Huafengdongli R4105T, R4105T1, R4105T6, R4105ZT, R4100ZD Operation And Maintenance Manual

...

HUAFENGDONGLI

R

Series

Diesel

Engine

OPERATION

AND

MAINTENAN

ANUAL

Shandong

Weichai

Huafeng

Power

Co.,

Ltd

Preface

R series diesel engine is a four

~troke

,vertical, water-cooled, inline and direct injecting combustion chamber type,high-speed diesel engine. Thjs series diesel engine is

specially designed for our country by Ricardo Consulting Engineers Co.

of

Britain,

and manufactured and developed firstly by Ricardo Consulting Engineers

Co.

cooper-

ated with Shandong Weichai Huafeng Power

Co.

, Ltd.

It'sanew

generation prod-

uct instead

of

the same type diesel engineinour country. This type diesel engine

possesses performances

of

high power,economy and easy starting, under the envi-

ronment

with

temperature higher than

-lOOC

,the dieael engine can be easily started

without preheating. The first overhaul period is 8000hrs. Its reliability and service life

achieved a advancde level among the same kind products all over the world.

Rseries diesel engine covers 8 types

as:

both four -cylinder and six-cylinder

with

bore

of

lOOmm,both four-cylinder and six-cylinder with bore of

l05mm,and

every style

has

two

models of matural aspirated and superchareged.

RIOS

series is bore -en-

larged from

Rl00 series,besides piston,piston ring,piston pin,cylinder liner,cylinder

liner seal ring and injection pump,

all

other parts

can

be exchanged between both

two

types of diesel engine.

R series diesel engine features easy adaptation

to

meet the various needs

of

matched equipments,accordingtothe requirement of users. It can be furnished

with

hydraulic pump for Ifting and steering purposes, air compressor and vacuum pump

for breaking purposes

and full power take-off from the front end

of

the crankshaft.

Through being changed for some

of

its parts accordingly, it can be used

to

match

with truck,tractor,small power generating station,engineering machinery,agricultru-

al

machinery,irrigation machinery,drilling machinery and so on. The output range

of

various version

of

R series diesel engine

is

35

KW

-125

KW

,its rated speed is 1500r/

min

-2800r/min.

The moder,its make-up rule and the meaningofthe symbol for ev-

ery type is

as

follows:

R

6 100 Z D 1 2

(1)@@

@@@

(j)

CD:

distinguish symbol, Expressed

with

number sequence

~:

Version symbol ,expressed

with

number sequence

@:

application featrue symbol,expressed

with

alphabet

no alphabet:for common usage; T:for tractor; G:for engineering machinery;

Q:

for vehicle;D:for generating

set;

C:for marine usage;P:for power take-off unit

@:

construction feature symbol,expressed with alphabet;no alphabet:for natural

#85-

pirated model;

Z:for

turbocharged model.

(S):cylingder bore(

mm)

@:cylinder number

(J):series symbol;stand for imported from RICARDO

This operating manual mainly introduces common usage type. For various versions;

only show their different features. As technology progresses and usage expands,the

aengine

wi'l be modified

and

improved from time

to

time,therefor the product

s'up-

plied hereafter may

be

slightly different from that describedinthis manual and the

users

are kindly advised to notice it.

Being obtained

as

the accidental test result, the characteristic

c.urvesinthe manual

are

only supplied for reference.' And the pictureinthe manual

cant

be the accord-

ance

of

check upon delivery.

/

The

manualiscompiled by Wang Jinghai, Zhao Ruian,

Yang

Lin,

Sun

Chuanhai,

Wang Luhai,

Dou

Yuxiang, Jiang Bo,

Yu

Caihong,

Liu

Taicheng, Zhuang Longping,

Wei Zhiyou,

Du

Zhijun, advised byLiPeiyan, Chen Ling,

Hao

Sixian, and finally ex-

amined and approved by

Chen

Ling.

For

the limit

of

the compilers, there may be

mistakes

in

the manual, if you find any, please point out so that they can be correc-

ted. Also, it will be appreciated if

you give your suggestions about our products.

The

compilers

June,

2005.

Attention

1. The diesel engine operators must familiarize themselves

with

this manual as well as engine

construction and strictly follow the procedures

of

operation

and maintenance especially the regulations for safety operation described

in

this manual.

2. Before operating

an

engine at full load

,the

60 hours running

in

should be carried

out

as

specified

in

the manual.

3. Increase its speed gradually after stating a cold engine,never

let it run

at

highs speed abruptly, and

don't

stop

the

engine

instantly while its cooling

water

is still

hot,

also

don't

let

the

engine running long

time

without

load.

4.

If

the

ambient temperature falls below +

SOC

,drain

the

cooling

water out

of

the radiator, the lubricating oil cooler and the

diesel engine itself completely after stopping the engine.

Con-

tinuous keeping the

water

in

the oil cooler should be forbid-

den.

5. Never run the diesel engine

without

and air cleaner so as

to

prevent the unfiltered air from entering the cylinders.

6. The engine

must

be filled

with

specified grade fuel and lubri-

\eating oil,and

a special

and

clean container for each oil should

be used. The fuel oil should

be settled for

72

hours and fil-

tered before using.

7. The inspection and repair

of

the components

in

electrical sys-

tem

must

be carried

out

by the person

who

has a good

knowledge

of

electricity.

8. If the

water

pump is

without

oil filler,

its

a ??? bearing wa-

.

ter

pump,

and neednt add lub oil to it.

9. Be sure

to

use

water

- cooling diesel engine. Please refer

to

P.43 for details.

10. The working environment

of

the diesel engine should be

well ventilated

to

avoid being polluted by

waste

gas or

smoke.

11.

The

power

rati~g

and

amending

of

the

diesel

engine

is

ac-

cording

to

GB6072.1"-2000 the first section

of

reciprocating

internal combustion engine:

sta"ndard

basic condition, the

rating

and

testing method of power, fuel consumption and

engine

oil

consumption.

12.

The

manufacturing of the diesel engine

is

according to the

common technical requirement for low

and

middle level

powered diesel engine

in

JB/T8895~1999

and

Q/WCGOOS

-2002R

series diesel engine enterprise standard.

13.

The

No.

of production license of this series diesel engine

is:

XK06-205

- 00160,

XK06

- 205 - 00161,

XK06

- 205 --

00279.

14.

The

position of safety warning marks:

(1)

Theres a guard against burning mark at the end of the

cylinder cover which

is

beside the exhaust manifold of the

diesel engine.

(2)

There~

a guard against fire mark

at

the ail filler.

(3)

Theresa guard against twinning mark

on

the inlet man-

ifold.

(

4)

There's a flywheel rotating direction mark

on

the fly-

wheel housing.

Contents

1.

Longitudinal sectional drawing for R4100,

R410S

diesel

engine(

Fig.la)

.•....•.• 1

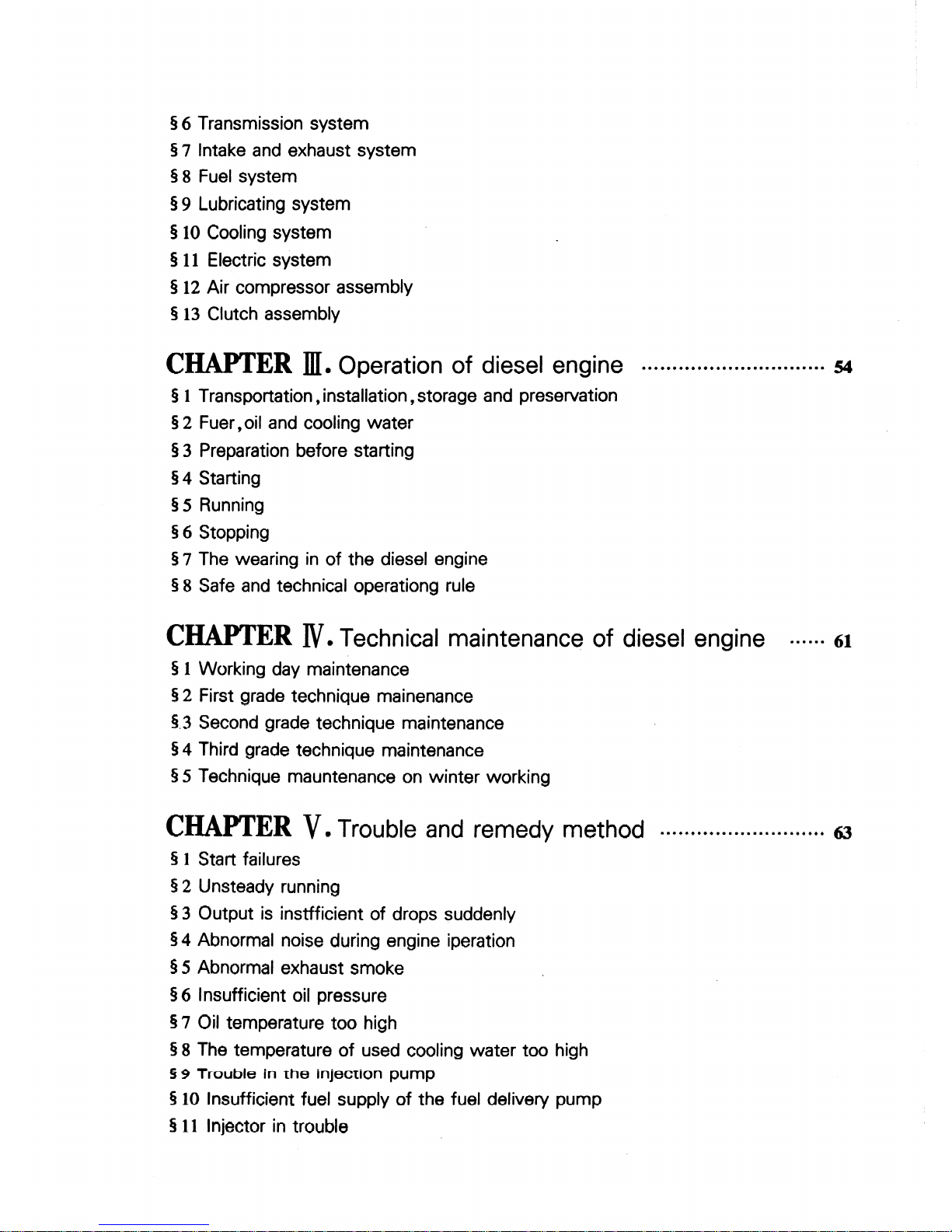

Cross sectional drawing for R4100, R4l05 diesel engine(

Fig.1b)

