SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual

Issue 13

Date 2023-04-28

HUAWEI TECHNOLOGIES CO., LTD.

Copyright © Huawei Technologies Co., Ltd. 2023. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specied in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees

or representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every eort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: https://e.huawei.com

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. i

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual About This Document

About This Document

Overview

This document describes the SUN2000-20KTL-M3, SUN2000-29.9KTL-M3,

SUN2000-30KTL-M3, SUN2000-36KTL-M3, and SUN2000-40KTL-M3 (also referred

to as SUN2000) in terms of their installation, electrical connections,

commissioning, maintenance, and troubleshooting. Before installing and operating

the SUN2000, ensure that you are familiar with the features, functions, and safety

precautions provided in this document.

Intended Audience

This document is applicable to:

● Installers

● Users

Symbol Conventions

The symbols that may be found in this document are

Symbol

dened as follows.

Description

Indicates a hazard with a high level of risk which, if not

avoided, will result in death or serious injury.

Indicates a hazard with a medium level of risk which, if

not avoided, could result in death or serious injury.

Indicates a hazard with a low level of risk which, if not

avoided, could result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in equipment damage, data loss,

performance deterioration, or unanticipated results.

NOTICE is used to address practices not related to

personal injury.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. ii

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual About This Document

Symbol Description

Supplements the important information in the main text.

NOTE is used to address information not related to

personal injury, equipment damage, and environment

deterioration.

Change History

Changes between document issues are cumulative. The latest document issue

contains all changes made in earlier issues.

Issue 13 (2023-04-28)

Updated A Grid Codes.

Added K Locating Insulation Resistance Faults.

Updated L Contact Information.

Issue 12 (2023-02-28)

Updated 2.1 Product Introduction.

Updated 5.2 Preparing Cables.

Updated 5.6 (Optional) Installing the Smart Dongle.

Updated 10 Technical

Issue 11 (2023-01-10)

Updated 1 Safety Information.

Updated 2.3 Label Description.

Updated 4.2 Tool Preparation.

Updated 7 Man-Machine Interaction.

Updated 8.3 Troubleshooting.

Specications.

Updated 10 Technical

Added L Contact Information.

Specications.

Issue 10 (2022-09-26)

Updated 5.2 Preparing Cables.

Updated 5.4 Connecting the AC Output Power Cable.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. iii

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual About This Document

Issue 09 (2022-06-30)

Updated 5.2 Preparing Cables.

Updated 5.5 Installing the DC Input Power Cable.

Updated 5.7.1 Communication Modes.

Updated 7 Man-Machine Interaction.

Updated 7.1.3 SmartLogger Networking Scenario.

Updated 8.3 Troubleshooting.

Updated 10 Technical

Added I PV String Access Detection.

Issue 08 (2022-04-14)

Updated 5.2 Preparing Cables.

Updated 5.7.1 Communication Modes.

Updated D Rapid Shutdown.

Issue 07 (2022-01-30)

Updated 4.3 Selecting an Installation Position.

Updated 8.2 Routine Maintenance.

Issue 06 (2022-01-04)

Updated 5.2 Preparing Cables.

Updated 7.1.2 Creating a PV Plant and a User.

Updated 7.3.1 Grid-tied Point Control.

Specications.

Updated 7.3.2 Apparent Power Control on the Inverter Output Side.

Updated 10 Technical

Updated A Grid Codes.

Specications.

Issue 05 (2021-11-25)

Updated 5.4 Connecting the AC Output Power Cable.

Issue 04 (2021-07-25)

Updated 5.2 Preparing Cables.

Updated 10 Technical

Specications.

Issue 03 (2021-04-15)

Updated 2.1 Product Introduction.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. iv

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual About This Document

Updated 5.2 Preparing Cables.

Updated 5.5 Installing the DC Input Power Cable.

Updated 10 Technical Specications.

Issue 02 (2020-11-20)

Updated 2.3 Label Description.

Updated 4.3 Selecting an Installation Position.

Updated 5.2 Preparing Cables.

Updated 5.7.1 Communication Modes.

Updated 10 Technical

Issue 01 (2020-10-15)

This issue is the

Specications.

rst ocial release.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. v

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual Contents

Contents

About This Document................................................................................................................ ii

1 Safety Information.................................................................................................................. 1

1.1 Personal Safety.........................................................................................................................................................................2

1.2 Electrical Safety........................................................................................................................................................................4

1.3 Environment Requirements................................................................................................................................................. 6

1.4 Mechanical Safety................................................................................................................................................................... 8

2 Overview................................................................................................................................. 13

2.1 Product Introduction............................................................................................................................................................ 13

2.2 Appearance............................................................................................................................................................................. 15

2.3 Label Description.................................................................................................................................................................. 16

2.4 Working Principles................................................................................................................................................................ 18

2.4.1 Circuit Diagram.................................................................................................................................................................. 18

2.4.2 Working Modes.................................................................................................................................................................. 18

3 SUN2000 Storage...................................................................................................................20

4 Installation..............................................................................................................................21

4.1 Checking Before Installation............................................................................................................................................. 21

4.2 Tool Preparation.................................................................................................................................................................... 22

4.3 Selecting an Installation Position.................................................................................................................................... 23

4.4 Moving the SUN2000.......................................................................................................................................................... 27

4.5 Installing the Mounting Bracket...................................................................................................................................... 28

4.5.1 Support-mounted Installation.......................................................................................................................................29

4.5.2 Wall-mounted Installation............................................................................................................................................. 30

4.6 Installing a SUN2000........................................................................................................................................................... 31

5 Electrical Connections.......................................................................................................... 33

5.1 Precautions.............................................................................................................................................................................. 33

5.2 Preparing Cables................................................................................................................................................................... 34

5.3 Connecting the PE Cable.................................................................................................................................................... 37

5.4 Connecting the AC Output Power Cable...................................................................................................................... 39

5.5 Installing the DC Input Power Cable.............................................................................................................................. 44

5.5.1 Cable Connection Description....................................................................................................................................... 44

5.5.2 Connecting Cables to Amphenol Helios H4 Connectors......................................................................................46

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. vi

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual Contents

5.5.3 Connecting Cables to Staubli MC4 Connectors...................................................................................................... 47

5.6 (Optional) Installing the Smart Dongle........................................................................................................................ 49

5.7 Connecting the Signal Cable............................................................................................................................................. 51

5.7.1 Communication Modes................................................................................................................................................... 54

5.7.2 (Optional) Connecting the RS485 Communications Cable to the SUN2000............................................... 56

5.7.3 (Optional) Connecting the RS485 Communications Cable to the Power Meter.........................................57

5.7.4 (Optional) Connecting the Power Grid Scheduling Signal Cable..................................................................... 58

5.7.5 (Optional) Connecting the Rapid Shutdown Signal Cable................................................................................. 59

6 Commissioning.......................................................................................................................60

6.1 Checking Before Power-On................................................................................................................................................60

6.2 System Power-On................................................................................................................................................................. 61

7 Man-Machine Interaction....................................................................................................63

7.1 Scenario in Which SUN2000s Are Connected to the FusionSolar Smart PV Management System.........64

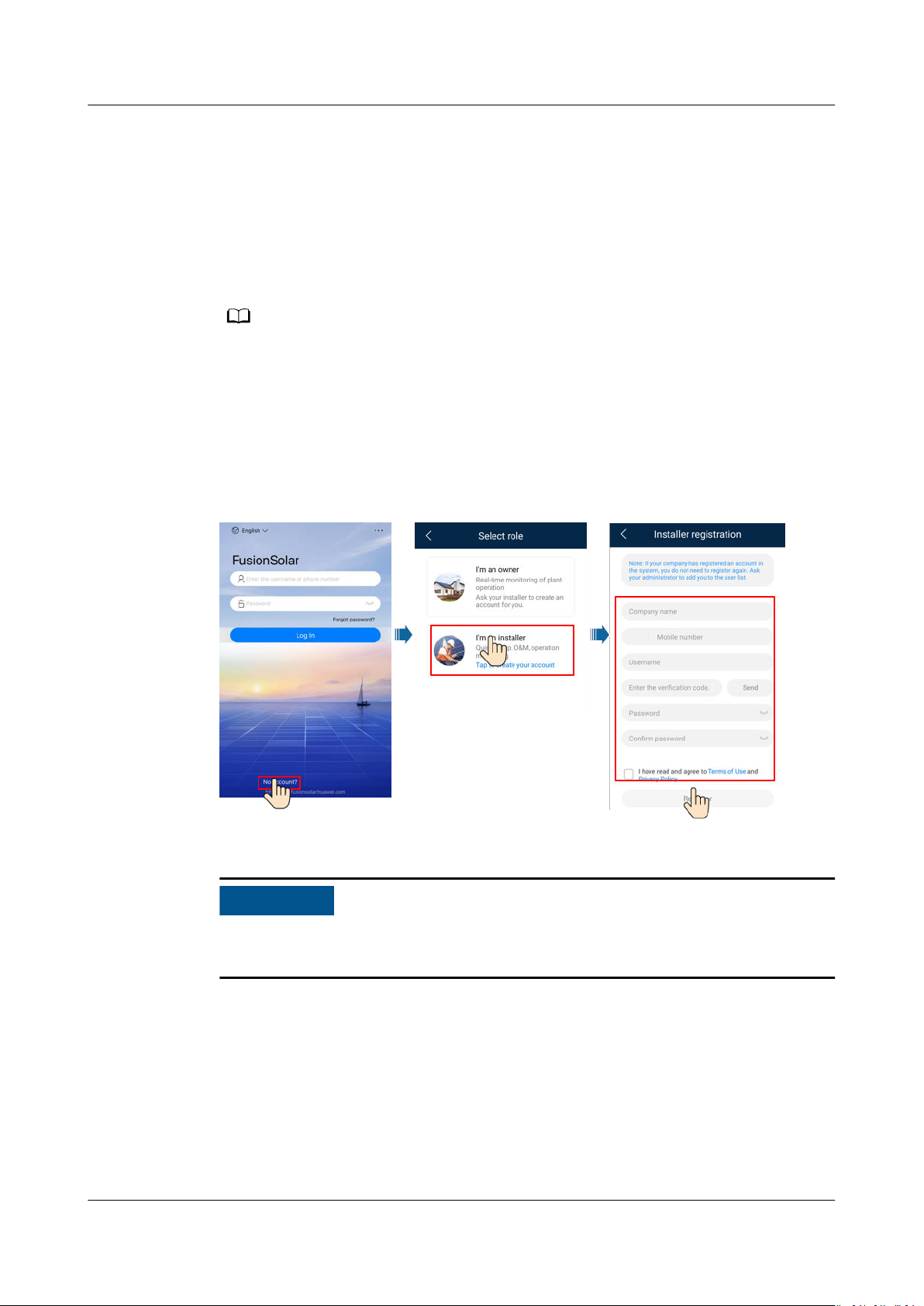

7.1.1 (Optional) Registering an Installer Account............................................................................................................ 64

7.1.2 Creating a PV Plant and a User.................................................................................................................................... 65

7.1.3 SmartLogger Networking Scenario............................................................................................................................. 65

7.2 Scenario in Which SUN2000s Are Connected to Other Management Systems..............................................66

7.3 Energy Control....................................................................................................................................................................... 66

7.3.1 Grid-tied Point Control.................................................................................................................................................... 66

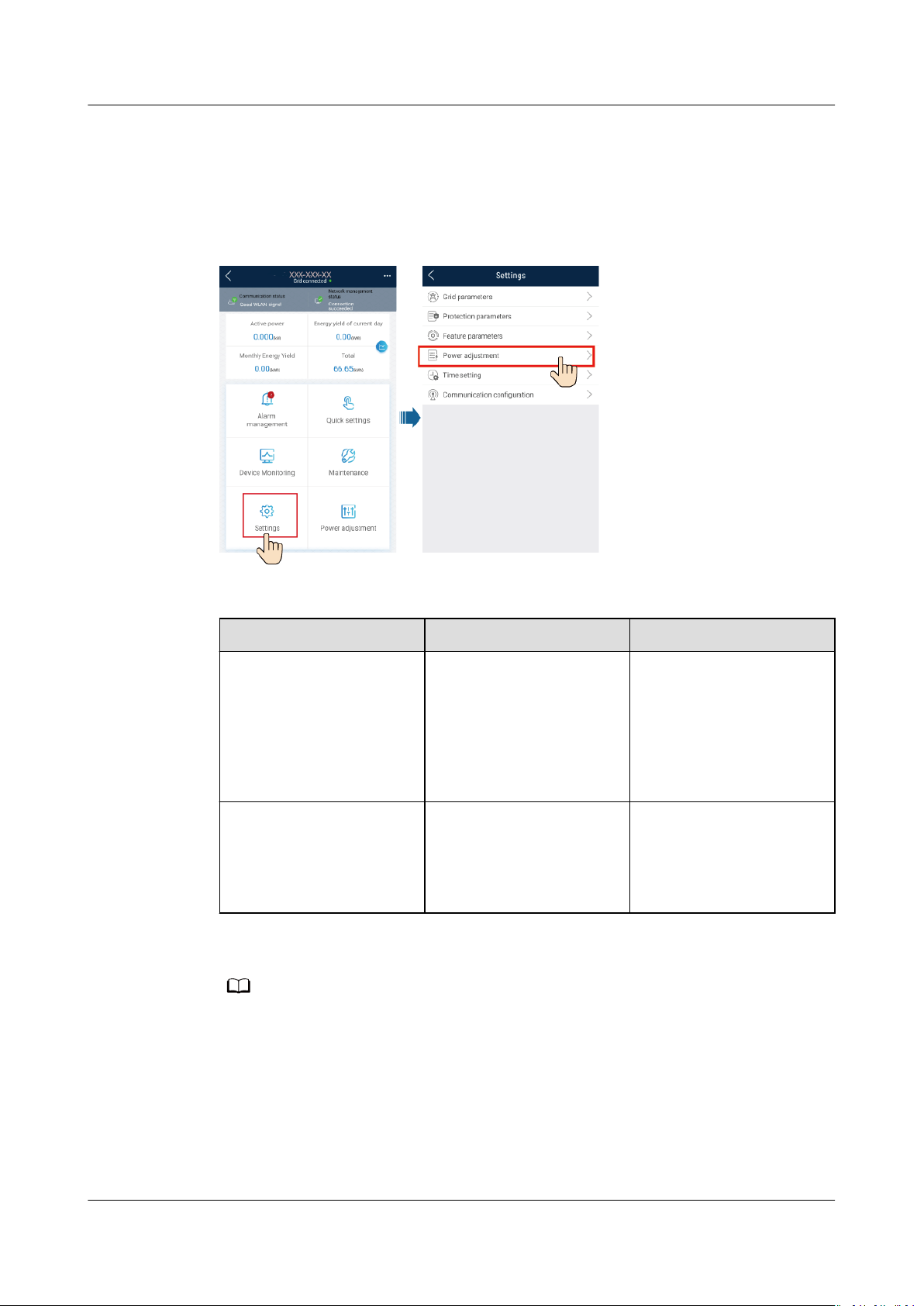

7.3.2 Apparent Power Control on the Inverter Output Side..........................................................................................71

8 Maintenance...........................................................................................................................72

8.1 System Power-O.................................................................................................................................................................72

8.2 Routine Maintenance.......................................................................................................................................................... 73

8.3 Troubleshooting..................................................................................................................................................................... 74

9 Handling the Inverter...........................................................................................................88

9.1 Removing the SUN2000..................................................................................................................................................... 88

9.2 Packing the SUN2000..........................................................................................................................................................88

9.3 Disposing of the SUN2000................................................................................................................................................ 88

10 Technical

Specications.....................................................................................................89

A Grid Codes...............................................................................................................................99

B Device Commissioning....................................................................................................... 112

C Built-in PID Recovery......................................................................................................... 115

D Rapid Shutdown................................................................................................................. 116

E NS Protection....................................................................................................................... 117

F Resetting Password.............................................................................................................118

G Setting Dry Contact Scheduling Parameters................................................................119

H AFCI........................................................................................................................................120

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. vii

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual Contents

I PV String Access Detection................................................................................................ 122

J Smart I-V Curve Diagnosis................................................................................................. 125

K Locating Insulation Resistance Faults........................................................................... 126

L Contact Information........................................................................................................... 129

M Acronyms and Abbreviations.......................................................................................... 131

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. viii

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 1 Safety Information

1 Safety Information

Statement

Before transporting, storing, installing, operating, using, and/or maintaining

the equipment, read this document, strictly follow the instructions provided

herein, and follow all the safety instructions on the equipment and in this

document. In this document, "equipment" refers to the products, software,

components, spare parts, and/or services related to this document; "the Company"

refers to the manufacturer (producer), seller, and/or service provider of the

equipment; "you" refers to the entity that transports, stores, installs, operates,

uses, and/or maintains the equipment.

