SUN2000-(3KTL-10KTL)-M1

User Manual

Issue

02

Date

2020-11-20

HUAWEI TECHNOLOGIES CO., LTD.

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

i

Copyright © Huawei Technologies Co., Ltd. 2021. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties,

guarantees or representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address:

Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website:

https://e.huawei.com

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

ii

SUN2000-(3KTL-10KTL)-M1

User Manual

About This Document

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

iii

Overview

Symbol

Description

Indicates a hazard with a high level of risk which, if not

avoided, will result in death or serious injury.

Indicates a hazard with a medium level of risk which, if

not avoided, could result in death or serious injury.

Indicates a hazard with a low level of risk which, if not

avoided, could result in minor or moderate injury.

About This Document

This document describes the SUN2000-3KTL-M1, SUN2000-4KTL-M1,

SUN2000-5KTL-M1, SUN2000-6KTL-M1, SUN2000-8KTL-M1, and

SUN2000-10KTL-M1 (SUN2000 for short) in terms of their installation, electrical

connections, commissioning, maintenance, and troubleshooting. Before installing

and operating the SUN2000, ensure that you are familiar with the features,

functions, and safety precautions provided in this document.

The SUN2000-8KTL-M1 and SUN2000-10KTL-M1 are not applicable to Australia.

Intended Audience

This document is applicable to:

Installers

Users

Symbol Conventions

The symbols that may be found in this document are defined as follows:

SUN2000-(3KTL-10KTL)-M1

User Manual

About This Document

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

iv

Symbol

Description

Indicates a potentially hazardous situation which, if

not avoided, could result in equipment damage, data

loss, performance deterioration, or unanticipated

results.

Notice is used to address practices not related to

personal injury.

Supplements the important information in the main

text.

NOTE is used to address information not related to

personal injury, equipment damage, and environment

deterioration.

Change History

Changes between document issues are cumulative. The latest document issue

contains all the changes made in earlier issues.

Issue 02 (2020-11-20)

Updated 7.2.1.2 Battery Control.

Issue 01 (2020-09-30)

This issue is used for first office application (FOA).

SUN2000-(3KTL-10KTL)-M1

User Manual

Contents

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

v

Contents

About This Document .................................................................................................................. iii

1 Safety Information ...................................................................................................................... 1

1.1 General Safety ........................................................................................................................................................... 1

1.2 Personnel Requirements .......................................................................................................................................... 2

1.3 Electrical Safety ......................................................................................................................................................... 3

1.4 Installation Environment Requirements ............................................................................................................... 4

1.5 Mechanical Safety ..................................................................................................................................................... 4

1.6 Commissioning .......................................................................................................................................................... 6

1.7 Maintenance and Replacement .............................................................................................................................. 6

2 Overview ........................................................................................................................................ 7

2.1 Product Introduction ................................................................................................................................................. 7

2.2 Appearance .............................................................................................................................................................. 11

2.3 Label Description ..................................................................................................................................................... 13

2.3.1 Enclosure Labels ................................................................................................................................................... 13

2.3.2 Product Nameplate .............................................................................................................................................. 15

2.4 Working Principles .................................................................................................................................................. 15

2.4.1 Circuit Diagram .................................................................................................................................................... 15

2.4.2 Working Modes .................................................................................................................................................... 16

3 Storage.......................................................................................................................................... 18

4 Installation .................................................................................................................................. 19

4.1 Checking Before Installation ................................................................................................................................. 19

4.2 Tools .......................................................................................................................................................................... 20

4.3 Determining the Installation Position ................................................................................................................. 21

4.3.1 Environment Requirements ................................................................................................................................ 21

4.3.2 Space Requirements ............................................................................................................................................ 22

4.4 Moving the SUN2000 ............................................................................................................................................. 25

4.5 Installing the Mounting Bracket........................................................................................................................... 26

4.5.1 Wall-mounted Installation ................................................................................................................................. 27

4.5.2 Support-mounted Installation ........................................................................................................................... 30

SUN2000-(3KTL-10KTL)-M1

User Manual

Contents

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

vi

5 Electrical Connections .............................................................................................................. 34

5.1 Installation Preparation ......................................................................................................................................... 34

5.2 Connecting the PE cable ........................................................................................................................................ 37

5.3 Connecting the AC Output Power Cable ............................................................................................................ 40

5.4 Installing DC input power cables ......................................................................................................................... 44

5.5 (Optional) Connecting Battery Cables ................................................................................................................ 49

5.6 Install the Smart Dongle ........................................................................................................................................ 51

5.7 (Optional) Connecting the Signal Cable ............................................................................................................. 53

5.7.1 Connecting the RS485 Communications Cable (Inverter Cascading) ........................................................ 57

5.7.2 Connecting the RS485 Communications Cable (Smart Power Sensor) ..................................................... 58

5.7.3 Connecting an RS485 Communications Cable (Between a Power Meter and a Battery) ...................... 61

5.7.4 Connecting the Power Grid Scheduling Signal Cable .................................................................................... 62

5.7.5 Connecting a Signal Cable to the Smart Backup Box ................................................................................... 64

6 Commissioning ........................................................................................................................... 66

6.1 Checking Before Power-On ................................................................................................................................... 66

6.2 SUN2000 power-on ................................................................................................................................................ 67

7 Man-Machine Interaction ....................................................................................................... 73

7.1 App Commissioning ................................................................................................................................................ 73

7.1.1 Downloading the FusionSolar App ................................................................................................................... 73

7.1.2 (Optional) Registering an Installer Account ................................................................................................... 73

7.1.3 Creating a PV Plant and a User ......................................................................................................................... 75

7.1.4 (Optional) Setting the Physical Layout of the Smart PV Optimizers ......................................................... 75

7.1.5 Detect optimizer disconnection ......................................................................................................................... 78

7.2 Parameters Settings ................................................................................................................................................ 79

7.2.1 Energy Control ...................................................................................................................................................... 79

7.2.1.1 Grid-tied Point Control ..................................................................................................................................... 79

7.2.1.2 Battery Control .................................................................................................................................................. 83

7.2.2 AFCI ......................................................................................................................................................................... 86

7.2.3 IPS Check (for Italy CEI0-21 Grid Code Only) ................................................................................................. 88

7.3 SmartLogger Networking Scenario ...................................................................................................................... 90

8 Maintenance ............................................................................................................................... 91

8.1 SUN2000 Power-Off ............................................................................................................................................... 91

8.2 Routine Maintenance ............................................................................................................................................. 92

8.3 Troubleshooting ...................................................................................................................................................... 92

9 Handling the Inverter ............................................................................................................. 105

9.1 Removing the SUN2000 ....................................................................................................................................... 105

9.2 Packing the SUN2000 ................................................................................................................................ ........... 105

SUN2000-(3KTL-10KTL)-M1

User Manual

Contents

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

vii

9.3 Disposing of the SUN2000 .................................................................................................................................. 105

10 Technical Specifications ....................................................................................................... 106

10.1 SUN2000 Technical Specifications ........................................................................................................................ 106

10.2 LUNA2000-5KW-C0 ............................................................................................................................................. 112

10.3 LUNA2000-5-E0 .................................................................................................................................................... 113

10.4 Optimizer Technical Specifications ........................................................................................................................ 114

A Grid Code .................................................................................................................................. 117

B Device Commissioning ........................................................................................................... 119

C Resetting Password ................................................................................................................ 123

D DRM Configuration Guide for Standard As NZS4777.2 .............................................. 127

E Rapid Shutdown ...................................................................................................................... 127

F Locating Insulation Resistance Faults ............................................................................... 129

G Acronyms and Abbreviations .............................................................................................. 133

SUN2000-(3KTL-10KTL)-M1

User Manual

1 Safety Information

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

1

1.1 General Safety

Statement

Before installing, operating, and maintaining the equipment, read this document

and observe all the safety instructions on the equipment and in this document.

1 Safety Information

The "NOTICE", "CAUTION", "WARNING", and "DANGER" statements in this

document do not cover all the safety instructions. They are only supplements to the

safety instructions. Huawei will not be liable for any consequence caused by the

violation of general safety requirements or design, production, and usage safety

standards.

Ensure that the equipment is used in environments that meet its design

specifications. Otherwise, the equipment may become faulty, and the resulting

equipment malfunction, component damage, personal injuries, or property damage

are not covered under the warranty.

Follow local laws and regulations when installing, operating, or maintaining the

equipment. The safety instructions in this document are only supplements to local

laws and regulations.

Huawei will not be liable for any consequences of the following circumstances:

Operation beyond the conditions specified in this document

Installation or use in environments which are not specified in relevant

international or national standards

Unauthorized modifications to the product or software code or removal of the

product

Failure to follow the operation instructions and safety precautions on the

product and in this document

Equipment damage due to force majeure, such as earthquakes, fire, and storms

Damage caused during transportation by the customer

SUN2000-(3KTL-10KTL)-M1

User Manual

1 Safety Information

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

2

Storage conditions that do not meet the requirements specified in this

document

General Requirements

Do not work with power on during installation.

