Page 1

SuperStor Contender

The solar energy system described in this manual, when properly installed and maintained, meets the minimum standards

established by the SRCC. This certification does not imply endorsement or warranty of this product by the SRCC.

NOTE TO CONSUMER: PLEASE KEEP ALL INSTRUCTIONS FOR FUTURE REFERENCE.

Solar Supplement

INSTALLATION

OPERATION

MAINTENANCE

TROUBLESHOOTING

SB Series* Models SE Series** Models

SSC-50SB / SSC-80SB SSC-50SE / SSC-80SE

SSC-119SB SSC-119SE

*With back-up heat exchanger **With back-up electric element

NOTICE: HTP reserves the right to make product changes or updates without notice and will not be held liable for typographical errors

in literature.

The surfaces of these products contacted by consumable water contain less than 0.25% lead by weight, as required by the Safe

Drinking Water Act, Section 1417.

120 Braley Rd. P.O. Box 429 East Freetown, MA 02717-0429 www.htproducts.com

LP-200 REV. 3.25.14

Page 2

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk

levels, or to important product information.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result in property

damage.

This manual must only be used by a qualified heating installer/service technician. Read and understand all instructions and safety

messages in this manual before installing, operating, or servicing this water heater. Perform steps in the order given. Failure to comply

could result in substantial property damage, severe personal injury, or death.

FOREWORD

This manual is intended to be used in conjunction with other literature provided with this Solar Water Heater. This includes all related

control information. It is important that this manual, all other documents included with this system, and additional publications including

Solar Water Heating System Design and Installation Guidelines, SRCC OG-300, be reviewed in their entirety before beginning any

work.

“The solar energy system described in this manual, when properly installed and maintained, meets the minimum standards established

by the SRCC. This certification does not imply endorsement or warranty of this product by the SRCC.”

The design of the SuperStor Contender solar system is approved by the Solar Rating and Certification Corporation (SRCC). Any

deviation from the approved specified SRCC components may affect your ability to certify this system.

Installation should be made in accordance with the regulations of the Authority Having Jurisdiction, local code authorities, and utility

companies which pertain to this type of water heating equipment.

Authority Having Jurisdiction (AHJ) – The Authority Having Jurisdiction may be a federal, state, local government, or individual such

as a fire chief, fire marshal, chief of a fire prevention bureau, labor department or health department, building official or electrical

inspector, or others having statutory authority. In some circumstances, the property owner of his/her agent assumes the role, and at

government installations, the commanding officer or departmental official may be the AHJ.

NOTE: HTP, Inc. reserves the right to modify product technical specifications and components without prior notice.

2

FOR THE INSTALLER

INSTALLATION OR SERVICE OF THIS SOLAR WATER TANK IS REQUIRED TO BE PERFORMED BY LICENSED

PROFESSIONALS WHERE SOLAR, PLUMBING AND ELECTRICAL WORK IS REQUIRED.

The installer should be guided by the instructions furnished with the tank, local codes and utility company requirements. Preference

should be given to codes and requirements where they differ from the furnished instructions. Always use the latest edition of codes.

INSTALLATIONS MUST COMPLY WITH:

Local, state, provincial, and national codes, laws, regulations and ordinances.

LP-200 REV. 3.25.14

Page 3

Solar Water Heating System Design and Installation Guidelines, SRCC OG-300, available from Solar Rating & Certification

Corporation, 400 High Point Drive, Suite 400, Cocoa, FL 32926-6630, www.solar-rating.org.

Code for the Installation of Heat Producing Appliances (latest version), from American Insurance Association, 85 John Street, New

York, NY 11038.

The latest version of the National Electrical Code, NFPA No. 70.

In Canada, refer to Canadian Electrical Code C 22.1, from Canadian Standards Association, 5060 Spectrum Way, Suite 100,

Mississauga, Ontario, Canada L4W 5N6.

TABLE OF CONTENTS

INTRODUCTION .......................................................................................................................................................................... 5

PART 1 - GENERAL SAFETY INFORMATION ........................................................................................................................... 5

A. PRECAUTIONS .......................................................................................................................................................................... 5

B. LOCAL INSTALLATION REGULATION ...................................................................................................................................... 6

C. CHEMICAL VAPOR CORROSION ............................................................................................................................................. 6

D. INSULATION BLANKETS ........................................................................................................................................................... 7

E. DOMESTIC HOT WATER TEMPERATURE ADJUSTMENT ...................................................................................................... 7

F. FREEZE PROTECTION .............................................................................................................................................................. 7

PART 2 – IMPORTANT INSTALLATION INFORMATION .......................................................................................................... 7

3

A. SCOPE OF MANUAL .................................................................................................................................................................. 7

B. LOCAL STANDARDS AND AUTHORIZED PERSONS .............................................................................................................. 7

C. TERMINOLOGY ......................................................................................................................................................................... 7

D. SYSTEM DESIGN ...................................................................................................................................................................... 8

E. FLUID QUALITY ......................................................................................................................................................................... 8

F. CORROSION ................................................................................................................................................................ .............. 8

G. FREEZE PROTECTION ............................................................................................................................................................. 8

PART 3 - GENERAL SOLAR INFORMATION ............................................................................................................................ 8

A. SYSTEM DESCRIPTION ................................................................................................ ................................ ............................ 8

B. SOLAR SYSTEM DESIGN ......................................................................................................................................................... 9

C. SOLAR COLLECTOR INSTALLATION ...................................................................................................................................... 9

D. COLLECTOR ANGLE, PLANE, AND DIRECTION ................................................................................................................... 10

1. COLLECTOR DIRECTION ........................................................................................................................................................... 10

2. COLLECTOR ANGLE (TILT) ........................................................................................................................................................ 10

3. COLLECTOR PLANE (HORIZONTAL OR VERTICAL) ................................................................................................................ 10

E. COLLECTOR PIPING ............................................................................................................................................................... 10

F. COLLECTOR LOOP PIPE INSULATION .................................................................................................................................. 11

G. COLLECTOR SENSOR PLACEMENT ..................................................................................................................................... 11

H. AVOID SHADE ......................................................................................................................................................................... 11

I. LOCATION ................................................................................................................................................................................. 11

J. LIGHTNING PROTECTION ....................................................................................................................................................... 11

K. GALVANIC REACTION ............................................................................................................................................................ 11

LP-200 REV. 3.25.14

Page 4

L. WIND STRESS.......................................................................................................................................................................... 11

M. SNOW LOAD ........................................................................................................................................................................... 12

N. HAIL RESISTANCE .................................................................................................................................................................. 12

O. STORAGE TANKS ................................................................................................................................................................... 12

P. THERMAL EXPANSION (CLOSED LOOP SYSTEMS) ............................................................................................................ 12

PART 4 – SPECIFICATIONS ..................................................................................................................................................... 13

PART 5 - INSTALLATION ......................................................................................................................................................... 15

A. INSTALLATION CHECKLIST ................................................................................................................................................... 15

B. SOLAR WATER HEATER LOCATION ..................................................................................................................................... 16

PART 6 – PIPING ...................................................................................................................................................................... 16

A. POTABLE WATER PIPING ...................................................................................................................................................... 16

B. WATER CHEMISTRY REQUIREMENTS ................................................................................................................................. 17

C. POTABLE WATER PIPING DETAIL ......................................................................................................................................... 18

D. SOLAR HEAT EXCHANGER PIPING ...................................................................................................................................... 19

E. TANK SENSOR PLACEMENT ................................................................................................................................................. 19

F. NECESSARY COMPONENTS FOR SOLAR WATER HEATER INSTALLATION .................................................................... 19

G. SOLAR WATER HEATER WITH BOILER BACK-UP ............................................................................................................... 22

H. SOLAR WATER HEATER WITH ELECTRIC BACK-UP ........................................................................................................... 23

I. BOILER BACK-UP HEAT EXCHANGER CONNECTION (SB MODELS ONLY) ....................................................................... 24

J. BOILER TANK CONTROL ........................................................................................................................................................ 24

K. CIRCULATOR SIZING .............................................................................................................................................................. 24

L. BOILER BACK-UP HEAT EXCHANGER (SB MODELS ONLY) ............................................................................................... 24

M. ELECTRICAL CONNECTION (SE MODELS ONLY) ............................................................................................................... 25

N. THERMOSTAT ADJUSTMENT ................................ ................................ ................................................................................ 26

O. COMBINATION “THERMOSTAT AND HIGH LIMIT CONTROL (ECO)” .................................................................................. 26

PART 7 - FLUID QUALITY ........................................................................................................................................................ 26

4

A. SOLAR LOOP FLUID QUALITY ............................................................................................................................................... 26

B. FLUID SAFETY LABELING ...................................................................................................................................................... 26

C. FREEZE PROTECTION ........................................................................................................................................................... 26

PART 8 – START-UP PREPARATION...................................................................................................................................... 27

A. CHARGING THE SYSTEM ....................................................................................................................................................... 27

B. COMMISSIONING THE SYSTEM ............................................................................................................................................ 27

PART 9 – SERVICE/MAINTENANCE PROCEDURES ............................................................................................................. 28

A. SHUTDOWN PROCEDURES ................................................................................................................................................... 28

B. VACATION SHUTDOWN .......................................................................................................................................................... 28

C. ESTIMATED LIFE OF COMPONENTS .................................................................................................................................... 28

D. TEMPERATURE AND PRESSURE RELIEF VALVE................................................................................................................ 28

PART 10 - TROUBLESHOOTING ............................................................................................................................................. 29

A. LEAKS ...................................................................................................................................................................................... 29

B. OTHER PROBLEMS ................................................................................................................................................................. 29

C. OPERATING SUGGESTIONS FOR THE USER ...................................................................................................................... 29

LP-200 REV. 3.25.14

Page 5

NOTE: Failure to follow the procedures described in this manual WILL VOID the warranty.

