Page 1

MODBUS

NOTE TO CONSUMER: PLEASE KEEP ALL INSTRUCTIONS FOR FUTURE REFERENCE.

INSTALLATION

TROUBLESHOOTING

MOD BUS Models

7350P-629

FOR USE WITH MODCON, MODCON VWH, PIONEER, VERSA-FLAME

MANUFACTURED ON OR AFTER JULY 1, 2011

FOR USE WITH ELITE, ELITE VWH

MANUFACTURED ON OR AFTER AUGUST 1, 2011

NOTICE: HTP reserves the right to make product changes or updates without notice and will not be held liable for typographical errors

in literature.

120 Braley Rd. P.O. Box 429 East Freetown, MA 02717-0429 www.htproducts.com

LP-372 Rev. 6.14.13

Page 2

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk

levels or to important information concerning the product.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result in property

damage.

FOREWORD

This manual provides guidelines for the use and installation of the Modbus communication system with HTP appliances.

2

FOR THE INSTALLER

The installer should be guided by the instructions furnished with the Modbus, local codes and utility company requirements. Preference

should be given to codes and requirements where they differ from the furnished instructions.

Additional publications which should guide the installer include:

The latest version of the National Electrical Code, NFPA No. 70.

In Canada, refer to Canadian Electrical Code C 22.1, from Canadian Standards Association, 5060 Spectrum Way, Suite 100,

Mississauga, Ontario, Canada L4W 5N6.

TABLE OF CONTENTS

PART 1 - GENERAL INFORMATION .......................................................................................................................................... 3

A. WHAT’S IN THE BOX ................................................................................................................................................................. 4

B. MINIMUM SYSTEM REQUIREMENTS ...................................................................................................................................... 4

C. DEFINITIONS ............................................................................................................................................................................. 4

PART 2 - INSTALLATION ........................................................................................................................................................... 5

A. WIRING REQUIREMENTS ........................................................................................................................................................ 5

B. JUMPER SETTING .................................................................................................................................................................... 6

PART 3 – COMMUNICATION CONFIGURATION (APPLIANCES WITH A 3 CHARACTER RED LED DISPLAY) .................. 7

A. MODBUS ENABLE ..................................................................................................................................................................... 7

B. MODBUS ADDRESS .................................................................................................................................................................. 7

C. BAUD RATE ............................................................................................................................................................................... 7

D. PARITY AND STOP BITS .......................................................................................................................................................... 8

PART 4 – COMMUNICATION CONFIGURATION (APPLIANCES WITH AN LCD TEXT DISPLAY) ......................................... 8

A. MODBUS ENABLE ..................................................................................................................................................................... 8

B. MODBUS ADDRESS .................................................................................................................................................................. 8

Page 3

If any system component(s) is/are exposed to the following, do not operate until the affected component(s) has/have been inspected by

a qualified serviceman.

1. FIRE

2. DAMAGE

3. SUBMERSION IN WATER

C. BAUD RATE ............................................................................................................................................................................... 9

D. PARITY AND STOP BITS .......................................................................................................................................................... 9

PART 5 – GENERAL MODBUS INFORMATION ........................................................................................................................ 9

A. DATA TRANSMISSION MODE .................................................................................................................................................. 9

B. MODBUS BOARD DIAGNOSTICS............................................................................................................................................. 9

C. MODBUS COMMUNICATION .................................................................................................................................................. 10

D. MODBUS FUNCTION SET ...................................................................................................................................................... 10

E. MODBUS EXCEPTION CODES .............................................................................................................................................. 11

PART 6 - REGISTER MAP ........................................................................................................................................................ 11

A. PRIMARY DATA TABLES ........................................................................................................................................................ 11

B. APPLIANCE MEMORY MAP .................................................................................................................................................... 11

C. BLOCKING CODES ................................................................................................................................................................. 13

D. LOCKOUT CODES .................................................................................................................................................................. 14

E. STATUS CODES ...................................................................................................................................................................... 14

F. CONFIGURATION BITS ........................................................................................................................................................... 14

PART 7 - APPLIANCE OPERATION......................................................................................................................................... 15

3

A. APPLIANCE OPERATION WITH MODBUS COMMUNICATIONS .......................................................................................... 15

B. EXAMPLE #1 ............................................................................................................................................................................ 15

C. EXAMPLE #2 ........................................................................................................................................................................... 15

1. SEND FIRING RATE COMMAND FROM MASTER .................................................................................................................... 15

2. SEND TEMPERATURE COMMAND FROM MASTER ................................................................................................................ 16

D. EXAMPLE #3 – HOT WATER GENERATION ......................................................................................................................... 16

E. CASCADE ................................................................................................................................................................................ 16

F. RATE AND TEMPERATURE CONVERSIONS ........................................................................................................................ 17

G. APPLIANCE STATUS CODES ................................................................................................................................................ 19

PART 8 - TROUBLESHOOTING ............................................................................................................................................... 19

A. PHYSICAL LAYER ................................................................................................................................................................... 19

B. COMMUNICATIONS ................................................................................................................................................................ 19

C. LED DIAGNOSTICS ................................................................................................................................................................. 19

D. MODBUS ERROR CODES ...................................................................................................................................................... 19

INSTALLATION AND MAINTENANCE NOTES .............................................................................................................................. 20

HTP CUSTOMER INSTALLATION RECORD FORM...................................................................................................................... 21

PART 1 - GENERAL INFORMATION

Modbus communication systems utilize a master-follower format where connected HTP appliances follow commands from a building

management system or other Modbus master device linked over an RS-485 serial connection.

Page 4

Any claims for damage or shortage in shipment must be filed immediately against the transportation company by the consignee.

ABBREVIATION OR ACRONYM

DEFINITION

ASCII

American Standard Code for Information Interchange

BAS

Building Automation System

Baud (Baud Rate)

Number of data bits transmitted per second (bps)

BMS

Building Management System

EMS

Energy Management System

FDX

Full-Duplex

HDX

Half-Duplex

Hex

Hexadecimal Number (0-9, A-F)

I/O Box

Input/Output

LSB

Least Significant Byte

A. WHAT’S IN THE BOX

1. One MODBUS Adapter

2. One bag of mounting hardware

3. One mounting template

B. MINIMUM SYSTEM REQUIREMENTS

1. A Modbus master device, such as a Building Automation System (BAS) or computer with Modbus master software, and an RS-485

serial port or USB port with a converter to RS-485.

