SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

Issue

Preliminary Version 3.0

Date

2019-12-08

HUAWEI TECHNOLOGIES CO., LTD.

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

i

Copyright © Huawei Technologies Co., Ltd. 2019. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address:

Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website:

https://e.huawei.com

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

About This Document

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

ii

Overview

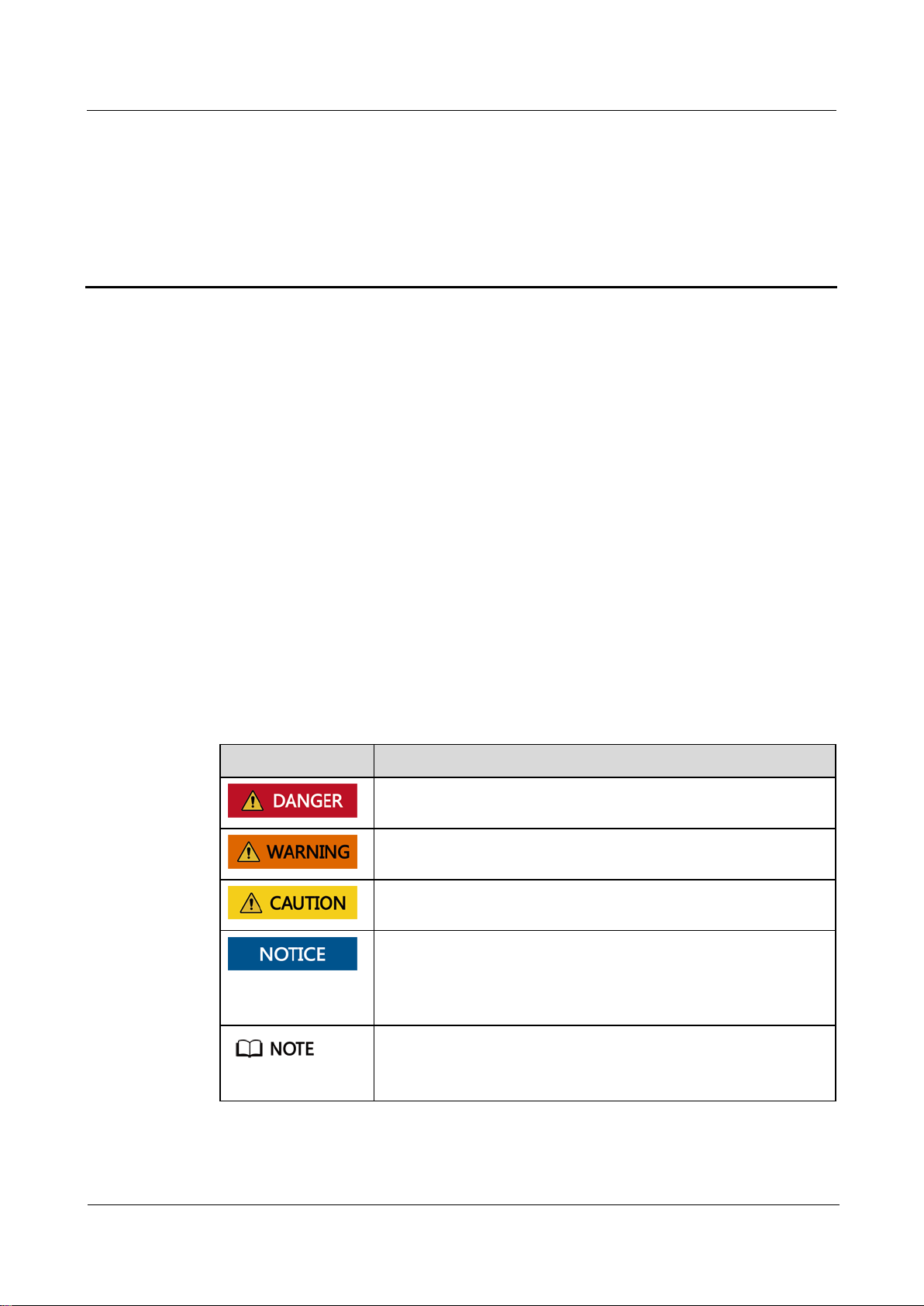

Symbol

Description

Indicates a hazard with a high level of risk which, if not avoided,

will result in death or serious injury.

Indicates a hazard with a medium level of risk which, if not

avoided, could result in death or serious injury.

Indicates a hazard with a low level of risk which, if not avoided,

could result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in equipment damage, data loss, performance

deterioration, or unanticipated results.

NOTICE is used to address practices not related to personal injury.

Supplements the important information in the main text.

NOTE is used to address information not related to personal injury,

equipment damage, and environment deterioration.

This document describes the SUN2000-125KTL-M0, SUN2000-110KTL-M0,

SUN2000-100KTL-M0, SUN2000-100KTL-M1 and SUN2000-100KTL-INM0 (SUN2000

for short) in terms of installation, electrical connection, commissioning, maintenance, and

troubleshooting. Before installing and operating the solar inverter, ensure that you are familiar

with the features, functions, and safety precautions provided in this document.

Intended Audience

About This Document

This document is intended for photovoltaic (PV) plant operating personnel and qualified

electricians.

Symbol Conventions

The symbols that may be found in this document are defined as follows.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

About This Document

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

iii

Change History

Changes between document issues are cumulative. The latest document issue contains all the

changes made in earlier issues.

Issue Preliminary Version 03 (2019-12-08)

Updated 3 Solar Inverter Storage.

Updated 4.5 Installing a Solar Inverter.

Updated 5.2 Preparing Cables.

Updated 5.6 Connecting an AC Output Power Cable.

Updated 5.7 Connecting DC Input Power Cables.

Updated 5.8 Connecting the RS485 Communications Cable.

Updated 7.1.1 App Introduction.

Updated 8.2 Power-Off for Troubleshooting.

Added 8.2 Power-Off for Troubleshooting.

Updated 10 Technical Specifications.

Added A Securing Y-Branch Connectors.

Updated B Grid Code.

Added C Domain Name List of Management Systems.

Issue 02 (2019-08-09)

Added the SUN2000-110KTL-M0, SUN2000-100KTL-M0, SUN2000-100KTL-M1, and

SUN2000-100KTL-INM0 models.

Issue 01 (2019-05-15)

This issue is used for first office application (FOA).

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

Contents

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

iv

Contents

About This Document .................................................................................................................... ii

1 Safety Information ........................................................................................................................ 1

1.1 General Safety .............................................................................................................................................................. 1

1.2 Personnel Requirements ............................................................................................................................................... 2

1.3 Electrical Safety ............................................................................................................................................................ 3

1.4 Installation Environment Requirements ....................................................................................................................... 4

1.5 Mechanical Safety ........................................................................................................................................................ 4

1.6 Commissioning ............................................................................................................................................................. 5

1.7 Maintenance and Replacement ..................................................................................................................................... 5

2 Overview ......................................................................................................................................... 7

2.1 Product Model .............................................................................................................................................................. 7

2.2 Overview ...................................................................................................................................................................... 9

2.3 Label Description ........................................................................................................................................................ 11

2.4 Product Appearance .................................................................................................................................................... 13

2.4.1 Product Appearance ................................................................................................................................................. 13

2.4.2 Indicator Status ........................................................................................................................................................ 15

2.5 Working Principles...................................................................................................................................................... 17

2.5.1 Circuit Diagram ....................................................................................................................................................... 17

2.5.2 Working Modes ........................................................................................................................................................ 19

3 Solar Inverter Storage ................................................................................................................. 22

4 Installation.................................................................................................................................... 24

4.1 Check Before Installation ........................................................................................................................................... 24

4.2 Tools ........................................................................................................................................................................... 24

4.3 Determining the Installation Position ......................................................................................................................... 26

4.4 Installing the Mounting Bracket ................................................................................................................................. 30

4.4.1 Support-mounted Installation .................................................................................................................................. 31

4.4.2 Wall-mounted Installation ........................................................................................................................................ 32

4.5 Installing a Solar Inverter ........................................................................................................................................... 33

5 Electrical Connections ................................................................................................................ 38

5.1 Precautions .................................................................................................................................................................. 38

5.2 Preparing Cables ......................................................................................................................................................... 38

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

Contents

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

v

5.3 Connecting the PE Cable ............................................................................................................................................ 47

5.4 Opening the Maintenance Compartment Door ........................................................................................................... 48

5.5 (Optional) Installing the Power Cable of the Tracking System .................................................................................. 51

5.6 Connecting an AC Output Power Cable ..................................................................................................................... 52

5.7 Connecting DC Input Power Cables ........................................................................................................................... 57

5.8 Connecting the RS485 Communications Cable .......................................................................................................... 63

6 Commissioning............................................................................................................................ 65

6.1 Check Before Power-on .............................................................................................................................................. 65

6.2 Powering On the SUN2000 ........................................................................................................................................ 65

7 Man-Machine Interactions ........................................................................................................ 67

7.1 Operations with the SUN2000 App ............................................................................................................................ 67

7.1.1 App Introduction ...................................................................................................................................................... 67

7.1.2 Downloading and Installing the App ....................................................................................................................... 71

7.1.3 App Login ................................................................................................................................................................ 71

7.1.4 Operations Related to the Common User ................................................................................................................ 74

7.1.4.1 Setting User Parameters ........................................................................................................................................ 74

7.1.4.2 Starting and Shutting Down the SUN2000 ........................................................................................................... 75

7.1.5 Operations Related to the Advanced User ............................................................................................................... 75

7.1.5.1 Parameter Settings ................................................................................................................................................ 75

7.1.5.1.1 Setting Grid Parameters ..................................................................................................................................... 75

7.1.5.1.2 Setting Protection Parameters ............................................................................................................................ 76

7.1.5.1.3 Setting Feature Parameters ................................................................................................................................ 76

7.1.5.1.4 Setting User Parameters ..................................................................................................................................... 81

7.1.5.1.5 Setting the Grid-tied Control Parameters ........................................................................................................... 82

7.1.5.1.6 Setting Communications Parameters ................................................................................................................. 84

7.1.5.1.7 Setting the Tracking System .............................................................................................................................. 86

7.1.5.1.8 Setting a File Save Path ..................................................................................................................................... 88

7.1.5.1.9 Configuring a PV Plant ...................................................................................................................................... 88

7.1.5.2 System Maintenance ............................................................................................................................................. 91

7.1.5.2.1 Device inspection ............................................................................................................................................... 91

7.1.5.2.2 Managing the License ........................................................................................................................................ 91

7.1.5.2.3 Device management ........................................................................................................................................... 92

7.1.5.2.4 PV String Access Detection ............................................................................................................................... 93

7.1.5.2.5 Starting and Shutting Down the SUN2000 ........................................................................................................ 95

7.1.5.2.6 Restoring Factory Settings ................................................................................................................................. 95

7.1.5.2.7 Resetting the SUN2000 ..................................................................................................................................... 95

7.1.5.2.8 Resetting Alarms ................................................................................................................................................ 96

