Page 1

ENGLISH

User manual

Copyright HT ITALIA 2013 Release EN 2.00 - 02/01/2013

Page 2

Page 3

HT7052

Table of Content:

1 PRECAUTIONS AND SAFETY MEASURES .............................................................................. 2

1.1 Preliminary instructions ........................................................................................................................ 2

1.2 During use ............................................................................................................................................ 3

1.3 After use ............................................................................................................................................... 3

1.4 Definition of measurement (overvoltage) category .............................................................................. 3

2 GENERAL DESCRIPTION .......................................................................................................... 4

2.1 Instrument features .............................................................................................................................. 4

3 PREPARATION FOR USE .......................................................................................................... 5

3.1 Initial inspections .................................................................................................................................. 5

3.2 Instrument power supply ...................................................................................................................... 5

3.3 Calibration ............................................................................................................................................ 5

3.4 Storage ................................................................................................................................................. 5

4 DESCRIPTION OF PARTS .......................................................................................................... 6

4.1 Instrument description .......................................................................................................................... 6

4.2 Description of test leads ....................................................................................................................... 7

5 INITIAL OPERATIONS ................................................................................................................ 8

5.1 Switching on the instrument ................................................................................................................. 8

5.1.1 Mains powered instrument operation ................................................................................................ 8

5.1.2 Backlight operation ............................................................................................................................ 8

5.1.3 Autocalibration ................................................................................................................................... 8

5.2 Configuration and Setup of systems parameters ................................................................................. 9

6 HOW TO PERFORM THE MEASUREMENTS .......................................................................... 10

6.1 Theory of insulation resistance measurement ................................................................................... 10

6.1.1 Time dependence test – Diagnostic test ......................................................................................... 12

6.1.2 Withstanding voltage test ................................................................................................................ 15

6.2 Guard terminal .................................................................................................................................... 16

6.3 Use of internal filters ........................................................................................................................... 17

6.3.1 The purpose of filtering .................................................................................................................... 17

6.4 Voltage measurement ........................................................................................................................ 18

6.5 Insulation resistance measurement ................................................................................................... 19

6.5.1 Setting of parameters ...................................................................................................................... 19

6.5.2 Perform the measurement ............................................................................................................... 20

6.6 Diagnostic test .................................................................................................................................... 22

6.6.1 Setting of parameters ...................................................................................................................... 22

6.6.2 Perform the measurement ............................................................................................................... 23

6.7 Insulation resistance with step voltage test ........................................................................................ 25

6.7.1 Setting of parameters ...................................................................................................................... 25

6.7.2 Perform the measurement ............................................................................................................... 26

6.8 Withstanding voltage test ................................................................................................................... 28

6.8.1 Setting of parameters ...................................................................................................................... 28

6.8.2 Perform the measurement ............................................................................................................... 29

7 MANAGEMENT OF MEMORY DATA ....................................................................................... 30

7.1 Saving, recall and clear measurement results ................................................................................... 30

8 CONNECTION OF THE INSTRUMENT TO PC ........................................................................ 31

8.1 Installation of software and initial configurations (Win XP) ................................................................ 31

9 MAINTENANCE ......................................................................................................................... 33

9.1 General information ............................................................................................................................ 33

9.2 Replacement and charging batteries ................................................................................................. 33

9.3 Cleaning the instrument ..................................................................................................................... 33

9.4 End of life............................................................................................................................................ 33

10TECHNICAL SPECIFICATIONS ............................................................................................... 34

10.1Safety standards ................................................................................................................................ 35

10.2General characteristics ....................................................................................................................... 36

10.3Environment ....................................................................................................................................... 36

10.4Accessories ........................................................................................................................................ 36

11SERVICE ................................................................................................................................... 37

11.1Warranty conditions ............................................................................................................................ 37

11.2Service ................................................................................................................................................ 37

EN - 1

Page 4

HT7052

1 PRECAUTIONS AND SAFETY MEASURES

The instrument has been designed in compliance with standards IEC/EN61557-1 and

IEC/EN61010-1 regarding electronic measuring instruments

For the operator’s safety and to prevent damaging the instrument, follow the

procedures described in this manual and carefully read all notes preceded by

the symbol

Before and during measurements, carefully observe the following instructions:

Do not perform any measurement in humid environments, in the presence of gas or

explosive or inflammable material or in dusty areas

Even when no measurements are being performed, avoid any contact with the circuit

being tested, with exposed metal parts, with unused measuring leads or circuits, etc

Do not perform any measurement when anomalies are found in the instrument, such as

deformations, breaks, substance leaks, no display view, etc

Pay special attention when measuring voltages above 25V in special environments

(building yards, swimming pools, etc.) and 50V in ordinary environments, as there is the

danger of electric shocks

In this manual and on the instrument, the following symbols are used:

WARNING: Observe the instructions reported in the manual. An improper use

could damage the instrument and lead to dangerous situations for the operator

DC voltage or current

CAUTION

Dangerous voltages: risk of electric shocks

Instrument with double insulation

1.1 PRELIMINARY INSTRUCTIONS

This instrument has been designed for use in an environment with pollution level 2

It may also be used to test industrial electrical systems up to CAT IV 600V to earth with

maximum voltage 600V between inputs

Follow the usual safety rules to protect the operator from dangerous currents and

protect the instrument against improper use

Never use the instrument resting on the floor, it must be placed over flat horizontal

surfaces

Only the accessories supplied with the instrument guarantee safety standards. They

must be in good conditions and replaced, if necessary, with identical models

Do not measure systems exceeding the current and voltage limit values specified

Do not perform measurements in environmental conditions not within the limit values

indicated in this manual

Before connecting the probes to the circuit to be tested, check that the correct function

is selected

EN - 2

Page 5

HT7052

1.2 DURING USE

Carefully read the following recommendations and instructions:

CAUTION

Failure to observe the warnings and/or instructions may damage the

instrument and/or its components or generate a danger for the operator. If,

during use, the low battery symbol appears on the display, insert the supply

cable into the Europlug socket to start battery recharge. During battery

recharge, it is possible to perform measurements

Before selecting a new function, disconnect the measuring probes from the circuit

When the instrument is connected to the circuit being tested, never touch any unused

lead

Avoid measuring resistance with external voltages. Even if the instrument is protected,

as an excess voltage may cause instrument malfunctions

In case of a capacitive test object (long tested cable etc.), automatic discharge of the

object may not be done immediately after finishing the measurement – “Please wait,

discharging” message will be displayed

Handling with capacitive loads note that 40nF charged to 1kV or 5nF charged to 10 kV

are hazardous live

1.3 AFTER USE

When measurements are completed, turn off the instrument by pressing the ON/OFF key

1.4 DEFINITION OF MEASUREMENT (OVERVOLTAGE) CATEGORY

Standard "IEC/EN61010-1: Safety requirements for electrical equipment for measurement,

control and laboratory use, Part 1: General requirements", defines what is intended for

measurement category, commonly known as overvoltage category. In § 6.7.4: Measuring

circuits, it reads:

Circuits are divided into the following measurement categories:

Measurement category IV is for measurements performed at the source of a low-

voltage installation

Examples are electric counters and measurements on primary devices protecting

against overcurrents and on ripple adjusting units

Measurement category III is for measurements performed on installations inside

buildings

Examples are measurements performed on distribution boards, circuit breakers, wiring

harnesses, including cables, bars, junction boxes, switches, sockets of fixed

installations and appliances designed for industrial use and other equipment, e.g.

stationary motors connected to fixed systems

Measurement category II is for measurements performed on circuits directly

connected to the low-voltage installation

Examples are measurements performed on household appliances, portable tools and

similar equipment

Measurement category I is for measurements performed on circuits not directly

connected to the MAINS

Examples are measurements performed on circuits not derived from the MAINS and on

circuits derived from the MAINS provided with a special (internal) protection. In this

latter case, the stress caused by the transients is variable; therefore, (OMISSIS) it is

necessary that the user knows the appliance’s resistance to transients

EN - 3

Page 6

HT7052

2 GENERAL DESCRIPTION

The instrument HT7052 You purchased, if used in compliance with the indications given in

this manual, guarantees accurate and reliable measurements and the utmost safety

thanks to a development of new conception which ensures double insulation and,

consequently, compliance with the requirements of overvoltage category IV

2.1 INSTRUMENT FEATURES

High insulation resistance measurement up to 10 T

Programmable test voltage from 500V up to 10 kV, step 25 V

R(t) Graphs

Programmable timer (1s up to 30 min)

Automatic discharge of test object after completion of measurement

Capacitance measurement

Insulation resistance measurement with step-up voltage test

Five discrete test voltages proportionately set within preset test voltage range

Programmable timer 1 min up to 30 min per step

Polarization Index (PI), Dielectric Absorption ratio (DAR) and Dielectric Discharge (DD)

ratio measurements

PI = Rins (t2) / Rins (t1)

DAR = R1min / R15s

DD = Idis1min / C*U

Withstanding voltage (DC) up to 10 kV

Programmable ramp test voltage from 500 V up to 10 kV

High resolution ramp (approx. 25 V per step)

Programmable threshold current up to 5mA

Voltage and frequency measurement up to 600 V AC/DC

A dot matrix LCD offers easy-to-read results and all associated parameters. The operation

is straightforward and clear to enable the user to operate the instrument without the need

for special training (except reading and understanding this user manual)

Test results can be stored on the instrument. The new professional PC SW enables

straightforward transfer of test results and other parameters in both directions between the

test instrument and PC

EN - 4

Page 7

HT7052

3 PREPARATION FOR USE

3.1 INITIAL INSPECTIONS

Before shipment, the instrument’s electronics and mechanics have been inspected. All

possible precautions have been taken in order for the instrument to be delivered without

damage

However, we recommend generally inspecting the instrument in order to detect any

damage suffered during transport. Should you detect any anomalies, immediately contact

the forwarding agent or the dealer

Moreover, we recommend checking that the package contains all parts listed in § 10.4.

Should you find any discrepancy, please contact the dealer. Should it become necessary

to return the instrument, please follow the instructions reported in § 11

3.2 INSTRUMENT POWER SUPPLY

The instrument is power-supplied through 6x1.2V IEC LR20 NiMH internal rechargeable

batteries which are recharged from the mains by means of a battery charger integrated in

the instrument itself. The symbol “ “ illuminated in the left bottom part indicates that

the batteries are flat and must be recharged. To recharge or replace the batteries, follow

the instructions given in § 10.2

Use only NiMh rechargeable batteries (IEC LR20)

Connect the instrument to the mains power supply for 20 hours to fully

charge batteries (typical charging current is 600mA). When you charge the

batteries for the first time, it normally takes about 3 charge and discharge

cycles for the batteries to regain full capacity

CAUTION

3.3 CALIBRATION

The instrument complies with the technical specifications reported in this manual. Its

correct operation is guaranteed for one year from the date of purchase

3.4 STORAGE

In order to guarantee accurate measurements and protect the instrument from possible

failures, after a long storage period under extreme environmental conditions, wait for the

instrument to return to a normal condition (see the environmental specifications listed in §

0)