2

2. Longitudinal sectional drawing for R6100,

R610S

diesel engine(Fig.

2a)

3

Cross sectional drawing for R6100,

R610S

diesel engine( Fig.

2b)

4

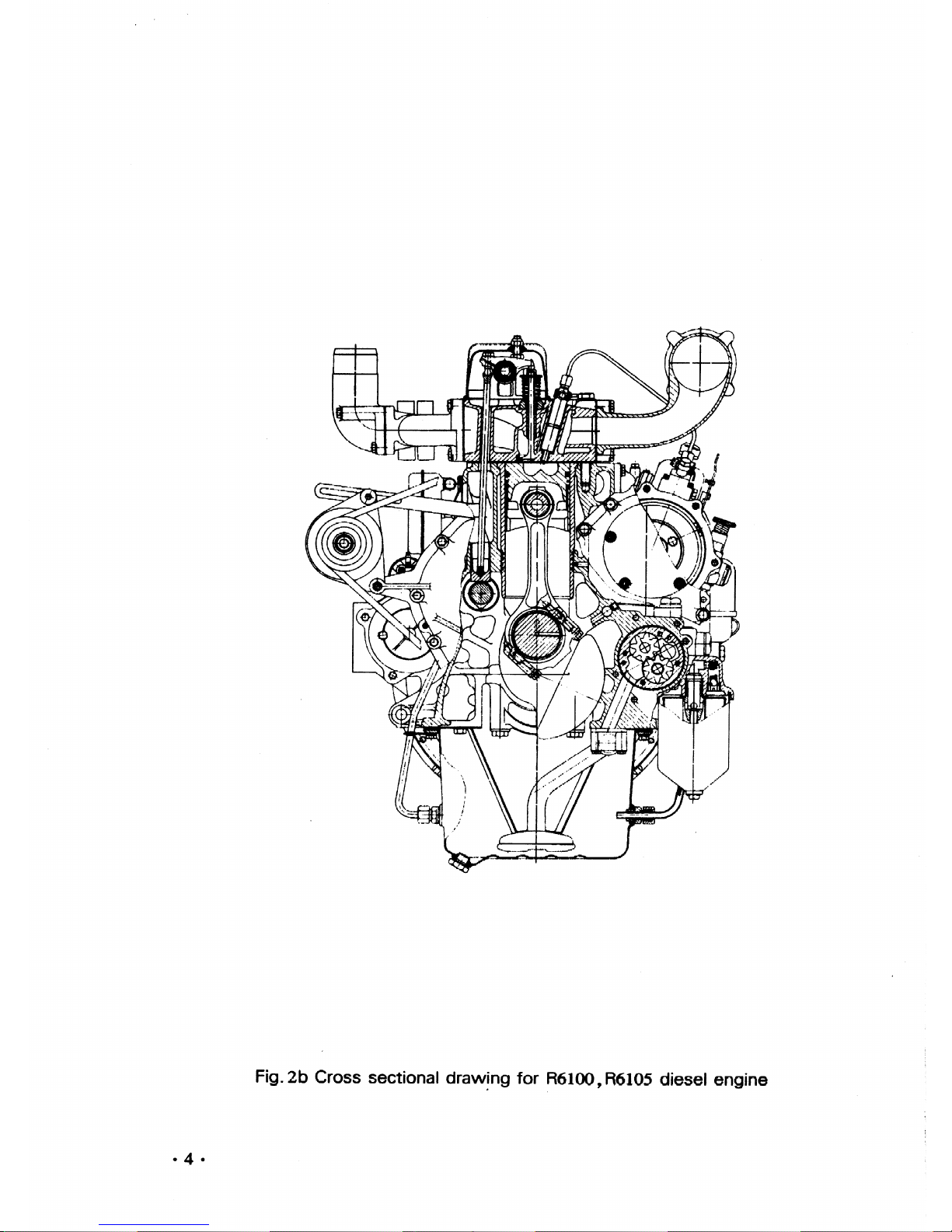

3. Speed and speed adjusted characteristic curve for Model

R410S,

R410SZ

diesel engine(

Fig.

3)

5

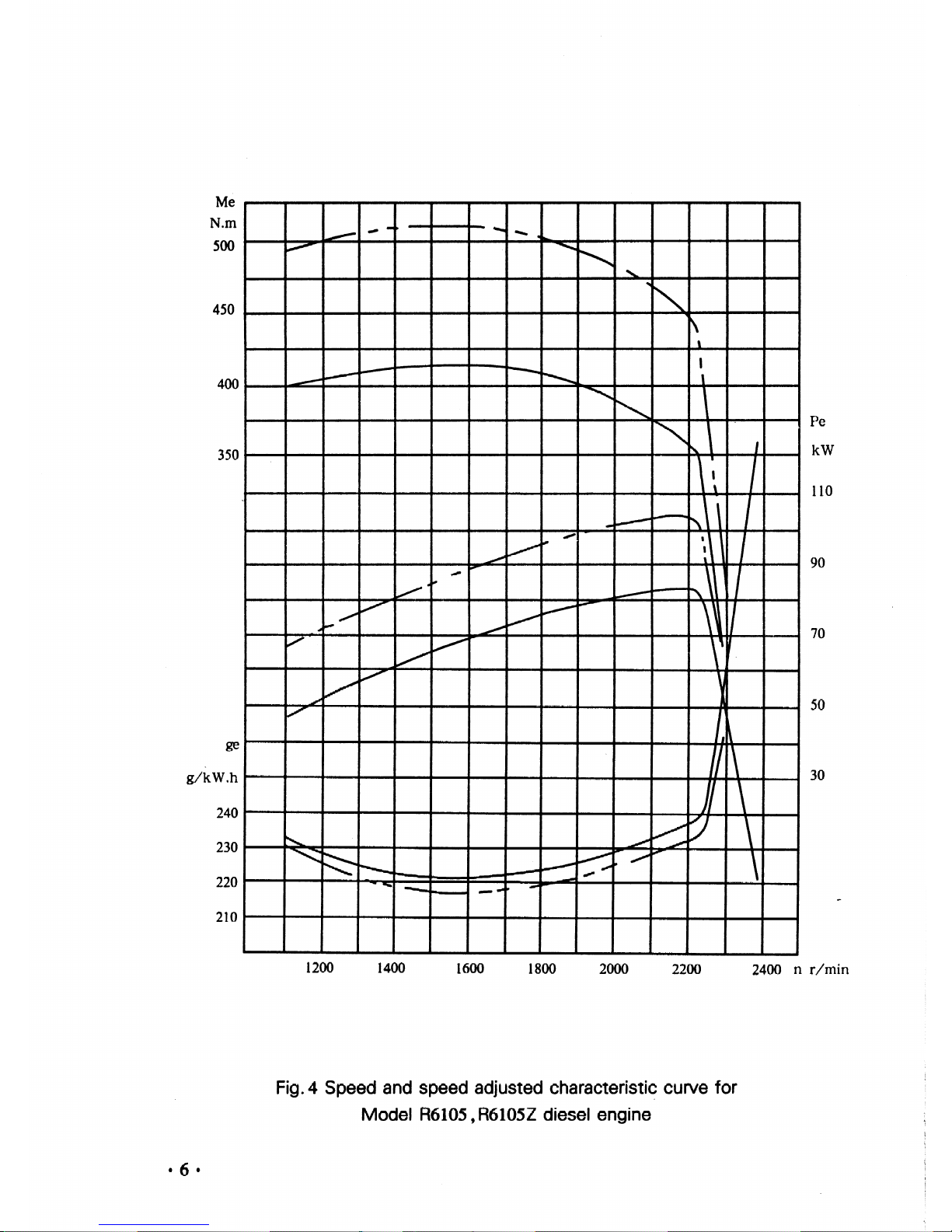

4. Speed and speed adjusted characteristic curve for Model

R610S,

R610SZ

diesel engine(

Fig.