7.1.5.2.9 Clearing Historical Energy Yield Data............................................................................................................... 96

7.1.5.2.10 Importing and Exporting Configuration Files .................................................................................................. 96

7.1.5.3 Device upgrade ..................................................................................................................................................... 96

7.1.5.4 Device Logs .......................................................................................................................................................... 98

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

Contents

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

vi

7.1.6 Operations Related to the Special User.................................................................................................................... 98

7.1.6.1 Parameter Settings ................................................................................................................................................ 98

7.1.6.1.1 Setting Grid Parameters ..................................................................................................................................... 98

7.1.6.1.2 Setting Protection Parameters .......................................................................................................................... 100

7.1.6.1.3 Setting Feature Parameters .............................................................................................................................. 102

7.1.6.1.4 Setting the Grid-tied Control Parameters ......................................................................................................... 104

7.1.6.1.5 Setting Power Adjustment Parameters ............................................................................................................. 106

7.1.6.1.6 Setting Reactive Power Control ....................................................................................................................... 109

7.1.6.1.7 Setting User Parameters ................................................................................................................................... 109

7.1.6.1.8 Setting a File Save Path ................................................................................................................................... 110

7.1.6.2 System Maintenance ........................................................................................................................................... 110

7.1.6.2.1 Device management ................................................................ ................................................................ ......... 110

7.1.6.2.2 Starting and Shutting Down the SUN2000 ...................................................................................................... 111

7.1.6.2.3 Restoring Factory Settings ............................................................................................................................... 112

7.1.6.3 Device upgrade ................................................................................................................................................... 112

7.1.6.4 Device Logs ........................................................................................................................................................ 114

7.1.7 Querying the Status ................................................................................................................................................ 114

7.1.7.1 Querying Alarm Records .................................................................................................................................... 114

7.1.7.2 Querying SUN2000 Running Information .......................................................................................................... 115

7.1.7.3 Querying Energy Yield Data ............................................................................................................................... 117

7.1.7.4 Viewing System Version Information ................................................................................................................. 117

7.1.8 Tool Kit .................................................................................................................................................................. 118

7.1.8.1 Scanning SN Bar Codes ...................................................................................................................................... 118

7.1.8.2 SUN2000 Maintenance Script ............................................................................................................................ 120

7.1.8.3 File Manager ....................................................................................................................................................... 121

7.1.8.4 Changing the WLAN password .......................................................................................................................... 121

7.1.8.5 About .................................................................................................................................................................. 122

7.2 (Optional) Installing a Smart Dongle ........................................................................................................................ 122

7.3 Operations with a USB Flash Drive.......................................................................................................................... 123

7.3.1 Exporting Configurations ...................................................................................................................................... 123

7.3.2 Importing Configurations ...................................................................................................................................... 125

7.3.3 Exporting Data ....................................................................................................................................................... 126

7.3.4 Upgrading .............................................................................................................................................................. 127

8 Maintenance ............................................................................................................................... 129

8.1 Shutdown and Power-Off ......................................................................................................................................... 129

8.2 Power-Off for Troubleshooting ................................................................................................................................. 129

8.3 Routine Maintenance ................................................................................................ ................................ ................ 131

8.4 Troubleshooting ........................................................................................................................................................ 132

8.5 Replacing a Fan ........................................................................................................................................................ 140

9 Handling the Inverter ............................................................................................................... 145

9.1 Removing the SUN2000 ........................................................................................................................................... 145

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

Contents

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

vii

9.2 Packing the SUN2000 ............................................................................................................................................... 145

9.3 Disposing of the SUN2000 ................................................................................................................................ ....... 145

10 Technical Specifications ........................................................................................................ 146

A Securing Y-Branch Connectors .............................................................................................. 151

B Grid Code ................................................................................................................................... 154

C Domain Name List of Management Systems ..................................................................... 160

D DRM Configuration Guide for Standard As NZS4777.2 ................................................. 161

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

1 Safety Information

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

1

1.1 General Safety

Statement

Before installing, operating, and maintaining the equipment, read this document and observe

all the safety instructions on the equipment and in this document.

1 Safety Information

The "NOTICE", "CAUTION", "WARNING", and "DANGER" statements in this document

do not cover all the safety instructions. They are only supplements to the safety instructions.

Huawei will not be liable for any consequence caused by the violation of general safety

requirements or design, production, and usage safety standards.

Ensure that the equipment is used in environments that meet its design specifications.

Otherwise, the equipment may become faulty, and the resulting equipment malfunction,

component damage, personal injuries, or property damage are not covered under the warranty.

Follow local laws and regulations when installing, operating, or maintaining the equipment.

The safety instructions in this document are only supplements to local laws and regulations.

Huawei will not be liable for any consequences of the following circumstances:

Operation beyond the conditions specified in this document

Installation or use in environments which are not specified in relevant international or

national standards

Unauthorized modifications to the product or software code or removal of the product

Failure to follow the operation instructions and safety precautions on the product and in

this document

Equipment damage due to force majeure, such as earthquakes, fire, and storms

Damage caused during transportation by the customer

Storage conditions that do not meet the requirements specified in this document

General Requirements

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

1 Safety Information

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

2

Do not work with power on during installation.

Do not install, use, or operate outdoor equipment and cables (including but not limited to

moving equipment, operating equipment and cables, inserting connectors to or removing

connectors from signal ports connected to outdoor facilities, working at heights, and

performing outdoor installation) in harsh weather conditions such as lightning, rain,

snow, and level 6 or stronger wind.

After installing the equipment, remove idle packing materials such as cartons, foam,

plastics, and cable ties from the equipment area.

In the case of a fire, immediately leave the building or the equipment area, and turn on

the fire alarm bell or make an emergency call. Do not enter the building on fire in any

case.

Do not scrawl, damage, or block any warning label on the equipment.

Tighten the screws using tools when installing the equipment.

Understand the components and functioning of a grid-tied PV power system and relevant

local standards.

Repaint any paint scratches caused during equipment transportation or installation in a

timely manner. Equipment with scratches cannot be exposed to an outdoor environment

for a long period of time.

Do not open the host panel of the equipment.

Personal Safety

If there is a probability of personal injury or equipment damage during operations on the

equipment, immediately stop the operations, report the case to the supervisor, and take

feasible protective measures.

Use tools correctly to avoid hurting people or damaging the equipment.

Do not touch the energized equipment, as the enclosure is hot.

1.2 Personnel Requirements

Personnel who plan to install or maintain Huawei equipment must receive thorough

training, understand all necessary safety precautions, and be able to correctly perform all

operations.

Only qualified professionals or trained personnel are allowed to install, operate, and

maintain the equipment.

Only qualified professionals are allowed to remove safety facilities and inspect the

equipment.

Personnel who will operate the equipment, including operators, trained personnel, and

professionals, should possess the local national required qualifications in special

operations such as high-voltage operations, working at heights, and operations of special

equipment.

Only professionals or authorized personnel are allowed to replace the equipment or

components (including software).

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

1 Safety Information

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

3

Professionals: personnel who are trained or experienced in equipment operations and are clear of the

sources and degree of various potential hazards in equipment installation, operation, and

maintenance

Trained personnel: personnel who are technically trained, have required experience, are aware of

possible hazards on themselves in certain operations, and are able to take protective measures to

minimize the hazards on themselves and other people

Operators: operation personnel who may come in contact with the equipment, except trained

personnel and professionals

1.3 Electrical Safety

Grounding

For the equipment that needs to be grounded, install the ground cable first when

installing the equipment and remove the ground cable last when removing the

equipment.

Do not damage the ground conductor.

Do not operate the equipment in the absence of a properly installed ground conductor.

Ensure that the equipment is connected permanently to the protective ground. Before

operating the equipment, check its electrical connection to ensure that it is securely

grounded.

General Requirements

Before connecting cables, ensure that the equipment is intact. Otherwise, electric shocks or

fire may occur.

Ensure that all electrical connections comply with local electrical standards.

Obtain approval from the local electric utility company before using the equipment in

grid-tied mode.

Ensure that the cables you prepared meet local regulations.

Use dedicated insulated tools when performing high-voltage operations.

AC and DC Power

Do not connect or disconnect power cables with power on. Transient contact between the core

of the power cable and the conductor will generate electric arcs or sparks, which may cause

fire or personal injury.

Before making electrical connections, switch off the disconnector on the upstream device

to cut off the power supply if people may contact energized components.

Before connecting a power cable, check that the label on the power cable is correct.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

1 Safety Information

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

4

If the equipment has multiple inputs, disconnect all the inputs before operating the

equipment.

Cabling

When routing cables, ensure that a distance of at least 30 mm exists between the cables

and heat-generating components or areas. This prevents damage to the insulation layer of

the cables.

Bind cables of the same type together. When routing cables of different types, ensure that

they are at least 30 mm away from each other.

Ensure that the cables used in a grid-tied PV power system are properly connected and

insulated and meet specifications.

1.4 Installation Environment Requirements

Ensure that the equipment is installed in a well ventilated environment.

To prevent fire due to high temperature, ensure that the ventilation vents or heat

dissipation system are not blocked when the equipment is running.

Do not expose the equipment to flammable or explosive gas or smoke. Do not perform

any operation on the equipment in such environments.

1.5 Mechanical Safety

Using Ladders

Use wooden or fiberglass ladders when you need to perform live working at heights.

When a step ladder is used, ensure that the pull ropes are secured and the ladder is held

firm.

Before using a ladder, check that it is intact and confirm its load bearing capacity. Do not

overload it.

Ensure that the wider end of the ladder is at the bottom, or protective measures have

been taken at the bottom to prevent the ladder from sliding.

Ensure that the ladder is securely positioned. The recommended angle for a ladder

against the floor is 75 degrees, as shown in the following figure. An angle rule can be

used to measure the angle.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

1 Safety Information

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

5

When climbing a ladder, take the following precautions to reduce risks and ensure

safety:

Keep your body steady.

Do not climb higher than the fourth rung of the ladder from the top.

Ensure that your body's center of gravity does not shift outside the legs of the ladder.

Drilling Holes

When drilling holes into a wall or floor, observe the following safety precautions: Wear

goggles and protective gloves when drilling holes.

When drilling holes, protect the equipment from shavings. After drilling, clean up any

shavings that have accumulated inside or outside the equipment.

Moving Heavy Objects

Be cautious to avoid injury when moving heavy objects.

When moving the equipment by hand, wear protective gloves to prevent injuries.

1.6 Commissioning

When the equipment is powered on for the first time, ensure that professional personnel set

parameters correctly. Incorrect settings may result in inconsistency with local certification and

affect the normal operation of the equipment.

1.7 Maintenance and Replacement

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

1 Safety Information

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

6

High voltage generated by the equipment during operation may cause an electric shock, which

could result in death, serious injury, or serious property damage. Prior to maintenance, power

off the equipment and strictly comply with the safety precautions in this document and

relevant documents.

Maintain the equipment with sufficient knowledge of this document and using proper

tools and testing equipment.

Before maintaining the equipment, power it off and follow the instructions on the

delayed discharge label to ensure that the equipment is powered off.