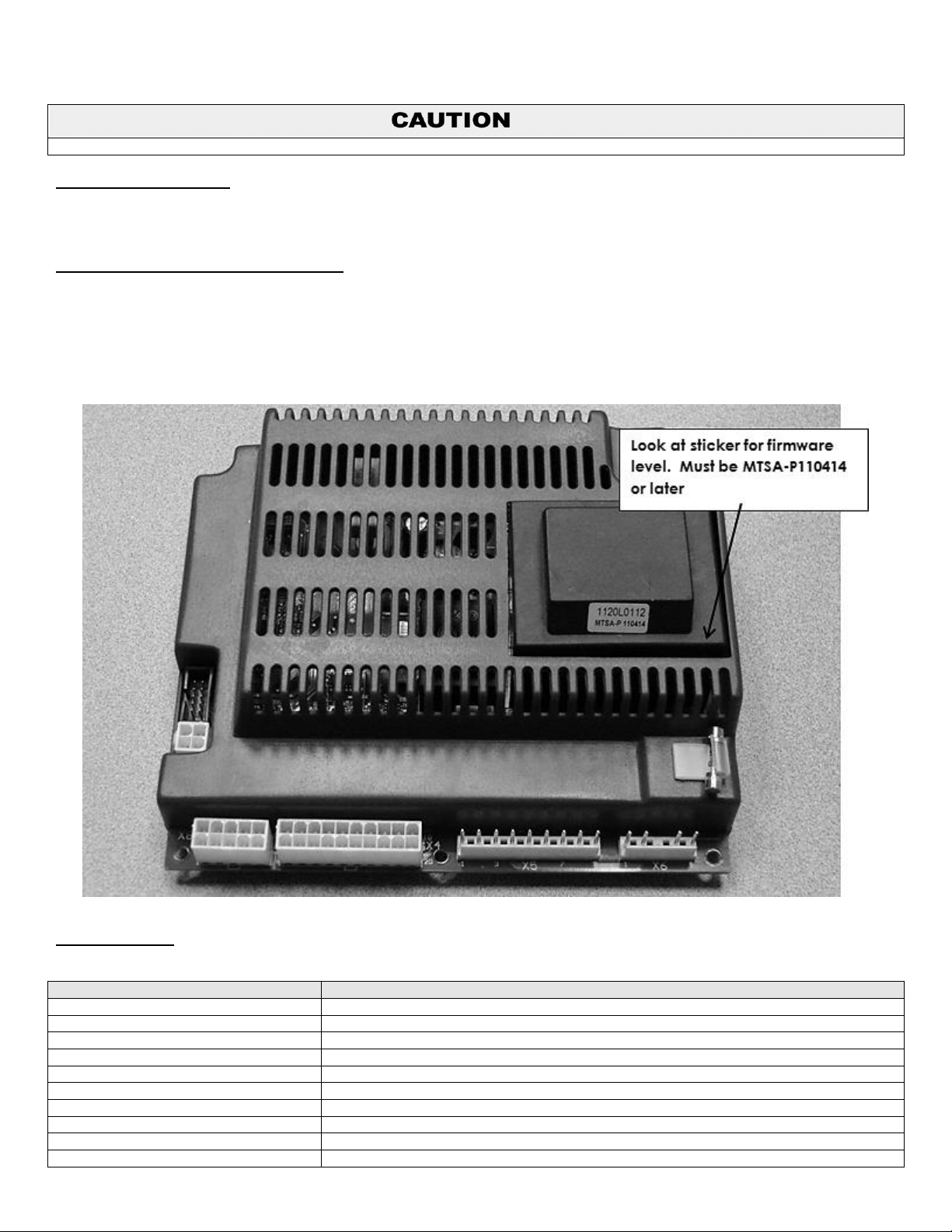

2. HTP Modbus adapter (this kit), and an HTP appliance/water heater equipped with a control with firmware revision MTSA-P110414 or

greater. To determine whether your product is compatible with this adapter, refer to Figure 1.

3. Shielded twisted pair communication cable.

4

Figure 1 – Controller Revision Label Location

C. DEFINITIONS

Table 1 is a list of definitions used throughout this manual.

Page 5

Modbus

A serial, half-duplex transmission protocol developed by AEG Modicon

MSB

Most Significant Byte

RS232

RS232 serial, full-duplex (FDX) transmission of data standard

RS485

RS-485 serial transmission of data standard

RTU

Remote Terminal Unit

PG

Industry Standard liquid-tight wiring entry connector

MB

MODBUS

Use the mounting screws provided with the adapter. Damage to Modbus adapter or appliance due to installation with other mounting

screws IS NOT covered by warranty.

Damage to Modbus adapter or appliance due to improper installation IS NOT covered by warranty.

Table 1 – Acronym definitions

PART 2 - INSTALLATION

The Modbus adapter should be mounted to a solid surface. The adapter has two tabs with four mounting holes designed specifically for

this purpose.

When mounting the unit, keep in mind that the top cover must be removed to connect the Modbus communication cable, and that the

appliance communication wire must reach the control inside the appliance.

The Modbus adapter can be mounted on the side of the appliance OR the wall next to the appliance, as long as care is taken to avoid

components behind the mounting surface. The mounting location must be within 3 feet of the appliance controller in order to be plugged

into the controller programming port.

NOTE: It is not recommended to install the Modbus adapter inside the appliance housing. Doing so may affect appliance operation or

damage the Modbus adapter.

5

A. WIRING REQUIREMENTS

RS-485 Communication Bus

Maximum length: 1000 feet

Cable specification: 24 AWG / A,B (twisted pair) and GND shielded, with characteristic impedance: 120 ohm

Maximum load: 32 units (32 nodes)

Wires will be passed through the PG connector on the side of the adapter, then connected to the three position connector marked “X5”

on the circuit board inside the adapter. A label is provided inside the adapter to ensure proper connections of A, B, and GND. Two wires

(MB IN and MB OUT) may be attached to each X5 screw.