Do not install, use, or operate outdoor equipment and cables (including but not

limited to moving equipment, operating equipment and cables, inserting

connectors to or removing connectors from signal ports connected to outdoor

facilities, working at heights, and performing outdoor installation) in harsh

weather conditions such as lightning, rain, snow, and level 6 or stronger wind.

After installing the equipment, remove idle packing materials such as cartons,

foam, plastics, and cable ties from the equipment area.

In the case of a fire, immediately leave the building or the equipment area, and

turn on the fire alarm bell or make an emergency call. Do not enter the

building on fire in any case.

Do not scrawl, damage, or block any warning label on the equipment.

Tighten the screws using tools when installing the equipment.

Understand the components and functioning of a grid-tied PV power system

and relevant local standards.

Repaint any paint scratches caused during equipment transportation or

installation in a timely manner. Equipment with scratches cannot be exposed to

an outdoor environment for a long period of time.

Do not open the host panel of the equipment.

Personal Safety

If there is a probability of personal injury or equipment damage during

operations on the equipment, immediately stop the operations, report the case

to the supervisor, and take feasible protective measures.

Use tools correctly to avoid hurting people or damaging the equipment.

Do not touch the energized equipment, as the enclosure is hot.

1.2 Personnel Requirements

Personnel who plan to install or maintain Huawei equipment must receive

thorough training, understand all necessary safety precautions, and be able to

correctly perform all operations.

Only qualified professionals or trained personnel are allowed to install, operate,

and maintain the equipment.

SUN2000-(3KTL-10KTL)-M1

User Manual

1 Safety Information

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

3

Only qualified professionals are allowed to remove safety facilities and inspect

the equipment.

Personnel who will operate the equipment, including operators, trained

personnel, and professionals, should possess the local national required

qualifications in special operations such as high-voltage operations, working at

heights, and operations of special equipment.

Only professionals or authorized personnel are allowed to replace the

equipment or components (including software).

Professionals: personnel who are trained or experienced in equipment operations and are

clear of the sources and degree of various potential hazards in equipment installation,

operation, and maintenance

Trained personnel: personnel who are technically trained, have required experience, are

aware of possible hazards on themselves in certain operations, and are able to take

protective measures to minimize the hazards on themselves and other people

Operators: operation personnel who may come in contact with the equipment, except

trained personnel and professionals

1.3 Electrical Safety

Grounding

For the equipment that needs to be grounded, install the ground cable first

when installing the equipment and remove the ground cable last when

removing the equipment.

Do not damage the ground conductor.

Do not operate the equipment in the absence of a properly installed ground

conductor.

Ensure that the equipment is connected permanently to the protective ground.

Before operating the equipment, check its electrical connection to ensure that it

is securely grounded.

General Requirements

Before connecting cables, ensure that the equipment is intact. Otherwise, electric

shocks or fire may occur.

Ensure that all electrical connections comply with local electrical standards.

Obtain approval from the local electric utility company before using the

equipment in grid-tied mode.

Ensure that the cables you prepared meet local regulations.

SUN2000-(3KTL-10KTL)-M1

User Manual

1 Safety Information

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

4

AC and DC Power

Do not connect or disconnect power cables with power on. Transient contact

between the core of the power cable and the conductor will generate electric arcs or

sparks, which may cause fire or personal injury.

Use dedicated insulated tools when performing high-voltage operations.

Before making electrical connections, switch off the disconnector on the

upstream device to cut off the power supply if people may contact energized

components.

Before connecting a power cable, check that the label on the power cable is

correct.

If the equipment has multiple inputs, disconnect all the inputs before operating

the equipment.

Cabling

When routing cables, ensure that a distance of at least 30 mm exists between

the cables and heat-generating components or areas. This prevents damage to

the insulation layer of the cables.

Bind cables of the same type together. When routing cables of different types,

ensure that they are at least 30 mm away from each other.

Ensure that the cables used in a grid-tied PV power system are properly

connected and insulated and meet specifications.

1.4 Installation Environment Requirements

Ensure that the equipment is installed in a well ventilated environment.

To prevent fire due to high temperature, ensure that the ventilation vents or

heat dissipation system are not blocked when the equipment is running.

Do not expose the equipment to flammable or explosive gas or smoke. Do not

perform any operation on the equipment in such environments.

1.5 Mechanical Safety

Using Ladders

Use wooden or fiberglass ladders when you need to perform live working at

heights.

SUN2000-(3KTL-10KTL)-M1

User Manual

1 Safety Information

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

5

When a step ladder is used, ensure that the pull ropes are secured and the

ladder is held firm.

Before using a ladder, check that it is intact and confirm its load bearing

capacity. Do not overload it.

Ensure that the wider end of the ladder is at the bottom, or protective

measures have been taken at the bottom to prevent the ladder from sliding.

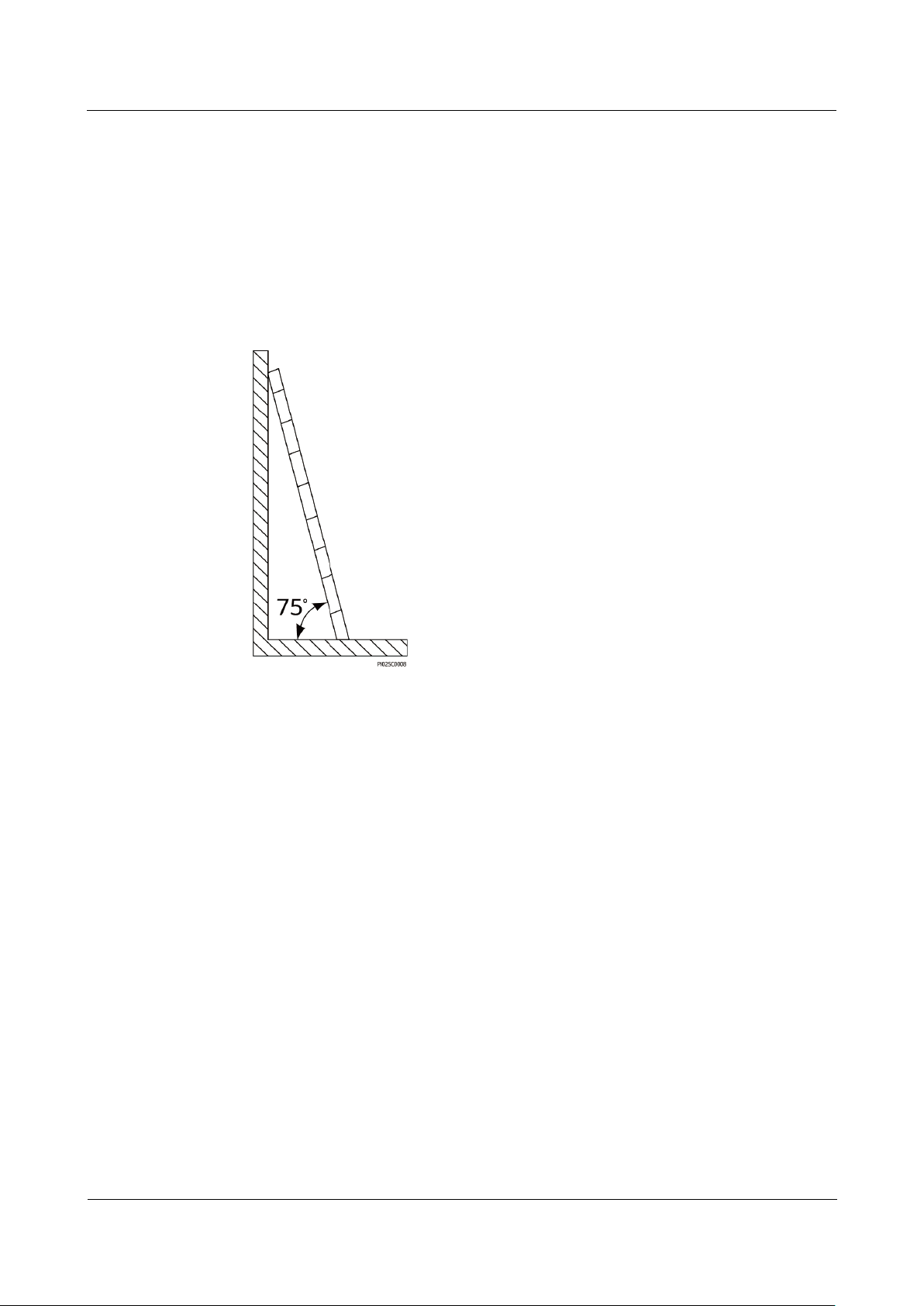

Ensure that the ladder is securely positioned. The recommended angle for a

ladder against the floor is 75 degrees, as shown in the following figure. An

angle rule can be used to measure the angle.