The Danger, Warning, Caution, and Notice statements described in this

document do not cover all the safety precautions. You also need to comply with

relevant international, national, or regional standards and industry practices. The

Company shall not be liable for any consequences that may arise due to

violations of safety requirements or safety standards concerning the design,

production, and usage of the equipment.

The equipment should be used in an environment that meets the design

specications. Otherwise, the equipment may be faulty, malfunctioning, or

damaged, which is not covered under the warranty. The Company shall not be

liable for any property loss, personal injury, or even death caused thereby.

Comply with applicable laws, regulations, standards, and specications during

transportation, storage, installation, operation, use, and maintenance.

Do not perform reverse engineering, decompilation, disassembly, adaptation,

implantation, or other derivative operations on the equipment software. Do not

study the internal implementation logic of the equipment, obtain the source code

of the equipment software, violate intellectual property rights, or disclose any of

the performance test results of the equipment software.

The Company shall not be liable for any of the following circumstances or

their consequences:

● The equipment is damaged due to force majeure such as earthquakes,

volcanic eruptions, debris ows, lightning strikes, res, wars, armed conicts,

typhoons, hurricanes, tornadoes, and other extreme weather conditions.

oods,

● The equipment is operated beyond the conditions

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 1

specied in this document.

D ANGER

D ANGER

D ANGER

D ANGER

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 1 Safety Information

● The equipment is installed or used in environments that do not comply with

international, national, or regional standards.

● The equipment is installed or used by unqualied personnel.

● You fail to follow the operation instructions and safety precautions on the

product and in the document.

● You remove or modify the product or modify the software code without

authorization.

● You or a third party authorized by you cause the equipment damage during

transportation.

● The equipment is damaged due to storage conditions that do not meet the

requirements

● You fail to prepare materials and tools that comply with local laws,

regulations, and related standards.

● The equipment is damaged due to your or a third party's negligence,

intentional breach, gross negligence, or improper operations, or other reasons

not related to the Company.

specied in the product document.

1.1 Personal Safety

Ensure that power is o during installation. Do not install or remove a cable with

power on. Transient contact between the core of the cable and the conductor will

generate electric arcs or sparks, which may cause a re or personal injury.

Non-standard and improper operations on the energized equipment may cause

re, electric shocks, or explosion, resulting in property damage, personal injury, or

even death.

Before operations, remove conductive objects such as watches, bracelets, bangles,

rings, and necklaces to prevent electric shocks.

During operations, use dedicated insulated tools to prevent electric shocks or short

circuits. The dielectric withstanding voltage level must comply with local laws,

regulations, standards, and

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 2

specications.

WARNING

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 1 Safety Information

During operations, wear personal protective equipment such as protective

clothing, insulated shoes, goggles, safety helmets, and insulated gloves.

Figure 1-1 Personal protective equipment

General Requirements

● Do not stop protective devices. Pay attention to the warnings, cautions, and

related precautionary measures in this document and on the equipment.

● If there is a likelihood of personal injury or equipment damage during

operations, immediately stop, report the case to the supervisor, and take

feasible protective measures.

● Do not power on the equipment before it is installed or

professionals.

● Do not touch the power supply equipment directly or with conductors such as

damp objects. Before touching any conductor surface or terminal, measure

the voltage at the contact point to ensure that there is no risk of electric

shock.

● Do not touch operating equipment because the enclosure is hot.

● Do not touch a running fan with your hands, components, screws, tools, or

boards. Otherwise, personal injury or equipment damage may occur.

● In the case of a

and activate the re alarm or call emergency services. Do not enter the

aected building or equipment area under any circumstances.

Personnel Requirements

conrmed by

re, immediately leave the building or the equipment area

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 3

● Only professionals and trained personnel are allowed to operate the

equipment.

– Professionals: personnel who are familiar with the working principles and

structure of the equipment, trained or experienced in equipment

operations and are clear of the sources and degree of various potential

hazards in equipment installation, operation, maintenance

D ANGER

D ANGER

D ANGER

WARNING

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 1 Safety Information

– Trained personnel: personnel who are trained in technology and safety,

have required experience, are aware of possible hazards on themselves in

certain operations, and are able to take protective measures to minimize

the hazards on themselves and other people

● Personnel who plan to install or maintain the equipment must receive

adequate training, be able to correctly perform all operations, and understand

all necessary safety precautions and local relevant standards.

● Only

● Only

● Personnel who will perform special tasks such as electrical operations,

● Only authorized professionals are allowed to replace the equipment or

● Only personnel who need to work on the equipment are allowed to access

qualied professionals or trained personnel are allowed to install,

operate, and maintain the equipment.

qualied professionals are allowed to remove safety facilities and inspect

the equipment.

working at heights, and operations of special equipment must possess the

required local

components (including software).

the equipment.

1.2 Electrical Safety

Before connecting cables, ensure that the equipment is intact. Otherwise, electric

shocks or re may occur.

qualications.

Non-standard and improper operations may result in re or electric shocks.

Prevent foreign matter from entering the equipment during operations. Otherwise,

equipment damage, load power derating, power failure, or personal injury may

occur.

For the equipment that needs to be grounded, install the ground cable rst when

installing the equipment and remove the ground cable last when removing the

equipment.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 4

CA UTION

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 1 Safety Information

Do not route cables near the air intake or exhaust vents of the equipment.

General Requirements

● Follow the procedures described in the document for installation, operation,

and maintenance. Do not reconstruct or alter the equipment, add

components, or change the installation sequence without permission.

● Obtain approval from the national or local electric utility company before

connecting the equipment to the grid.

● Observe the power plant safety regulations, such as the operation and work

ticket mechanisms.

● Install temporary fences or warning ropes and hang "No Entry" signs around

the operation area to keep unauthorized personnel away from the area.

● Before installing or removing power cables, turn

equipment and its upstream and downstream switches.

● Before performing operations on the equipment, check that all tools meet the

requirements and record the tools. After the operations are complete, collect

all of the tools to prevent them from being left inside the equipment.

● Before installing power cables, check that cable labels are correct and cable

terminals are insulated.

● When installing the equipment, use a torque tool of a proper measurement

range to tighten the screws. When using a wrench to tighten the screws,

ensure that the wrench does not tilt and the torque error does not exceed

10% of the

specied value.

● Ensure that bolts are tightened with a torque tool and marked in red and blue

after double-check. Installation personnel mark tightened bolts in blue.

Quality inspection personnel

conrm that the bolts are tightened and then

mark them in red. (The marks should cross the edges of the bolts.)

o the switches of the

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 5

● If the equipment has multiple inputs, disconnect all the inputs before

operating the equipment.

● Before maintaining a downstream electrical or power distribution device, turn

o the output switch on the power supply equipment.

● During equipment maintenance, attach "Do not switch on" labels near the

upstream and downstream switches or circuit breakers as well as warning

signs to prevent accidental connection. The equipment can be powered on

only after troubleshooting is complete.

● Do not open equipment panels.

● Check equipment connections periodically, ensuring that all screws are

securely tightened.

● Only

qualied professionals can replace a damaged cable.

● Do not scrawl, damage, or block any labels or nameplates on the equipment.

Promptly replace labels that have worn out.

D ANGER

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 1 Safety Information

● Do not use solvents such as water, alcohol, or oil to clean electrical

components inside or outside of the equipment.

Grounding

● Ensure that the grounding impedance of the equipment complies with local

electrical standards.

● Ensure that the equipment is connected permanently to the protective

ground. Before operating the equipment, check its electrical connection to

ensure that it is reliably grounded.

● Do not work on the equipment in the absence of a properly installed ground

conductor.

● Do not damage the ground conductor.

Cabling Requirements

● When selecting, installing, and routing cables, follow local safety regulations

and rules.

● When routing power cables, ensure that there is no coiling or twisting. Do not

join or weld power cables. If necessary, use a longer cable.

● Ensure that all cables are properly connected and insulated, and meet

specications.

● Ensure that the slots and holes for routing cables are free from sharp edges,

and that the positions where cables are routed through pipes or cable holes

are equipped with cushion materials to prevent the cables from being

damaged by sharp edges or burrs.

● Ensure that cables of the same type are bound together neatly and straight

and that the cable sheath is intact. When routing cables of

ensure that they are away from each other without entanglement and

overlapping.

● Secure buried cables using cable supports and cable clips. Ensure that the

cables in the

cable deformation or damage during

● If the external conditions (such as the cable layout or ambient temperature)

change, verify the cable usage in accordance with the IEC-60364-5-52 or local

laws and regulations. For example, check that the current-carrying capacity

meets requirements.

● When routing cables, reserve at least 30 mm clearance between the cables

and heat-generating components or areas. This prevents deterioration or

damage to the cable insulation layer.

backll area are in close contact with the ground to prevent

backlling.

dierent types,

1.3 Environment Requirements

Do not expose the equipment to ammable or explosive gas or smoke. Do not

perform any operation on the equipment in such environments.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 6

D ANGER

D ANGER

WARNING

WARNING

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 1 Safety Information

Do not store any ammable or explosive materials in the equipment area.

Do not place the equipment near heat sources or re sources, such as smoke,

candles, heaters, or other heating devices. Overheat may damage the equipment

or cause a

re.

Install the equipment in an area far away from liquids. Do not install it under

areas prone to condensation, such as under water pipes and air exhaust vents, or

areas prone to water leakage, such as air conditioner vents, ventilation vents, or

feeder windows of the equipment room. Ensure that no liquid enters the

equipment to prevent faults or short circuits.

To prevent damage or re due to high temperature, ensure that the ventilation

vents or heat dissipation systems are not obstructed or covered by other objects

while the equipment is running.

General Requirements

● Ensure that the equipment is stored in a clean, dry, and well ventilated area

with proper temperature and humidity and is protected from dust and

condensation.

● Keep the installation and operating environments of the equipment within the

allowed ranges. Otherwise, its performance and safety will be compromised.

● Do not install, use, or operate outdoor equipment and cables (including but

not limited to moving equipment, operating equipment and cables, inserting

connectors to or removing connectors from signal ports connected to outdoor

facilities, working at heights, performing outdoor installation, and opening

doors) in harsh weather conditions such as lightning, rain, snow, and level 6

or stronger wind.

● Do not install the equipment in an environment with dust, smoke, volatile or

corrosive gases, infrared and other radiations, organic solvents, or salty air.

● Do not install the equipment in an environment with conductive metal or

magnetic dust.

● Do not install the equipment in an area conducive to the growth of

microorganisms such as fungus or mildew.

● Do not install the equipment in an area with strong vibration, noise, or

electromagnetic interference.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 7

WARNING

WARNING

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 1 Safety Information

● Ensure that the site complies with local laws, regulations, and related

standards.

● Ensure that the ground in the installation environment is solid, free from

spongy or soft soil, and not prone to subsidence. The site must not be located

in a low-lying land prone to water or snow accumulation, and the horizontal

level of the site must be above the highest water level of that area in history.

● Do not install the equipment in a position that may be submerged in water.

● If the equipment is installed in a place with abundant vegetation, in addition

to routine weeding, harden the ground underneath the equipment using

cement or gravel (recommended area: 3 m x 2.5 m).

● Do not install the equipment outdoors in salt-aected areas because it may

be corroded. A

coast or prone to sea breeze. Regions prone to sea breeze vary with weather

conditions (such as typhoons and monsoons) or terrains (such as dams and

hills).

● Before opening doors during the installation, operation, and maintenance of

the equipment, clean up any water, ice, snow, or other foreign objects on the

top of the equipment to prevent foreign objects from falling into the

equipment.

● When installing the equipment, ensure that the installation surface is solid

enough to bear the weight of the equipment.

● After installing the equipment, remove the packing materials such as cartons,

foam, plastics, and cable ties from the equipment area.

salt-aected area refers to the region within 500 m of the

1.4 Mechanical Safety

Ensure that all necessary tools are ready and inspected by a professional

organization. Do not use tools that have signs of scratches or fail to pass the

inspection or whose inspection validity period has expired. Ensure that the tools

are secure and not overloaded.

Do not drill holes into the equipment. Doing so may aect the sealing

performance and electromagnetic containment of the equipment and damage

components or cables inside. Metal shavings from drilling may short-circuit boards

inside the equipment.

General Requirements

● Repaint any paint scratches caused during equipment transportation or

installation in a timely manner. Equipment with scratches cannot be exposed

for an extended period of time.

● Do not perform operations such as arc welding and cutting on the equipment

without evaluation by the Company.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 8

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 1 Safety Information

● Do not install other devices on the top of the equipment without evaluation

by the Company.

● When performing operations over the top of the equipment, take measures to

protect the equipment against damage.

● Use correct tools and operate them in the correct way.

Moving Heavy Objects

● Be cautious to prevent injury when moving heavy objects.

● If multiple persons need to move a heavy object together, determine the

manpower and work division with consideration of height and other

conditions to ensure that the weight is equally distributed.

● If two persons or more move a heavy object together, ensure that the object

is lifted and landed simultaneously and moved at a uniform pace under the

supervision of one person.

● Wear personal protective gears such as protective gloves and shoes when

manually moving the equipment.

● To move an object by hand, approach to the object, squat down, and then lift

the object gently and stably by the force of the legs instead of your back. Do

not lift it suddenly or turn your body around.

● Do not quickly lift a heavy object above your waist. Place the object on a

workbench that is half-waist high or any other appropriate place, adjust the

positions of your palms, and then lift it.

● Move a heavy object stably with balanced force at an even and low speed. Put

down the object stably and slowly to prevent any collision or drop from

scratching the surface of the equipment or damaging the components and

cables.

● When moving a heavy object, be aware of the workbench, slope, staircase,

and slippery places. When moving a heavy object through a door, ensure that

the door is wide enough to move the object and avoid bumping or injury.

● When transferring a heavy object, move your feet instead of turning your

waist around. When lifting and transferring a heavy object, ensure that your

feet point to the target direction of movement.

● When transporting the equipment using a pallet truck or forklift, ensure that

the tynes are properly positioned so that the equipment does not topple.

Before moving the equipment, secure it to the pallet truck or forklift using

ropes. When moving the equipment, assign dedicated personnel to take care

of it.

● Choose sea or roads in good conditions for transportation as transportation

by railway or air is not supported. Avoid tilt or jolt during transportation.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 9

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 1 Safety Information

Using Ladders

● Use wooden or insulated ladders when you need to perform live-line working

at heights.

● Platform ladders with protective rails are preferred. Single ladders are not

recommended.

● Before using a ladder, check that it is intact and

capacity. Do not overload it.

● Ensure that the ladder is securely positioned and held rm.

conrm its load bearing

● When climbing up the ladder, keep your body stable and your center of

gravity between the side rails, and do not overreach to the sides.