Place temporary warning signs or erect fences to prevent unauthorized access to the

maintenance site.

If the equipment is faulty, contact your dealer.

The equipment can be powered on only after all faults are rectified. Failing to do so may

escalate faults or damage the equipment.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

7

2.1 Product Model

No.

Description

Value

1

Series

SUN2000: grid-tied solar inverter

Model Description

2 Overview

The SUN2000-125KTL-M0, SUN2000-110KTL-M0, and SUN2000-100KTL-M0 are

applicable only to the Chinese mainland. For other countries or regions, Huawei does not

provide quality assurance.

This document covers the following product models:

SUN2000-125KTL-M0

SUN2000-110KTL-M0

SUN2000-100KTL-M0

SUN2000-100KTL-M1

SUN2000-100KTL-INM0

Figure 2-1 Model

Table 2-1 Model description

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

8

No.

Description

Value

2

Power 125K: The power level is 125 kW.

110K: The power level is 110 kW.

100K: The power level is 100 kW.

3

Topology

TL: transformerless

4

Region

IN: India

5

Design code

M0 and M1: product series with an input voltage level of

1100 V DC

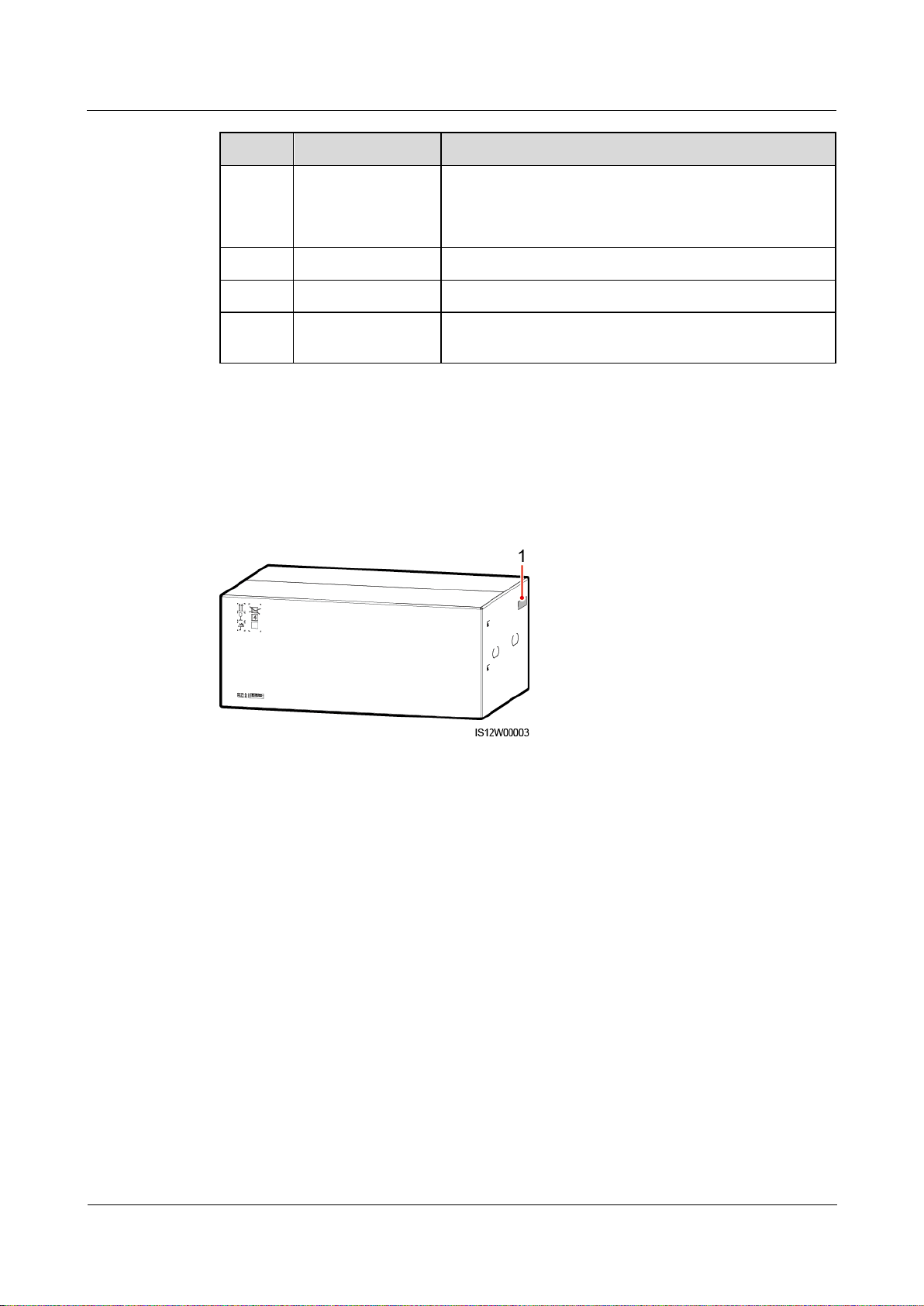

(1) Position of the model label

Model Identification

You can obtain the solar inverter model from the model label on the external package and the

nameplate on the side of the enclosure.

Figure 2-2 Position of the model label on the external package

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

9

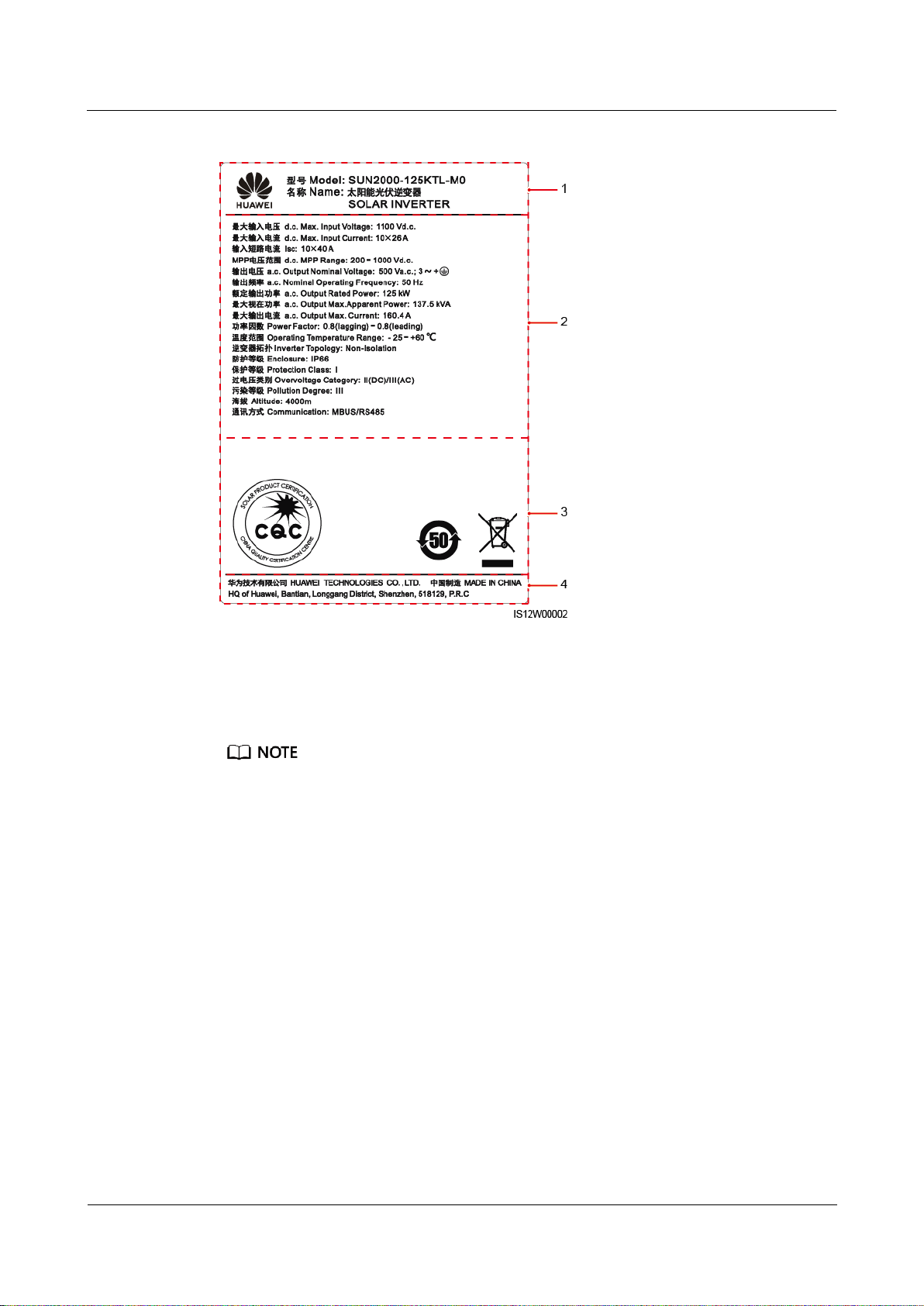

Figure 2-3 Nameplate

(1) Trademark and product model

(2) Key technical specifications

(3) Compliance symbols

(4) Company name and country of origin

The nameplate figure is for reference only.

2.2 Overview

Description

SUN2000 solar inverters are grid-tied PV string inverters that convert the DC power

generated by PV strings into AC power and feed the power into the power grid.

Characteristics

Smart

Ten independent maximum power point tracking (MPPT) circuits and 20 PV string

inputs. Flexible configuration of PV strings is supported.

Smart PV module self-learning: Automatically detects PV module failures, helping

rectify faults. Optimizes the working mode to obtain the optimal working mode of the

system.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

10

Networking

(1) PV string

(2) SUN2000

(3) AC combiner box

(4) Transformer station

(5) Power grid

Smart air cooling: Adjusts the fan speed based on the ambient temperature and load to

ensure the service life of fans and avoid frequent maintenance.

MBUS networking: Uses the existing power line for communication and does not require

additional communications cable, which reduces the construction and maintenance costs

and improves communication reliability and efficiency.

Smart I-V curve diagnosis: Implements I-V scanning and health diagnosis for PV strings.

In this way, potential risks and faults can be detected in time, improving the plant

operation & maintenance (O&M) quality.

Safe

Embedded DC and AC surge protection devices (SPDs): all-dimensional surge protection

Embedded residual current monitoring unit: Immediately disconnects from the power

grid upon detecting that the residual current exceeds the threshold.

SUN2000 solar inverters apply to grid-tied systems of large-scale PV plants and commercial

distributed grid-tied systems. Typically, a grid-tied PV system consists of the PV string, solar

inverter, AC combiner box, and transformer station.

Figure 2-4 Networking

The SUN2000-125KTL-M0 is powered by a dedicated power transformer instead of connecting to

low-voltage overhead power lines.

