HTP America 200-AC-DC Owner’s Manual

IJTP^-,,,**

lnvertig

Owner's

Manual

200

ACIDC

America,

HTP

1.8OO.USA-WELD.

lnc.

.

Nordic

3200

847-357-0700

.

Road

Arlington

.

FAX: 847-357-0744

Heights,

lL 60005-4729

www.usaweld'com

'

I

NI anufacturer's

gr

HTP

against

agreed

expressly

It is

Dcaler.

Warrantv

HTPAmerica,

rvorkmanship

Agrerica,

Anterica,

HTp

satisfaction

expressed

a,,ihorize,

rvarran{

This

senice

reiiabiliry,

LITP America,

breach

w'arranN

of

under

will

Inc.

to have

implied,

or

any other

departments

nor

rvarranty

of

specifying

HTp America,

products at

This

purchase.

any

rvarranry'is

\Yarran

America,

Inc.

ty

there are

that

Inc.

delective

materials

warrants each

normal

repair and

with transponation

Inc.

thus

been

all other

and

person

not apply

shall

in any

has been subjected

r.vhich

Inc. shall

not be

within not more

the claimed defect.

Inc. has

reserved

without incurring

time

void unlcss

no warranties,

products or

on

or

nerv

use and

service

replace,

defective.

obligations

to assume

welding

to any

way so as

liable in any

than 30

the right

rvarranry card

expressed

parts fumished

workmanship

welding machine

for three

at its factory,

charges

This

for it any

the

in

to misuse,

to make

any obligation

any

prepaid and

warranty being

liabilities

or

other

machine

judgment

negligence

unless

event,

days after

change

to HTPAmerica,

is

sent

or

hereunder,

as follows:

free

to be

years after

part

or

which

expressly

on

liabiliry

has been

rvhich

HTPAmerica,

of

HTP America,

discovery,

the

in design

to install

from

delivery

thereof,

made

except

defects

to the original

implied,

parts

its examination

in lieu ofall

part

and

its

in connection

repaired

Inc.

accident.

or

Inc. receives

actual or

or add

on equipment

same

w'ithin

Inc.

by either

the

the Salesman,

Manufacturer's

in material

and

purchaser. HTP

products

neither assumes

it

with the

to affect

to be

shall

other

sale

or altered

its stabiliry

disclose

warranties,

of its

by unauthorized

notice of

construction

any improvements

l5 Lievs

trom dlte

retumed

to its

nor

machines.

and

alleged

alleged

to its

to

breach

oi

Note:

Warrantl':

Exclusions

to

l. ThcTigWelciingTorchiswarrantedforapcriodolninery(90)De-vsagainstdeiectsrnmaterial

rvorkmanship.

and

\\'T{iCFi CARRY

2. Thc

NO

rungstcn,

collet,

\\ARRANTY:

colietboCl-.

ceramic

nozzles

consumabie

are

iten-rs.

'il

Safety

Elcctric

harmful

lightrveight

br:rn

are

ignite.

trousers, and

helmet

precautions will

and

.

.

.

.

.

Suggestions

*,elding

arc

to skin and

clothing,

the skin and

not oily or

Wear a heavy,

*,ith a number

hot material.

To avoid

tloors. Concrete

Do not

they

Provide adequate

Do not

materials unless POSITIVE

Thesc materials

Do not

op.rations. Chlorinated

the

Ii

during

indication that

r,,eid

frre, do

weld

have been

rveld

',veld

ultra-violet

y'ou

develop

rvelding, stop

until

produces

eyes.

reflect from light colored surfaces,

eyes.

greasy.

pocket-less,

high-topped

eight or

protect

not weld on

masonry floors are safest.

or

on drums,

cleared as described

ventilation in the welding area at all

galvanized

on

produce toxic fumes.

in areas close

ra,vs and form

momentary eye,

ventilation is not adequate. Do

ventilation is improved.

ultra-violet rays,

Ultra-violet

Wear flameproof

The oit or

grease

long sleeve shirt,

work shoes.

darker lens and a cap.