INSTALLER – Read all instructions in this manual before installing. Perform steps in the order given.

USER – This manual is for use only by a qualified heating installer/service technician. Have this solar water heating system

serviced/inspected by a qualified service technician annually.

FAILURE TO ADHERE TO THE GUIDELINES ON THIS PAGE AND HAVE THIS SOLAR WATER HEATING SYSTEM

SERVICED/INSPECTED ANNUALLY CAN RESULT IN SUBSTANTIAL PROPERTY DAMAGE, SEVERE PERSONAL INJURY, OR

DEATH.

NOTE: If any component of the solar water heating system is exposed to the following, do not operate until all corrective steps have

been made by a qualified serviceman:

1. FIRE

2. DAMAGE

3. WATER

Any claims for damage or shortage in shipment must be filed immediately against the transportation company by the consignee.

Be sure to disconnect electrical power from the solar water heating system before performing service. Failure to do so could result in an

electrical shock, property damage, serious personal injury, or death.

PART 11 - SYSTEM PARTS LISTING....................................................................................................................................... 30

A. ESTIMATED COMPONENT LIFE ............................................................................................................................................. 30

B. WARRANTIES AND DISCLAIMERS ........................................................................................................................................ 30

MAINTENANCE NOTES .................................................................................................................................................................. 38

HTP CUSTOMER INSTALLATION RECORD FORM ...................................................................................................................... 39

INTRODUCTION

Your solar water heater has an internal solar heat exchanger for use with solar collectors. When there is not sufficient solar energy, the

water heater utilizes a backup system to provide hot water. In SB Series water heater models, the tank has an extra heat exchanger

that connects to a boiler. In SE Series models, the water heater has an electric heating element. (Refer to solar piping details in this

manual for suggested piping applications of both models.)

Your solar system uses a circulation pump to circulate a propylene glycol/water heat transfer fluid solution (HTF) throughout a closed

loop system. Closed loop propylene glycol systems provide freeze protection for the solar components.

This manual intends to familiarize you with the proper installation and maintenance of your solar water heating system. This system

must be installed by a licensed solar or plumbing contractor in accordance with SRCC Standard OG-300 and all applicable national,

state, and local codes.

Job site conditions will require your installation contractor to supply some or all of the following:

Plumbing Connections

Piping and Insulation

Valves Between the Existing Domestic Water System and the Solar System

NOTE: Solar system performance and efficiency varies with factors such as: household hot water load, ambient air temperature,

collector/roof pitch, collector orientation, and seasonal intensity.

5

PART 1 - GENERAL SAFETY INFORMATION

A. PRECAUTIONS

NOTE: When inquiring about service or troubleshooting, reference the model and serial numbers from the solar water heater rating

label.

NOTE: OBTAIN ALL APPLICABLE PERMITS AND OBEY ALL LOCAL CODES.

LP-200 REV. 3.25.14

Page 6

DO NOT USE THIS SOLAR WATER HEATING SYSTEM IF ANY PART HAS BEEN SUBMERGED IN WATER. Immediately call a

qualified service technician. Components MUST BE replaced if submerged. Attempting to operate a solar water heating system that

has been even partially submerged could create numerous harmful conditions, such as a potential gas leakage causing a fire and/or

explosion, or the release of mold, bacteria, or other harmful particulates into the air. Operating a previously submerged solar water

heating system could result in property damage, severe personal injury, or death.

NOTE: Damage due to flood or submersion is considered an Act of God, and IS NOT covered under product warranty.

NOTE: Install all system components and piping in such a manner that does not reduce the performance of any fire rated assembly.

Improper installation or use may result in property damage. Such damage IS NOT covered by warranty.

NOTE: HTP DOES NOT WARRANT THIS WATER HEATER AGAINST FREEZE RELATED DAMAGE.

Only use this solar hot water system as intended and described in this installation manual. Any use other than described will void

warranty and may lead to fire, property damage, personal injury, or death.

High heat sources (sources generating heat 100oF / 37oC or greater, such as stove pipes, space heaters, etc.) may damage plastic

components of the water heater as well as plastic vent pipe materials. Such damages ARE NOT covered by warranty. It is

recommended to keep a minimum clearance of 8” from high heat sources. Observe heat source manufacturer instructions, as well as

local, state, provincial, and national codes, laws, regulations and ordinances when installing this water heater and related components

near high heat sources.

NOTE: DAMAGE TO THE SOLAR WATER TANK, COLLECTOR, OR RELATED COMPONENTS CAUSED BY EXPOSURE TO

CORROSIVE VAPORS IS NOT COVERED BY WARRANTY. The limited warranty is voided when failure of water tank is due to a

corrosive atmosphere. (Refer to the limited warranty for complete terms and conditions).

PRODUCTS TO AVOID

AREAS LIKELY TO HAVE CONTAMINANTS

Spray cans containing fluorocarbons

Dry cleaning/laundry areas and establishments

Permanent wave solutions

Swimming pools

Chlorinated waxes/cleaners

Metal fabrication plants

Chlorine-based swimming pool chemicals

Beauty shops

Calcium chloride used for thawing

Refrigeration repair shops

Sodium chloride used for water softening

Photo processing plants

Refrigerant leaks

Auto body shops

Paint or varnish removers

Plastic manufacturing plants

Hydrochloric or Muriatic acid

Furniture refinishing areas and establishments

Cements and glues

New building construction

Antistatic fabric softeners used in clothes dryers

Remodeling areas

Chlorine-type bleaches, laundry detergents, and cleaning solvents

Garages and workshops

Adhesives used to fasten building products

ALL PIPING AND PLUMBING CONNECTIONS IN CLOSED LOOP SYSTEMS SHOULD BE MADE WITH COPPER PIPE ONLY. No

less than ¾” I.D. copper tube of the type meeting local codes must be used for piping. Pipe runs must be solidly attached with proper

clamping methods. Soldered connections should be secured with 95/5 lead-free solder. Use only pipe rated for 250oF minimum on both

the collector return and supply piping.

6

B. LOCAL INSTALLATION REGULATION

Installation of this solar water heater may be governed by individual local rules and regulations for this type of product, which must be

observed. Always use the latest edition of codes. The installation, adjustment, service, and maintenance of the solar water heater must

be done by a licensed professional who is qualified and experienced in the installation, service, and maintenance of solar hot water

systems.