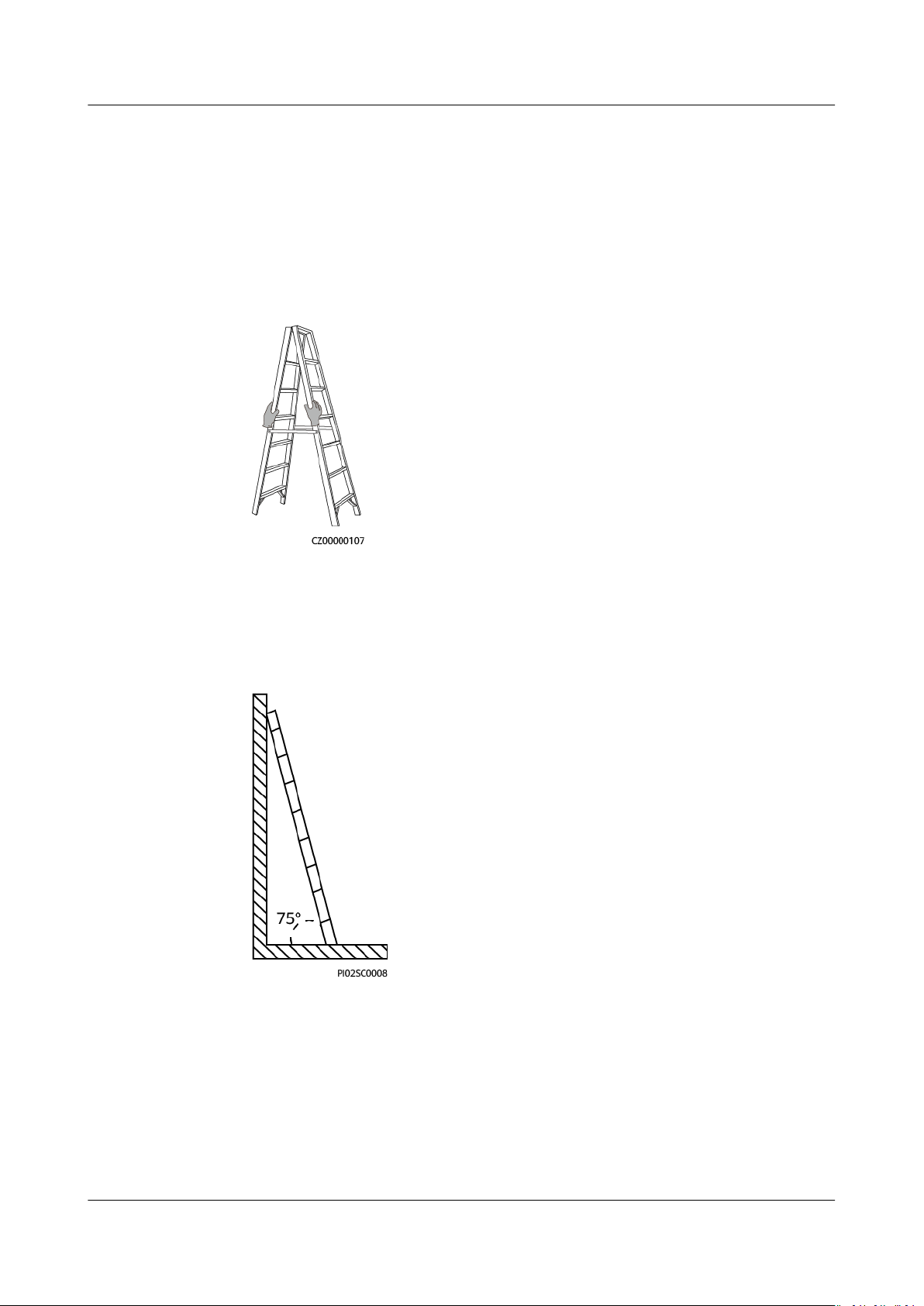

● When a step ladder is used, ensure that the pull ropes are secured.

● If a single ladder is used, the recommended angle for the ladder against the

oor is 75 degrees, as shown in the following gure. A square can be used to

measure the angle.

● If a single ladder is used, ensure that the wider end of the ladder is at the

bottom, and take protective measures to prevent the ladder from sliding.

● If a single ladder is used, do not climb higher than the fourth rung of the

ladder from the top.

● If you use a single ladder to climb up to a platform, ensure that the ladder is

at least 1 m higher than the platform.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 10

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 1 Safety Information

Hoisting

● Only trained and qualied personnel are allowed to perform hoisting

operations.

● Install temporary warning signs or fences to isolate the hoisting area.

● Ensure that the foundation where hoisting is performed on meets the loadbearing requirements.

● Before hoisting objects, ensure that hoisting tools are

xed object or wall that meets the load-bearing requirements.

● During hoisting, do not stand or walk under the crane or the hoisted objects.

● Do not drag steel ropes and hoisting tools or bump the hoisted objects

against hard objects during hoisting.

● Ensure that the angle between two hoisting ropes is no more than 90

degrees, as shown in the following gure.

rmly secured onto a

Drilling Holes

● Obtain consent from the customer and contractor before drilling holes.

● Wear protective equipment such as safety goggles and protective gloves when

drilling holes.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 11

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 1 Safety Information

● To avoid short circuits or other risks, do not drill holes into buried pipes or

cables.

● When drilling holes, protect the equipment from shavings. After drilling, clean

up any shavings.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 12

NO TE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 2 Overview

2 Overview

2.1 Product Introduction

Function

Model

The SUN2000 inverter is a three-phase grid-tied PV string inverter that converts

the DC power generated by PV strings into AC power and feeds the power into the

power grid.

This document covers the following SUN2000 models:

● SUN2000-20KTL-M3

● SUN2000-29.9KTL-M3

● SUN2000-30KTL-M3

● SUN2000-36KTL-M3

● SUN2000-40KTL-M3

The SUN2000-20KTL-M3 supports 220 V (line voltage) power grids.

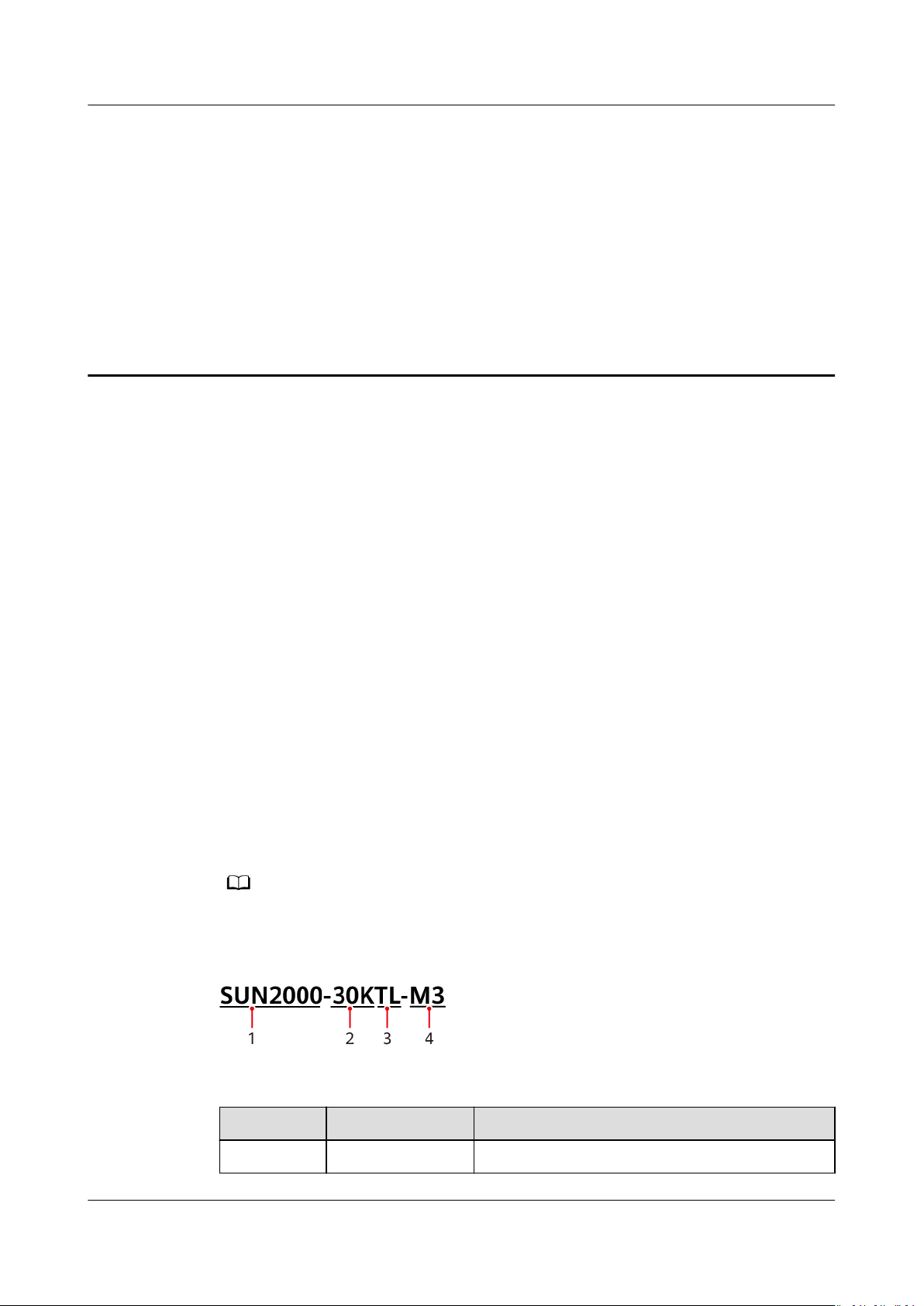

Figure 2-1 Model description (SUN2000-30KTL-M3 is used as an example)

Table 2-1 Model description

ID

1 Series name SUN2000: grid-tied solar inverter

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 13

Meaning Value

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 2 Overview

ID Meaning Value

2 Power class ● 20K: rated power of 20 kW

● 29.9K: rated power of 29.9 kW

● 30K: rated power of 30 kW

● 36K: rated power of 36 kW

● 40K: rated power of 40 kW

3 Topology TL: transformerless

4 Product code M3: product series with an input voltage level

of 1100 V DC

Note a: The maximum DC input voltage of SUN2000-20KTL-M3 is 800 V. For

details, see 10 Technical

Specications.

a

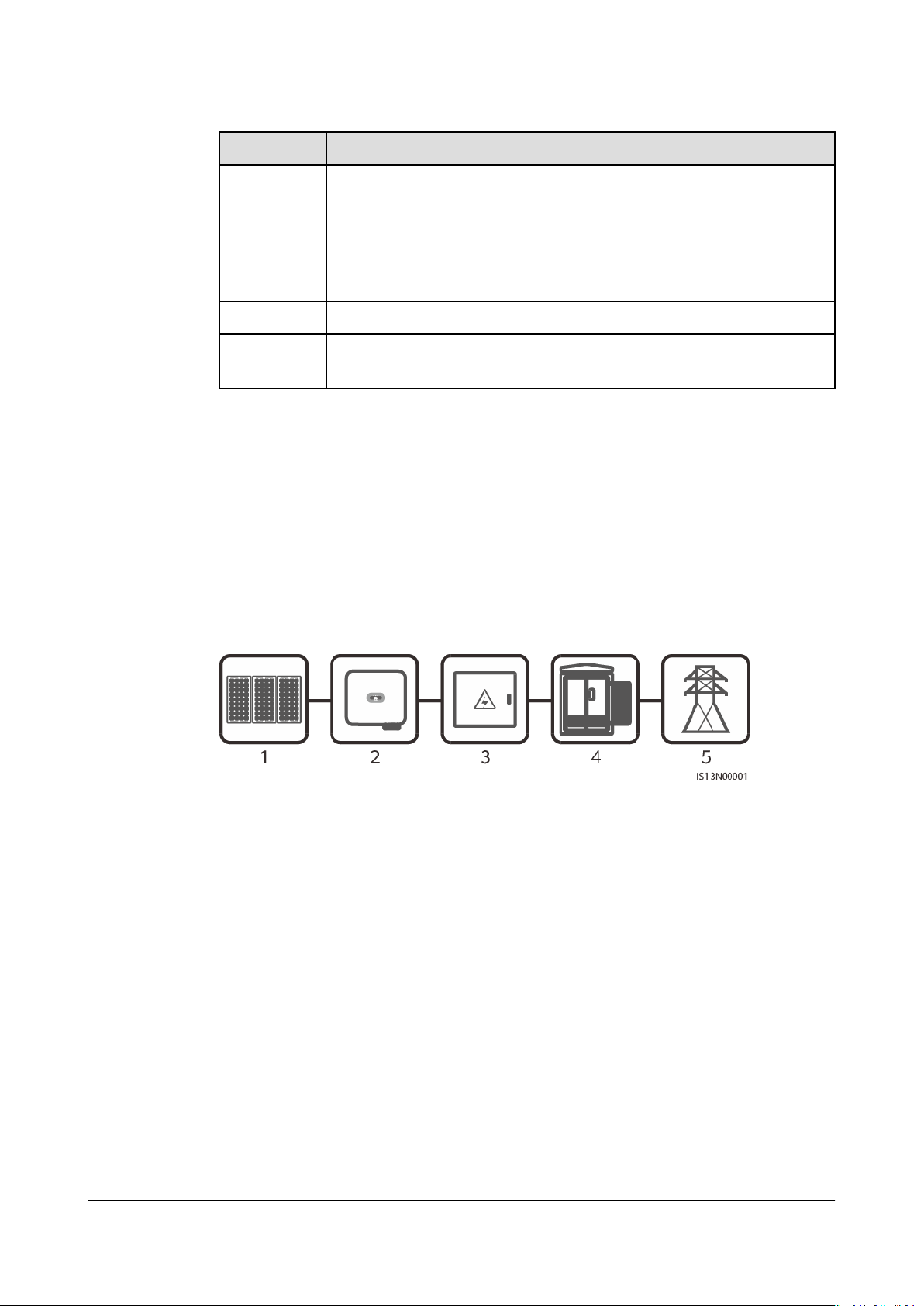

Networking Application

The SUN2000 applies to the grid-tied systems of industrial and commercial

rooftops and small ground PV plants. Typically, a grid-tied system consists of PV

strings, grid-tied inverters, AC switches, and power distribution units.

Figure 2-2 Networking application - single inverter scenario

(1) PV string

(4) Isolation transformer (5) Power grid

Supported Power Grid Types

(2) SUN2000 (3) AC power distribution

unit

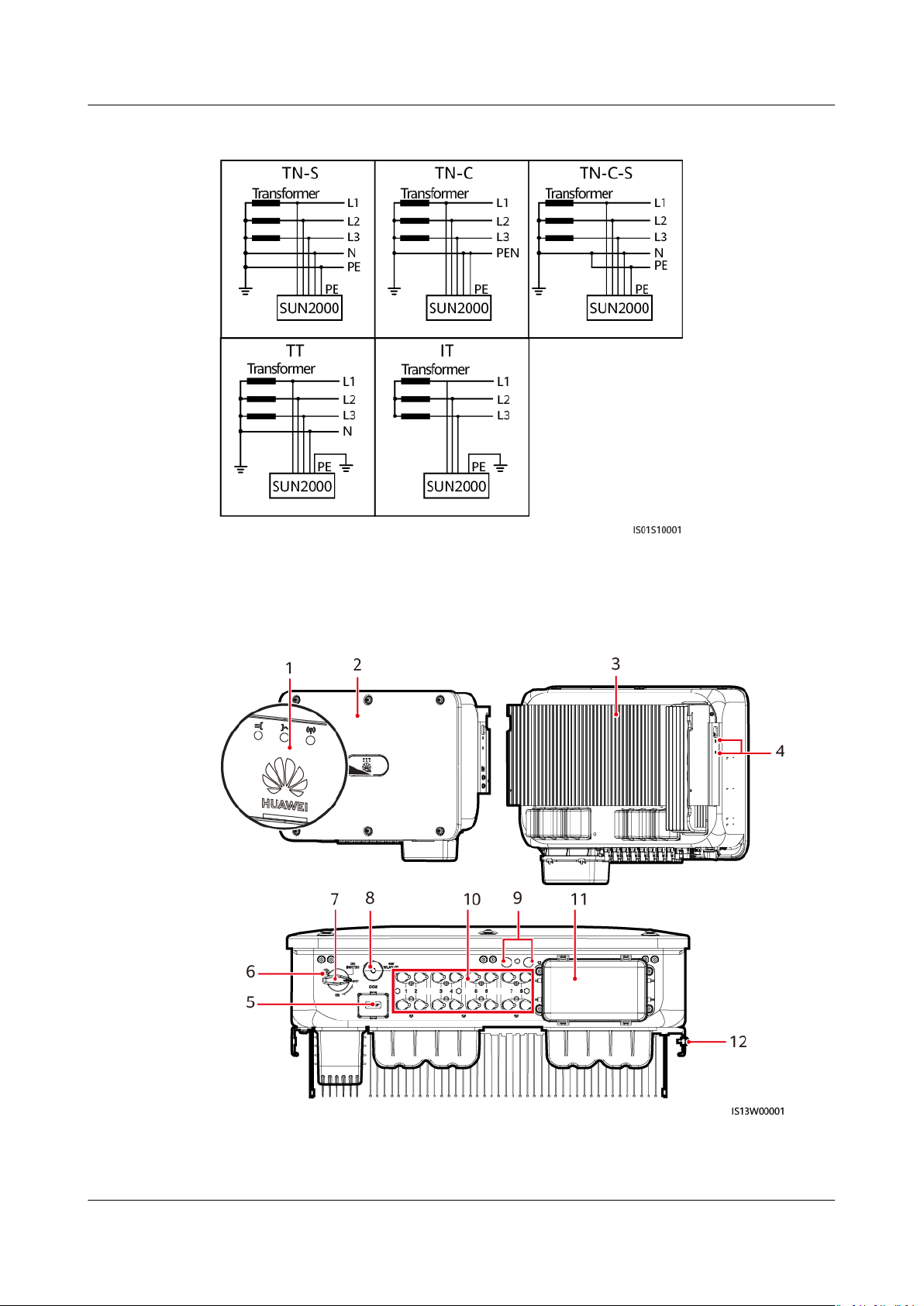

The SUN2000 supports TN-S, TN-C, TN-C-S, TT, and IT power grids.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 14

