HUALIAN FS-600H, FS-800H, FS-100H Operating Instructions Manual

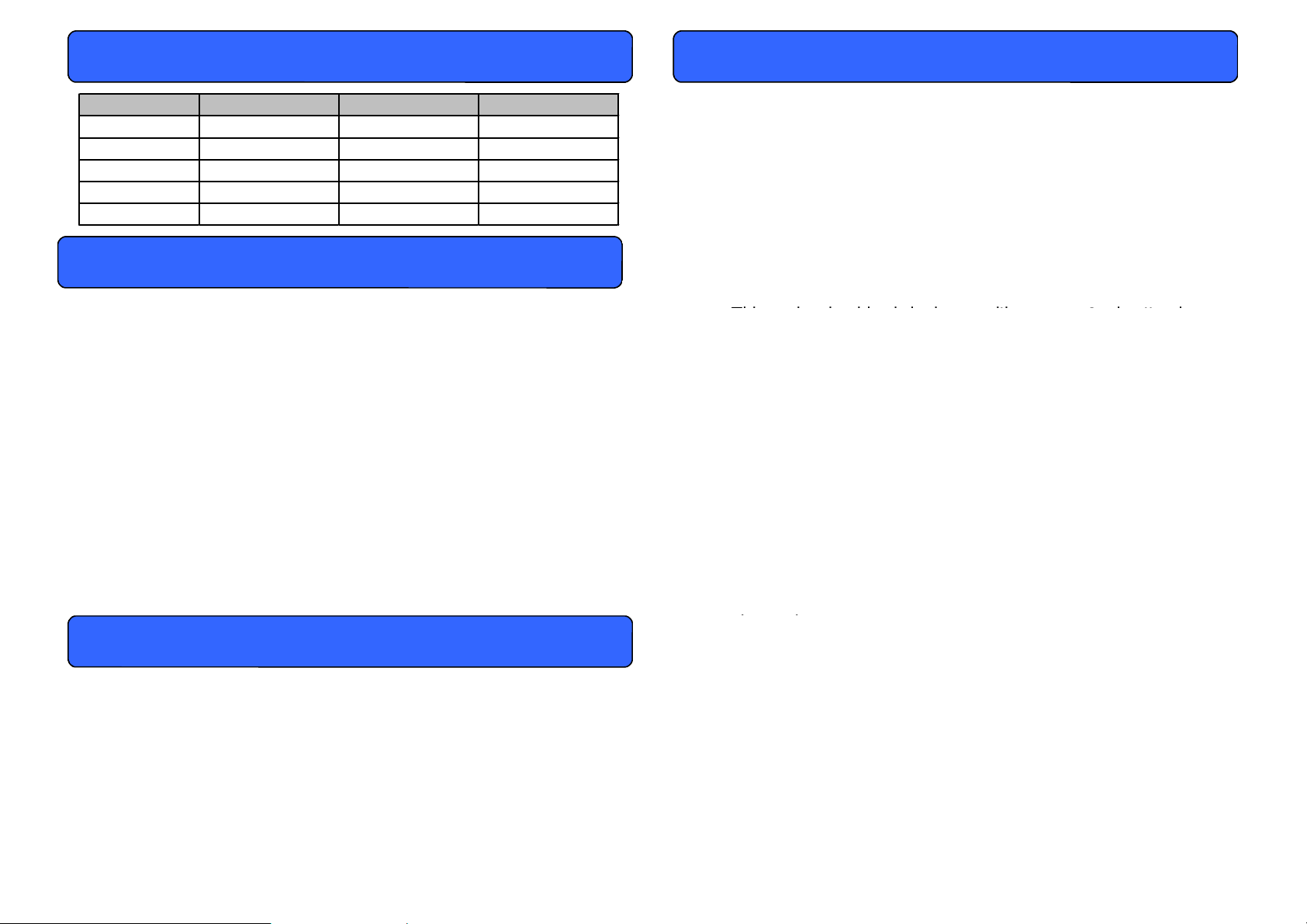

TROUBLESHOOTING

Terminals of the heating

Cooling time is not enough

upper lever for 1

-

2

MALFUNCTIONS REASONS SUGGESTIONS

No sealing

Power lamp is off

Disconnected plug

Power cord is broken

Transformer is broken

Check or change the plug

Replace or repair the cord

Replace the transformer

LONG HAND

IMPULSE SEALER

OPERATING INSTRUCTIONS

No sealing

Power lamp is on

Sealing lamp is on

No sealing

Power lamp is on

Sealing lamp is off

Teflon cloth burn Timer malfunction

Heating wire breaks Worn Teflon adhesive Replace the Teflon

Seal is wrinkled Heating timer is set too

Heater (heating element) is

broken

Spring hook our mounting

spring is loose or in poor

contact

element are in poor

contact

Microswitch is activated

Defective microswitch

Prolonged heating time

high

Replace the heater

Clean or tighten spring

hook connection

Clean the terminals and

adjust if needed

Adjust the microswitch

lever

Adjust the microswitch

position

Replace the microswitch

Replace timer or relay

Decrease the timer

setting

adhesive

Lower the timer setting

Continue pressing the

seconds after the light

goes off

MODELS

FS-600H, FS-800H, FS-100H

Imperfect seal Worn Teflon cloth

Broken seal Prolonged sealing time Decrease timer setting

Non-full-weld seal Sealing time is too short Increase sealing time

Seal sticking Dirty Teflon cloth

Worn silicone rubber

Dirty sealing bar

Replace Teflon cloth

Replace silicone rubber

Clean the Teflon cover

Clean the silicone rubber

sealing bar

SPECIFICATIONS

This sealer should only be in use with an

operator

in attendance.

Before operating, check the heating element,

PTFE

cover,

PTFE

sharp edge.

IMPORTANT POINTS TO REMEMBER

Model FS-600H FS-800H FS-1000H

Power 110V/780W 110V/1050W 110V/1350W

Sealing Length 23.6" 31.5" 39.4"

Seal Type 2.8mm 2.8mm 2.8mm

Heating Time 0.2-3 secs 0.2-3 secs 0.2-3 secs

Weight (lbs) 16 20 20

OPERATING INSTRUCTIONS

adhesive and sealing pad (silicone rubber).

1. Set the Power Switch to the ON position.

2. Adjust the timer setting according to the thickness of the

sealing material. Note: Always start with the lowest