C. CHEMICAL VAPOR CORROSION

Table 1 – Chemical Contaminants

LP-200 REV. 3.25.14

Page 7

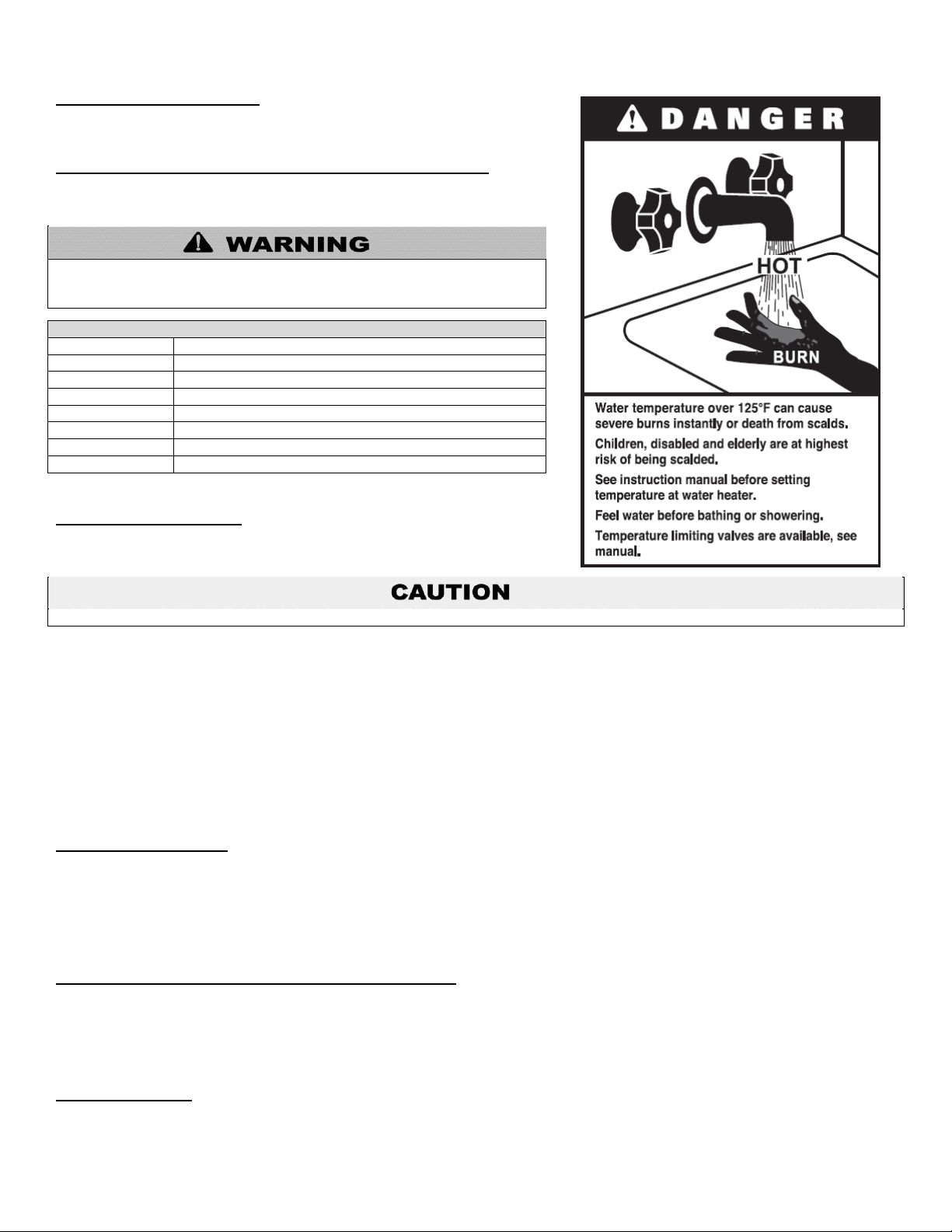

Households with small children, disabled, or elderly persons may require a

120oF or lower temperature setting to prevent severe personal injury or death

due to scalding.

Failure of the solar system due to freeze related damage IS NOT covered by warranty.

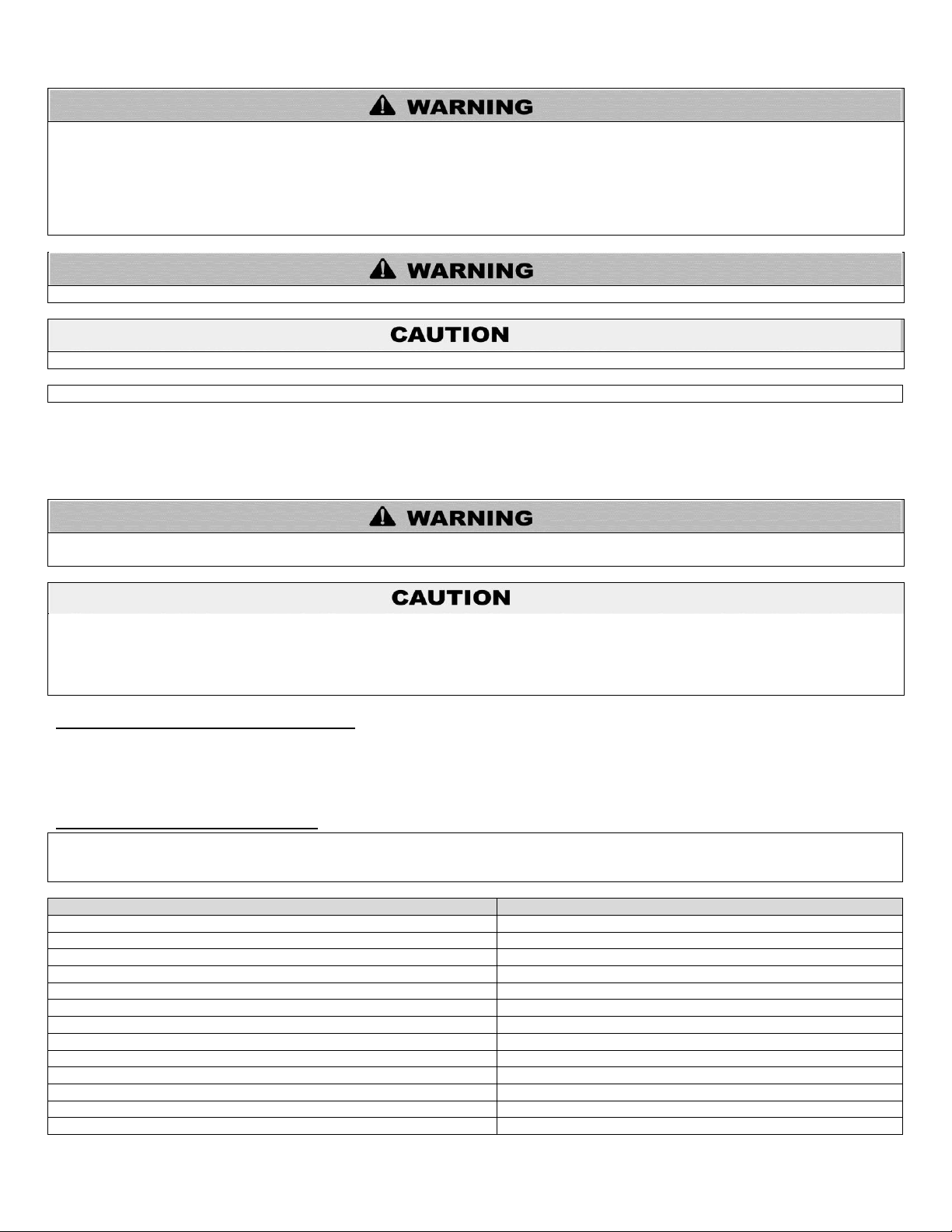

APPROXIMATE TIME / TEMPERATURE RELATIONSHIPS IN SCALDS

120oF

More than 5 minutes

125oF

1 ½ to 2 minutes

130oF

About 30 seconds

135oF

About 10 seconds

140oF

Less than 5 seconds

145oF

Less than 3 seconds

150oF

About 1 ½ seconds

155oF

About 1 second

Table 2

D. INSULATION BLANKETS

For installation of insulation blankets, refer to Solar Water Heating System Design

and Installation Guidelines, SRCC OG-300.

E. DOMESTIC HOT WATER TEMPERATURE ADJUSTMENT

An ASSE 1017 rated mixing valve to avoid severe burns or death from scalding

temperature IS REQUIRED PER SRCC OG-300.

7

F. FREEZE PROTECTION

NOTE: Consider piping and installation when determining heater location. Place

heater in location not prone to freezing.

In order to meet health and safety regulations, solar system antifreeze fluid should be food grade polypropylene glycol, FDA rated as

“generally recognized as safe” (GRAS). The recommended glycol is DOWFROST or equivalent. Using proper concentrations of glycol,

solar systems can be operated at ambient temperatures as low as -60oF. Freeze tolerance limits are based upon an assumed set of

environmental conditions. Refer to the specification sheet included with the glycol for recommended concentrations. A glycol/water mix

must not exceed 50%, unless the manufacture specifies that a different ratio is recommended for use with solar water heaters. Glycol

may need to be changed periodically (every 3-5 years) to prevent it from becoming acidic; please refer to the guidelines provided by the

glycol manufacturer regarding replacement.

PART 2 – IMPORTANT INSTALLATION INFORMATION

A. SCOPE OF MANUAL

This manual pertains only to the installation and operation of the HTP SuperStor Ultra solar water heater. Details for the installation,

operation, and maintenance of the complete solar water heating system, including, but not limited to: the solar collector(s), boiler, pump,

system controller, valves, and other plumbing components, should be provided separately by their respective manufacturers.

NOTE: This manual is primarily a reference document for authorized persons, as the solar water heater is not permitted to be installed

by non-authorized persons.

B. LOCAL STANDARDS AND AUTHORIZED PERSONS

Installation must be completed in accordance with local standards and regulations.

Installation must also be completed by a qualified tradesperson who holds relevant industry licenses or certificates. The term

“authorized person(s)” refers to a suitably qualified professional. Unless otherwise specified, no part of the HTP solar water heater may

be inspected, repaired, or maintained by anybody other than an authorized person.

C. TERMINOLOGY

Solar terminology differs from region to region. To avoid confusion, please note the following:

Supply – The plumbing line running from the outlet of the collector to the tank (or heat exchanger).

LP-200 REV. 3.25.14

Page 8

Return – The plumbing line running from the tank (or heat exchanger) to the inlet of the collector. This line incorporates the circulation

pump.

D. SYSTEM DESIGN

PRESSURIZED CLOSED LOOP SYSTEMS

A closed loop system uses non-potable HTF and must be pressurized to less than 72.5 psi. Closed loop systems require an expansion

tank to accommodate HTF expansion. The system should be designed to minimize stagnation after the tank temperature has been met;

extensive stagnation may increase pH levels and glycol deterioration.

The expansion tank and plumbing must be properly sized so that the safety pressure relief valve will not activate except in the event of

component failure or extreme conditions. The pressure release must be set at no more than 90 psi. (There may be exceptions in

engineered designs for tall buildings.)

E. FLUID QUALITY

Water quality is very important. Water in direct flow through the solar collectors must first meet potable water requirements; any fluid

circulated through the collectors should be non-corrosive to copper. In addition, water quality must meet the following requirements.

