SmartLogger2000

User Manual

Date 2016-06-20

HUAWEI TECHNOLOGIES CO., LTD.

Copyright © Huawei Technologies Co., Lt d. 2016 . All right s reserv ed.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: http://www.huawei.com

Email: support@huawei.com

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

i

SmartLogger2000

User Manual About This Document

About This Document

Overview

This document introduces the SmartLogger2000 (SmartLogger for short) in terms of

installation, cable connections, system operation and maintenance, and troubleshooting.

Readers should understand the SmartLogger features, functions, and safety precautions

provided in this document before installing and operating the SmartLogger.

The figures provided in this document are for reference only. The actual product appearance

prevails.

You can print the document based on your requirements. Store the paper copy properly for

future use. You can log in to http://support.huawei.com/carrier/, click Product Support, and

search for SmartLogger to view and obtain the latest user manual.

Intended Audience

This document is intended for photovoltaic (PV) plant operators and qualified electrical

technical personnel.

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Symbol Description

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in equipment damage, data loss,

performance deterioration, or unanticipated results.

NOTICE is used to address practices not related to personal

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

ii

SmartLogger2000

User Manual About This Document

Symbol Description

injury.

Change History

Changes between document issues are cumulative. The latest document issue contains all the

changes made in earlier issues.

Calls attention to important information, best practices and

tips.

NOTE is used to address information not related to personal

injury, equipment damage, and environment deterioration.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iii

SmartLogger2000

User Manual Contents

Contents

About This Document .................................................................................................................... ii

1 Safety Precautions ......................................................................................................................... 1

2 Overview ......................................................................................................................................... 3

2.1 Overview ...................................................................................................................................................................... 3

2.2 Appearance ................................................................................................................................................................... 6

2.3 Nameplate Description ............................................................................................................................................... 10

2.4 Typical Networking Scenarios .................................................................................................................................... 11

2.5 System Wiring Diagram.............................................................................................................................................. 14

3 Installation.................................................................................................................................... 22

3.1 Checking Before Installation ...................................................................................................................................... 22

3.2 Preparing Tools ........................................................................................................................................................... 23

3.3 Determining the Installation Position ......................................................................................................................... 25

3.4 Installing the SmartLogger ......................................................................................................................................... 27

3.4.1 Mounting the SmartLogger on a Wall ...................................................................................................................... 27

3.4.2 Mounting the SmartLogger Along a Guide Rail ...................................................................................................... 31

3.5 Installing the RS485 signal SPD ................................................................................................................................. 34

4 Connecting Cables ...................................................................................................................... 36

4.1 Connection Description .............................................................................................................................................. 37

4.2 Connecting the PE Cable ............................................................................................................................................ 37

4.2.1 Connecting the PE Cable for the SmartLogger ........................................................................................................ 37

4.2.2 Connecting the PE Cable for the RS485 Signal SPD .............................................................................................. 39

4.3 Connecting the RS485 signal SPD ............................................................................................................................. 40

4.4 Connecting Inverters ................................................................................................................................................... 44

4.4.1 Connecting the SUN2000 ........................................................................................................................................ 44

4.4.2 Connecting the SUN8000 ........................................................................................................................................ 52

4.4.3 Connecting Multiple Inverters to the SmartLogger ................................................................................................. 54

4.5 Connecting an EMI ..................................................................................................................................................... 56

4.6 Connecting a Power Meter ......................................................................................................................................... 58

4.7 Connecting the Box-type Transformer ........................................................................................................................ 59

4.8 Connecting a PID Module .......................................................................................................................................... 61

4.9 Connecting a Ripple Control Receiver ....................................................................................................................... 62

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iv

SmartLogger2000

User Manual Contents

4.10 Connecting an Ethernet Network Cable ................................................................................................................... 65

4.11 Connecting Optical Fibers ........................................................................................................................................ 66

5 System Operation ........................................................................................................................ 69

5.1 Checking Before Power-On ........................................................................................................................................ 69

5.2 Powering On the System............................................................................................................................................. 70

6 User Interface ............................................................................................................................... 72

6.1 USB Flash Drive Operations ...................................................................................................................................... 72

6.1.1 Exporting Data ......................................................................................................................................................... 72

6.1.2 Exporting All Files ................................................................................................................................................... 73

6.1.3 Importing All Files ................................................................................................................................................... 74

6.1.4 Upgrading the Application ....................................................................................................................................... 76

6.1.5 Upgrading the BSP .................................................................................................................................................. 77

6.2 NMS Operations ......................................................................................................................................................... 78

6.3 APP Operations ........................................................................................................................................................... 78

7 Maintenance ................................................................................................................................. 79

7.1 Daily Maintenance ...................................................................................................................................................... 79

7.2 Troubleshooting .......................................................................................................................................................... 79

7.3 Alarms ......................................................................................................................................................................... 81

8 Disposing of the SmartLogger .................................................................................................. 84

9 Certification Declaration ........................................................................................................... 85

9.1 CE ............................................................................................................................................................................... 85

9.2 FCC ............................................................................................................................................................................. 85

10 Technical Specifications .......................................................................................................... 86

A Product User Lists ...................................................................................................................... 88

B Acronyms and Abbreviations .................................................................................................. 89

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

v

SmartLogger2000

User Manual 1 Safety Precautions

1 Safety Precautions

Read the safety precautions carefully. Otherwise, human injury and equipment damage may

occur.

Personnel Requirements

Only qualified and trained electrical technicians are allowed to install and operate the

SmartLogger.

Operation personnel should understand the composition and working principles of the

PV grid-tied power generating system and local regulations.

Read this document thoroughly before operations. Huawei shall not be liable for any

consequence caused by violation of the storage, transportation, installation, and operation

regulations specified in this document.

Identification Protection

The signs on the SmartLogger shell specify important information about secure

operations. Do not damage the signs.

The nameplate attached to the bottom of the SmartLogger lists the SmartLogger

parameters. Do not damage the nameplate.

Installation

Before installation, read this document carefully. Huawei shall not be liable for any

consequence caused by violation of the regulations specified in this document.

Before installing the SmartLogger, ensure that it is not connected or energized.

Install the SmartLogger in well-ventilated environments to ensure system performance.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1

SmartLogger2000

User Manual 1 Safety Precautions

Ensure that the heat dissipation holes of the SmartLogger are not blocked.

Do not move the components inside the shelf except for the wiring terminals at the

bottom.

Install the SmartLogger in a dedicated area.

Operation

Strictly comply with the safety precautions in this document and associated documents to

operate the SmartLogger.

When operating the SmartLogger, follow local laws and regulations.

Maintenance and Replacement

A faulty SmartLogger requires overall maintenance. Contact the dealer if any fault

occurs in the SmartLogger shelf.

Maintain the SmartLogger after you get familiar with this document and tools and testing

equipment are available.

When maintaining the SmartLogger, wear ESD gloves and comply with ESD

precautions.

The device has multiple inputs. Switch off all inputs before the maintenance.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

2

SmartLogger2000

User Manual 2 Overview

2 Overview

About This Chapter

2.1 Overview

2.2 Appearance

2.3 Nameplate Description

2.4 Typical Networking Scenarios

2.5 System Wiring Diagram

2.1 Overview

Function

The SmartLogger is a highly integrated device dedicated for monitoring and managing the PV

power system. It converges ports, converts protocols, collects and stores data, and centrally

monitors and maintains devices in the PV power system.

Features

The SmartLogger provides the following features:

Wide application

− Industrial-grade application, wide temperature range: –40°C to +60°C

− High altitude: applicable at an altitude of 4000 m

Various communications modes

− Bluetooth

Has a built-in Bluetooth module through which the SUN2000 APP (APP for short)

connects to the SmartLogger for parameter configuration and device maintenance.

The SmartLogger Bluetooth is named as LOG+the last eight figures of the ESN

of the SmartLogger.

− Optical fiber ring switch

Provides two 100M Ethernet optical ports that support RSTP and STP to implement

fiber ring networking. If RSTP is used, fiber ring protection can be completed

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

3

SmartLogger2000

User Manual 2 Overview

within 10 seconds. If STP is used, fiber ring protection can be completed within 60

seconds.

− PLC

Has a built-in PLC CCO module through which southbound devices connect to the

SmartLogger over AC power cables.

− Ethernet electrical port

Provides two 10/100M Ethernet electrical ports that can be used as southbound

ports to connect to southbound devices or used as northbound ports to connect to an

NMS.

A southbound port connects to a downstream device for collecting data and setting parameters.

Southbound devices include the inverter, environmental monitoring instrument (EMI), power meter,

box-type transformer, and PID module.

A northbound port connects to an upstream NMS for uploading data.

− RS485

Supports six RS485 routes and access of devices that use Modbus-RTU, IEC103,

and DL/T645.

Graphical data

− In addition to displaying the electricity yield and real-time monitoring information

in graphic and text format, the embedded WebUI can also display performance data

of power stations and devices in tables or curves.

− The APP displays the electricity yield and real-time monitoring information in

graphic and text format.

Centralized monitoring

− Manages a maximum of 200 devices in centralized mode and supports the access of

up to 80 inverters.

− Allows you to monitor and manage the PV power system on the embedded WebUI,

for example, viewing real-time information about power stations, devices, and

faults, setting device parameters, and maintaining devices in remote mode.

− Allows you to monitor the devices in the PV power system on the APP in real time,

such as viewing information about power stations, devices, products, and faults,

setting device parameters, and maintaining devices.

Easy maintenance

− Allows users to upgrade the firmware of the SmartLogger and export data by using

a USB flash drive.

− Allows you to upgrade the firmware of the SmartLogger, inverter, AC combiner box,

PLC module, and PID module, and export logs and data over the embedded WebUI.

− Allows you to manage the devices connecting to the SmartLogger and classify

alarms over the APP.

Intelligent management

− Automatically searches for and accesses Huawei inverters, AC combiner boxes,

PLC modules, and PID modules. If you import a parameter configuration table, the

SmartLogger can access third-party devices that support Modbus-RTU and IEC103.

− Automatically assigns RS485 addresses to the connected Huawei inverters, AC

combiner boxes, and PID modules, and allows for RS485 address adjustment based

on ESNs to facilitate remote configuration and maintenance.

− Supports remote configuration of inverter parameters over the embedded WebUI

and synchronizes the parameters from one inverter to other inverters in batches.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

4

SmartLogger2000

User Manual 2 Overview

− Automatically collects the data generated during the communication disconnection

from the inverter or manually collects the data over the embedded WebUI after the

connection resumes.

Remote maintenance

− Simultaneously accesses multiple NMSs (including Huawei NetEco and third-party

NMSs) that support Modbus-TCP, IEC103, and IEC104. Huawei NetEco features

centralized O&M, big data analysis, intelligent diagnosis, and mobile O&M.

− Supports connection to a third-party NMS over File Transfer Protocol (FTP).

− Sends electricity yield and alarms to users by emails.

Grid scheduling

− The SmartLogger supports various power grid scheduling modes and therefore can

meet the requirements of power grid companies in different countries.

− Implements rapid active power control and reactive power compensation for all the

inverters connecting to the SmartLogger.