4)

6

5. Speed adjusted characteristic curve for Model

R4105T

and R410STI

diesel engine for tractor usinn(Fig.

S)

u

•••••••••••••••••••••••••••••••

7

6. Speed and speed adjusted characteristic curve for Model

R410SG

diesel engine

used for engineering machine (Fig.

6)

......................•...........•..•.............

8

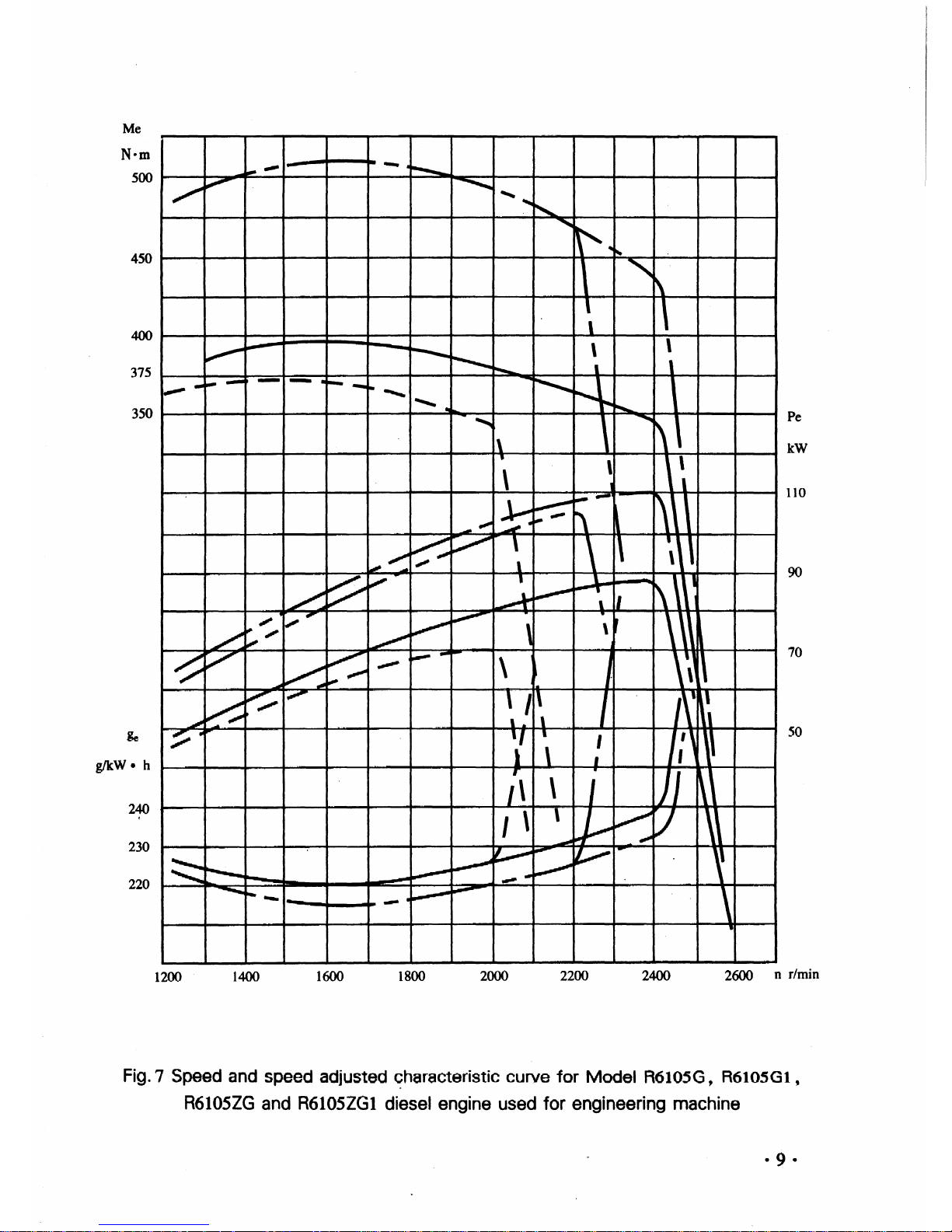

7.

Speed and speed adjusted characteristic curve for Model R6105G, R610SGt,

R610SZG

and R610SZGl diesel engine used for engineering machine (Fig.

7)

···9

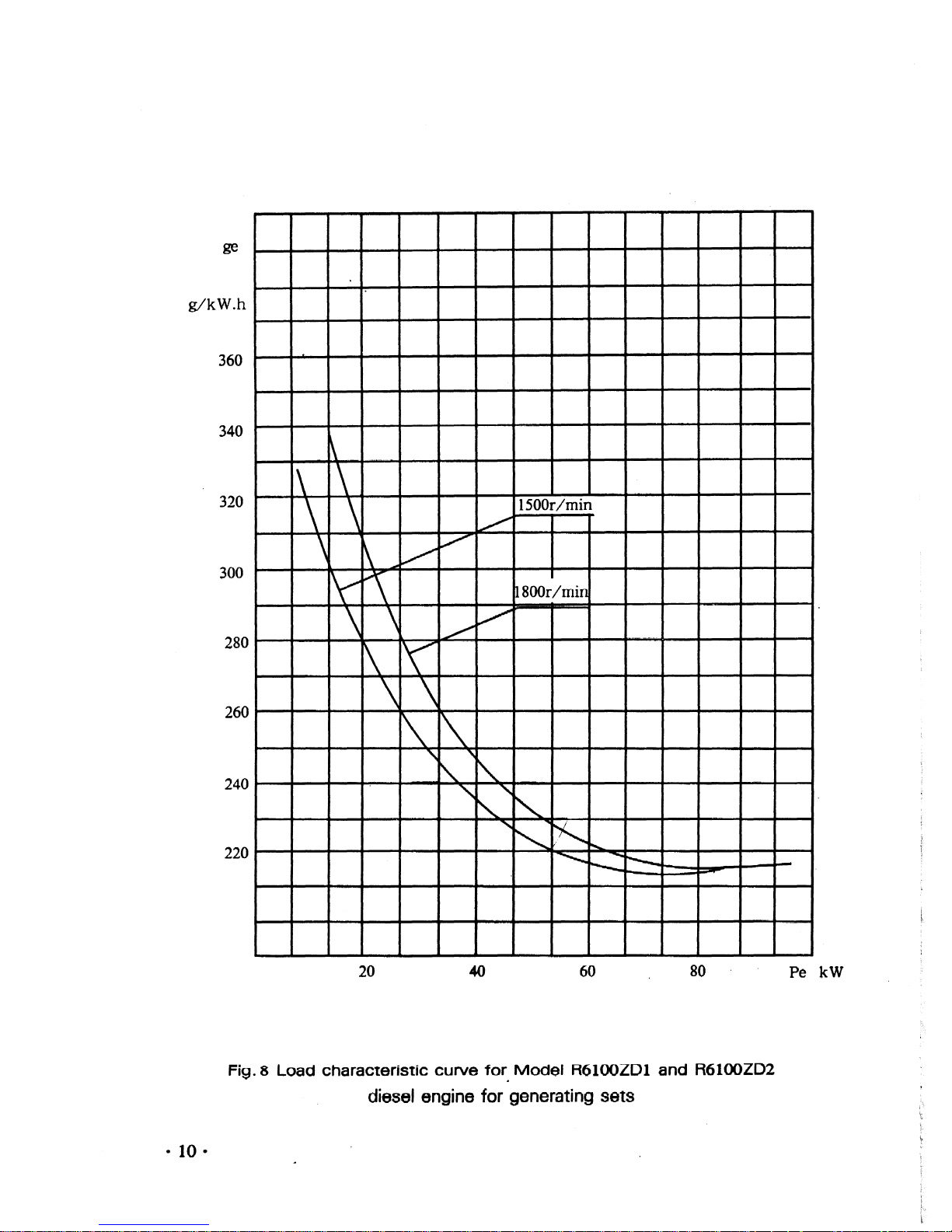

8. Load characteristic curve for Model R6100ZDl and

R6100ZD2

diesel engine for

generating sets (Fig..

8)

· · ····..· ·..·

....•......