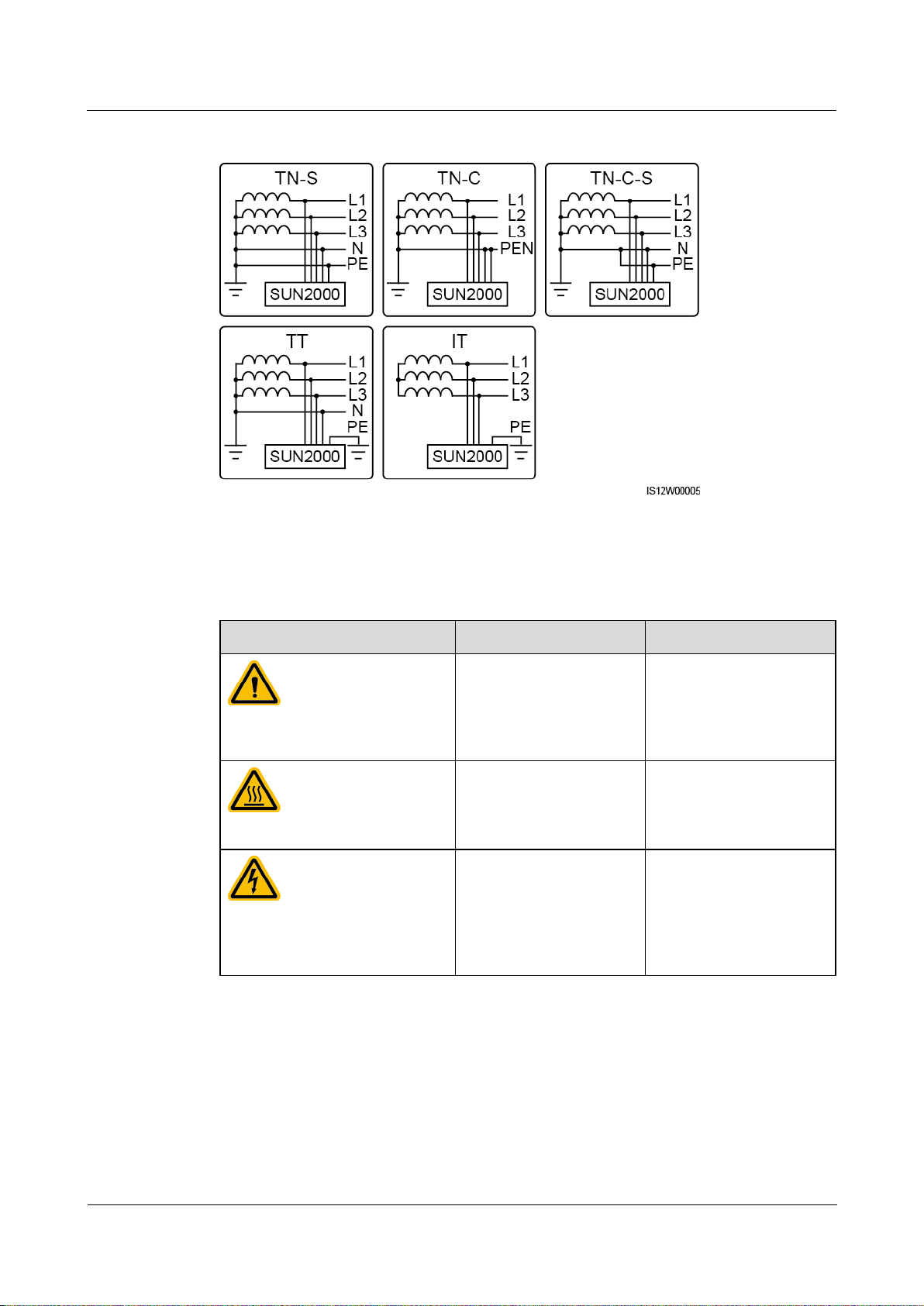

Supported Power Grids

SUN2000-110KTL-M0, SUN2000-100KTL-M0, SUN2000-100KTL-M1 and

SUN2000-100KTL-INM0 solar inverters support the TN-S, TN-C, TN-C-S, TT, and IT

power grids.

The SUN2000-125KTL-M0 supports only the IT power grid.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

11

Figure 2-5 Supported Power Grids

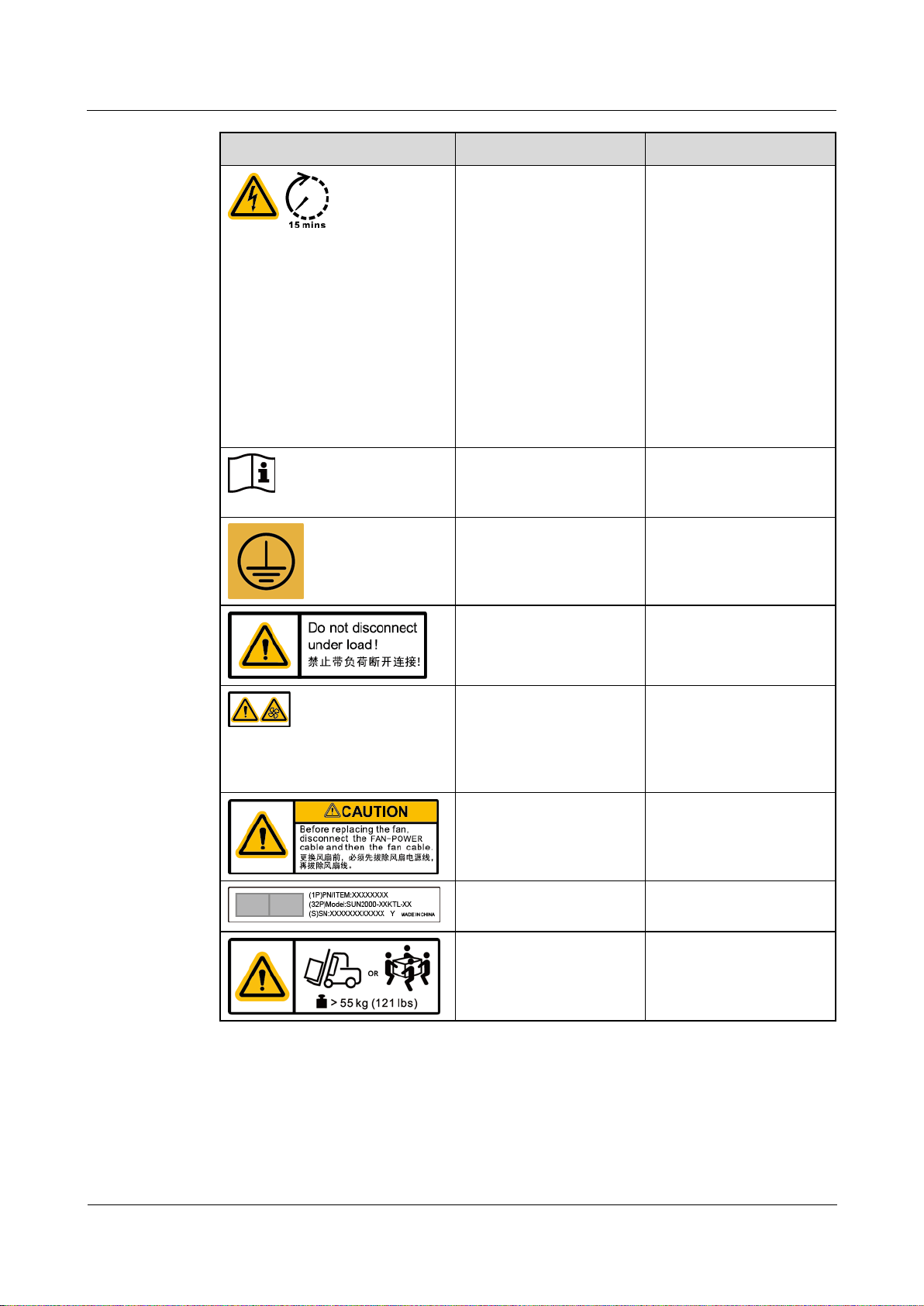

Symbol

Name

Meaning

Running warning

Potential hazards exist

after the inverter is

powered on. Take

protective measures when

operating the inverter.

Burn warning

Do not touch a running

inverter, as the shell

becomes hot during

operation.

Large current warning

Before powering on the

inverter, ensure that the

inverter is grounded

because there is a large

contact current after the

inverter is powered on.

2.3 Label Description

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

12

Symbol

Name

Meaning

Delayed discharge

High voltage exists

after the inverter is

powered on. Only

qualified and trained

electrical technicians

are allowed to perform

operations on the

inverter.

Residual voltage exists

after the inverter is

powered off. It takes

15 minutes for the

inverter to discharge to

the safe voltage.

Refer to documentation

Reminds operators to

refer to the documents

shipped with the inverter.

Grounding

Indicates the position for

connecting the protective

earthing (PE) cable.

Operation warning

Do not remove the DC

input connector when the

inverter is running.

Fan operation warning

High voltage exists after

the inverter is powered

on. Do not touch the fans

when the inverter is

working.

Fan replacement warning

Before replacing a fan,

disconnect its power

connectors.

Inverter ESN label

Indicates the inverter

serial number.

Weight label

The inverter needs to be

carried by four persons or

using a pallet truck.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

13

2.4 Product Appearance

(1) Panel

(2) LED indicators

(3) Maintenance compartment

door

(4) Mounting bracket

(5) External fan tray

(6) DC input terminal group 1 (PV1–PV8, controlled by

DC SWITCH 1)

(7) DC switch 1 (DC SWITCH

1)

(8) DC input terminal group 2 (PV9–PV14, controlled by

DC SWITCH 2)

(9) DC switch 2 (DC SWITCH

2)

(10) DC input terminal group 3 (PV15–PV20, controlled

by DC SWITCH 3)

(11) DC switch 3 (DC

SWITCH 3)

(12) Ventilation valve

(13) USB port (USB)

(14) Communications port (COM)