When climbing a ladder, take the following precautions to reduce risks and

ensure safety:

− Keep your body steady.

− Do not climb higher than the fourth rung of the ladder from the top.

− Ensure that your body's center of gravity does not shift outside the legs of

the ladder.

Drilling Holes

When drilling holes into a wall or floor, observe the following safety precautions:

Wear goggles and protective gloves when drilling holes.

When drilling holes, protect the equipment from shavings. After drilling, clean

up any shavings that have accumulated inside or outside the equipment.

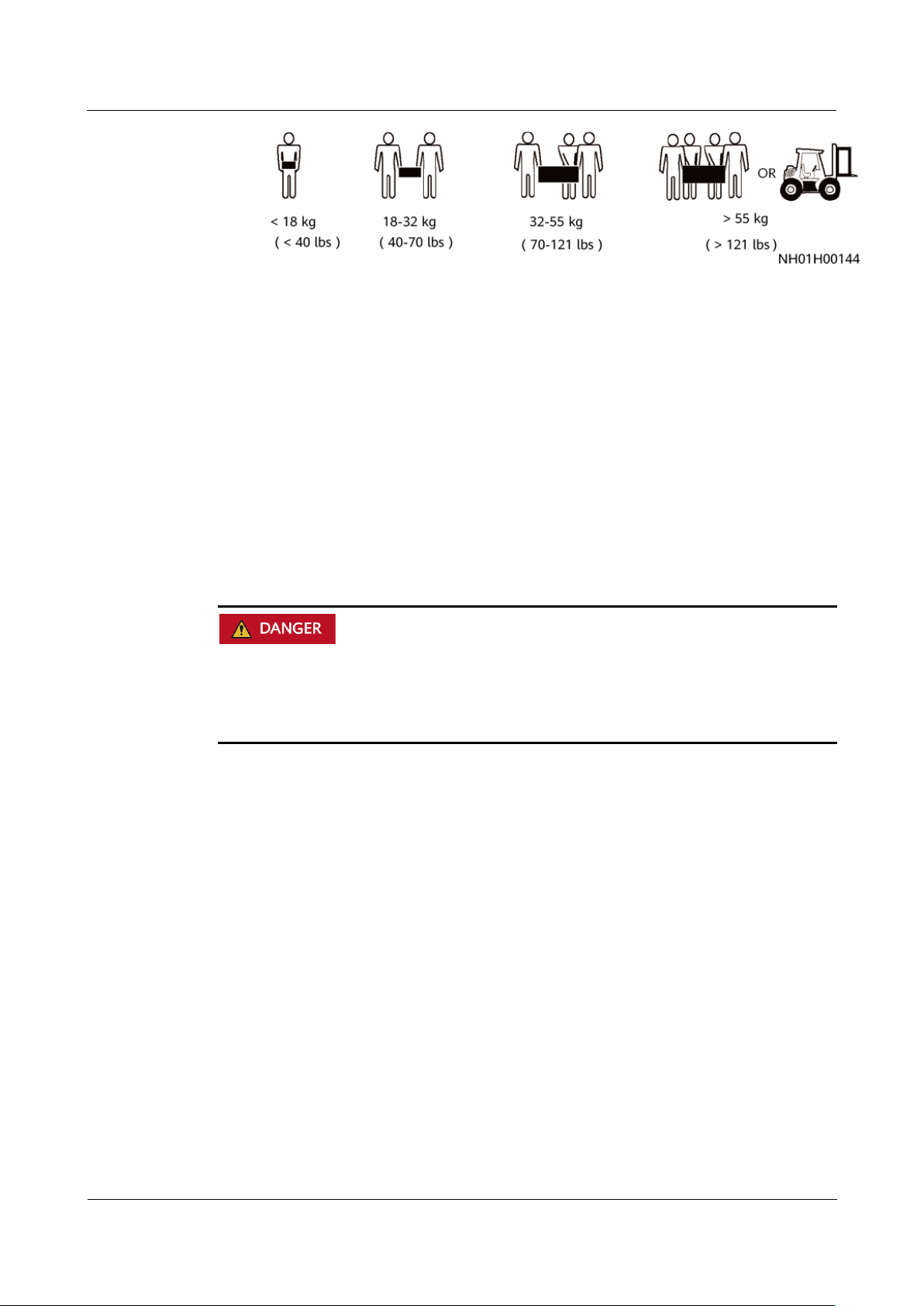

Moving Heavy Objects

Be cautious to avoid injury when moving heavy objects.

SUN2000-(3KTL-10KTL)-M1

User Manual

1 Safety Information

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

6

When moving the equipment by hand, wear protective gloves to prevent

injuries.

1.6 Commissioning

When the equipment is powered on for the first time, ensure that professional

personnel set parameters correctly. Incorrect settings may result in inconsistency

with local certification and affect the normal operation of the equipment.

1.7 Maintenance and Replacement

High voltage generated by the equipment during operation may cause an electric

shock, which could result in death, serious injury, or serious property damage. Prior

to maintenance, power off the equipment and strictly comply with the safety

precautions in this document and relevant documents.

Maintain the equipment with sufficient knowledge of this document and using

proper tools and testing equipment.

Before maintaining the equipment, power it off and follow the instructions on

the delayed discharge label to ensure that the equipment is powered off.

Place temporary warning signs or erect fences to prevent unauthorized access

to the maintenance site.

If the equipment is faulty, contact your dealer.

The equipment can be powered on only after all faults are rectified. Failing to

do so may escalate faults or damage the equipment.

SUN2000-(3KTL-10KTL)-M1

User Manual

2 Overview

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

7

2.1 Product Introduction

Functions

The SUN2000 inverter is a three-phase grid-tied PV string inverter that converts the

DC power generated by PV strings into AC power and feeds the power into the

power grid.

2 Overview

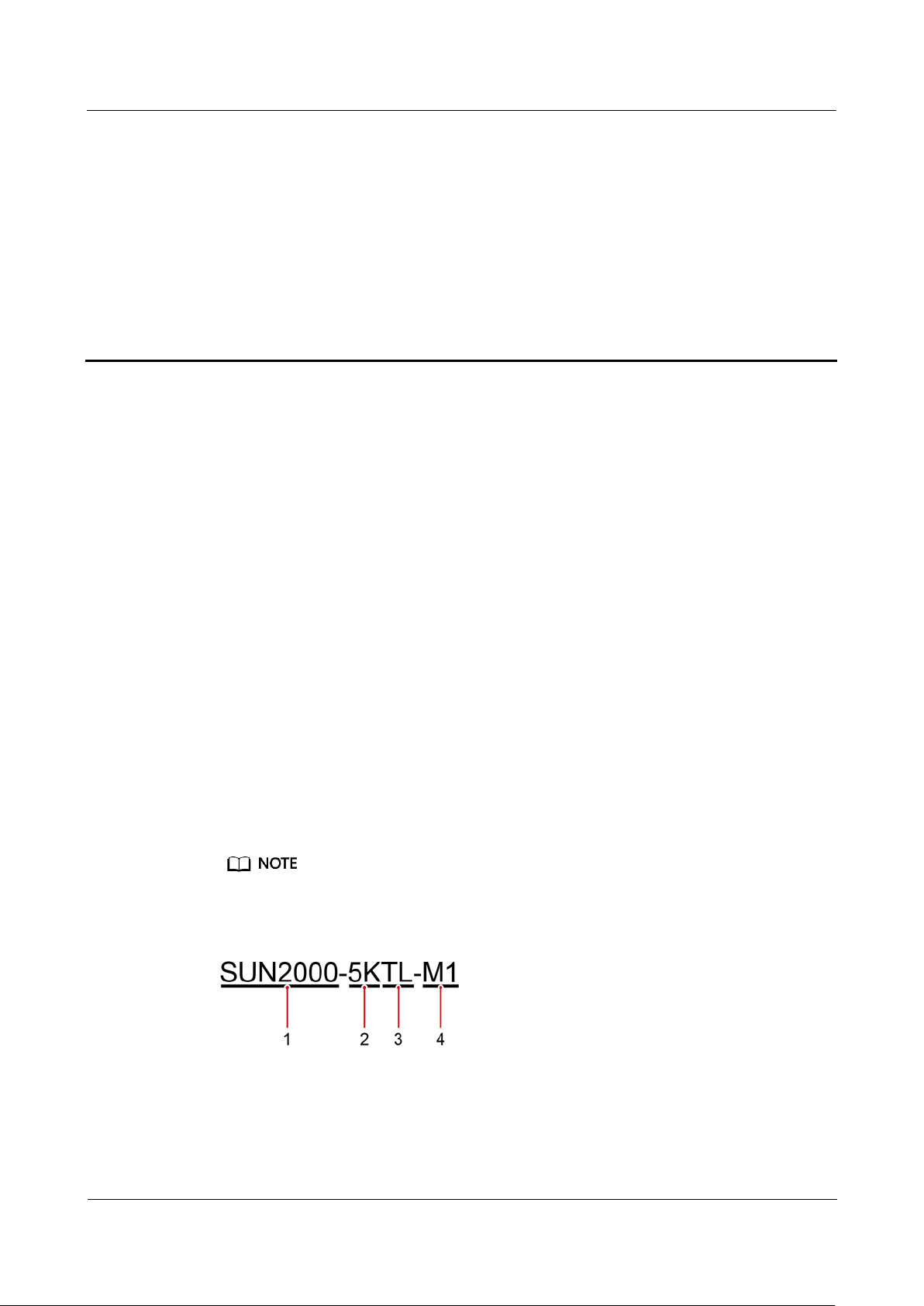

Model

This document covers the following SUN2000 models:

SUN2000-3KTL-M1

SUN2000-4KTL-M1

SUN2000-5KTL-M1

SUN2000-6KTL-M1

SUN2000-8KTL-M1

SUN2000-10KTL-M1

The SUN2000-8KTL-M1 and SUN2000-10KTL-M1 are not applicable to Australia.

