HTP America MIG 200i Owner’s Manual

MIG 200i

Owner’s Manual

180 Joey Drive

Elk Grove Village, IL 60007-1304

Ph: (847) 357-0700 · Fax: (847) 357-0744

Web: www.usaweld.com

MANUFACTURER’S WARRANTY

It is expressly agreed that there are no warranties, expressed or implied, made by either the Salesman, Dealer, or HTP

America, Inc. on products or parts furnished hereunder, except the Manufacturer’s Warranty against defective

materials or workmanship as follows:

HTP America, Inc. warrants each new welding machine to be free from defects in material and workmanship under

normal use and service for Three (3) Years after delivery to the original purchaser. HTP America, Inc. will repair and

replace, at its factory, any part or parts thereof. Products should be returned to HTP America, Inc., with transportation

charges prepaid, and which its examination shall disclose to its satisfaction to have been thus defective. This warranty

being in lieu of all other warranties, expressed or implied, and all other obligations or liabilities on its part and it

neither assumes nor authorizes any person to assume for it any liability in connection with the sale of its machines.

This warranty shall not apply to any welding machine which has been repaired or altered by unauthorized service

departments in any way so as, in the judgment of HTP America, Inc., to affect its stability and reliability, nor which

has been subjected to misuse, negligence, or accident.

HTP America, Inc. shall not be liable in any event, unless HTP America, Inc. receives notice of alleged breach of

warranty, actual or constructed, specifying the claimed defect within not more than Thirty (30) Days after discovery.

HTP America, Inc. has reserved the right to make changes in design or add any improvements to its products, at any

time, without incurring any obligation to install the same on equipment.

This warranty is void unless the warranty card is sent to HTP America, Inc. within Fifteen (15) Business Days from

the date of purchase.

Exclusions to Warranty:

1. The MIG Welding Gun/Torch is warranted for a period of Ninety (90) Days against defects in material and

workmanship.

2. The contact tips, tip holders, gas diffusers, gas nozzles, and liners are consumable items, WHICH CARRY NO

WARRANTY.

