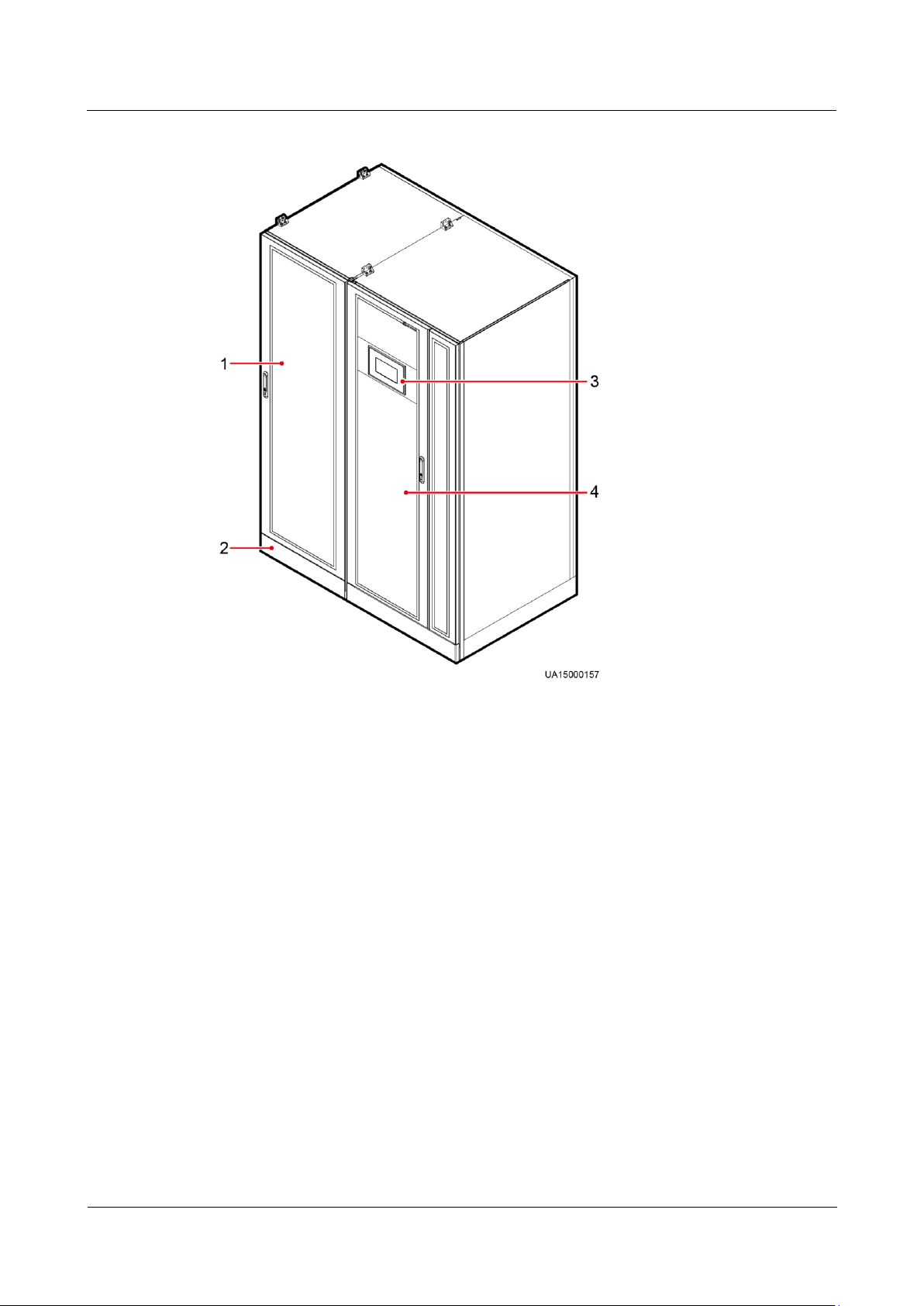

2.3.2 Product Appearance (300K-FT, 400K, 500K, 600K, 800K)

(1) Power cabinet

(2) Anchor baffle plates

(3) MDU

(4) Bypass cabinet

Figure 2-10 UPS appearance (300K-FT, 400K, 500K)