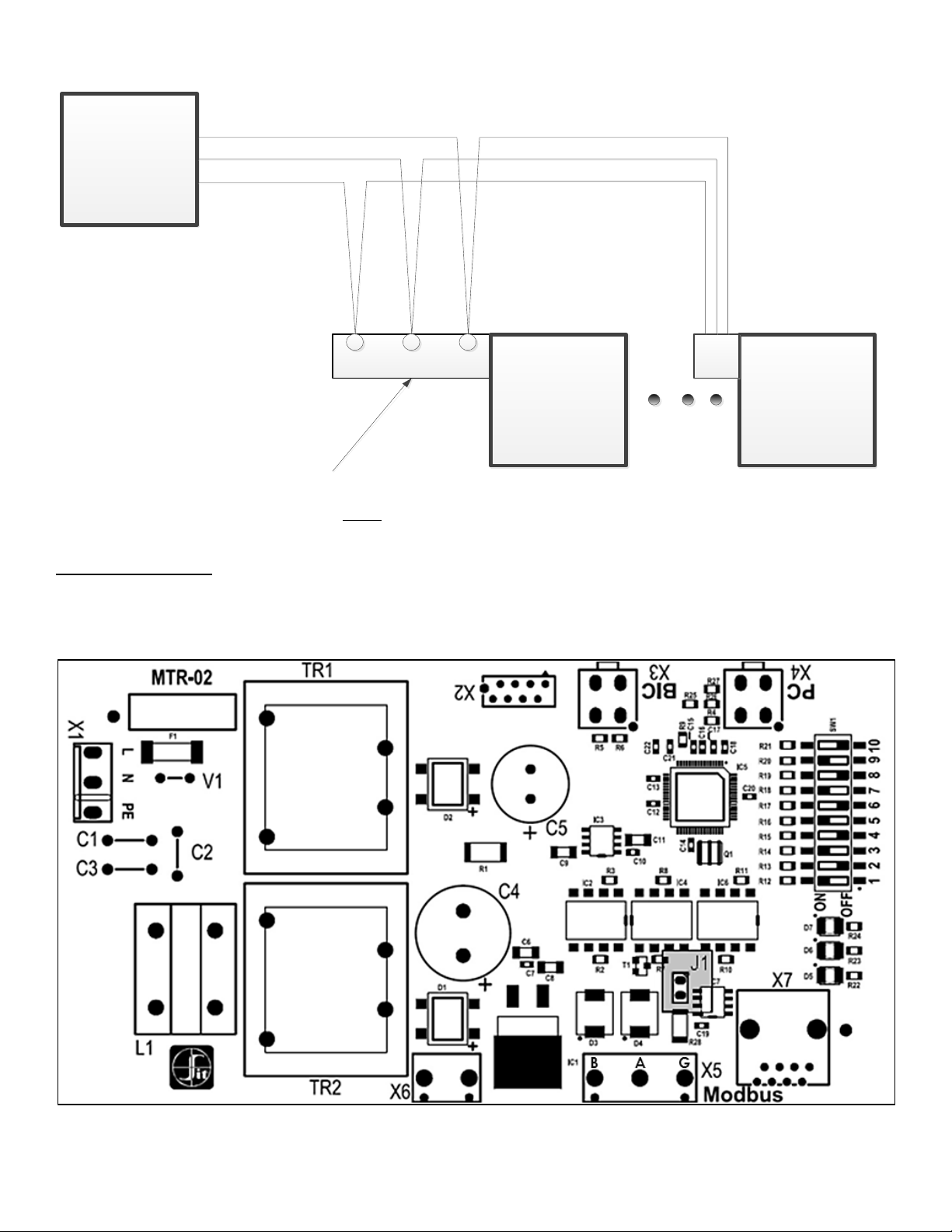

See Figure 2 for an example wiring diagram.

Page 6

6

BMS

APPLIANCE X

X5X5

B

A

G

REMOVE JUMPER

(J1) FROM THIS

ADAPTER ONLY!

MODBUS ADAPTER

APPLIANCE 1

X5

Figure 2 – Jumper Configurations in a Modbus Network

B. JUMPER SETTING

The appliance display handles most of the Modbus adapter configuration. There is one jumper on the Modbus adapter. When this

jumper is in place (factory default) it connects a termination resistor across the data lines of the RS-485 connection. Leave the jumper

in if the Modbus adapter is at the end of the RS-485 bus. Remove the jumper if the Modbus adapter is one of many connections and

not at the end of the bus. See Figures 2 and 3.

Figure 3 – Modbus Termination Jumper Location (Highlighted in Grey)

Page 7

Parameter

Setting

Description

37

0

MODBUS “DISABLED” (factory default)

37

1

MODBUS “ON”

37

2

MODBUS “AUTO” (enables automatic detection of a PC or Adapter)

Parameter

Setting

Description

39

0

BAUD RATE = 9600 (factory default)

39

1

BAUD RATE = 19200

PART 3 – COMMUNICATION CONFIGURATION (APPLIANCES WITH A 3

CHARACTER RED LED DISPLAY)

A. MODBUS ENABLE

1. Press and hold ENTER and RESET simultaneously. Use the UP and DOWN arrows to show 925 on the display, then press and hold

ENTER to enter the installer menu.

2. Once in the Installer Menu, use the ENTER button to navigate to Parameter 37. When at Parameter 37, use UP or DOWN select the

desired setting from the table below:

Table 2 – Parameter 37 Settings

Please do not leave the Installer Menu after making this selection. Configure the Address, Baud Rate, and Parity settings described

below.

B. MODBUS ADDRESS

NOTE: Modbus must be enabled on the appliance as outlined above for the following parameters to be viewed and changed.

The Modbus address space is comprised of 256 addresses. These are defined as follows:

Address 0 is a broadcast address. The master can send data to address 0 and all followers will process the data.

Addresses 1 – 247 are free to be assigned to Modbus devices on the bus. Each address can be assigned to only one Modbus

device on the bus.

Addresses 248 – 256 are not available for use.

MODBUS ADDRESSING SUGGESTIONS*

Each device must have a unique address.

It is not recommended to use 1 as an address, as this is often the default address for various other Modbus devices

that may be on the bus.

In order to keep track of addresses for future maintenance purposes, record all device addresses in the Installation

and Maintenance Notes section included in this manual.

*SAVE THIS DOCUMENT IN A SECURE LOCATION FOR FUTURE REFERENCE.

To set the Modbus adapter address in the appliance installer menu:

From the Installer Menu, press the ENTER key to advance to Parameter 38. Use the UP and DOWN arrows to set the desired address.

Press the RESET button to store the address.

Press the DOWN button to advance to Parameter 39 - Baud Rate.

7

C. BAUD RATE

The baud rate (communication speed) can be set to either 9600 or 19200 baud. All HTP appliances, as well as any other device on the

same bus and the Modbus master, must have the same baud rate setting. Select the highest baud rate that offers the most reliable

communication performance over the bus.

Some things that can affect communications are:

Long wire runs

Wire quality

A noisy electrical environment

The number of devices on the bus.

These conditions may require using a lower baud rate.

Use the UP and DOWN buttons to select the desired setting from the table below:

Table 3 – Parameter 39 Settings

Press RESET to store the baud rate. Press the DOWN button to advance to Parameter 40 - Parity and Stop Bits.

Page 8

Parameter

Setting

Description

40

0

No parity 1 stop bit (factory default)

40

1

No parity 2 stop bits

40

2

Even parity 1 stop bit

40

3

Odd parity 1 stop bit

Parameter

Setting

Description

37

OFF

MODBUS “DISABLED” (factory default)

37

ON

MODBUS “ON”

37

AUTOMATIC

MODBUS “AUTO” (enables automatic detection of a PC or Adapter)

ENTER MENU CODE

925

MODBUS MODE

OFF 37

MODBUS ADDRES

0 38

D. PARITY AND STOP BITS

The parity/stop bits parameter of the Modbus adapter must be set to match the rest of the devices on the bus. Although it is common to

set serial devices to use no parity, setting the parity to even or odd may improve communications reliability on all connected devices on

the bus.