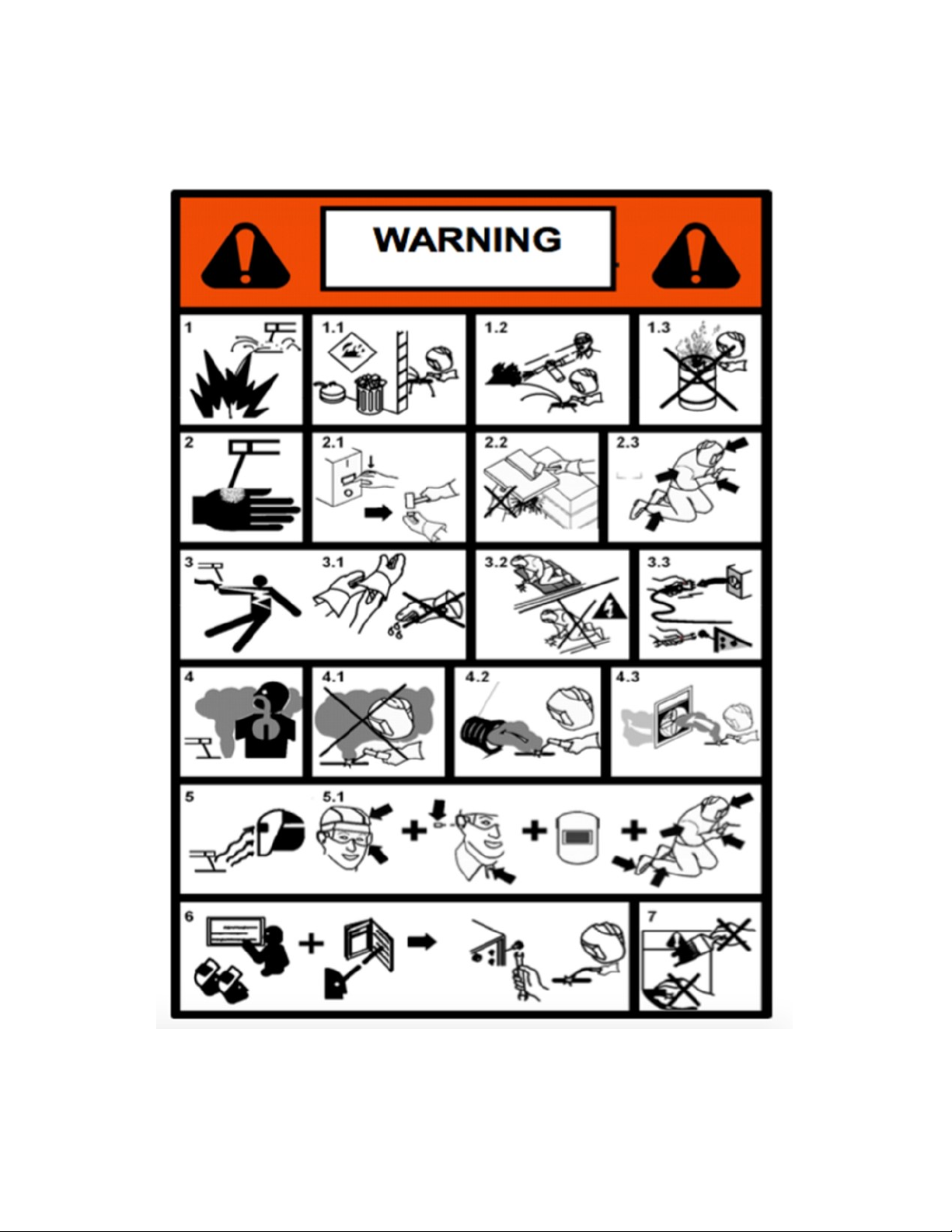

SAFETY SUGGESTIONS

It is forbidden for people with PACEMAKERS to use or come near the machine.

Electric arc welding produces ultra-violet rays, which are harmful to skin and eyes. Ultr a-violet radiation can

penetrate lightweight clothing, reflect from light colored surfaces, and burn the skin and eyes.

Wear a heavy, pocket-less, long-sleeved shirt, cuff-less trousers, and high-topped work shoes.

Wear a full-faced welding helmet with a number ten or darker lens and a cap.

Electric arc welding produces flying sparks and hot material, which can cause fire.

To avoid fire, do not weld on wood, plastic tile, or carpeted floors. Concrete or masonry floors are safest.

Do not weld on pressurized containers.

Do not weld on drums, barrels, tanks, or other containers until they have been cleared and cleaned as described in

AWS Standard A6.01.

Do not wear flammable materials.

Wear non-oily/non-greasy, flameproof welding gloves; the oil or grease on the gloves may ignite.

Avoid having any type of fuel, such as cigarette lighters or matches, on your person as you weld.

Ensure that there is a fire extinguisher in the welding area.

Noise can damage your hearing. Pr otect yourself suitably to avoid hear ing damage.

The welding arc can cause burns. Keep the tip of the welding gun/torch far from your body and fr om other

persons.

2

Electric arc welding produces toxic fumes.

Provide adequate ventilation in the welding area at all times.

Do not weld on galvanized zinc, cadmium, or lead beryllium materials unless you are POSITIVE that sufficient

ventilation is provided. These materials produce toxic fumes.

Do not weld in areas close to degreasing or spraying operations. Chlorinated hydrocarbon vapors may react with

the ultra-violet rays and form highly toxic phosphate gas.

If you develop momentary eye, nose, or throat irritation during welding, stop welding immediately. This is an

indication that ventilation is not adequate. Do not continue to weld until ventilation is improved.

ELECTRIC SHOCK CAN KILL.

Exposed, electrically hot conductors, other bare metal in the welding circuit, or ungrounded, electrically hot

equipment can fatally shock a person whose body becomes a conductor. Do not stand, sit, lie, lean on, or touch a wet

surface when welding.

Disconnect the power supply before working on the welding machine.

Do not work with deteriorated or damaged cables.

Frequently inspect cables for wear, cracks, and damage. Replace those with excessively worn insulation to avoid

a possible lethal shock from bared cable.

Do not touch bare electrical parts.

Ensure that all of the panels covering the welding machine are firmly secured in place when the machine is

connected to the power supply.

Insulate yourself from the workbench and from the floor (ground); use insulating footwear and gloves.