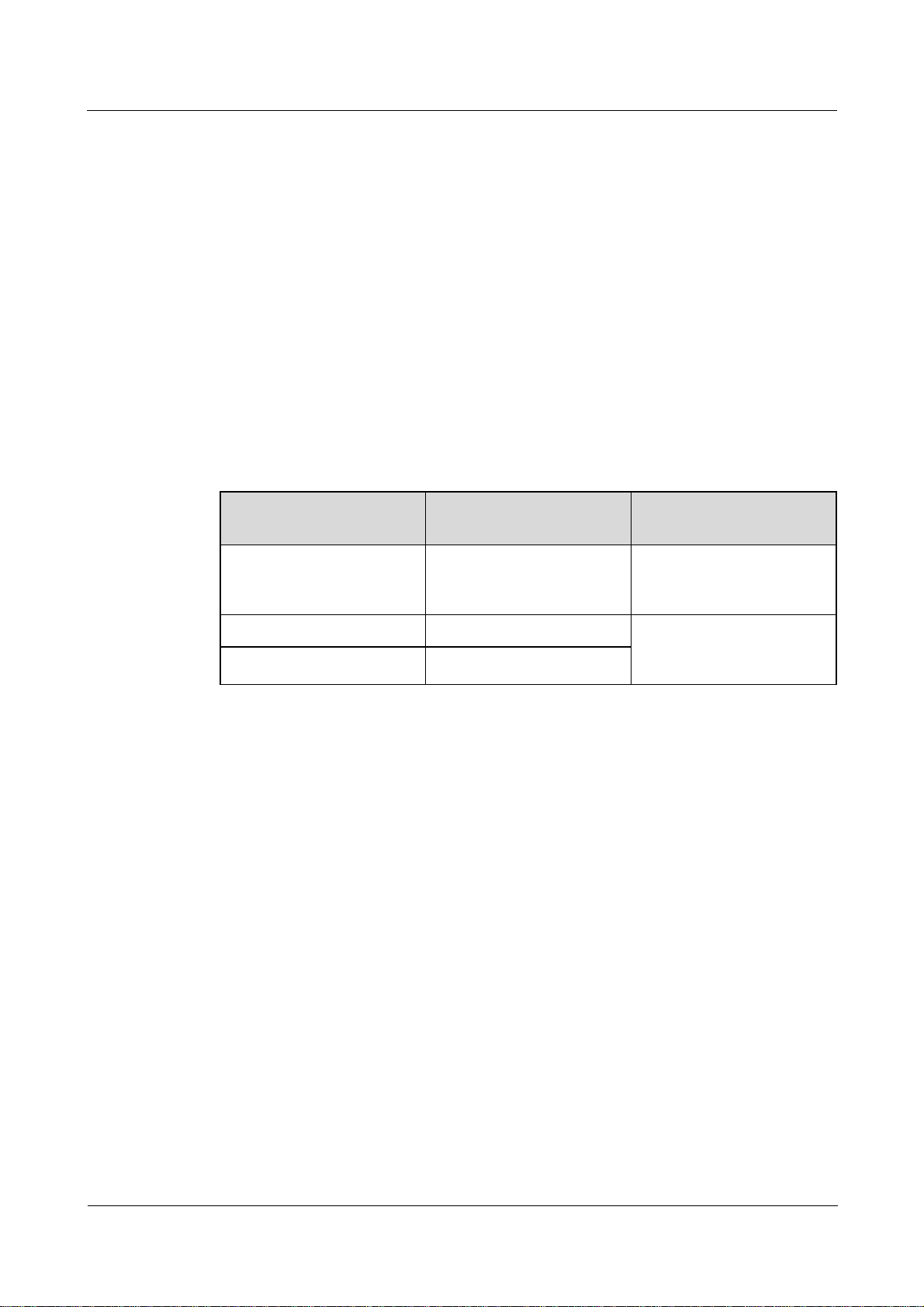

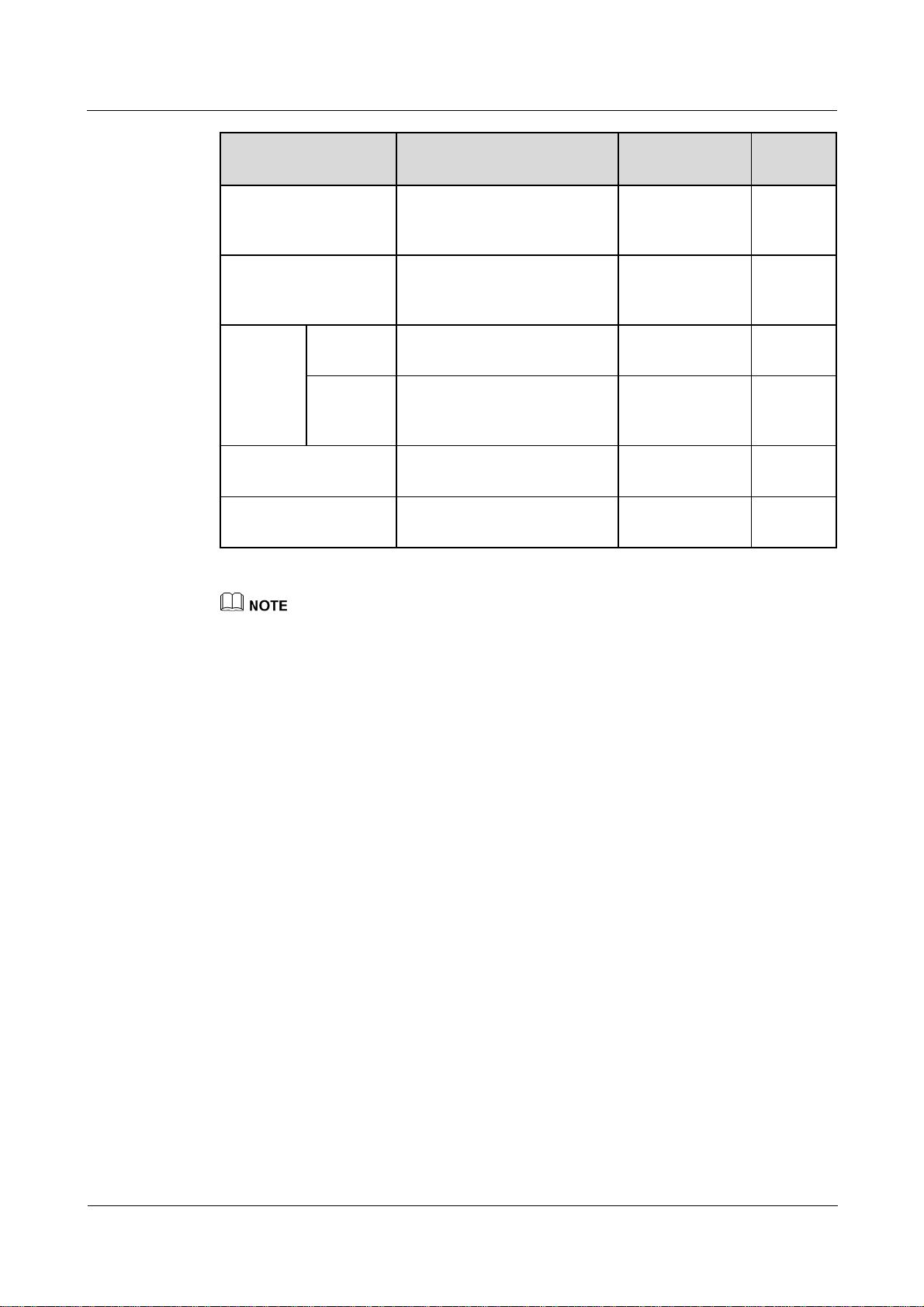

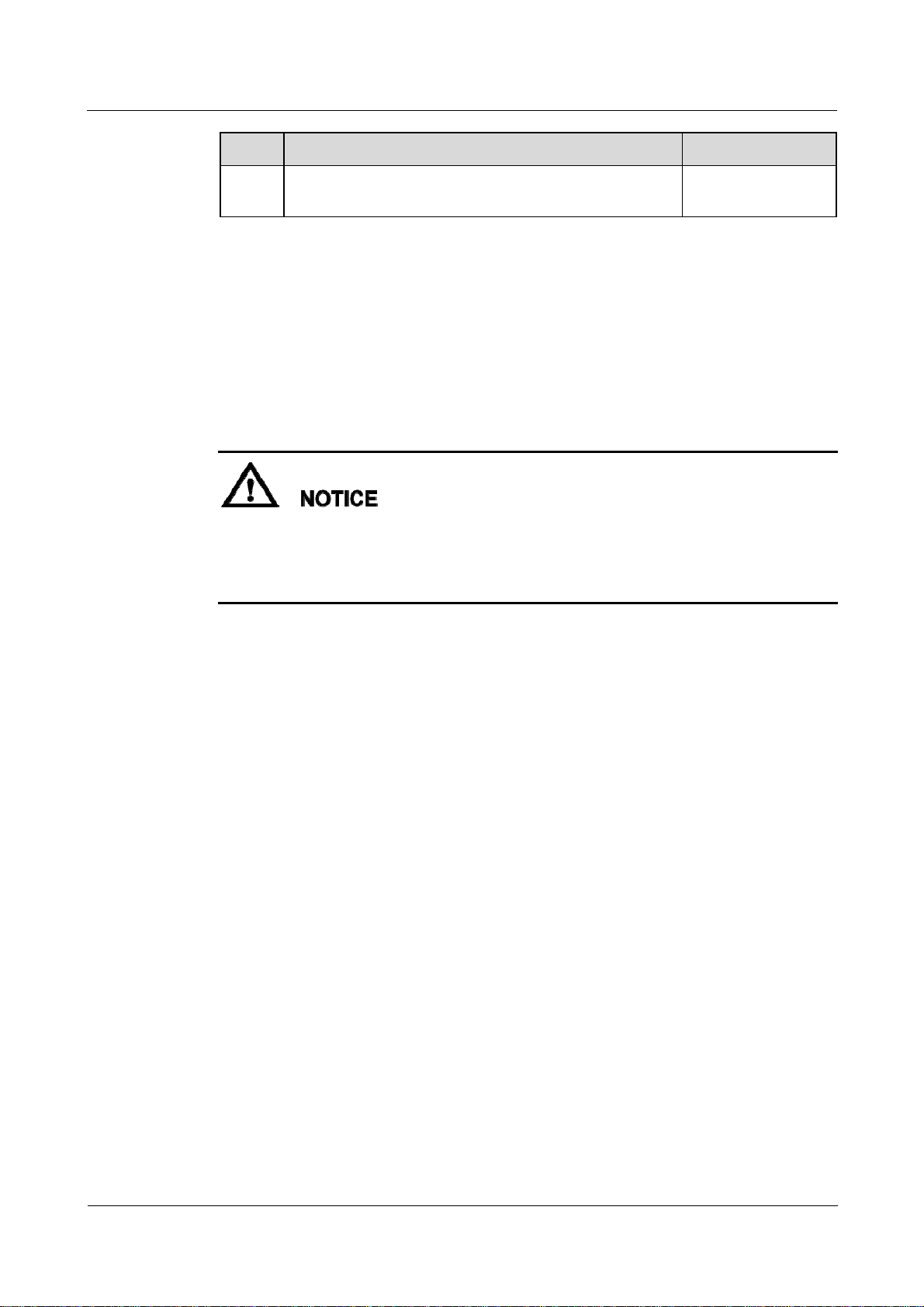

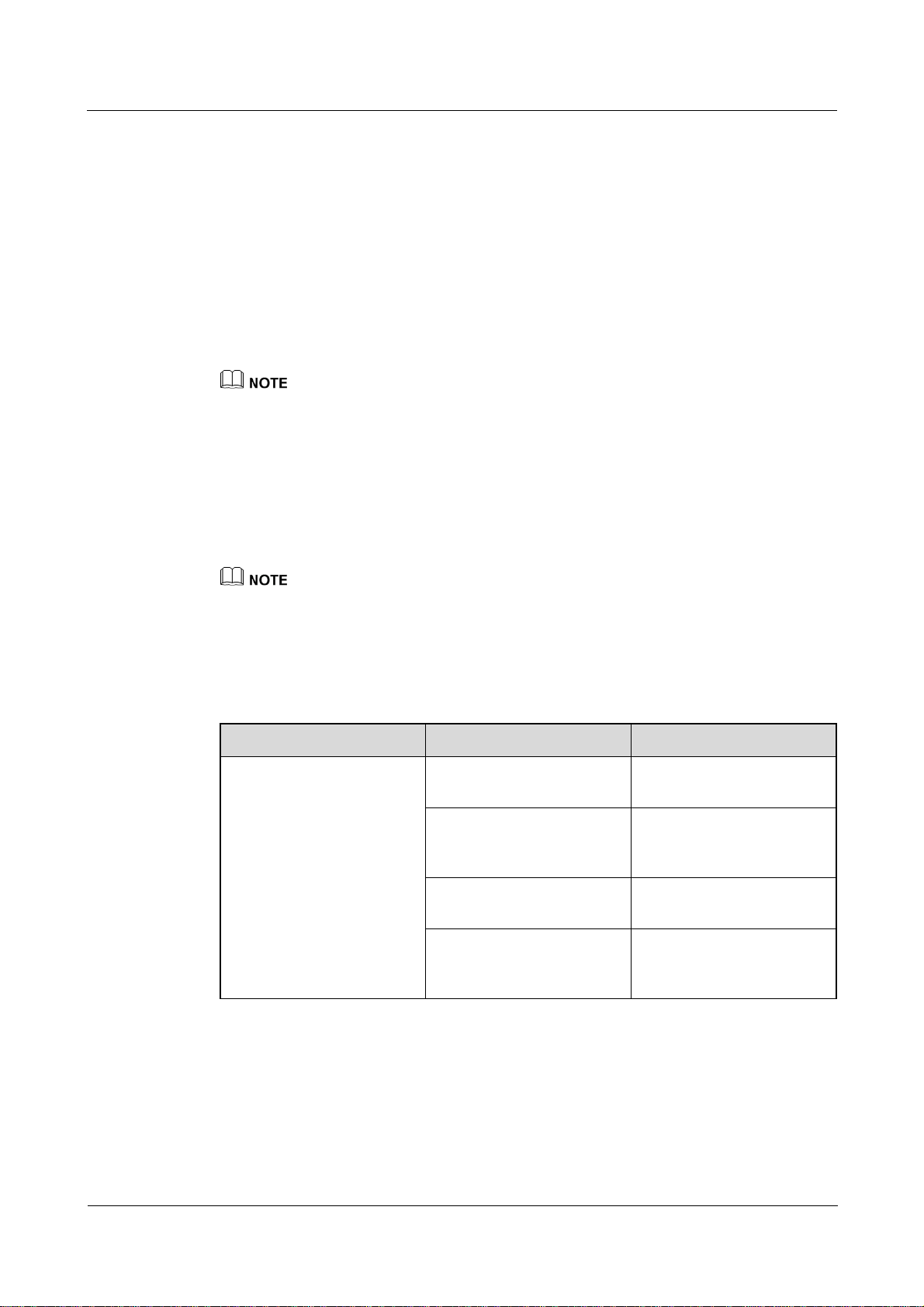

Model Description

Model PLC Module

Remarks

Configured?

SmartLogger2000-10 Yes The built-in Bluetooth

module supports only

Android APP.

SmartLogger2000-10-B Yes The built-in Bluetooth

module supports both

SmartLogger2000-11-B No

Android APP and IOS APP.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

5

SmartLogger2000

User Manual 2 Overview

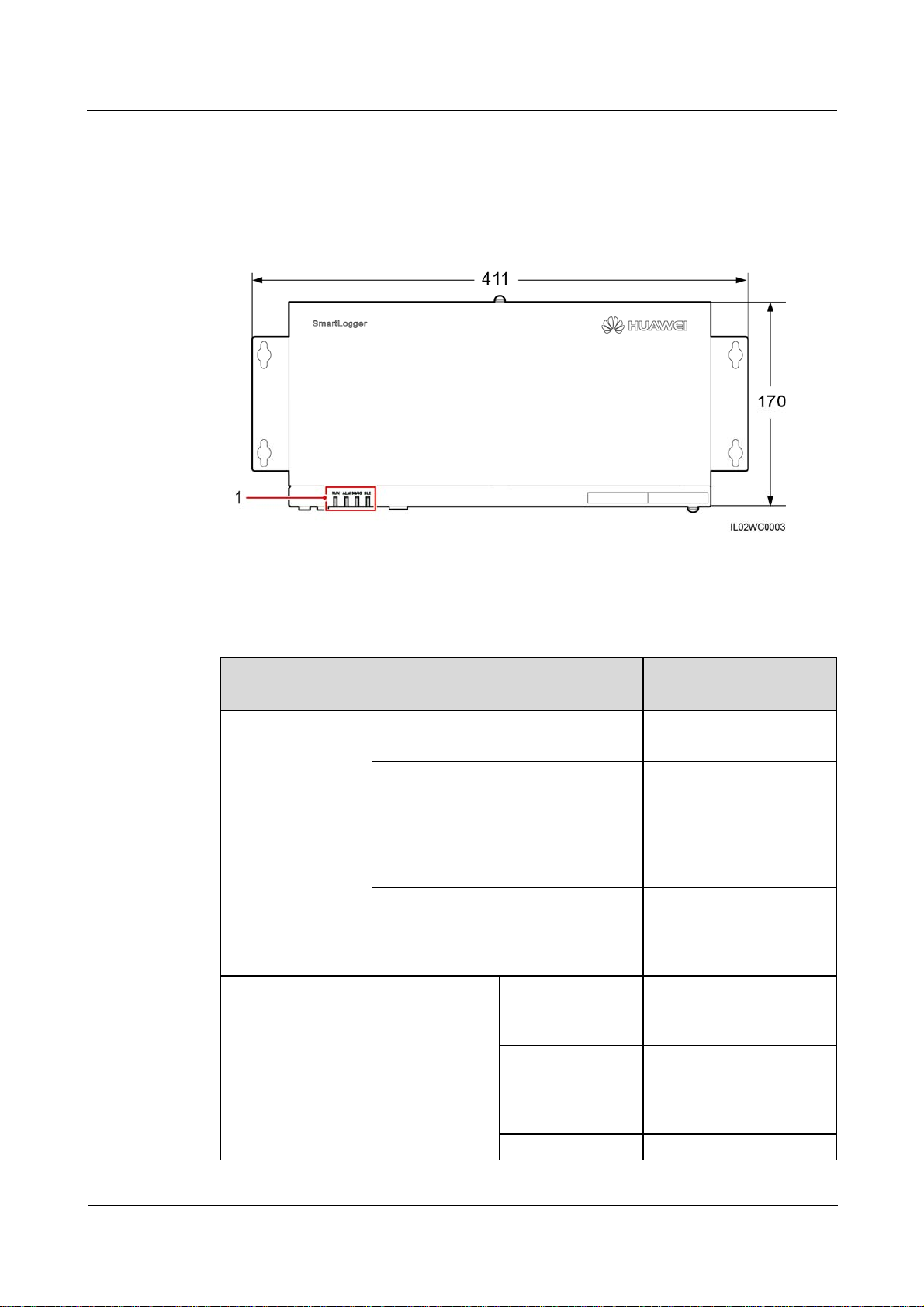

2.2 Appearance

Front View of the Shell

Figure 2-1 SmartLogger front view (unit: mm)

(1) Indicators

Table 2-1 Description of the LED indicators (from left to right)

Indicator (Silk

Screen)

RUN indicator Green off The SmartLogger is not

Alarm/maintenance

indicator (ALM)

Status Meaning

powered on.

Blinking green at short intervals (on

for 0.125s and then off for 0.125s)

Blinking green at long intervals (on

for 1s and then off for 1s)

Alarm status Red off The SmartLogger and the

a

The SmartLogger and the

NMS (the NetEco or a

third-party NMS) are not

connected or the

communication between

them is interrupted.

The SmartLogger properly

communicates with the

NMS (NetEco or a

third-party NMS).

devices accessing it do not

generate any alarm.

Blinking red at

long intervals (on

for 1s and then off

for 4s)

Blinking red at The SmartLogger or the

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

The SmartLogger or the

devices accessing it

generate warnings.

6

SmartLogger2000

User Manual 2 Overview

Indicator (Silk

Screen)

Status Meaning

short intervals (on

for 0.5s and then

devices accessing it

generate minor alarms.

off for 0.5s)

Steady red The SmartLogger or the

devices accessing it

generate major alarms.

Maintenance

status

Green off No local maintenance is

underway

Blinking green at

long intervals (on

Local maintenance is in

progress.

for 1s and then off

for 1s)

Steady green Local maintenance

succeeds.

Blinking green at

Local maintenance fails.

short intervals (on

for 0.125s and then

off for 0.125s)

b

.

3G/4G indicator - Reserved.

Bluetooth indicator

(BLE)

Green off You have not logged in to

the APP or login failed.

The SmartLogger is not

connected to the APP or

Blinking green at long intervals (on

for 1s and then off for 1s)

the communication has

been interrupted

You have successfully

logged in to the APP.

c

.

a: If an alarm and local maintenance happen concurrently, the alarm/maintenance indicator

shows the near-end maintenance state first. After the USB flash drive is removed, the

indicator shows the alarm state.

b: Local maintenance refers to operations performed by connecting a USB flash drive to the

SmartLogger USB port, such as full data import and export using a USB flash drive.

c: After the communication between the SmartLogger and the APP fails, the disconnection

is normal if the green indicator goes off immediately, and is abnormal if the indicator goes

off after blinking slowly for 30s.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

7

SmartLogger2000

User Manual 2 Overview

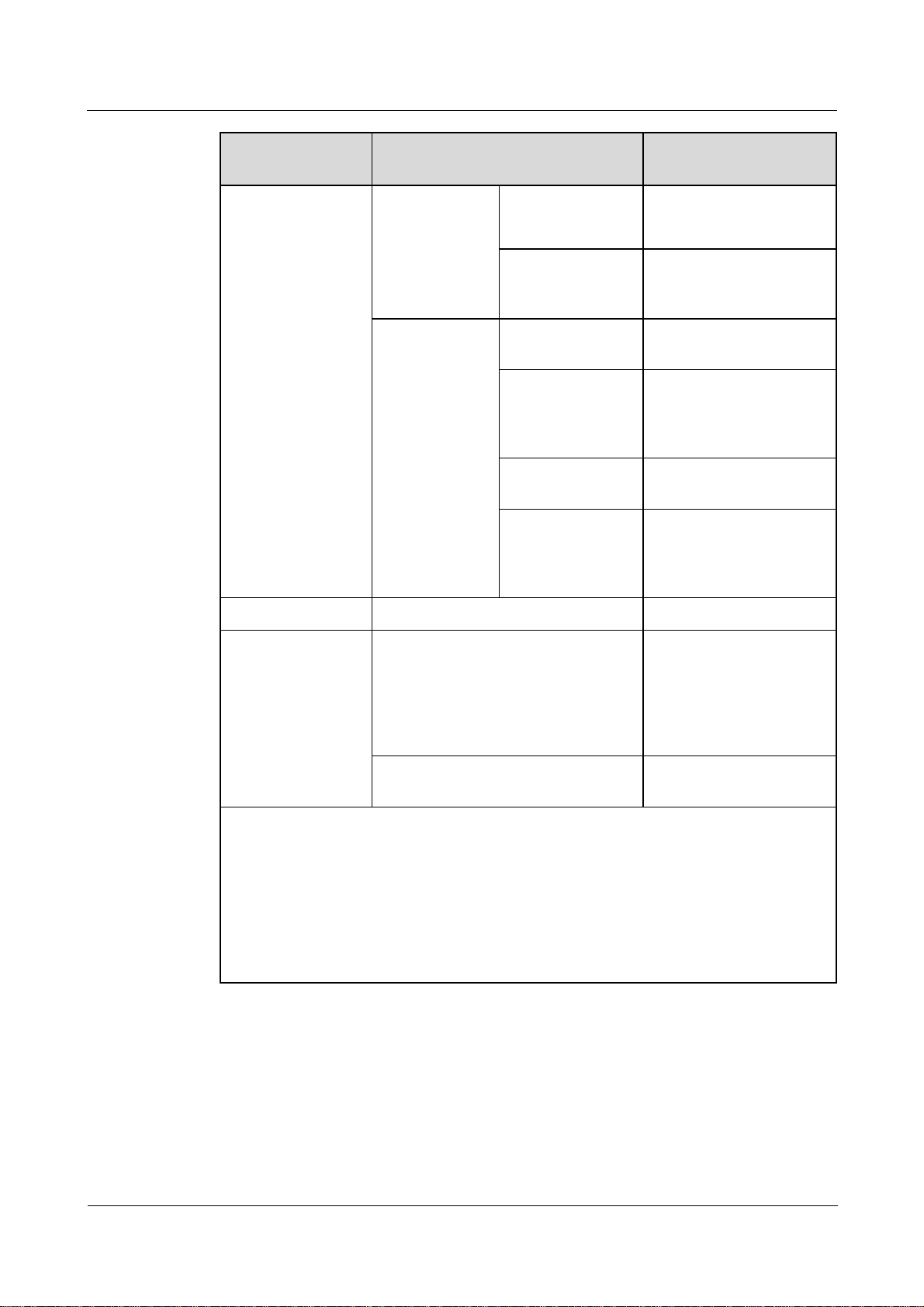

Side View of the Shell

Figure 2-2 SmartLogger side view (unit: mm)

(1) Heat dissipation hole (2) SIM card slot (reserved)

Rear View of the Shell

Figure 2-3 SmartLogger rear view (unit: mm)

(1) Wall-mounting ears

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

8

SmartLogger2000

User Manual 2 Overview

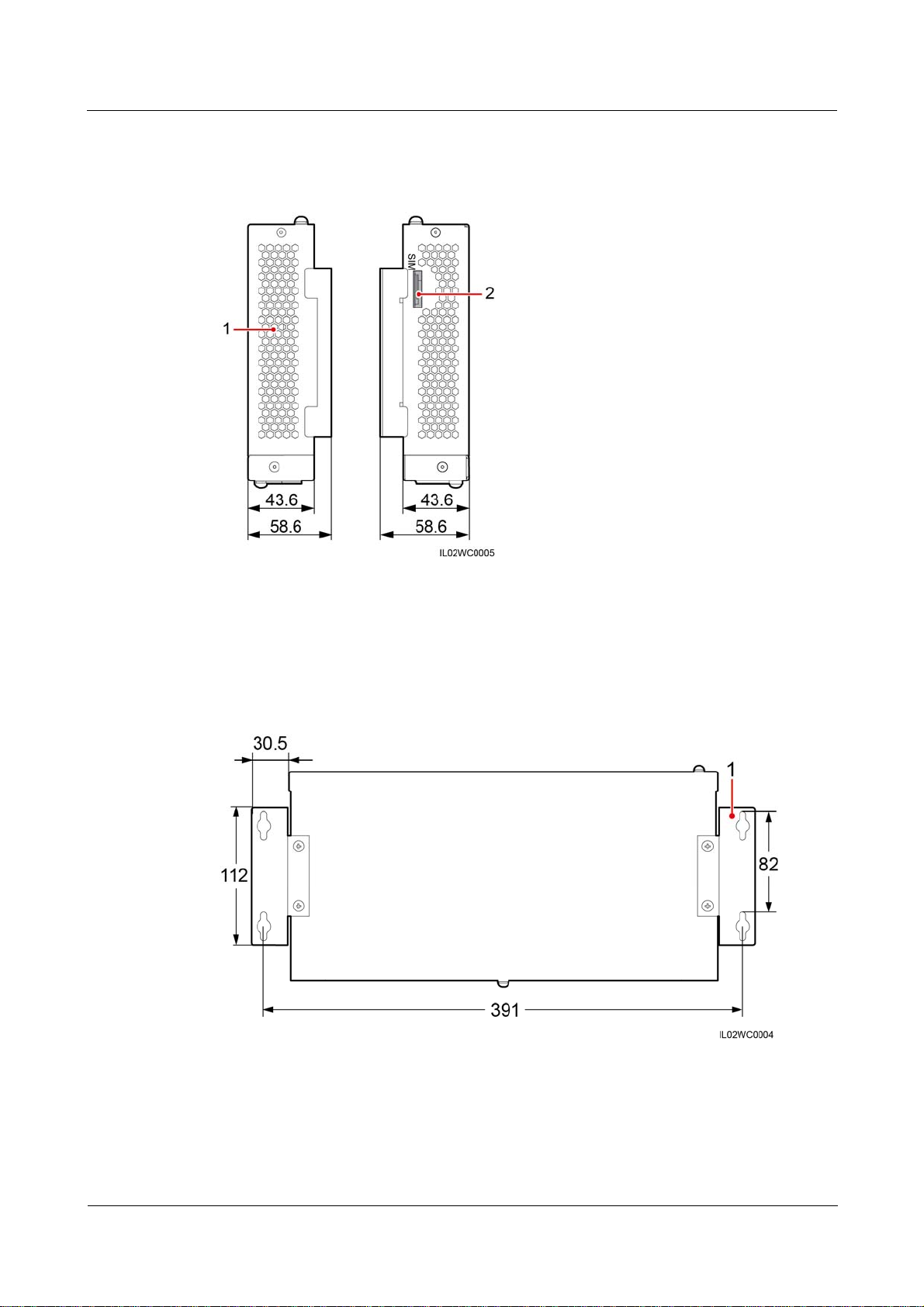

Bottom of the Shell

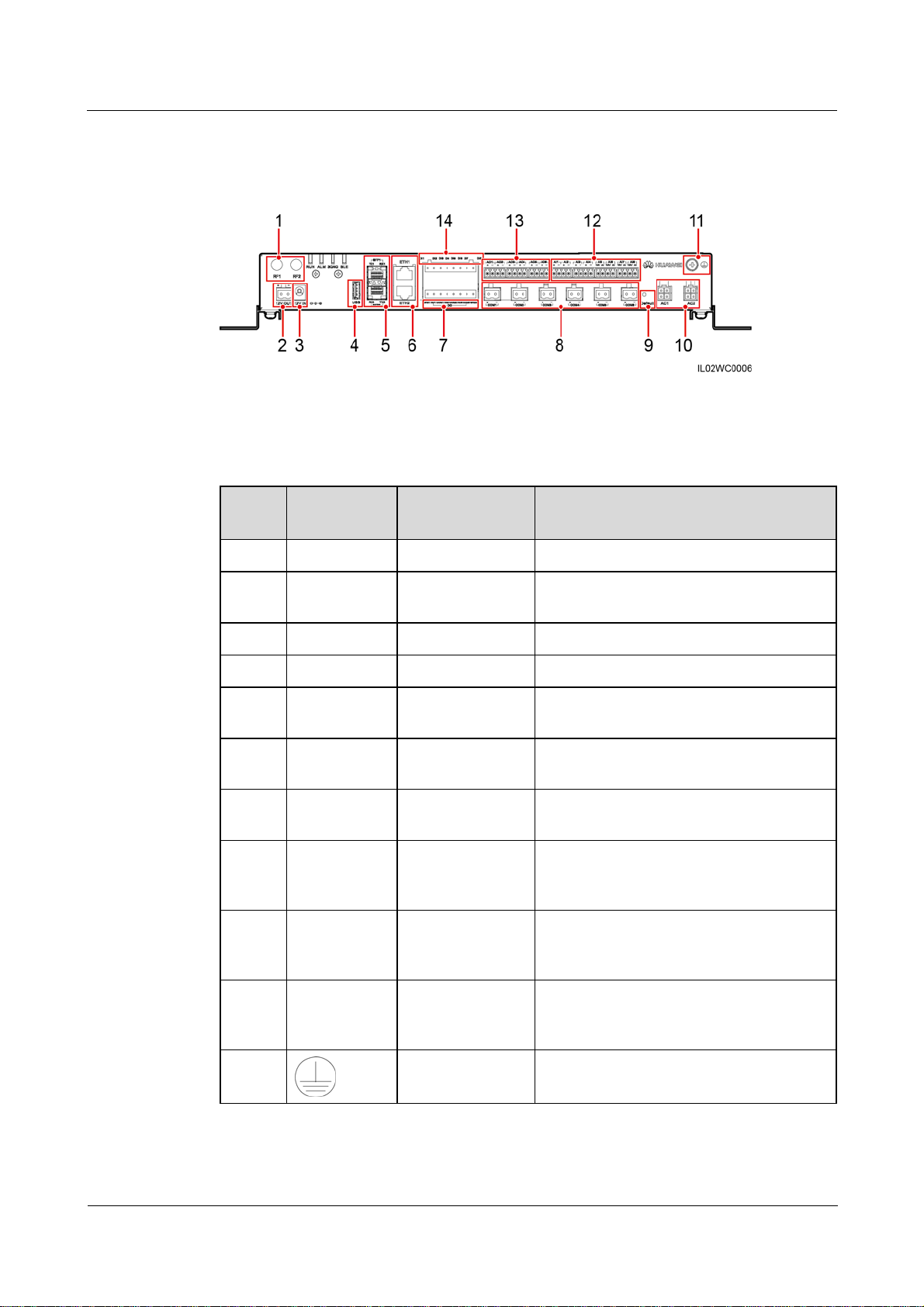

Figure 2-4 Bottom view of the SmartLogger

Table 2-2 describes the functions of ports on the SmartLogger.