~

·

10

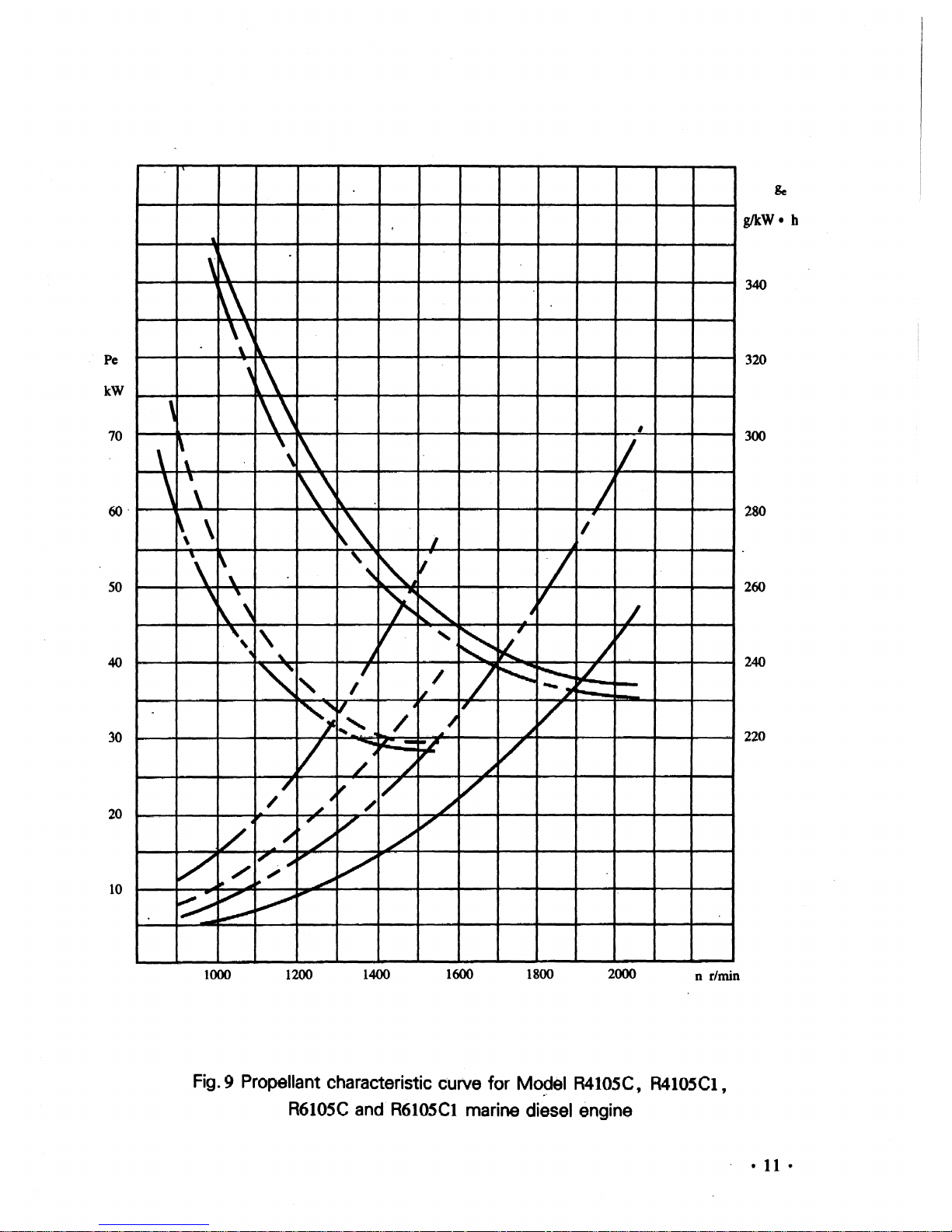

9. Propellant characteristic curve for Model R4105C, R410SCl,

R610SC

and R6105Cl

marine diesel engine (Fig.

9)

11

10.

Load

characteristic curve for Model

R41OSP,

R410SZP

and

R610SP

diesel engine

for generating unit(

Fig.

to)

12

CHAPTER

I.

Main Technical Specifications

and

Data

for the

diesel engine 13

§ 1 Main techincal specifications

§ 2 Range for various temperature and pressure

§ 3 Tightening torque

of

main bolts

§ 4 Main adjusting data

§ 5 Matxhed clearances and wear limit

of

main parts

CHAPTER

II.

Main structure of diesel engine .......•................ 28

§ 1 Cylinder head assembly

§ 2 Cylinder block and relatea

assemoly

§ 3 Camshaft assembly

§ 4 Piston and connecting rod assembly

§ 5 crankshaft and flywheel assembly

§ 6 Transmission

system

§ 7 Intake and exhaust

system

§ 8 Fuel

system

§ 9

Lubricating

system

§ 10 Cooling

system

§

11

Electric

system

§

12

Air

compressor assembly

§

13

Clutch assembly

CHAPTER

m.

Operation of diesel engine 54

§ 1 Transportation,installation,storage and preservation

§ 2 Fuer,oil and cooling

water

§ 3 Preparation before starting

§ 4 Starting

§ 5 Running

§6

Stopping

§ 7 The wearing in

of

the

diesel engine

§ 8 Safe and technical operationg rule

CHAPTER

N.Technical maintenance of diesel engine 61

§ 1 Working day maintenance

§ 2 First grade technique mainenance

§,3 Second grade technique maintenance

§ 4 Third grade technique maintenance

§ 5 Technique mauntenance on

winter

working

CHAPTER

V.

Trouble

and

remedy method 63

§ 1 Start failures

§ 2 Unsteady running

§ 3

Output

is instfficient

of

drops suddenly

§ 4 Abnormal noise during engine iperation

§ 5 Abnormal exhaust

smoke

§ 6 Insufficient oil pressure

§ 7

Oil

temperature

too

high

§ 8 The temperature

of

used cooling

water

too high

§ 9

Trouble

in

the

injection

pump

§

10

Insufficient fuel supplyofthe fuel delivery pump

§

11

Injector in trouble

§

12

Governorintrouble

§

13

Engine stops suddenly

§

14

Charged dynamo outoforder

§

15

Starting motor beintrouble

§

16

Governorintrouble

§

17

Turbochargerintrouble

§

18

Air compressorintrouble

§

19

Clutch in trouble

CHAPTER

VI.