This parameter has 4 possible selections which should be sufficient to establish communication with other devices. These selections

are outlined in Table 4.

Table 4 – Parameter 40 Settings

Press and Hold the RESET button to store all parameters and exit the Installer Menu.

PART 4 – COMMUNICATION CONFIGURATION (APPLIANCES WITH AN LCD TEXT

DISPLAY)

A. MODBUS ENABLE

1. Press and hold the ENTER key until you see the screen at right.

Use the RIGHT arrow to select a character, then use the UP and DOWN arrows to

select the desired character value. RIGHT arrow over to the next character and repeat the selection. Once you have 925 on the screen,

press and hold ENTER on the display to enter the Installer Menu.

2. Once in the Installer Menu, use the RIGHT arrow to navigate to Parameter 37. When at Parameter 37, press ENTER. The current

setting should be flashing. Press UP or DOWN to select the desired setting from Table 5:

8

Table 5 – Parameter 37 Settings

FUNCTION 37

Press ENTER once the desired setting is flashing on the display. Once accepted, the

selection should not flash.

Please do not leave the Installer Menu. Configure the Address, Baud Rate, and Parity settings described below.

B. MODBUS ADDRESS

NOTE: Modbus must be enabled on the appliance as outlined above for the following parameter to be viewed and changed.

The Modbus address space is comprised of 256 addresses. These are defined as follows:

Address 0 is a broadcast address. The master can send data to address 0 and all followers will process the data.

Addresses 1 – 247 are free to be assigned to Modbus devices on the bus. Each address can be assigned to only one Modbus

device on the bus.

Addresses 248 – 256 are not available for use.

MODBUS ADDRESSING SUGGESTIONS*

Each device must have a unique address.

It is not recommended to use 1 as an address, as this is often the default address for various Modbus devices.

In order to keep track of addresses for future maintenance purposes, record all device addresses in the Installation

and Maintenance Notes section, included in this manual.

*SAVE THIS DOCUMENT IN A SECURE LOCATION FOR FUTURE REFERENCE.

In the Installer Menu, press RIGHT to advance to Parameter 38.

FUNCTION 38

Press ENTER. The address value will blink. Use the UP and DOWN arrows to set the

desired address. Press ENTER again to accept your selection (and stop the display from

Page 9

PARAMETER 40 SETTING TEXT DISPLAY

PARITY / STOP BITS

1 ST

No parity 1 stop bit

2 ST

No parity 2 stop bits

E PA

Even parity 1 stop bit

O PA

Odd parity 1 stop bit

MODBUS SPEED

009600 39

MODBUS STOP/PARITY

1 ST 40

blinking).

Press the RIGHT button to advance to Parameter 39 - Baud Rate.

C. BAUD RATE

The baud rate (communication speed) can be set to either 9600 or 19200 baud. All HTP appliances, as well as any other device on the

same bus and the Modbus master, must have the same baud rate setting. Select the highest baud rate that offers the most reliable

communication performance over the bus.

Some things that can affect communications are:

Long wire runs

Wire quality

A noisy electrical environment

The number of devices on the bus

These conditions may require using a lower baud rate.

FUNCTION 39

Press ENTER. The baud rate number will blink. Use the UP and DOWN arrows to toggle

between 009600 and 019200. Press ENTER again to select the baud rate and stop the

display from blinking.

Press DOWN to advance to Parameter 40 - Parity and Stop Bits.

D. PARITY AND STOP BITS

The parity/stop bits parameter of the Modbus adapter must be set to match the rest of the devices on the bus. Although it is common to

set serial devices to use no parity, setting the parity to even or odd may improve communications reliability on all connected devices on

the bus.

This parameter has 4 possible selections which should be sufficient to establish communication with other devices. These selections

are outlined in Table 6.

9

Table 6 – Parameter 40 Settings

FUNCTION 40

Press ENTER. The STOP/PARITY value will blink. Use the UP and DOWN arrows to

toggle between 1 ST, 2 ST, E PA, and O PA. Make your selection based on the table

above. Press ENTER again to select the STOP/PARITY value and stop the display from

blinking.

Configuration is now complete. Press RESET to permanently store ALL the Modbus settings.

PART 5 – GENERAL MODBUS INFORMATION

A. DATA TRANSMISSION MODE

Many Modbus master devices can be configured to transmit data in either RTU or ASCII modes. Since RTU messages use fewer data

bits and are more efficient, RTU has been chosen for all communication with the Modbus adapter. Please ensure that the master

device is configured for RTU communications.

B. MODBUS BOARD DIAGNOSTICS

The Modbus board is equipped with three LEDs for visual diagnostics: Two yellow and one green. These LEDs are located under the

Modbus cover. One yellow LED (D5) is used to indicate reception of data. The other yellow LED (D6) is used to indicate transmission of

data. The green LED (D7) shows internal faults. See Figure 4 for LED locations.

Internal Faults (Green LED):

Normal Operation = 1 second on, 1 second off

Controller Fault = Continuously on

No Burner Control Communication = 0.5 seconds on, 1.5 seconds off

No Modbus Communication = 1.5 seconds on, 0.5 seconds off

Page 10

10

FUNCTION

SUB FUNCTION

HEX

DESCRIPTION

DEC

HEX

DEC

1

01

Read coil status

2

02

Read input status

3

03

Read holding registers

4

04

Read input registers

5

05

Force single coil

6

06

Preset single register

7

07

Read exception status

8

08 0 00

Diagnostic – Return query data

1

01

Diagnostic – Restart communication

2

02

Diagnostic – Return diagnostic register

4

04

Diagnostic – Force listen mode

10

0A

Diagnostic – Clear counters and diagnostic registers

11

0B

Diagnostic – Return bus message count

12

0C

Diagnostic – Return bus exception error count

13

0D

Diagnostic – Bus exception error count

14

0E

Diagnostic – Return follower message count

15

0F

Diagnostic – Return communication error count

16

10

Diagnostic – Return follower NAK count

Figure 4 – Modbus Diagnostic LEDs

C. MODBUS COMMUNICATION

The Modbus communication commands can be found in Parts 3 and 4 of this manual, and exception codes supported by the

communication board can be found in Part 5, Section E.

D. MODBUS FUNCTION SET

Page 11

FUNCTION

SUB FUNCTION

HEX

DESCRIPTION

DEC

HEX

DEC

17

11

Diagnostic – Return follower busy count

18

12

Diagnostic – Return bus character overrun count

20

14

Diagnostic – Clear overrun counter and flag

11

0B

Get communication event counter

12

0C

Get communication event log

15

0F

Write multiple coils

16

10

Write multiple registers

17

11

Report follower ID

22

Mask write register

23

17

Write multiple registers

24

Read FIFO Queue

CODE

NAME

MEANING

01

ILLEGAL FUNCTION

This code is received when an illegal action is entered into the building management

system. This may be because the function code is only applicable to newer devices,

or the follower device is in the wrong state to process a request of this type.