Table 2-2 Port description

No. Port (Silk

Function Description

Screen)

1 RF1, RF2 Reserved Reserved.

2 12V OUT 12 V DC output Provides 12 V DC power supply with a

maximum current of 100 mA.

3 12V IN 12 V DC input Connects to a power adapter.

4 USB USB port Connects a USB flash drive.

5 SFP1, SFP2 Ethernet optical

port

6 ETH1, ETH2 Ethernet electrical

port

7 DO Digital parameter

Connects to an ATB or another cascaded

SmartLogger.

Connects to an Ethernet switch, router,

POE module, or PC.

Relay output.

output

8 COM1–COM6 RS485

communication

Six RS485 ports that can be connected to

devices such as the inverter, box-type

transformer, power meter, or EMI.

9 Default Default key Resets and restarts the Bluetooth module or

resets the SmartLogger IP address to the

default IP address

d

.

10 AC1, AC2 AC power cable

ports

Connects to A, B, and C three-phase inputs

for power line communication (PLC) with

the inverter.

11

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

External

grounding

-

9

SmartLogger2000

User Manual 2 Overview

No. Port (Silk

Function Description

Screen)

12 AI1–AI8 Analog input SmartLogger2000-10CN: AI1–AI4:

4–20 mA and 0–20 mA input current

(passive); AI5–AI8: 4–20mA and 0–20

mA input current (active)

Other models: AI1: 0–10 V input

voltage (passive); AI2–AI4: 4–20 mA

and 0–20 mA input current (passive);

AI5–AI8: 4–20 mA and 0–20 mA input

current (active)

13 AO1–AO6 Analog output 4–20 mA and 0–20 mA current output.

14 DI1–DI8 Digital parameter

Connects to a dry contact input.

input

d:

If the APP fails to connect to the SmartLogger or you have forgotten the IP address, you

can press the Default key to reset the Bluetooth module or restore the IP address to the

default IP address (192.168.0.10).

To reset and restart the Bluetooth module, press and hold down the Default key for

3–10s until the BLU indicator blinks at short intervals (0.125s on and 0.125s off) and all

other indicators are off, and then release the Default key.

To restore the IP address to the default IP address, press and hold down the Default key

for more than 10s until the RUN indicator blinks at short intervals (0.125s on and

0.125s off) and all other indicators are off, and then release the Default key. The

operation is valid within 5 minutes.

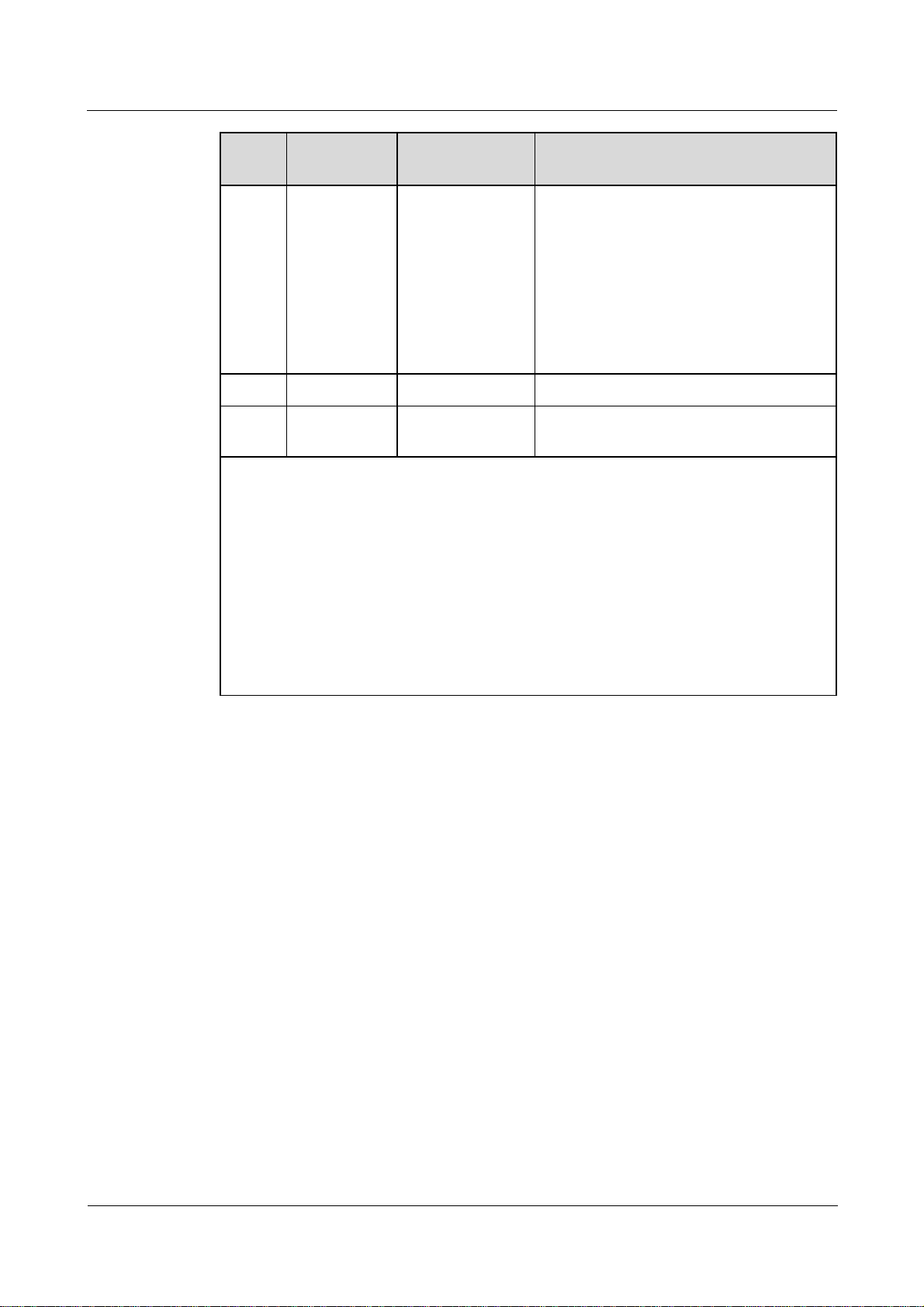

2.3 Nameplate Description

A nameplate is attached at the back of the SmartLogger. The content of the nameplate

includes the SmartLogger model, rated power supply specifications, and compliance symbols,

as shown in Figure 2-5.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

10

SmartLogger2000

User Manual 2 Overview

Figure 2-5 Nameplate

(1) Trademark, product model, and rated power

supply specifications

(3) Company name and country of manufacture

Table 2-3 Compliance symbols

Symbol Name Meaning

Environmentally friendly

use period (EFUP) label

EU waste electrical and

electronic equipment

(WEEE) label

(2) Compliance symbols

This product does not

pollute the environment

during a specified period.

Do not dispose of the

SmartLogger as household

garbage. For details about

how to deal with the

undesirable SmartLogger,

refer to 8 Disposing of the

SmartLogger.

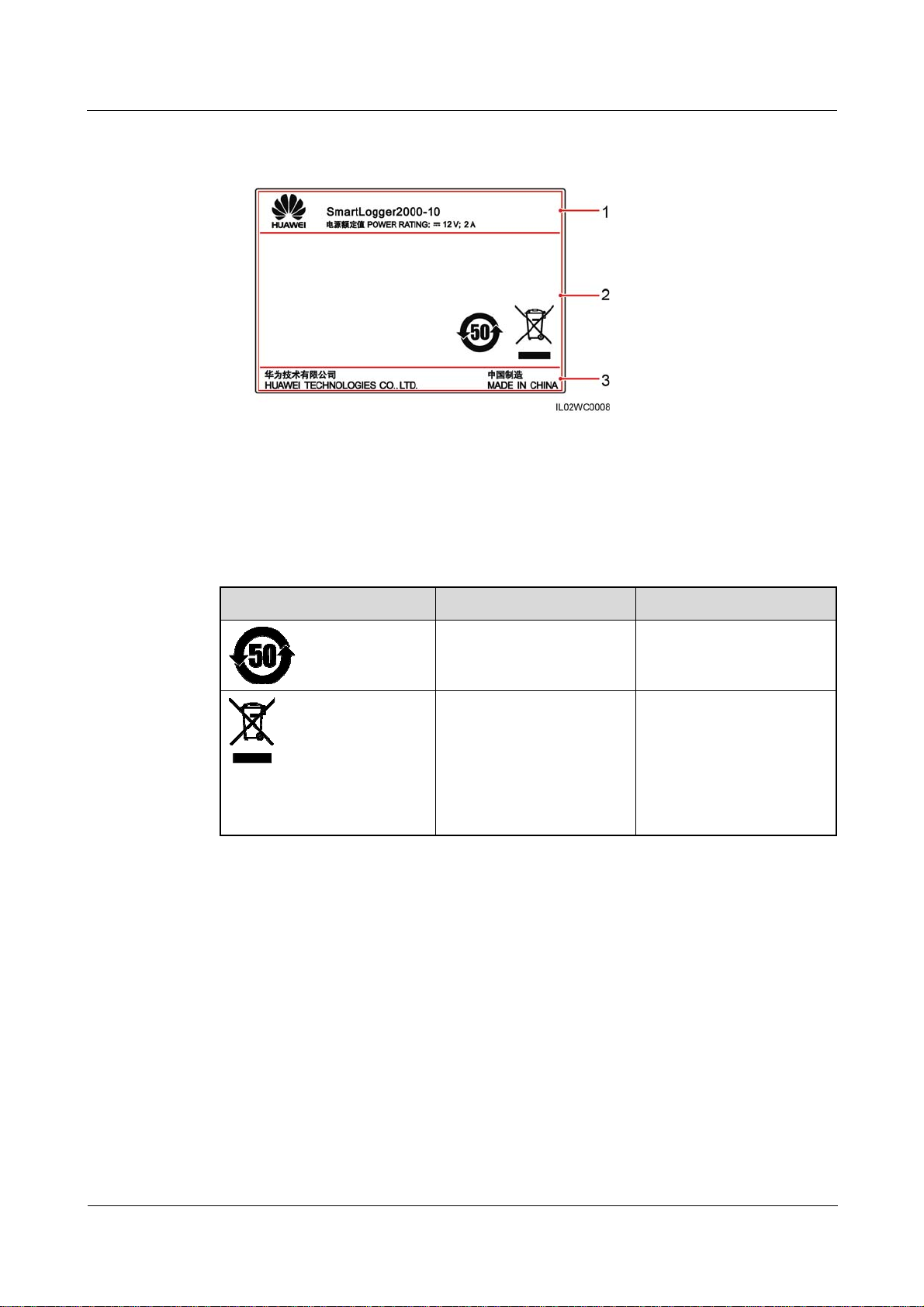

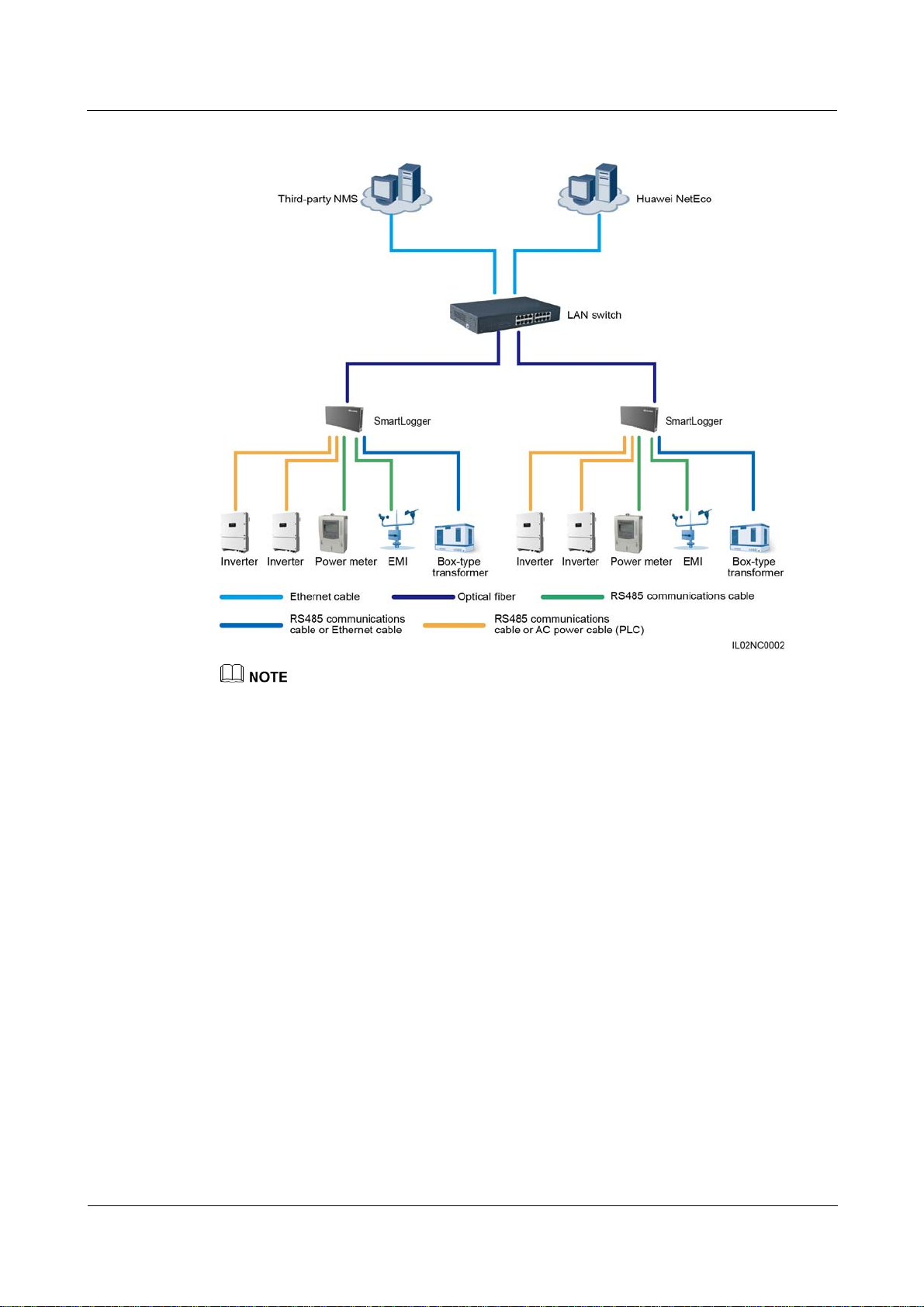

2.4 Typical Networking Scenarios

Fiber+RS485/PLC Networking

A fiber network can be a ring network or a star network, as shown in Figure 2-6 and Figure

2-7 respectively.

In the fiber networking, the SmartLogger connects to an inverter over an RS485

communications cable or an AC power cable, connects to a box-type transformer over the

RS485 communications cable or Ethernet network cable, and connects to southbound devices

such as the EMI and power meter over the RS485 communications cable.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

11

SmartLogger2000

User Manual 2 Overview

The SmartLogger is integrated with the PLC central coordinator (CCO) that can work with the

SUN2000 integrated with the PLC station (STA) to implement power line communication (PLC)

networking over power cables.

Figure 2-6 Ring fiber network diagram

The SmartLogger provides two 100M Ethernet optical ports to implement ring networking.

A maximum of 16 SmartLoggers can be connected to form a fiber ring network. Each SmartLogger

can connect to southbound devices such as the inverter, EMI, and power meter.

Multiple fiber ring networks can converge over an Ethernet switch or SmartLogger and then connect

to an NMS.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

12

SmartLogger2000

User Manual 2 Overview

Figure 2-7 Start fiber network diagram

Multiple SmartLoggers can converge over an Ethernet switch and then connect to an NMS.

The SmartLogger connects to the Ethernet switch over optical fibers with the maximum

communications distance of 12 km in between.

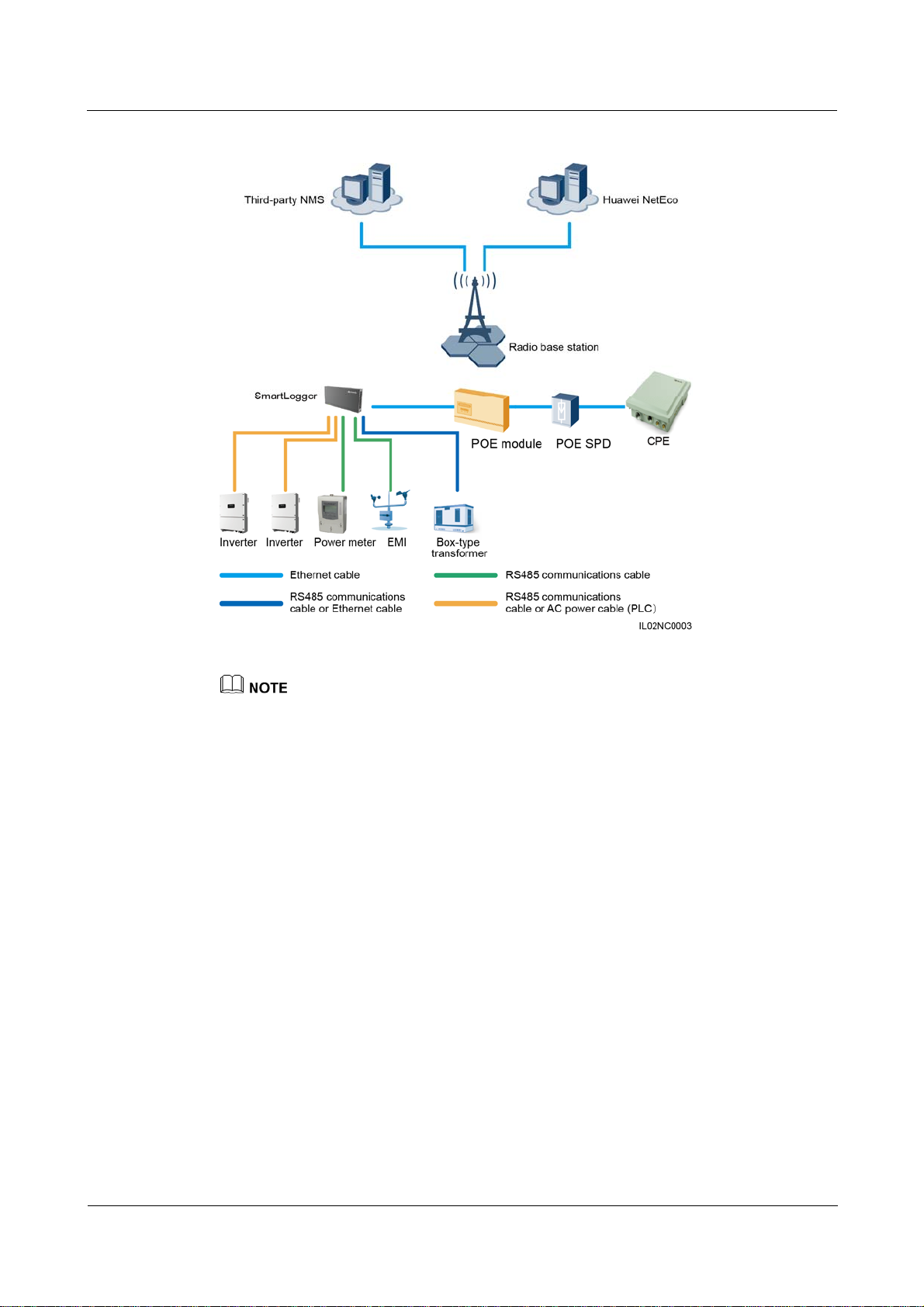

LTE+RS485/PLC Networking

Figure 2-8 shows the LTE+RS485/PLC networking diagram.