Installation instruction for diesel engine

generating set

76

.Fig.laLongitudinal sectional drawing for R4100,

R4105

die~el

engine

• 1 •

~-=-

\

\

~~~--1:I-..L.-'~--~

~AlIIIJ/'r'7"7""'7'/.L.-J

Fig.lb.Crcss

sectional drawing for R4100,R4105 diesel engine

· 2 ·

Fig.2a longitudinal

s~ctional

drawing

for R6100, R6105 diesel

engine

· 3 •

· 4 ·

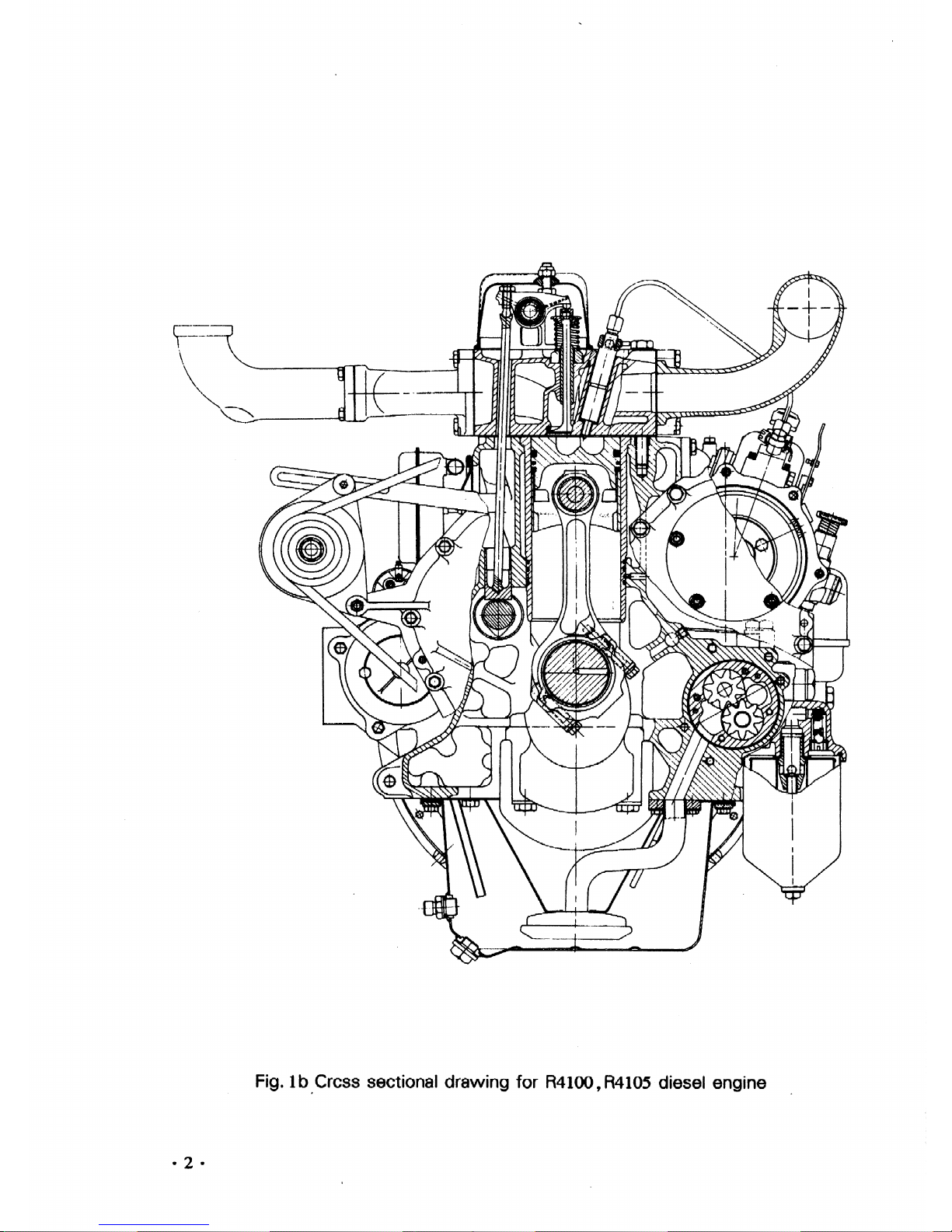

Fig.2b

Cross sectional

draw~ng

for

R6100,

R610S

diesel engine

Me

N.m

350

300

250

200

ge

g/kW.h

240

230

220

210

~

.--

....

-

...

~

~

~

1"""-

.....

~

',,-

~

~

~

~

----.

j'----....

\

I~

~

...............

.......

........

~

i\ "

----

-------

~1\

---

l/

v

~\

,

\\\

~;

./

V

~

~

~~

il

/

~

/'

~V-

~

\'\~

v

V~

/

v

\ J

./

V

V

V

~

/

v

J\

V

I

/'

1/

~

/I

\

~

/

r;

\

~

F:::::-

~

~

~"""".

,,.,,..-

...............

~

---

~

----

~

r-----

~

.--

-----

--

,.

Pe

kW

70

60

50

40

30

20

1200

1400

1600

1800

2000

2200

2400

'1 r/

TTl

in

Fig. 3 Speed and speed adujsted cha.racteristic curve for

Model

R4105,

R410SZ

.diesel

engine

• 5 •

Me

N.m

SOO

450

400

350

ge

g/kW.h

240

230

220

210

..--

-...

------

......

~

--.....

"

'-

-""'

1\

,

I

----

~

--....

r-............

,

.---

~

~

""'-,

I

\

~

I

------

~

, \

I

."

I

I

~"

I

~

,

~

~

I

~

~

-

"

V-

~

..,-

I

~/

~

~

V

~

, I

~

/

~

~

~

./

J,\

,\

~

\

"-

~

~

'/

\

~

~

r----.

~

~

/""'"'"

\

-

-----

-

."...

--

--.

_

...

-

-

Pe

kW

110

90

70

50

30

1200

1400

1600

1800

2000 2200

2400

n

r/min

• 6 ·

Fig.4 Speed

and

speed adjusted

characteristi~

curve for

Model R6105,

R6105Z

diesel engine

n r/min

2200

2000

1800

1600

1400

1200

ge

g/kW.h

280

270

260

250

240

230

220

210

--

-

--

---

----

-

""'"""-

/

/

J

4

/

V,

1/

/

./

~

.,

~

~

"",'"

~,...

-~

"

~-

\

./

~

~

\

I

i\

~

"

A

V

I'

~

~

"

~

A

~

,

'-

/?

~'

~

~

..

/.

~

~

~

~

V'

~

"'f'::

~

~

~

0

v

l":

.....

-.

1(.--

.-/

~

........

~

~

t/"

~

Me

N.m

280

240

200

160

120

80

40

10

20

30

40

Pe

kW

Fig. 5 Speed and speed

adjusted

characteristic

curve

fo~

Model R4105T and R410STl diesel engine used

for

tractors

· 7 ·

Me

275

250

225

200

glkW·

h

240

230

220

210

~

~

---....

~

y

~

"'

K

\

,

•

1\

/

~

n

\

/

'/

\

V

~

,

~

V

l A

V

:, 1

/

t

~

V

1\

.

r

J

I

J

,

~V

v

~

.............

r----.

~

~

\

~

-~

Pc

kW

60

50

40

30

20

1000

1300

1600

1900

2200

2500

2800

n

r/min

· 8 ·

Fig. 6

~peed

and speed adjusted characteristic curve

for

Model

R4105G

diesel engine used

for

engineering machine

Me

N·ro

500

450

400

375

350

L

g/kW.

h

240

230

220