(15) Hole for the AC output

power cable

(16) Hole for the tracking system power cable

2.4.1 Product Appearance

Appearance

Figure 2-6 Appearance

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

14

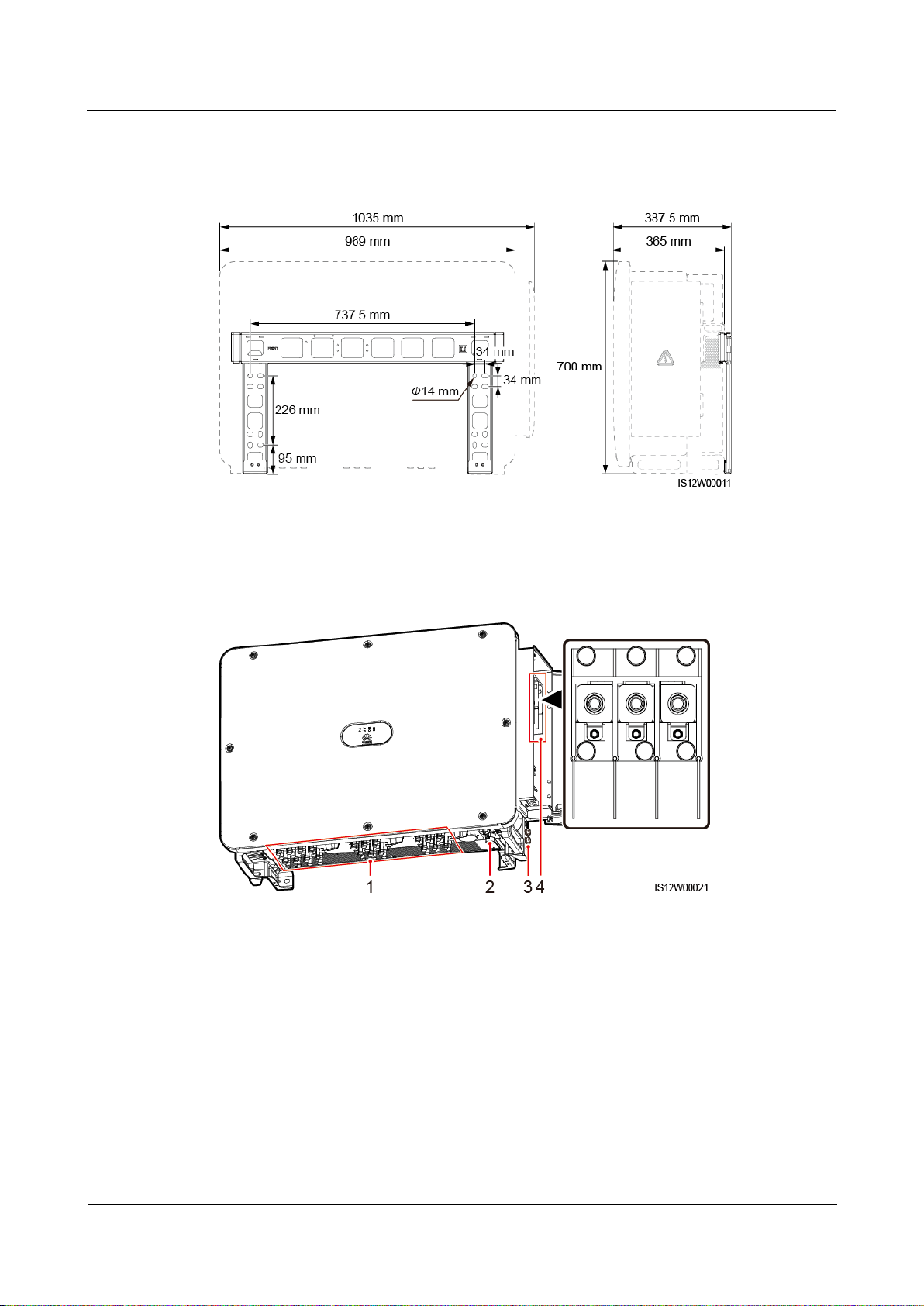

Dimensions

(1) DC input terminals

(2) RS485 port

(3) Ground point on the enclosure

(4) AC terminal block (3-pin)

Wiring Area

Figure 2-7 Dimensions

Figure 2-8 Wiring port of a 3-pin model (SUN2000-125KTL-M0)

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

15

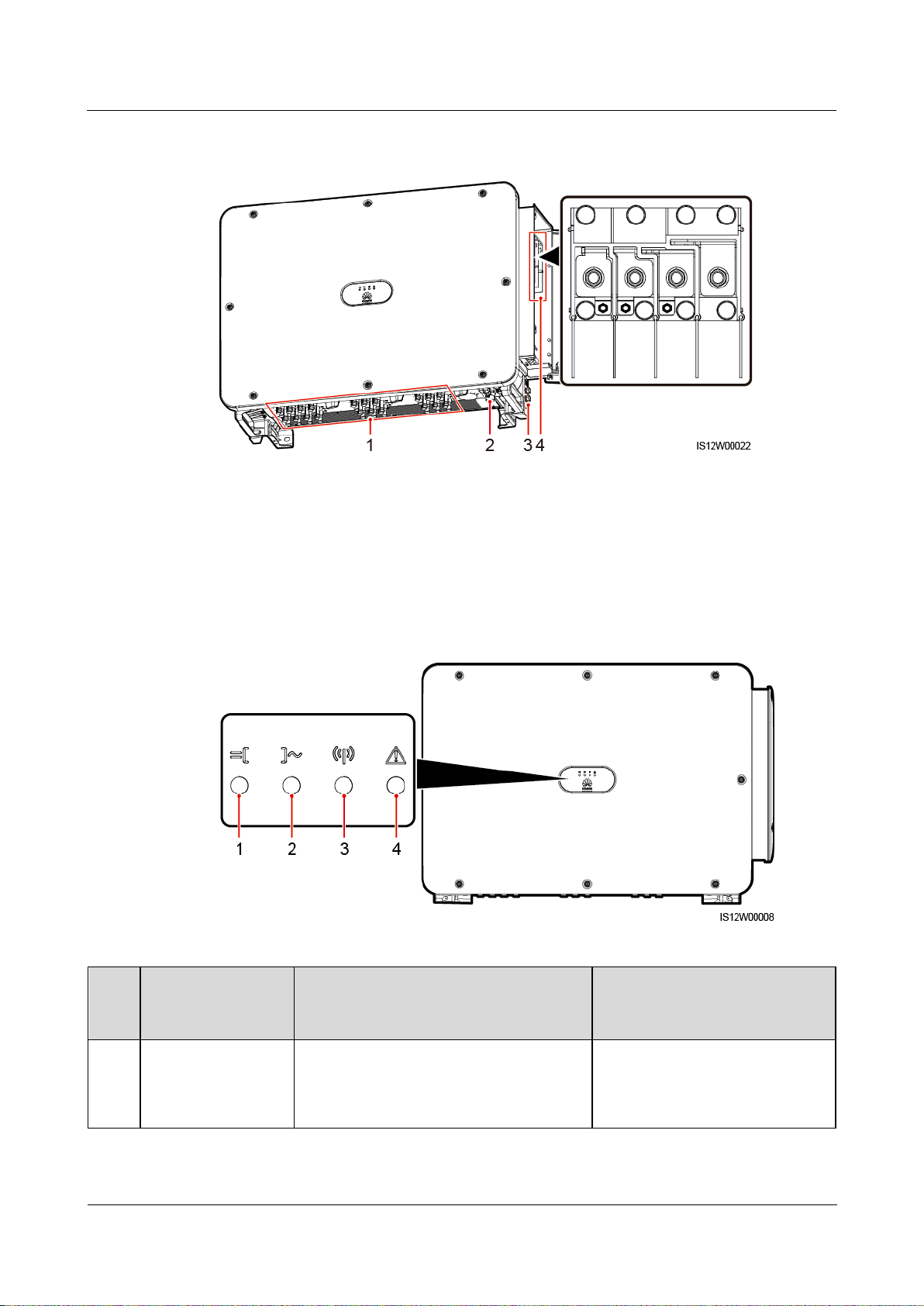

Figure 2-9 Wiring port of 4-pin models (SUN2000-110KTL-M0, SUN2000-100KTL-M0,

(1) DC input terminals

(2) RS485 port

(3) Ground point on the enclosure

(4) AC terminal block (4-pin)

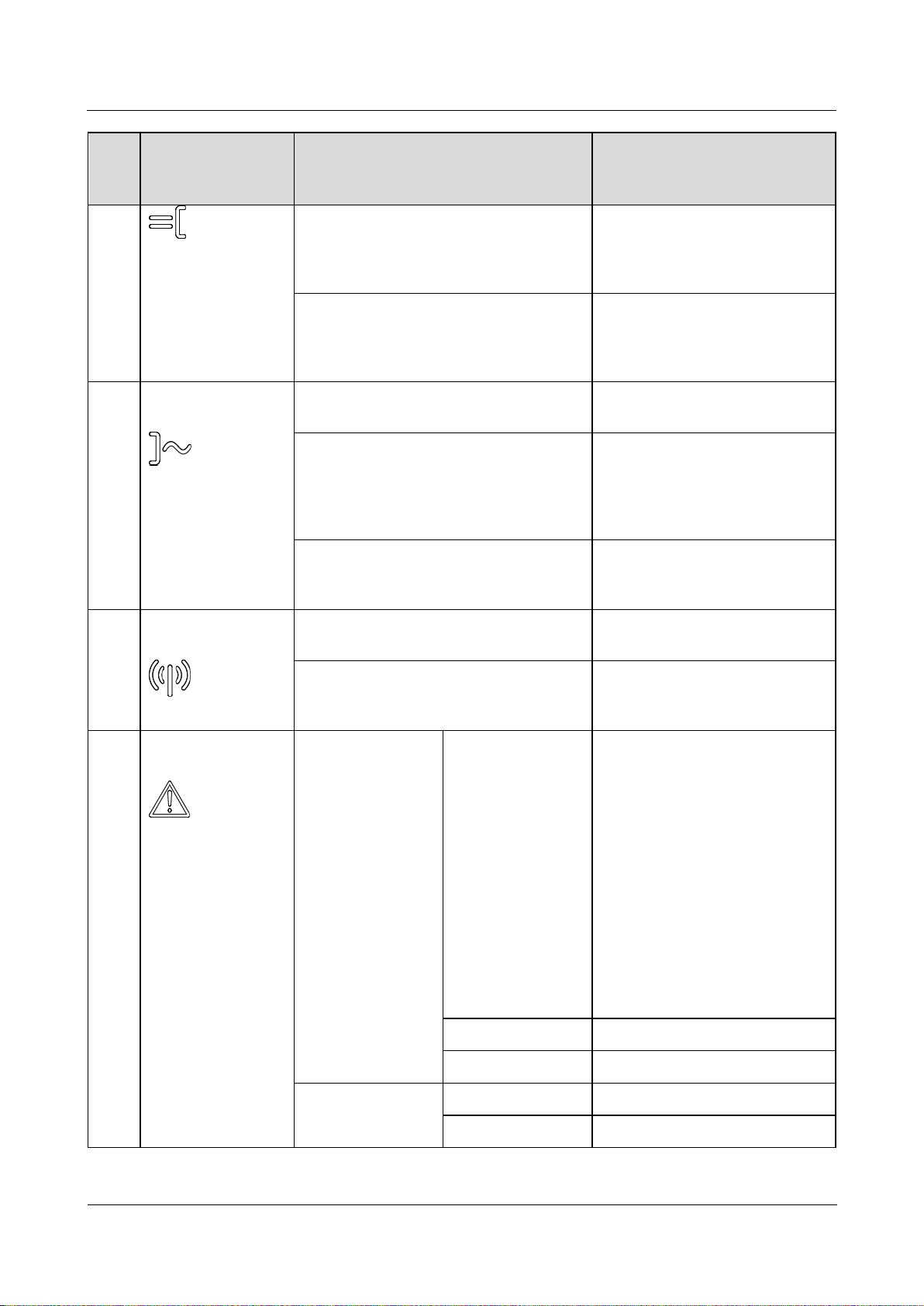

No.

Indicator

Status (Blinking Fast: On for 0.2s and

then Off for 0.2s; Blinking Slowly:

On for 1s and then Off for 1s)

Description

1

PV connection

indicator

Steady green

At least one PV string is properly

connected, and the DC input

voltage of the corresponding

MPPT circuit is at least 200 V.

