HUALIAN M-PE, BS5530M-PE, BS5540M-PE Operation Manual

PE SHRINK PACKING MACHINE

中 国●华 联 机 械 有 限 公 司

BS5530M-PE

&

BS5540M-PE

OPERATION MANUAL

I. USE:

Shrink packing machine is one of the advanced packaging ways in the international

market at present. It adopts shrink film to products or being packed articles, and

then to heat the shrink packing material & tightening products or being packed

articles, so that the appearance of the articles is shown fully, so that the articles can

be put well on display and which may also increase the their beauty and value.

Besides, the packed articles can be sealed, damp proof, dustproof and protect

themselves from outside shock and thus have the better functions. Especially for

packing glassware, which can prevent household utensils from scattering when they

are broken? In addition, this way can decrease the torn and stolen possibility of the

products. As the shrink film shrinks, some pressure can be created to tighten a

group of packed articles together and trays so this product can be used widely for

shrinking all kinds of shrink packing material.

II. FUNCTION & FEATURE:

PE shrink packing machine manufactured by our company is the latest automatic

continuous shrink packing equipment both at home at present. It adopts quartz

far-infrared capsule to heat for saving electricity 9save over 15%).Shrink packing

machine adopts frequency con troll motor, whose speed can be adjusted within

wide range, and the maximum load bearing can reach to 40kg. The stove inside

adopts fully closedown hot wind circulating equipment to get perfect sealing effect.

This machine has a nice appearance an with easy maintenance, can applicable to

all the shrinking package of all kinds of PVC, POF & PP ETC. shrinking films,

specially suitable for PE shrink film’s packing.

III. SPECIFICATION

Model Voltage Power

BS5530M-PE 380 16.8 40 550×300 2500×750×1300 0~10 210

BS5540M-PE 380 18 40 550×400 2500×750×1400 0~10 240

Weight

loading

Heat tunnel

size(mm)

Dimension(mm)

Conveying

speed

Weight

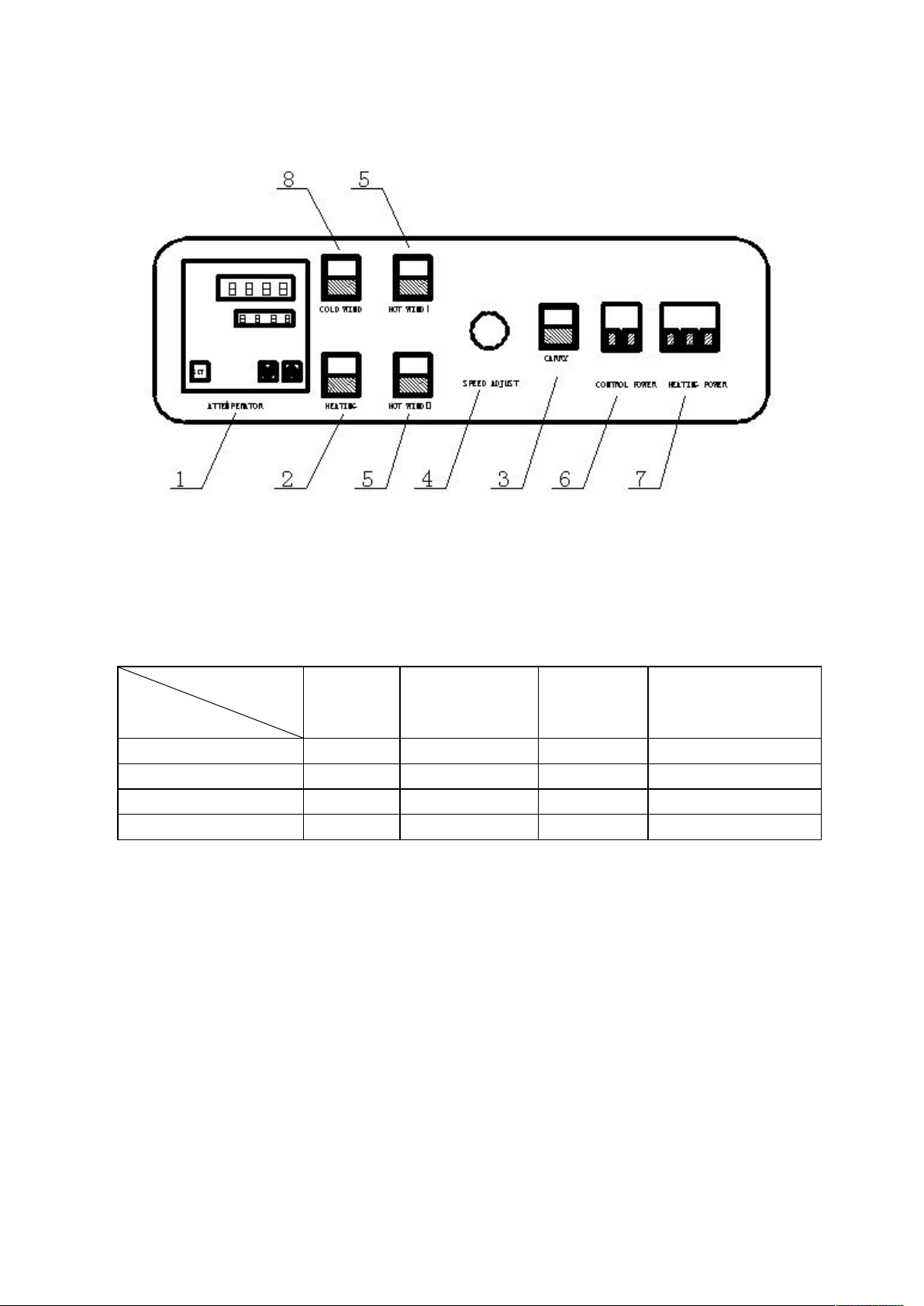

IV. CONTROL PANEL:

1. Intelligent temperature regulator 2. Heating switch 3. Conveying switch

Shrinking room

temperature (℃)

4. Electronic speed regulator 5. Hot wind switch II 6. master control switch

7. Heating master switch 8. cooling switch

V. TEMPERATURE & TIME FOR SHRINK FILM:

Term

Film

Polyvinyl chloride PVC 0.02~0.06 5~10 110~130

Polypropylene PP 0.02~0.04 6~12 130~170

Polyethylene PE 0.03~0.10 20~30 170~200

Polyethylene

Name Thickness (mm) Heating(S)

PE 0.12~0.20 30~60 180~220

VI. OPERATION PROCEDURES & NOTICE:

1. This machine is three phases with four pieces of power wires (380V), and thus in

addition to connecting to the three pieces of live wires, you should connect it to the

zero line as well.

2. Closing the master controlling switch (5) and master heating switch (7).

3. Closing the master controlling switch (5) and adjusting the conveying button (4)

4. Pressing the heating switch (2), the machine starts to heat. The shrinking

temperature of PE film is generally set at 180~200℃, if you want to set the

temperature, please firstly press SET key, then press UP or DOWN key, and at last

press SET key after your confirmation.

5. During the operation, if there are too many rumples, please decrease the conveying

speed of increase the heating temperature Whereas, if the shrinking film broken,

then please increase the conveying speed of decrease the heating temperature.

Loading...

Loading...