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 2 Overview

Figure 2-3 Power grid types

2.2 Appearance

Figure 2-4 Appearance

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 15

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 2 Overview

(1) LED indicator (2) Front panel

(3) Heat sink (4) Screws for xing the awning

(5) Communications port (COM) (6) Hole for the DC switch locking

screw

(7) DC switch (DC SWITCH) (8) Smart Dongle port (4G/WLAN-FE)

(9) Ventilation valve (10) DC input terminals (PV1–PV8)

(11) AC output port (12) Ground point

2.3 Label Description

Enclosure Labels

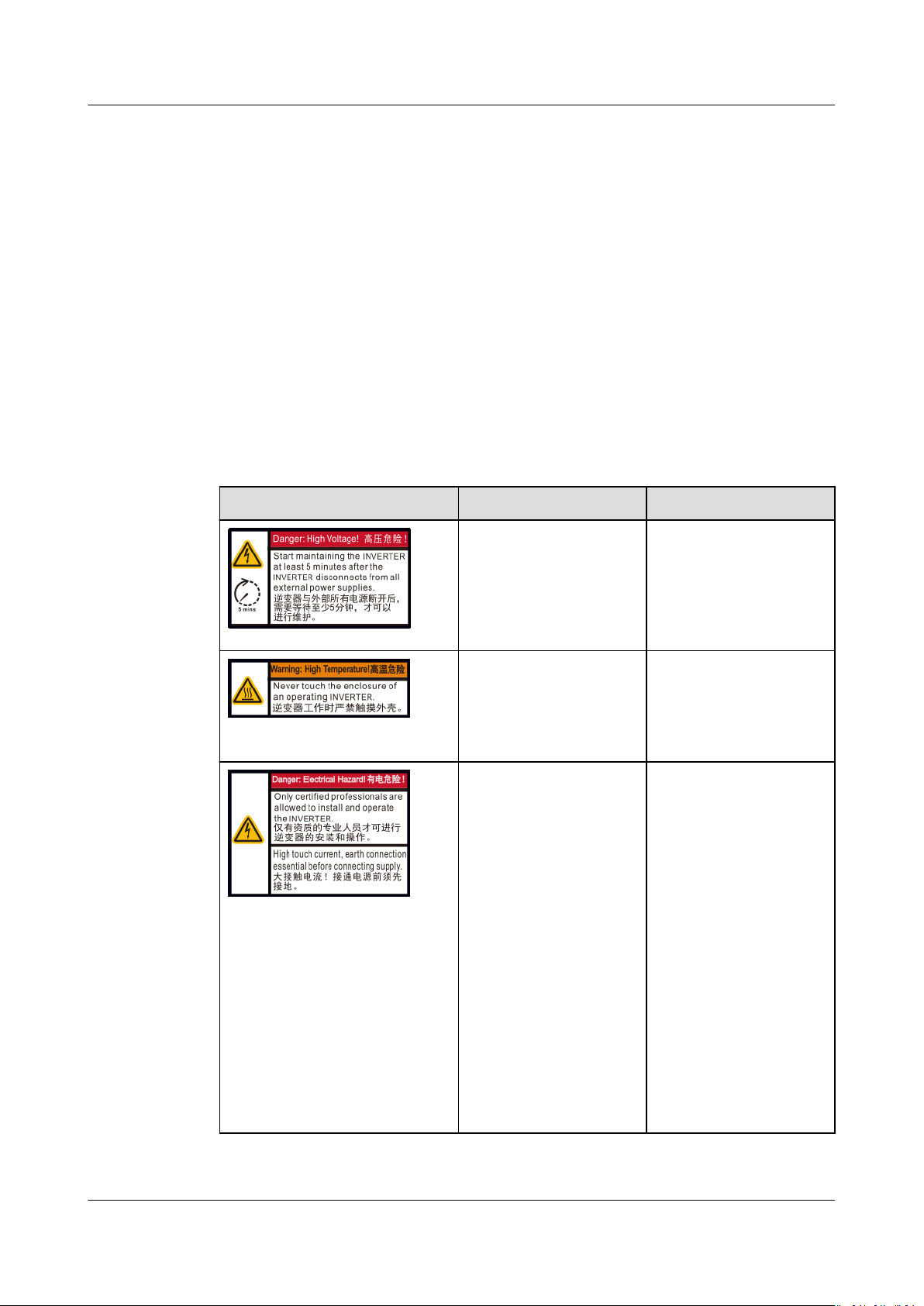

Symbol Name Description

Delay discharge Residual voltage exists

after the SUN2000 is

powered o. It takes 5

minutes for the

SUN2000 to discharge

to the safe voltage.

Burn warning Do not touch a

running SUN2000

because it generates

high temperatures on

the shell.

Electric shock warning ● High voltage exists

after the SUN2000

is powered on. Only

qualied and

trained electrical

technicians are

allowed to perform

operations on the

SUN2000.

● High touch current

exists after the

SUN2000 is

powered on. Before

powering on the

SUN2000, ensure

that the SUN2000

is properly

grounded.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 16

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 2 Overview

Symbol Name Description

Refer to

documentation

Reminds operators to

refer to the documents

delivered with the

SUN2000.

Grounding label Indicates the position

for connecting the PE

cable.

Operation warning Do not remove the DC

input connector or AC

output connector with

power on.

Weight label The SUN2000 is heavy

and needs to be

carried by three

persons.

Burn warning on

inverter handles

Do not touch the

handles within 10

minutes after the

inverter is shut down.

Indicator Indicates the SUN2000

operating information.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 17

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 2 Overview

Symbol Name Description

2.4 Working Principles

2.4.1 Circuit Diagram

A SUN2000 can connect to a maximum of eight PV strings and has four MPPT

circuits inside. Each MPPT circuit tracks the maximum power point of two PV

strings. The SUN2000 converts DC power into single-phase AC power through an

inverter circuit. Surge protection is supported on both the DC and AC sides.

Figure 2-5 Schematic diagram

SUN2000 serial

number

SUN2000 Wi-Fi login

QR code

Indicates the serial

number.

Scan the QR code to

connect to the Huawei

SUN2000 Wi-Fi

network.

2.4.2 Working Modes

The SUN2000 can work in Standby, Operating, or Shutdown mode.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 18

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 2 Overview

Figure 2-6 Working modes

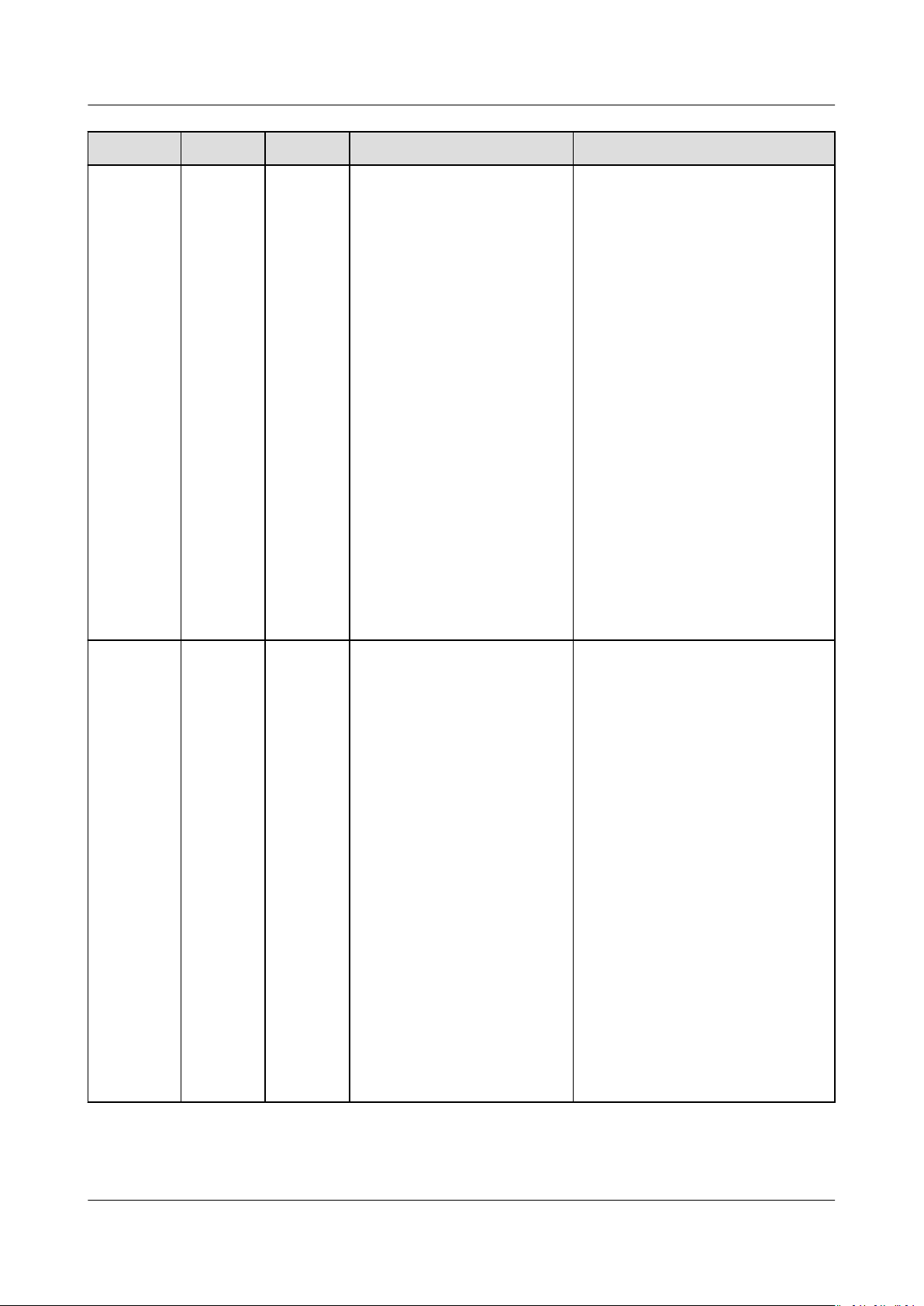

Table 2-2 Working mode description

Working

Description

Mode

Standby The SUN2000 enters Standby mode when the external

environment does not meet the operating requirements. In

Standby mode:

● The SUN2000 continuously performs status check and enters

the Operating mode once the operating requirements are met.

● The SUN2000 enters Shutdown mode after detecting a

shutdown command or a fault after startup.

Operating In Operating mode:

● The SUN2000 converts DC power from PV strings into AC power

and feeds the power to the power grid.

● The SUN2000 tracks the maximum power point to maximize

the PV string output.

● If the SUN2000 detects a fault or a shutdown command, it

enters the Shutdown mode.

● The SUN2000 enters Standby mode after detecting that the PV

string output power is not suitable for connecting to the power

grid for generating power.

Shutdown ● In Standby or Operating mode, the SUN2000 enters Shutdown

mode after detecting a fault or shutdown command.

● In Shutdown mode, the SUN2000 enters Standby mode after

detecting a startup command or that the fault is rectied.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 19

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 3 SUN2000 Storage

3 SUN2000 Storage

The following requirements should be met if the SUN2000 is not put into use

directly:

● Do not unpack the SUN2000.

● Keep the storage temperature at –40°C to +70°C and the humidity at 5%–

95% RH.

● Store the SUN2000 in a clean and dry place and protect it from dust and

water vapor corrosion.

● A maximum of six SUN2000s can be stacked. To avoid personal injury or

device damage, stack SUN2000s with caution to prevent them from falling

over.

● During the storage period, check the SUN2000 periodically (recommended:

every three months). If any rodent bites are found on the packing materials,

replace the packing materials immediately.

● If the SUN2000 has been stored for more than two years, it must be checked

and tested by professionals before being put into use.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 20

NO TE

NO TICE

NO TE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 4 Installation

4 Installation

4.1 Checking Before Installation

Outer Packing Materials

Before unpacking the inverter, check the outer packing materials for damage, such

as holes and cracks, and check the inverter model. If any damage is found or the

inverter model is not what you requested, do not unpack the package and contact

your supplier as soon as possible.

You are advised to remove the packing materials within 24 hours before installing the

inverter.

Package Contents

● After placing the equipment in the installation position, unpack it with care to

prevent scratches. Keep the equipment stable during unpacking.

After unpacking the inverter, check that the contents are intact and complete. If

any damage is found or any component is missing, contact your supplier.

For details about the number of contents, see the

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 21

Packing List

in the packing case.

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 4 Installation

4.2 Tool Preparation

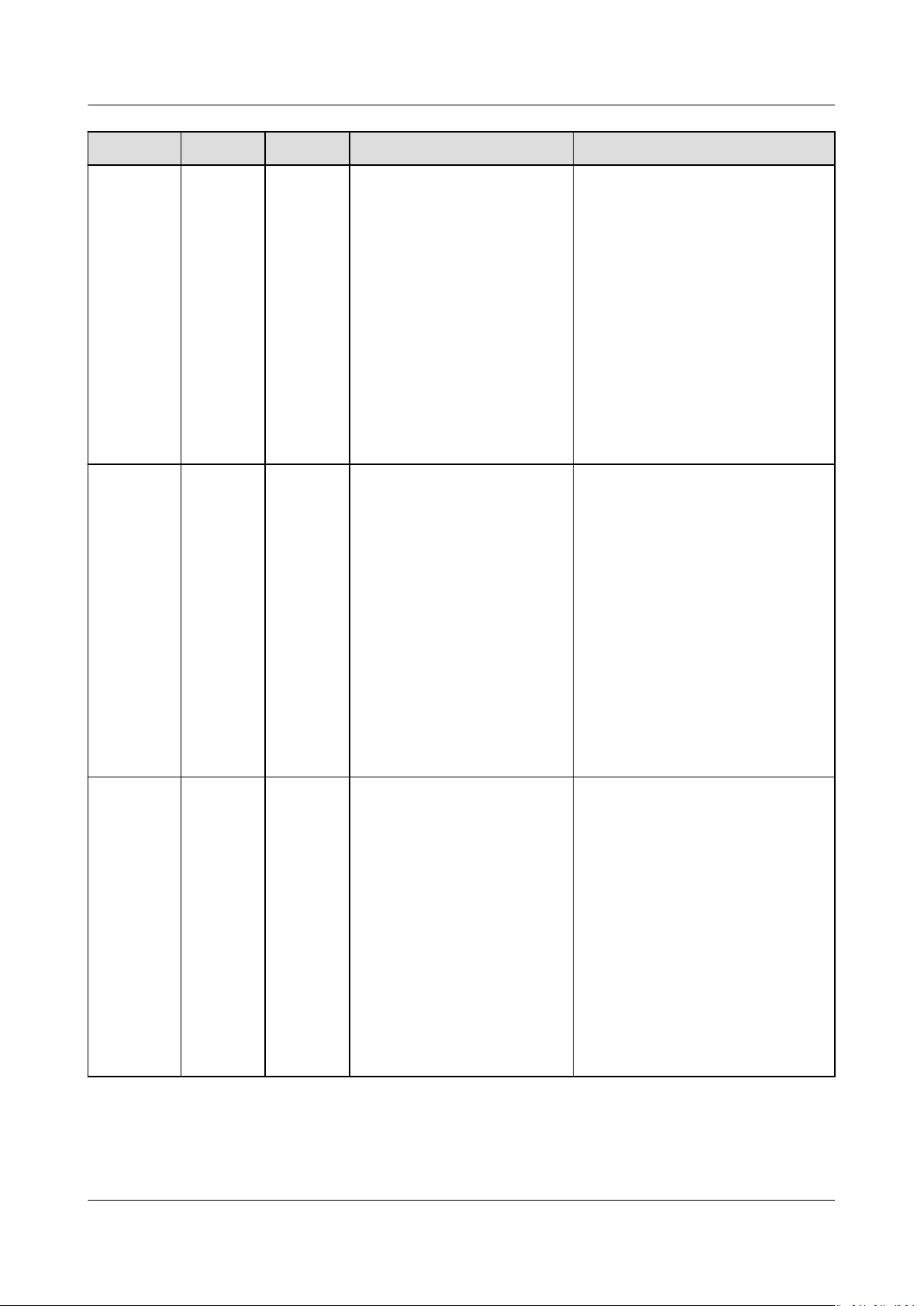

Type Tools and Instruments

Install

ation

Insulated torque socket

wrench (including an

extension bar)

Hammer drill Drill bit Rubber mallet

Utility knife Marker Hydraulic pliers

Insulated torque socket

wrench (including an

extended socket)

Phillips insulated torque

screwdriver

Cable cutter Wire stripper Diagonal pliers

Crimping tool

H4TC0003 (Amphenol)

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 22

Open-end wrench

H4TW0001 (Amphenol)

Heat shrink tubing

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 4 Installation

Type Tools and Instruments

Person

al

protec

tive

equip

ment

(PPE)

Crimping tool (model:

PV-CZM-22100)

Steel measuring tape Level Multimeter

Cable tie Vacuum cleaner

Goggles Work shoes Dust mask

Open-end wrench (model:

PV-MS-HZ or PV-MS openend wrench)

Heat gun

-

-

Protective gloves Insulated gloves

4.3 Selecting an Installation Position

Basic Requirements

● The SUN2000 is IP66-rated and can be installed indoors or outdoors.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 23

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 4 Installation

● Do not install the SUN2000 in a place where a person can easily be exposed

to its enclosure and heat sinks, because these parts are extremely hot during

operation.