SUN2000-100KTL-M1, and SUN2000-100KTL-INM0)

2.4.2 Indicator Status

Figure 2-10 Indicator

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

16

No.

Indicator

Status (Blinking Fast: On for 0.2s and

then Off for 0.2s; Blinking Slowly:

On for 1s and then Off for 1s)

Description

Blinking green fast

If the alarm/maintenance indicator

is red, an environmental fault at

the DC side of the solar inverter is

generated.

Off

The solar inverter disconnects

from all PV strings, or the DC

input voltage of all MPPT circuits

is less than 200 V.

2

Grid connection

indicator

Steady green

The solar inverter is in grid-tied

mode.

Blinking green fast

If the alarm/maintenance indicator

is red, an environmental fault

(excluding Grid Loss) at the AC

side of the solar inverter is

generated.

Off

The solar inverter is not in

grid-tied mode (due to reasons

including Grid Loss).

3

Communications

indicator

Blinking green fast

The solar inverter receives

communication data normally.

Off

The solar inverter has not received

communication data for 10

seconds.

4

Alarm/Maintenance

indicator

Alarm status

Steady red

A major alarm is generated.

If the PV connection indicator

or grid connection indicator is

blinking green fast,

troubleshoot DC or AC

environmental faults as

instructed by the SUN2000

app.

If the PV connection indicator

and grid connection indicator

are both not blinking green

fast, replace components or the

solar inverter as instructed by

the SUN2000 app.

Blinking red fast

A minor alarm is generated.

Blinking red slowly

A warning alarm is generated.

Local maintenance

status

Steady green

Local maintenance succeeds.

Blinking green fast

Local maintenance fails.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

17

No.

Indicator

Status (Blinking Fast: On for 0.2s and

then Off for 0.2s; Blinking Slowly:

On for 1s and then Off for 1s)

Description

Blinking green

slowly

In local maintenance or shuts

down over a command.

The PV connection indicator and the grid connection indicator preferentially indicate environmental

faults.

Local maintenance refers to operations performed after a USB flash drive, a WLAN module, a

Bluetooth module, or a USB data cable is inserted into the USB port of the solar inverter. For

example, local maintenance includes data import and export using a USB flash drive, and connecting

to the SUN2000 app over a WLAN module, a Bluetooth module, or a USB data cable.

If an alarm is generated during local maintenance, the alarm/maintenance indicator shows the local

maintenance state first. After the USB flash drive, WLAN module, Bluetooth module, or USB data

cable is removed, the indicator shows the alarm state.

2.5 Working Principles

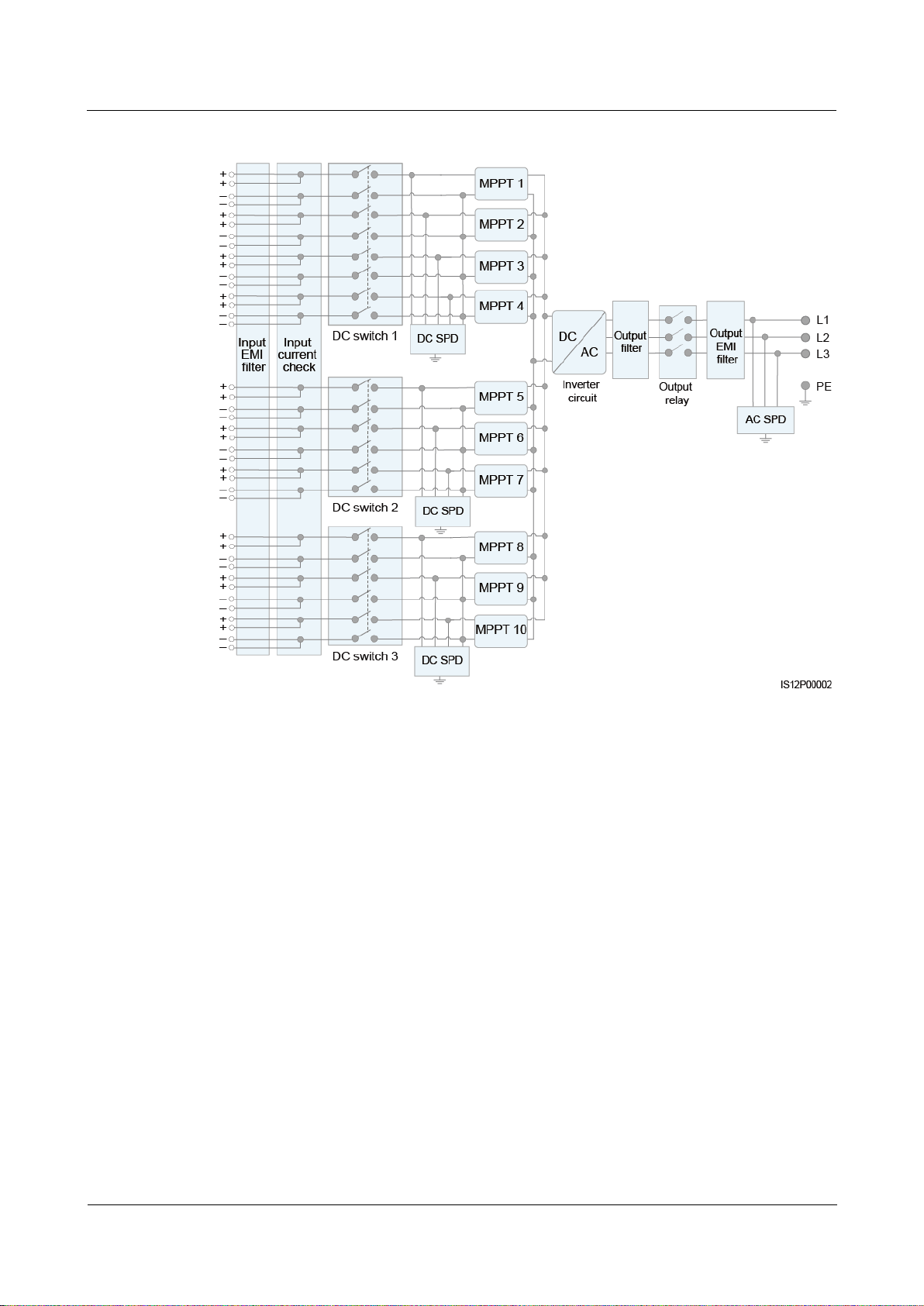

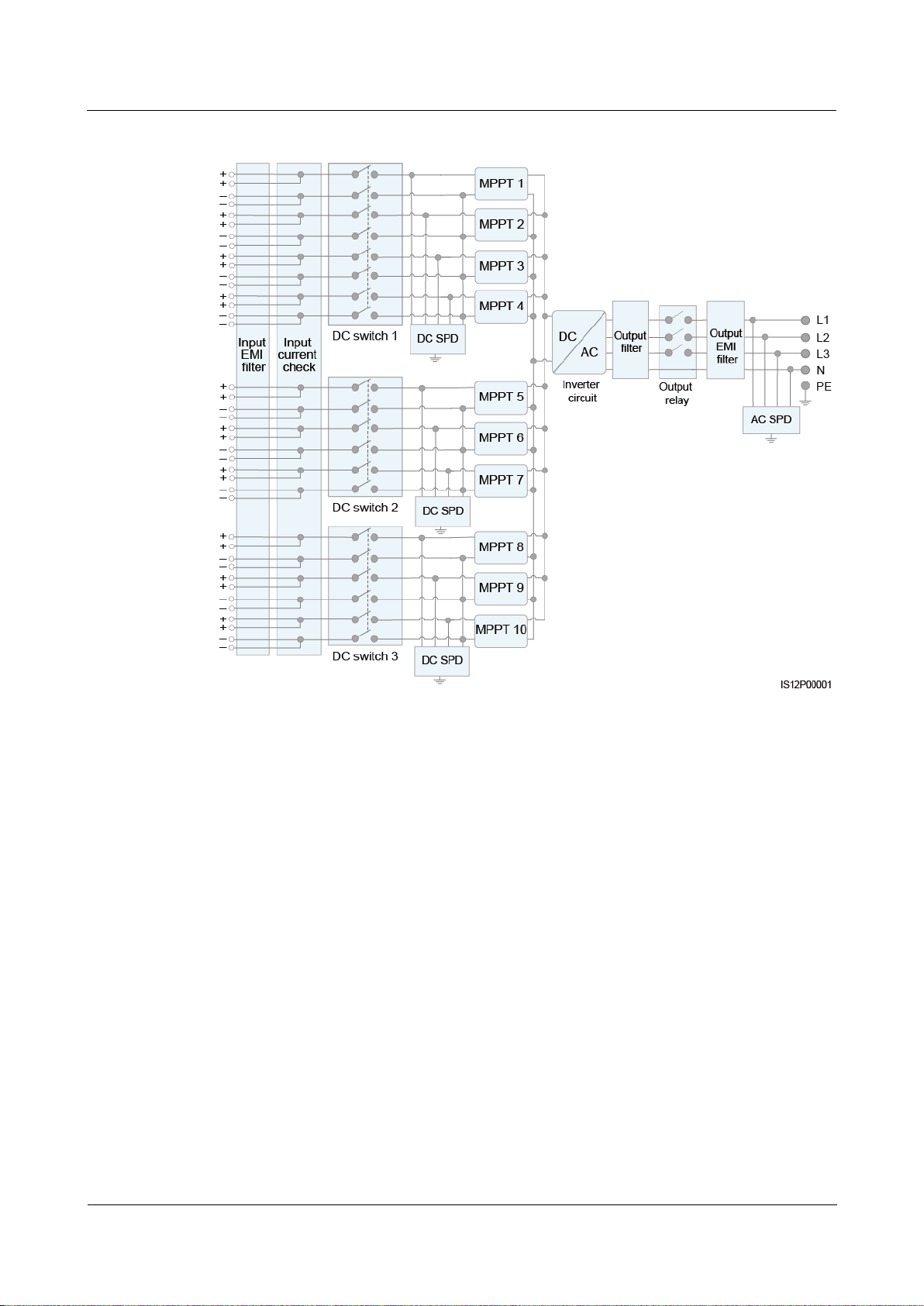

2.5.1 Circuit Diagram

The solar inverter receives inputs from 20 PV strings. The inputs are grouped into 10 MPPT

circuits inside the solar inverter to track the maximum power point of the PV strings. The DC

power is then converted into three-phase AC power through an inverter circuit. Surge

protection is supported on both the DC and AC sides.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