02

ILLEGAL DATA ADDRESS

This code is received when an illegal data address is entered into the building

management system. More specifically, the combination of reference number and

transfer length is invalid.

03

ILLEGAL DATA VALUE

This code indicates that an illegal value has been entered into the building

management system.

04

FOLLOWER DEVICE FAILURE

An error occurred while the follower was attempting to perform the requested action.

05

ACKNOWLEDGE

Indicates that the server (or follower) has accepted the request, but will take a

significant amount of time to process it. This response prevents a timeout error.

06

FOLLOWER DEVICE BUSY

This is received when a follower device is busy processing a programmed command.

User should query this device at a later time.

08

MEMORY PARITY ERROR

The server (or follower) attempted to read a file, but detected a parity error in the

memory. The user can retry the request, but service may be necessary to fix this

error.

0A

GATEWAY PATH UNAVAILABLE

Indicates that the gateway was unable to allocate an internal communication path

from the input port to the output port.

0B

GATEWAY TARGET DEVICE

FAILED TO RESPOND

Specialized use in conjunction with gateways - indicates that no response was

obtained from the target device. Usually means that the device is not present on the

network.

TABLE

DATA TYPE

READ/WRITE

DESCRIPTION

Discrete Inputs

Single bit

Read only

Data can be provided by an I/O system.

Coils

Single bit

Read / Write

Data can be altered by an application program.

Input Registers

16-bit word

Read only

Data can be provided by an I/O system.

Holding Registers

16-bit word

Read / Write

Data can be altered by an application program.

ADDRESS

DESCRIPTION

DEFAULT

UNIT

MIN

MAX

RESOLUTION

COILS

00001

Appliance enable / Room

thermostat / Stage 1

0

1 = on, 0 = off

0

1

1

00005

Tank thermostat

0

1 = on, 0 = off

0

1

1

00006

Table 7 – Modbus function set

E. MODBUS EXCEPTION CODES

11

Table 8 – Modbus exception codes

PART 6 - REGISTER MAP

A. PRIMARY DATA TABLES

Table 9 – Supplementary information

B. APPLIANCE MEMORY MAP

Page 12

12

DISCRETE INPUTS

ADDRESS

DESCRIPTION

DEFAULT

UNIT

MIN

MAX

RESOLUTION

10001

Manual reset high limit 1

0

1 = on, 0 = off

0

1

1

10002

Flow switch 1

0

1 = on, 0 = off

0

1

1

10003

Gas pressure switch 1

0

1 = on, 0 = off

0

1

1

10004

Louver switch 1 (NOT USED)

0

1 = on, 0 = off

0

1 1 10005

Air pressure switch / flap valve

0

1 = on, 0 = off

0

1 1 10006

Blocked drain switch

0

1 = on, 0 = off

0

1 1 10007

Auto reset high limit 1

0

1 = on, 0 = off

0

1

1

10008

Flame 1

0

1 = on, 0 = off

0

1

1

10009

Enable / room thermostat / stage

1

0

1 = on, 0 = off

0

1

1

10010

Tank thermostat

0

1 = on, 0 = off

0

1

1

10011

Extra appliance signal

0

1 = on, 0 = off

0

1 1 10033

Run contacts

0

1 = on, 0 = off

0

1

1

10034

Alarm contact 1

(EXCEPT Versa-Hydro)

0

1 = on, 0 = off

0

1

1

10035

CH pump 1

0

1 = on, 0 = off

0

1

1

10036

DHW pump 1

0

1 = on, 0 = off

0

1 1 10038

Gas valve 1

0

1 = on, 0 = off

0

1 1 10039

System pump

0

1 = on, 0 = off

0

1

1

10049

Appliance 0 burning (same as

10008)

0

1 = on, 0 = off

0

1 1 10050

Appliance 1 burning (same as

10023)

0

1 = on, 0 = off

0

1

1

10051

Appliance 2 burning

0

1 = on, 0 = off

0

1 1 10052

Appliance 3 burning

0

1 = on, 0 = off

0

1 1 10053

Appliance 4 burning

0

1 = on, 0 = off

0

1

1

10054

Appliance 5 burning

0

1 = on, 0 = off

0

1

1

10055

Appliance 6 burning

0

1 = on, 0 = off

0

1

1

10056

Appliance 7 burning

0

1 = on, 0 = off

0

1

1

10057

Appliance 0 lockout (same as

10034)

0

1 = on, 0 = off

0

1

1

10058

Appliance 1 lockout (same as

10042)

0

1 = on, 0 = off

0

1

1

10059

Appliance 2 lockout

0

1 = on, 0 = off

0

1

1

10060

Appliance 3 lockout

0

1 = on, 0 = off

0

1

1

10061

Appliance 4 lockout

0

1 = on, 0 = off

0

1 1 10062

Appliance 5 lockout

0

1 = on, 0 = off

0

1 1 10063

Appliance 6 lockout

0

1 = on, 0 = off

0

1 1 10064

Appliance 7 lockout

0

1 = on, 0 = off

0

1

1

10065

Alarm relay

(Versa-Hydro ONLY)