Page 30

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

21

Figure 2-11 UPS appearance (600K)

(1) Power cabinet

(2) Anchor baffle plates

(3) MDU

(4) Bypass cabinet

Page 31

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

22

Figure 2-12 UPS appearance (800K)

(1) Power cabinet 1

(2) Power cabinet 2

(3) Anchor baffle plates

(4) MDU

(5) Bypass cabinet 2

(6) Bypass cabinet 1

Page 32

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

23

2.3.3 Product Structure (200K, 300K)

(1) Power units

(2) Bypass unit

(3) Control unit

(4) Power distribution subrack cover

(5) Maintenance bypass switch

(6) MDU

(7) Folder

(1) Power units

(2) Bypass unit

(3) Control unit

Figure 2-13 UPS5000-A-200K-ST structure

Figure 2-14 UPS5000-A-200K-FT structure

Page 33

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

24

(4) Power distribution subrack

cover

(5) Maintenance bypass

switch

(6) MDU

(7) Folder

(8) Bypass input switch

(9) Mains input

switch

(10) Output switch

(1) Cover

(2) Mains input

switch

(3) Bypass input

switch

(4) Maintenance bypass

switch

(5) Output switch

(6) Control unit

(7) Bypass unit

(8) Power units

(9) Monitor display

unit

(10) Folder

Figure 2-15 UPS5000-A-200K-FT (isolation protection) structure

Page 34

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

25

Figure 2-16 UPS5000-A-300K-STT structure

(1) Power units

(2) Bypass unit

(3) Control unit

(4) Power distribution subrack cover

(5) Maintenance bypass switch

(6) MDU

(1) Power units

(2) Bypass unit

(3) Control unit

(4) Power distribution subrack cover

(5) Maintenance bypass switch

(6) MDU

(7) Folder

Figure 2-17 UPS5000-A-300KTTL structure

Page 35

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

26

(1) Cover

(2) Maintenance bypass switch

(3) Control unit

(4) Bypass unit

(5) Power units

(6) Monitor display unit

Figure 2-18 UPS5000-A-300K-STT (isolation protection) structure

2.3.4 Product Structure (300K-FT, 400K, 500K, 600K, 800K)

The following figures show a UPS with its front door open.