● Do not install the SUN2000 in areas with ammable or explosive materials.

● If inverters are installed in a place with abundant vegetation, in addition to

routine weeding, harden the ground underneath the inverters using cement or

gravel (recommended area: 3 m x 2.5 m).

● Do not install the SUN2000 in a place within children's reach.

● The SUN2000 will be corroded in salt areas, and the salt corrosion may cause

re. Do not install the SUN2000 outdoors in salt areas. A salt area refers to

the region within 500 m from the coast or prone to sea breeze. The

from sea breeze depends on weather conditions (such as typhoon and season

wind) or terrains (such as dams and hills).

eect

Site Requirements

● The SUN2000 should be installed in a well-ventilated environment to ensure

good heat dissipation.

● If the SUN2000 is installed in a place exposed to direct sunlight, the power

may decrease as the temperature rises.

● You are advised to install the SUN2000 in a sheltered place or install an

awning over it.

Mounting Structure Requirements

● The mounting structure where the SUN2000 is installed must be

● Do not install the SUN2000 on ammable building materials.

● The SUN2000 is heavy. Ensure that the installation surface is solid enough to

bear the weight load.

● In residential areas, do not install the SUN2000 on drywalls or walls made of

similar materials which have a weak sound insulation performance because

the noise generated by the SUN2000 is noticeable.

Installation Angle Requirements

The SUN2000 can be wall-mounted or support-mounted. Requirements for the

installation angle:

● Install the SUN2000 vertically or at a maximum back tilt of 15 degrees to

facilitate heat dissipation.

● Do not install the SUN2000 with a front tilt, excessive back tilt, side tilt,

horizontally, or upside down.

re resistant.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 24

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 4 Installation

Figure 4-1 Installation angle

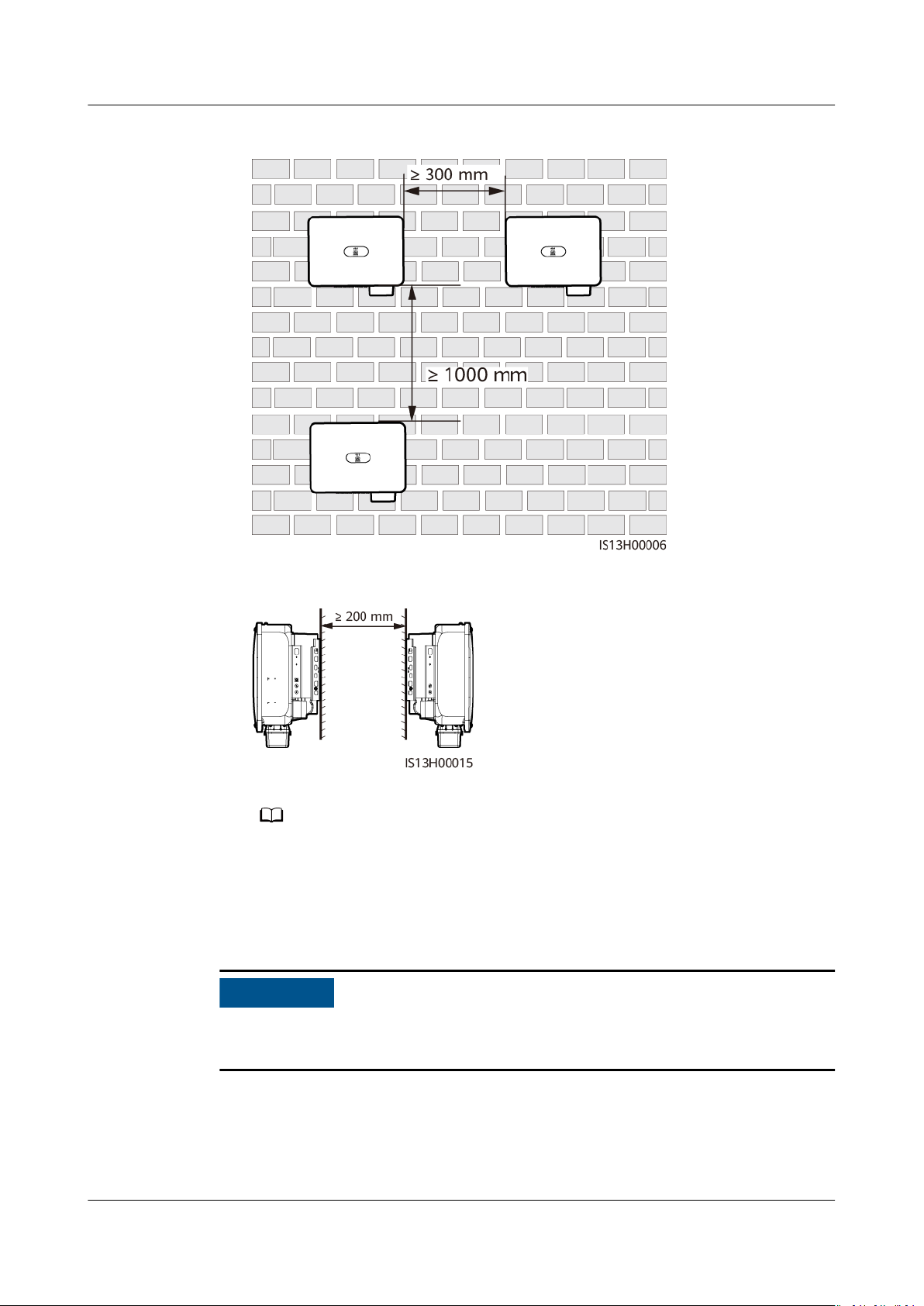

Installation Space Requirements

● Reserve enough clearance around the SUN2000 to ensure sucient space for

installation and heat dissipation.

Figure 4-2 Installation space

● When installing multiple SUN2000s, install them in horizontal mode if ample

space is available and install them in triangle mode if no ample space is

available. Stacked installation is not recommended.

Figure 4-3 Horizontal installation (recommended)

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 25

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 4 Installation

Figure 4-4 Two-layer triangle installation (recommended)

Figure 4-5 Three-layer triangle installation (not recommended)

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 26

NO TE

NO TICE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 4 Installation

Figure 4-6 Stacked installation (not recommended)

Figure 4-7 Back-to-back installation (not recommended)

The installation diagrams are for reference only and are irrelevant to the SUN2000

cascading scenario.

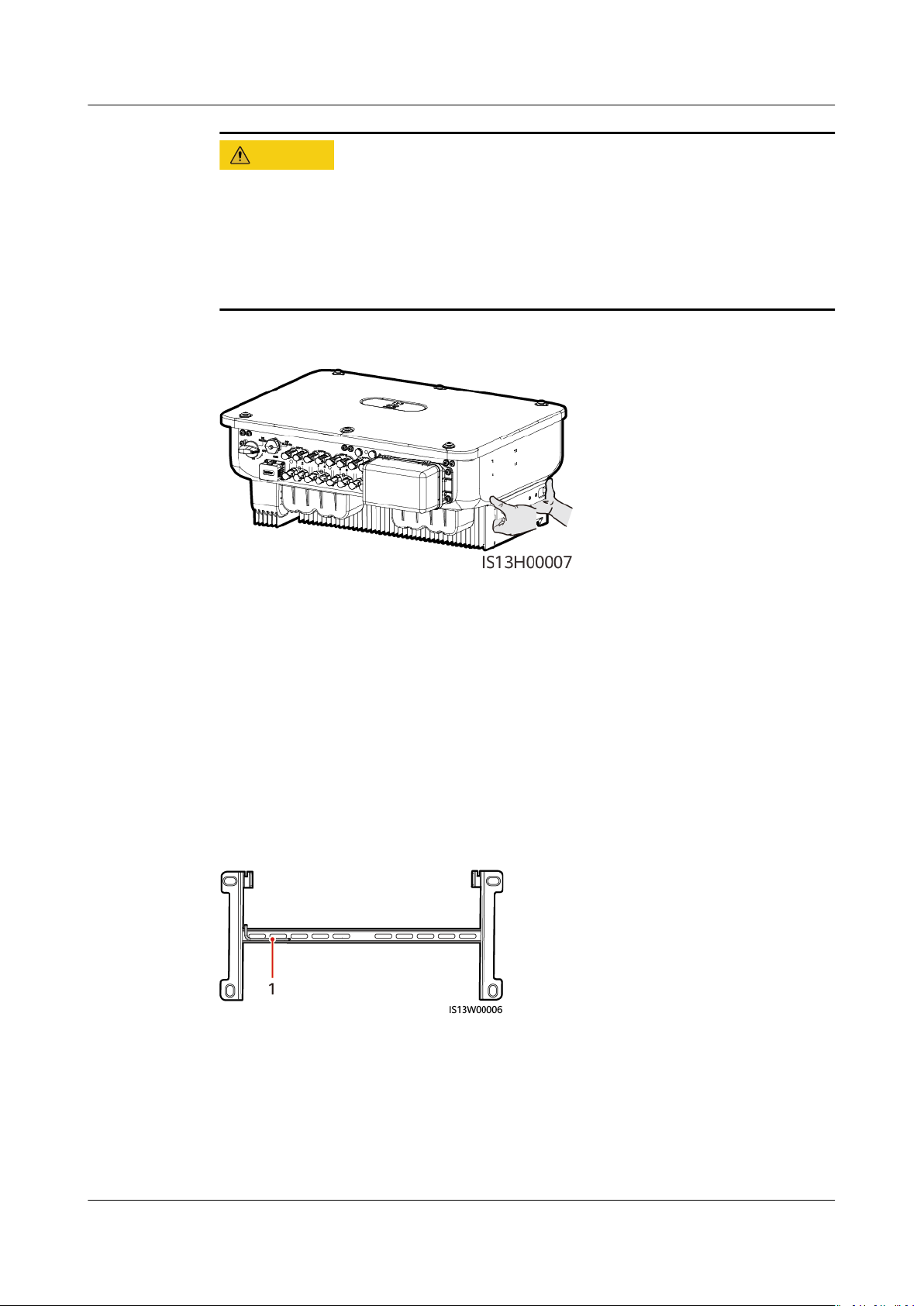

4.4 Moving the SUN2000

● After placing the equipment in the installation position, unpack it with care to

prevent scratches. Keep the equipment stable during unpacking.

Procedure

Step 1 Lift the SUN2000 from the packing case and move it to the specied installation

position.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 27

CA UTION

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 4 Installation

● Move the SUN2000 with care to prevent device damage and personal injury.

● Do not use the wiring terminals and ports at the bottom to support any weight

of the SUN2000.

● Place a foam pad or cardboard under the SUN2000 to protect the SUN2000

enclosure from damage.

Figure 4-8 Moving the SUN2000

----End

4.5 Installing the Mounting Bracket

Installation Precautions

Before installing the mounting bracket, remove the security Torx wrench and set it

aside.

Figure 4-9 Position for binding the security Torx wrench

(1) Security Torx wrench

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 28

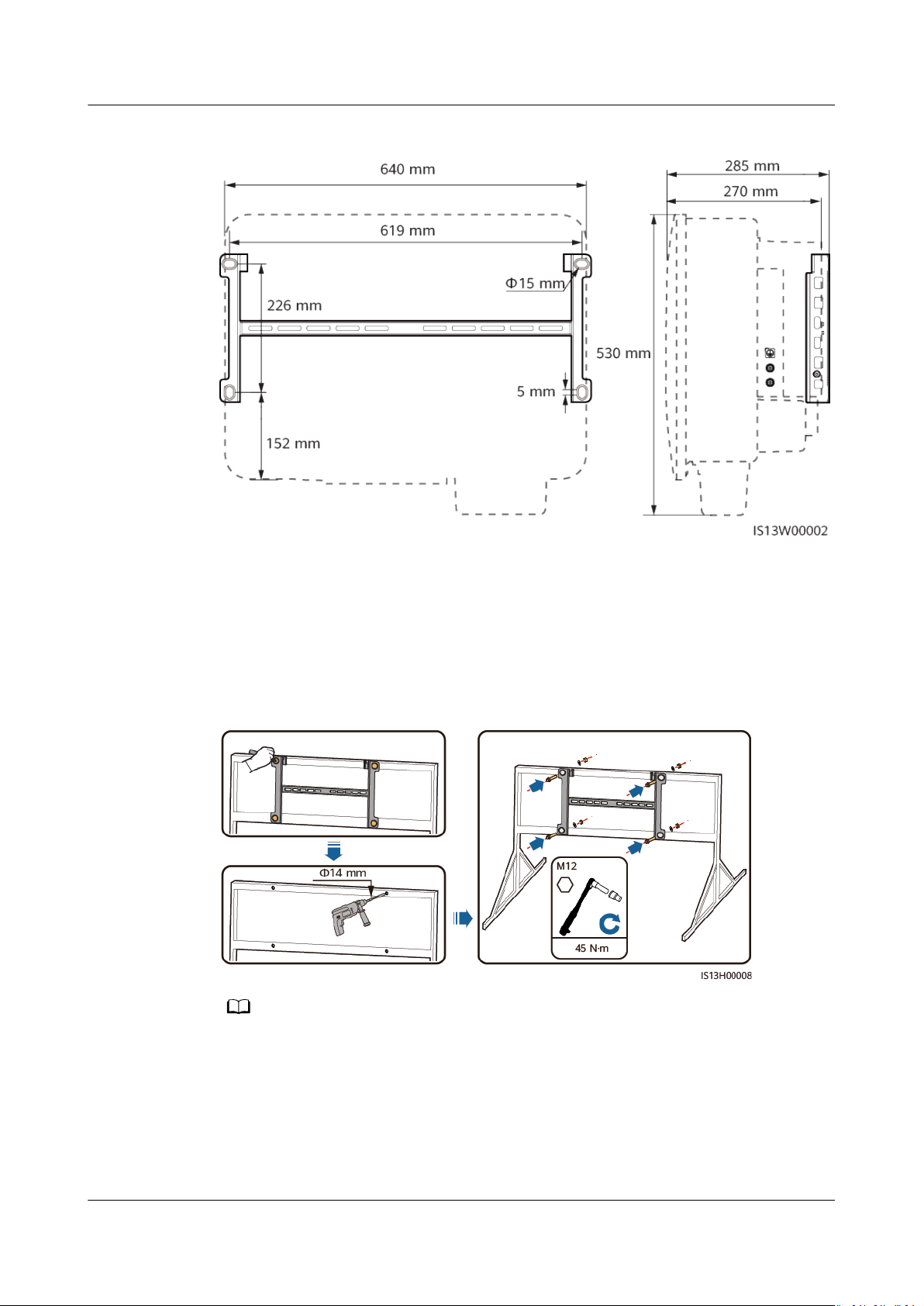

Figure 4-10 shows the dimensions of the mounting holes for the SUN2000.