Hardness: Less than 7 grains

Chloride levels: Less than 100 ppm

pH levels: 6-8

TDS: Less than 2000 ppm

Sodium: Less than 20 mGL

In order to meet health and safety regulations, glycol used should be food grade propylene glycol, FDA rated as “generally recognized

as safe” (GRAS). If using a glycol/water mix, distilled water is preferred. If distilled water is unavailable, the water must meet the above

requirements. The glycol content of the liquid must not exceed 50%, unless the manufacturer specifies that a different ratio is

recommended for use with solar water heaters. Glycol should be checked periodically to prevent it from becoming acidic. Please refer

to guidelines provided by the glycol manufacturer regarding glycol maintenance.

8

F. CORROSION

Both copper and stainless steel are susceptible to corrosion when, amongst other factors, high concentrations of chlorine are present.

NOTE: Leakage of the solar water heater due to corrosion caused by improper water quality IS NOT covered by product warranty.

G. FREEZE PROTECTION

Freeze protection must be implemented in any regions that may experience freezing conditions at any time throughout the year.

“Freeze tolerance limits are based upon an assumed set of environmental conditions. Extended periods of cold weather, including

ambient air temperatures below the specified limit, may cause freezing in exposed parts of the system. It is the owner’s responsibility to

keep the system’s freeze protection levels maintained in accordance with the supplier’s instructions if the air temperature is expected to

approach the specified freeze tolerance limit.”

Closed loop systems: In areas with temperatures not falling below 23oF, a differential solar controller with freeze protection may be

used (e.g. requiring pump to circulate if the manifold temperature approaches freezing). In an open loop system, a freeze valve (which

opens to allow water to dribble out) could also be considered.

Closed loop systems: In areas with temperatures falling below 23oF, a propylene glycol/water mix should be used to provide freeze

protection. Please refer to glycol manufacturer’s specifications about the temperature ranges the liquid can withstand. Only food grade

propylene glycol, FDA rated as GRAS, should be used.

NOTE: HTP DOES NOT WARRANT THE SOLAR WATER HEATER AGAINST FREEZE-RELATED DAMAGE.

PART 3 - GENERAL SOLAR INFORMATION

A. SYSTEM DESCRIPTION

By using the sun’s energy to heat water, solar hot water heating systems help reduce the nation’s dependence on polluting fossil fuels.

This reliable, efficient solar water heater meets the certification requirements of SRCC-OG-300.

Basic components of the solar water heating system include: the solar collector(s), a solar water heater, a circulator pump, a differential

solar control, and an expansion tank. The types of solar systems in which the solar water heater can be installed include:

LP-200 REV. 3.25.14

Page 9

Do not introduce HTF into any fittings on the heater except those clearly marked for that purpose.

All persons working on roofs should have completed a fall safety course and must be properly outfitted with appropriate safety

equipment. Failure to follow this information could result in property damage, severe personal injury, or death.

Solar collectors should be covered at all times until installation is complete. Failure to follow this information could result in severe

personal injury or death.

Pressurized Closed Loop Systems – These systems use a glycol/water mix as HTF, which protects the system from freezing. These

systems operate at high pressures.

In systems using a glycol/water mix, freeze protection fluid must be non-toxic propylene glycol, FDA rated as GRAS. To protect the heat

exchanger and other system components, regular scheduled maintenance must be established to monitor and maintain proper HTF pH

levels.

The system components should carry temperature and pressure ratings equivalent to the design of the solar collector. To ensure

system is appropriate for the installation climate, the solar collector ratings should be verified against the collector manufacturer

specifications. Collector and storage tank temperatures can be read from the system controllers. Typical tank operating temperatures

range from 40-80oF on the cold supply line to the 175oF tank high limit. The collector temperature sensor should be 5-20oF higher than

the tank sensor during normal charging operation. During idle period, when there is no sun, the collector sensor will read the ambient

temperature; in full sun, the sensor will read as high as 250oF. Temperatures vary depending on installation climate.

Using proper concentrations of glycol, solar systems can be operated at ambient temperatures as low as -60oF. Freeze tolerance limits

are based upon an assumed set of environmental conditions. Refer to the manufacturer’s specification sheet for recommended

concentrations.

Depending on the controller model, the differential controller uses 10k ohm thermistors or 1k ohm RTDs to monitor the temperature

difference between the collector and the solar water heater. The controller turns on when the collector is 12-20oF above tank

temperature and turns off when the differential drops to 4oF.

9

B. SOLAR SYSTEM DESIGN

System design should be completed prior to installation. Solar collectors need to be installed correctly to ensure high efficiency and,

most importantly, safe and reliable operation. Please seek professional advice for the design and installation of your solar heating

system.

NOTE: Only authorized licensed contractors are permitted to install the solar collector.

C. SOLAR COLLECTOR INSTALLATION

NOTE: The solar collector instructions are general in nature. Reference the solar collector manufacturer’s instructions for more specific

and detailed installation information.

The solar collector installation contractor shall obtain all required permits and approvals when installing the solar system. The

installation shall conform to all federal, state and local regulations governing solar water heating system installations. The contractor

shall adhere to sound building safety and trade practices. Special consideration must be given to building code requirements for the

penetration of structural members and fire rated assemblies.

Before installation, the contractor shall inspect the condition of the roof and notify the homeowner of any existing roof damage or

necessary repairs. The most important structural consideration is to securely anchor the solar collector and solar strut mounting

hardware to the structural members of the roof with stainless steel hanger or lag bolts. Consult with the collector manufacturer

installation manual for proper guidelines in your application.

Preserving the integrity of the roof membrane is the most important roofing consideration. Ensure that all roof penetrations required to

plumb and mount the solar collector are properly flashed and sealed in accordance with standard roofing practices. The recommended

elastomer for sealing roof penetrations is Tremco “POLYroof”.

LP-200 REV. 3.25.14

Page 10

10

Never use dielectric unions or galvanized steel fittings in the collector loop. Doing so will lead to corrosion, property damage, and

possible early water heater failure. Such damage IS NOT covered by warranty. Use only copper and brass fittings.