Page 36

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

27

Figure 2-19 UPS5000-A-300K-FT structure

(1) Power units

(2) Control unit

(3) Mains input switch

(4) Output switch

(5) Power distribution unit

cover

(6) Maintenance bypass

switch

(7) Bypass input

switch

(8) Bypass unit

(1) Power units

(2) Control unit

(3) Power distribution unit cover

(4) Maintenance bypass switch

(5) Bypass unit

Figure 2-20 UPS5000-A-400K-SC structure

Page 37

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

28

(1) Power units

(2) Control unit

(3) Mains input switch

(4) Output switch

(5) Power distribution unit

cover

(6) Maintenance bypass

switch

(7) Bypass input

switch

(8) Bypass unit

(1) Power units

(2) Control unit

(3) Power distribution unit cover

Figure 2-21 UPS5000-A-400K-FC structure

Figure 2-22 UPS5000-A-500K-SC structure

Page 38

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

29

(4) Maintenance bypass switch

(5) Bypass unit

(1) Power units

(2) Control unit

(3) Mains input switch

(4) Output switch

(5) Power distribution unit

cover

(6) Maintenance bypass

switch

(7) Bypass input

switch

(8) Bypass unit

Figure 2-23 UPS5000-A-500K-FC structure

Page 39

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

30

Figure 2-24 UPS5000-A-600K-F600-SC structure

(1) Power units

(2) Control unit

(3) Power distribution unit cover

(4) Maintenance bypass switch

(5) Bypass unit

(1) Power units

(2) Control unit

(3) Mains input switch

(4) Output switch

(5) Power distribution unit

cover

(6) Maintenance bypass

switch

(7) Bypass input

switch

(8) Bypass unit

Figure 2-25 UPS5000-A-600K-F600-FC structure

Page 40

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

31

Figure 2-26 UPS5000-A-800K-F800-SC structure

(1) Power units

(2) Control unit

(3) Maintenance bypass switch

(4) Power distribution unit cover

(5) Bypass unit

(1) Power units

(2) Control unit

(3) Maintenance bypass

switch

(4) Power distribution unit

cover

(5) Bypass unit

(6) Mains input switch

(7) Output switch

(8) Bypass input

switch

Figure 2-27 UPS5000-A-800K-F800-FC structure

Page 41

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

32

2.4 Control Unit

(1) Ground terminal

(2) Parallel port 1

(3) BSC port 1

(4) ECM 1 ready

switch

(5) Indicators for ECM 1

(6) Parallel port 2

(7) BSC port 2

(8) ECM 2 ready switch

(9) Indicators for ECM 2

(10) Dry contact card

(11) Dry contacts

(12) MDU port

(13) RS485 port

(14) Fast Ethernet (FE) port

(15) COM2 port

(16) COM1 port

(17) Battery temperature sensor

port

(18) Optional card subrack

cover

2.4.1 Overview

In a standard configuration, the control unit consists of two energy control modules (ECMs),

one dry contact card, and one monitoring interface card. The four cards are hot swappable.

One subrack is reserved above the dry contact card. A backfeed protection card or dry contact

extended card can be inserted into this subrack.

Figure 2-28 Signal panel on the control unit

2.4.2 ECM

The control unit consists of two ECMs in active/standby mode. Each ECM provides one bus

synchronization controller (BSC) port and one parallel port, as shown in Figure 2-29.

Figure 2-29 ECM

Page 42

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

33

Table 2-4 Ports on the ECM

Silk Screen

Description

PARALLEL

The PARALLEL port transmits parallel signals.

BSC

This port is used in a dual-bus system to balance output frequencies and

phases between UPS systems, ensuring that two buses can switch with

each other.

BSC cables are hot-swappable.

Indicator

Color

Status

Description

NORMAL

Green

Steady on

This ECM is the active ECM.

Blinking at 0.5

Hz

This ECM is the standby ECM and it is

ready.

Off

This ECM is not ready or the CPLD of

this ECM is being upgraded.

Blinking at 4 Hz

The DSP of the ECM is being upgraded or

not configured.

ALM

Yellow

Steady on

The ECM has a minor alarm, but it does

not need to be replaced.

Off

The ECM has no minor alarm or the DSP

of the ECM is being upgraded.

FAULT

Red

Steady on

The ECM has a critical alarm.

Off

The ECM has no critical alarm or the DSP

of the ECM is being upgraded.

For a single UPS, the parallel cable is not needed.

Table 2-5 Indicator description

2.4.3 Dry contact card

Appearance

Figure 2-30 Dry contact card

Page 43

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

34

Table 2-6 Ports on the dry contact card

Silk

Screen

Description

Status

Initial Status

BTG

Port for detecting battery

grounding faults

Connected: battery

grounding fault

Disconnected: no

battery grounding

fault

Disconnected

0V

Port for signal ground

GEN

Port for detecting diesel

generator (D.G.) mode

Connected: D.G.

mode

Disconnected:

non-D.G. mode

Disconnected

0V

Port for signal ground

BCB_OL

Port for detecting the BCB

box

Grounded: BCB

box connected

Disconnected:

BCB box not

connected

Grounded

BCB_STA

Port for monitoring the

battery switch

Connected: battery

switch ON

Disconnected:

battery switch

OFF

Disconnected

BCB_DR

V

Controls battery circuit

breaker trip. When the

voltage is +12 V, the circuit

breaker trips.

0 V: battery

switch not tripped

12 V: battery

switch tripped

0 V

BCB_0V

Port for signal ground

EPO_NO

Emergency power-off

(EPO) port

If the normally open

(NO) port is

connected to the

EPO_12V port, EPO

is triggered.

Disconnected

EPO_12V

+12 V

EPO_NC

EPO port

If the normally closed

(NC) port is

disconnected from the

EPO_12V port, EPO

is triggered.