In the LTE wireless networking scenario, the SmartLogger connects to the inverter over an

RS485 communications cable or an AC power cable, connects to a box-type transformer over

the RS485 communications cable or Ethernet network cable, connects to southbound devices

such as the EMI and power meter over the RS485 communications cable, connects to a

customer premises equipment (CPE) over an Ethernet electrical port, and transmits

information collected from southbound devices to an NMS in wireless mode.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

13

SmartLogger2000

User Manual 2 Overview

Figure 2-8 LTE+RS485/PLC network diagram

The IP addresses for the SmartLogger, CPE, and monitoring devices in the box-type transformer

must be in the same network segment.

The IP address planned for the SmartLogger needs to be imported to the third-party NMS for the

NMS to proactively connect to the SmartLogger.

The IP address planned for the box-type transformer needs to be imported to the third-party NMS for

the NMS to proactively connect to the box-type transformer.

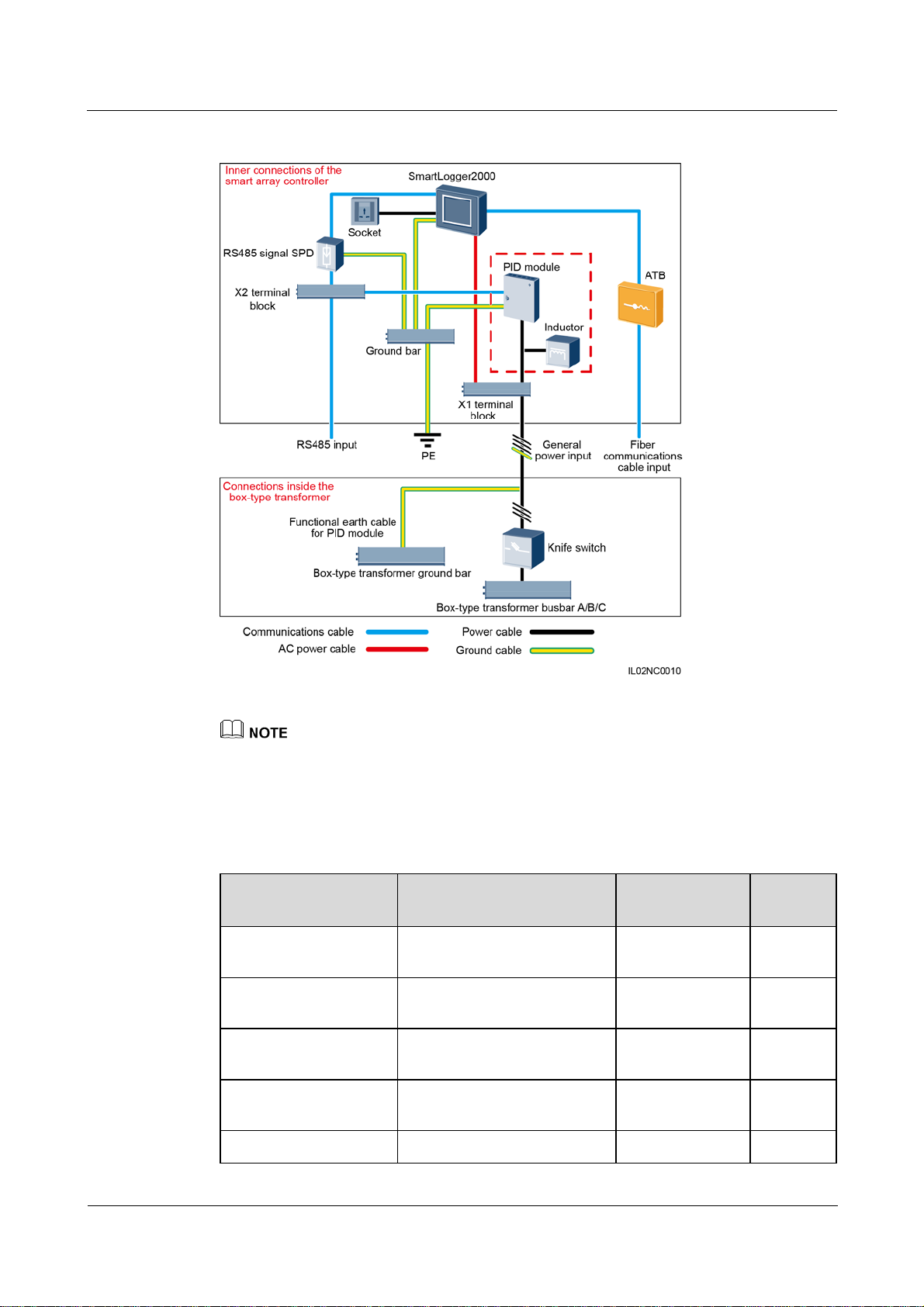

2.5 System Wiring Diagram

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

14

SmartLogger2000

User Manual 2 Overview

The general power input cable of the SmartACU2000 smart array controller (smart array

controller for short) needs to be prepared by the customer. Recommended cable: four-core

multi-wire (L1, L2, L3, and GND) armored; operating voltage to the ground: ≥ 600 V; and

cross sectional area of a single core: 4mm

The cable from the busbar to the knife switch needs to be prepared by the customer.

Recommended cable: three-core multi-wire (L1, L2, and L3); operating voltage to the

ground: ≥ 600 V; cross sectional area of a single core: 4 mm

The SmartLogger can be connected to the SUN2000 through an RS485 communications

2

.

2

.

cable or AC power cable. If the RS485 communications mode is used, no AC power cable

is required between the SmartLogger and the X1 terminal block in the scenario with smart

array controllers; no AC power cable is required between the SmartLogger and the MCB

in the scenario without smart array controllers.

If the SmartLogger uses the RS485 communications mode, it is recommended that at least

two RS485 signal SPDs be installed. A maximum of three RS485 signal SPDs can be

installed for each site.

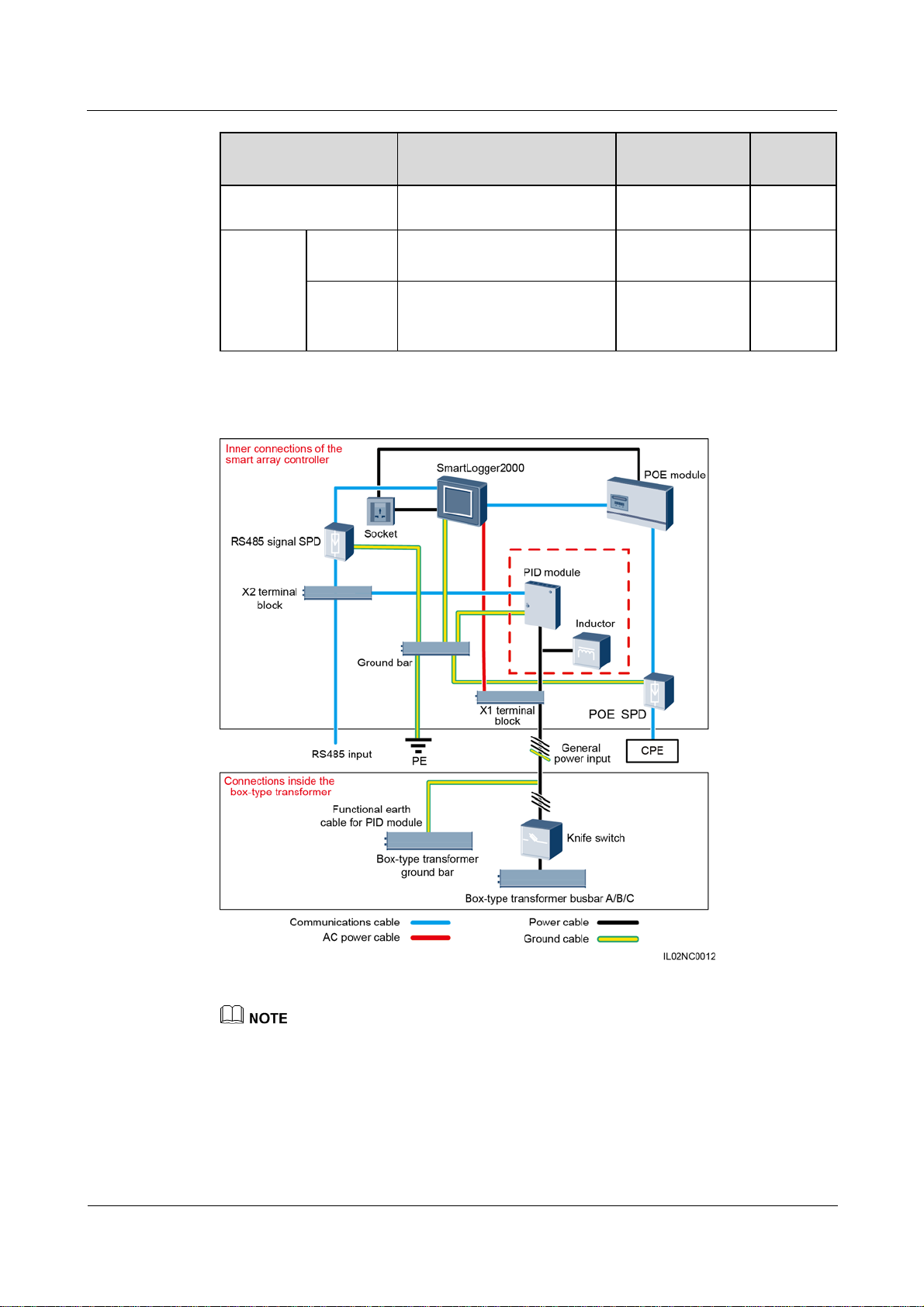

Scenario With a Smart Array Controller

The smart array controller, also a communication box, is an outdoor cabinet that controls the

communication of the PV array in a PV plant. The cabinet can house components such as the

SmartLogger, RS485 signal SPD, PID module, inductor, ATB, PoE module, and PoE SPD.

The PID module and inductor are configured only in the smart array controller with the PID module

and have been installed before delivery.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

15

SmartLogger2000

User Manual 2 Overview

Figure 2-9 Fiber+RS485/PLC

The X1 terminal block (general power input and AC output) and X2 terminal block (RS485

communications port) are in the upper part on the rear of the smart array controller.

Table 2-4 lists the components required for the fiber+RS485/PLC networking mode in the

scenario with a smart array controller.

Table 2-4 Components required

Component Recommended Model or

Type Quantity

Specifications

PID module (optional) PID01 Installed before

1 PCS

delivery

PID inductor (working

with the PID module)

SmartLogger SmartLogger2000 Installed before

EIFI50ohm Installed before

1 PCS

delivery

1 PCS

delivery

RS485 signal SPD SPM01A Installed before

3 PCS

delivery

ATB CT-GZF2PJ-8 or Optional; can be 1 PCS

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

16

SmartLogger2000

User Manual 2 Overview

Component Recommended Model or

Specifications

CT-GPH-A-8

Knife

switch

Fuse Rated voltage: ≥ 500 V; rated

current: 6 A

Knife

switch box

Rated voltage: ≥ 500 V; rated

current: ≥ 6 A; number of

phases: three

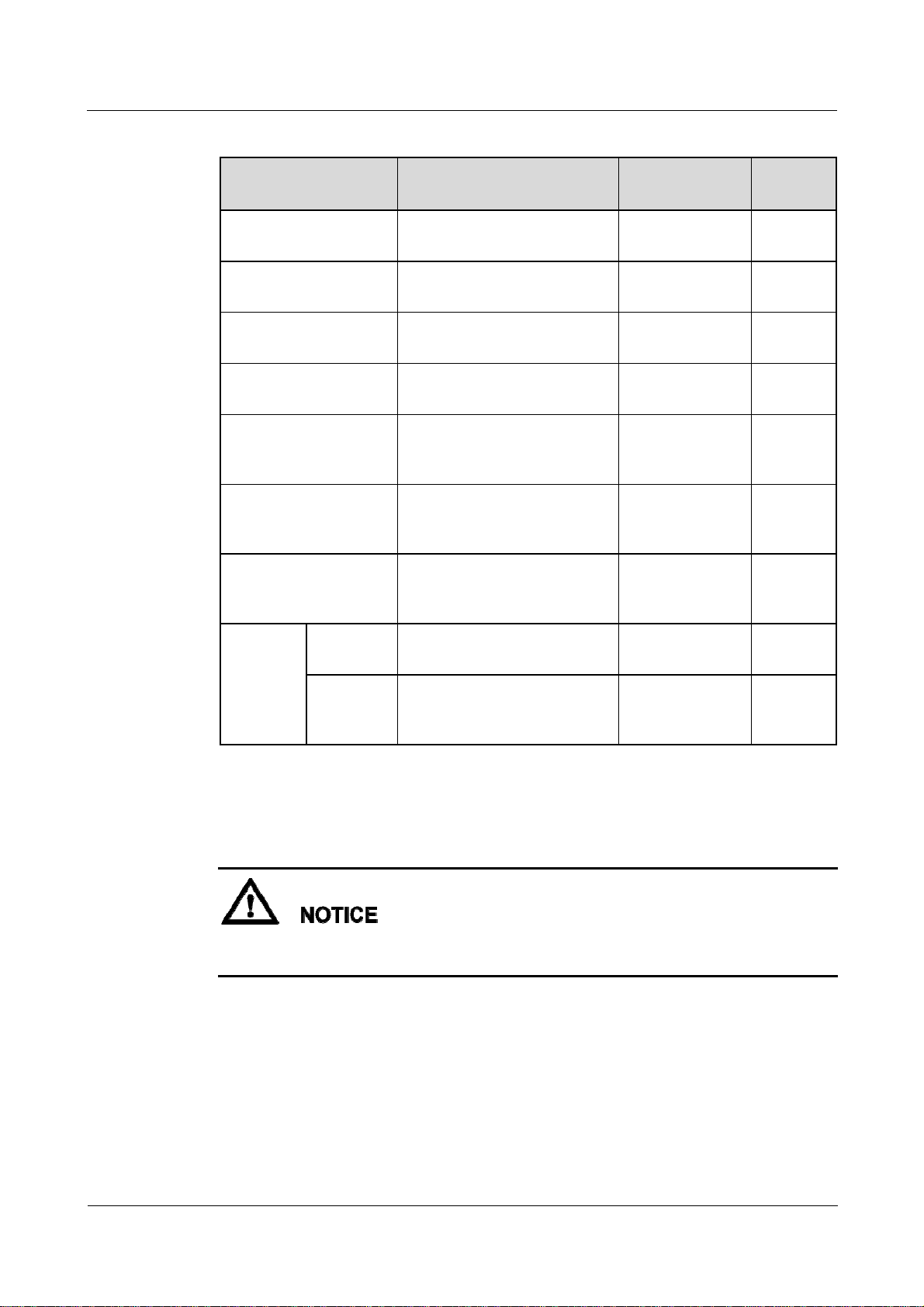

Figure 2-10 LTE+RS485/PLC

Type Quantity

purchased from

Huawei

Prepared by the

3 PCS

customer

Prepared by the

1 PCS

customer

The X1 terminal block (general power input and AC output) and X2 terminal block (RS485

communications port) are in the upper part on the rear of the smart array controller.

Table 2-5 lists the components required for the LTE+RS485/PLC networking mode in the

scenario with a smart array controller.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

17

SmartLogger2000

User Manual 2 Overview

Table 2-5 Components required

Component Recommended Model or

Type Quantity

Specifications

PID module (optional) PID01 Installed before

1 PCS

delivery

PID inductor (working

with the PID module)

SmartLogger SmartLogger2000 Installed before

EIFI50ohm Installed before

1 PCS

delivery

1 PCS

delivery

RS485 signal SPD SPM01A Installed before

3 PCS

delivery

PoE module POE35-54A or POE85-56A Optional; can be

1 PCS

purchased from

Huawei

POE SPD POE-2A Optional; can be

1 PCS

purchased from

Huawei

CPE EG860V2-C71 Optional; can be

1 PCS

purchased from

Huawei

Knife

switch

Fuse Rated voltage: ≥ 500 V; rated

current: 6 A

Knife

switch box

Rated voltage: ≥ 500 V; rated

current: ≥ 6 A; number of

phases: three

Scenario Without a Smart Array Controller

If the SmartLogger uses an AC power cable for communication, an MCB or a knife switch

needs to be installed to prevent device damage in the case of short circuits

Prepared by the

customer

Prepared by the

customer

3 PCS

1 PCS

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

18

SmartLogger2000

User Manual 2 Overview

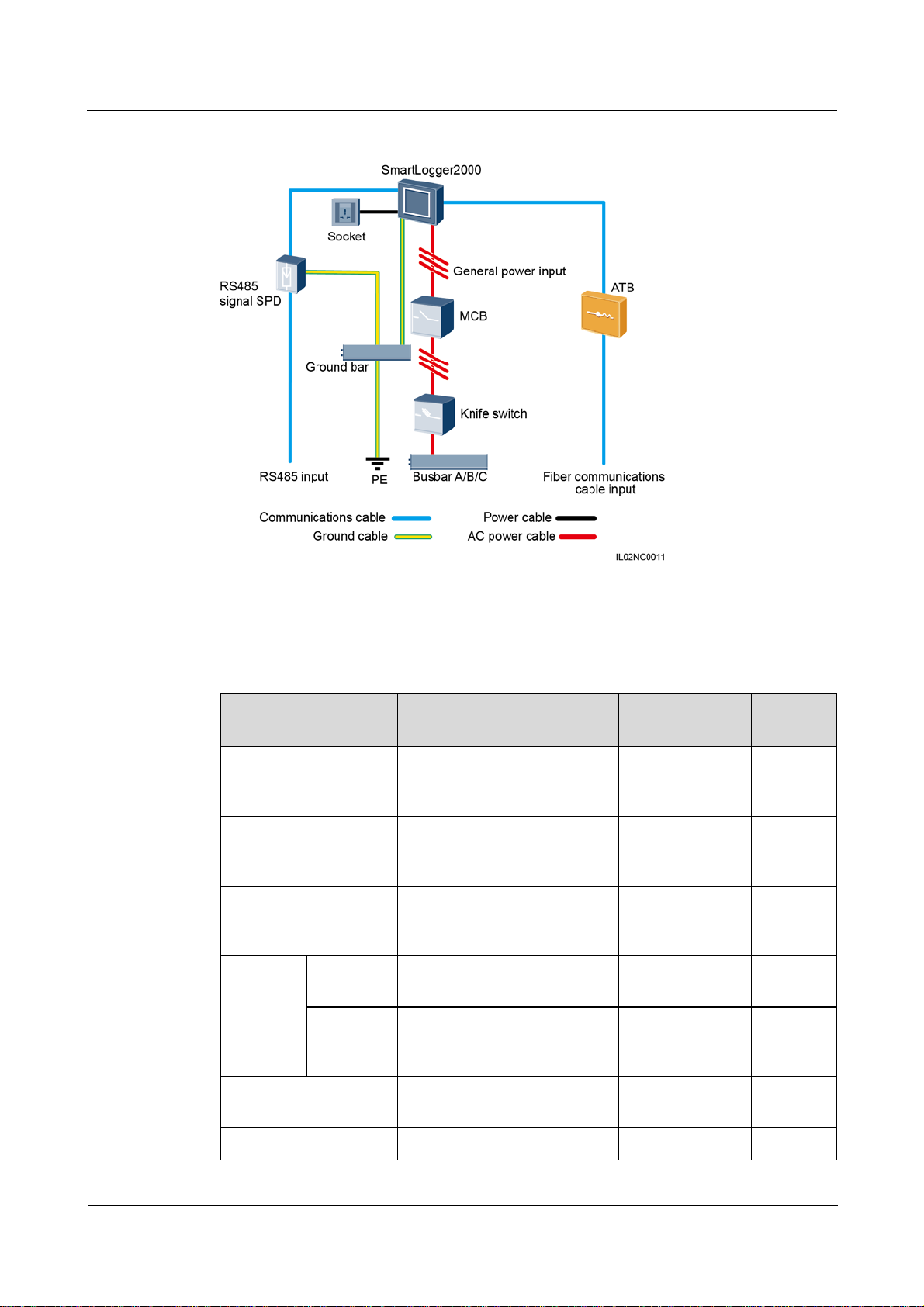

Figure 2-11 Fiber+RS485/PLC

Table 2-6 lists the components required for the fiber+RS485/PLC networking mode in the

scenario without a smart array controller.