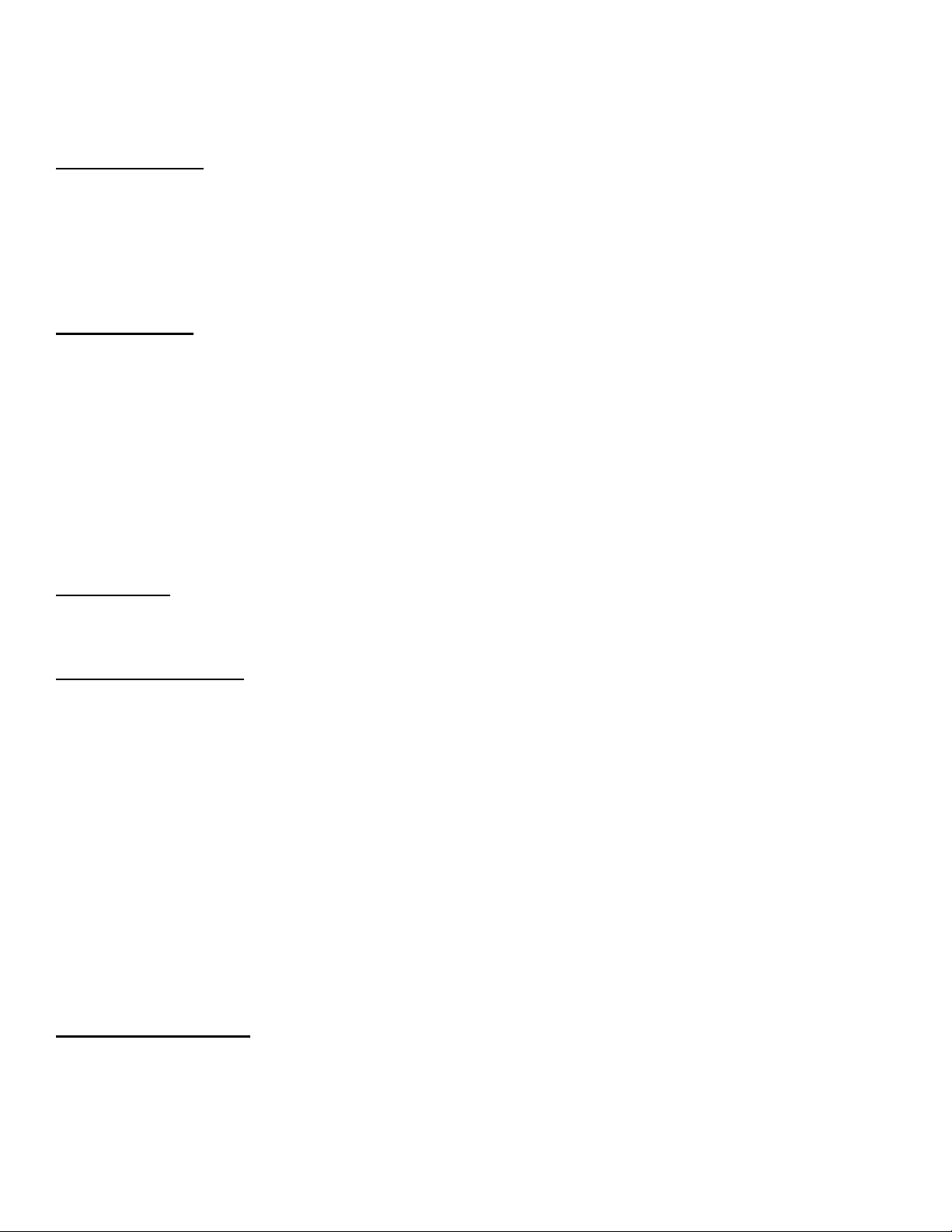

Figure 1 - Suggested placement of solar collectors

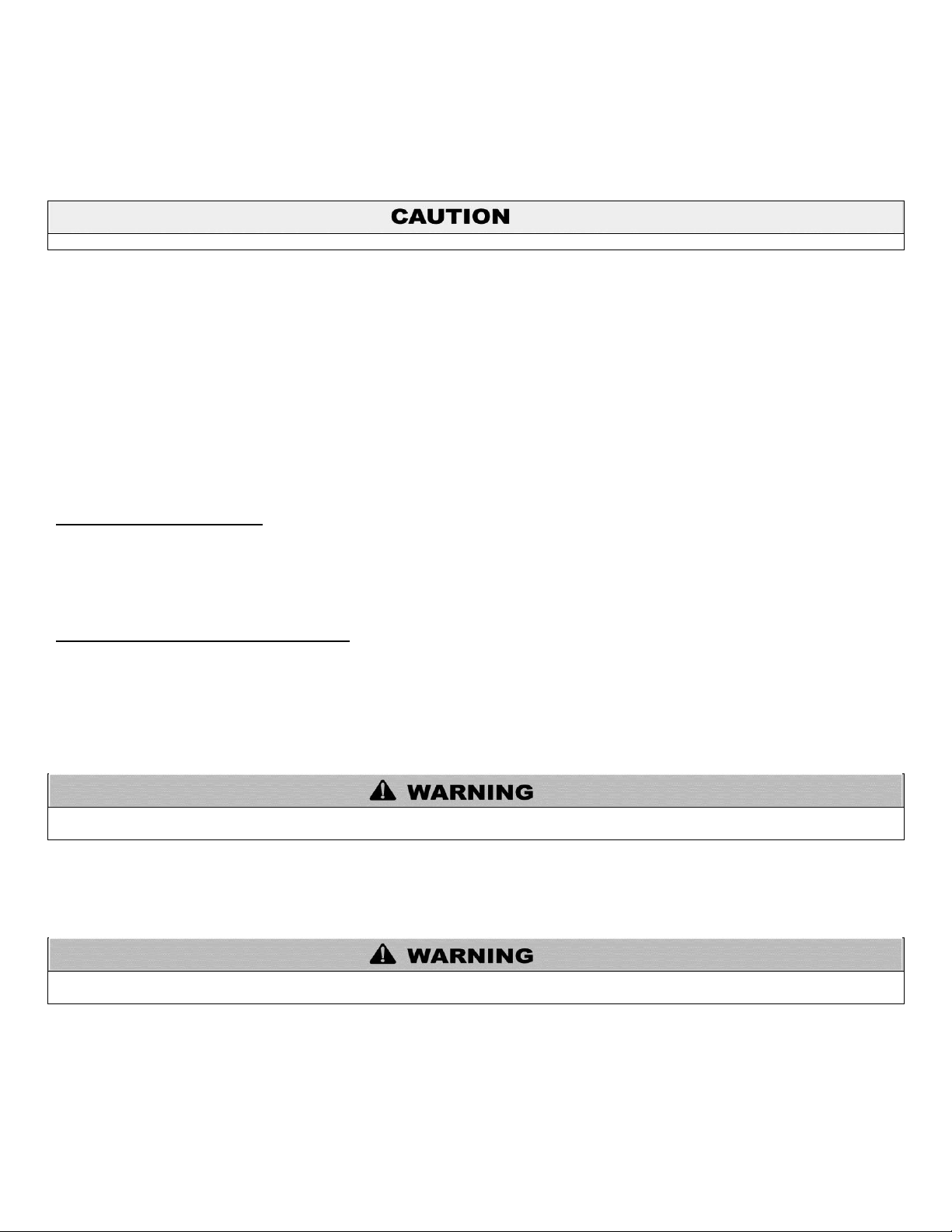

Figure 2 – Sensor Placement

D. COLLECTOR ANGLE, PLANE, AND DIRECTION

1. COLLECTOR DIRECTION

The collector should face the equator. In the northern hemisphere, this is due south, and in the southern hemisphere, due north. Facing

the collector in the correct direction and angle is important to ensure

optimal heat output. A deviation of up to 15o from due south is

acceptable, and will have minimal effect on heat output.

2. COLLECTOR ANGLE (TILT)

It is common for collectors to be installed at an angle that corresponds

to the installation latitude. While adhering to this guideline, an angle of

latitude +/- 10o is acceptable, and will not greatly reduce solar output.

The solar collector should be installed at an angle of between 20 – 80o

to ensure optimal operation.

For year-round domestic hot water, the collector should be tilted to an

angle of equal to the latitude of the installation site. Add 15o to the

latitude to optimize for winter performance (space heating). Subtract

15o from the latitude to optimize for summer performance (pool

heating).

Given the formula above, a solar collector installed at 30oN latitude

should face due south at an angle of 45o for wintertime advantage, and

15o for summertime heating.

Preventing Overheating

To reduce summer heat output, angle the collector for optimal winter

absorption. This is achieved by installing the collector at an angle of around 15o above the latitude angle (e.g. 45o at 30oN latitude). This

angle corresponds closely to the angle of the sun in the sky during the winter months, thus maximizing winter output. Conversely,

during the summer when the sun is high in the sky, the relative collector surface area exposed to sunlight is reduced, cutting overall

heat production considerably (by about 15%). This option is ideal for installations where solar thermal is being used for space heating.

3. COLLECTOR PLANE (HORIZONTAL OR VERTICAL)

The collector could be installed vertically, but may be installed at an angle, such as sideways on a pitched roof. In vertical installations,

collectors may be installed level, or with ¼” pitch towards the return port. See more detail in Part 2, Section D, Number 3.

E. COLLECTOR PIPING

Collector piping requires the use of copper and brass fittings in the collector loop. To

avoid leaks and fluid loss, copper and brass ground joint unions should be used to join

the collectors. Use only lead-free solder. Engelhard Silvabrite 100 or equivalent is the

required soldering material. Use of 50/50 lead solder is expressly prohibited. Use of

galvanized steel, CPVC, PVC or any other non-rated plastic pipe is prohibited.

Penetrations through walls or other surfaces shall not allow intrusion by insects and/or

other vermin. Ensure that all structural penetrations are properly sealed with an

elastomer, such as Tremco “POLYroof”.

Piping in new solar installations may have dirt, grease, solder flux, or other impurities

that will affect the quality of HTF over time. Thorough cleaning is required before

charging new solar installations with glycol.

Ensure that there are no dips or low points in solar piping that could trap fluid and possibly rupture in freezing conditions. Copper

plumbers tape or tube strap is the required strapping material. The pipe insulation may not be compressed or crimped by the strapping

material.

The installation of all piping may not reduce the performance or rating of structural members or fire rated assemblies and must adhere

to all applicable local codes and ordinances.

LP-200 REV. 3.25.14

Page 11

11

Zinc galvanized components should NOT be installed in direct contact with stainless steel or aluminum, as galvanic reaction between

metals can cause premature oxidation of the zinc coating, as well as the steel and aluminum underneath.

F. COLLECTOR LOOP PIPE INSULATION

The collector loop supply and return lines must be well insulated with high quality, flexible, closed cell insulation to minimize heat loss.

Wall thickness of pipe insulation should not be less than ¾". 1" wall thickness is required in all areas prone to annual hard freeze

conditions. When it comes to pipe insulation the rule is simple: thicker is better. The specified insulation material is HT/Armaflex or

equivalent.

Whenever possible, slide the insulation material over the pipe without cutting or taping. All butt joints must be sealed with contact

adhesive. HT/Armaflex should be sealed with Armaflex HT 625 adhesive. Use of rigid polyethylene pipe insulation is prohibited.

Temperatures generated by your collector in the summer months or under stagnation conditions can melt this type of material.

Any above ground exterior pipe insulation is subject to UV degradation and must be wrapped with PVC pipe wrap or painted with two

coats of high quality water-based acrylic resin coating as supplied by the insulation manufacturer. Foil tape should not be used as it will

fail. The required coating material is Armaflex WB Finish or equivalent. Prior to applying finish, wipe insulation clean with denatured

alcohol. Paint insulation with two coats of finish. Do not tint the finish.

G. COLLECTOR SENSOR PLACEMENT

The collector sensor must be located on the hot water return line as close to the collector as possible. Some collectors have insertion

wells to measure temperatures more accurately at the manifold.

Sensors are typically accurate to +/– 1/2 °F if properly installed and weatherized. To maximize sensor accuracy, attach the flanged

portion of the sensor to the collector header pipe with a stainless steel hose clamp. Wire nuts used to connect the sensor and low

voltage wiring shall be all plastic, sealed with silicone and thoroughly wrapped in electrician's tape.

The low voltage wiring used to connect the sensors to the controller should be a minimum 18 AWG. The wiring should be bare or tinned

copper, two conductor, PVC insulated, with a PVC UV rated gray jacket suitable for exterior use. Use Eastman Wire & Cable no. 5704,

Beldon Wire and Cable no. 8461 or equivalent.