Figure 2-1 Model description (using SUN2000-5KTL-M1 as an example)

SUN2000-(3KTL-10KTL)-M1

User Manual

2 Overview

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

8

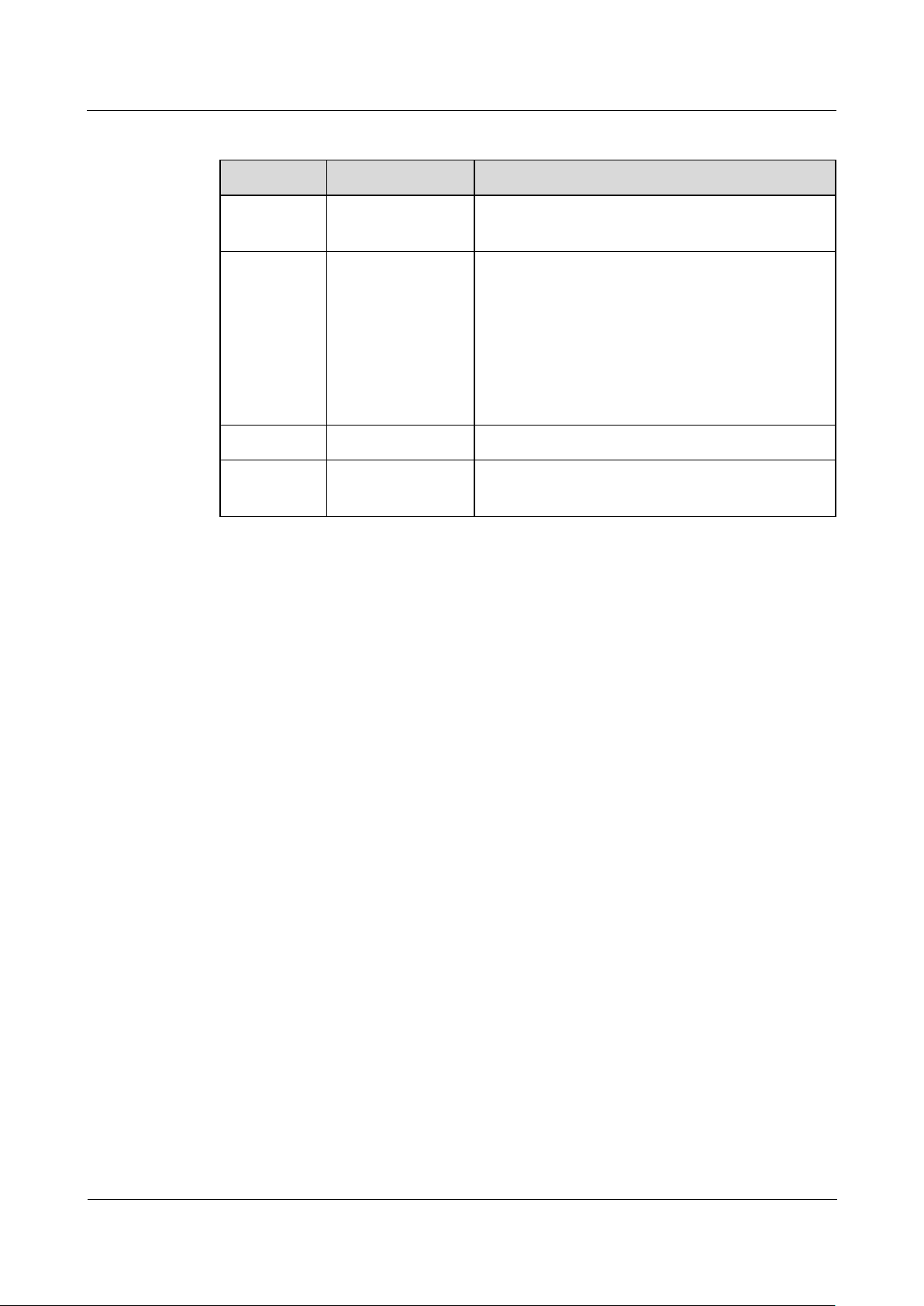

Table 2-1 Model description

Identifier

Description

Value

1

Series name

SUN2000: three-phase grid-tied PV string

inverter

2

Power class

3K: rated power of 3 kW

4K: rated power of 4 kW

5K: rated power of 5 kW

6K: rated power of 6 kW

8K: rated power of 8 kW

10K: rated power of 10 kW

3

Topology

TL: transformerless

4

Product code

M1: product series with an input voltage level

of 1100 V DC

Networking Application

The SUN2000 applies to residential rooftop grid-tied systems and small-sized

ground PV plant grid-tied systems. Typically, a grid-tied system consists of PV

strings, grid-tied inverters, AC switches, and power distribution units.

SUN2000-(3KTL-10KTL)-M1

User Manual

2 Overview

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

9

Figure 2-2 Networking application (dashed boxes indicate optional components)

If the built-in WiFi module of the SUN2000 connects to the app, only device

commissioning can be performed.

In the SUN2000 cascading scenario, the master inverter model can be

SUN2000-(3KTL-10KTL)-M1, and the slave inverter model can be

SUN2000-(3KTL-10KTL)-M1, SUN2000-(5KTL–20KTL)-M0,

SUN2000-50KTL/60KTL/65KTL-M0, SUN2000-29.9KTL/36KTL, or SUN2000-33KTL-A.

Supported Power Grid Types

The SUN2000 supports TN-S, TN-C, TN-C-S, TT, and IT power grids.

SUN2000-(3KTL-10KTL)-M1

User Manual

2 Overview

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

10

Figure 2-3 Power grid types

When the SUN2000 is used in the TT power grid, the N-to-PE voltage must be less than 30

V.

When the SUN2000 is used in the IT power grid, set Isolation to Input ungrounded, with

TF.