Table 2-6 Components required

Component Recommended Model or

Type Quantity

Specifications

SmartLogger SmartLogger2000 Optional; can be

1 PCS

purchased from

Huawei

RS485 signal SPD X4B-05 Optional; can be

3 PCS

purchased from

Huawei

ATB CT-GZF2PJ-8 or

CT-GPH-A-8

Optional; can be

purchased from

1 PCS

Huawei

Knife

switch

Fuse Rated voltage: ≥ 500 V; rated

current: 6 A

Prepared by the

customer

3 PCS

Knife

switch box

Rated voltage: ≥ 500 V; rated

current: ≥ 6 A; number of

Prepared by the

customer

1 PCS

phases: three

MCB Rated voltage: ≥ 500 V; rated

current: ≥ 6 A

Prepared by the

customer

1 PCS

Socket Matching with the power Prepared by the 1 PCS

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

19

SmartLogger2000

User Manual 2 Overview

Component Recommended Model or

Type Quantity

Specifications

adapter customer

Length of the cable used for connecting components depends on the survey result.

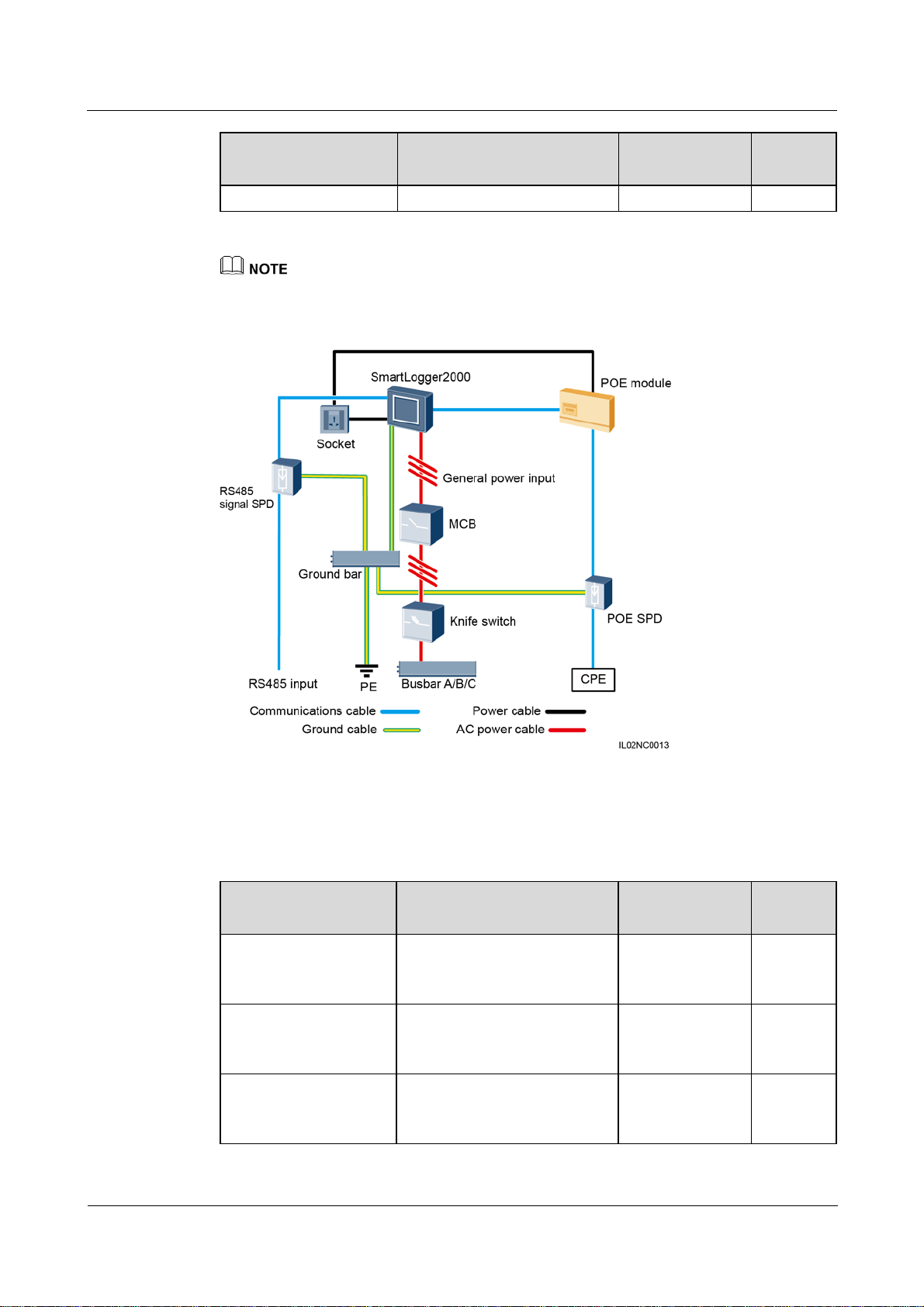

Figure 2-12 LTE+RS485/PLC

Table 2-7 lists the components required for the LTE+RS485/PLC networking mode in the

scenario without a smart array controller.

Table 2-7 Components required

Component Recommended Model or

Type Quantity

Specifications

SmartLogger SmartLogger2000 Optional; can be

1 PCS

purchased from

Huawei

RS485 signal SPD X4B-05 Optional; can be

3 PCS

purchased from

Huawei

PoE module POE35-54A or POE85-56A Optional; can be

1 PCS

purchased from

Huawei

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

20

SmartLogger2000

User Manual 2 Overview

Component Recommended Model or

Type Quantity

Specifications

POE SPD POE-2A Optional; can be

purchased from

Huawei

CPE EG860V2-C71 Optional; can be

purchased from

Huawei

Knife

switch

Fuse Rated voltage: ≥ 500 V; rated

current: 6 A

Knife

switch box

Rated voltage: ≥ 500 V; rated

current: ≥ 6 A; number of

Prepared by the

customer

Prepared by the

customer

phases: three

MCB Rated voltage: ≥ 500 V; rated

current: ≥ 6 A

Socket Matching with the power

adapter

Prepared by the

customer

Prepared by the

customer

1 PCS

1 PCS

3 PCS

1 PCS

1 PCS

1 PCS

Length of the cable used for connecting components depends on the survey result.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

21

SmartLogger2000

User Manual 3 Installation

3 Installation

About This Chapter

This topic describes how to install the SmartLogger.

Context

Install the SmartLogger in an appropriate position and surface.

Do not store the SmartLogger in areas with flammable or explosive materials.

Do not install the SmartLogger on flammable building materials.

3.1 Checking Before Installation

3.2 Preparing Tools

3.3 Determining the Installation Position

3.4 Installing the SmartLogger

3.5 Installing the RS485 signal SPD

3.1 Checking Before Installation

Checking Outer Packing Materials

Check the outer packing materials for damage before unpack the SmartLogger, such as holes

and cracks. If any damage is found, do not unpack the SmartLogger and contact the dealer as

soon as possible.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

22

SmartLogger2000

User Manual 3 Installation

Checking Deliverables

After unpacking the SmartLogger, check whether deliverables are intact and complete. If any

damage is found or any component is missing, contact the dealer.

For details about the number of accessories delivered with the SmartLogger, see the Packing List in the

packing case.

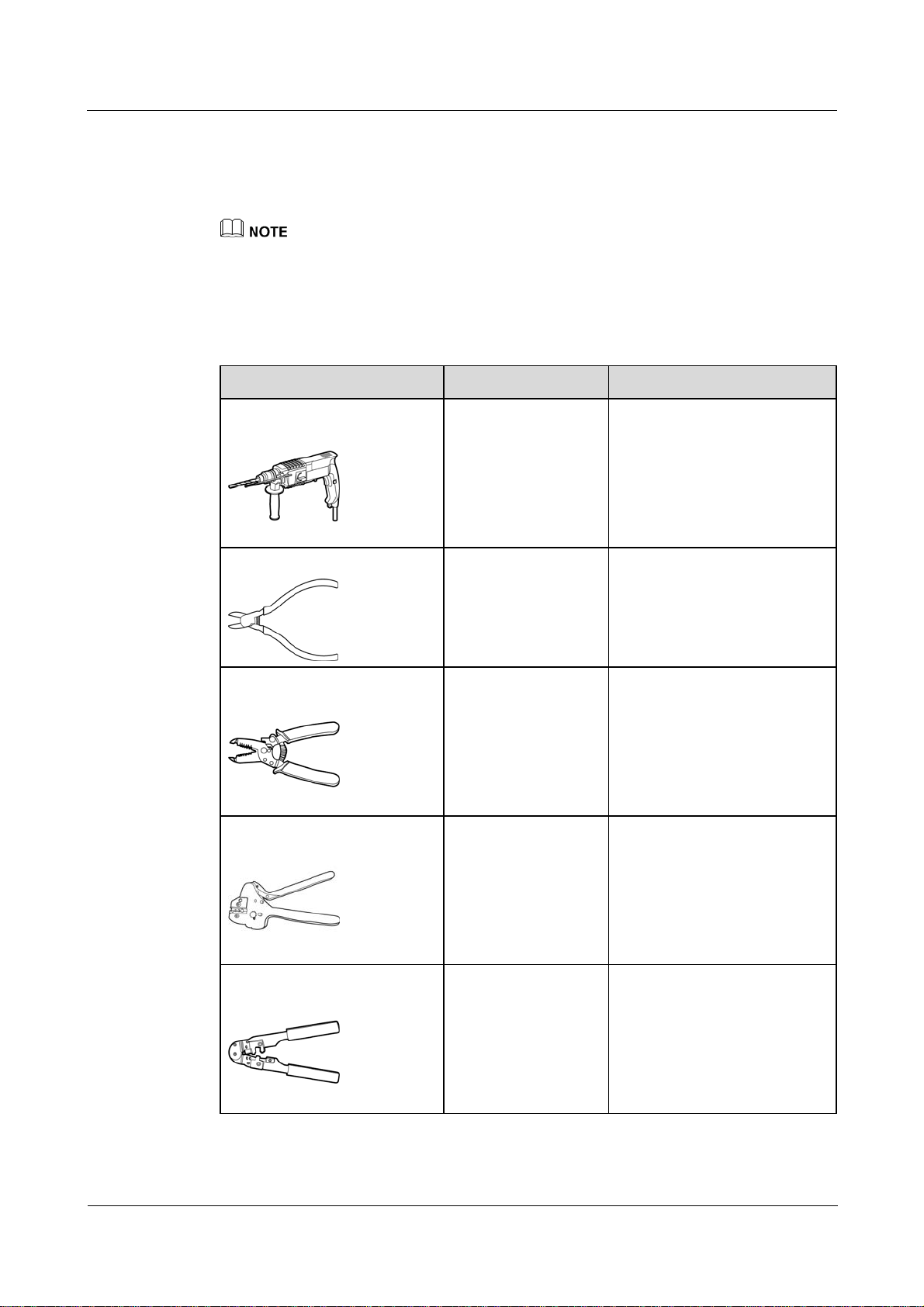

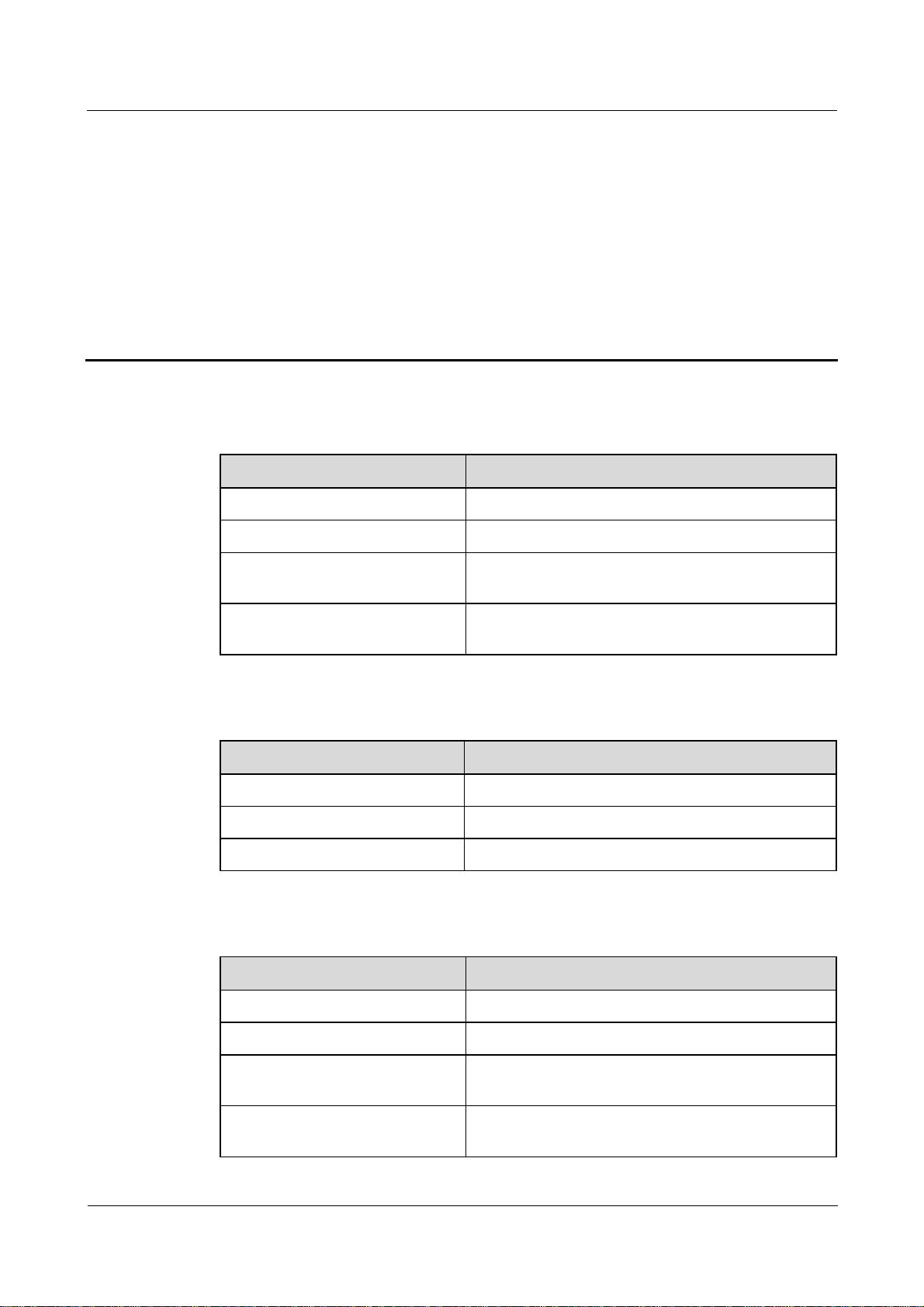

3.2 Preparing Tools

Tools Model Function

Hammer drill

Diagonal pliers

Wire stripper

Crimping tool

Drill bit (Ф6 mm) Drills holes in the wall when

the SmartLogger is

wall-mounted.

N/A Cuts and tighten cable ties.

N/A Peels cable jackets.

H4TC0001

Manufacturer:

AMPHENOL

Crimps cables.

RJ45 crimping tool

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

N/A Crimps RJ45 connectors for

communications cables.

23

SmartLogger2000

User Manual 3 Installation

Tools Model Function

Flat-head screwdriver

Rubber mallet

Guarded blade utility knife

Cable cutter

3x100 Tightens screws on the cable

terminal block.

N/A Hammers expansion sleeves

into holes.

N/A Removes package.

N/A Cuts cables.

Vacuum cleaner

Marker

N/A Cleans up dust after holes are

drilled.

Diameter: ≤ 10 mm Marks signs.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

24

SmartLogger2000

User Manual 3 Installation

Tools Model Function

Measuring tape

Safety goggles

Anti-dust respirator

Torque screwdriver

N/A Measures distance

N/A Protect your eyes during hole

drilling.

N/A Prevents dust from entering

your mouth and nostrils during

hole drilling.

Phillips head: M4 and

ST3.5

Tightens screws during device

installation.

Heat gun

N/A Heat-shrinks a tube.

Cable tie

N/A Binds cables.

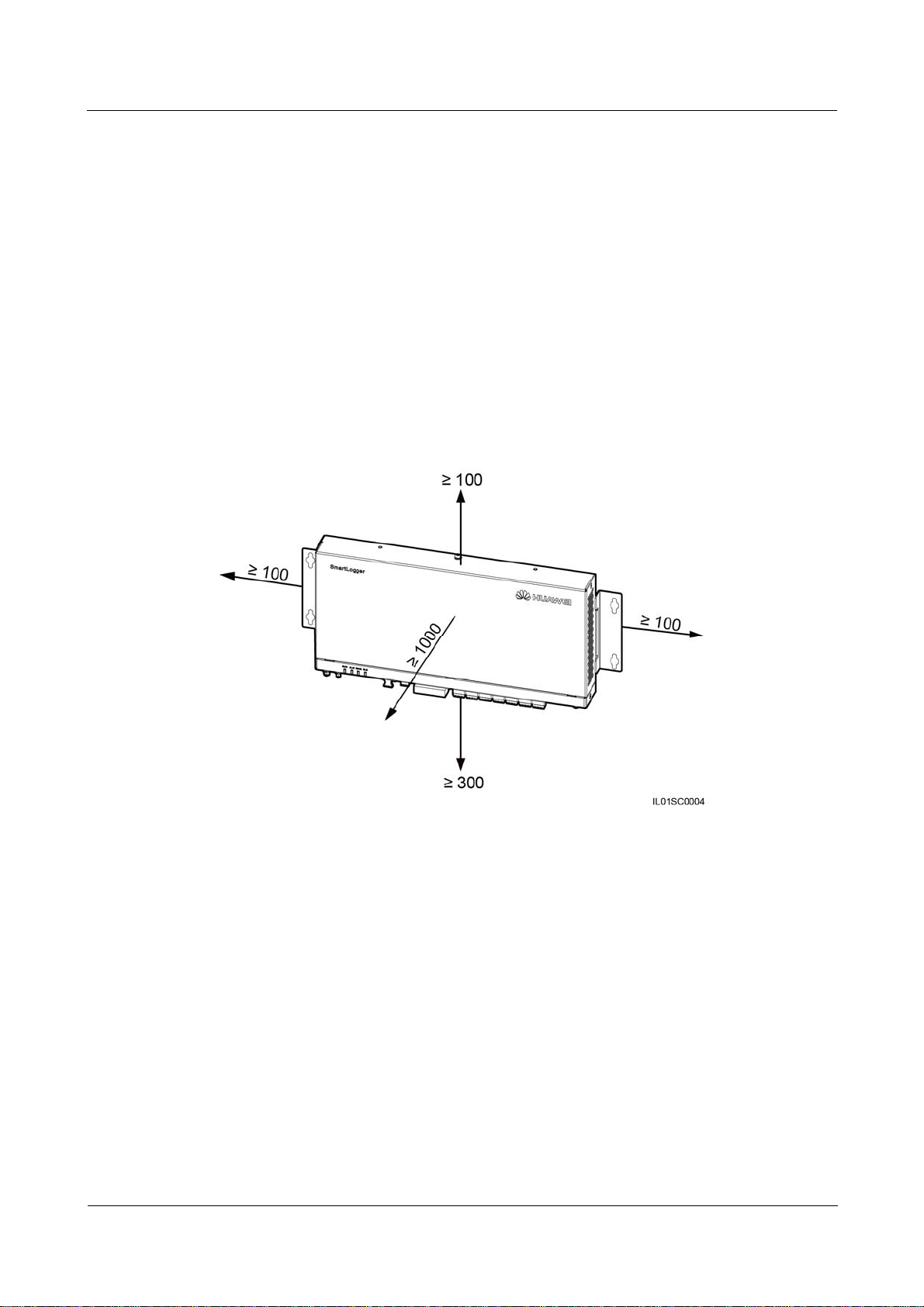

3.3 Determining the Installation Position

Observe the following requirements when determining the installation position:

Do not install the SmartLogger outdoors because it is protected to IP20.

Install the SmartLogger in a dry environment to protect it against water.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

25

SmartLogger2000

User Manual 3 Installation

Keep the product in an ambient temperature range of –40°C to +60°C and away from

direct sunlight.

The communications distance must not exceed 1000 m for the RS485 port, and must not

exceed 100 m for the Ethernet port.

Install the SmartLogger at a proper height to facilitate operation and maintenance.

Do not place the SmartLogger upside down; otherwise, dust will fall into ports at the

bottom of the SmartLogger, thereby reducing the service life.

The installation mode and position must be suitable for the SmartLogger weight (3800 g)

and dimensions with mounting ears (H x W x D: 411 mm x 170 mm x 58.6 mm).

If you install the SmartLogger on a wall or along a guide rail, the area for connecting

cables should be downwards.

Figure 3-1 and Figure 3-2 show the minimum distance between the SmartLogger and

surrounding objects.

Figure 3-1 The minimum clearance for wall-mounting (unit: mm)

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

26

SmartLogger2000

User Manual 3 Installation

Figure 3-2 The minimum clearance for guide rail–mounting (unit: mm)

3.4 Installing the SmartLogger

Context

For a smart array controller, the SmartLogger is installed before delivery. In other scenarios,

the SmartLogger can be mounted on a wall or guide rail.

3.4.1 Mounting the SmartLogger on a Wall

Context

Install the SmartLogger on a solid and smooth wall to ensure that it can be secured on the

wall.

Before hanging the SmartLogger on the screws, secure the expansion sleeves, washers,

and tapping screws into the wall.