NO TE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 4 Installation

Figure 4-10 Mounting bracket dimensions

4.5.1 Support-mounted Installation

Procedure

Step 1 Secure the mounting bracket.

Figure 4-11 Securing the mounting bracket

You are advised to apply anti-rust paint on the hole positions for protection.

----End

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 29

D ANGER

NO TICE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 4 Installation

4.5.2 Wall-mounted Installation

Prerequisites

To install the SUN2000, you need to prepare expansion bolts. M12x60 stainless

steel expansion bolts are recommended.

Procedure

Step 1 Determine the positions for drilling holes and mark the positions using a marker.

Step 2 Secure the mounting bracket.

Avoid drilling holes in the water pipes and cables buried in the wall.

Figure 4-12 Expansion bolt composition

(1) Bolt (2) Nut (3) Spring washer

(4) Flat washer (5) Expansion sleeve

● To prevent dust inhalation or contact with eyes, wear safety goggles and an

anti-dust mask when drilling holes.

● Clean up any dust in and around the holes using a vacuum cleaner and

measure the distance between holes. If the holes are inaccurately positioned,

drill holes again.

● Level the front of the expansion sleeve with the concrete wall after removing

the bolt, spring washer, and

not be securely installed on the concrete wall.

at washer. Otherwise, the mounting bracket will

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 30

NO TE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 4 Installation

Figure 4-13 Installing expansion bolts

----End

4.6 Installing a SUN2000

Step 1 (Optional) Install the locking screw for the DC switch.

● The DC switch locking screw is used to lock the DC switch to prevent the switch from

rotating.

● For models used in Australia, install the DC switch locking screw according to local

standards. The DC switch locking screw is delivered with the SUN2000.

Figure 4-14 Installing the locking screw for the DC switch

Step 2 Install the SUN2000 onto the mounting bracket.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 31

NO TICE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 4 Installation

Figure 4-15 Installing a SUN2000

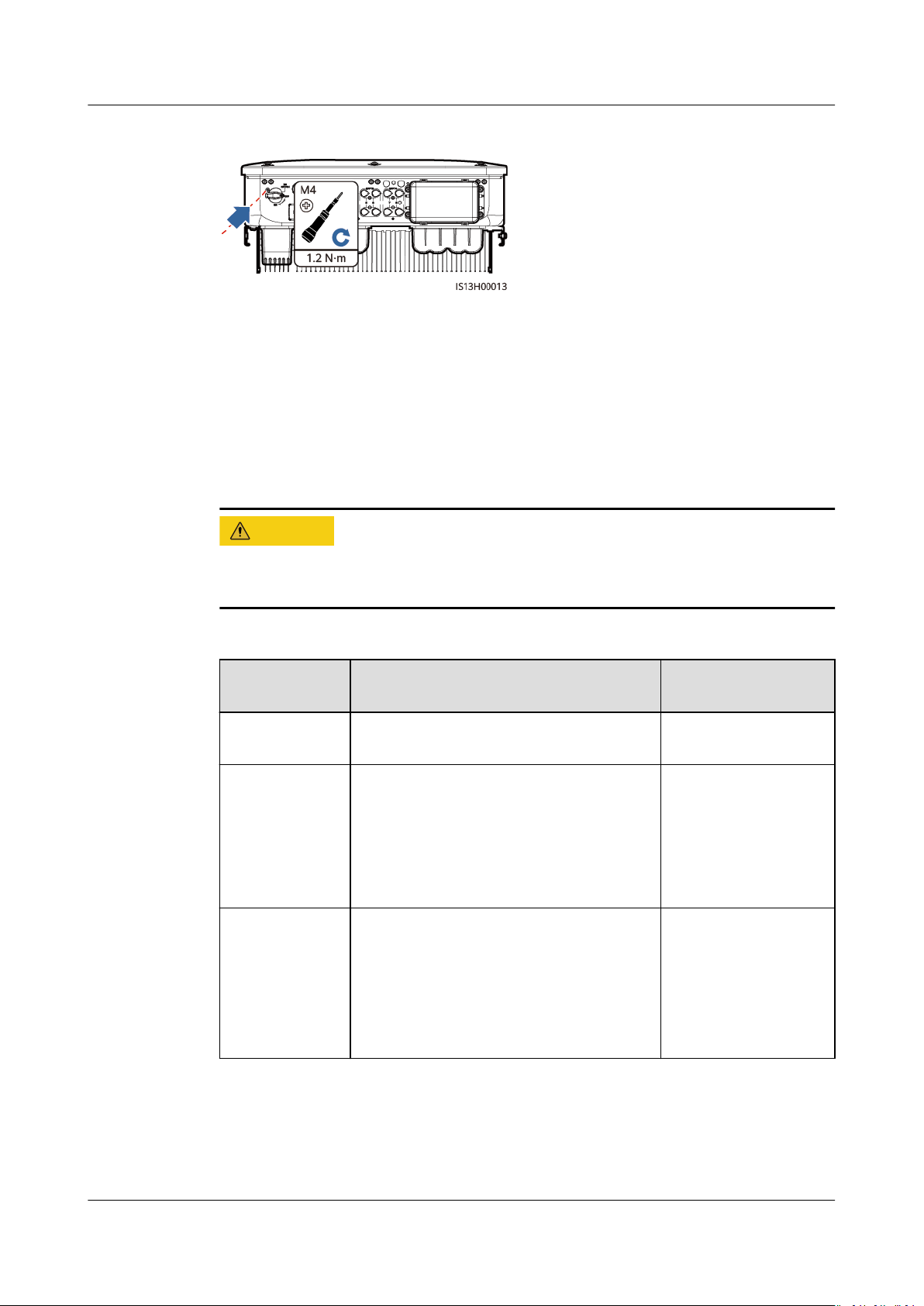

Step 3 Tighten the nuts on both sides of the SUN2000.

Figure 4-16 Tightening the nut

Secure the screws on the sides before connecting cables.

----End

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 32

D ANGER

D ANGER

WARNING

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

5 Electrical Connections

5.1 Precautions

When exposed to sunlight, the PV arrays supply DC voltage to the inverter. Before

connecting cables, ensure that all DC SWITCH on the inverter are OFF. Otherwise,

the high voltage of the inverter may result in electric shocks.

● The site must be equipped with qualied re ghting facilities, such as re

sand and carbon dioxide re extinguishers.

● Wear personal protective equipment and use dedicated insulated tools to avoid

electric shocks or short circuits.

● The equipment damage caused by incorrect cable connections is beyond the

warranty scope.

● Only

● Operation personnel must wear PPE when connecting cables.

● Before connecting cables to ports, leave enough slack to reduce the tension on

certied electrician can perform electrical terminations.

the cables and prevent poor cable connections.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 33

CA UTION

NO TE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

● Stay away from the equipment when preparing cables to prevent cable scraps

from entering the equipment. Cable scraps may cause sparks and result in

personal injury and equipment damage.

● When routing PV cables, the positive and negative PV string cables should be

routed in dierent pipes to prevent cable damage and short circuits caused by

improper operations during construction.

The cable colors shown in the electrical connection diagrams provided in this section are for

reference only. Select cables in accordance with local cable specications (green-and-yellow

cables are only used for protective earthing).

5.2 Preparing Cables

Figure 5-1 SUN2000 cable connections (dashed boxes indicate optional

components)

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 34

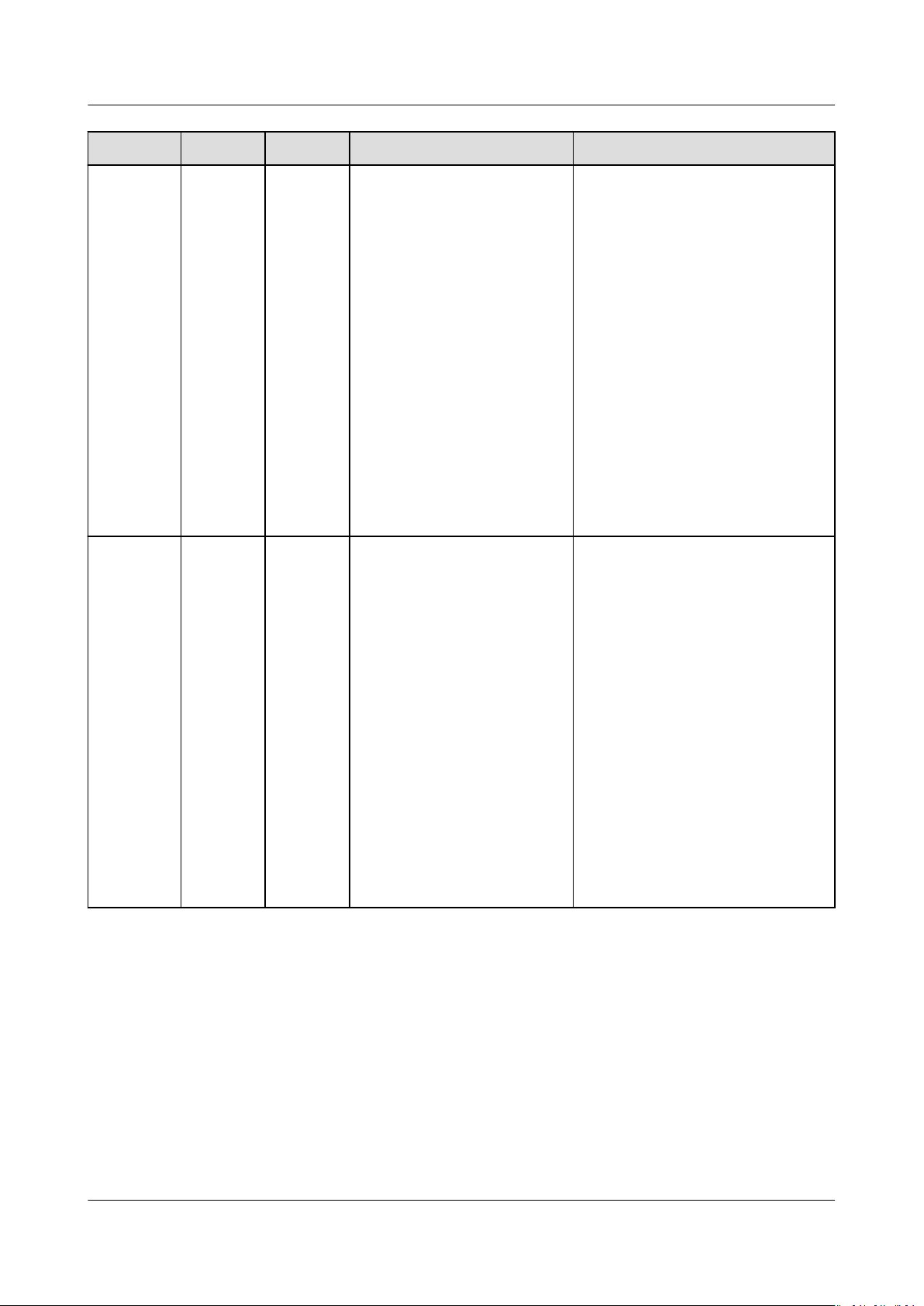

Table 5-1 Components

No.

Component Description Source

A PV string ● A PV string consists of PV

modules connected in series.

● The SUN2000 supports the input

from eight PV strings.

Prepared by users

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

No. Component Description Source

B AC switch To ensure that the inverter can be

safely disconnected from the power

grid when an exception occurs,

connect an AC switch to the AC side

of the inverter. Select an

appropriate AC switch in

accordance with local industry

standards and regulations. Huawei

recommends the following switch

specications:

Recommended: a three-phase AC

circuit breaker with a rated voltage

greater than or equal to 500 V AC

and a rated current of:

● 63 A (SUN2000-29.9KTL/30KTLM3)

● 80 A (SUN2000-20KTL-M3)

● 100 A (SUN2000-36KTL/40KTLM3)

C Power

meter

[1]

The SUN2000 can connect to the

DTSU666-H, DTSU666-HW,

YDS60-80 and YDS60-C24 power

[2]

meter.

Prepared by users

Purchased from

Huawei

D SUN2000 Select a proper model as required. Purchased from

Huawei

E SmartLogger SmartLogger3000 Purchased from

Huawei

F Smart

Dongle

G Smart PV

optimizer

[3]

Select a proper model as required. Purchased from

Huawei

MERC-1300W-P, MERC-1100W-P,

SUN2000-600W-P, SUN2000-450W-

Purchased from

Huawei

P2, SUN2000-450W-P.

Note [1]: For details about meter operations, see

DTSU666-HW Smart Power

Sensor Quick Guide, YDS60-80 Smart Power Sensor Quick Guide, YDS60-C24

Smart Power Sensor Quick Guide, DTSU666-H and DTSU666-H 250 A (50

mA) Smart Power Sensor Quick Guide

Smart Power Sensor User Manual

and

DTSU666-H 100 A and 250 A

.

Note [2]: SUN2000MA V100R001C20SPC116 and later versions can connect to

DTSU666-HW power meter.

Note [3]: For details about how to operate optimizers, see MERC Smart PV

Optimizer User Manual and SUN2000 Smart PV Optimizer User Manual.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 35

NO TICE

NO TICE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

The cable specications must comply with local standards.

Table 5-2 Cable description

No. Cable Type Recommended

Specications

1 DC input

power

cable

Common PV cable in the

industry

(Recommended model:

PV1-F)

● Conductor crosssectional area: 4–6

2

mm

● Cable outer

diameter: 5.5–9

mm

2 AC

output

power

cable

Outdoor copper-core/

aluminum-core cable

● Conductor crosssectional area:

16-50 mm

2

outdoor coppercore cable or 35-50

mm2 outdoor

aluminum-core

cable

● Cable outer

diameter: 16–38

mm

3 (Option

al)

Signal

cable

Two-core outdoor

shielded twisted pair

(recommended model:

DJYP2VP2-2x2x0.75)

● Conductor crosssectional area: 0.2–

2

1 mm

● Cable outer

diameter: 4–11 mm

Source

Prepare

d by

users

Prepare

d by

users

Prepare

d by

users

4 PE cable Single-core outdoor

copper-core cable

Conductor crosssectional area ≥ 16

2

mm

Prepare

d by

users

Note a: Five-core cables with a cross-sectional area of 5 x 35 mm2 or 5 x 50

mm2 are not supported.

If the SUN2000 is used with an optimizer, route the AC and DC power cables

separate to avoid interference to the communication of the optimizer.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 36

D ANGER

NO TE

NO TICE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

5.3 Connecting the PE Cable

● Ensure that the PE cable is securely connected. Otherwise, electric shocks may

occur.

● Do not connect the neutral wire to the enclosure as a PE cable. Otherwise,

electric shocks may occur.

● The PE point at the AC output port is used only as a PE equipotential point, not a

substitute for the PE point on the enclosure.

● It is recommended that silicone sealant or paint be applied around the ground terminal

after the PE cable is connected.

Procedure

Step 1 Crimp OT terminals.

● Avoid scratching the core wire when stripping a cable.

● The cavity formed after the conductor crimp strip of the OT terminal is crimped

must wrap the core wires completely. The core wires must contact the OT

terminal closely.

● Wrap the wire crimping area with heat shrink tubing or PVC insulation tape.

The heat shrink tubing is used as an example.

● When using a heat gun, protect devices from being scorched.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 37

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

Figure 5-2 Crimping an OT terminal

(1) Cable (2) Core (3) Heat shrink tubing

(4) OT terminal (5) Crimping tool (6) Heat gun

Step 2 Connect the PE cable.

Figure 5-3 Connecting the PE cable

(1) Reserved PE point

----End

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 38

WARNING

CA UTION

NO TICE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

5.4 Connecting the AC Output Power Cable

Precautions

An AC switch must be installed on the AC side of the SUN2000 to ensure that the

SUN2000 can be safely disconnected from the power grid.

● Do not connect loads between the inverter and the AC switch that directly

connects to the inverter. Otherwise, the switch may trip by mistake.

● If an AC switch is used with specications beyond local standards, regulations,

or Huawei's recommendations, the switch may fail to turn

manner in case of exceptions, causing serious faults.

o in a timely

Each inverter must be equipped with an AC output switch. Multiple inverters

cannot connect to the same AC output switch.

● If the external AC switch can perform earth leakage protection, the rated

leakage action current should be greater than or equal to 300 mA.

● If multiple SUN2000s connect to the general residual current device (RCD)

through their respective external AC switches, the rated leakage action current

of the general RCD should be greater than or equal to the number of

SUN2000s multiplied by 300 mA.