EN - 5

Page 8

HT7052

4 DESCRIPTION OF PARTS

4.1 INSTRUMENT DESCRIPTION

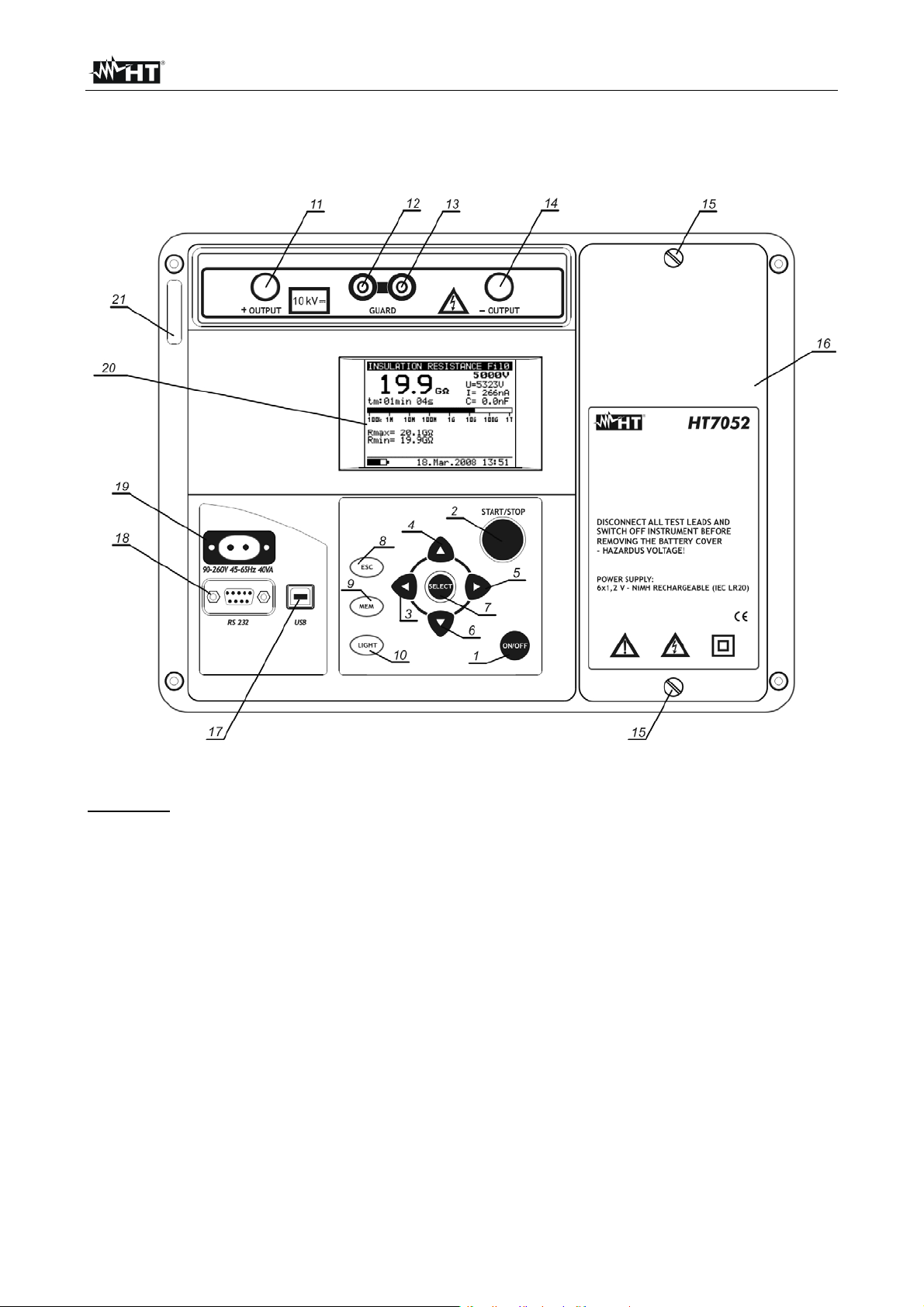

Fig. 1: Instrument description

LEGEND:

1 ON/OFF key to switch the instrument ON or OFF

2 START/STOP key to start or stop any measurement

3-4-5-6 , , , arrow keys to select parameters and set values

7 SELECT key to enter set-up mode parameters

8 ESC key to exit the selected mode

9 MEM key to store, recall and erase results

10 Light key to turn the display backlight ON or OFF

11 Positive insulation resistance test terminal +OUTPUT

12 -13 GUARD test terminals intended to lead away potential leakage current

14 Negative insulation resistance test terminal –OUTPUT

15 Screw to fixing battery cover

16 Battery cover

17 USB galvanic port for connection to PC

18 RS-232 galvanic port for connection to PC

19 Mains connector to connect the instrument to the mains supply

20 LCD display

21 Label with serial number of the instrument

EN - 6

Page 9

HT7052

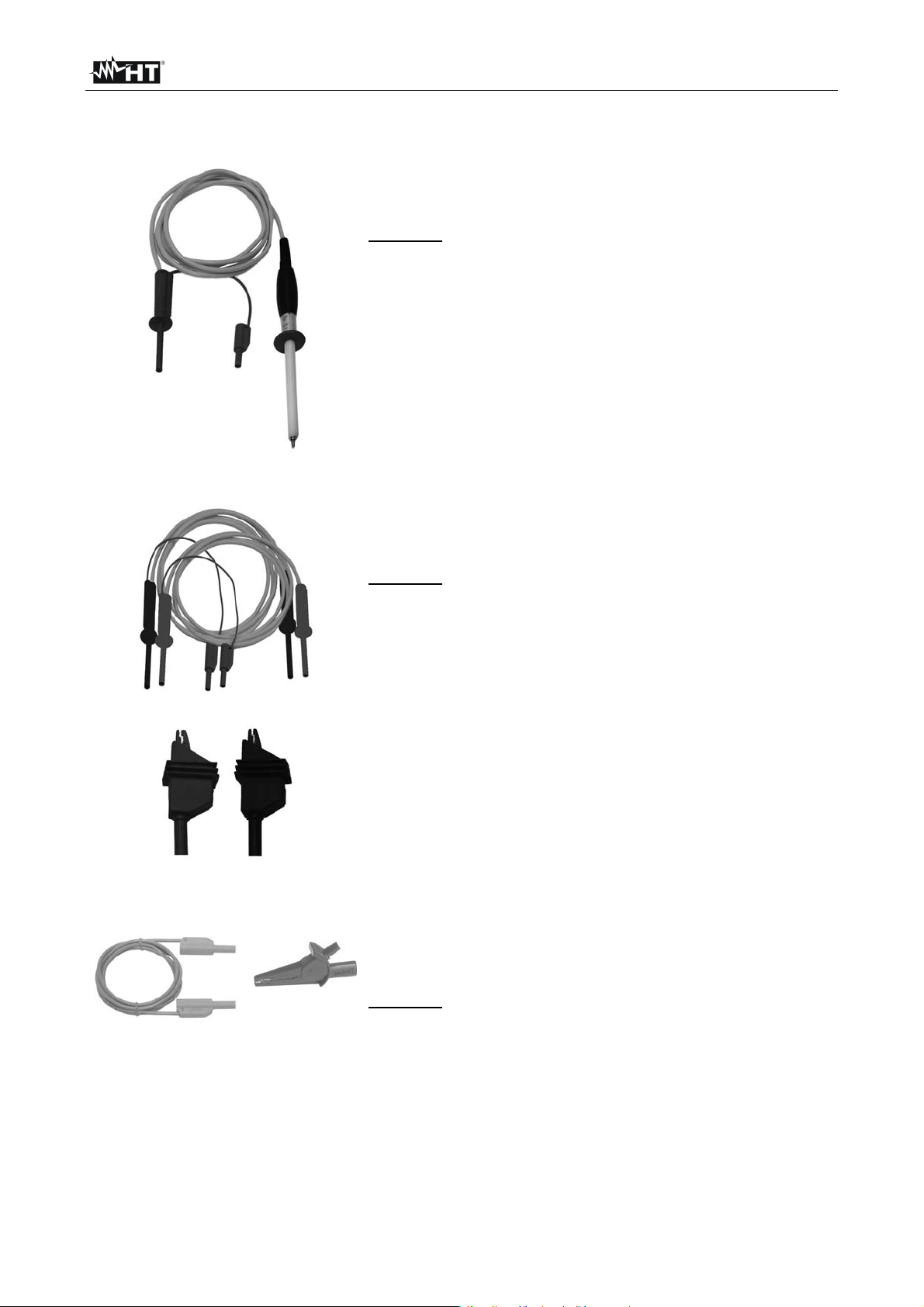

4.2 DESCRIPTION OF TEST LEADS

Test lead 1

This test lead is designed for hand held testing of

insulation resistance

Features

Shielded cable in order to increase the immunity to

external disturb and improve the accuracy of

measurements

Insulation of yellow shielded cable: 12kVDC

Length cable = 2m

Test lead with double insulation and protection

10kVDC

Red banana connector with basic protection 10kVDC

and double protection 5kVDC

Test leads 2

Guard test lead

Green guard banana connector: CAT IV 600V

These test leads is designed for diagnostic testing of

insulation

Features

Shielded cables in order to increase the immunity to

external disturb and improve the accuracy of

measurements

Insulation of yellow shielded cables: 12kVDC

Length cables = 2m

Red/black banana connectors with basic protection

10kVDC and double protection 5kVDC

Green guard banana connectors: CAT IV 600V

Red/Black alligator clips with basic protection

10kVDC and double protection 5kVDC

This test lead is used in connection with the object on

test in order to reduce or cancel the surface leakage

current (see § 6.2)