18

Figure 2-11 Schematic diagram of a 3-pin model

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

19

Figure 2-12 Schematic diagram of 4-pin models

2.5.2 Working Modes

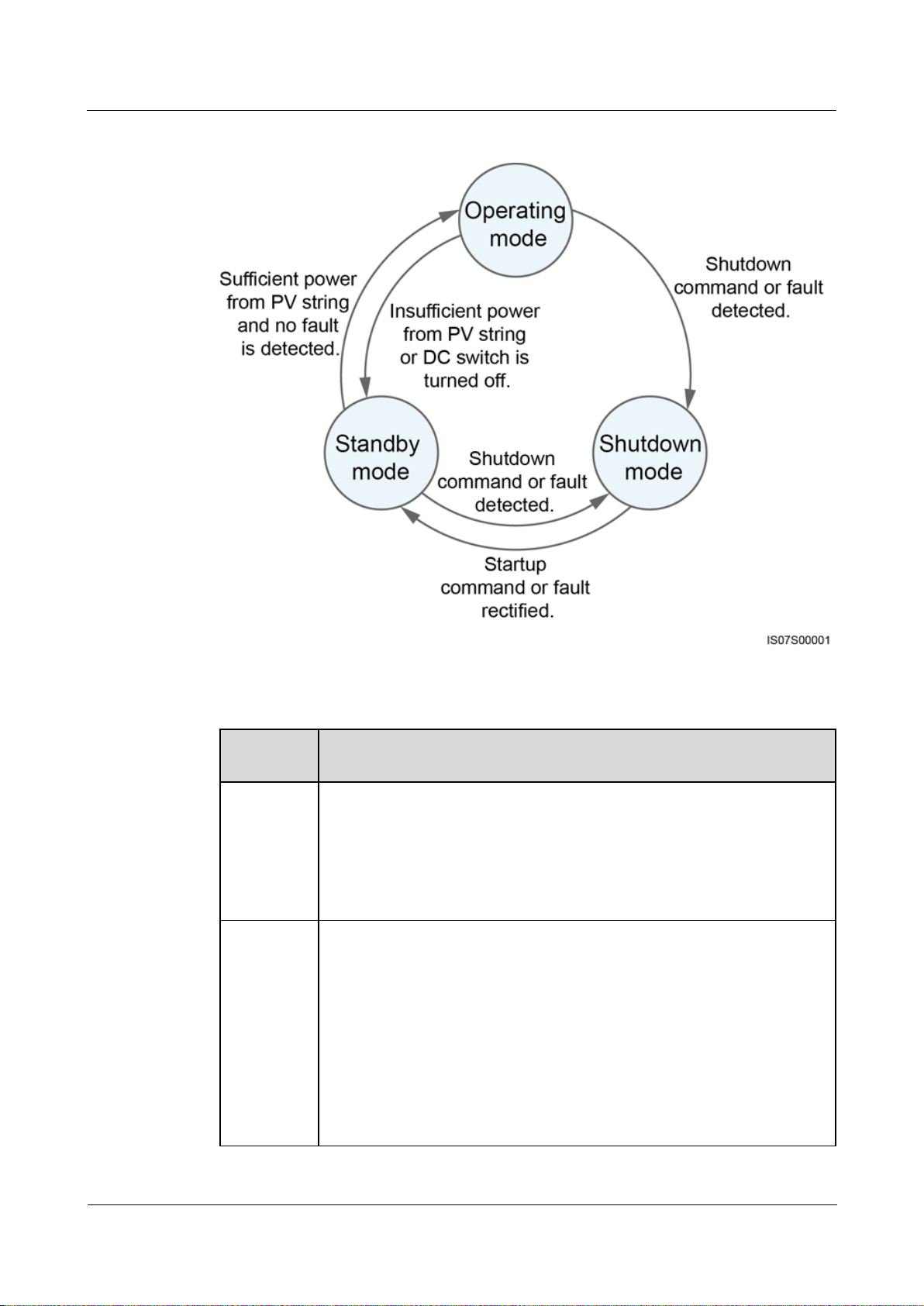

The SUN2000 can work in Standby, Operating, or Shutdown mode.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

20

Figure 2-13 Working modes

Working

Mode

Description

Standby

The SUN2000 enters Standby mode when the external environment does not

meet the operating requirements. In Standby mode:

The SUN2000 continuously performs status check and enters the

Operating mode once the operating requirements are met.

The SUN2000 enters Shutdown mode after detecting a shutdown

command or a fault after startup.

Operating

In Operating mode:

The SUN2000 converts DC power from PV strings into AC power and

feeds the power to the power grid.

The SUN2000 tracks the maximum power point to maximize the PV

string output.

If the SUN2000 detects a fault or a shutdown command, it enters the

Shutdown mode.

The SUN2000 enters Standby mode after detecting that the PV string

output power is not suitable for connecting to the power grid for

generating power.

Table 2-2 Working mode description

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

2 Overview

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

21

Working

Mode

Description

Shutdown

In Standby or Operating mode, the SUN2000 enters Shutdown mode

after detecting a fault or shutdown command.

In Shutdown mode, the SUN2000 enters Standby mode after detecting a

startup command or that the fault is rectified.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

3 Solar Inverter Storage

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

22

3 Solar Inverter Storage

The following requirements should be met if the solar inverter is not put into use immediately:

Do not remove the packing materials, and check the packing materials regularly

(recommended: every three months). If any rodent bites are found, replace the packing

materials immediately. If the solar inverter is unpacked but not put into use immediately,

put it inside the original package with the desiccant bag, and seal it using tape.

The ambient temperature and humidity should be suitable for the storage. The air must

not contain corrosive or flammable gases.

Figure 3-1 Storage temperature and humidity

The solar inverter should be stored in a clean and dry place and be protected from dust

and water vapor corrosion. The solar inverter must be protected against rain and water.

Do not tilt the package or place it upside down.

To avoid personal injury or device damage, stack inverters with caution to prevent them

from falling over.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

3 Solar Inverter Storage

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

23

Figure 3-2 Maximum number of pile-up layers allowed

If the solar inverter has been stored for more than two years, it must be checked and

tested by professionals before being put into use.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

24

4.1 Check Before Installation

Category

Tool

Installation tools

Hammer drill (with

Ф14 mm and Ф16

mm drill bits)

Socket wrench set

Torque wrench

Torque screwdriver

(Phillips head: M3

and M4; flat head:

M3 and M4)

Checking Outer Packing Materials

Before unpacking the solar inverter, check the outer packing materials for damage, such as

holes and cracks, and check the solar inverter model. If any damage is found or the solar

inverter model is not what you requested, do not unpack the package and contact your

supplier as soon as possible.

4 Installation

You are advised to remove the packing materials within 24 hours before installing the solar inverter.

Checking Accessories

After unpacking the solar inverter, check that the components are intact and complete. If any

damage is found or any component is missing, contact your dealer.

For details about the number of accessories delivered with the solar inverter, see the Packing List in the

packing case.

4.2 Tools

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

25

Category

Tool

Diagonal pliers

Wire strippers

Flat-head

screwdriver (head:

M3)

Rubber mallet

Utility knife

Cable cutter

Crimping tool

(model:

PV-CZM-22100)

RJ45 crimping tool

Open-end wrench

(model: PV-MS)

Vacuum cleaner

Multimeter (DC

voltage

measurement range

≥ 1100 V DC)

Marker

Measuring tape

Bubble or digital

level

Hydraulic pliers

Heat shrink tubing

Heat gun

Cable tie

Scissors

N/A

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

26

Category

Tool

Personal protective

equipment (PPE)

Safety gloves

Safety goggles

Anti-dust respirator

Safety boots

4.3 Determining the Installation Position

Installation Environment Requirements

The solar inverter can be installed indoors or outdoors.

Do not install the solar inverter near flammable or explosive materials.

Do not install the solar inverter where its enclosure and heat sink are easily accessible,

because the voltage is high and these parts are hot during operation.

Install the solar inverter in a well-ventilated environment for heat dissipation

When the solar inverter is installed under direct sunlight, the power may be derated due

to the temperature rise. You are advised to install the solar inverter in a sheltered place or

install an awning over it.

The SUN2000-125KTL-M0 should be physically separated from third-party wireless

communication facilities and residential environments by distance greater than 30 m.

Figure 4-1 Installation environment

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

27

Mounting Structure Requirements

The mounting structure where the solar inverter is installed must be fire resistant. Do not

install the solar inverter on flammable building materials.

Ensure that the installation surface is solid enough to bear the solar inverter.

In residential areas, do not install the solar inverter on drywalls or walls made of similar

materials with a weak sound insulation performance because the noise generated by the

solar inverter may interfere with residents.

Figure 4-2 Mounting structure

Installation Angle Requirements

The solar inverter can be support-mounted or wall-mounted. The installation angle

requirements are as follows:

Install the solar inverter vertically or at a maximum back tilt of 75 degrees to facilitate

heat dissipation.

Do not install the solar inverter at forward tilted, excessive back tilted, side tilted,

horizontal, or upside down positions.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

28

Figure 4-3 Angle

Installation Dimensions Requirements

Reserve enough space around the solar inverter for installation and heat dissipation.

Figure 4-4 Installation dimensions

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

29

For ease of installing the solar inverter on the mounting bracket, connecting cables to the bottom of the

solar inverter, and maintaining the solar inverter in future, it is recommended that the bottom clearance

be between 600 mm and 730 mm. If you have any question about the clearance, consult the local

technical support engineers.

When installing multiple solar inverters, install them in horizontal mode if sufficient space is

available and install them in triangle mode if no sufficient space is available. Stacked

installation is not recommended.

Figure 4-5 Horizontal installation mode (recommended)

Figure 4-6 Triangle installation mode (recommended)

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

30

Figure 4-7 Stacked installation mode (not recommended)

(1) Security Torx wrench

4.4 Installing the Mounting Bracket

Before installing the mounting bracket, remove the security Torx wrench and keep it for later

use.

Figure 4-8 Position for binding the security Torx wrench

The mounting bracket of the solar inverter has four groups of tapped holes, each group

containing four tapped holes. Mark any hole in each group based on site requirements and

mark four holes in total. The two round holes are recommended.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

31

Figure 4-9 Hole dimensions

4.4.1 Support-mounted Installation

Prerequisites

M12x40 bolt assemblies are supplied with the mounting bracket. If the bolt length does not

meet the installation requirements, prepare M12 bolt assemblies by yourself and use them

together with the supplied M12 nuts.

Procedure

Step 1 Determine the positions for drilling holes using the mounting bracket. Level the positions of

Step 2 Drill holes using a hammer drill. It is recommended that anti-rust measures be taken on the

Step 3 Secure the mounting bracket.

mounting holes using a bubble or digital level, and mark the positions with a marker.

positions for drilling holes.

Figure 4-10 Installing the mounting bracket

----End

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

32

4.4.2 Wall-mounted Installation

Prerequisites

You have prepared expansion bolts. M12x60 stainless steel expansion bolts are recommended.

Procedure

Step 1 Determine the positions for drilling holes using the mounting bracket. Level the positions of

mounting holes using a bubble or digital level, and mark the positions with a marker.

Step 2 Drill holes using a hammer drill and install expansion bolts.

Avoid drilling holes in the position of the wall with water pipes and power cables buried

inside.

To prevent dust inhalation or contact with eyes, wear safety goggles and an anti-dust

respirator when drilling holes.