Keep gloves, footwear, clothes, the work area, and the welding equipment clean and dry.

Check the machine power cable frequently; the power cable must be free from damage to the insulation. BARE

CABLES ARE DANGEROUS. Do not use the machine if the power cable is damaged; a damaged power cable

must be replaced immediately.

If it is necessary to open the machine, first disconnect the power supply. Wait Five (5) Minutes to allow the

capacitors to discharge. Failure to take this precaution may expose you to the dangerous risk of electric shock.

For more information, refer to the following standards and comply as applicable.

ANSI Standard Z49.1 SAFETY IN WELDING AND CUTTING, obtainable from the American National

Standards Institute, 1430 Broadway, New York, NY 10018.

ANSI Standard Z87.1 SAFE PRACTICE FOR OCCUPATIONAL AND EDUCATIONAL EYE AND FACE

PROTECTION, obtainable from the American National Standards Institute, 1430 Broadway, New York, NY

10018.

AWS Standard A6.0 WELDING AND CUTTING CONTAINERS WHICH HAVE HELD COMBUSTIBLES,

obtainable from the American Welding Society, 2051 NW 7th St., Miami, FL 33125.

NFPA Standard 51 OXYGEN-FUEL GAS SYSTEMS FOR WELDING AND CUTTING, obtainable from the

National Fire Protection Association, 470 Atlantic Ave., Boston, MA 02210.

NFPA Standard 51B CUTTING AND WELDING PROCESSES, obtainable from the National Fire Protection

Association, 470 Atlantic Ave., Boston, MA 02210.

CGA Pamphlet P-1 SAFE HANDLING OF COMPRESSED GASES IN CYLINDERS, obtainable from the

Compressed Gas Association, 500 Fifth Ave., New York, NY 10036.

OSHA Standard 29 CFR, Part 1910, Subpart Q WELDING, CUTTING, AND BRAZING.

3

Fig. 1

4

GENERAL CHARACTERISTICS

The MIG 200i features an incredible arc dynamic, which makes the MIG 200i suitable for any kind of wire and for

any material thickness from 26 gauge up to 1/4”. With the MIG 200i, you can weld in manual mode or in synergic

mode with Easy Set™ technology. The Easy Set feature makes set up a breeze by automatically setting your welder,

in a couple of simple steps, to the correct parameters. A simple polarity reversal allows you to weld with gas (solid

wire) or without gas (flux-cored wire). The MIG 200i also features manual wire feed, manual gas purge, and start

speed adjustment.

The HTP MIG 200i, which features electronic adjustments controlled by a microprocessor, allows you to achieve

excellent welding quality thanks to the advanced technologies applied. The microprocessor circuit controls and

optimizes arc transfer irrespective of the load variation and of the impedance of the welding cables. The inverter

technology used in the HTP MIG 200i, as well as other welding machines in our product line, enabled us to obtain the

following:

Machines with extremely low weight and compact dimensions.

Reduced energy consumption.

Excellent dynamic response.

Very high power factor and yields.

Better welding characteristics.

The sensitive electronic components are cooled with forced air by fans with low noise production, and the MIG 200i

features sophisticated, electronic overheat protection to prevent damage to your machine.

NOTE: The HTP MIG 200i is not suitable for thawing pipes.

The MIG 200i package includes:

HTP MIG 200i Power Source

10’ MIG Welding Gun

10’ Ground Cable and Clamp Assembly

Flow Meter

6’ Gas Hose

Owner’s Manual

NOTE: A 12’ or 15’ MIG welding gun may be purchased in place of, or in addition to, the 10’ MIG welding

gun.

Check that all of the material listed above is included in the package. Inform HTP America, Inc. if anything is

missing. Check that the machine has not been damaged in transit. If you see any sign(s) of damage, consult the

COMPLAINTS section for instr uctions. Befor e working with the machine, please r ead the entire Owner ’s

Manual.

COMPLAINTS

Complaints for damage during transit: If your equipment is damaged dur ing tr ansit, you must pr esent a claim

to the carrier.

Complaints for faulty goods: All equipment shipped by HTP America, Inc. is subjected to strict quality contr ol.

However, if your equipment does not work properly, consult technical support at HTP America, Inc. as soon as

possible.

5

Loading...

Loading...