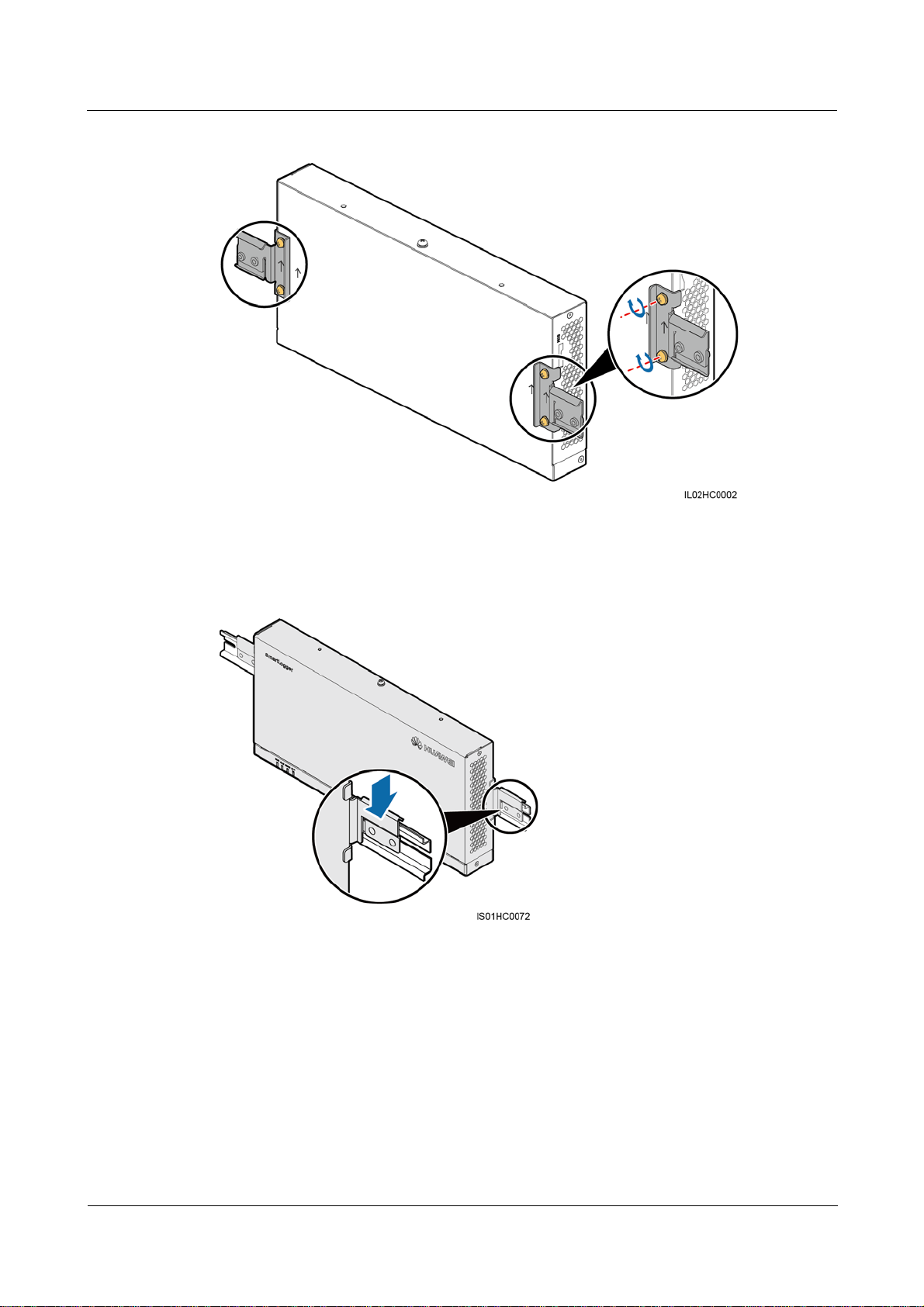

Figure 3-3 shows the distances between screw holes on the SmartLogger mounting ears.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

27

SmartLogger2000

User Manual 3 Installation

Figure 3-3 Distances between screw holes (unit: mm)

Figure 3-4 shows the screw assembly for wall-mounting:

Figure 3-4 Screw assembly for wall-mounting

Procedure

Step 1 Determine mounting holes based on the hole positions in the mounting ears, and mark the

(1) ST3.5 tapping screw (2) Washer (3) Expansion sleeve

mounting holes using a marker, as shown in Figure 3-5.

If you need to use a ladder to install the device on a high position, take measures to protect

yourself from falling down.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

28

SmartLogger2000

User Manual 3 Installation

Figure 3-5 Hole positions and dimensions (unit: mm)

Step 2 Drill holes by using a hammer drill and install expansion sleeves, washers, and tapping screws,

as shown in Figure 3-6.

Figure 3-6 Drilling holes and installing expansion sleeves, washers, and tapping screws (unit:

mm)

1. Put a hammer drill with a Ф6 mm drill bit on a marked hole position perpendicularly

against the wall and drill to a depth greater than or equal to 40 mm.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

29

SmartLogger2000

User Manual 3 Installation

To prevent dust inhalation or contact with eyes, wear safety goggles and an anti-dust

respirator when drilling holes.

Wipe away any dust in or around the holes and measure the hole distance. If the holes are

inaccurately positioned, drill holes again.

2. Slightly tighten the expansion sleeves, vertically insert them into holes, and knock them

completely into the holes by using a rubber mallet.

3. Drive the tapping screws into the expansion sleeves, and reserve 10 mm outside of the

holes.

Step 3 Put the tapping screws through the SmartLogger mounting ears and washers into the

mounting holes in the wall.

Ensure that the area for connecting cables in the SmartLogger is downwards for the ease of

electrical connections and maintenance.

Step 4 Tighten the tapping screws to a torque of 0.3 N·m using a torque screwdriver, as shown in

Figure 3-7.

Figure 3-7 Tightening the tapping screws

----End

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

30

SmartLogger2000

User Manual 3 Installation

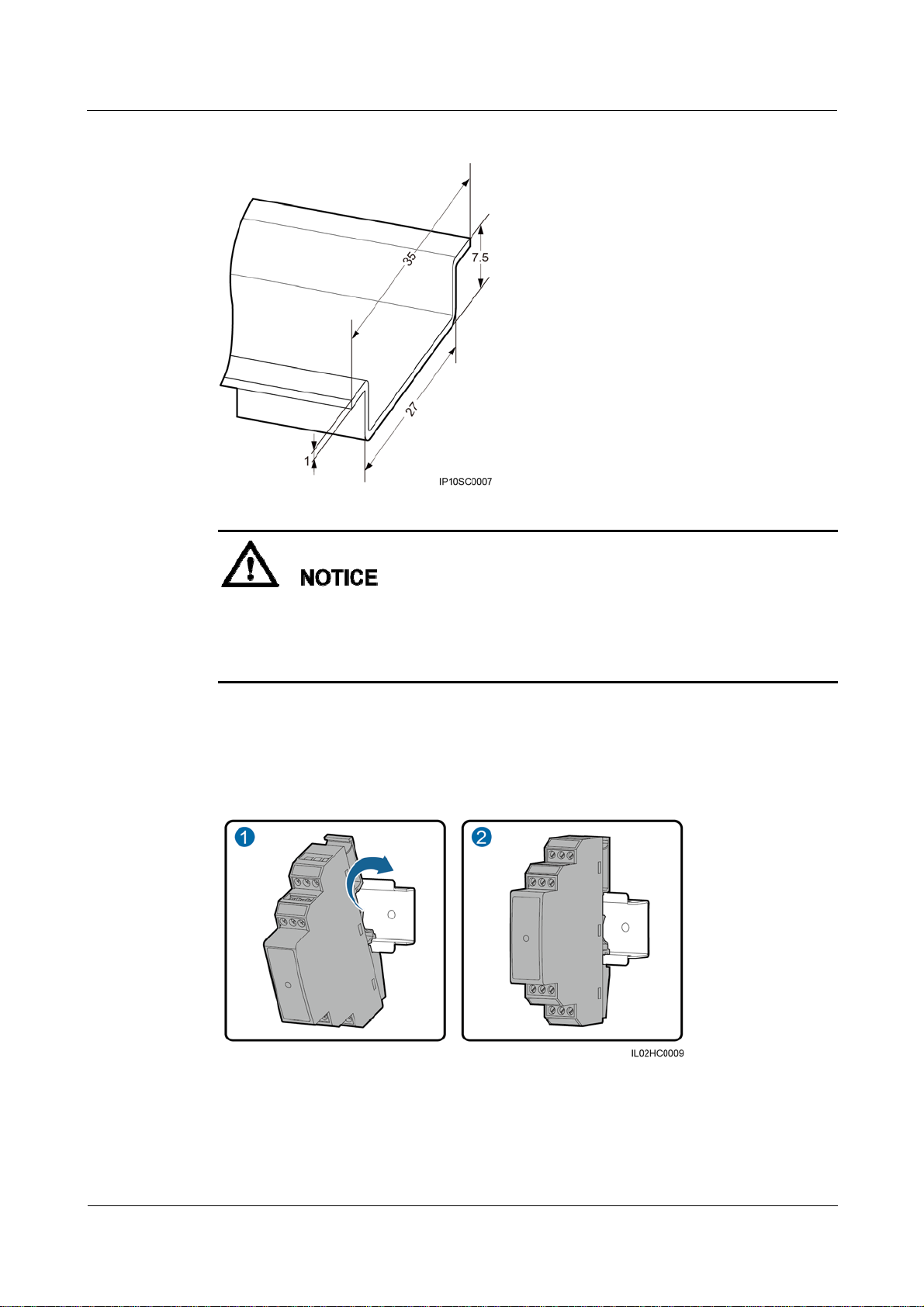

3.4.2 Mounting the SmartLogger Along a Guide Rail

Context

No guide rail is delivered with a SmartLogger. If you need to install a SmartLogger on a guide

rail, prepare a standard 35 mm wide guide rail. For details about the guide rail dimensions, see

Figure 3-8.

Figure 3-8 Guide rail dimensions (unit: mm)

Procedure

Step 1 Remove the mounting ears from the SmartLogger using a Phillips screwdriver, as shown in

Verify that the length of the guide rail is sufficient for securing the SmartLogger. The

recommended length is 450 mm or greater. If an RS485 signal SPD needs to be installed

on the guide rail, the recommended guide rail length is 600 mm or greater.

Secure the guide rail before mounting the SmartLogger.

Figure 3-9.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

31

SmartLogger2000

User Manual 3 Installation

Figure 3-9 Removing the mounting ears

Step 2 Secure the guide rail clamps using M4x8 screws removed from the mounting ears, and tight

the screws to a torque of 1.2 N·m, as shown in Figure 3-10.

Install the guide rail clamps exactly as shown in the figure; otherwise, you may not be able to

mount the SmartLogger onto the guide rail.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

32

SmartLogger2000

User Manual 3 Installation

Figure 3-10 Installing the guide rail clamps

Step 3 Mount the SmartLogger onto the guide rail, as shown in Figure 3-11.

Figure 3-11 Mounting the SmartLogger onto the guide rail

Step 4 Install the guide rails fastener using M4x12 screws, and tighten the screws to a torque wrench

of 1.2 N·m, as shown in Figure 3-12.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

33

SmartLogger2000

User Manual 3 Installation

Figure 3-12 Installing guide rail fasteners

----End

3.5 Installing the RS485 signal SPD

Context

If the SmartLogger needs to be connected to outdoor equipment through the COM port,

it is recommended that an RS485 signal SPD be installed.

Each RS485 signal SPD can connect to two COM ports. Each SmartLogger can be

configured with a maximum of three RS485 signal SPDs.

For a smart array controller, the RS485 signal SPD is installed before delivery. In other

scenarios, the RS485 signal SPD can be mounted on guide rail.

When determining the installation position, verify that the linear distance between the RS485 signal SPD

and the SmartLogger is no greater than 500 mm.

No guide rail is delivered with an RS485 signal SPD. If you need to install an RS485 signal

SPD on a guide rail, prepare a standard 35 mm wide guide rail with a length no less than 80

mm. For details about the guide rail dimensions, see Figure 3-8.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

34

SmartLogger2000

User Manual 3 Installation

Figure 3-13 Guide rail dimensions (unit: mm)

Procedure

Step 1 Secure the RS485 signal SPD to the guide rail, as shown in Figure 3-14.

If the SmartLogger is installed on a guide rail, the RS485 signal SPD can share the guide

rail with the SmartLogger. In this case, the recommended guide rail length is 600 mm or

greater.

Secure the guide rail before mounting the RS485 signal SPD.

Figure 3-14 Securing the RS485 signal SPD to the guide rail

----End

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

35

SmartLogger2000

User Manual 4 Connecting Cables

4 Connecting Cables

About This Chapter

Context

This section describes how to connect the SmartLogger to inverters and other devices in the scenario

without a smart array controller.

For a smart array controller, the SmartLogger and RS485 signal SPDs are installed before delivery.

For devices using the RS485 communications mode, connect the RS485 communications cable to

the X2 terminal block on the smart array controller. For devices using the PLC mode, connect the

AC power cable to the X1 terminal block on the smart array controller. For details about the two

connection methods, see SmartACU2000-C Smart Array Controller User Manual.

Ensure that all cables are connected securely.

The SmartLogger has no start key. Before the cable connections for the SmartLogger are

complete, do not connect a power adapter to it.

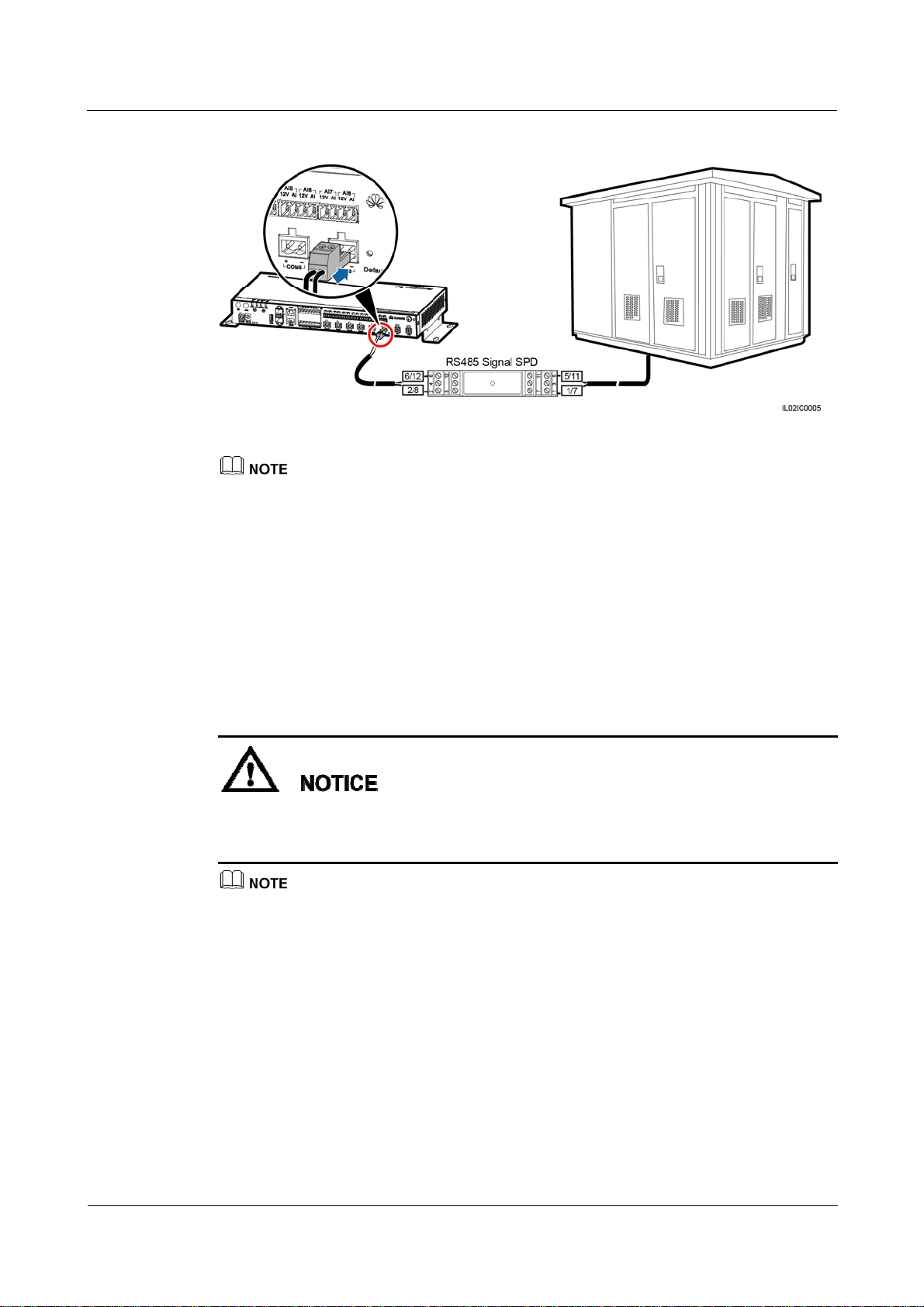

4.1 Connection Description

4.2 Connecting the PE Cable

The SmartLogger and SPD are separately connected to the ground bar for grounding

protection through a PE cable.

4.3 Connecting the RS485 signal SPD

4.4 Connecting Inverters

4.5 Connecting an EMI

4.6 Connecting a Power Meter

4.7 Connecting the Box-type Transformer

4.8 Connecting a PID Module

4.9 Connecting a Ripple Control Receiver

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

36

SmartLogger2000

User Manual 4 Connecting Cables

4.10 Connecting an Ethernet Network Cable

4.11 Connecting Optical Fibers

4.1 Connection Description

Port Description

For the bottom view of the SmartLogger and port description, see Bottom of the Shell in 2.2

Appearance.

Device Connection Description

Figure 4-1 shows the recommended method for connecting the SmartLogger to multiple

devices through the COM ports. For details, see 4.3 Connecting the RS485 signal SPD–4.8

Connecting a PID Module.

Figure 4-1 Connecting the SmartLogger to multiple devices through the COM ports

4.2 Connecting the PE Cable

The SmartLogger and SPD are separately connected to the ground bar for grounding

protection through a PE cable.

4.2.1 Connecting the PE Cable for the SmartLogger

Prerequisites

The ground cable and OT terminals are available.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

37

SmartLogger2000

User Manual 4 Connecting Cables

Ground cable: outdoor copper-core cables with a cross sectional area of 4–6 mm2 or

12–10 AWG are recommended.