setting and gradually increase to the correct setting.

3. Pull the film to be sealed in between the base and sealing

jaw.

4. Place the object to be sealed between the sheets of film.

5. Press the sealing bar down and seal.

6. Wait 2-3 seconds to allow the seal to set and lift the

handle.

Read all instructions before use. Save these instructions for later

use.

Follow all warnings and instructions marked on the product.

Unplug this product from the power source before cleaning and/or

changing any parts

Do not rest anything on the power cord. Do not place the machine

where the power cord may be stepped on or pulled.

Always keep out of reach of children and pets.

Never insert clothing, hands, fingers between the sealing jaws of

sealers.

Never touch the heating elements with bare hands while the

sealer is plugged into a power source, or in operation, or just

finished operation. It will be HOT.

Be sure to check for worn parts before starting operation.

Do not operate with a damaged power cord or plug.

Always keep the unit clean. Do not use water. Silicone spray may

be used to clean the unit. Be sure the unit is unplugged from the

power source before cleaning.

When changing blade (for sealers with cutters), be careful of the

ADDITIONAL INFORMATION

• Always unplug the unit from the power source before

attempting any maintenance.

• Always keep the sealing platform clean and remove any

residue found on the platform and Teflon tape. Silicone

spray may be used for this purpose.

• When replacing the Heating Element, always replace the

PTFE adhesive.

• Occasionally check the condition of the Silicone Rubber for

wear and burn. A damaged or worn Silicone Rubber will

affect the quality of the seal.

When changing the teflon adhesive, be sure the entire surface

under the heating element is covered with a teflon adhesive.

Bend down the excess teflon adhesive on both ends. This

prevents the heating element from breaking and the machine from

grounding.

When replacing the fuse, be sure the exact voltage and ampere is

used.

Be sure to keep a record of your model number. Specify this

number when ordering parts.

When replacing any parts, be sure to mark down the exact

locations of the connections.

Loading...

Loading...