SUN2000-(3KTL-10KTL)-M1

User Manual

2 Overview

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

11

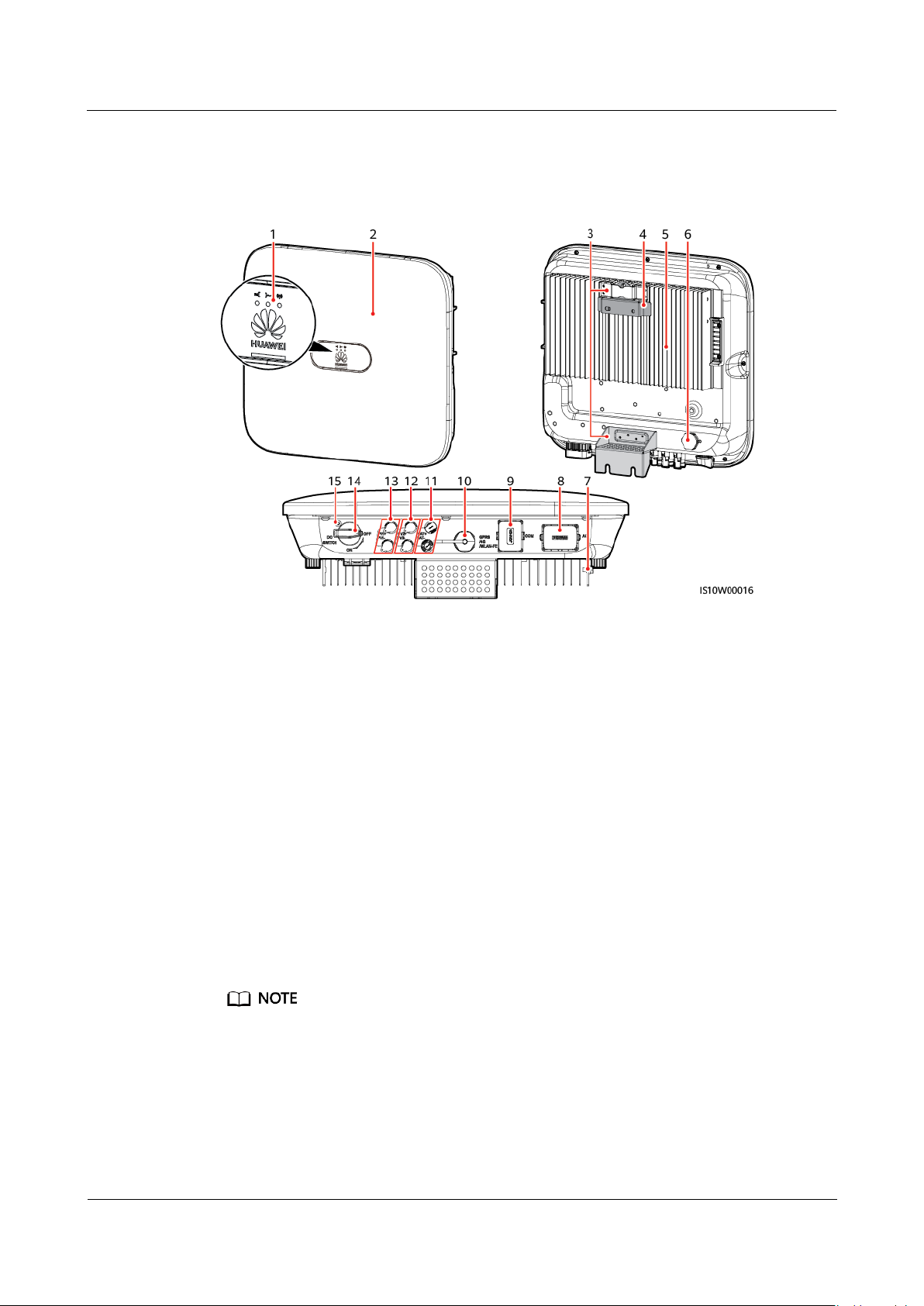

2.2 Appearance

(1) LED indicator

(2) Front panel

(3) Hanging kit

(4) Mounting bracket

(5) Heat sink

(6) Ventilation valve

(7) Ground screw

(8) AC output port (AC)

(9) Communications port (COM)

(10) Smart Dongle port

(GPRS/4G/WLAN-FE)

(11) Battery terminals (BAT+/BAT–)

(12) DC input terminals (PV2+/PV2–)

(13) DC input terminals (PV1+/PV1–)

(14) DC switch (DC SWITCH)

(15) Hole for the DC switch locking screw

Figure 2-4 Appearance

Two M6 screw holes are reserved on the left and right sides of the SUN2000 for installing the

awning.

SUN2000-(3KTL-10KTL)-M1

User Manual

2 Overview

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

12

Category

Status

Description

Running

indicator

LED1

LED2

-

Steady

green

Steady green

The SUN2000 is operating

in grid-tied mode.

Blinking

green at

long

intervals

(on for 1s

and then

off for 1s)

Off

The DC is on and the AC is

off.

Blinking

green at

long

intervals

(on for 1s

and then

off for 1s)

Blinking green at long

intervals (on for 1s and

then off for 1s)

Both the DC and AC are

on, and the SUN2000 is

not supplying power to

the power grid.

Off

Blinking green at long

intervals (on for 1s and

then off for 1s)

The DC is off and the AC

is on.

Off

Off

Both the DC and AC are

off.

Blinking

red at

short

intervals

(on for

0.2s and

then off

for 0.2s)

-

DC environment alarm.

For example, the input

voltage of the PV string is

high, the PV string is

reversely connected, or

the insulation resistance

is low.

-

Blinking red at short

intervals

AC environment alarm.

For example, the power

grid is undervoltage,

overvoltage,

overfrequency, or

underfrequency.

Steady red

Steady red

Fault

Communica

LED3

-

Table 2-2 Indicator description

SUN2000-(3KTL-10KTL)-M1

User Manual

2 Overview

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

13

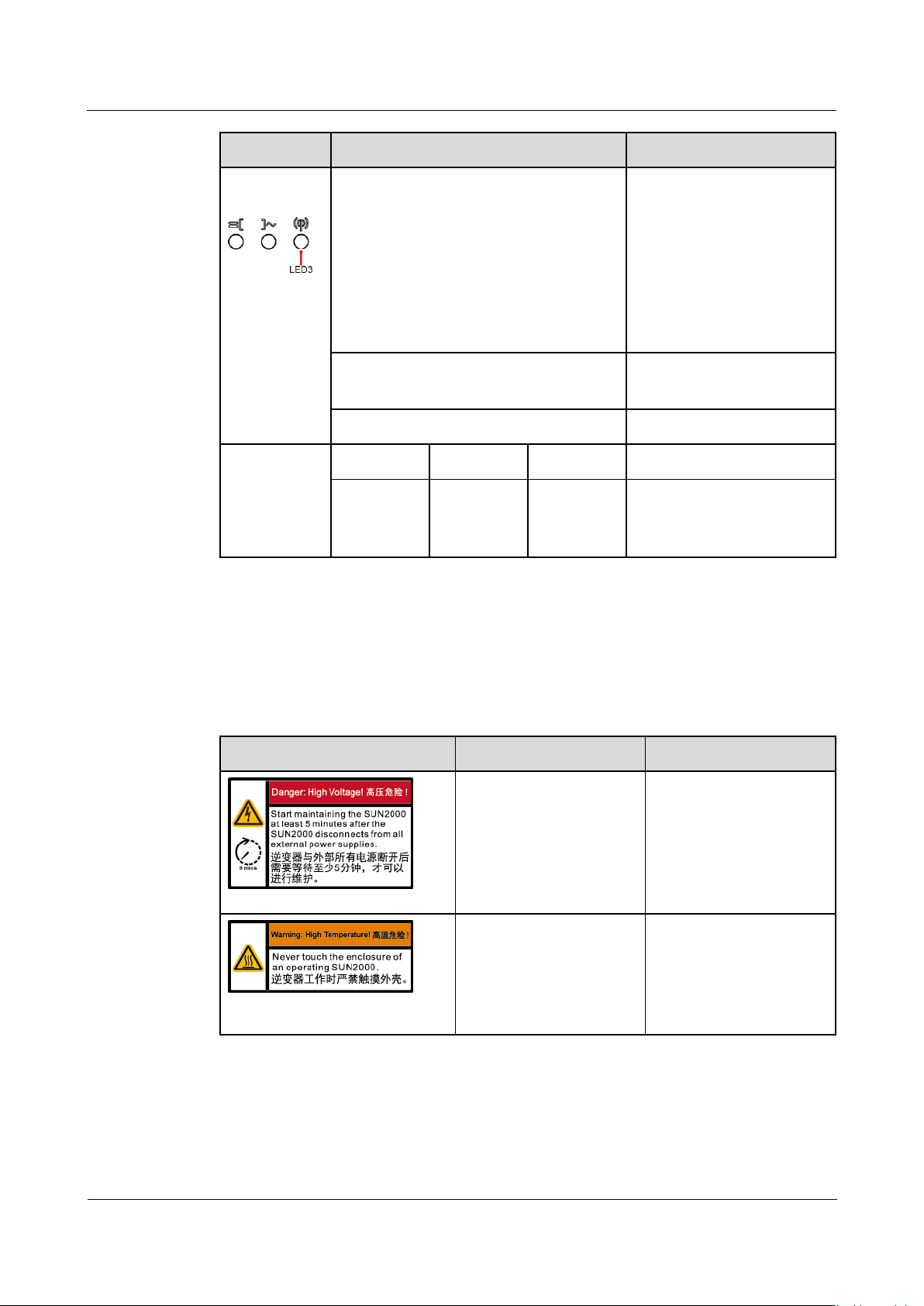

Category

Status

Description

tions

indicator

Blinking green at short intervals (on

for 0.2s and then off for 0.2s)

Communication is in

progress. (When a mobile

phone is connected to the

SUN2000, the indicator

blinks green at long

intervals, indicating that

the phone is connected to

the SUN2000.)

Blinking green at long intervals (on

for 1s and then off for 1s)

Mobile phone access

Off

No communication

Device

replacement

indicator

LED1

LED2

LED3

–

Steady red

Steady red

Steady red

The SUN2000 hardware is

faulty and the SUN2000

needs to be replaced.