Features

Cable banana-banana with protection CAT IV 600V

Alligator clip CAT IV 600V

EN - 7

Page 10

HT7052

5 INITIAL OPERATIONS

5.1 SWITCHING ON THE INSTRUMENT

5.1.1 Mains powered instrument operation

If you connect instrument to the mains supply when instrument is turned

OFF, internal charger will begin to charge the batteries but instrument will

remain turned OFF. In button left angle of LCD, flashing battery indicator

will appear to indicate that the batteries are charging

If batteries are defective or missing and the instrument is connected

to the mains, the instrument do not switch on

If batteries are defective or missing, the charger will not work. In

button left corner of LCD screen only plug character will be appeared

If the instrument is connected to the mains supply when the instrument is

turn ON, the instrument will automatically switch from the battery supply to

the main supply. In button left corner of the LCD screen, the plug character

will appear

If instrument is not in measuring mode*, the internal charger will begin to

charge the batteries. In button left corner of LCD screen battery indicator

will start to flash, indicating that the batteries are charging

It is recommended to DO NOT connect or disconnect the instrument to

mains supply while the instrument is in measuring mode

5.1.2 Backlight operation

Instrument supplied by the batteries

After turning the instrument ON the LCD backlight is automatically turned ON. It can be

turned OFF and ON by simply clicking the LIGHT key

Instrument supplied by the mains

After turning the instrument ON the LCD backlight is automatically turned OFF. It can be

turned OFF and ON by simply clicking the LIGHT key

Auto power OFF

The instrument can be switched OFF only by pressing the ON/OFF key. The auto-off

function is not available to allow long-term measurements to be performed

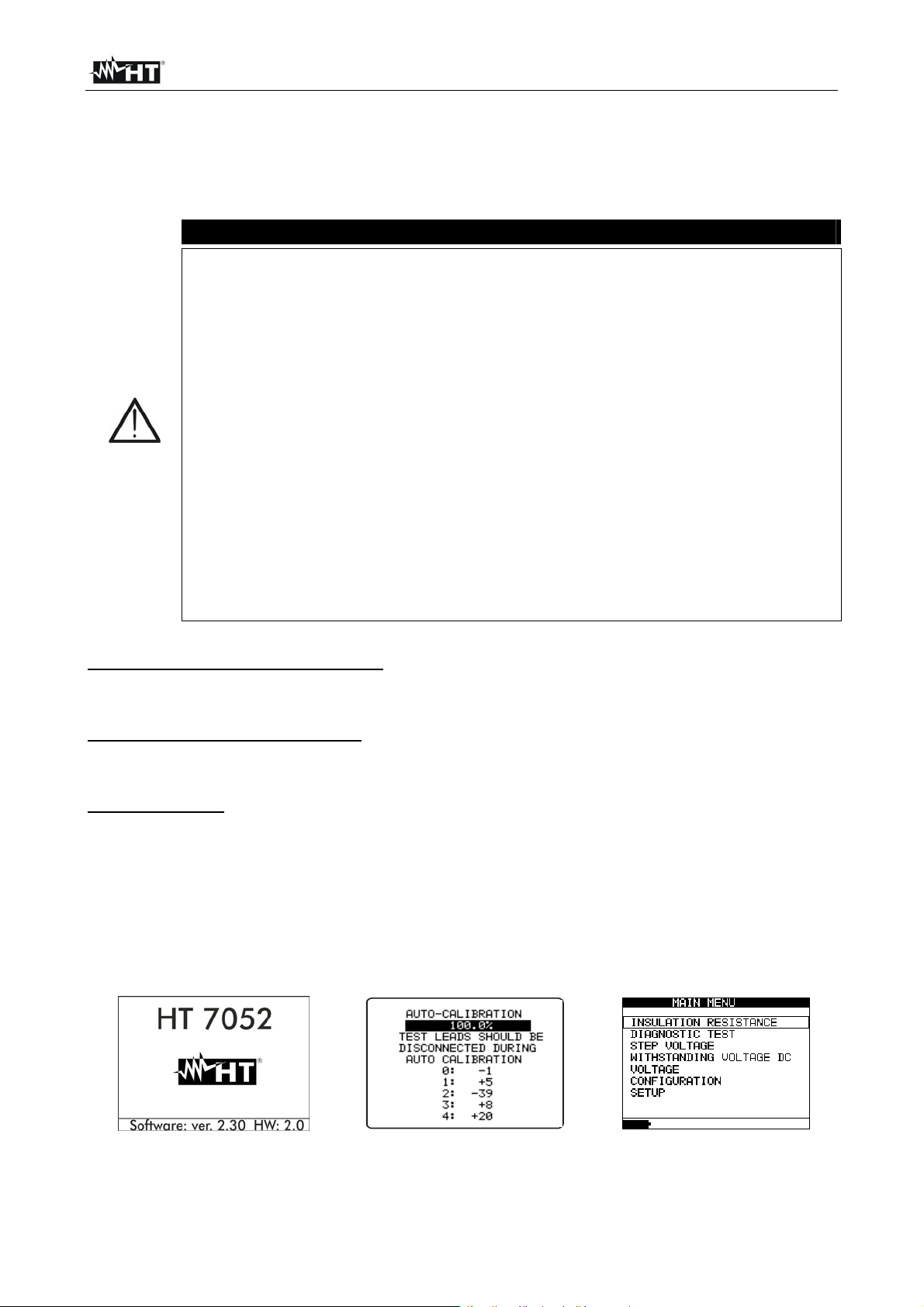

5.1.3 Autocalibration

The instrument is switched ON by pressing the ON/OFF key. After turning on, the

instrument will perform the autocalibration (see Fig. 3). Measuring test leads should be

disconnected during autocalibration. If not, the autocalibration procedure could be false

and instrument will require disconnection of the test leads and repeat switching OFF and

ON

CAUTION

Fig. 2: Spash screen Fig. 3: Autocalibration Fig. 4: Main menu

After finishing the autocalibration, the main menu (see Fig. 4) will appear and instrument

is ready for normal operation

EN - 8

Page 11

HT7052

Auto-calibration prevents the reduction in accuracy when measuring very low currents. It

compensates the effects caused by ageing, temperature and humidity changes etc. A new

auto-calibration is recommended when the temperature changes by more than 5C. If the

instrument detects an incorrect state during the autocalibration, the following warning

message will be displayed:

CAUTION

TEST LEADS CONNECTED: DISCONNECT AND SWITCH ON THE

INSTRUMENT AGAIN

CONDITIONS OUT OF RANGE: PRESS START TO CONTINUE

Possible reasons for out of range conditions are excessive humidity, excessively high

temperature, etc. In this case it is possible to perform measurements by pressing the