OT terminal: M6

Procedure

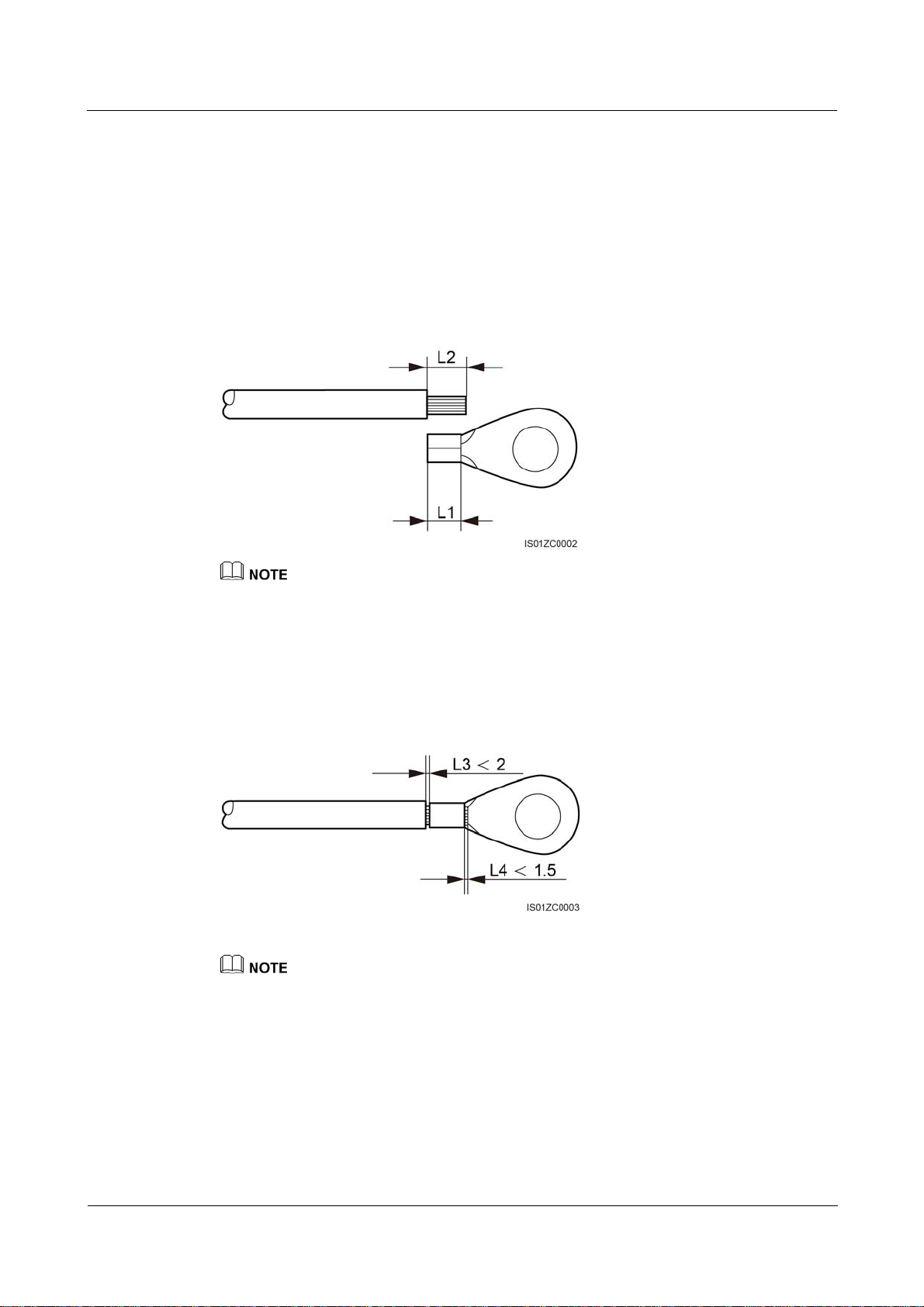

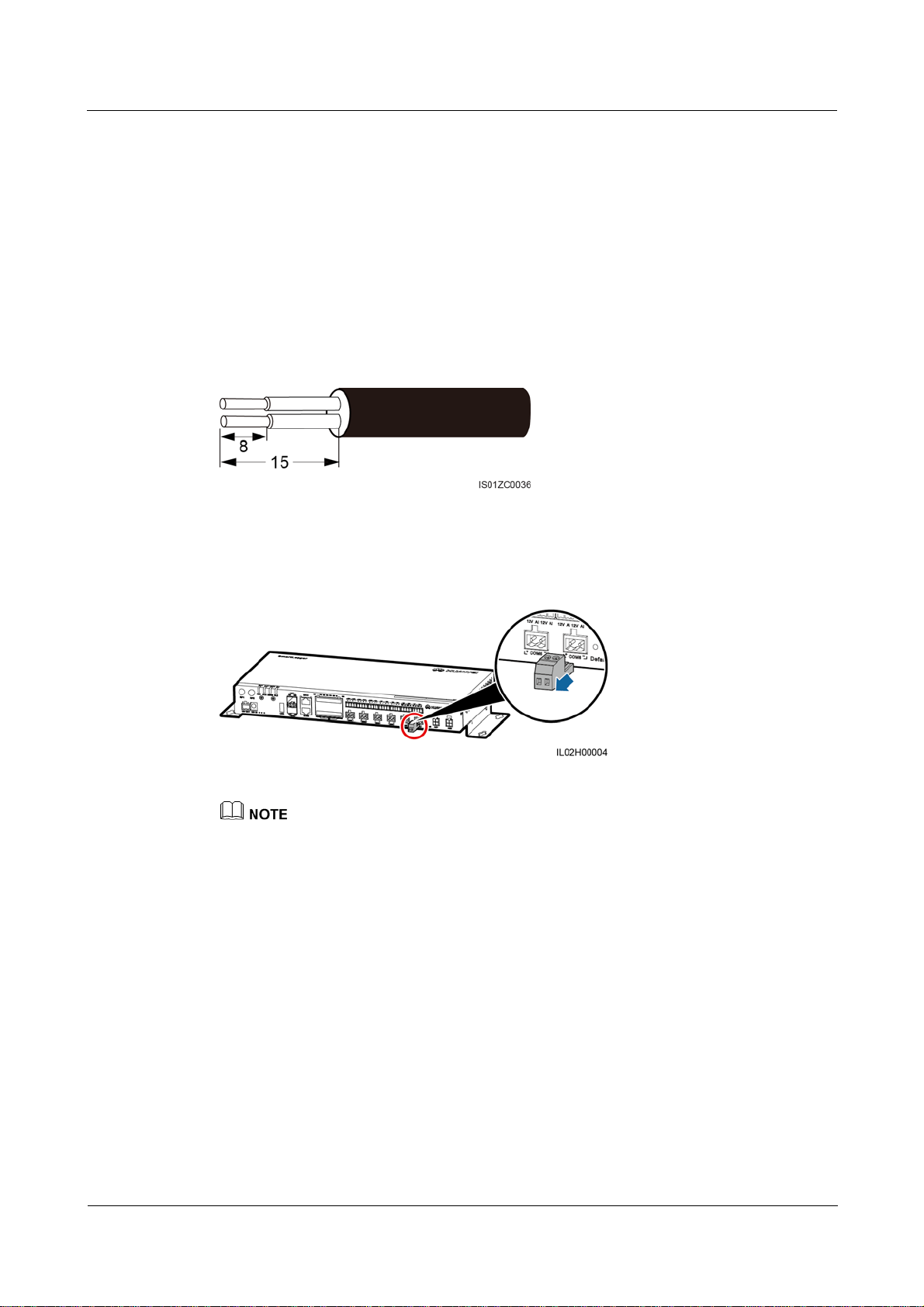

Step 1 Strip an appropriate length of the insulation layer using a wire stripper, as shown in Figure

4-2.

Figure 4-2 Stripping a PE cable (unit: mm)

The length of removed insulation layer (L2) must be 2–3 mm longer than the cable crimping length of

the OT terminal (L1).

Step 2 Insert the bare cable cores into the OT terminal and crimp them by using a crimping tool, as

shown in Figure 4-3.

Figure 4-3 Crimping the cable (unit: mm)

The cavity formed after the conductor crimp strip is crimped must wrap the core wires completely. The

core wires must contact the terminal closely.

Step 3 Remove the screws, spring washers, and flat washers from the ground point.

Step 4 Install the crimped OT terminal, flat washer, and spring washer onto the screw, and tighten

the screw to a torque of 1.4 N·m using a torque screwdriver, as shown in Figure 4-4.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

38

SmartLogger2000

User Manual 4 Connecting Cables

Figure 4-4 Connecting the PE cable to the SmartLogger

To enhance the anti-corrosion performance of the ground terminal, apply silica gel or paint on it after

connecting the PE cable.

For details about how to make the OT terminal at the other end of the cable, see Step 1 and

Step 2.

Connect the other end of the PE cable to the ground bar.

----End

4.2.2 Connecting the PE Cable for the RS485 Signal SPD

Prerequisites

The ground cable and OT terminals are available.

Ground cable: outdoor copper-core cables with a cross sectional area of 4 mm2 or 12

AWG are recommended.

OT terminal: M6

Procedure

Step 1 Remove 8 mm of the insulation layer from the ground cable using the wire stripper.

Step 2 Insert the bare cable cores into port 3 of the RS485 signal SPD, as shown by (1) in Figure 4-5.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

39

SmartLogger2000

User Manual 4 Connecting Cables

Figure 4-5 Connecting the PE cable for the RS485 signal SPD

Step 3 Use a flat-head screwdriver to tighten the screws on port 3, as shown by (2) in Figure 4-5.

To enhance the anti-corrosion performance of the ground terminal, apply silica gel or paint on it after

connecting the PE cable.

For details about how to make the OT terminal at the other end of the cable, see Step 1 and

Step 2 in 4.2.1 Connecting the PE Cable for the SmartLogger.

Connect the other end of the PE cable to the ground bar.

----End

4.3 Connecting the RS485 signal SPD

Prerequisites

A two-core or multi-core communications cable with a wire cross sectional area of 0.5–2.5

2

has been prepared.

mm

Context

The way of connecting two to three RS485 signal SPDs is the same as the way of connecting one RS485

signal SPD.

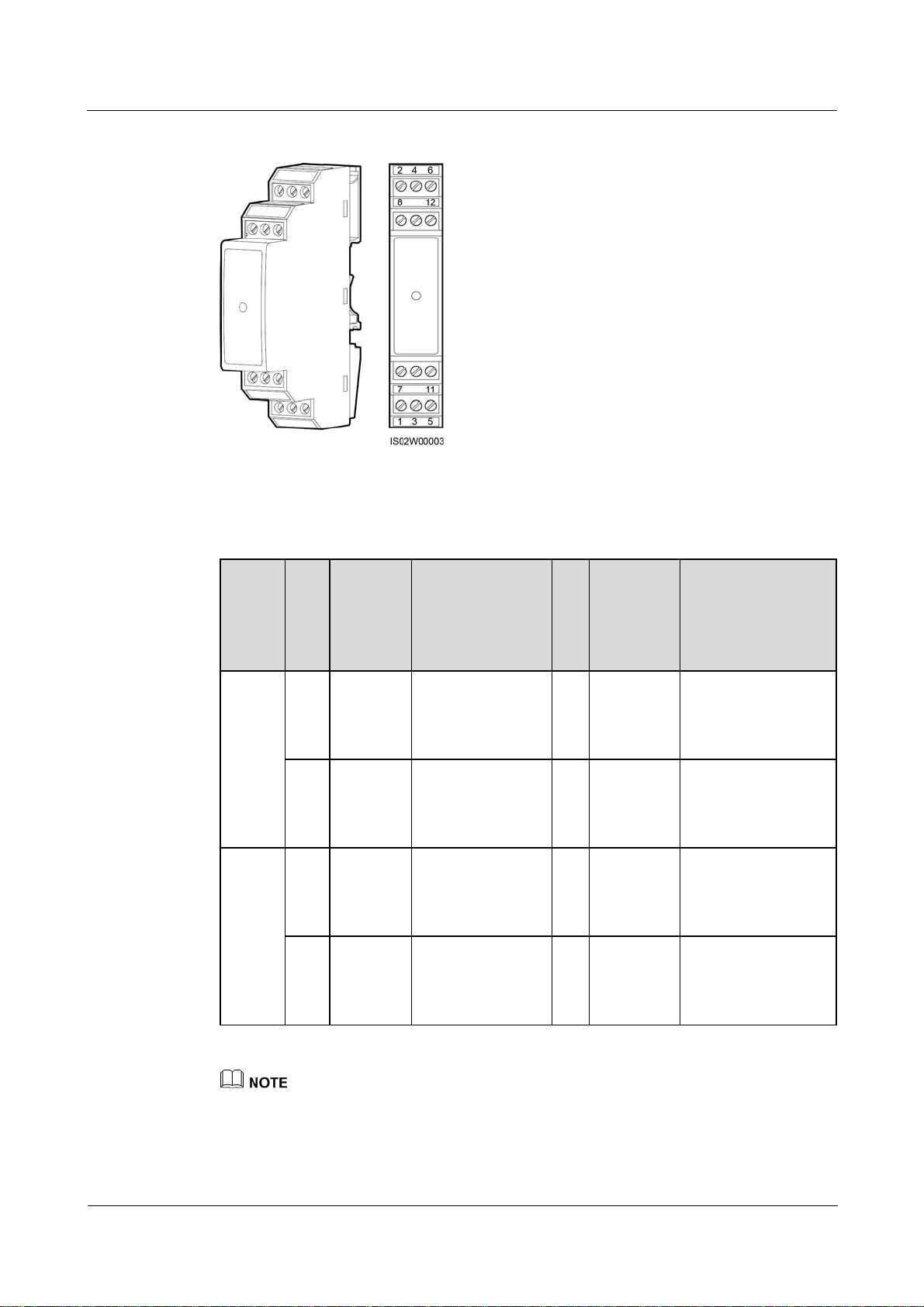

One RS485 signal SPD provides two RS485 surge protection ports, as shown in Figure 4-6.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

40

SmartLogger2000

User Manual 4 Connecting Cables

Figure 4-6 Ports on an RS485 signal SPD

Table 4-1 describes the surge protection ports.

Table 4-1 Port description

RS485

Surge

Protec

tion

Port

RS485

surge

Pro

Port

tect

Definiti

ion

on

Por

t

2 RS485A

IN

protect

ion

port 1

6 RS485B

IN

RS485

surge

8 RS485A

IN

protect

ion

port 2

12 RS485B

IN

Function Su

rg

e

Po

rt

RS485A, for

1 RS485A

RS485 positive

differential

signaling

RS485B, for

5 RS485B

RS485 negative

differential

signaling

RS485A, for

7 RS485A

RS485 positive

differential

signaling

RS485B, for

11 RS485B

RS485 negative

differential

signaling

Port

Definitio

n

OUT

OUT

OUT

OUT

Function

RS485A, for RS485

positive differential

signaling

RS485B, for RS485

negative differential

signaling

RS485A, for RS485

positive differential

signaling

RS485B, for RS485

negative differential

signaling

Protection ports are connected to COM ports on the SmartLogger. Port 4 is not connected.

Surge ports are connected to RS485 ports of other devices. Port 3 is the ground port.

Protection ports and Surge ports must not be reversely connected.

One RS485 signal SPD can protect two COM ports.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

41

SmartLogger2000

User Manual 4 Connecting Cables

Protection ports 2 and 6 and Surge ports 1 and 5 form an RS485 signal SPD port for protecting one

COM port. Protection ports 8 and 12 and Surge ports 7 and 11 form another RS485 signal SPD port

for protecting one more COM port.

An RS485 signal SPD port supports cables with a maximum cross sectional area of 2.5 mm2. If

devices need to be connected to an RS485 port in parallel, use cables with a cross sectional area of 1

mm2, and connect no more than two cables to the same port.

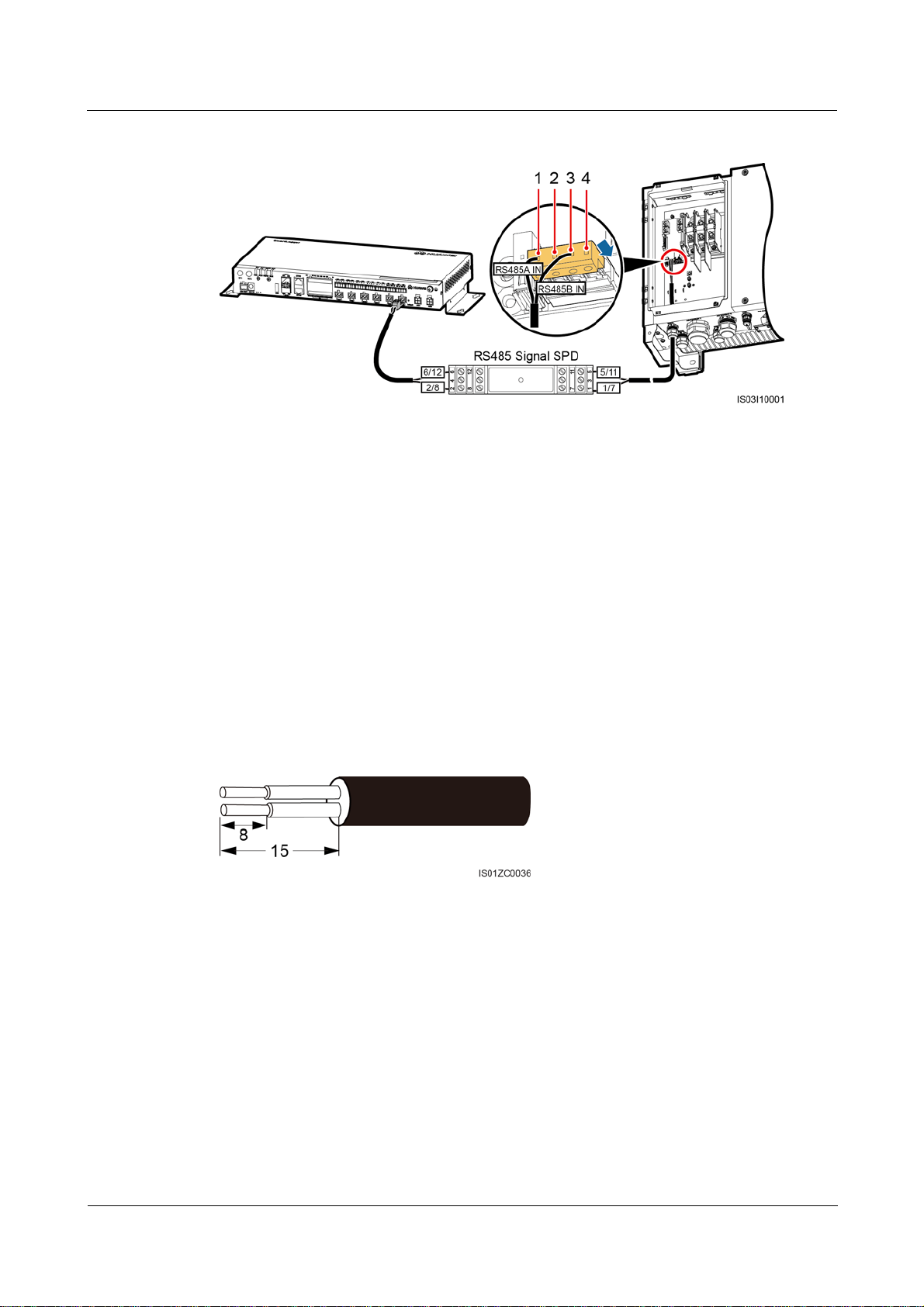

Procedure

Step 1 Remove an appropriate length of steel armor and insulation layer from the cable using a wire

stripper, as shown in Figure 4-7.

Figure 4-7 Stripping an RS485 communications cable (unit: mm)

Step 2 Remove the terminal block from the SmartLogger COM port, as shown in Figure 4-8.

Figure 4-8 Connecting the terminal block

For details about the definitions of SmartLogger COM ports, see Context in Connecting the

SUN2000 Using an RS485 Communications Cable of 4.4.1 Connecting the SUN2000.

Remove the terminal block using a flat-head screwdriver.

Step 3 Insert the bare cable cores into the terminal block, as shown by (1) in Figure 4-9.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

42

SmartLogger2000

User Manual 4 Connecting Cables

Figure 4-9 Cable connection for the terminal block

Step 4 Use a flat-head screwdriver to tighten the screws on the terminal block, as shown by (2) in

Figure 4-9.

Step 5 Insert the terminal block into the SmartLogger COM port.

Step 6 Insert the bare cable cores at the other end of the cable into a Protection port of the RS485

signal SPD, as shown by (1) in Figure 4-10.

Figure 4-10 Wiring diagram for the RS485 signal SPD

Verify that the COM+ (RS485A) port on the SmartLogger is connected to Protection port 2

or 8 on the RS485 signal SPD, and that the COM- (RS485B) port on the SmartLogger is

connected to Protection port 6 or 12 on the RS485 signal SPD.

Step 7 Use a flat-head screwdriver to tighten the screws on the Protection ports, as shown by (2) in

Figure 4-10.

----End

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

43

SmartLogger2000

User Manual 4 Connecting Cables

Follow-up Procedure

Disconnection can be performed in reverse order.

4.4 Connecting Inverters

4.4.1 Connecting the SUN2000

The SmartLogger can be connected to the SUN2000 through an RS485 communications cable

or AC power cable. Communication modes for the SUN2000 with PLC and those without

PLC are different. Select an appropriate communication mode based on the actual situation.

For models with the PLC function, you can select either the PLC or RS485 communications

mode. For models without the PLC function, you can select only the RS485 communications

mode.

The RS485 and PLC communication modes are mutually exclusive.

If the RS485 communications mode is selected, do not connect an AC power cable to the PLC power

input port of the SmartLogger.

If the PLC communications mode is selected, do not connect the RS485 communications cable, and

do not connect the RS485 signal SPDs.

Connecting the SUN2000 Using an RS485 Communications Cable

Context

The SmartLogger provides six COM ports for RS485 communication, as shown in Figure

4-11.

Figure 4-11 COM ports of the SmartLogger

Table 4-2 describes the COM ports.

Table 4-2 COM port description

Port Silk Screen Function

+ RS485A, for RS485 positive differential signaling

COM1

- RS485B, for RS485 negative differential signaling

COM2 + RS485A, for RS485 positive differential signaling

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

44

SmartLogger2000

User Manual 4 Connecting Cables

Port Silk Screen Function

- RS485B, for RS485 negative differential signaling

+ RS485A, for RS485 positive differential signaling

COM3

- RS485B, for RS485 negative differential signaling

+ RS485A, for RS485 positive differential signaling

COM4

- RS485B, for RS485 negative differential signaling

+ RS485A, for RS485 positive differential signaling

COM5

- RS485B, for RS485 negative differential signaling

+ RS485A, for RS485 positive differential signaling

COM6

- RS485B, for RS485 negative differential signaling

The RS485 communications port of the SUN2000 is the RS485 terminal block or RJ45 port.

Terminal block connection

Terminal block of the SUN2000-50KTL/50KTL-C1 is connected in a different way from

the terminal blocks of other models of inverters.

− SUN2000-50KTL/50KTL-C1

Figure 4-12 shows the position of the terminal block in the

SUN2000-50KTL/50KTL-C1. Figure 4-13 describes the functions.