hair, face, and skin from

e-ves,

wood,

barrels,

tanks

radiation

Wear

plastic

rvhich are

can

rvelding gloves rvhich

gloves

the

on

a full-face

tile, or carpeted

or other

containers until

inAWS Standard,4.6.0l.

zinc, cadmium or

sufficient

to degreasing

hydrocarbon

highly toxic

nose

vapors

or

lead beryllium

ventilation is

or spraying

may

phosgene gas.

throat irritrtion

welding immediately. This is an

not

penetrate

and

may

cuffless

welding

These

arc rays

times.

provided.

r'r'ith

react

continue

For more information,

cornply

I ANSI Standard

CUTTING,

2051 NW 7th St..

2. ANSI Standard

OCCUPATION

PROTECTION,

Standards

3. America

CUTTING

COMBUSTIBLES,

4. NFPA STANDARD

FOR

National Fire

Boston,

5 NFPA Standard

PROCIESSES. obtainable same

6 CG.{

CO\lPRESSED

the Compr.-sseC

Ne* \'ork. N\'

7.

to

OSHA

CUTTTi..iG

as applicable.

249 1 SAFETY

obtainable lrom

287.I SAFE

AND EDUCATIONAL

Instirute, 1430

Welding

CONTAINERS

\IELDING

Protection

lvIA 02210.

PA\{PHLET

10016

Standrrd

AND

to the follorving

refer

IN

the American

N{iami. FL 33 125.

standards and

WELDING

\\'elding

.\ND

PRACTICE FOR

EYE AND

obtainable

Sociery Standard A6.0

from

American

Broadway, New York, NY

National

WELDING

WHICH HAVE HELD

obtainable

51. OXYGEN.FIJEL

same as item l.

GAS

SYSTENIS

AND CUTTIIJG. obtainable from the

Assoc., 470 Atlantic Avenrre.

lB CUTTING AND

5

P-1

SAFE

GASES

Gas Association. 500

29 CFR, Part

IN CYLL|'JDERS, obtarn:rble tiom

1910,

WELDING

-1.

as item

HANDLING OF

Filth

Avenue.

Subpart

Q

WELDNC.

BRAZING.

Societl.

FACE

100 18.

AND

.

Exposed, electrically

w'eiding

the

can tatall.v shock

Do not stand. sit,

,.r'e1cling.

Fr.-qlienih inspect cabi:s for

"

R:pilcc

f -.ssi'cii

circuit, or

thos;

l:th:rl shock

hot conductors or other bare

a person

1ie, lean on or

lvith

exce ssivel.'

tiom b,rr:11 cablc.

metal in

ungrounded electricall.v hot equipment

rvhose

body becomcs a

touch

w

ear, cracks, anil drmrce.

u'orn

*'et

a

insulrrtior,

surfice

1,,-.

conductor.

*'hen

.t

r'''oi"i

Electrical Connection

\bur Invertig

power

shipped

jiailrl',\'-gieen

2C0 ACIDC operate s on single-phrse l,lll

[(*'-

15',r) 195.5

to 25+.i r"oitsl. The rnr,:i',:n-- rs n-r

i,ith a clug. Th;

qrrL:iri.

w

i:: is

ir; nct 1er,:s.

.,,ii'

I::ir":t

Lroir':l

rn:

l:..:',.,:,'r Ii-.t.:t-

l: 100 rmp:.

eiectrical air:-,:..iii:i.rs

-\ii

::;cliicirn in

iccal cocles r.i.,c.

lc;.-.i-J:L:'.:c

iidrn.inc.ii.

inS,Lll pc\.\ li

--,liri

hl'

rLri lh: bii:: :lltri :i.r'.i i'.

a::-'r.:t.

sl:r-r'-i:.i t.'i,r!'ri.iin.d

r.,rllt tltl

).t:litlr.rl

Fl-'-,r'lr.il

.'.'ir::,

-l

.t.

"

'.,'..