START/STOP button again but results could be out of technical specification

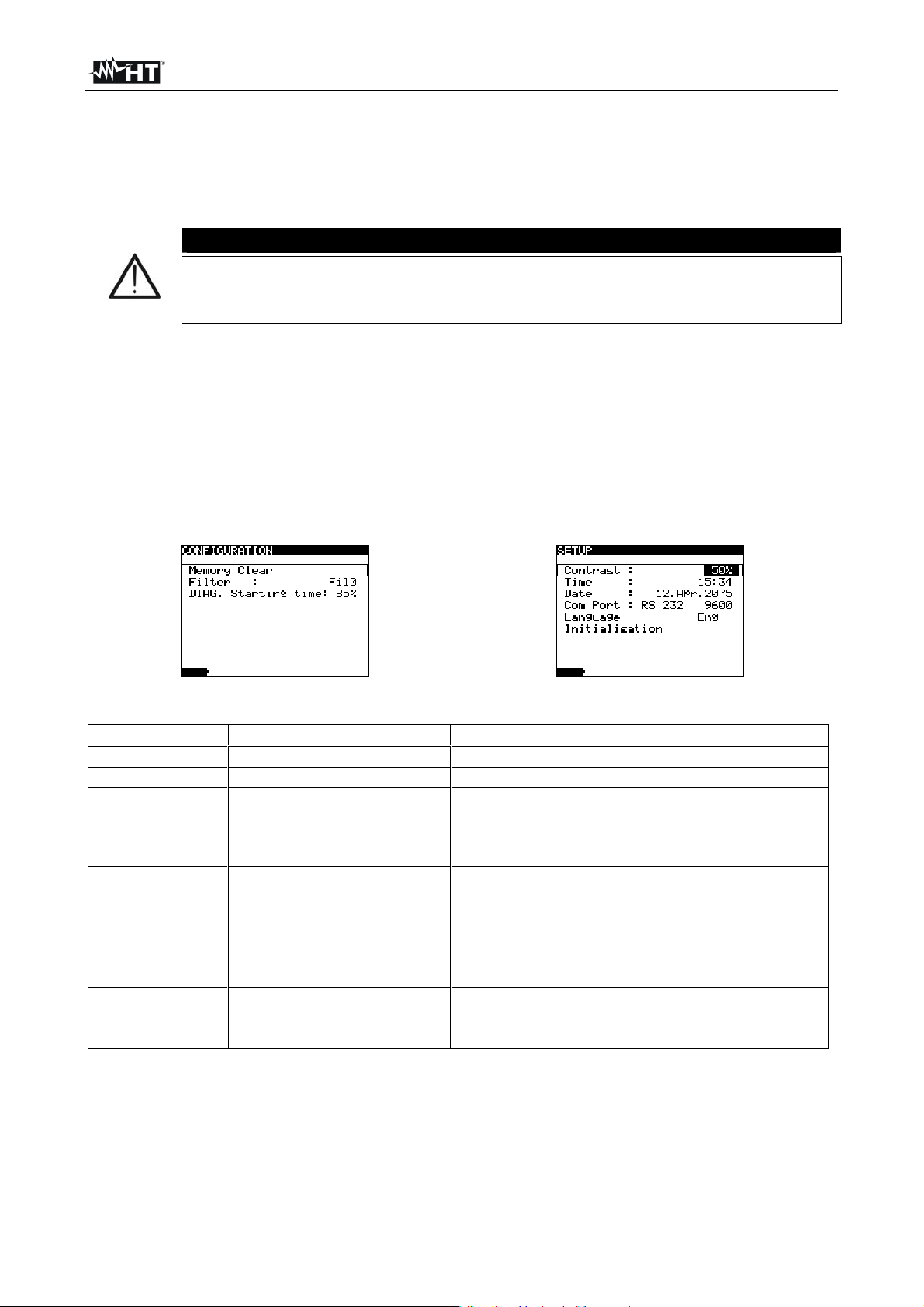

5.2 CONFIGURATION AND SETUP OF SYSTEMS PARAMETERS

The configuration and setup function enables the selection and adjustment of the

parameters (see Table 1) that are not directly involved in the measurement procedure (see

Fig. 5 and Fig. 6). In the lower section of the display the power supply status is shown

Fig. 5: Configuration menu Fig. 6: Setup menu

PARAMETERS VALUE DESCRIPTION

Memory clear

Filter

DIAG. Starting

time

Contrast

Time

Date

COM port

Language

Initialization

Fil1, Fil2, Fil3, Fil0 Selection of noise rejecting filter (see § 6.3)

RS232 2400, RS232 4800,

RS232 9600,RS232 19200,

USB 115000

Ita, Eng, Esp, Deu Set system language

Clear all memory locations

Adjustment of start of the timer in the

0%…90%

0%…100% Adjustment of the LCD contrast

Set real time (hour: minute)

Set current date (day-month-year)

For internal factory and service maintenance

DIAGNOSTIC TEST functions, according to the

nominal voltage Unominal. See additional

explanation in § 6.1)

Set communication mode and rate

only

Table 1: Configuration of system parameters

1. Use and arrows to select parameter (line) to be adjusted

2. Use or arrows to change the value of the selected parameter. If there are two or

more sub-parameters in one line (e.g. date and time) then use the SELECT key to skip

to the next sub-parameters and back

3. Press the ESC key to exit from configuration and back to the main menu

EN - 9

Page 12

HT7052

6 HOW TO PERFORM THE MEASUREMENTS

6.1 THEORY OF INSULATION RESISTANCE MEASUREMENT

The purpose of insulation tests

Insulating materials are important parts of almost every electrical product. The material’s

properties depend not only on its compound characteristics but also on temperature,

pollution, moisture, ageing, electrical and mechanical stress, etc. Safety and operational

reliability require the regular maintenance and testing of the insulation material to ensure it

is kept in good operational condition.

materials

DC vs. AC testing voltage

Testing with a DC voltage is widely accepted as being useful as testing with AC and / or

pulsed voltages. DC voltages can be used for breakdown tests especially where high

capacitive leakage currents interfere with measurements using AC or pulsed voltages. DC

is mostly used for insulation resistance measurement tests. In this type of test, the voltage

is defined by the appropriate product application group. This voltage is lower than the

voltage used in the withstanding voltage test so the tests can be applied more frequently

without stressing the test material

Typical insulation tests

In general, insulation resistance tests consist of the following possible procedures:

Simple insulation resistance measurement also called a spot test

Measurement of the relationship between voltage and insulation resistance

Measurement of the relationship between time and insulation resistance

Test of residual charge after the dielectric discharge

The results of this test can indicate whether the replacement of the insulation system is

required. Typical examples of where testing insulation resistance and its diagnosis are

recommended are transformer and motor insulation systems, cables and other electrical

equipment

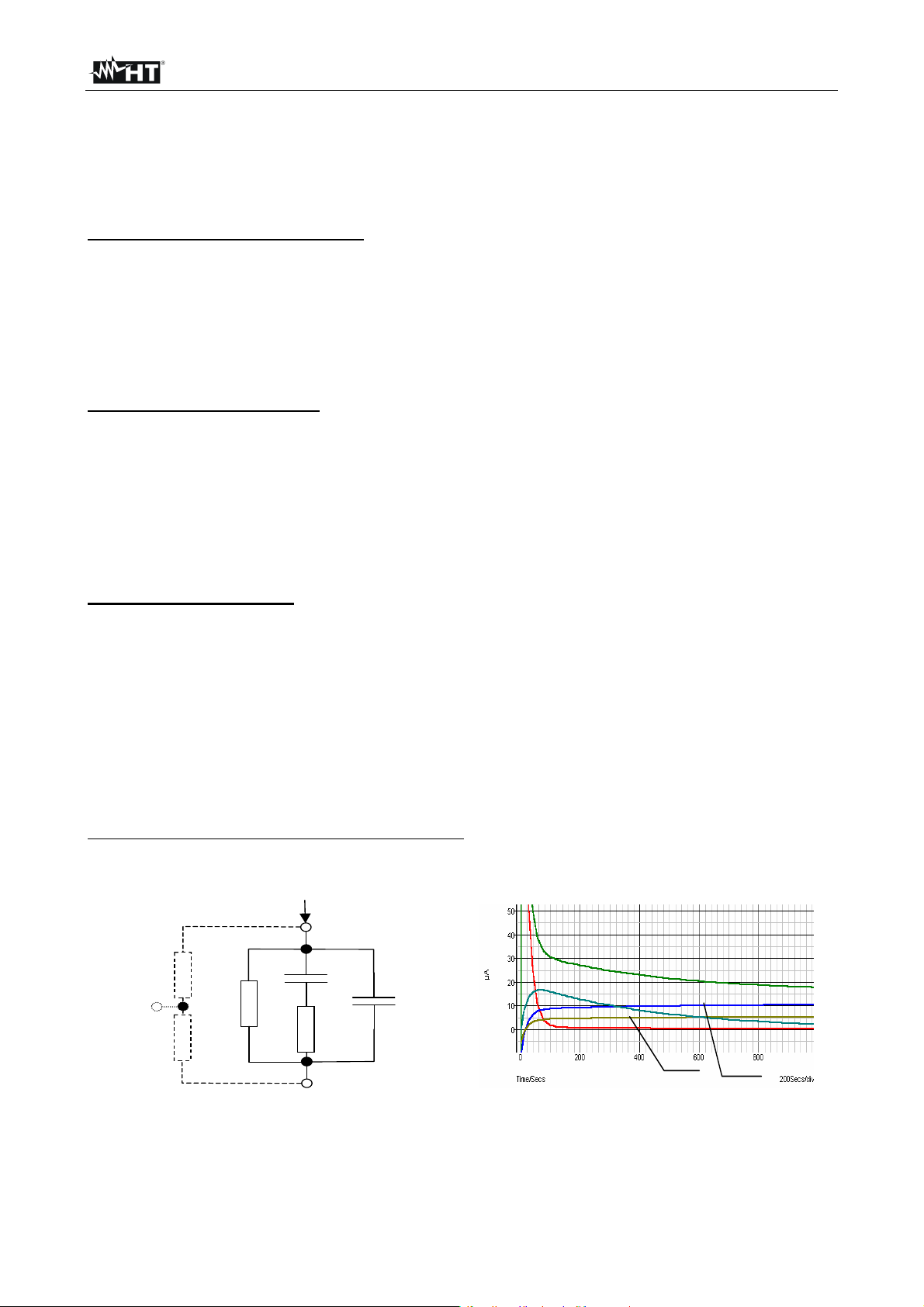

Electrical representation of insulating material

The represents the equivalent electrical circuit of an insulating material

Guard

surface

Riss1

Riso

Riss2

Itest

+

Rpi

-

material

Cpi

Fig. 7: Equivalent electrical circuit Fig. 8: Current graphs

High voltage tests are used to test insulating

t

Ites

IPI

Ciso

I

Ciso

I

I

Riso

Riss

EN - 10

Page 13

HT7052

R

, R

iss1

R

= the actual insulation resistance of material

iso

C

= capacitance of material

iso

Cpi, Rpi = represents polarization effects

The Fig. 8 shows typical currents for that circuit, where:

I

= overall test current (I

test

I

= polarization absorption current

PI

I

RISO

I

RISS

= surface resistivity (position of optional guard connection)

iss2

= IPI+ I

test

RISO

+ I

RISS

)

= actual insulation current

= surface leakage current

Basic Insulation resistance test

Virtually every standard concerning the safety of electrical equipment and installations

requires the performance of a basic insulation testing. When testing lower values (in the

range of M), the basic insulation resistance (R

) usually dominates. The results are

iso

adequate and stabilize quickly

It is important to remember the following:

The voltage, time and limit are usually given in the appropriate standard or regulation

Measuring time should be set to 60 s or the minimum time required for the Insulation

capacitance Ciso to be charged up

Sometimes it is required to take ambient temperature into account and adjust the result

for a standard temperature of 40C

If surface leakage currents interfere with the measurements (see Riss above) use the

guard connection (see § 5.2.). This becomes critical when measured values are in the G