Clean up any dust in and around the holes using a vacuum cleaner and measure the

distance between holes. If the holes are inaccurately positioned, drill a new set of holes.

Level the head of the expansion sleeve with the concrete wall after removing the bolt,

spring washer, and flat washer. Otherwise, the mounting bracket will not be securely

installed on the wall.

Step 3 Secure the mounting bracket.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

33

Figure 4-11 Installing the mounting bracket

----End

4.5 Installing a Solar Inverter

Context

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

34

(A) Transportation scenario

(B) Installation scenario

Move the solar inverter with care to prevent device damage and personal injury.

It takes multiple persons or a pallet truck to move the solar inverter.

Do not use the ports and wiring terminals at the bottom to support any weight of the solar

inverter.

When you need to temporally place the solar inverter on the ground, use foam, paper, or

other protection material to prevent damage to its cover.

Use the handles to facilitate installation. Handles are optional and delivered separately.

Ensure that the handles are securely installed. After the installation is complete, remove

the handles and keep them properly.

To avoid damage to the equipment, do not lift or hoist a solar inverter with an improper

hold as shown in Figure 4-13.

Figure 4-12 Positions for installing the handles

Procedure

Step 1 Lift the solar inverter from the packing case and move it to the installation position.

Figure 4-13 Lifting positions

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

35

Figure 4-14 Taking out the solar inverter

Step 2 Lift the solar inverter and keep it upright.

Figure 4-15 Lifting the solar inverter and keeping it upright

Step 3 If the installation position is too high to install the solar inverter on the mounting bracket, run

a rope that is strong enough to bear the solar inverter through the two lifting eyes, and hoist

the solar inverter.

Hoist the solar inverter with care to protect it from colliding with the wall or other objects.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

36

Figure 4-16 Hoisting the solar inverter

Step 4 Install the solar inverter on the mounting bracket and align the solar inverter enclosure with

the mounting bracket.

Figure 4-17 Mounting the solar inverter

Step 5 Secure the solar inverter.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

4 Installation

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

37

Precautions

Figure 4-18 Tightening security Torx screws

----End

If the equipment is installed in a public place or in an area of people activities, such as a

parking lot, station, factory building, or residential area, install a protective net outside the

equipment and erect a safety warning sign to isolate the equipment. The purpose is to

avoid personal injury or property loss caused by contact with the equipment by

nonprofessionals or other reasons during the operation of the equipment.

If the solar inverter has not been running for more than half a year after being mounted, it

must be checked and tested by professionals before being put into operation.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

5 Electrical Connections

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

38

5.1 Precautions

After the PV array receives solar irradiance, it transmits the DC voltage to the solar inverter.

Before connecting cables, ensure that the three DC switches on the solar inverter are set to

OFF. Otherwise, the high voltage of the solar inverter may result in electric shocks.

5 Electrical Connections

The device damage caused by incorrect cable connections is beyond the warranty scope.

Only qualified technicians can perform operations about electrical connection.

Wear proper PPE at all time when connecting cables.

To prevent poor cable connection due to overstress, leave enough slack before connecting

the cables to the appropriate ports.

The cable colors shown in the electrical connection diagrams provided in this chapter are for reference

only. Select cables in accordance with local cable specifications (green-and-yellow cables are only used

for protective earthing).

5.2 Preparing Cables

SUN2000 solar inverters support RS485 communication and MBUS communication.

The MBUS communication is applicable to medium-voltage grid connection scenarios and

non-low-voltage public grid connection scenarios (industrial environment).

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

5 Electrical Connections

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

39

(A) PV string

(B) SUN2000

(C) AC combiner box

(D) Transformer station

(E) Power grid

(F) SmartLogger

(G) Management system

In the networking diagram, indicates the power cable, indicates the power flow direction,

and and indicate the signal flow.

Figure 5-1 RS485 networking (SmartLogger)

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

5 Electrical Connections

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

40

Figure 5-2 RS485 networking (SDongle)

(A) PV string

(B) SUN2000

(C) AC combiner box

(D) Transformer station

(E) Power grid

(F) SDongle

(G) Management system

(A) PV string

(B) SUN2000

(C) AC combiner box

(D) Transformer station

(E) Power grid

(F) SmartLogger

Figure 5-3 MBUS networking (SmartLogger)

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

5 Electrical Connections

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

41

(G) Management system

(A) PV string

(B) SUN2000

(C) AC combiner box

(D) Transformer station

(E) Power grid

(F) SDongle

(G) Management system

Figure 5-4 MBUS networking (SDongle)

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

5 Electrical Connections

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

42

No.

Component

Description

Source

A

PV string

PV strings consist of PV modules in

series.

A solar inverter supports 20 PV string

inputs.

Prepared by the

customer

To ensure the system response speed, it is recommended that less than 30 solar inverters be

connected to each COM port on the SmartLogger and that less than 10 solar inverters be

cascaded over the SDongle.

The RS485 communication distance between the last solar inverter and the SmartLogger

cannot exceed 1000 m.

Figure 5-5 Cable connections (configure the components in the dotted box as required)

Table 5-1 Components

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

5 Electrical Connections

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

43

No.

Component

Description

Source

B

Environmental monitoring

instrument (EMI)

When the SmartLogger is used, the EMI

can be directly connected to the

SmartLogger or connected to the last

solar inverter cascaded over RS485.

When the SDongle is used, the EMI is a

cascaded device that needs to be

connected to the solar inverter where the

SDongle is installed.

Prepared by the

customer

C

SmartLogger

The solar inverter communicates with the

management system through the

SmartLogger.

Purchased from

Huawei

D

Power Meter

Implements power control at the grid-tied

point in low voltage scenarios using a power

meter.

Prepared by the

customer

E

Support tracking system

Adjusts the angle of the supports.

Prepared by the

customer

F

Fuse/Circuit breaker

The tracking system should be equipped with

an overcurrent protection device or

component. The power cable between the

device or component and the wiring terminal

should be no longer than 2.5 m.

Therefore, a fuse or a circuit breaker is

recommended.

Installed between the solar inverter and

tracking control box

Fuse specifications: rated voltage ≥ 500

V; rated current: 16 A; protection: gG

Circuit breaker specifications: rated

voltage ≥ 500 V; rated current: 16 A;

tripping: C

Prepared by the

customer

G

AC switch

Installed in the AC combiner box

Recommended: a three-phase AC circuit

breaker with a rated voltage greater than

or equal to 500 V AC and a rated current

of 250 A

Prepared by the

customer

H

SDongle

The solar inverter communicates with the

management system through the SDongle.

Purchased from

Huawei

The solar inverter has an RCMU inside. Its external AC switch should be a three-phase circuit

breaker or other AC load circuit breakers to safely disconnect the solar inverter from the

power grid.

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

5 Electrical Connections

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

44

Table 5-2 Cable description of a 3-pin model (S: cross-sectional area of the AC cable conductor; Sp: cross-sectional

No.

Cable

Category

Conductor

Cross-Sectional

Area Range

Outer

Diameter

Source

1

DC input power

cable

PV cable that meets the 1100

V standard

4–6 mm2

5.5–9 mm

Prepared

by the

customer

2

RS485

communications

cable

Outdoor shielded twisted

pair that meets the local

standard

0.25–1 mm2

One or two

communicat

ions cables:

4–11 mm

Three

communicat

ions cables:

4–8 mm

Prepared

by the

customer

3

Protective

earthing (PE)

cable

Single-core outdoor copper

cable and M10 OT/DT

terminals

NOTICE

You are advised to choose the

ground point on the enclosure.

The ground point in the

maintenance compartment is

used for connecting to the PE

cable contained in the

multi-core AC power cable.

Sp ≥ S/2

N/A

Prepared

by the

customer

4

Tracking system

power cable

Three-core outdoor copper

cable with dual-layer

protection

10 mm2

15–18 mm

Prepared

by the

customer

5

AC output

power cable

(multi-core)

If you connect a PE cable

to the ground point on the

enclosure, you are

advised to use a

three-core (L1, L2, and

L3) outdoor cable and

M12 OT/DT terminals

(L1, L2, and L3).

If you connect a PE cable

to the ground point in the

maintenance

compartment, you are

advised to use a four-core

(L1, L2, L3, and PE)

outdoor cable, M12

OT/DT terminals (L1,

L2, and L3), and M10

OT/DT terminals (PE).

You do not need to

prepare a PE cable.

Copper cable:

− S: 70–240

mm2

− S

p

≥ S/2

Aluminum

alloy cable or

copper-clad

aluminum

cable:

− S: 95–240

mm2

− S

p

≥ S/2

24–66 mm

Prepared

by the

customer

area of the protective earthing cable conductor)

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

5 Electrical Connections

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

45

No.

Cable

Category

Conductor

Cross-Sectional

Area Range

Outer

Diameter

Source

AC output

power cable

(single-core)

You are advised to use a

single-core outdoor cable

and M12 OT/DT terminals.

Copper cable:

− S: 70–240

mm2

Aluminum

alloy cable or

copper-clad

aluminum

cable:

− S: 95–240

mm2

14–32 mm

Prepared

by the

customer

The value of Sp is valid only if the conductors of the PE cable and AC power cable use the same material. If the

materials are different, ensure that the conductor of the PE cable with a proper cross-sectional area produces a

conductance equivalent to that of the cable specified in the table.

No.

Cable

Category

Conductor

Cross-Sectional

Area Range

Outer

Diameter

Source

1

DC input power

cable

PV cable that meets the 1100

V standard

4–6 mm2

5.5–9 mm

Prepared

by the

customer

2

RS485

communications

cable

Outdoor shielded twisted

pair that meets the local

standard

0.25–1 mm2

One or two

communicat

ions cables:

4–11 mm

Three

communicat

ions cables:

4–8 mm

Prepared

by the

customer

3

PE cable

Single-core outdoor copper

cable and M10 OT/DT

terminals

NOTICE

You are advised to choose the

ground point on the enclosure.

The ground point in the

maintenance compartment is

used for connecting to the PE

cable contained in the

multi-core AC power cable.

Sp ≥ S/2

N/A

Prepared

by the

customer

Table 5-3 Cable description of 4-pin models (S: cross-sectional area of the AC cable conductor; Sp: cross-sectional area

of the PE cable conductor)

SUN2000-(100KTL, 110KTL, 125KTL) Series

User Manual

5 Electrical Connections

Issue Preliminary Version 3.0

(2019-12-08)

Copyright © Huawei Technologies Co., Ltd.

46

No.

Cable

Category

Conductor

Cross-Sectional

Area Range

Outer

Diameter

Source

4

Tracking system

power cable

Three-core outdoor copper

cable with dual-layer

protection

10 mm2

15–18 mm

Prepared

by the

customer

5

AC output

power cable

(multi-core)

If you connect a PE cable

to the ground point on the

enclosure and the neutral

wire is not used, you are

advised to use a

three-core (L1, L2, and

L3) outdoor cable and

M12 OT/DT terminals

(L1, L2, and L3).

If you connect a PE cable

to the ground point in the

maintenance

compartment and the

neutral wire is not used,

you are advised to use a