The sensor must be placed on the solar collector return line as close to the collector header as possible. Place the sensor wire over the

rubber pipe insulation, under the insulation tape or PVC pipe wrap. Thoroughly wrap and weatherize the insulation with electrician's

tape or insulation tape as provided by the manufacturer.

H. AVOID SHADE

Collectors should be located so that shading does not occur between 9 AM and 3 PM local time. Partial shading due to small objects

such as antennas and flues is not of great concern.

I. LOCATION

To avoid long pipe runs, the collector should be positioned as close as possible to the storage tank. Storage tank location should

therefore be considered part of the location requirements of the solar collector. The storage tank should be located as close as possible

to the most frequent draw off points in the building.

J. LIGHTNING PROTECTION

To avoid lightning related damage or electrical safety issues, it is advisable to earth/ground the frame and copper circulation loop of the

collector.

K. GALVANIC REACTION

Avoid using galvanized steel bolts. Use stainless steel components instead. If galvanized components ARE used, avoid direct contact

between two metals by using rubber/plastic separators.

If roof surface is galvanized steel, refer to manufacturer’s corrugated roof installation guidelines.

L. WIND STRESS

When installing the solar collector(s), please consider the issue of wind resistance and the resultant stress on attachment points.

Adhere to relevant building codes/regulations regarding installation of such objects.

It is the responsibility of the installation contractor to ensure that the frame mounting is of suitable strength. Where applicable,

inspection by building department officer or equivalent should be completed to ensure the installation is in accordance with relevant

regulations.

LP-200 REV. 3.25.14

Page 12

12

To dissipate hydrogen safely, it is recommended that a hot water tap be turned on for several minutes at a sink, basin, or bath, but not a

dishwasher, clothes washer, or other electrical or heat producing appliance. During this process, there must be no smoking, open

flame, or electrical appliance operating nearby. Hydrogen discharged through the tap will sound like air escaping. Failure to dissipate

hydrogen properly could result in explosion and fire, serious property damage, severe personal injury, or death.

M. SNOW LOAD

In areas prone to heavy snowfall, the solar collector(s) should ideally be installed at an angle of 50o or greater to help promote snow

sliding off the collectors. In addition, it is advisable to raise the lower collector frame off the roof surface 6 – 8 inches or higher. Doing

this places the collector above moderate snowfall accumulation and allows drifting snow to more easily slide out from under the

collector, which helps ensure that snow does not cover the collector array.

Please refer to local regulations regarding snow loading precautions.

N. HAIL RESISTANCE

Solar collectors are surprisingly strong and able to handle significant impact stresses once installed. Testing and impact stress

modeling proves that when installed at an angle of 40o or greater, collectors are able to withstand impact from hail larger than 1” in

diameter. The ability of collectors to withstand hail impact is greatly influenced by the angle of impact, so installing the collectors at low

angles does reduce their impact resistance.

O. STORAGE TANKS

It is recommended that the lever on the pressure and temperature relief valves (PTRV) on main pressure hot water storage tanks be

operated once every 6 months to ensure reliable operation. It is important to raise and lower the lever gently, and be careful as the

water released will be HOT. Failure to operate the PTRV on a regular basis could lead to failure of the component and the possibility of

the storage tank exploding.

It is recommended, and may also be a local regulation, that, in order to expel water safely, the PTRV have a copper pipe connected

and run to an appropriate drainage location. The PTRV and drain outlet pipe must not be sealed or blocked.

NOTE: If the water heater is left in an operating condition and not used for two weeks or more, a quantity of highly flammable hydrogen

may accumulate in the top of the water cylinder.

P. THERMAL EXPANSION (CLOSED LOOP SYSTEMS)

As water is heated, it expands. This is known as thermal expansion. Thermal expansion can cause premature component failure. Such

failures ARE NOT covered under product warranty.

An expansion tank, properly sized for your solar system, should be installed to control thermal expansion. Refer to expansion tank

manufacturer’s specifications for proper sizing guidelines.

LP-200 REV. 3.25.14

Page 13

PART 4 – SPECIFICATIONS

13

Figure 3 – SB Series Water Heater Dimensions and Specifications

LP-200 REV. 3.25.14

Page 14

14

Figure 4 – SE Series Water Heater Dimensions and Specifications

LP-200 REV. 3.25.14

Page 15

15

PART 5 - INSTALLATION

A. INSTALLATION CHECKLIST

Location

Sufficient room to service water heater, piping, and related controls

Provisions made to protect area from water damage

Centrally located to fixtures

Protected from freezing temperatures

Area free of flammable and/or corrosive vapors

Potable Water Supply

All related piping free from leaks

Thermal expansion tank installed

Water heater and fixtures have been properly purged of air

ASSE 1017 rated thermostatic mixing valve IS REQUIRED PER SRCC OG-300

Have water supply tested and ensure it meets the requirements outlined in the Part 2, Section E of this manual

Relief Valve

Temperature and Pressure relief valve properly installed and discharge line runs to open drain

Discharge line not exposed to freezing temperatures

Discharge line constructed of copper

Wiring; SE models

Power supply voltage agrees with the water heater rating plate

Branch circuit wire fusing or circuit breaker properly sized

Electrical connections tight and unit properly grounded

Wiring; SB models

Water heater control is secure and in control well

Boiler backup control is wired to the boiler control or relay center

Solar Heat Exchanger to Solar Panel; SE and SB models

Anti-freeze (if used) is added and rated as non-toxic with copy of MSDS sheet for homeowner

Solar heat exchanger completely purged of air

Expansion tank and temperature and pressure gauge operating properly

Solar control shows circulators operating properly on the solar panels

Boiler Heat Exchanger; SB models only

Boiler heat exchanger completely purged of air

Expansion tank and temperature and pressure gauge operating properly

Boiler control shows circulators operating properly on the solar panels

Anti-Freeze Fluid (if used in system)

Make sure freeze protection fluids are certified non-toxic, FDA rated GRAS

Glycol percentage must be calculated per local area freeze level

Provide glycol MSDS sheet to end user

NOTE: Make sure you have all necessary tools, materials and accessories before beginning work on the solar system.

TOOLS AND MATERIALS

Electric Drill Torch and Striker

Drill Index (w/ ½”, ¾”, 1” and 1 ¼” Wood Bits) Putty Knife

Hack Saw High Temperature Joint Compound

Tubing Cutter Wire Nuts or Connectors

Tin Snips Miscellaneous Copper Pipe & Fittings (3/4”)

16’ Tape Measure 1” x ¾” Copper Sweat Couplings

24” Level 1” Copper Sweat Caps

Flashlight Silicon Caulk and Roof Sealant

Extension Cord Minimum ¾” I.D. Type M Copper Tubing

Slip Joint Pliers Needle Nose Pliers

Pipe Wrenches, 10” and 14” Angle Iron

Open End Wrenches, 9/16 & 7/16 Threaded Rod, Nuts, & Washers

Screw Driver 6” Flat Blade Stainless Screw Clamps

Screw Driver 6” Philips Thermal Adhesive

LP-200 REV. 3.25.14

Page 16

Filled hot water storage tanks are very heavy, and should be located in areas that can structurally support such weight. Failure to

properly locate water storage tanks could result in property damage, personal injury, or death.

It is very important that you do the potable piping before you pipe into your solar system. Failure to do so may damage your water

heater.

Do not introduce HTF into any fittings on the heater except those clearly marked for that purpose.

Figure 5 – Clearances

Wire Stripper or Knife Aluminum Flashing Sheet

Wire Cutters Black Latex Outdoor Paint

Adjustable Wrenches 8” & 10” 7/8” x ¾” and 1 1/8” x ¾” pipe insulation

Solder Flux Emory Paper

B. SOLAR WATER HEATER LOCATION

To minimize expense and heat loss, locate the solar water heater as centrally to the domestic piping system and near the solar

collectors as possible. The water heater must also be located in an area where it will not be exposed to freezing temperatures. All

piping should be insulated to protect against freezing and heat loss.

In addition, the solar water heater and all related solar system components should be installed with plenty of clearance for inspection

and service. If minimum clearances are not met, it may not be possible to service the solar system without removing component parts

from installation locations.

The solar water heater should also be installed in a place where T&P discharge or a leak will not result in damage to the surrounding

area. Install a 2” high catch pan with a minimum of ¾” drain line to prevent water damage if leakage should occur (see Figure 5).

16

PART 6 – PIPING

The design and installation of the solar water heating system should be done by qualified individuals. It is important that good design

and installation practice be followed to assure that your system will operate properly. Failure to follow installation guidelines for you

solar water heater system could cause component failure and possible safety issues.

A. POTABLE WATER PIPING

It is mandatory that all plumbing be done in accordance with local and state codes or warranty will be void. It is also necessary to use

both thread tape and pipe dope on all mechanical connections. The potable water piping is located on the side of your solar water

LP-200 REV. 3.25.14

Page 17

Chemical imbalance of the water supply may affect efficiency and cause severe damage to the water heater and associated equipment.

HTP recommends having water quality professionally analyzed to determine whether it is necessary to install a water softener. It is

important that the water chemistry on both the domestic hot water and central heating sides are checked before installing the water

heater, as water quality will affect the reliability of the system. Failure of a water heater due to lime scale build-up, low pH, or other

chemical imbalance IS NOT covered by the warranty.