0

1 = on, 0 = off

0

1

1

INPUT REGISTERS

30001

Discrete inputs 1 - 16

0

NA

0

65535

1

30002

Discrete inputs 17 – 32

0

NA

0

65535

1

30003

Discrete inputs 33 – 48

0

NA

0

65535

1

30004

System / cascade set point /

system pump speed / PUMP 4

0

Deg F

0

212

0, 1

30005

SPEED 0 %

0

100

1

30006

Cascade total power

0

%

0

800

1

30007

Cascade current power

0

%

0

800 1 30008

Outlet set point 0

0

Deg F

-76

212

0, 1

30009

Outlet temp 0

0

Deg F

-76

266

0, 1

30010

Inlet temp 0

0

Deg F

-76

266

0, 1

30011

Flue temp 0

0

Deg F

0

266

0, 1

30012

Firing rate 0 / Appliance 0 pump

speed / Pump 5

0

%

0

100

0, 1

30013

SPEED 0 %

0

100

1

30014

Appliance 0 status code

0

NA

0

65535

30015

Appliance 0 blocking code

0

NA

0

65535 30016

Appliance 0 lockout code

0

NA

0

65535 30017

Outlet set point 1

0

Deg F

-76

212

0, 1

Page 13

13

ADDRESS

DESCRIPTION

DEFAULT

UNIT

MIN

MAX

RESOLUTION

30018

Outlet temp 1

0

Deg F

-76

266

0, 1

30019

Inlet temp 1

0

Deg F

-76

266

0, 1

30020

Flue temp 1

0

Deg F

-76

266

0, 1

30021

Firing rate 1 / Appliance 1 pump

speed / Pump 4

0

%

0

100

0, 1

30022

OUTPUT 0 %

0

100

1

30023

Appliance 1 status code

0

NA

0

65535

30024

Appliance 1 blocking code

0

NA

0

65535 30025

Appliance 1 lockout code

0

NA

0

65535 30026

Appliance 2 outlet temperature

0

Deg F

-76

266

0, 1

30027

Appliance 2 firing rate

0

%

0

100

1

30028

Appliance 2 status

0

NA

0

65535

30029

Appliance 2 lockout code

0

NA

0

65535 30030

Appliance 3 supply temperature

0

Deg F

-76

266

0, 1

30031

Appliance 3 firing rate

0

%

0

100 1 30032

Appliance 3 status

0

NA

0

65535

30033

Appliance 3 lockout code

0

NA

0

65535

30034

Appliance 4 supply temperature

0

Deg F

-76

266

0, 1

30035

Appliance 4 firing rate

0

%

0

100

1

30036

Appliance 4 status

0

NA

0

65535 30037

Appliance 4 lockout code

0

NA

0

65535

30038

Appliance 5 supply temperature

0

Deg F

-76

266

0, 1

30039

Appliance 5 firing rate

0

%

0

100

1

30040

Appliance 5 status

0

NA

0

65535

30041

Appliance 5 lockout code

0

NA

0

65535 30042

Appliance 6 supply temperature

0

Deg F

-76

266

0, 1

30043

Appliance 6 firing rate

0

%

0

100 1 30044

Appliance 6 status

0

NA

0

65535

30045

Appliance 6 lockout code

NA

0

65535

30046

Appliance 7 supply temperature

0

Deg F

-76

266

0, 1

30047

Appliance 7 firing rate

0

%

0

100 1 30048

Appliance 7 status

0

NA

0

65535 30049

Appliance 7 lockout code

0

NA

0

65535

30050

Discrete inputs 49 - 64

0

NA

0

65535

30051

NTC 6 temperature

0

Deg F

-76

266

0, 1

30052

NTC 7 temperature

0

Deg F

-76

266

0, 1

30053

Solar Panel temperature

0

Deg F

-76

266

0, 1

30054

Solar flow 0 LPM

0

100

0, 1

30055

Solar temp

0

Deg F

14

248

0, 1

HOLDING REGISTERS

40001

Configuration

See below

40002

Coils

40003

0 – 10 volt / rate / set point CMD

V 0

248

0, 1

40004

Tank set point

Deg F

0

10

0, 1

40005

Tank temperature

Deg F

-76

212

0, 1

40006

Outdoor temperature

Deg F

-76

266

0, 1

40007

System supply temperature

Deg F

-76

266

0, 1

40008

System return temperature

Deg F

266 40009

I4 for direct mode

20

Deg F

0

36

0, 1

40010

CH post purge

0

Seconds

0

255

1

40011

DH post purge

0

Seconds

0

255

1

40012

Solar Pump speed

0

%

0

100

0, 1

40014

Extra 0 – 10 volt output

0

%

0

100

0, 1

BLOCKING CODES (INPUT REGISTERS 30015 AND 30024)

NUMBER

DEFINITION

0

None

11

water pressure low

Table 10 – Modbus memory map

NOTE: Use Blocking Codes and Lockout Codes to interpret remote boiler operating conditions.

C. BLOCKING CODES

Page 14

NUMBER

DEFINITION

12

S1 temperature high

13

S2 temperature high

14

Flue temperature high

16

Regulation temperature high

17

Not enough water flow

21

Anti-cycling CH

23

max flue pressure switch/ max start cycles

25

Max temperature increase limiting CH

26

24 V to low

30

Water level low 1

31

Water level high 1

32

Water level low 2

33

Water level high 2

LOCKOUT CODES (INPUT REGISTERS 30016, 30025, 30029, 30033, 30037, 30041, 30045, AND 30049)

NUMBER

DEFINITION

240

Flue thermostat open

239

Safety thermostat open

237

False Flame

236

APS stuck open

235

APS stuck closed

233

No flame after ignition

232

No flame during running

230

Fan fault

204

Parameters damaged

205

Parameters programmed

206

Error during programming

207

Parameter EEPROM failure

190

S1 maximum temperature

191

S2 maximum temperature

192

S1 shorted

193

S1 interrupted

194

S2 shorted

195

S2 interrupted

196

Low water lockout

197

Flue sensor shorted

198

Flue sensor interrupted

199

Low water lockout 2

185

ECS6 temperature lockout

186

ECS7 temperature lockout

STATUS CODES (INPUT REGISTERS 30014, 30023, 30028, 30032, 30036, 30040, 30044, AND 30048)

NUMBER

DEFINITION

0

Standby

96

Running

100

DHW Mode or Blocking for Cascade

101

Low Water Blocking

Table 11

D. LOCKOUT CODES

14

Table 12

E. STATUS CODES

Table 13

F. CONFIGURATION BITS

Address 40001 contains configuration bits sent from the BAS to the appliance. These bits tell the appliance to use its own internal

inputs, or inputs from the BAS. When a bit is set to 1, the appliance will ignore the corresponding value contained internally and expect

the BAS to write that value into the holding registers.

The configuration bits are as follows:

Page 15

HOLDING REGISTER 40001

DEFINITION

0 = TAKEN FROM CONTROL

1 = TAKEN FROM MODBUS

B0

Boiler enable

0/1

B1

Tank enable

0/1

B2

Rate command / 0 – 10V input / set point command (40003)

0/1

B3

DHW set point (40004)

0/1

B4

DHW temperature (40005)

0/1

B5

Outdoor temperature (40006)

0/1

B6

System supply temperature (40007)

0/1

B7

System return temperature (40008)

0/1

B8

I4 offset (40009)

0/1

B9

CH post purge (40010)

0/1

HOLDING REGISTER 40001

DEFINITION

0 = TAKEN FROM CONTROL

1 = TAKEN FROM MODBUS

B10

DHW post purge (40011)

0/1

B11

Pump 4 speed (40012)

0/1

B12

Pump 5 speed (40013)

0/1

B13

Extra 0 – 10 V output (40014)

0/1

HOLDING REGISTER 40002

DEFINITION

Coil 01 b0

Room thermostat Coil 05 b4

Tank thermostat

HOLDING REGISTERS

DEFINITION

VALUE

ACTION

40001

Configuration

00 01

Set configuration to read 40002

40002

Coils

00 01

Enables CH Demand (00 00 disables demand)

40002

Coils

00 10

Enables DHW demand on appliance (00 00 disables demand)

40002

Coils

00 11

Enables both CH and DHW demand. DHW demand will have priority

Table 14 – Modbus holding registers

PART 7 - APPLIANCE OPERATION

15

A. APPLIANCE OPERATION WITH MODBUS COMMUNICATIONS

The appliance is equipped with a Modbus communication timer. Timeout is set for four minutes. The purpose of the timer is to ensure

proper temperature data is communicated to the appliance in a timely manner.