. :... ,.._-

r'. l:l::.rir.l,-.1

,.

rrti,r

r

oll

Ti:

i.j:

.'r,..:

-lr.:

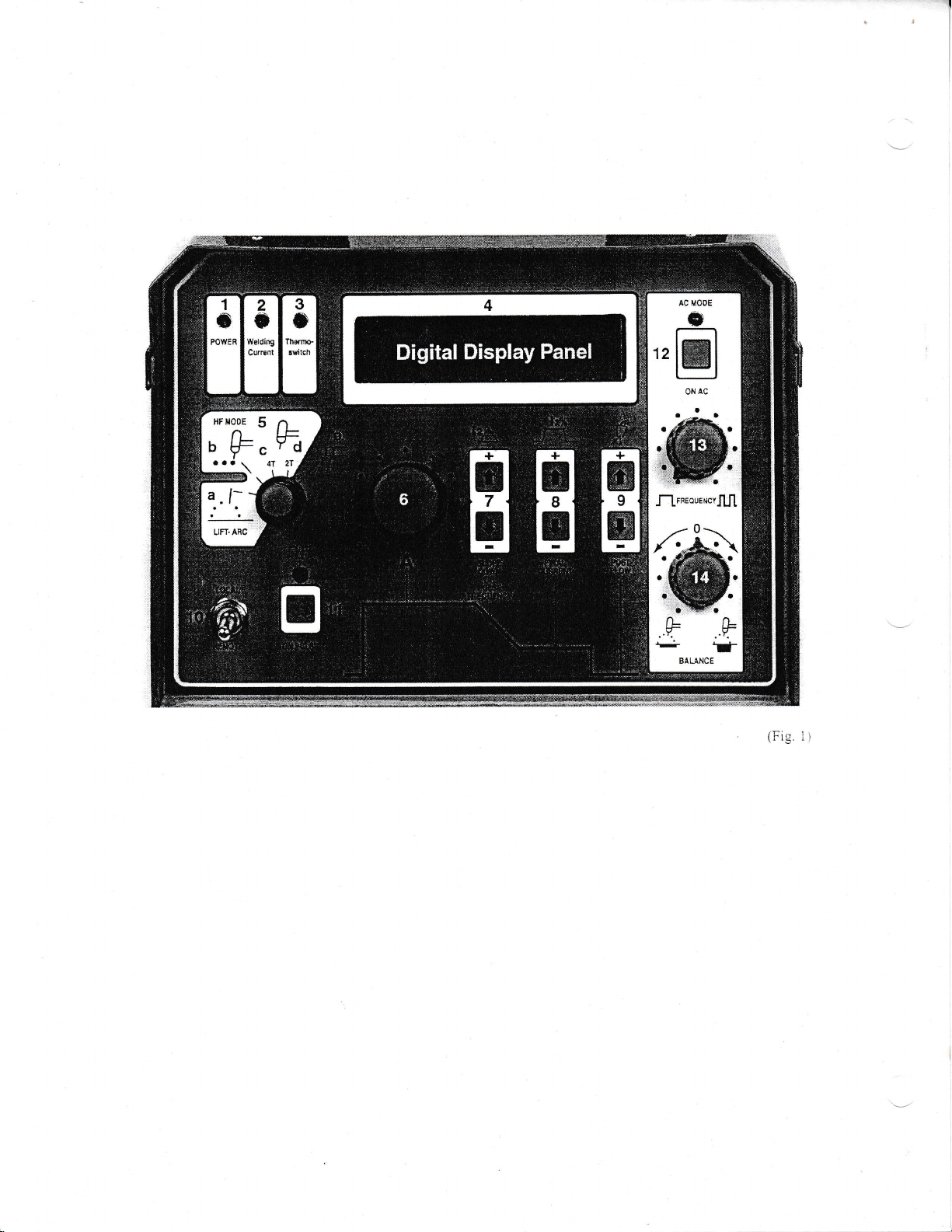

(Fig.

1)

Front Panel

(See

Fig.

