Jointly issued by: National Energy Key Laboratory for Wind and

Solar Simulation, Testing and Certification, China General

Certification Center, and Huawei Technologies Co., Ltd.

November 2020

White Paper on SDS Intelligent

Joint Control Technology for

Inverters and Trackers

C

urrently, the smart DC system (SDS), an

intelligent joint control technology for inverters

and trackers developed by Huawei Technologies

Co., Ltd. (hereinafter referred to as "Huawei"),

has entered the large-scale application phase. Entrusted

by Huawei, China General Certification Center (CGC) has

carried out a comprehensive review and verification of

the SDS to verify its technical performance and

application effect. Based on the review and verification

results, the National Energy Key Laboratory for Wind

and Solar Simulation, Testing and Certification, CGC,

and Huawei jointly released the

White Paper on SDS

Intelligent Joint Control Technology for Inverters and

Trackers

. This white paper describes the development

background, technical features, and application effects of

the SDS in detail, helping the industry comprehensively

and deeply understand the technology.

Preface

1

White Paper on SDS Intelligent Joint Control Technology

for Inverters and Trackers

01

Technology Development Background

The trackers have been used for a long time, but the

following issues may also exist in actual applications:

Traditional astronomical algorithms are used, in which

the impact of terrain conditions, blocking in the

morning and evening, and weather changes is not fully

considered. Due to miscalculations of the optimum

tracking angle, energy yield loss may occur in some

time periods and in special weather conditions. Figure

1-2 and Figure 1-3 show the examples.

Figure 1-2 Examples of shading between arrays in special

areas and in the morning and evening

Continuously improving the efficiency of PV power

systems is a sedulous pursuit in the industry. For this

purpose, at the device end, the main goal is to

improve the optical-to-electrical conversion efficiency

of PV modules and reduce the energy loss of other

devices. At the system end, the main goal is to

increase the radiation received at the surface of the

PV modules and reduce the efficiency loss.

In recent years, the efficiency improvement

achievements at the device end are remarkable, but

there is not much room for improvement.

The industry has shifted the focus on the system end.

The application percentage of various technologies,

especially the tracking technology, is increasing, aiming

to improve the radiation received by the PV module

surface. Figure 1-1 shows the application percentage of

trackers in bases of the second and third phases of PV

Forerunner, a PV demonstration project initiated by

National Energy Administration, in China. The figure

indicates that the application percentage of trackers

increased significantly in the third batch of bases. In

addition, according to the data released by GTM, the

shipments of trackers in 2017, 2018, and 2019 increased

by 34%, 36%, and 66% year on year. In 2019, the global

shipment of trackers was about 35 GW.

Total Installed

Capacity (MW)

600

500

400

300

200

100

0

70%

60%

50%

40%

30%

20%

10%

0%

Ruicheng

(Phase 2, 2017)

Xintai

(Phase 2, 2017)

Sihong

(Phase 3, 2018)

Dalad

(Phase 3, end of 2018)

13%

24%

33%

60%

2

White Paper on SDS Intelligent Joint Control Technology

for Inverters and Trackers

Figure 1-1 Comparison of application scale and percentage of trackers

in the second and third batches of PV Forerunner bases (partially)

Tracker Installed

Capacity (MW)

Tracker Installation

Percentage

(1) Most tracking system algorithms are provided

by the tracker manufacturer.

(MV)

Figure 1-3 Difference of received radiation at

different angles on cloudy weather

As mentioned above, with the improvement of

reliability and cost-effectiveness, the application

percentage of the trackers, including the power

generation technology using the combination of

trackers and bifacial PV modules, will gradually

increase.

(2) To solve the problems in common astronomical

algorithms, the backtracking technology is used in

the industry. However, the tracker angle control is

relatively independent and is not associated with

the I-V perception or change of the PV strings or

control units. Therefore, refined adjustment or

precise control cannot be implemented.

(3) In recent years, the power generation technology

using the combination of trackers and bifacial PV

modules has become one of the mainstream

forms. This kind of system needs to dynamically

adjust the control policy according to the change

of external conditions. Figure 1-4 compares the

daily cumulative radiation of the front and rear

sides of a random 15-day period selected from the

3-month monitoring data of the CGC Inner Mongolia

empirical research system (horizontal single axis and

bifacial PV module power generation).

As shown in Figure 1-4, the ratio of the radiation

received from the front side to that from the rear side

varies greatly due to the weather. In special weather

conditions, the daily accumulated radiation on the rear

side is even higher than that on the front side. This

means that the angle of the PV modules needs to be

dynamically optimized and adjusted based on the

weather conditions for the bifacial tracking power

generation system, maximizing the control unit output.

Ratio of Daily Received Radiation on the

Front Side to the Reference Value

Ratio of Daily Received Radiation on the Rear Side to

Received Radiation on the Front Side on the Current Day

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11 D12 D13 D14 D15

Ratio

3

White Paper on SDS Intelligent Joint Control Technology

for Inverters and Trackers

Figure 1-4 Comparison of daily accumulated radiation on

the front and rear sides (horizontal single axis)

To solve the issues in the application of the trackers,

the big data and AI technologies are used to optimize

the inverter and tracker control linkage, further

improving the increase effect of the trackers. This has

become one of the development directions of the

tracking technology.