1.---

1--

---I

--............

/

~

...............

"

'-

"'"

t'.~

\

"\

\

\

,

~

~

---

r-----.

\

\

~

~

,

,

."..,.-

...

-

-

- .

~

...

--~

~

1

~

.......

.........

~

~

\

...........

\\

1\

J

,

,

\

,

,

__

'-'1

-

,

J...:

~

,

\

.-.-'

".

.-Ii'

,...-:

~

/'

\

\

\ \

".

,

~

"",

I

,

-

I

~

........+

.......

....-r-

,

i\

I

,

,,-

","

,.....",-

~

\

..

,'

/

".

,.

~

\

~

~

~

~

.,..-

........

~

\

J

',\\

~~

~

~

~

..

~

\ I

\

I

I'

\'

.JII'

,

,

~.

-'I

I

,

"

"

i

\

,

,

,.

JI

\\

1\

\

I

I \

\

J,

,....,...

[/

l1

..-.

,

~

....

V-

"

::::::

~

,........

~

----

----

~

......

•

........

......

~

""..,.-

\

1-

....

Pe

kW

110

90

70

50

1200

1400

1600

1800

2000

2200 2400

2600 n

T/min

Fig. 7 Speed and speed adjusted

~haracteristic

curve

for

Model

R6105G,

R6105Gl,

R6105ZG

and R6105ZGl diesel engine used

for

engineering machine

ge

g/kW.h

360

340

320

300

280

260

240

220

~

\

\

\

\

1500r/min

~

\

~

~

V

~

~

r\

~800r/min

\

\

~

v

~

1\

\

'\

1\

1\

"

"-

~

~

"

"'

'..

~

'",

~

~

..............

......

:::----

~

t'----.

L-

~

20

40

60

80

Pe

kW

Fig. 8

Load

characteristic

curve

for.

Model

R6100ZDl

and

R6100ZD2

diesel engine for generating sets

• 10 •

Pc

kW

70

50

40

30

20

10

..

~

\~

~\

"

\

~

\\

,

\\

,

\

\

\

1/

\

\

\

\

,

~\

/

\

~.

\

~'\

~

\ \

I

\

i

'\

~

,

~.

.

/

If

\.

\

,'

~

~

'I

/

~

"

J

,

\

(.

,

~

,

,

,

~

/

,

"

J

'"

I

/

I

r'...:::

~

~--

"

I

...

~

-

~

~

-

"

'I

4

"

~/

;.

...

'

/

I

~

V

-..

l.C.:....-

.,.,

V

4

--

~

/

/

~

/

l;'

17

V

/

J

/

/

~

,

V

V

V

...

/

/

/'

:/

r,.

~

'f'

V

./

~;

~

~

~

"",

....

",.

V

".

~

~

~

glkw.

h

340

320

300

280

260

240

220

1000

1200

1400

1600

1800

2000

n r/min

Fig.

9 Propellant characteristic curve for

Mo~el

R4105C, R4105CI,

R610SC

and R610SCI marine diesel engine

•II•

ge

g/kW.h

380

360

340

320

300

280

260

240

220

\

1\

\ 1

\

\~

\

\

'\

\

~\

\

\

\\

\

1\

\

\

\

R4105Zpi\ \

f\

R4105P

" R6105P

\

~

,

\

'"

'\

~

t'..

""-

'"

"'

"

...

~

......

,

1.0-

......

--

--

-

--

~

r-....

1--_

I-

10

20

30 40

50

60

70

Pe

kW

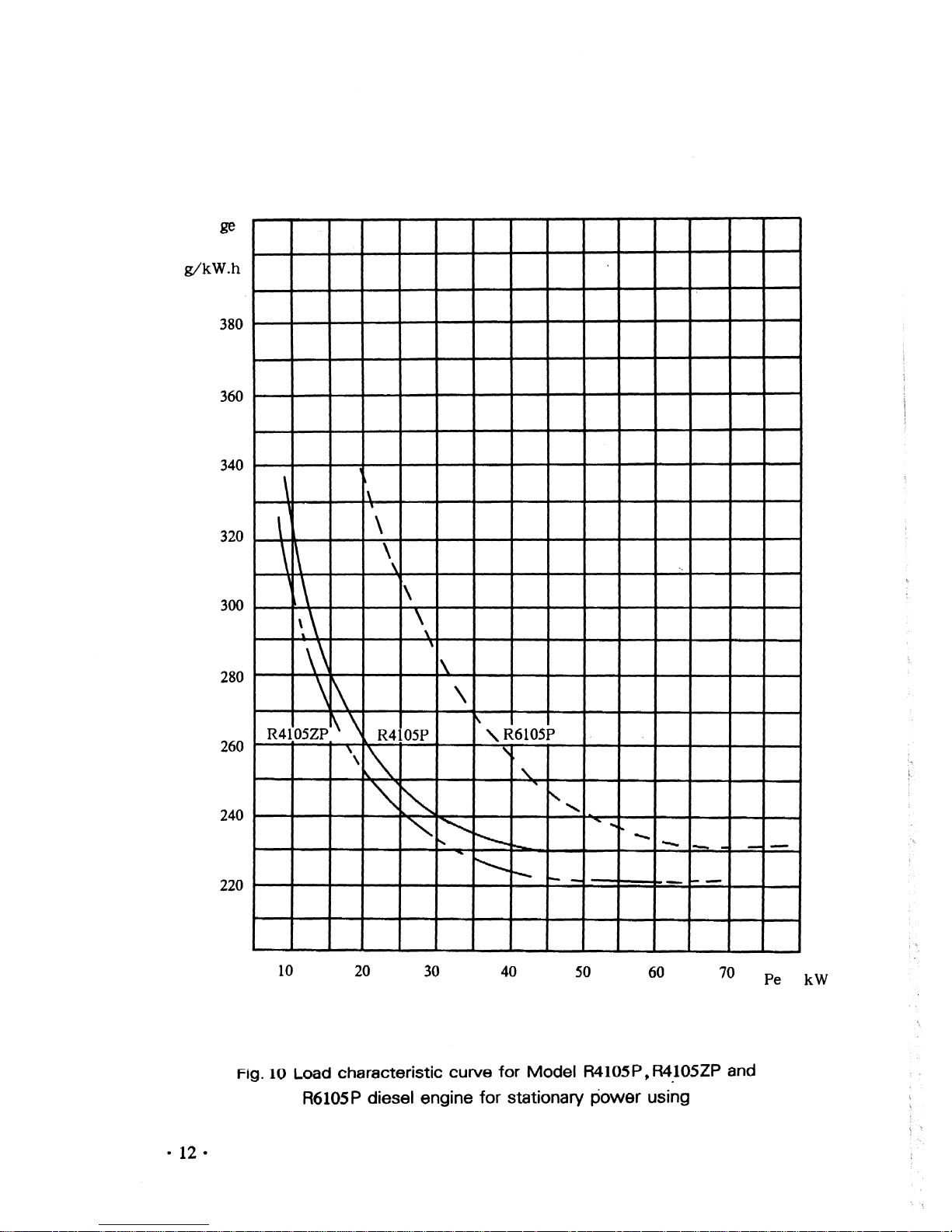

Fig.

10

Load

characteristic

curve

for

Model

R4105P,

R4.105ZP

and

R610SP

diesel engine for stationary power using

•12•

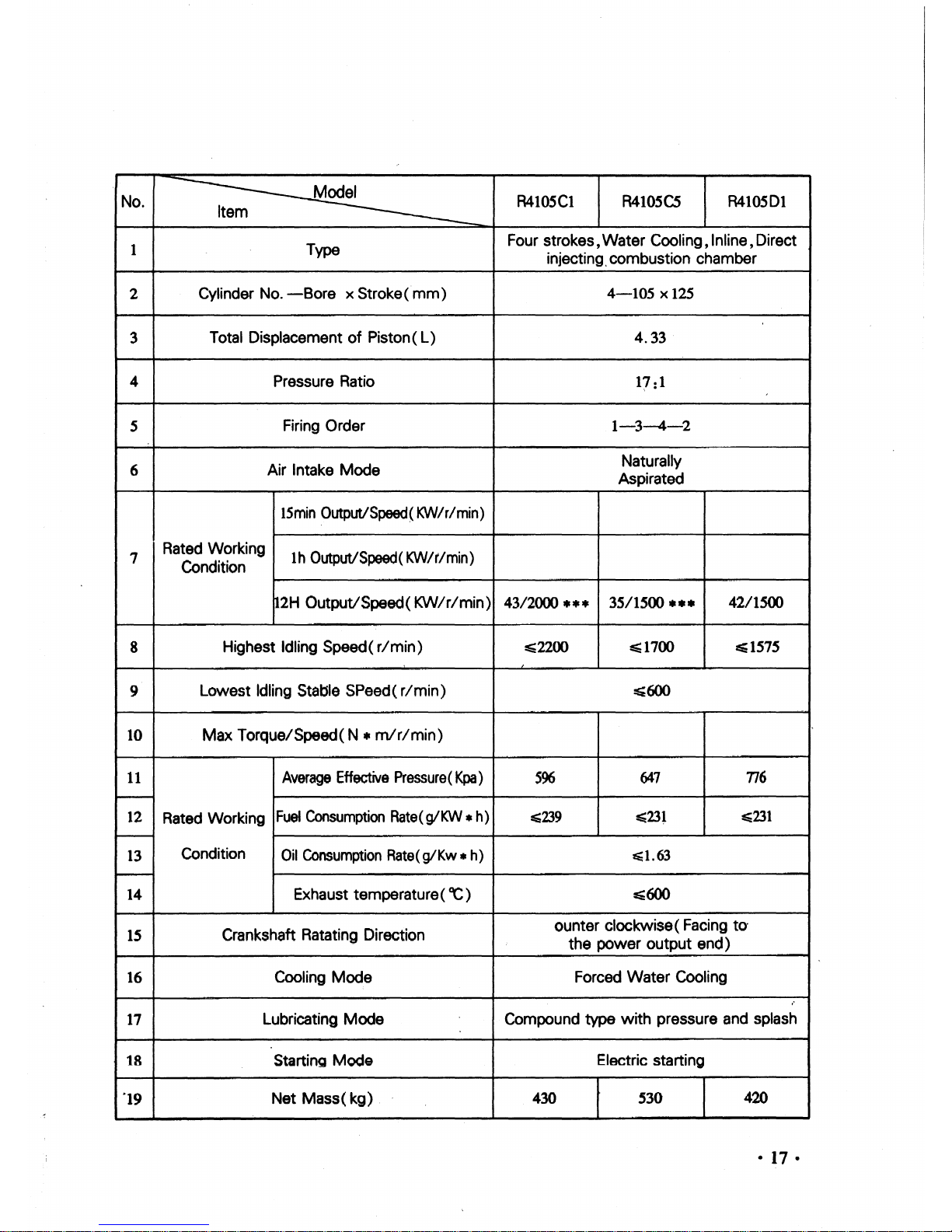

CHAPTER 1 Main Technical Specifications

and

DataofDiesel Engine

§ 1 Main Technical Specifications

No.

R4100Dl R4100D2

R4100ZD

Item

1

Type

Four

strokes,

Water

Cooling,Inline,Direct

injecting combustion chamber

2 Cylinder No.