● Use a socket wrench and extension rod to connect the AC power cable. The

extension rod must be longer than 100 mm.

Sucient slack should be provided in the PE cable to ensure that the last cable

●

bearing the force is the PE cable when the AC output power cable bears pulling

force due to force majeure.

● Do not install third-party devices in the AC connection box.

● You need to prepare M8 OT terminals by yourself.

● If the AC MBUS is used, multi-core cables are recommended, supporting a

maximum communication distance of 1000 m. To use other types of AC power

cables, contact the Company's technical support.

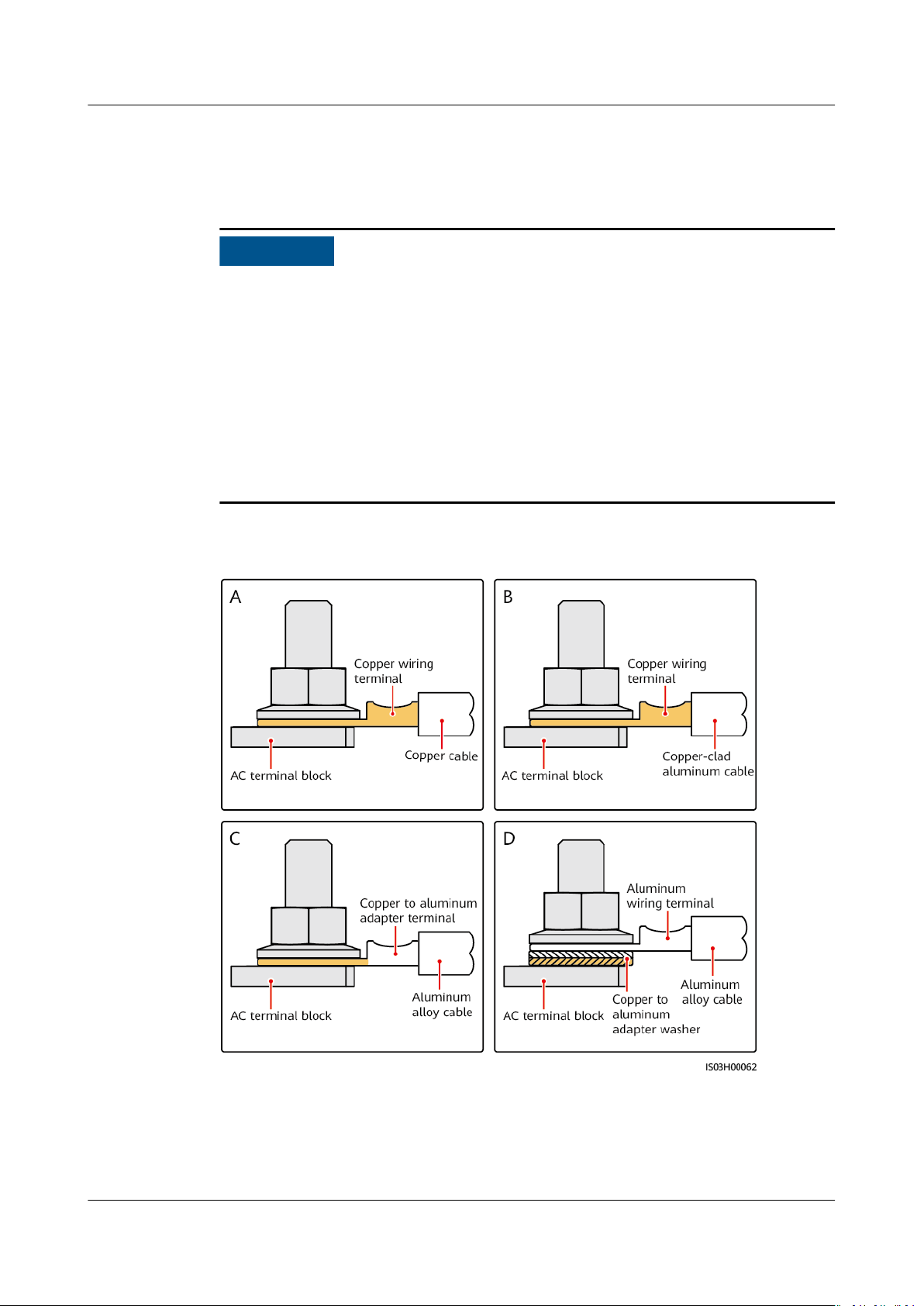

Requirements for the OT or DT Terminal

● If a copper cable is used, use copper wiring terminals.

● If a copper-clad aluminum cable is used, use copper wiring terminals.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 39

NO TICE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

● If an aluminum alloy cable is used, use copper-aluminum transition wiring

terminals, or aluminum wiring terminals along with copper-aluminum

transition spacers.

● Do not connect aluminum wiring terminals to the AC terminal block. Otherwise

the electrochemical corrosion will occur and aect the reliability of cable

connections.

● Comply with the IEC61238-1 requirements when using copper-aluminum

transition wiring terminals, or aluminum wiring terminals along with copperaluminum transition spacers.

● If copper-aluminum transition spacers are used, pay attention to the front and

rear sides. Ensure that the aluminum sides of spacers are in contact with

aluminum wiring terminals, and copper sides of spacers are in contact with the

AC terminal block.

Figure 5-4 Requirements for the OT/DT terminal

Procedure

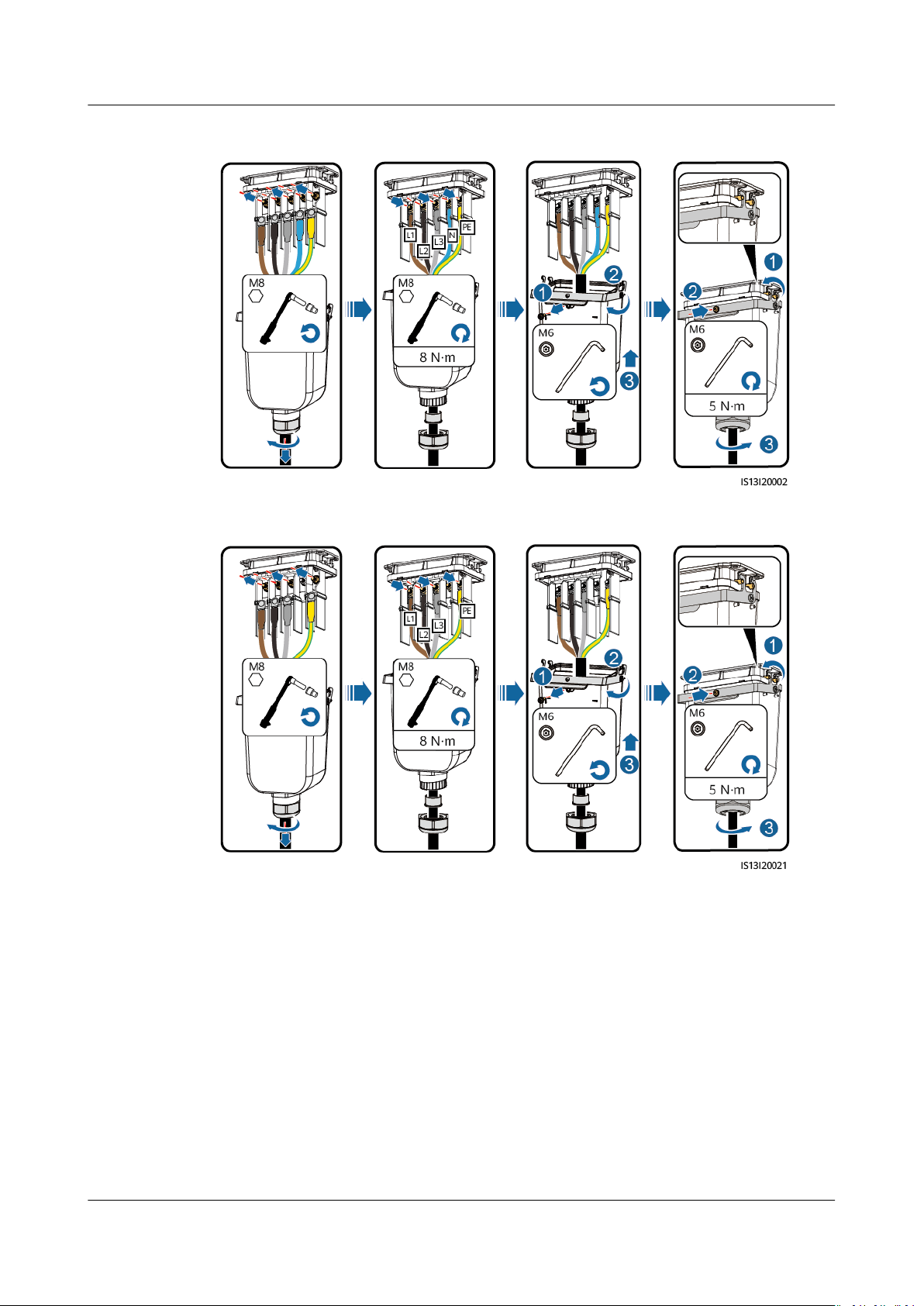

Step 1 Remove the AC terminal box and install partition boards.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 40

NO TE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

Figure 5-5 Removing the AC terminal box

Step 2 Connect the AC output power cable.

● To avoid damaging the rubber liner, do not route a cable with a crimped OT terminal

directly through it.

● It is recommended that the length of the PE cable to be stripped be 15 mm longer than

the length of other cables.

● The cable colors in gures are for reference only. Select appropriate cables according to

the local standards.

Figure 5-6 Stripping the AC power cable (using a ve-core cable as an example)

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 41

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

Figure 5-7 Five-core cable (L1, L2, L3, N, and PE)

Figure 5-8 Four-core cable (L1, L2, L3, and PE)

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 42

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

Figure 5-9 Four-core cable (L1, L2, L3, and N)

Figure 5-10 Three-core cable (L1, L2, and L3)

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 43

D ANGER

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

Figure 5-11 Wiring requirements

----End

5.5 Installing the DC Input Power Cable

5.5.1 Cable Connection Description

Precautions

● Before connecting the DC input power cables, ensure that the DC voltage is

within the safe range (lower than 60 V DC) and that the DC switch on the

SUN2000 is OFF. Failing to do so may result in electric shocks.

● When the SUN2000 is running, it is not allowed to work on the DC input power

cables, such as connecting or disconnecting a PV string or a PV module in a PV

string. Failing to do so may cause electric shocks.

● If no PV string connects to a DC input terminal of the SUN2000, do not remove

the watertight cap from the DC input terminals. Otherwise, the IP rating of the

SUN2000 will be

aected.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 44

WARNING

NO TICE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

Ensure that the following conditions are met. Otherwise, the SUN2000 may be

damaged, or even a re could happen.

● PV modules connected in series in each PV string are of the same specications.

● The DC input voltage of the SUN2000-29.9KTL/30KTL/36KTL/40KTL-M3 shall

not exceed 1100 V DC under any circumstance.

● The DC input voltage of the SUN2000-20KTL-M3 shall not exceed 800 V DC

under any circumstance.

● The polarities of electric connections are correct on the DC input side. The

positive and negative terminals of a PV string connect to corresponding positive

and negative DC input terminals of the SUN2000.

● If polarity of the DC input power cable is reversed and the DC switch is ON, do

not turn

o the DC switch immediately or remove positive and negative

connectors. Wait until the solar irradiance declines at night and the PV string

current reduces to below 0.5 A, and then turn

o the DC switch and remove

the positive and negative connectors. Correct the PV string polarity before

reconnecting the PV string to the SUN2000.

● The SUN2000 does not support power supplies other than PV strings. Since the

output of the PV string connected to the SUN2000 cannot be grounded, ensure

that the PV module output is well insulated to ground.

● During the installation of PV strings and the SUN2000, the positive or negative

terminals of PV strings may be short-circuited to ground if the power cable is

not properly installed or routed. In this case, an AC or DC short circuit may

occur and damage the SUN2000. The caused device damage is not covered

under any warranty.

Figure 5-12 DC input terminals

When the DC input is not fully congured, the DC input terminals must meet the

following requirements:

1. Distribute the DC input power cables evenly over four MPPT circuits, and

connect them preferentially through MPPT1 and MPPT4.