Additionally, the communication timer will provide fail safe operation should Modbus communication be lost. This timer will cause the

appliance to revert back to internal appliance controls should the Modbus communication be interrupted longer than the Modbus timer.

The timer resets every time a Modbus write command is received with updated temperatures or commands.

The master should update temperature registers at least once per minute, but no more than once per second.

B. EXAMPLE #1

In this configuration, the appliance is controlled by setting the set points locally on the appliance and providing an enable signal through

Modbus communications.

All sensors and limiting devices (excluding the thermostat enable and tank thermostat enable signals, which will be sent to the

appliance via Modbus) should be hardwired to the proper terminals in the appliance.

The holding registers need to be set as follows:

Table 15

C. EXAMPLE #2

1. SEND FIRING RATE COMMAND FROM MASTER

In this configuration, the appliance is controlled by setting the modulation set point from 0 – 100%. Rate command will be 0 – 100% of

the modulation range. All sensors and limiting devices (excluding the 0 – 10 Vdc signal, which will be sent to the Modbus) should be

hardwired to the terminal strip on the back of the appliance.

For this command to function on Munchkin and Mod Con models, set Installer Parameter 16 at 2 and Installer Parameter 17 at 1. On

Elite models, Function 16, Optional Input must be set to 0-10 volt and Function 17 0-10 volt function must be set on Temperature.

The holding registers need to be set as follows:

Page 16

16

HOLDING REGISTERS

DEFINITION

VALUE

ACTION

40001

Configuration

00 04

Set configuration to read 40003

40003

Rate Command

00 00

Sets modulation %

HOLDING REGISTERS

DEFINITION

VALUE

ACTION

40001

Configuration

00 1A

Set configuration to read 40002, 4 and 5

40002

Coils

00 10

Enables tank Tstat (00 00 disables appliance)

40004

Tank set point

0# ##

Sets set point

40005

Tank Temperature

0# ##

Passes tank temp from remote sensor

Table 16

Register 40003 needs to receive the rate command as follows: Acceptable rang is 0 to 100. Value needs to be greater than 15

for the boiler to fire. When the command is 16, the boiler will run at minimum fan speed (firing rate). When the command is

100 the boiler will run at max fan speed (firing rate). If the command value is anywhere between 16 and 100, the boiler will run

at a fan speed proportional to the command sent between minimum and maximum firing rates.

NOTE: To ensure proper operation, resend the configuration bits to holding register 40001 prior to issuing a command. For proper

hexadecimal conversion of rate percentage, please refer to the rate and temperature conversion section of this manual.

2. SEND TEMPERATURE COMMAND FROM MASTER

In this configuration, the appliance is controlled by setting the boiler temperature via the Modbus adapter. The temperature range is the

range of the value of Installer Parameter 12 (all except Elite) or Function 12 Min Boiler Temp on the Elite, and the temperature setting

of the CH value on the User Menu (all except Elite) or CENTRAL HEAT setting on the Elite. All sensors and limiting devices (excluding

the 0-10 Vdc signal, which will be sent to the Modbus) should be hardwired to the terminal strip on the appliance.

For this command to function on Munchkin and Mod Con models, Installer Parameter 16 needs to be set at 2 and Installer Parameter

17 needs to be set at 0. On Elite models, Function 16, Optional Input must be set to 0-10 volt and Function 17 0-10 volt function must

be set on Temperature.

NOTE: The holding registers are same as above, in Table 15.

Register 40003 needs to receive the rate command as follows: Acceptable rang is 0 to 100. Value needs to be greater than 15

for the boiler to fire. When the command is 16, the boiler will run at minimum temperature (value of Installer Parameter 12

above). When the command is 100 the boiler will run at maximum temperature (CH temperature above). If the command value

is anywhere between 16 and 100, the boiler will run at a temperature proportional to the command sent between minimum and

maximum temperatures described above.

NOTE: To ensure proper operation, resend the configuration bits to holding register 40001 prior to issuing a command. For proper

hexadecimal conversion of rate percentage, please refer to the rate and temperature conversion section of this manual.

D. EXAMPLE #3 – HOT WATER GENERATION

Hot water generation can be accomplished using one of two methods when an appliance is connected to a BAS system, DHW with

direct control, and DHW with remote control.

DHW WITH DIRECT CONTROL

This is the typical installation with a hot water generator in close proximity to the appliance with the tank thermostat, or tank temperature

sensor, wired to the terminal strip of the appliance

DHW WITH REMOTE CONTROL

This installation may or may not have the hot water generator in close proximity to the appliance. Its sensors and thermostat values are

only available through the Modbus communication bus.

To ensure that the appliance can properly respond to a call for hot water generation, the following holding registers must be set in

addition to other commands:

Table 17

NOTE: To ensure proper operation, resend the configuration bits to holding register 40001 prior to issuing a command. For proper

hexadecimal conversion of rate percentage, please refer to the rate and temperature conversion section of this manual.

E. CASCADE

In order to operate the appliance in cascade with Modbus communications, configure the master appliance. Connect the remaining

appliances in the cascade through the normal cascade communications wiring. Cascade control can then be accomplished

automatically through the master appliance.

Page 17

17

RATE %

HEX

0

00

20

14

45

2D

60

3C

80

50

95

5F

100

64

PARAMETER

DEFAULT VALUES

DEFAULT

Deg C

Deg F

Voltages

BMS temperature set point at low analog input

21

69.8

2

BMS temperature set point at high analog input

82

179.6

10

Please note that with Modbus communication connected only to the master appliance, only total cascade information can be seen

through the communications link. Information from the follower boilers is limited to follower appliance rate command, supply

temperature, fault code, and fault status.

If you want to see complete data from each follower, or use the Modbus master to control cascading of multiple appliances, each

appliance will need a Modbus communication board.

Monitoring Only

Any appliance can be equipped with the Modbus communication accessory and then be set up to operate with its own internal controls.

The Modbus master can then poll the Modbus accessory for the read only variables.

F. RATE AND TEMPERATURE CONVERSIONS

Rate

When issuing a rate command, the rate can be communicated as percent modulation or a desired set point temperature depending on

the setting of parameter 16 in the appliance Installer Menu. Proper data format for the modulation percentage is direct conversion to

hexadecimal. This conversion can be accomplished through online number based converters or some scientific calculators.

For example:

Table 18

Temperature Conversions

To send a desired set point, the hexadecimal value must be determined through linear interpolation of programmable parameters on

the BMS setup menu.