Operating temperatures above 135oF will further accelerate the build-up of lime scale and may shorten the service life of the water

heater. Failure of the water heater due to lime scale build-up on the heating surface, low pH, or other chemical imbalance IS NOT

covered by the warranty.

CLASSIFICATION

MG/L OR PPM

GRAINS/GAL

Soft

0 – 17.1

0 - 1

Slightly Hard

17.1 – 60

1 – 3.5

Moderately Hard

60 – 120

3.5 – 7.0

Hard

120 – 180

7.0 – 10.5

Very Hard

180 and over

10.5 and over

heater and marked Hot and Cold. It is recommended that unions or flexible copper connectors be used so heater can be easily

serviced. Install a shut-off valve on the cold feed near the solar water heater to isolate the tank for future service.

Provide clear access to the storage tank, pump, expansion tank, mixing valve, time clock and other key components. The components

on the potable side of the system may require future service or maintenance, so it is recommended that the connections be made with

brass unions. You must use copper and brass fittings in plumbing the solar storage tank and expansion tank. The use of galvanized

fittings, nipples, dielectric unions, CPVC, PVC, or other plastic pipe is prohibited.

Hard copper connections to the city cold water supply line and home hot water feed lines are recommended.

The gaskets in standard water heater flex hose connectors can become brittle and compressed over time and begin leaking on the

water heater. If not detected in a timely manner, a drip or leak may cause serious damage to the tank’s electrical components, or, in

extreme cases, cause the tank to leak from the outside in.

B. WATER CHEMISTRY REQUIREMENTS

17

Outlined below are water quality parameters which need to be met in order for the system to operate efficiently for many years.

Water Hardness

Water hardness is mainly due to the presence of calcium and magnesium salts dissolved in water. The concentration of these salts is

expressed in mg/L, ppm, or grains per gallon as a measure of relative water hardness. Grains per gallon is the common reference

measurement used in the U.S. water heater industry. Hardness expressed as mg/L or ppm may be divided by 17.1 to convert to grains

per gallon. Water may be classified as very soft, slightly hard, moderately hard, or hard based on its hardness number. The minerals in

the water precipitate out as the water is heated and cause accelerated lime scale accumulation on a heat transfer surface. This lime

scale build-up may result in premature failure of the water heater. Operating temperatures above 135oF will further accelerate the buildup of lime scale and may shorten the service life of the water heater.

Water that is classified as hard and very hard must be softened to avoid water heater failure.

If the hardness of the water exceeds the maximum level of 7 grains per gallon, water should be softened to a hardness level no lower

than 5 grains per gallon. Water softened as low as 0 to 1 grain per gallon may be under-saturated with respect to calcium carbonate,

resulting in water that is aggressive and corrosive.

pH of Water

pH is a measure of relative acidity, neutrality or alkalinity. Dissolved minerals and gases affect water pH. The pH scale ranges from 0 to

14. Water with a pH of 7 is considered neutral. Water with a pH lower than 7 is considered acidic. Water pH higher than 7 is considered

alkaline. A neutral pH (around 7) is desirable for most potable water applications. Corrosion damage and tank failures resulting

from water pH levels of lower than 6 or higher than 8 ARE NOT covered by the warranty. The ideal pH range for water used in a

water heater is 7.2 to 7.8.

Total Dissolved Solids

Total Dissolved Solids (TDS) is a measurement of all minerals and solids dissolved in a water sample. The concentration of total

dissolved solids is usually expressed in parts per million (ppm).

LP-200 REV. 3.25.14

Page 18

18

Water with a high TDS concentration will greatly accelerate lime and scale formation in the hot water system. Most high TDS

concentrations precipitate out of the water when heated. This can generate a scale accumulation that will greatly reduce the service life

of a water heater.

The manufacturer of the water heater has no control over water quality, especially TDS levels in your system. Total dissolved solids in

excess of 2,000 ppm will accelerate lime and scale formation on the element or heat exchanger. Water heater failure due to total

dissolved solids in excess of 2,000 ppm is a non-warrantable condition. Failure of a water heater due to lime scale build up IS NOT

covered by the warranty.

Hardness: 7 grains

Chloride levels: 100 ppm

pH levels: 6-8

TDS: 2000 ppm

Sodium: 20 mGL

C. POTABLE WATER PIPING DETAIL

Figure 6 - This drawing is meant to demonstrate solar system piping concept only.

LP-200 REV. 3.25.14

Page 19

19

D. SOLAR HEAT EXCHANGER PIPING

Set up the primary balance of the system components following the piping detail in Figure 6.

Run ½” type M or larger copper pipes, or flex line sets, to and from the collector following the direction of supports, penetrations, and

other relative items.

Only copper, cast iron, or brass are to be allowed in the collector piping loop due to transient operating temperatures that may reach as

high as 300oF. PEX, PVC, CPVC, and other polymers are expressly prohibited in the piping network of closed loop systems.

When making a connection to the heat exchanger, use Teflon Tape and joint compound to prevent leaks. The connections to the heat

exchanger are 1” NPT. Do not apply heat directly to the heat exchanger thread connection when sweating fittings.

Line pressure and temperature gauge shall be installed in the collector supply and return lines to allow for a simple diagnostic check of

proper system operation. On a sunny day, the hot water return line should be approximately 5 – 12oF warmer than the water in the

collector supply line. Compare the temperature readings in the two line thermometers. The ¾” cold water supply line to the storage tank

must be insulated with a minimum 7/8” x ½” pipe insulation to a minimum distance of 5’ behind the storage tank, or to the wall if closer

than 5’.

E. TANK SENSOR PLACEMENT

Make sure the sensor is secured on the stud located in the lower section of the water heater. Secure the sensor by packing Armaflex

insulation behind it. This will also help the sensor react to temperature change.

Non-toxic freeze protection fluid must be used to protect the system from freezing. Use a mixture appropriate for your climate. Do not

use a higher glycol to water concentration than necessary, as this will adversely impact heat transfer efficiency. See the DowFrost

Data Sheet in the back of this manual for recommended concentrations. A copy of the MSDS sheet must be left with the end user of

the solar system. See “EMERGENCY OVERVIEW” as part of the DowFrost Data Sheet in the back of this manual.

The collector loop must be charged with HTF. The use of regular tap water as a mixing agent is prohibited. Use distilled water as a

mixing agent ONLY. Regular scheduled maintenance must be established to monitor and maintain the proper pH level of HTF in the

system to protect the heat exchanger and other components in the system.

F. NECESSARY COMPONENTS FOR SOLAR WATER HEATER INSTALLATION

Listed below are components needed for installation of the solar water heater.

Solar Collector

Absorbs and transfers the sun’s energy into the solar heat exchanger located on the bottom of the solar water heater.

Solar Air Release Vent*

This air vent allows air contained in the solar system to release. The air vent valve must be designed to work in high temperatures (as

high as 350oF) with a glycol medium. (This is typical of solar systems.)

*Remove and cap the solar air release vent after commissioning the system.

Solar Collector Sensor

This sensor is wired to the solar controller and automatically turns on the circulator pump when the differential set point is reached

between the solar water heater and collector.

Tank and Heat Exchanger Temperature and Pressure Gauge

The temperature and pressure gauge on the solar piping will show the user the actual temperature and pressure supplied and returned

to the solar collector.

Check Valve

Helps minimize convective heat loss at night when the system is not operating. If a check valve is not installed, most of the heater

energy stored during the day would be transferred into the panel and lost.

Collector Isolation Valve (Valve #6)

Valve #6 and 11 (for solar collector isolation) isolates the collector loop from the solar water heater.

Pressure Relief Valve (for Solar System)

Releases pressure in the solar loop when it exceeds 150psi. Contact your installation contractor immediately if this valve opens

and releases fluids.

System Fill Valve (Valve #8)

Fills the system with HTF. Also eliminates air from the system.

LP-200 REV. 3.25.14

Page 20

20

Expansion Tank

Pre-charged with air to allow for the expansion and contraction of HTF.

Drain Valve (Valve #10)

Used to charge the collector loop with glycol, purge air from the loop and drain the solar water heater heat exchanger of fluid.

Collector Isolation Valve (for system fill) (Valve #11)

Used to direct the flow of HTF and to pressurize and eliminate air from the solar system.

Ball Valve (for circulator) Valve #12

Used to isolate the circulator pump for service. Close both ball valves to isolate pump.

Circulator (#13)

Circulates the HTF from the solar collector into the solar heat exchanger.

Drain Valve (Tank) (Valve #14)

Flushes sediment which may accumulate on the bottom of the solar water heater and also provides a means of draining the tank.

Tank Sensor

Is wired to the solar controller to measure the temperature on the bottom of the solar water heater in conjunction with the solar collector

sensor. Turns the circulating pump on and off at the solar control preset temperature differentials.

Solar Controller

The solar controller turns on or off the circulator depending on heat gained from solar operation. The controller also limits overheating in

the solar water heater. Some controllers have various options. The controller should always be set in the “auto” position so that it

operates the array automatically when there is solar energy to be collected.

Solar Heat Exchanger

The solar heat exchanger has an integral finned tube designed to transfer heated energy rapidly from the solar collector into potable

water. The heat exchanger is constructed in 90/10 copper nickel for superior corrosion resistance and long-term reliability.