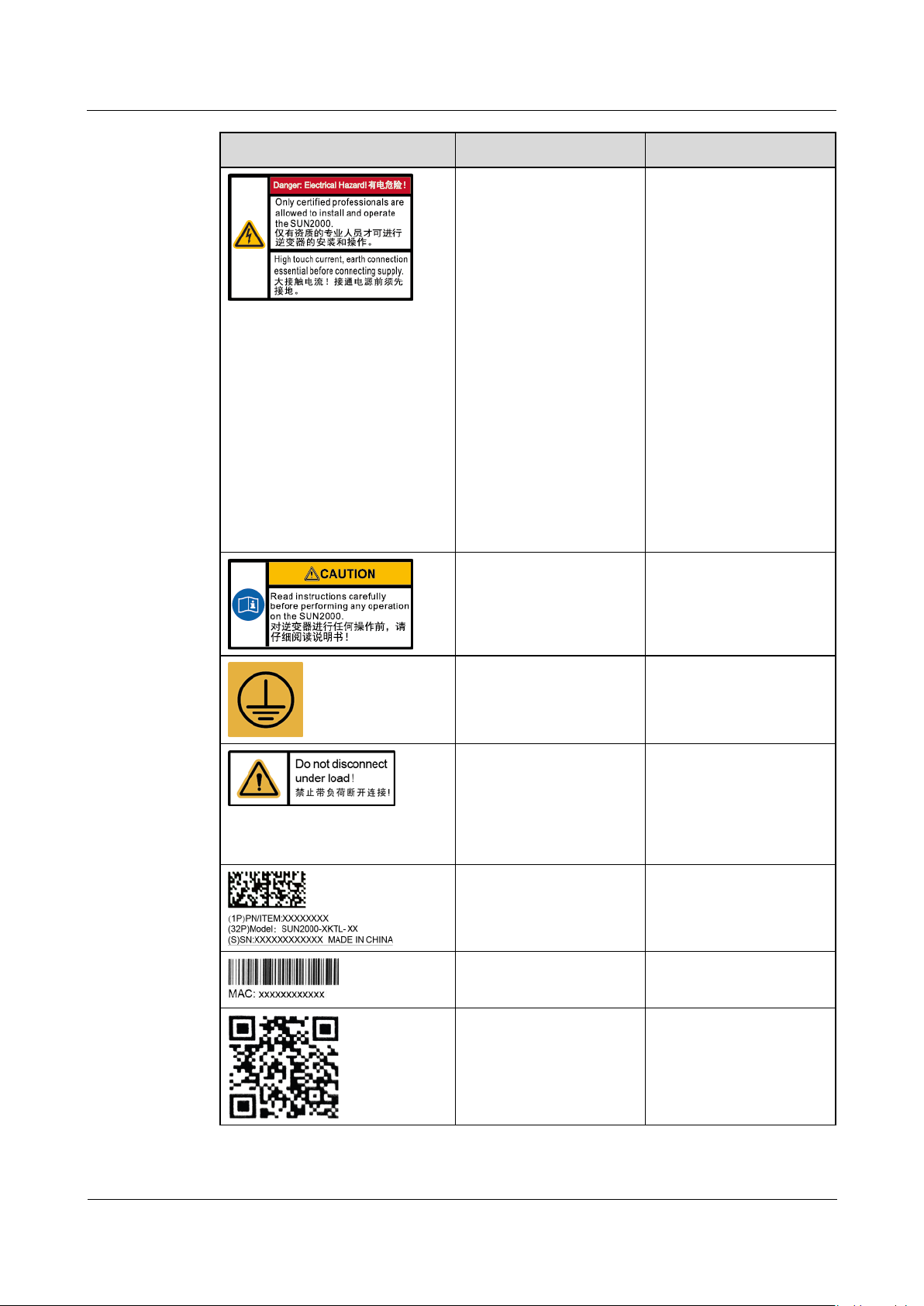

Symbol

Name

Description

Delay discharge

Residual voltage exists

after the SUN2000 is

powered off. It takes 5

minutes for the

SUN2000 to discharge

to the safe voltage.

Burn warning

Do not touch a running

SUN2000 because it

generates high

temperatures on the

shell.

2.3 Label Description

2.3.1 Enclosure Labels

SUN2000-(3KTL-10KTL)-M1

User Manual

2 Overview

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

14

Symbol

Name

Description

Electric shock warning

High voltage exists

after the SUN2000

is powered on. Only

qualified and

trained electrical

technicians are

allowed to perform

operations on the

SUN2000.

High touch current

exists after the

SUN2000 is

powered on. Before

powering on the

SUN2000, ensure

that the SUN2000 is

properly grounded.

Refer to

documentation

Reminds operators to

refer to the documents

delivered with the

SUN2000.

Grounding label

Indicates the position

for connecting the PE

cable.

Operation warning

Do not remove the DC

input connector or AC

output connector when

the SUN2000 is

running.

SUN2000 serial

number

Indicates the serial

number.

SUN2000 MAC address

Indicates the MAC

address.

SUN2000 WiFi login

QR code

Scan the QR code to

connect to the Huawei

SUN2000 WiFi

network.

SUN2000-(3KTL-10KTL)-M1

User Manual

2 Overview

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

15

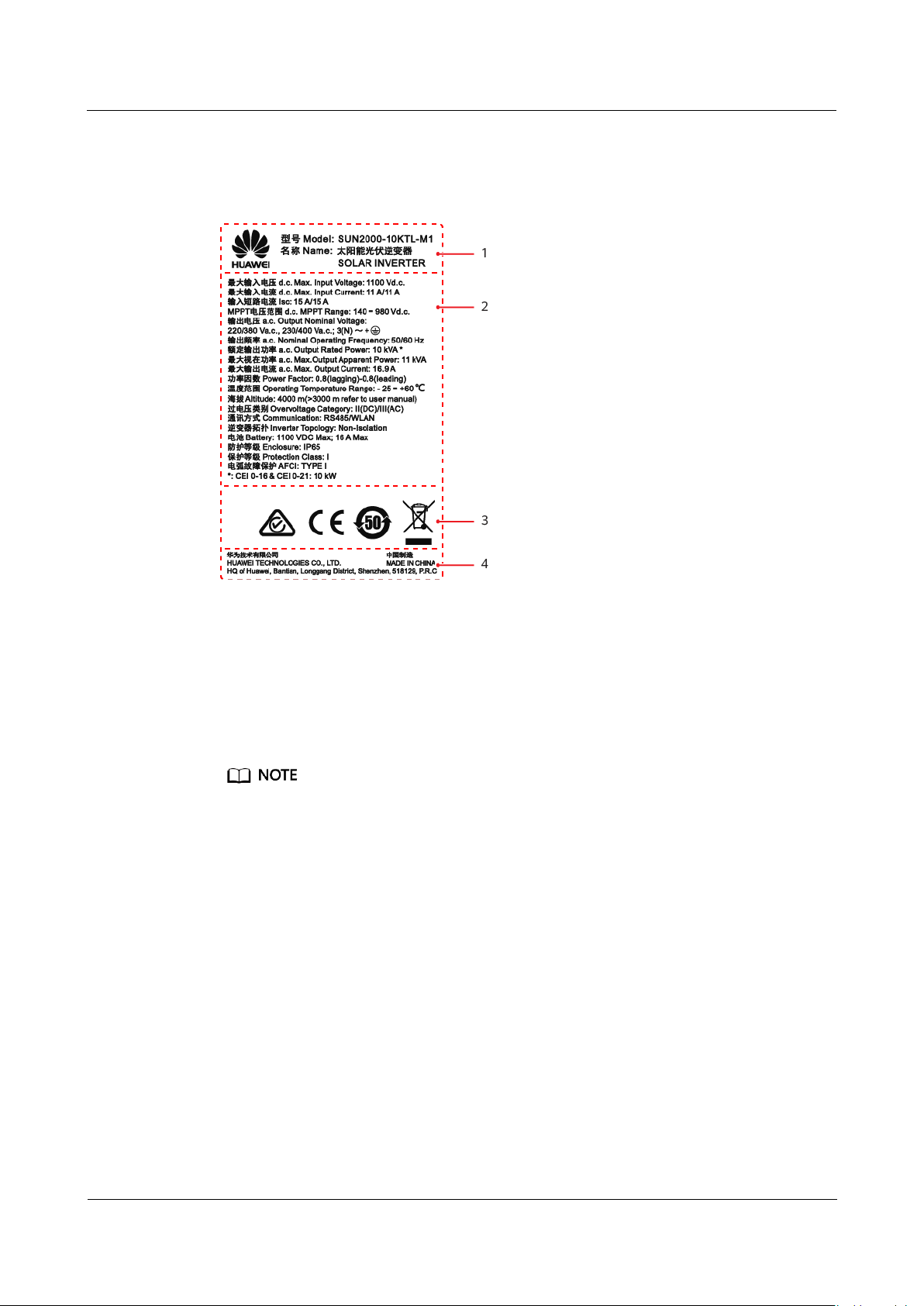

2.3.2 Product Nameplate

(1) Trademark and product model

(2) Key technical parameters

(3) Certification marks

(4) Company name and country of

origin

Figure 2-5 Nameplate (using SUN2000-10KTL-M1 as an example)

The nameplate figure is for reference only.