Controls

1)

l) Porver Indicator

illuminated

lamp rs

This

your

Invertig

the unit is correctlv

2) Welding Current

When either

torch is depressed,

welding

torch and

illuminated.

your Invertig

If

rvelding

3)

The

c,vcle

current

Thermosrvitch

thermoswitch

your Invertig

of

this Iamp is

because

the machine

piugged in and tumed

Ailow

dorvn.

thcrmoswitch

be ready'to

-l)

Digital

The Digital

parameters are.

amperage.

rvclding cmperf,gc.

rcrur!

you

When

in the AC

Frequency and

thc AC

\\'hen the machine

press either

drsplay'rvilL

rirgitrl

s:conds

and the Post

\\'hcn the nachir.re

e ither

ir:-is

ti-.e Post Flou. Button

Do*'n

Slopc

pcrcint olbase

\\'hen the machine

the

press

de

*'i11 drsplay

is rurned

200

foot

the

welding current

the

200 AC/DC

indicator

Indicator

indicator

illuminated,

the machine

should

weld.

Display

Display

For example,

you

As

press

the "AC on" button

Weiding N{ode,

tile T2 button

rhe Tl button

Time

cunent.

"On

Pulse"

pulse frequency in hertz

the

Lamp

when the

On-Off

to the I or

or

to 220

LamP

trigger

the

connected

Indicator

pedal

Welding Current

the

is in

will be illuminated

lamp

LamP

lamp will light up

200 AC/DC

the machine

has overheated.

the cooling fans can

on so

to cool for l5

automatically and

reset

Panel

Panel allows

depress

the AC balance.

is in the 2T

displa.v

gas

flo"v

the'1T

is in

you

normal

the

the foot

the digital displa;"'panel

rvelding mode

(#7)

the

or

the Slope Do*n

in

seconiis.

w'clding mcCe

(=7), thc

(;9)

the

digitai

(T2)

in seconds,

the Post

and

in the Pulse

is

button

Welding N{ode and

(#1

switch on

position,

"On"

volt

will

power,

AC

on

switch

be applied

Indicator

stick-welding

when the dury

has

been

exceeded.

will no longer

the machine

Leave

to

minutes,

30

your Invertig

to see

'"vhat

display

pedal,

,vou

"vill

(#12)

rvhen the machine

(5d),

F|:rv Button

Post

Tirne

(5c).

Finai Currenr

will

display

the Final Current

in seconds.

Florv

Gas

1) the digital

display

(cycles per

the back of

indicating

the TIG

to the

will be

Lamp

the

mode,

the time.

all

When

weld

the unit

cool

the

your rvelding

r,r,'elding

the

is

the

see

rvill

displ:i

and vou

(=9

(T2)

in

anrl

.v''or-r

(;:ir.

Button

the

display

(i2)

you

panel

second).

in

*i11

I

tir:

\1'elding

5)

The

Invertig 200 AC/DC.

A)

B) Spot

CJ

is

D

t

l:

E) )rc

6) Amperage

This knob

.vour

amperage

lccaL,remote

lVlode Srvitch

welding mode switch

LiJtArc Mode-

w'elding arc

environment

interference

computers.

aluminum

or

for both AC

TIG Weld

To

tungsten

depress

with the

contact

this method for

able

being

lVelding

weld

for between

automaticali)-

performing a series

*'ere

Tcr seiect

i.r s;lcct

Ccrrn

..iT

no,le

\\'e

sugeest

*hich

is

trigger on

y'ou release the

When

you

depress

rvill

arc

['hen

using

rveld rvithout ha.,

:o

c:t

no\\'

..

is not sugg"'sr:ci

Ir

notj:

)T

Invertig

our

l

r:ieesed..

o..rf,tion

ll'eLding

electrode

operate.

the

without

r,vhere the

with

sensitive

good

A

repair

and DC

using

workpiece, activate

to the

the foot

pedal

work, the arc

Stick

to vary

tlode

stop.

the spot

a time bcnveen

This is Iike a

-

using

mounted on

the torch,

the trigger again

extinguish.

the h:rnd amperxge controi.

ancrtt-'

\\-irh th* i,:rch

-

2C0

unit

the

ri'ith the tl:ot

this

-

rvill alwa';s be

Adjustment

determines

can be adiusted

Invertig

200

is displa,ved

srvitch

the welding mode of

selects

lift arc mode aliorvs

you

high frequency. This is

high frequency arc

of this

components or

rvould be

Lift Arc mode

electrical

example

in hospitals. The

welding.