2. Maximize the number of connected MPPT circuits.

Issue 13 (2023-04-28) Copyright © Huawei Technologies Co., Ltd. 45

CA UTION

NO TICE

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)M3

User Manual 5 Electrical Connections

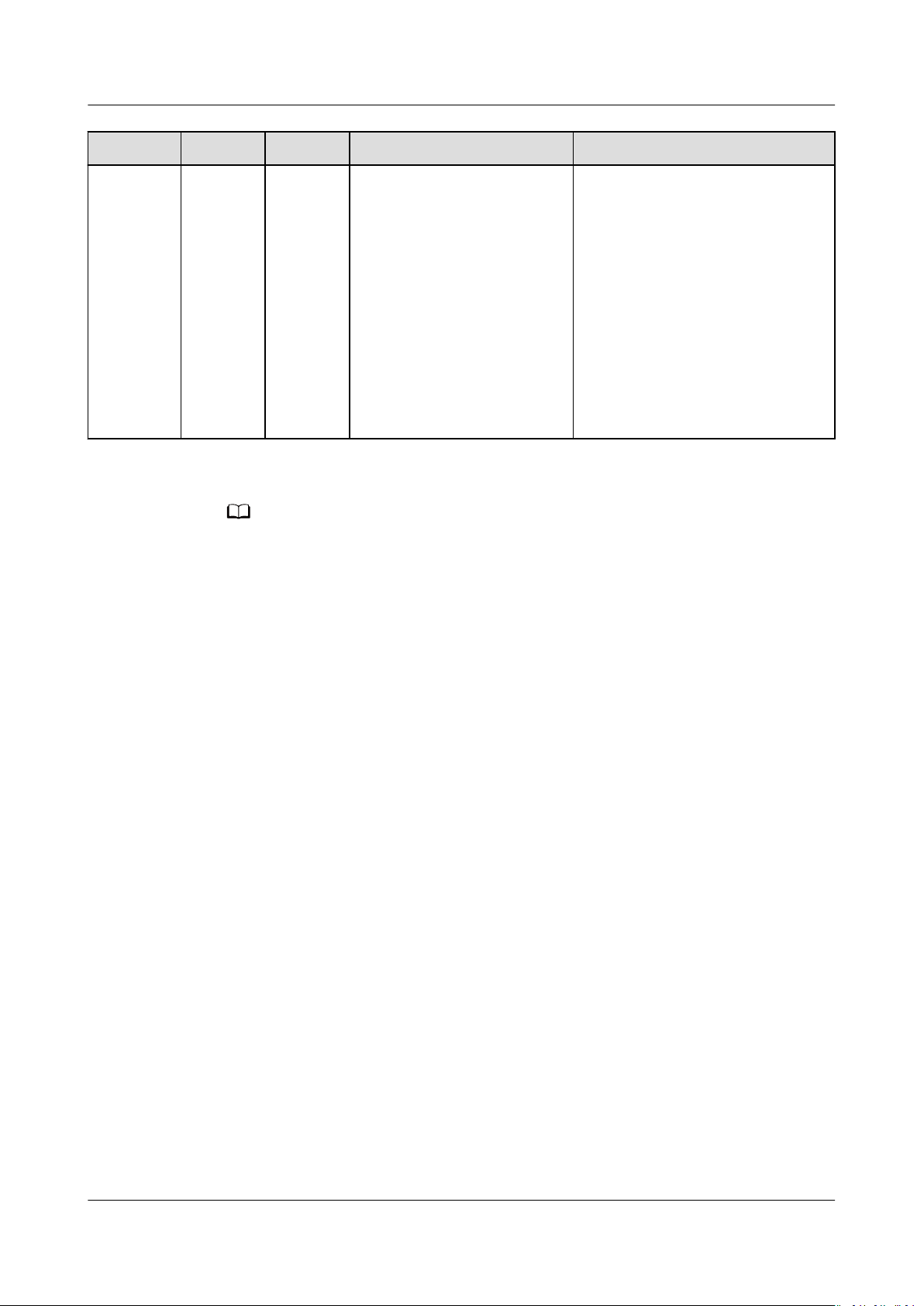

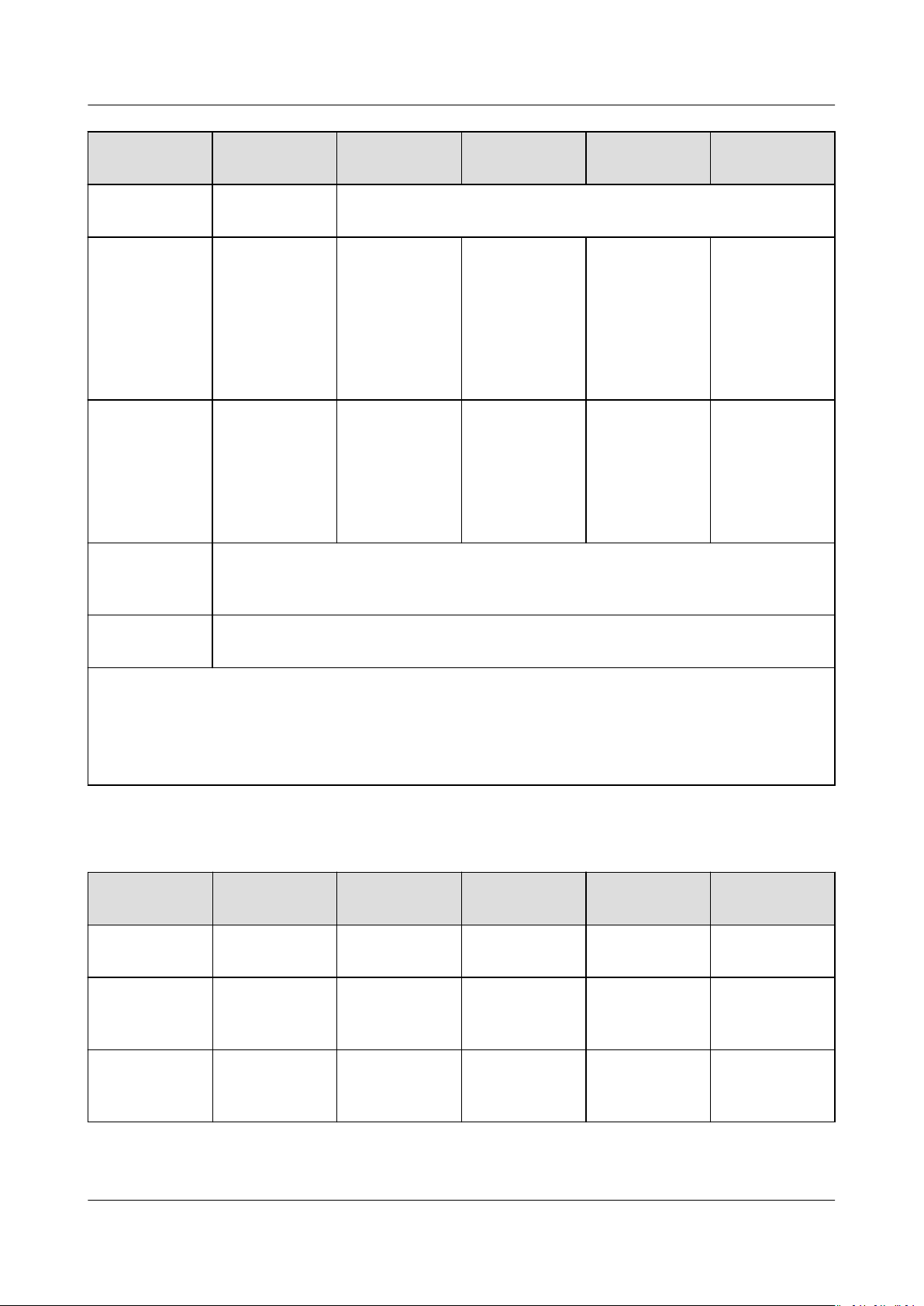

Number

of PV

Strings

1 PV1 2 PV1 and PV7

3 PV1, PV3 and PV7 4 PV1, PV3, PV5 and PV7

5 PV1, PV2, PV3, PV5 and

7 PV1, PV2, PV3, PV4, PV5,

Terminal Selection Number

of PV

Strings

6 PV1, PV2, PV3, PV5, PV7

PV7

8 PV1, PV2, PV3, PV4, PV5,

PV7 and PV8

Terminal Selection

and PV8

PV6, PV7 and PV8

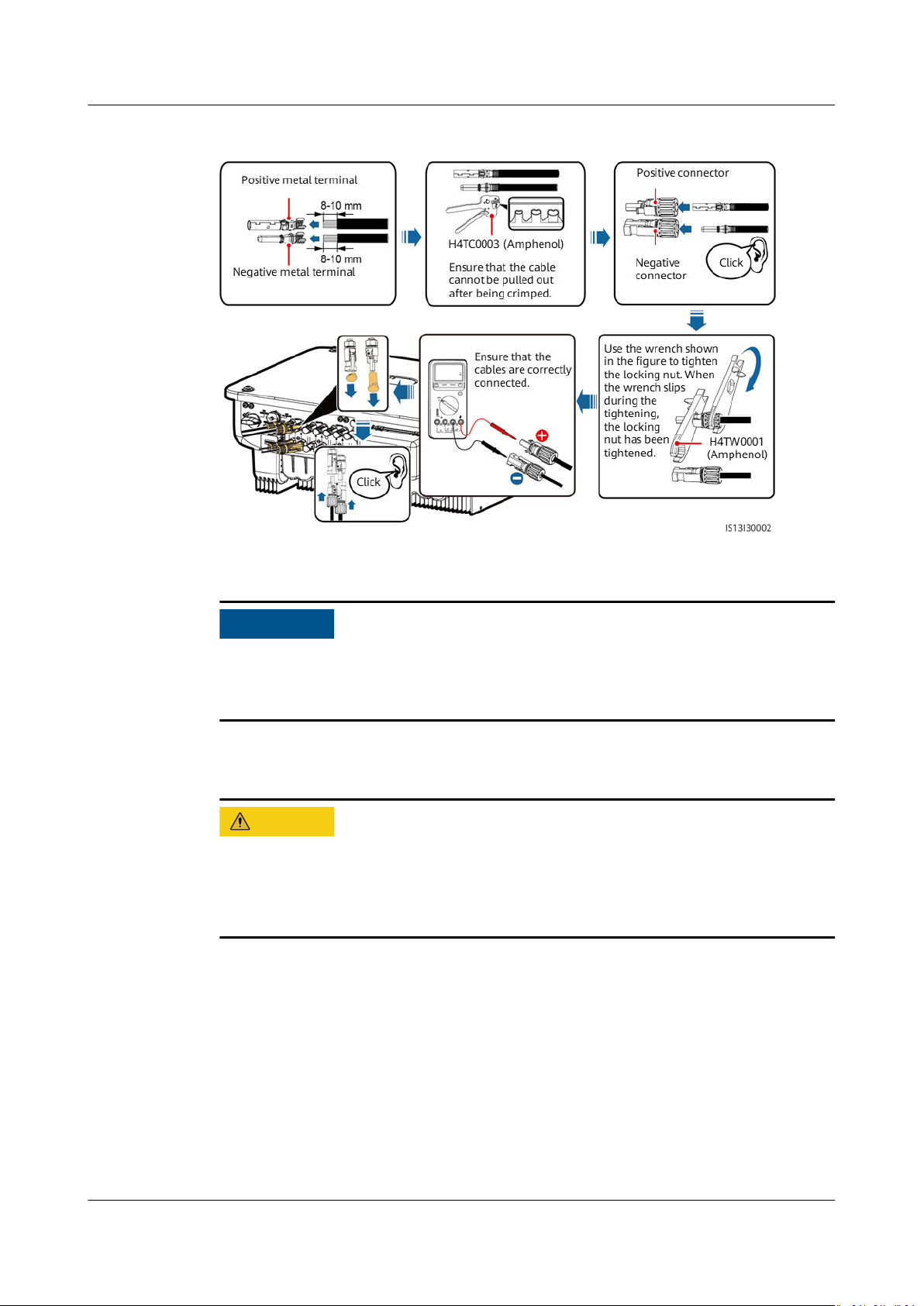

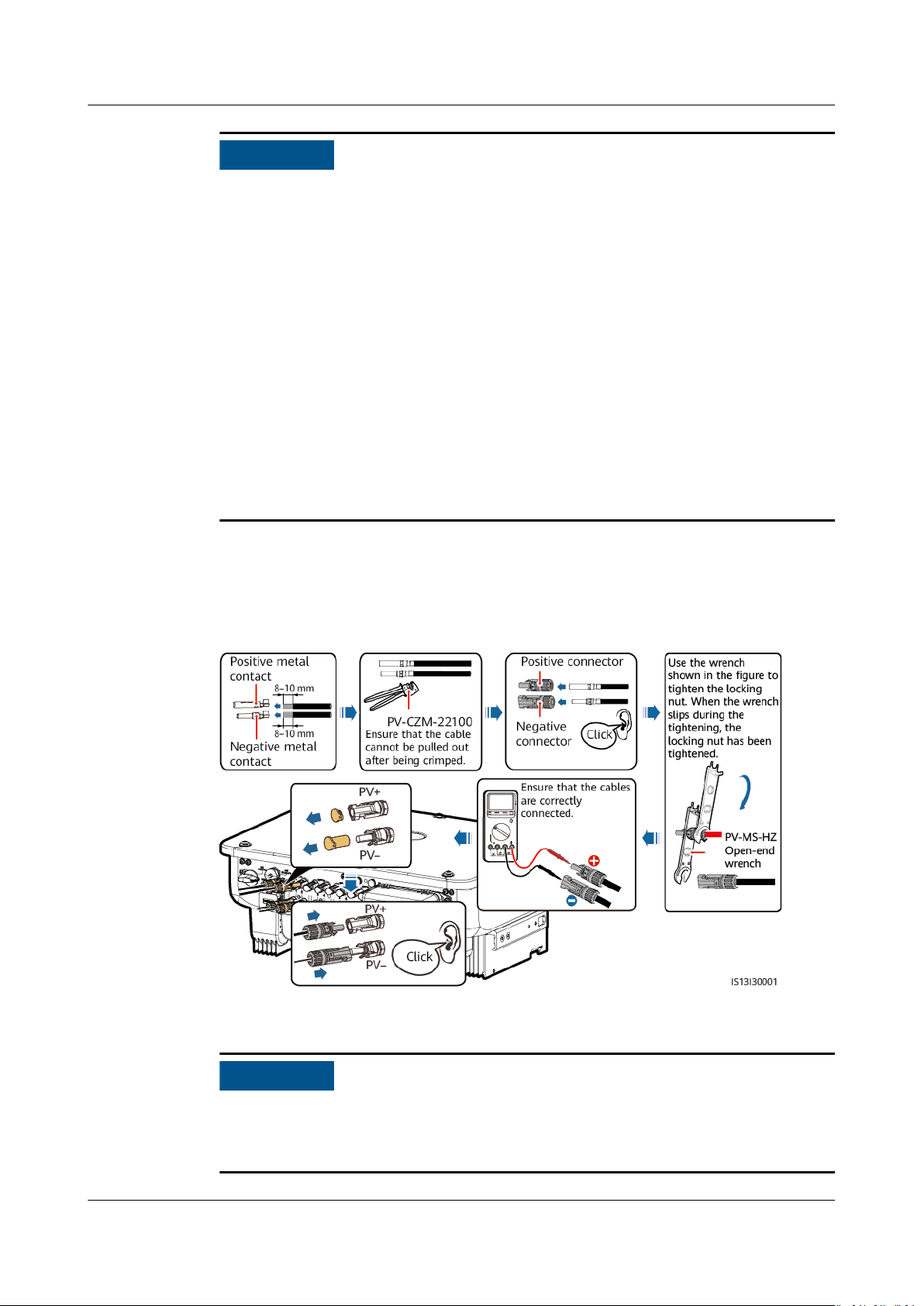

5.5.2 Connecting Cables to Amphenol Helios H4 Connectors

Use the positive and negative Amphenol Helios H4 metal terminals and DC

connectors supplied with the solar inverter. Using incompatible positive and

negative metal terminals and DC connectors may result in serious consequences.

The caused device damage is not covered under any warranty.

Procedure

Step 1 Connect the DC power cable.

● You are advised to use the H4TC0003 (Amphenol) crimping tool and do not use

it with the positioning block. Otherwise, the metal terminals may be damaged.

● The H4TW0001 (Amphenol) open-end wrench is recommended.

● Cables with high rigidity, such as armored cables, are not recommended as DC

input power cables, because poor contact may be caused by the bending of the

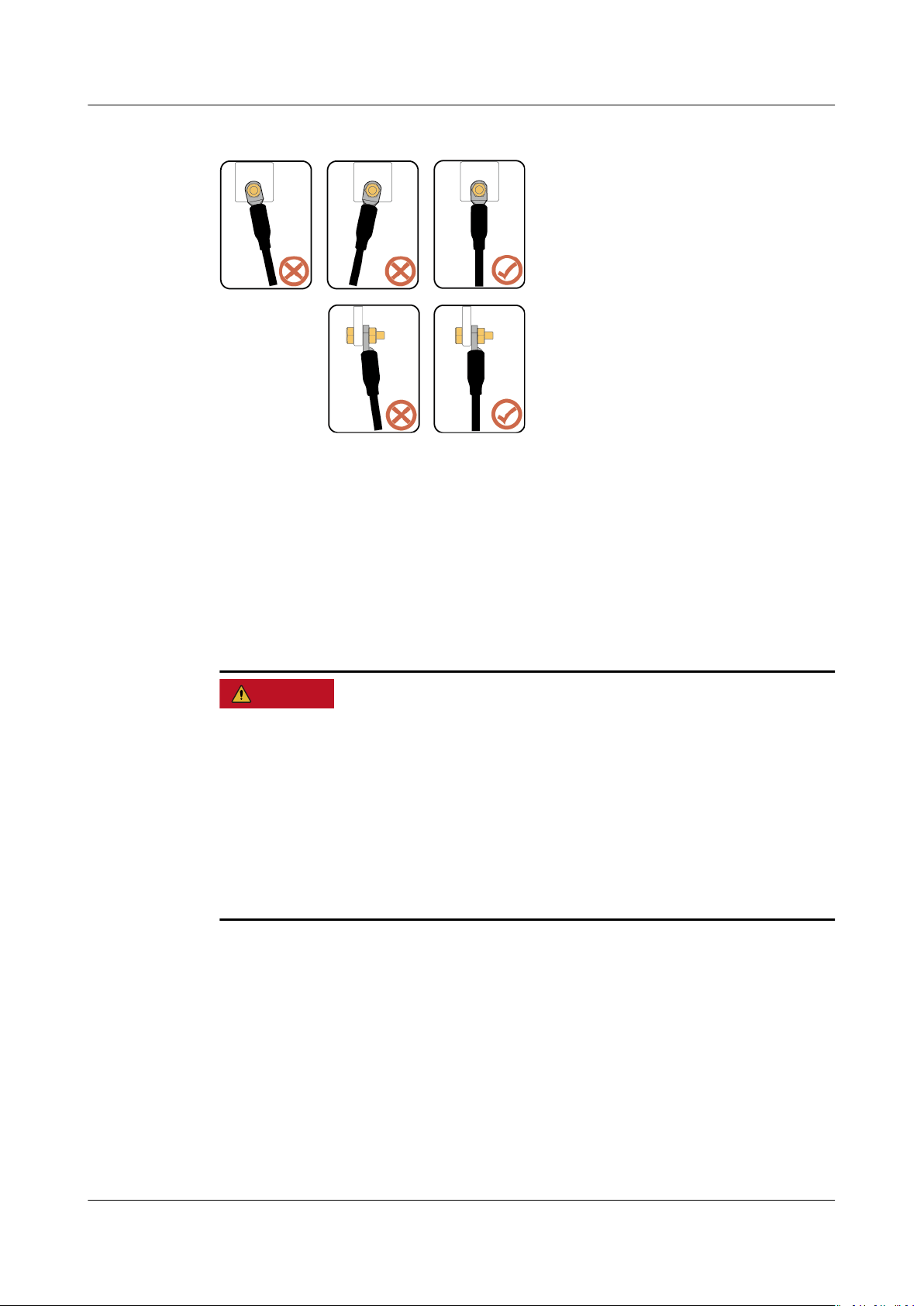

cables.

● Before assembling DC connectors, label the cable polarities correctly to ensure

correct cable connections.

● After the positive and negative connectors snap into place, pull the DC input