2.4 Working Principles

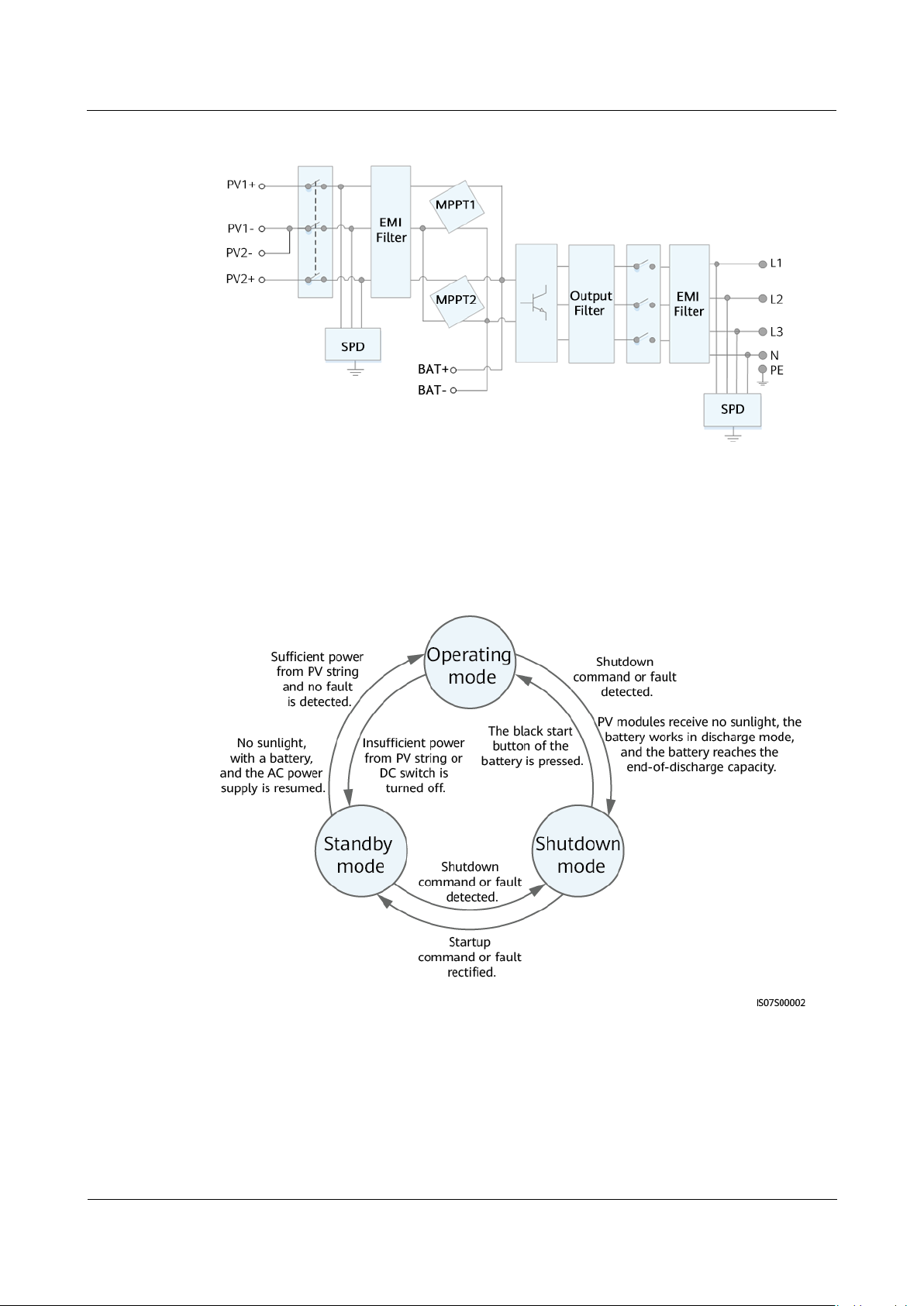

2.4.1 Circuit Diagram

Two PV strings connect to the SUN2000, and their maximum power points are

tracked by two maximum power point tracking (MPPT) circuits. The SUN2000

converts DC power into three-phase AC power through an inverter circuit. Surge

protection is supported on both the DC and AC sides.

SUN2000-(3KTL-10KTL)-M1

User Manual

2 Overview

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

16

Figure 2-6 SUN2000 conceptual diagram

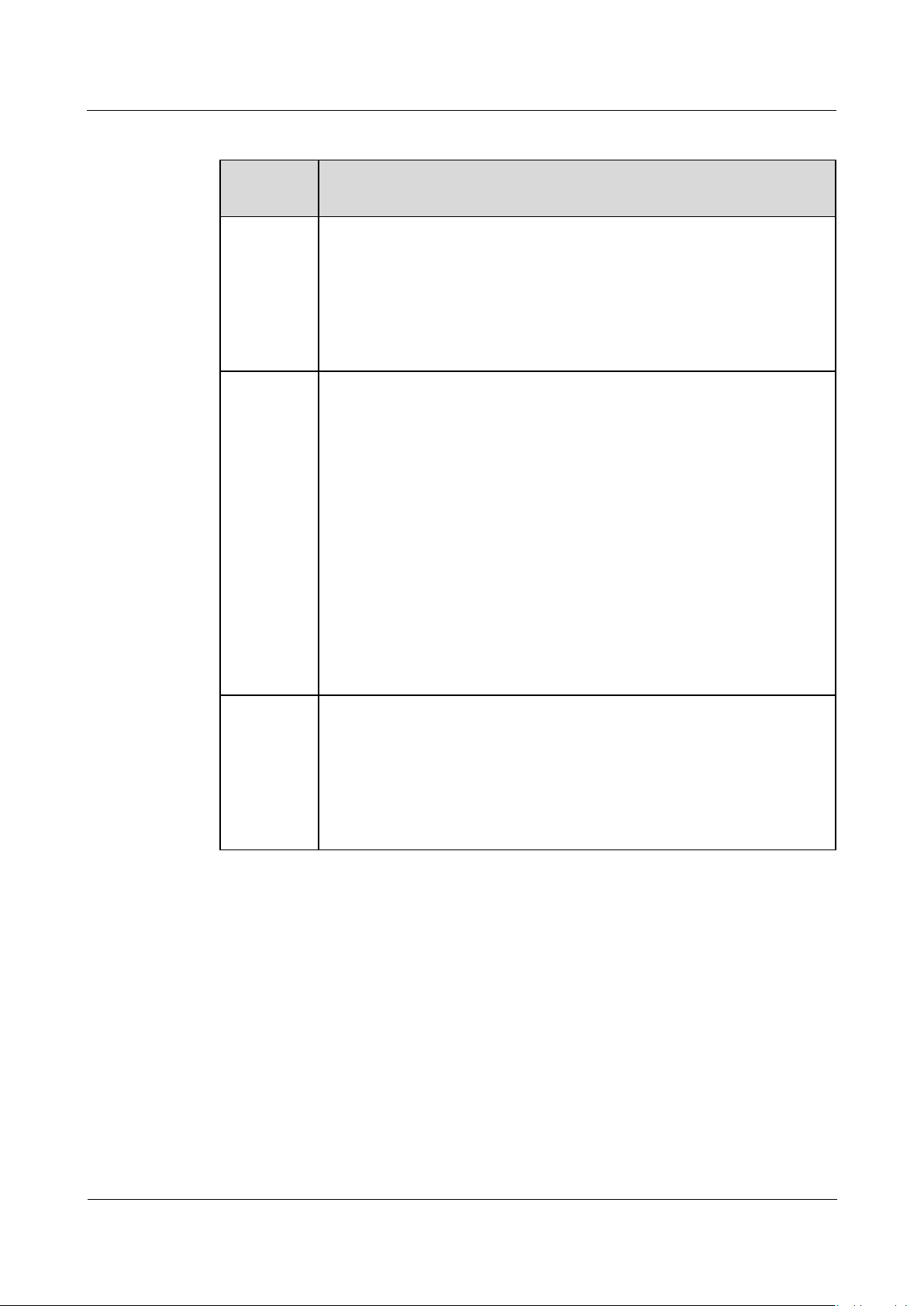

2.4.2 Working Modes

The SUN2000 can work in Standby, Operating, or Shutdown mode.

Figure 2-7 Working modes

SUN2000-(3KTL-10KTL)-M1

User Manual

2 Overview

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

17

Table 2-3 Working mode description

Working

Mode

Description

Standby

The SUN2000 enters Standby mode when the external environment

does not meet the operating requirements. In Standby mode:

The SUN2000 continuously performs status check and enters the

Operating mode once the operating requirements are met.

The SUN2000 enters Shutdown mode after detecting a shutdown

command or a fault after startup.

Operating

In Operating mode:

The SUN2000 converts DC power from PV strings into AC power

and feeds the power to the power grid.

The SUN2000 tracks the maximum power point to maximize the

PV string output.