the Lift Arc Mode, simply

the torch trigger or

lift ofi

and

welding

your

amperage

the

spot

-

0.1 and 10 seconds

rvould

This

of repetitive

w'elding time, adjust

When

rvill

start.

rvith

the added benefit

with the foot

welding mode allow s

and then

good

be a

tack

thc T2

0.lsec and 10.0 sec.

lock

this mode'"vith

the torch.

your Invertig 200

trigger, it

inq to keep

:h-' :rrt:;err:

to

use

trigger on a drill or

on

the hand amperage control.

y'ou

When

rvill

rvill

continue

and release it at

thc trieger depres.;'ri. .1i1.-r'.i

crrt:::.'l

-'

-1T

tir:

nci:

''it:lt

tri:3:r or ioot

ili stafi

the

*

u

iil stop.

pctlli

mode is itsed

hot and the

Knob

the welding anlperage.

the digital drsplav

in

(#10)

in the local

is

arc.

Seli:ct

from 5

\\'he n the tn-:':ct t.

rvciiing

this

u'hen arc

gas

to 200 amps.

positron.

your

to initiate thc

importlnt in

rvill

cause

stainless steel

rvorks

the

touch

rungsten breaks

the

You can also use

ol

pedal.

you to

the unrt

selection tf vou

rvelds.

br:ttons up or

depress

stan

to

which timr- rhe

it a]iorrs',,-rr-i

t:: lr,;:

pe

,1rl

u'eldLng Thc

solenoid

Thc amperagc on

panel

"i

grinder

the

lveLdins

rveld r-rntil

l,t

i:.:.i.

,.

.::;,'-''

-

i11:

nr,

*'i11

nor

Thc

(+'1t.'r'hen

rrnr

i11

11'11

'..

I

th:

When

using a remote

adjuslment knob is

your particular

.050' 606 1

100 amps rvith the local/remote

alloy aluminum, I

This rs about 20% more

aluminum rvith.

position

remote

amperage

completely, the

Sening the machine

the

Iess

of 5 amps. If I were to

maximum

sensitive. Ivlore

smaller variance

heat and therefore

7) T2 buttons

The T2

buttons are multi-function

clepends

in.

Lift-Arc, 4T,

the

slope dorvn time. The

0. I sec to 10.0

times

example, it is

in the

rnode.

each

if

vou

foot pe<ial.

as

),'ou

re more

Spor

time tiom

Pr.il-sr mode

:node

Dlrrion

.\C nrrrde

rvhich

on

and 2T

can be

set

possible

2T mode,

\bur Invertig

rvelding

\\'elding

mode.

are

using a torch

it rs advisable

are conrolling

amperage control

ivlode - the T2

0.1

sec

on

rvilldisplalr

is on

io

adjust the pr"rlse

and tiom 0.-1 Hz to

amperage

used to

select the

welding

and the

maximum

application.

porver

placed

I then

digital display

amperage would

so the maximum

output of the machine

of a movement

the

of

amperage,

easier to

control

welding mode

\!'elding

slope dorvn time

sec in 0.1 sec increments.

for

each of the three lvelding

to have the

3 sec in the 4T

200 will remember

mounted remore

to set the

the

slope dorvn

or foot pedal.

to 10.0

sec in

d.:pressing

-

the Puise

the pulsine

ir:qLrenc,,-'lrom

control,

the amperage

maximum amperage

For

example, when welding

adjusted the

srvitch in the

than

the

depress the

making

amperage

will

I

be

local/remote

showed the

amperage

200

of

pedal

in the

it easier to

your

puddle.

buttons. The

the welding

Nlodes - the

T2 burtons

Different

slope dorvn

mode and

5 sec in the lift

the

ampcrage

slope down

manually

buttons

adjust the

0.1 scc incremenrs.

button r.r'hen the puise

lrequencv

0..1

Hz in th;-

-100

knob to

position.

local

welding

the

switch

minimum

foot pedal

now be 100

is 100

amps, the

results in

control

function

modc

selector is

is adjustable

slope do*,n

modes. For

time set to

slope

dorvn

control or a

time to

rvith

vour

rvclding

spot

in Hz.