Connected

EPO_12V

+12 V

SWITCH

STATUS_

OUT

Port for monitoring the UPS

output circuit breaker

Connected: circuit

breaker ON

Disconnected:

circuit breaker

OFF

Connected

SWITCH

STATUS_

0V

Port for signal ground

Page 44

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

35

Silk

Screen

Description

Status

Initial Status

SWITCH

STATUS_

MT

Port for monitoring the

maintenance circuit breaker

Disconnected:

circuit breaker ON

Connected: circuit

breaker OFF

Disconnected

SWITCH

STATUS_

0V

Port for signal ground

SWITCH

STATUS_

BP

Port for monitoring the

bypass input circuit breaker

Connected: circuit

breaker ON

Disconnected:

circuit breaker

OFF

Connected

SWITCH

STATUS_

0V

Port for signal ground

SPD

Port for monitoring the

input AC surge protective

device (SPD)

Connected: SPD

enabled

Disconnected:

SPD disabled

Connected

0V

Port for signal ground

The dry contact interface card takes effect only after it is set on the monitoring system. Set the

unused dry contact signal to the unused status.

Set the EPO port to NO or NC as required.

When multiple UPSs are paralleled, all dry contact signals to be used need to connect to each UPS.

Single cables require dual-insulated twisted cables. If the length of a power cable is within 25–50 m,

its cross-sectional area must be 0.5 mm2 to 1.5 mm2.

Functions

The dry contact card allows the UPS to detect and manage the switch status of the battery

system (including the external battery switch) and implement remote emergency power-off

(EPO).

Specifications

Hot-swappable

0.5 U high

2.4.4 Monitoring interface card

Page 45

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

36

Port

Silk

Screen

Description

DO_1

NO

DO_1 is used to output alarms and indicates critical alarms by

default. It can be set to indicate minor alarms, bypass mode,

battery mode, or low battery voltage.

COM

DO_2

NO

DO_2 is used to output alarms and indicates minor alarms by

default. It can be set to indicate critical alarms, bypass mode,

battery mode, or low battery voltage.

COM

DO_3

NO

DO_3 is used to output alarms and indicates bypass mode by

default. It can be set to indicate critical alarms, minor alarms,

battery mode, or low battery voltage.

COM

DO_4

NO

DO_4 is used to output alarms and indicates battery mode by

default. It can be set to indicate critical alarms, minor alarms,

bypass mode, or low battery voltage.

COM

The FE port resembles the RS485 port. Therefore, follow the silk screen when you connect

communications cables. If you mistake the RS485 port as the FE port during cable

connection, the WebUI and MDU communication fails. If you mistake the FE port as the

RS485 port during cable connection, RS485 communication fails.

Dry contact signals take effect after you set them. Set unused dry contact signals to the

unused state on the WebUI or LCD.

In a parallel system, ensure that used dry contacts properly connect to each UPS.

The monitoring interface card provides external ports as well as monitoring and control

functions for the MDU. The ports include the ambient temperature and humidity sensor port,

FE port, battery temperature monitoring port, and network management port. The MDU

monitors the UPS, allows users to set parameters, delivers commands, reports information,

and displays the UPS key information and parameters on the LCD.

Figure 2-31 Monitoring interface card

DO_1 to DO_4 meet the maximum voltage and current requirements of 30 V DC/1 A or 60 V DC/0.5 A.

Table 2-7 Ports on the monitoring interface card

Page 46

UPS5000-A-(200 kVA-800 kVA)

User Manual

2 Overview

Issue 03 (2019-02-15)

Copyright © Huawei Technologies Co., Ltd.

37

Port

Silk

Screen

Description

DB26

MDU

Provides FE, RS485, Inter-Integrated Circuit (I2C), and control

area network (CAN) signals.

Battery

temper

ature

sensor

port

B_TEMP

Connects to an indoor battery temperature sensor.

Southb

ound

port 1

COM1

Connects to an ambient temperature and humidity sensor over two

wires.

Southb

ound

port 2

COM2

Connects to a southbound device.

Networ

k port

FE

Connects to the network port on a PC.

Northb

ound

commu

nications

port

RS485

Connects to a northbound network management device or

third-party network management device over two wires.