If the SUN2000 detects a fault or a shutdown command, it enters

the Shutdown mode.

The SUN2000 enters Standby mode after detecting that the PV

string output power is not suitable for connecting to the power

grid for generating power.

If the PV modules receive no sunlight, the battery works in

discharge mode, and the battery reaches the end-of-discharge

capacity, the SUN2000 enters Shutdown mode.

Shutdown

In Standby or Operating mode, the SUN2000 enters Shutdown

mode after detecting a fault or shutdown command.

In Shutdown mode, the SUN2000 enters Standby mode after

detecting a startup command or that the fault is rectified.

In Shutdown mode, if the black start button of the battery is

pressed, the SUN2000 enters Operating mode.

SUN2000-(3KTL-10KTL)-M1

User Manual

3 Storage

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

18

3 Storage

The following requirements should be met if the SUN2000 is not put into use

directly:

Do not unpack the SUN2000.

Keep the storage temperature at –40°C to +70°C and the humidity at 5%–95%

RH.

The SUN2000 should be stored in a clean and dry place and be protected from

dust and water vapor corrosion.

A maximum of eight SUN2000s can be stacked. To avoid personal injury or

device damage, stack SUN2000s with caution to prevent them from falling

over.

Periodic inspections are required during the storage. Replace the packing

materials if necessary.

If the SUN2000 has been long-term stored, inspections and tests should be

conducted by qualified personnel before it is put into use.

SUN2000-(3KTL-10KTL)-M1

User Manual

4 Installation

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

19

4.1 Checking Before Installation

Outer Packing Materials

Before unpacking the inverter, check the outer packing materials for damage, such

as holes and cracks, and check the inverter model. If any damage is found or the

inverter model is not what you requested, do not unpack the package and contact

your supplier as soon as possible.

4 Installation

You are advised to remove the packing materials within 24 hours before installing the

inverter.

Package Contents

After unpacking the inverter, check that the contents are intact and complete. If any

damage is found or any component is missing, contact your supplier.

For details about the number of contents, see the

Packing List

in the packing case.

SUN2000-(3KTL-10KTL)-M1

User Manual

4 Installation

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

20

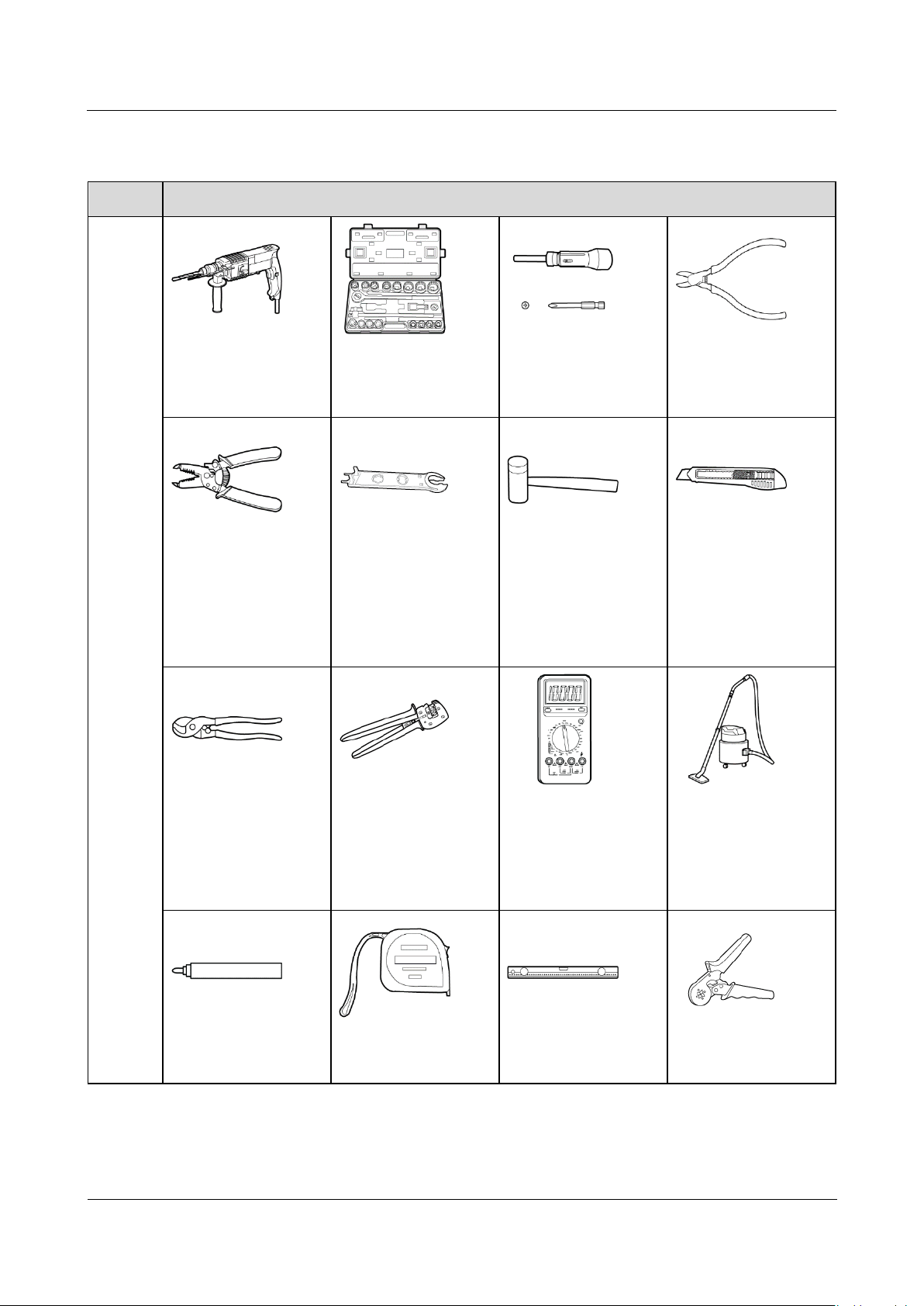

Type

Tool

Installa

tion

Tools

Hammer drill

Drill bit: Φ8 mm and

Φ6 mm

Socket wrench set

Torque screwdriver

Phillips head: M3

Diagonal pliers

Wire stripper

Removal wrench

Model: PV-MS-HZ

Open-end Wrench;

manufacturer:

Staubli

Rubber mallet

Utility knife

Cable cutter

Crimping tool

Model:

PV-CZM-22100;

manufacturer:

Staubli

Multimeter

DC voltage

measurement range

≥ 1100 V DC

Vacuum cleaner

Marker

Measuring tape

Bubble or digital

level

Cord end terminal

crimper

4.2 Tools

SUN2000-(3KTL-10KTL)-M1

User Manual

4 Installation

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

21

Type

Tool

Heat shrink tubing

Heat gun

Cable tie

Hydraulic pliers

PPE

Safety gloves

Safety goggles

Anti-dust respirator

Safety shoes

4.3 Determining the Installation Position

4.3.1 Environment Requirements

Basic Requirements

The SUN2000 is protected to IP65 and can be installed indoors or outdoors.

Do not install the SUN2000 in a place where personnel are easy to come into

contact with its enclosure and heat sinks, because these parts are extremely hot

during operation.

Do not install the SUN2000 in areas with flammable or explosive materials.

Do not install the SUN2000 at a place within children's reach.

Do not install the SUN2000 outdoors in salt areas because it will be corroded

there and may cause fire. A salt area refers to the region within 500 meters

from the coast or prone to sea breeze. The regions prone to sea breeze vary

depending on weather conditions (such as typhoons and monsoons) or terrains

(such as dams and hills).

The SUN2000 must be installed in a well-ventilated environment to ensure

good heat dissipation.

Recommended: Install the SUN2000 in a sheltered place or a place with an

awning.

Mounting Structure Requirements

The mounting structure where the SUN2000 is installed must be fireproof.

Do not install the SUN2000 on flammable building materials.

SUN2000-(3KTL-10KTL)-M1

User Manual

4 Installation

Issue 02 (2020-11-20)

Copyright © Huawei Technologies Co.,

Ltd.

22

The SUN2000 is heavy. Ensure that the installation surface is solid enough to

bear the weight load.

In residential areas, do not install the SUN2000 on drywalls or walls made of

similar materials which have a weak sound insulation performance because the

noise generated by the SUN2000 is noticeable.

4.3.2 Space Requirements

Installation Angle Requirements

The SUN2000 can be wall-mounted or pole-mounted. The installation angle

requirements are as follows:

Install the SUN2000 vertically or at a maximum back tilt of 15 degrees to

facilitate heat dissipation.

Do not install the SUN2000 at forward tilted, excessive back tilted, side tilted,

horizontal, or upside down positions.

Figure 4-1 Installation tilts

Installation Space Requirements

Reserve enough space around the SUN2000 to ensure sufficient space for

installation and heat dissipation.

Loading...

Loading...