range

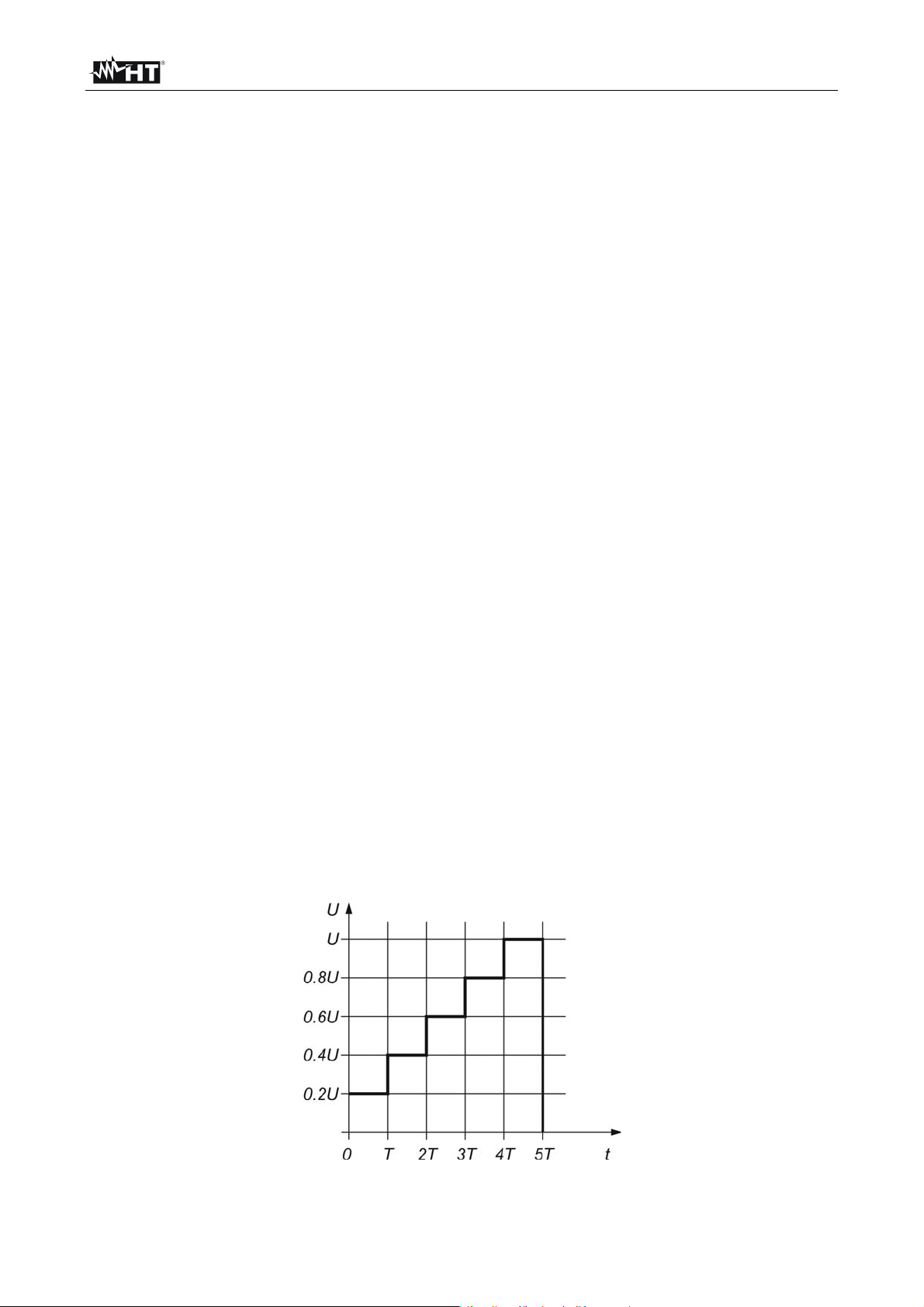

Voltage dependence test – Step voltage test

This test shows if the insulation under test has been electrically or mechanically stressed.

In this instance the quantity and size of insulation anomalies (e.g. cracks, local

breakdowns, conductive parts, etc). is increased and the overall breakdown voltage is

reduced. Excessive humidity and pollution have an important role especially in the case of

mechanical stress. If the results of successive tests show a reduction in the tested

insulation resistance the insulation should be replaced

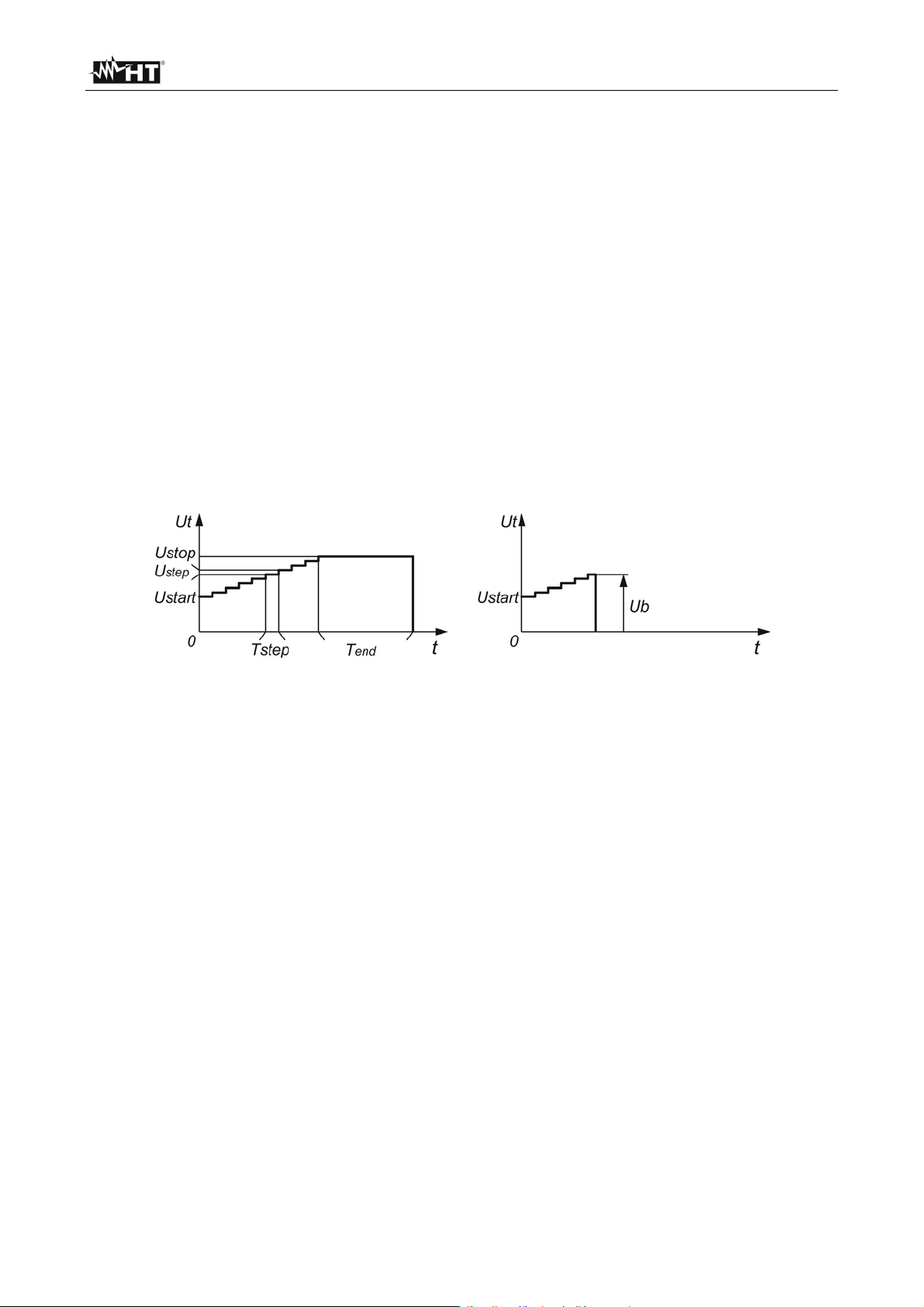

In this function the instrument measure the insulation resistance by considering 5 equal

time intervals with the test voltage divided from 1/5 of nominal value to the set nominal

value (see Fig. 9)