Figure 4-12 Position of the terminal block in the SUN2000

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

45

SmartLogger2000

User Manual 4 Connecting Cables

Figure 4-13 Terminal block

Table 4-3 Functions of the RS485 terminal block

No. Port Definition Function

1 RS485A IN RS485A, for RS485 positive

differential signaling

2 RS485A OUT RS485A, for RS485 positive

differential signaling

3 RS485B IN RS485B, for RS485

negative differential

signaling

4 RS485B OUT RS485B, for RS485

negative differential

signaling

− Other models of SUN2000s

Figure 4-14 shows the position of the terminal block in the

SUN2000-33KTL/40KTL. Figure 4-15 describes the functions.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

46

SmartLogger2000

User Manual 4 Connecting Cables

Figure 4-14 Position of the terminal block in the SUN2000

Figure 4-15 Terminal block

Table 4-4 Functions of the RS485 terminal block

No. Function No. Function

5 RS485A (IN), for RS485

positive differential signaling

6 RS485A (OUT), for RS485

positive differential signaling

7 RS485B (IN), for RS485

8 RS485B (OUT), for RS485

positive differential signaling

RJ45 network port connection

The RJ45 port needs to be connected using an RJ45 connector, as shown in Figure 4-16.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

negative differential signaling

47

SmartLogger2000

User Manual 4 Connecting Cables

Figure 4-16 RS485 RJ45 connector of the SUN2000 (side view without the fastener)

Table 4-5 lists the wire colors and functions.

Table 4-5 Wire colors and functions

No. Color Function

1 White and orange RS485A, for RS485 positive

differential signaling

2 Orange RS485B, for RS485 negative

differential signaling

3 White and green -

4 Blue RS485A, for RS485 positive

differential signaling

5 White and blue RS485B, for RS485 negative

differential signaling

6 Green -

7 White and brown -

8 Brown -

This section describes how to connect the SUN2000-50KTL to the SmartLogger through a terminal

block.

Figure 4-17 shows how to connect the SmartLogger to the SUN2000 through an RS485 signal

SPD.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

48

SmartLogger2000

User Manual 4 Connecting Cables

Figure 4-17 Connecting the SmartLogger to the SUN2000

(1) RS485A IN (2) RS485A OUT (3) RS485B IN (4) RS485B OUT

Procedure

Step 1 Prepare a cable with an appropriate length, strip a proper part of the insulation layer from one

end, and connect the end to the SUN2000 terminal block.

The DJYP2VP2-22 2x2x1 network cable or a communications cable with a cross

sectional area of 1 mm

For details about how to strip and connect the wires, see SUN2000-(50KTL, 50KTL-C1)

2

and outer diameter of 14–18 mm is recommended.

User Manual.

Step 2 Remove an appropriate length of the steel armor and wire insulation layer from the other end

of the cable using a wire stripper, as shown in Figure 4-18.

Figure 4-18 Stripping an RS485 communications cable (unit: mm)

Step 3 Insert the bare cable cores into the Surge port of the RS485 signal SPD, as shown by (1) in

Figure 4-19.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

49

SmartLogger2000

User Manual 4 Connecting Cables

Figure 4-19 Connecting the Surge port of the RS485 signal SPD

Verify that the RS485A (IN) port on the SUN2000 is connected to Surge port 1 or 7 on the

RS485 signal SPD, and that the RS485B (IN) port on the SUN2000 is connected to Surge

port 5 or 11 on the RS485 signal SPD.

Step 4 Use a flat-head screwdriver to tighten the screws on the Surge ports, as shown by (2) in

Figure 4-19.

Step 5 Set Baud Rate to the same value for the SUN2000 and SmartLogger.

For details about the communications parameters settings for the SmartLogger, see

Setting RS485 Parameters or SUN2000 APP User Manual.

For details about the communications parameters settings for the SUN2000, see

SUN2000 APP User Manual.

----End

Follow-up Procedure

Disconnection can be performed in reverse order.

Connecting the SUN2000 Through an AC Power Cable

Context

The SmartLogger is integrated with the PLC central coordinator (CCO) that can work with

the SUN2000 integrated with the PLC station (STA) to implement power line communication

(PLC) networking over power cables.

Procedure

Step 1 Connect one end of the delivered AC power cable to an MCB.

Step 2 Connect the AC1 and AC2 terminals at the other end of the cable to the AC1 and AC2 ports

on the SmartLogger respectively, as shown in Figure 4-20.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

50

SmartLogger2000

User Manual 4 Connecting Cables

Figure 4-20 Connecting an AC power cable to the SmartLogger

Table 4-6 describes the components shown in Figure 4-20.

Table 4-6 Component

No. Component Item Quantity

1 Busbar A/B/C - 1 PCS

2 Fuse Rated voltage: ≥ 500 V; rated current: 6 A 3 PCS

3 Knife switch

box

4 MCB Rated voltage: ≥ 500 V; rated current: ≥

Rated voltage: ≥ 500 V; rated current: ≥

6 A; number of phases: three

1 PCS

1 PCS

6 A

Each SmartLogger can be connected to a maximum of 80 SUN2000s.

If the SmartLogger is connected to the SUN2000 through an AC power cable, no RS485

communications cable needs to be connected.

After connecting cables, log in to the WebUI and enable the PLC function in the SmartLogger. For

details, see Connecting a Device. PLC describes how to configure PLC parameters for the

SmartLogger.

The port used for PLC networking is RS485-0. The recommended Baud Rate for the port is 115200

bit/s, which can provide optimal communications performance.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

51

SmartLogger2000

User Manual 4 Connecting Cables

----End

Follow-up Procedure

Disconnection can be performed in reverse order.

4.4.2 Connecting the SUN8000

Context

Figure 4-21 shows the wiring terminals of the RS485 ports of the SUN8000.

Figure 4-21 RS485 wiring terminals for the SUN8000

Ports 07, 08, 09, 10, 11, and 12 are communications ports. Table 4-7 describes the functions

of these ports.

Table 4-7 Port description

No. Function Description

07 S485A RS485A, RS485 differential signal + (reserved)

08 S485B RS485B, RS485 differential signal - (reserved)

09 N485A_OUT RS485A, RS485 differential signal +

10 N485A_IN RS485A, RS485 differential signal +

11 N485B_OUT RS485B, RS485 differential signal -

12 N485B_IN RS485B, RS485 differential signal -

There are six RS485 ports in the SmartLogger. For the port descriptions, see Context in

Connecting the SUN2000 Using an RS485 Communications Cable of 4.4.1 Connecting the

SUN2000.

Figure 4-22 shows how to connect the SmartLogger to the SUN8000 through an RS485 signal

SPD.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

52

SmartLogger2000

User Manual 4 Connecting Cables

Figure 4-22 Connecting the SmartLogger to the SUN8000

Procedure

Step 1 Configure a shielded network cable with an appropriate length. Connect two core wires of the

Step 2 Remove 15 mm of the insulation layer from the dual-core shielded cable using a wire stripper.

Step 3 Remove 8 mm of the insulation layer from the two core wires using the wire stripper.

Step 4 Insert the bare cable cores into the Surge port of the RS485 signal SPD, as shown by (1) in

cable to the N485A_IN and N485B_IN ports of the RS485 port for the SUN8000.

Recommended communications cable: dual-core shielded network cable (outdoor

shielded network cables are also acceptable, if only two core wires are connected).

For details about connecting the RS485 ports for the SUN8000, see the

SUN8000-500KTL User Manual.

Figure 4-23.

Figure 4-23 Connecting the Surge port of the RS485 signal SPD

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

53

SmartLogger2000

User Manual 4 Connecting Cables

Verify that the N485A_IN port on the SUN8000 is connected to Surge port 1 or 7 on the

RS485 signal SPD, and that the N485B_IN port on the SUN8000 is connected to Surge port 5

or 11 on the RS485 signal SPD.

Step 5 Use a flat-head screwdriver to tighten the screws on the Surge ports, as shown by (2) in

Figure 4-23.

Step 6 Set Baud Rate for the SUN8000 to the same Baud Rate configured for the SmartLogger.

For details about the communications parameters settings for the SmartLogger, see

Setting RS485 Parameters or SUN2000 APP User Manual.

For details about the communications parameters settings for the SUN8000, see

SUN8000-500KTL User Manual.

----End

Follow-up Procedure

Take operations in reversed order to disconnect the SmartLogger from the SUN8000.

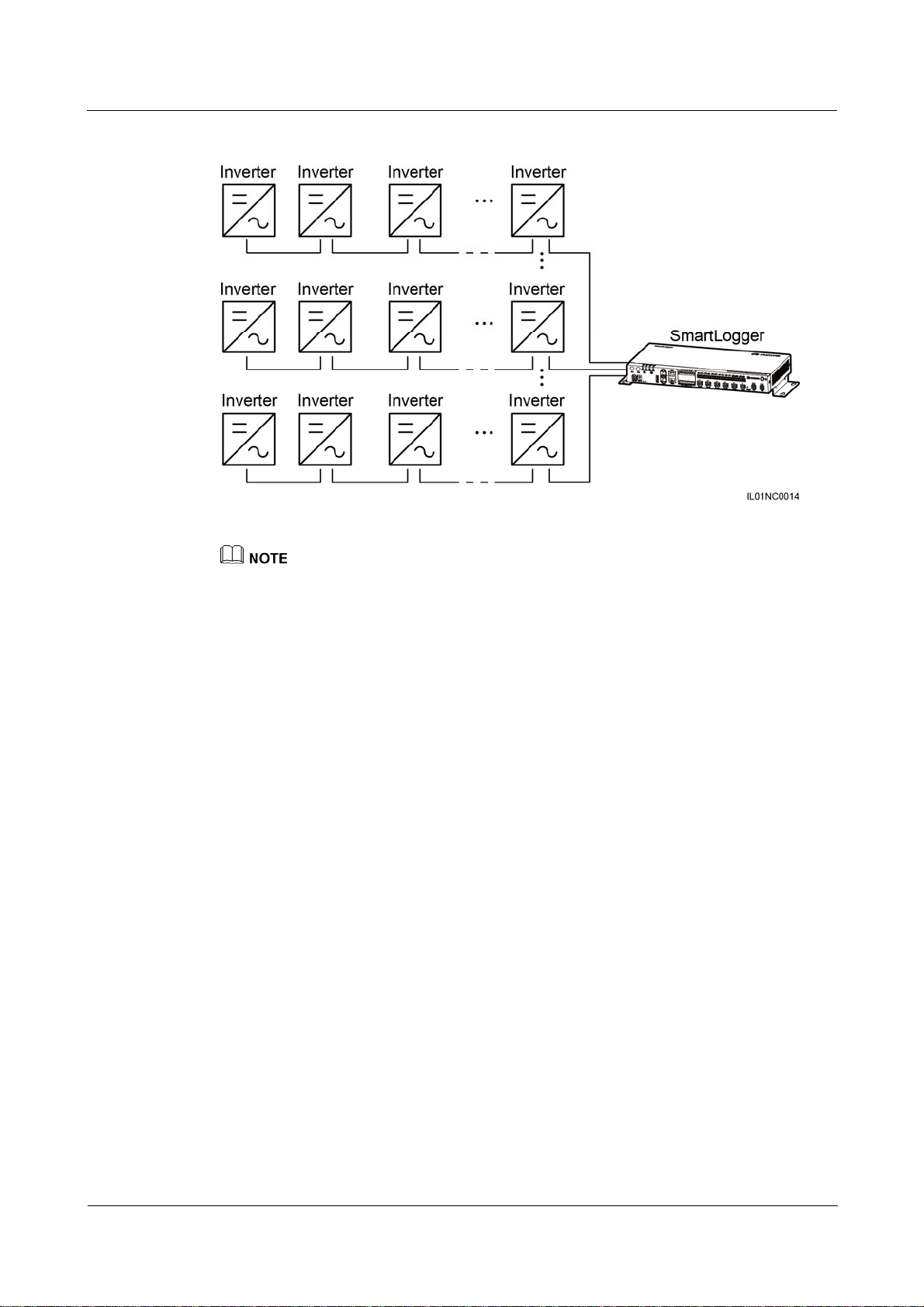

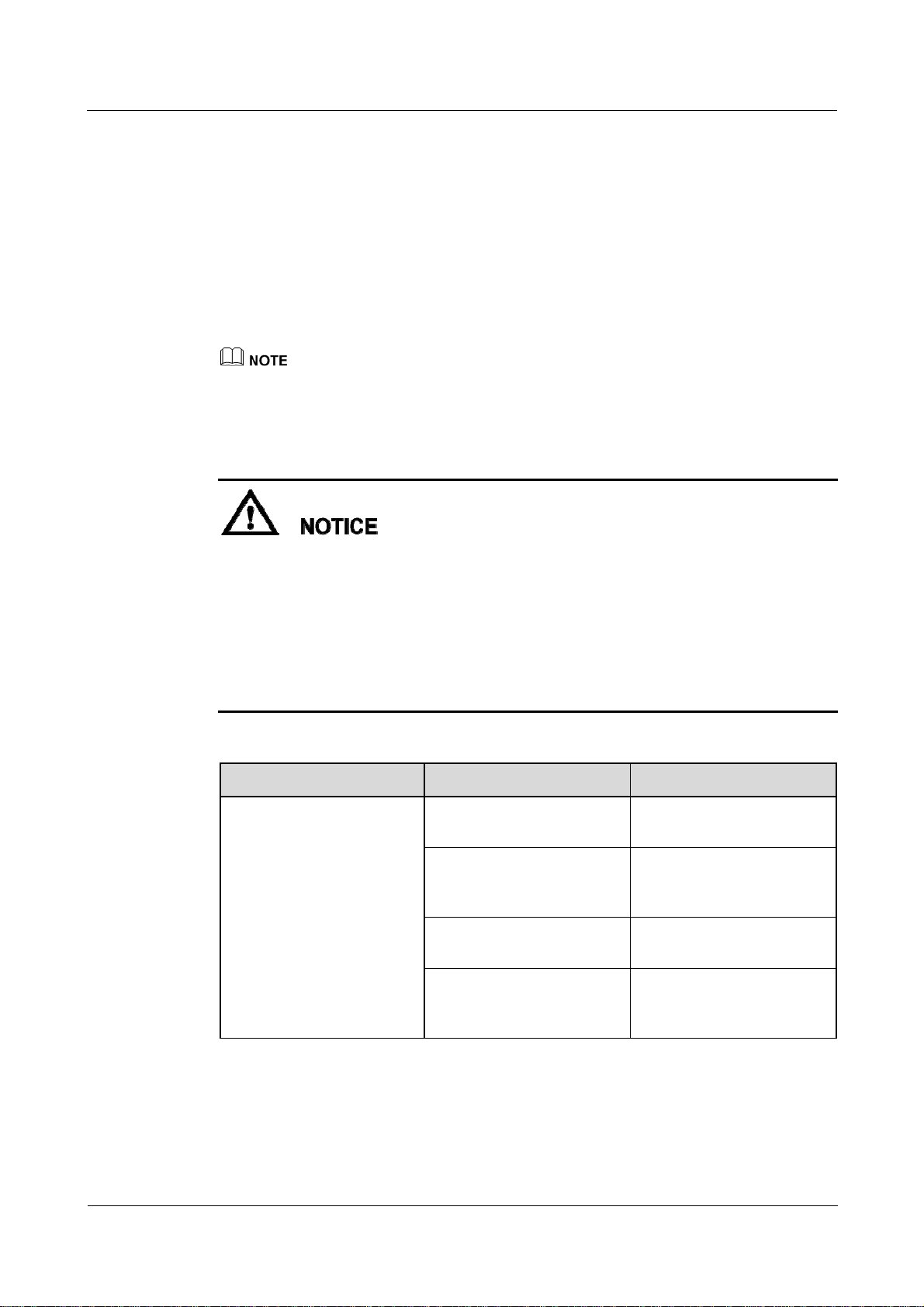

4.4.3 Connecting Multiple Inverters to the SmartLogger

The SmartLogger can connect to multiple inverters through a daisy chain or an AC power

cable.

Daisy Chain Connection

In the daisy chain connection mode, the RS485OUT of one inverter is connected to the

RS485IN port of the next inverter, and the first inverter is connected to the SmartLogger as

described in Connecting the SUN2000 Using an RS485 Communications Cable or 4.4.2

Connecting the SUN8000 in 4.4.1 Connecting the SUN2000. Figure 4-24 shows the

connection.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

54

SmartLogger2000

User Manual 4 Connecting Cables

Figure 4-24 Connecting the SmartLogger to multiple inverters

A maximum of 200 devices can be connected to one SmartLogger. You are advised to connect fewer

than 30 devices to each RS485 route. Each SmartLogger can be connected to a maximum of 80

inverters.

If an EMI is to be connected, connect it at the end of the chain.

Set Build-out Resistor to Enable under Comm. Param. for the inverter at the end of each daisy

chain. For details, see SUN2000 APP User Manual.

The addresses for all devices in the daisy chain should be within the searching scope set in the

SmartLogger and they must differ from each other. Otherwise, the communications would fail

between the device and the SmartLogger.

You can perform the Assign Address operation on the built-in WebUI of the SmartLogger. If an

RS485 address conflict is detected for inverters, the SmartLogger automatically reassigns the

addresses without the need for local address upgrade for the inverters.

Baud rate of all the devices in one daisy chain should stay consistent with those of the

SmartLogger.

AC Power Cable Connection

Figure 4-25 shows the method for connecting the SmartLogger to multiple SUN2000s over an

AC power cable.

(2016-06-20) Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

55

SmartLogger2000

User Manual 4 Connecting Cables

Figure 4-25 PLC networking

Only PLC models of the SUN2000s can be connected to the SmartLogger over an AC power cable.

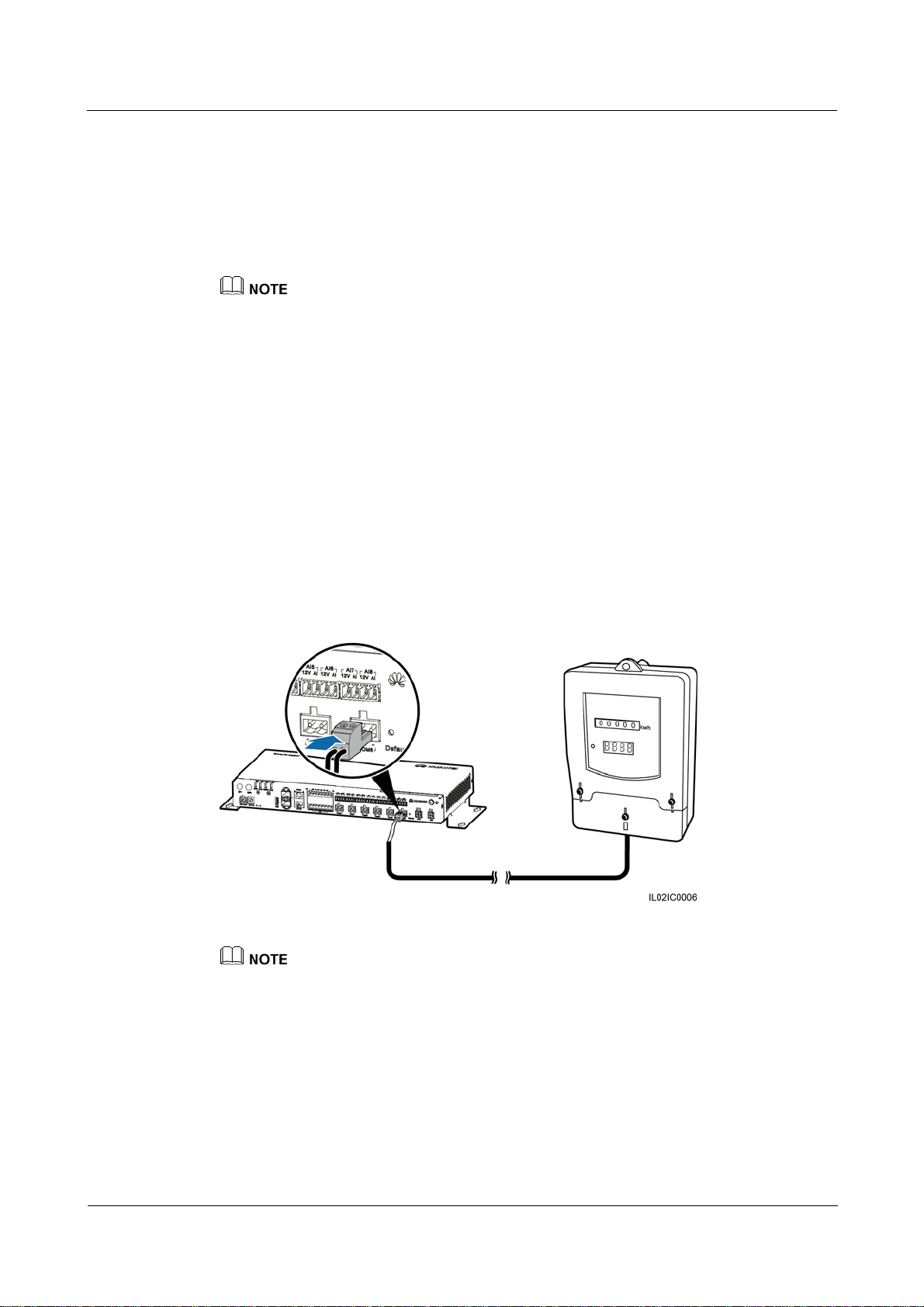

4.5 Connecting an EMI

Context

The SmartLogger can be connected to an EMI that supports the standard Modbus-RTU

protocol. One SmartLogger can be connected to and manage only one EMI.

Devices from different vendors may support different protocols. To obtain information from