-Bore

x

St~oke(

mm)

4-100x125

3

Total DisplacementofPiston(

L)

3.93

4

Pressure Ratio

17

:1

16:1

5 Firing Order

1-3--4-2

6

Air Intake

Mode

Naturally

Turbocharged

Aspirated

ISmin

OutpuVSpeed(

KW/r/min)

7

Rated Working

Ih

OutpuVSpeed(

KW/r/min)

Condition

!2H

Output/Speed(

KW/r/min)

3611500

42/1800 47/1500

8

Highest Idling Speed(

r/min)

~1575

~1890

~1575

9

Lowest

Idling Stable SPeed(

r/min)

e:;;600

10

Max

Torque/Speed(N...

m1r/min)

11

Average

Effective

Pressure(

Kpa)

733

712

951

-

12

Rated Working

Fuel

Consumption

Rate(glKW

*h)

~231

~224

-

13

Condition

Oil

Consumption

Rate(

glKw

*h)

~1.63

-

14

Exhaust

temperature(

OC)

Ei600

15

Crankshaft Ratating Direction

ounter

clockwise(

Facing

to

the

power

output

end)

16

Cooling

Mode

Forced

Water

Cooling

17

Lubricating

Mode

Compound

type

with

pressure and splash

tg

St~rting

Modo

I;loctri~

~t~rting

19

'

Net

Mass(

kg)

420

490

•13•

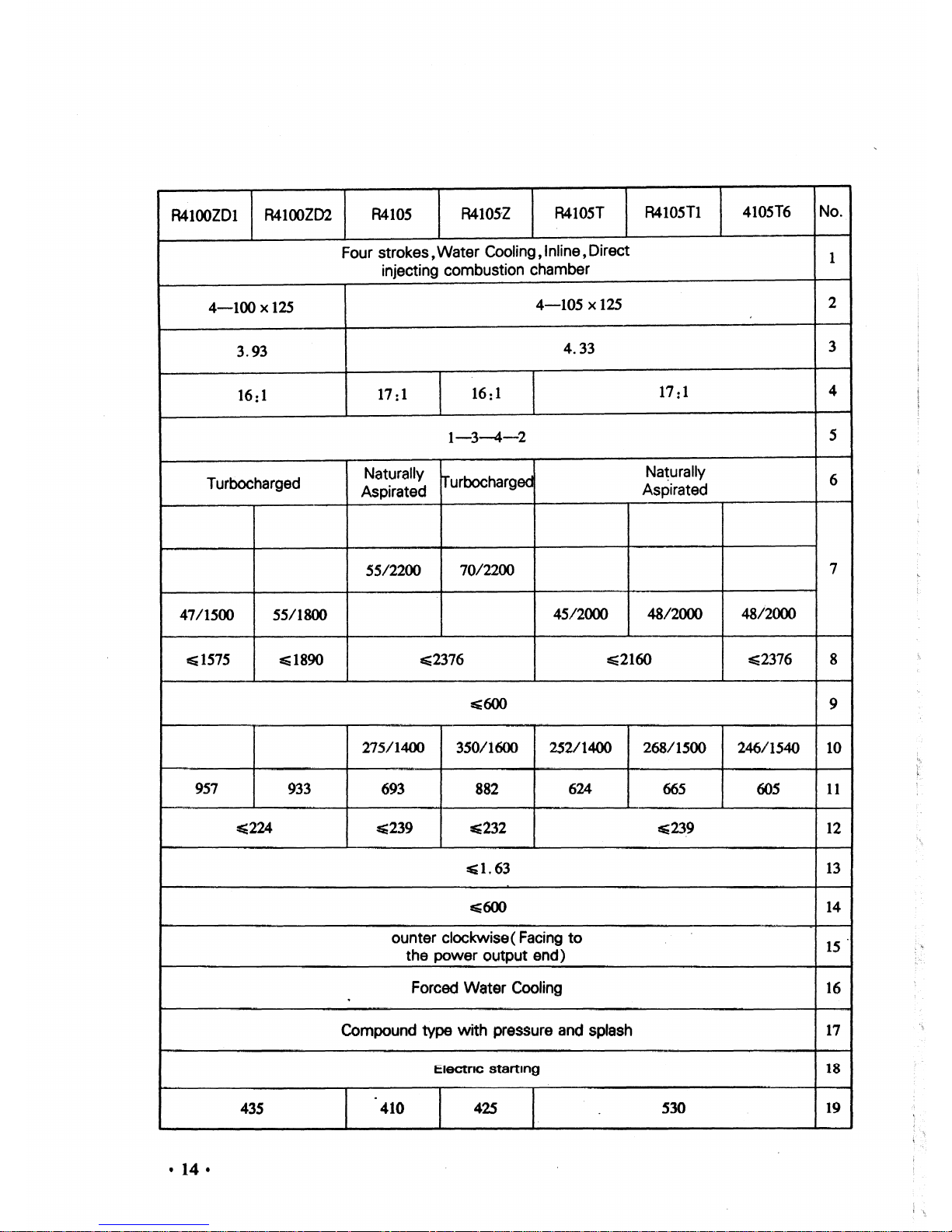

R4100ZDl

R4100ZD2

R410S

R410SZ

R410ST

R4105Tl

4105T6

No.

Four

strokes,

Water

Cooling,Inline,Direct

1

injecting combustion chamber

4-100x125

4-105x125

2

3.93

4.33

3

16:1

17

:1

16:1

17

:1

4

1-3--4-2

5

Turbocharged

Naturally

Irurbocharged

Na~urally

6

Aspirated

Aspirated

55/2200

70/2200

7

47/1500 55/1800

45/2000

48/2000

48/2000

~1575

E;1890

~2376

~2160

=5:2376

8

~600

9

275/1400

350/1600

252/1400

268/1500

246/1540

10

957

933

693

882

624

665

605

11

~224

~239

~232

~23.9

12

Etl.63

13

E;600

14

ounter clockwise( Facing

to

15

the power output end)

Forced

Water

Cooling

16

Compound

type

with

pressure and splash

17

ElectrIC

starting

18

435

410

425

S30

19

• 14 •

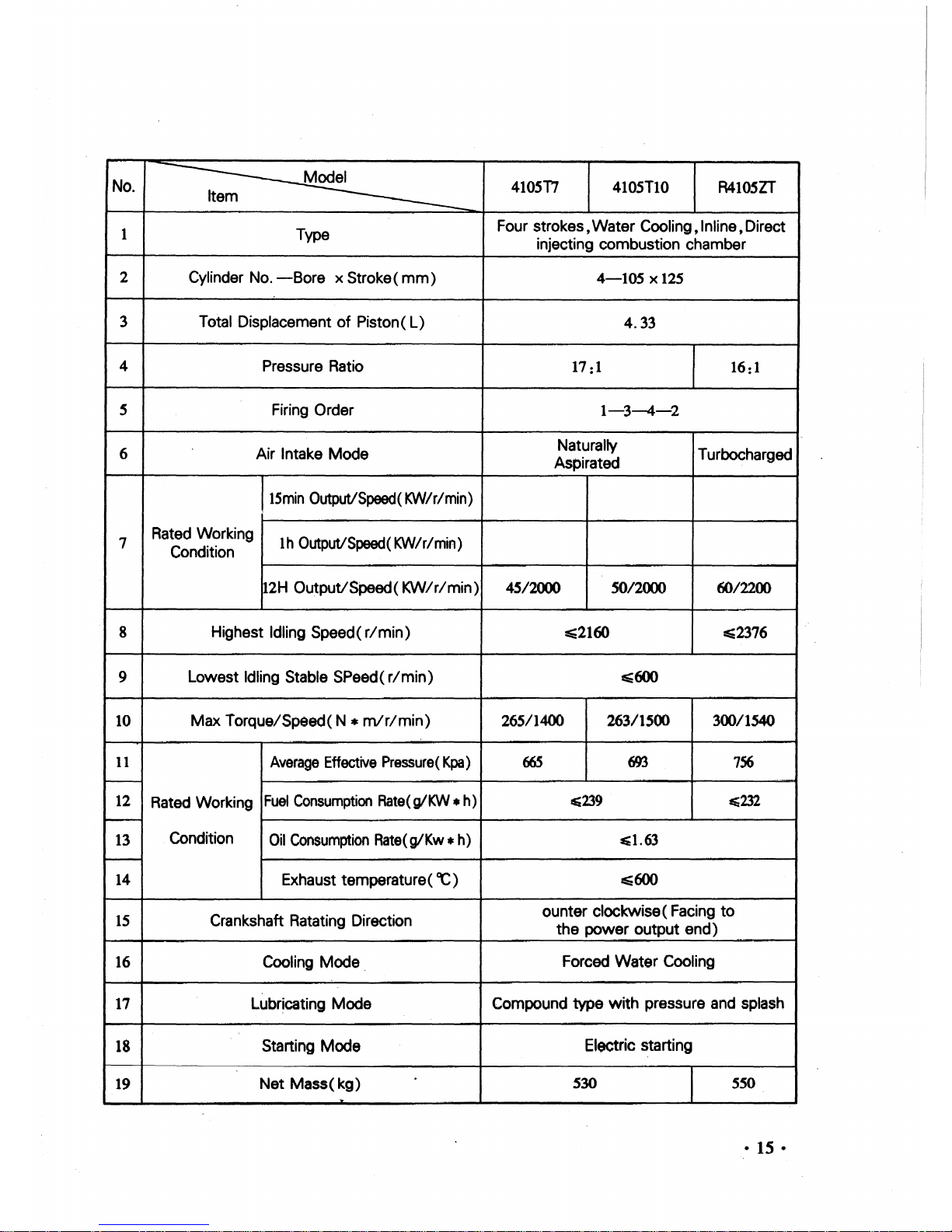

No.

4105T7

410STIO

R4105ZT

Item

1

Type

Four

strokes,

Water

Cooling,Inline,Direct

injecting

combustion

chamber

2

Cylinder No.

-Bore

x Stroke (

mm)

4-105

x 125

3 Total Displacement

of

Piston(

L)

4.33

4

Pressure Ratio

17

:1

16:1

5 Firing Order

1-3-4-2

6

Air Intake

Mode

Naturally

Turbocharged

Aspirated

15min

OutpuVSpeed( KW/r/min)

7

Rated Working

Ih

OutputiSpeed(KW/r/min)

Condition

12H

OutpuVSpeed(

KW/r/min)

4SI2000 50/2000 6012200

8

Highest Idling Speed(

r/min)

E;2160

:s=2376

9

Lowest

Idling Stable SPeed(

r/min)

~600

10

Max

Torque/Speed(

N *

mlr/min)

265/1400

26311500 300/1540

11

Average

Effective

Pressure(

Kpa)

66S

693

756

-

12

Rated Working

Fuel

Consumption

Rate

(gIKW• h)

=s;239

tti232

-

13

Condition

Oil

Consumption

Rate(

g/Kw.

h)

~1.63

-

14

Exhaust temperature (

ac

) Ei600

15

Crankshaft Ratating Direction

ounter

clockwise ( Facing

to

the

power

output

end)

16

Cooling Mode.

Forced