02

Technology Description

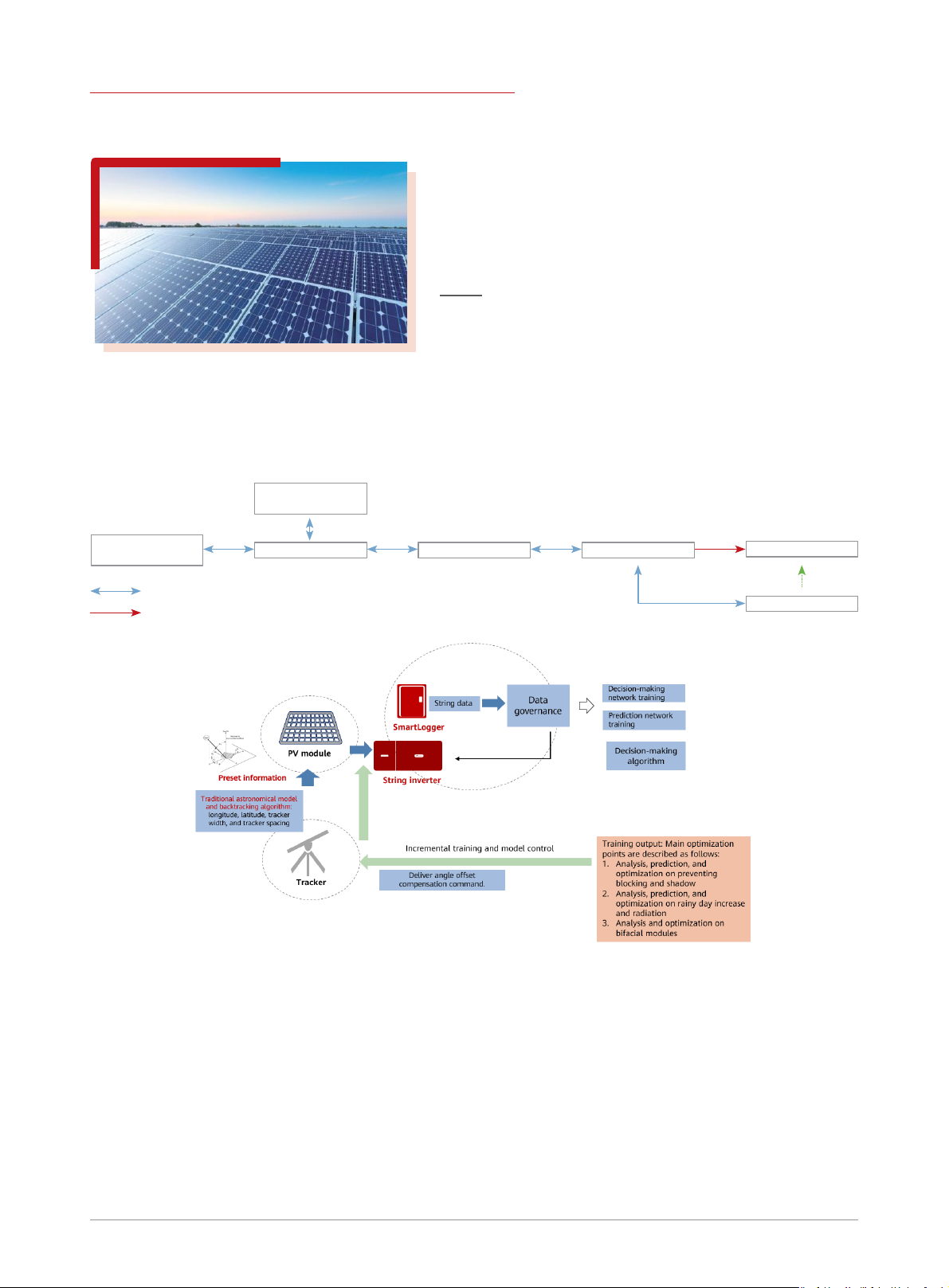

Figure 2-2 Logical block diagram of algorithm

design and angle optimization

Figure 2-1 and Figure 2-2 show the SDS block diagram, and logical block diagram of algorithm design and angle

optimization, respectively.

Figure 2-1 SDS block diagram

Signal Flow

Drive Signal

SmartLogger

WebUI

Inclination sensor

SmartLogger Inverter Tracking controller

Tracker motor

SmartPVMS (in

and outside China)

The SDS technology developed by Huawei has the

following features:

(1) The inverter is linked with the tracker control system

and performs closed-loop control to ensure that the

system runs with the maximum radiation volume

received by PV modules and optimal power output.

(2) No additional sensor device is required. AI technologies

are used to automatically detect shading and weather

changes and automatically optimize and control the

tracking angle, eliminating manual operations and

experience dependence.

(3) The inverter integrates the tracker communication

and power supply functions and the tracker power

supply cables and communication cables are

reduced thanks to MBUS.

4

White Paper on SDS Intelligent Joint Control Technology

for Inverters and Trackers

Loading...

Loading...