Hot Water Outlet

Each solar water heater has a hot water dip tube outlet which draws water from the top of the heater. This helps to keep heat trapped

inside the highly insulated storage tank.

Solar Tank Temperature and Pressure Relief Valve

The relief valve must comply with standards for relief valves (ANSI Z21.22) by a nationally recognized lab that maintains periodic

inspections of production listed equipment. No valve of any type should be installed between the relief valve and tank. Local codes

govern installation of relief valves.

The relief valve outlet must be piped to a suitable open drain so that the discharge water cannot contact live electric parts to eliminate

potential damage. Piping used should be approved for hot water distribution. The discharge line must be no smaller than the outlet of

the relief valve and must pitch downward to allow complete drainage. The end of the discharge piping should not be threaded or

concealed and must be protected from freezing. No valve of any type, restriction or reducer coupling should be installed in the

discharge line.

Mixing Valve (Rated ASSE 1017) REQUIRED PER SRCC OG-300

Automatically blends hot and cold water feed lines to control discharge to an acceptable and safe temperature. This also increases the

amount of hot water drawn from the solar water heater by not allowing incoming cold water to fully temper the hot water stored inside

the tank. To help prevent injury due to scalding, it is recommended that the mixing valve be set at 120oF.

Back-up Electric Element with Thermostat (SE Models)

The back-up electric element will only activate when the desired minimum set point temperature set on the back-up thermostat cannot

be satisfied by the solar gain achieved from the solar collector.

Boiler Back-up Heat Exchanger (SB Models)

The back-up boiler will only activate when the desired minimum set point temperature set on the back-up thermostat cannot be satisfied

by the solar input from the solar collector.

Boiler Back-up Aquastat

The boiler back-up aquastat will activate the boiler to circulate the hot water generated from the boiler into the heat exchanger located

on the top section of SB models. Once the system has reached the desired set point, the controller will shut off the boiler. This back-up

portion will only activate if the solar gain from the collector cannot keep the tank at the minimum desired temperature setting.

Ball Valve (for cold water shut-off) (Valve #24)

The cold water shut off valve should be used in the event of an emergency shutdown.

LP-200 REV. 3.25.14

Page 21

21

It is very important that you do the potable piping before you pipe into the solar system. Failure to do so may damage your water

heater. Improper installation IS NOT covered by warranty.

Dielectric unions or galvanized steel fittings must be used on the domestic water connections or auxiliary connections. Teflon thread

sealant must be used on all connections. Failure to do so could result in premature water heater failure. Such failure IS NOT covered by

warranty.

LP-200 REV. 3.25.14

Page 22

G. SOLAR WATER HEATER WITH BOILER BACK-UP

22

Figure 7 – Solar Water Heater with Boiler Back-up – FIGURE NOTES:

1. This drawing is meant to show system piping concept only. The installer is responsible for all equipment and detailing by local codes.

2. Antifreeze, non-potable HTF shall be used for the solar heat exchanger circuit only. Never introduce antifreeze solution to any connection other than

the solar loop.

3. If there is a check valve on the cold water feed line, a thermal expansion tank suitable for potable water must be sized and installed within this piping

system between the check valve and cold water inlet of the solar water heater.

4. An ASSE 1017 mixing valve is required per SRCC OG-300.

5. A minimum of 12 diameters of straight pipe must be installed upstream of all circulators.

6. Make sure tank is fully purged of air before power is turned on to the backup heat source.

7. Circulators shown in the above hydronic piping should have an integral flow check or alternately use a stock pump with an external spring type check

valve. (Due to extreme temperatures, circulators with integral flow checks are not to be used in solar systems. If circulator comes equipped

with an integral flow check, remove it.)

LP-200 REV. 3.25.14

Page 23

H. SOLAR WATER HEATER WITH ELECTRIC BACK-UP

23

Figure 8 – Solar Water Heater with Electric Back-up

FIGURE NOTES:

1. This drawing is meant to show system piping concept only. The installer is responsible for all equipment and detailing by local codes.

2. Antifreeze, non-potable HTF shall be used for the solar heat exchanger circuit only. Never introduce antifreeze solution to any connection other than

the solar loop.

3. If there is a check valve on the cold water feed line, a thermal expansion tank suitable for potable water must be sized and installed within this piping

system between the check valve and cold water inlet of the solar water heater.

4. An ASSE 1017 mixing valve is required per SRCC OG-300.

5. A minimum of 12 diameters of straight pipe must be installed upstream of all circulators.

6. For all SE models, make sure tank is fully purged of air before power is turned on to the backup heat source.

7. Circulators shown in the above hydronic piping should have an integral flow check or alternately use a stock pump with an external spring type check

valve. (Due to extreme temperatures, circulators with integral flow checks are not to be used in solar systems. If circulator comes equipped

with an integral flow check, remove it.)

LP-200 REV. 3.25.14

Page 24

Figure 9 – Sensor Installation Detail

I. BOILER BACK-UP HEAT EXCHANGER

CONNECTION (SB MODELS ONLY)

The boiler heat exchanger connections are located in the

front of the solar water heater. Use a 1” minimum pipe

size when connecting zone valves or circulators.

The inlet of the circulator must be connected to the hot

outlet side of the boiler. Be sure the direction of the arrow

on the circulator is facing toward the flow direction from

the boiler to the boiler inlet of the water heater. On the

water heater, the boiler return must be connected to the

return side of the boiler. The return from the heating loop

should have a flow check or swing check valve installed

before the return pipe from the boiler heat exchanger.

J. BOILER TANK CONTROL

Insert the boiler tank control into the control well provided

in the front of the water heater. Wire the boiler tank

control to the boiler control or relay center. Additional

equipment may be needed in order to wire the control to

the existing system. Controls also have the ability to

monitor and display solar collector temperature and upper

and lower tank temperature. See Figure 9 for installation

detail.

K. CIRCULATOR SIZING

The circulator pump must be sized for the related piping and pressure drop of the heat exchanger, and for situations specific to your

solar system. The following graph represents the pressure drop of the solar heat exchanger. Consult the solar panel manufacturer for

flow requirements to assist in pump selection.

24

Figure 10 – Pressure Drop through the Solar Water Heater Heat Exchanger

L. BOILER BACK-UP HEAT EXCHANGER (SB MODELS ONLY)

To assure the correct flow through the boiler back-up heat exchanger, refer to Figure 10 to correctly size the circulator to the boiler or

auxiliary heat exchanger. HTP recommends a flow rate of 1 gpm for every 10,000 BTU based on a 20oF temperature difference

between the supply and return of the heat exchanger.

Example: Boiler is 100,000 BTU / 10,000 BTU = 10 gpm flow rate. The heat exchanger at 10 gpm will require a circulator that will

operate at 8 feet of friction.

LP-200 REV. 3.25.14

Page 25

25

Tank must be full before unit is turned on. The heating element will be damaged if energized for even a short period of time while tank

is dry. This damage IS NOT covered by warranty.

Be sure to ground the water heater. The preferred way to ground is with rigid metal conduit between the main panel and the water

heater junction box with approved end fittings (check codes on the use of flexible conduit). If making a separate ground, a green ground

wire is provided in the water heater junction box. Replace the junction box cover and insulation after you have made the wiring

connections.

Installation, attachment, or use of any unapproved devices in conjunction with this water heater WILL VOID the warranty. The use of

unauthorized energy saving devices may shorten the life of the water heater and possibly endanger property and life. The manufacturer

disclaims any responsibility for any loss or injury resulting from the use of such unauthorized devices.

Do not use SE model water heaters with any voltage other than shown on the model rating plate. Failure to use the correct voltage

shown on the rating plate could result in property damage, serious personal injury, or death.

Figure 11 - SE Series Electrical Connection Detail

M. ELECTRICAL CONNECTION (SE MODELS ONLY)

This unit is factory wired to a junction box on top of the water heater. A 4 x 4 x 2 junction box is located on top of the unit for field wiring

connection. These heaters are equipped and wired as standard 120 volt AC (for point of use heaters) and 240 volt AC (for dual element

heaters). The voltage requirement and dedicated wattage load for the heater is specified on the rating label. A minimum 30 amp circuit

is required to connect the water heater. Consult your local power company to determine if your electrical service is adequate for the

additional load of the heater.

Refer to the wiring diagrams below for field connections. 240V electrical installation should be done by a qualified licensed electrician or

by your local electric utility. All wiring must conform to local code and the National Electric Code. Grounding can be accomplished by

using approved conduit and fittings or other approved conductive material. A grounding wire is provided on the junction bracket. This

grounding wire must be used in the installation.

After the water and electrical connections have been made and the tank has been filled with water and purged of air, turn on power to

the heater. The heater is now operational.

LP-200 REV. 3.25.14

Page 26

26

Figure 12 – Thermostat Detail

N. THERMOSTAT ADJUSTMENT

The thermostat is located in the front of the heater. The access cover must be removed to adjust the factory default setting of 119oF.

This temperature is satisfactory for average household use.

If an adjustment is necessary, turn off the power to the heater, remove the black access cover and insulation. The thermostat protective

cover should not be removed. Set the temperature indicator to the desired temperature, replace insulation and access cover. Turn on

power to the heater.

O. COMBINATION “THERMOSTAT AND HIGH LIMIT CONTROL (ECO)”

This heater is equipped with a combination thermostat and high limit safety. If for any