Water

Cooling

17

LUbr~cating

Mode

Compound

type

with

pressure and splash

18

Stal1ing

Mode

Electric starting

19

Net

Mass(

kg)

S30

550

..

•15•

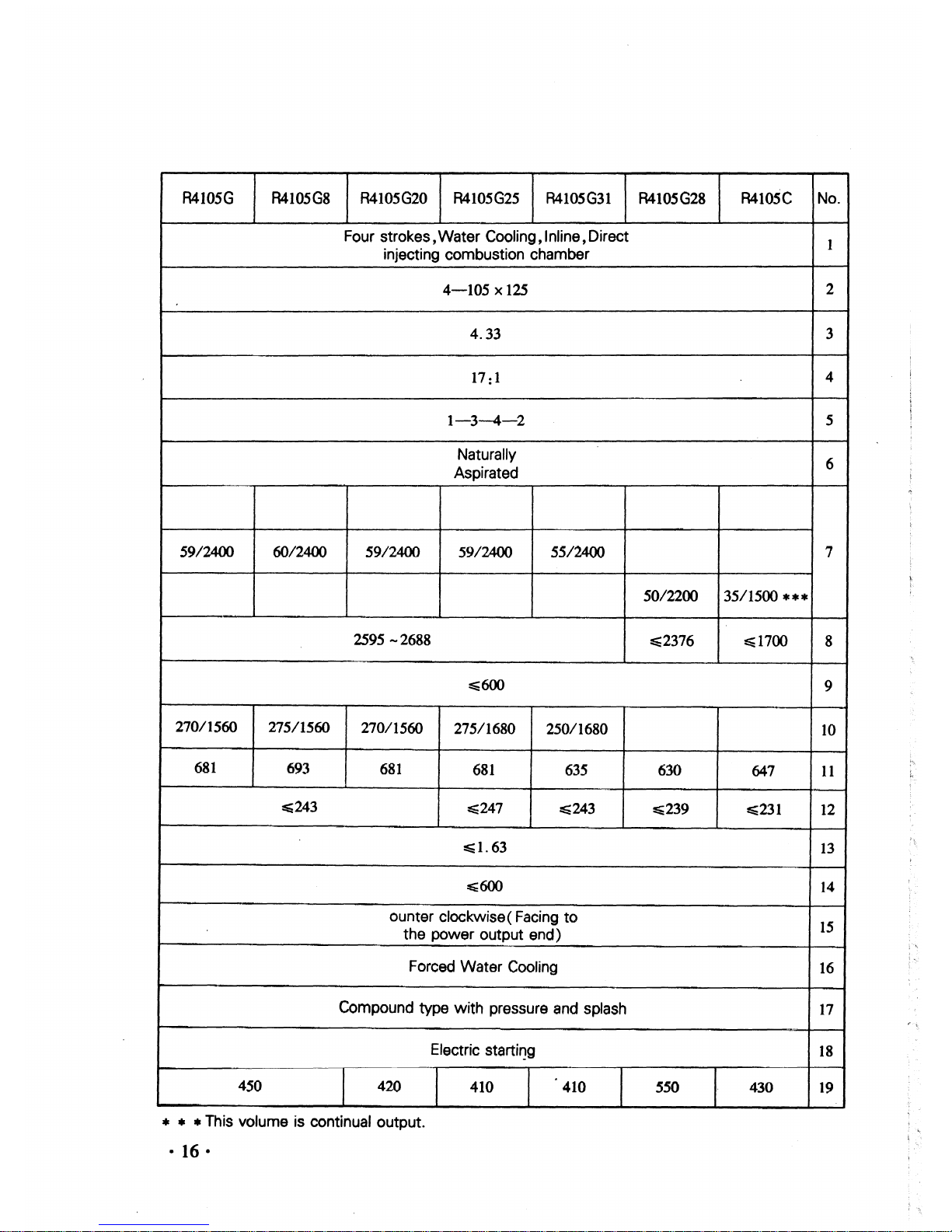

R4105G

R4105G8

R4105G20

R4105G25

R4105G31

R4105G28

R4105C

No.

Four

strokes,

Water

Cooling,Inline,Direct

1

injecting combustion chamber

4-105x125

2

4.33 3

17:1

4

1-3-4-2

5

Naturally

6

Aspirated

59/2400 60/2400 59/2400

59/2400 55/2400 7

50/2200

35/1500

***

2595

-2688

~2376

~1700

8

E;600

9

270/1560

275/1560

270/1560

275/1680

250/1680

10

681

693

681

681

635

630

647

11

~243

~247

E;243

~239

~231

12

:E:

1.63

13

~600

14

ounter clockwise ( Facing

to

15

the

power output

end)

Forced

Water

Cooling

16

Compound type

with

pressure and splash

17

Electric starti'1Q

18

450 420

410

410

550

430

19

• • • This

VOlume

is continual output.

•16•

No.

R410SCI

R410SCS

R410SDI

Item

1

Type

Four strokes,Water Cooling,Inline,Direct

injecting.combustion chamber

2

Cylinder No.

-Bore

x Stroke(

mm)

4-105

x 125

3

Total DisplacementofPiston(

L)

4.33

4 Pressure Ratio

17

:1

S

Firing Order

1-3-4-2

6

Air Intake

Mode

Naturally

Aspirated

lSmin

OutputlSpeed( KW/r/min)

7

Rated Working

Ih Output/Speed( KW/r/min)

Condition

12H

Output/Speed(

KW/r/min)

43/2000

•••

35/1500

•••

42/1500

8

Highest Idling Speed(

r/min)

E;2200

E;;1700

E:1575

9

Lowest Idling Staljle SPeed(

r/min)

~600

10 Max Torque/Speed(N •

mlr/min)

11

Average

Effective

Pressure

(

Kpa

)

596

647

176

-

12

Rated Working

Fuel

Consumption

Rate

(gIKW

*h)

E;239

~23.

E:231

-

13

Condition

Oil

Consumption

Rate

(glKw*h)

~1.63

~

14

Exhaust temperature(

CC

)

E;600

15

Crankshaft Ratating Direction

ounter clockwise( Facing to'

the

power

ou~put

end)

16

Cooling

Mode

Forced Water Cooling

17

Lubricating

Mode

Compound

type

with

pressure and splash

18

StartinQ

Mode

Electric starting

·19

Net Mass(

kg)

430

'30

420

•

17

•

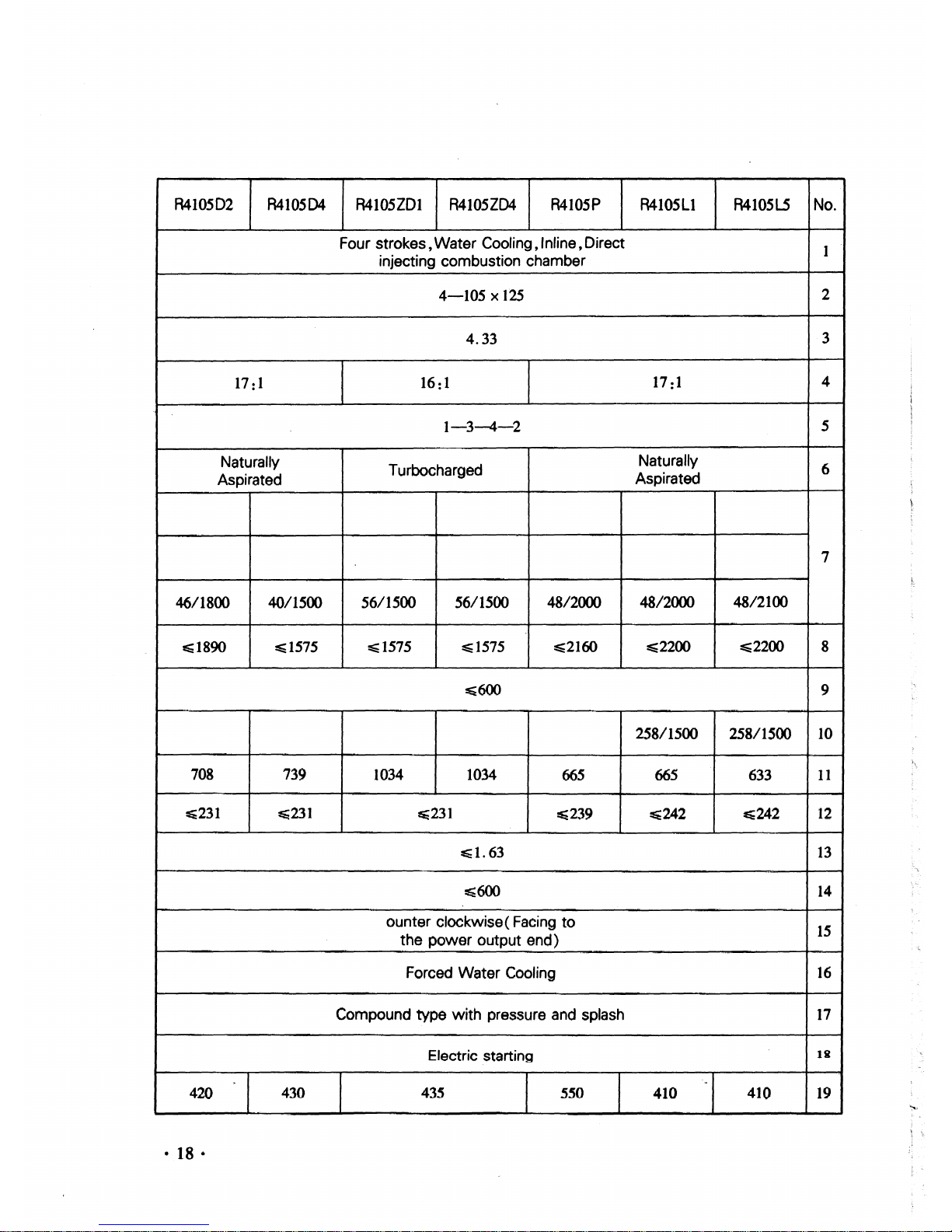

R4105D2

R410SD4

R410SZDl

R4105ZD4

R410SP

R4105Ll R410SL5

No.

Four strokes, Water Cooling, Inline,Direct

1

injecting combustion chamber

4-105x125

2

4.33

3

17:

1

16:

1

17 :1

4

1-3-4-2

5

Naturally

Turbocharged

Naturally

6

Aspirated

Aspirated

7

46/1800

40/1500

56/1500

56/1500

48/2000 48/2000

48/2100

Ei1890

~lS7S

~1575

~1575

E;2I60

~2200

E;2200

8

~600

9

258/1500

258/1500

10

708

739

1034 1034

665

665

633

II

~231 ~231

~231

~239

~242

E;242

12

~1.63

13

~600

14

ounter clockwise( Facing

to

15

the power output end)

Forced Water Cooling

16

Compound type

with

pressure and splash

17

Electric starting

tg

420

430

43.5

5.50

410 410

19

--

Loading...

Loading...