BMS temperature set point at low analog input

BMS temperature set point at high analog input

These variables set the temperature values corresponding to the minimum and maximum voltage settings of the 0 – 10 volt signal. The

defaults are as follows:

Table 19

For example: Send a set point of 110oF. The formula to use for the interpolation is:

Rate Command =

(Desired set point – BMS temp at low analog input) (High voltage – low voltage) + Low voltage

(BMS temp at high analog input – BMS temp at low analog input)

From the default values:

Desired set point = 110

BMS temp at low analog input = 68

BMS temp at high analog input = 158

High voltage = 10

Low voltage = 2

[(110 - 69.8)(10-2)/(179.6 - 69.8)] + 2 = 4.92 volts

(4.92/10) x 100 = 49.2

49 = 31 Hexadecimal

A value of [00] [31] in hexadecimal would be written to holding register 40003 to issue a command for a 110oF set point.

Page 18

Setpoint

Hex

Setpoint

Hex

Setpoint

Hex

Setpoint

Hex

68

12

101

2A

134

42

167

5A

69

13

102

2B

135

43

168

5B

70

14

103

2C

136

44

169

5C

71

14

104

2C

137

44

170

5D

72

15

105

2D

138

45

171

5D

73

16

106

2E

139

46

172

5E

74

17

107

2F

140

47

173

5F

Setpoint

Hex Setpoint

Hex

Setpoint

Hex Setpoint

Hex

75

17

108

2F

141

47

174

5F

76

18

109

30

142

48

175

60

77

19

110

31

143

49

176

61

78

19

111

32

144

4A

177

62

79

1A

112

32

145

4A

178

62

80

1B

113

33

146

4B

179

63

81

1C

114

34

147

4C

180

64

82

1C

115

34

148

4C

83

1D

116

35

149

4D

84

1E

117

36

150

4E

85

1F 118

37 151

4F

MODBUS Register 40004 Setpoint Conversion Table

86

1F

119

37

152

4F

87

20

120

38

153

50

88

21

121

39

154

51

89

21

122

3A

155

52

90

22

123

3A

156

52

91

23

124

3B

157

53

92

24

125

3C

158

54

93

24

126

3C

159

54

94

25

127

3D

160

55

95

26

128

3E

161

56

96

27

129

3F

162

57

97

27

130

3F

163

57

98

28

131

40

164

58

99

29

132

41

165

59

100

2A

133

42

166

5A

DECIMAL HEX

805 325

The table below lists temperature to hexadecimal conversions.

18

Temperature

The Modbus adapter passes temperature data to the appliance in degrees Fahrenheit. Also, to accommodate decimal places, the

decimal value must be divided by 10. The data sent over the Modbus is passed as an unsigned 16 bit integer. This poses no problem

unless the data becomes negative, such as temperatures below zero. In this case, the compliment has to be calculated as follows:

Temperature to be sent over Modbus = -22oF. First multiply by 10. -22 X 10 = -220. Calculate compliment 65536-220 = 65316.

Decimal = 65316. Hex = FF24. Binary = 1111111100100100.

To read the outdoor temperature from the appliance, do the opposite. Read register 40006 and get 65316. Since this value is greater

than 32767, the temperature is negative. To calculate the negative value: 65536 – 65316 = 220, then 220/10 = 22. 22 X -1 = -22oF.

For example:

Outdoor temperature from remote sensor on BAS system = 80.5oF.

Table 20

Outdoor temperature from remote sensor on BAS system = -25oF. Data that needs to be transmitted is -25 X 10 = -250. 65536250=65286

Page 19

DECIMAL HEX

65286 FF06

DECIMAL HEX

1550 60E

STATUS CODES (INPUT REGISTERS 30014 AND 30023)

NUMBER

DEFINITION

0

standby

96

Running

100

DHW mode or blocking for Cascade

101

Low Water blocking

Table 21

Outlet temperature from appliance sensor = 155oF. 155oF X 10 = 1550.

Table 22

G. APPLIANCE STATUS CODES

The appliance displays an appliance state code on the building screen to help aid in troubleshooting. The appliance state indicates

what the appliance is actually doing. This state should be compared to the command issued and what is expected. If the appliance

state does not agree with the command, check communication and configuration.

Table 23

PART 8 - TROUBLESHOOTING

Should you encounter problems communicating over Modbus, the following items should be checked in this order.

1. Physical layer

2. Communications configuration and port settings

3. Modbus error codes

4. Appliance status / blocking / lockout codes

19

A. PHYSICAL LAYER

1. Verify the correct Modbus communication cable (twisted pair) is being used.

2. Check that all components have power (appliance, Modbus adapter, gateway, BAS master).

3. Check for broken wires.

4. Check A, B terminal connections.

5. Check for terminating resistors (120 ohms) at each end of the RS-485 bus only.

6. Check all wire lengths. Are any drops too long?

7. Check proper shield grounding.

B. COMMUNICATIONS

1. Verify controller is configured for MODBUS (AUTO or ON)

2. Check baud rate (9600, 19200).

3. Check parity.

4. Check Modbus address.

5. Check port setting on master, gateway, and computers.

6. Check the status of the LEDs, referring to the LED Diagnostics section below.

C. LED DIAGNOSTICS

There are two yellow LED’s and one green LED on the board that provide diagnostic information.

One of the yellow LED’s (D6) is used for indicating reception of data from Modbus and the other LED (D5) indicates transmission of

data to Modbus.

The green LED (D7) is used to show the following:

Internal Faults

Modbus Adapter fault: Continuously Bright

General Faults

No MODBUS (RS-485) communication: 1.5 second bright - 0.5 second off

No Burner Control (RS-232) communication: 0.5 second bright - 1.5 seconds off

In case both communication modes fail the LED will not be lit No Faults

Normal running: 1 second Bright and 1 second Dim

D. MODBUS ERROR CODES

1. Check Modbus communication error codes (see in Part 5, Section E in this manual for Modbus exception codes).

Page 20

20

2. Check Follower ID.

3. Check Modbus command.

4. Check configuration bits for holding register 40001.

5. Check commands and data for holding registers 40002 – 40007.

INSTALLATION AND MAINTENANCE NOTES

_________________________________________________________________________________________

Page 21

Customer’s Name:

Installation Address:

Date of Installation:

Installer’s Code/Name:

Product Serial Number(s):

Modbus Adapter Address (As Configured by the Installer)

Comments:

Installer’s Phone Number:

Signed by Installer:

Signed by Customer:

HTP CUSTOMER INSTALLATION RECORD FORM

The following form should be completed by the installer for you to keep as a record of the installation in case of a warranty claim. After

reading the important notes at the bottom of the page, please also sign this document.

21

IMPORTANT NOTES:

Customer: Please only sign after the installer has reviewed the installation, safety, proper operation and maintenance of the

system. In the case that the system has any problems, please call the installer. If you are unable to make contact, please

contact your HTP Sales Representative.

Distributor/Dealer: Please insert contact details.

LP-372 Rev. 6.14.13

Loading...

Loading...