Use

Hz to

2.0 Hz in th:

DC mcdc.

for

the

in

amps.

amps

pedal

a

conrrols

tiom

0.1 sec

arc

time

0.1 scc.

tht

8) 12 buttons

The 12 buttons control the

rvhen your

final

that is

the

if

final

This is

4T position,

The

vs

is

the

which time the

current that

Depressing the torch tngger

final current value.

amount

to the

finai current

released, the

9) Post

The

increments. Post

extinguished.

possibilitl

the an.rrosphcre . causing

the

The

lor

the

of

remove the

been completed. A

5.0 sec. Ilyou are

critical

to

a higher value

1C) Local/Rernote

\\'hgn

the amperage

Invertig 200

current is adjustable

set by the amperage

amperage adjustment

current is set to l5%, the

achieved

pre-gas

of time in

by the

depressing the torch

will

cycle

arc

is set by

which

final current. The

the trigger

until

post gas

Gas Flo*'

post gas

flo$ is

thL.

gas

the gas

if

moiten

runssien ttcm becoming

gas

tlow

should

fungsten to disappear.

torch

TIC

allovs it rna,v be nccr-ssarv

in the Loc,.ll posirion.

adj':stmeni knob

The amperate ait,.rslr-l:;nr

n:,-tr

Tl

i m uil

\\'hen

a'Jjustabie

rmperx-:c

machine

localiremote

adjustment knob

local/remote

panel

pedal,

foot

makes the

puddle.

,vour

tpiii rr | \'ii

ou

ihe

in

rernc:e oositron. thc

b_v- eith;r

contro..

to 100 amps, w'ith

srvitch to the

(*j1

switch to the

should read 5 amps.

the amperage displayed

pedal

foot

Final

is set in the

lrorn

adjustment

knob

follorving: with

continue

will

ignite.

the

amperage

again rvill

The

slope down time

the

machine w,ill

,"vi1l

cycle

adjustable

flow'is

stopped florving

*e1d

puddle

r,,,.eld

contaminated

run

long

lrom

the weld

good

starting

rvelding

at

switch

thc

k:lob c:rn

ur I n',.

thc

To lrr:ri tir.:

pcdai

fbot

the foot pedal

local

adjust the

remore

Now, when you

less sensitive

Current.

This

is only

4T u,elding

1% to99ok

of the

knob (#5).

is ser to

final

trigger

100

currenr will

the

welding

starts the

amps.

until the trigger

The unit will

adjustmenr

current goes

reduce

(T2)

from

weld

knob

the

determrnes

the

continue

is

released.

start.

from 2

necessary

sec to 20

because

would

Once the

immediarell,..

comc

delects. Additionalll

the

by

enough to

It

is important

allow the

to remember

until the post

point

for the

posr

higher amperages

ro

increase

lmDcrtji

1=5;on

ihi

ri

lli l,.e

iirtitr

the

lis,: D: us:il

t,

;r:r,: I

C.

lrnoerag:

or

tl',e

is iniLn:::.,

roich

n-lLr,"iiij.l

n:,rrimu,r.rrnper.r:-'.

plugged

position.

amperage to

position.

Using the

100 a1.rps.

The

fully

should

be 100 amps.

and makes

it easier

applicable

mode.

The

base

currenr

For

example.

and

the

be l5 amps.

mode

pre-gas

is

released,

at the

base

(#j;.

current

to the

base

current

to weld

at the

trigger

sec in

0.2

atier the

in contact

or on

rt:;r:-.,,i--rii::

t.-,..,r-..:

digital

depress the

arc

rhcre

ir prercnts

atmosphere.

orange

nor

c-v''cle

sas

gas

flow is

mor.

post

gas

r,:-,t,s:-..i

ii.,.

. ti-'

in,

i'iip the

amperage

Flip thc

drsplav

This

to conrroi

in

flolv.

at

the

is

sec

is

is

r.vith

color

has

flo,,i

i:_.

the

a

to

Loading...

Loading...