Fig. 9: Insulation measurement with step voltage test

EN - 11

Page 14

HT7052

R

6.1.1 Time dependence test – Diagnostic test

Diagnostic test is a long duration test for evaluating the quality of the insulation material

under test. The results of this test enable the decision to be made on the preventive

replacement of the insulation material

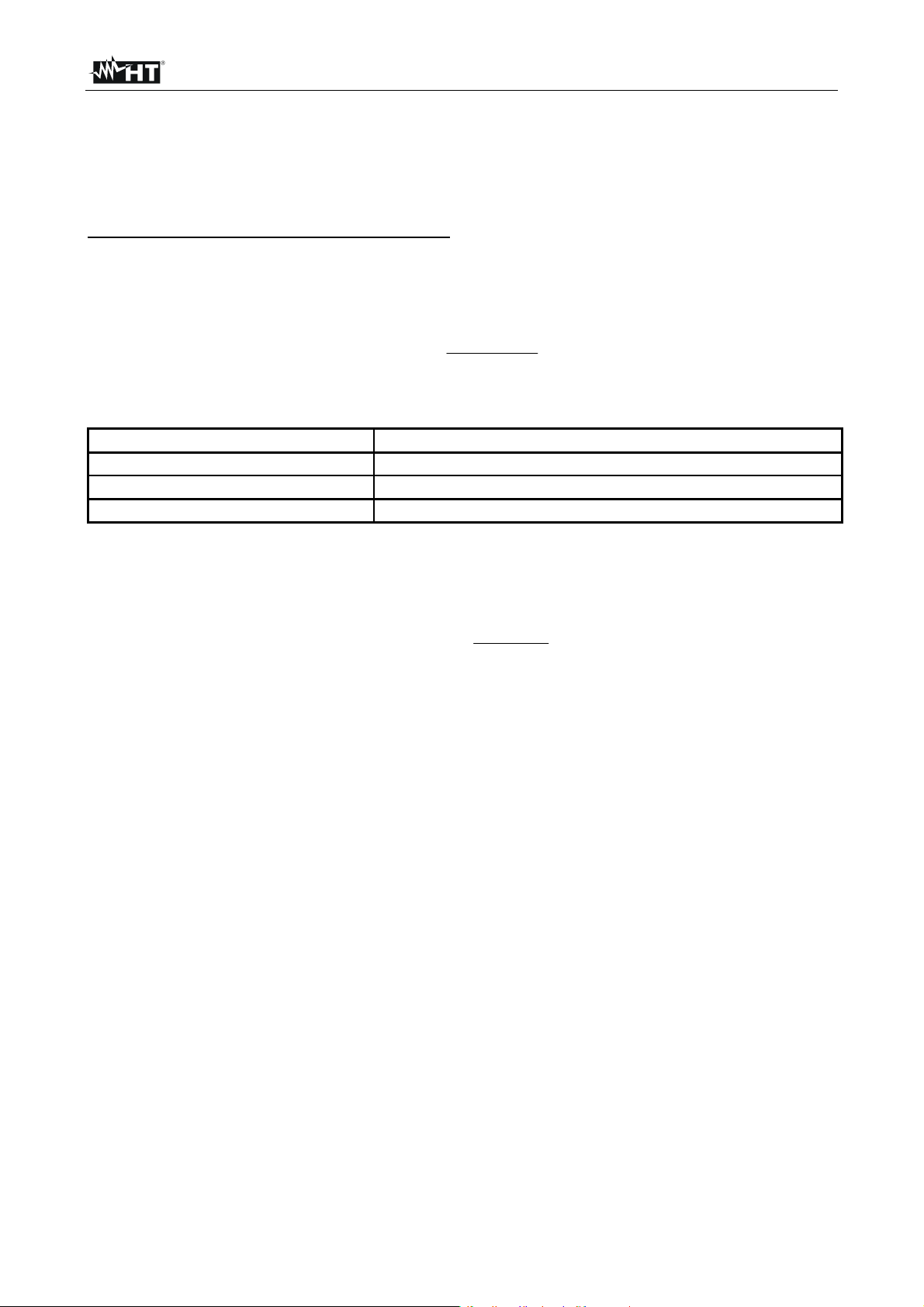

DIELECTRIC ABSORPTION RATIO (DAR)

DAR is ratio of Insulation Resistance values measured after 15s and after 1 minute. The

DC test voltage is present during the whole period of the test (also an Insulation

Resistance measurement is continually running). At the end, the DAR ratio is displayed:

iso

15

iso

s

tC10

U

min1

s

.

V

3

DAR

Some applicable values:

DAR value Tested material status

< 1.25 Not acceptable

< 1.6 Considered as good insulation

> 1.6 Excellent

When determining Riso (15s) pay attention to the capacitance of the test object. It has to

be charged-up in the first time section (15s). Approximate maximum capacitance using:

max

where:

t = period of first time unit (e.g. 15s)

U = test voltage.

To avoid this problem, increase the DIAG. Starting time parameter in CONFIGURATION

menu, because start of timer in the DIAGNOSTIC TEST functions depends on the test

voltage. The timer begins to run when test voltage reaches the threshold voltage, which is

product of the DIAG. Starting time and nominal test voltage (Unominal)

Using filters (fil1, fil2, fil3) in the DAR function is not recommended!

Analysing the change in the measured insulation resistance over time and calculating the

DAR and PI are very useful maintenance tests of an insulating material

R

F

EN - 12

Page 15

HT7052

R

POLARIZATION INDEX (PI)

PI is the ratio of Insulation Resistance values measured after 1 minute and after 10

minutes. The DC test voltage is present during the whole period of the measurement (an

Insulation Resistance measurement is also running). On completion of the test the PI ratio

is displayed:

R

PI

General applicable values:

PI value Tested material status

1 to 1.5 Not acceptable (older types)

2 to 4 (typically 3) Considered as good insulation (older types)

>4(very high insulation resistance) Modern type of (good) insulation systems

When determining Riso (1min) pay close attention to the capacitance of the object under

test. It has to be charged-up in the first time section (1 min). Approximate maximum

capacitance using:

F

max

where:

t = period of first time unit (e.g. 1min)

U = test voltage

To avoid this problem, increase the DIAG. Starting time parameter in CONFIGURATION

menu, because start of timer in the DIAGNOSTIC TEST functions depends on the test

voltage. The timer begins to run when test voltage reaches the threshold voltage, which is

product of the DIAG. Starting time and nominal test voltage (Unominal)

min10

iso

min1

iso

tC10

U

s

.

V

3

EN - 13

Page 16

HT7052

DIELECTRIC DISCHARGE RATIO (DD)

An additional effect of polarization is the recovered charge (from Cpi) after the regular

discharging of a completed test. This can also be a supplementary measurement for

evaluation of the quality of insulating material. This effect is generally found in insulating

systems with large capacitance Ciso. The polarisation effect (described in “Polarisation

Index”) causes a capacitance to form (Cpi). Ideally this charge would dissipate

immediately a voltage was removed from the material. In practice, this is not the case

DD is the diagnostic insulation test carried out after the completion of the Insulation

Resistance measurement. Typically the insulation material is left connected to the test

voltage for 10 30 min and then discharged before the DD test is carried out. After 1

minute a discharge current is measured to detect the charge re-absorption of the insulation

material. A high re-absorption current indicates contaminated insulation (mainly based on

moisture:

mAIdis

DD

where:

Idis 1min = discharging current measured 1 min after regular discharge

U= test voltage

C= capacitance of test object

General applicable values:

DD Value Tested material status

> 4 Bad

2 - 4 Critical

< 2 Good

min1

FCVU

.

EN - 14

Page 17

HT7052

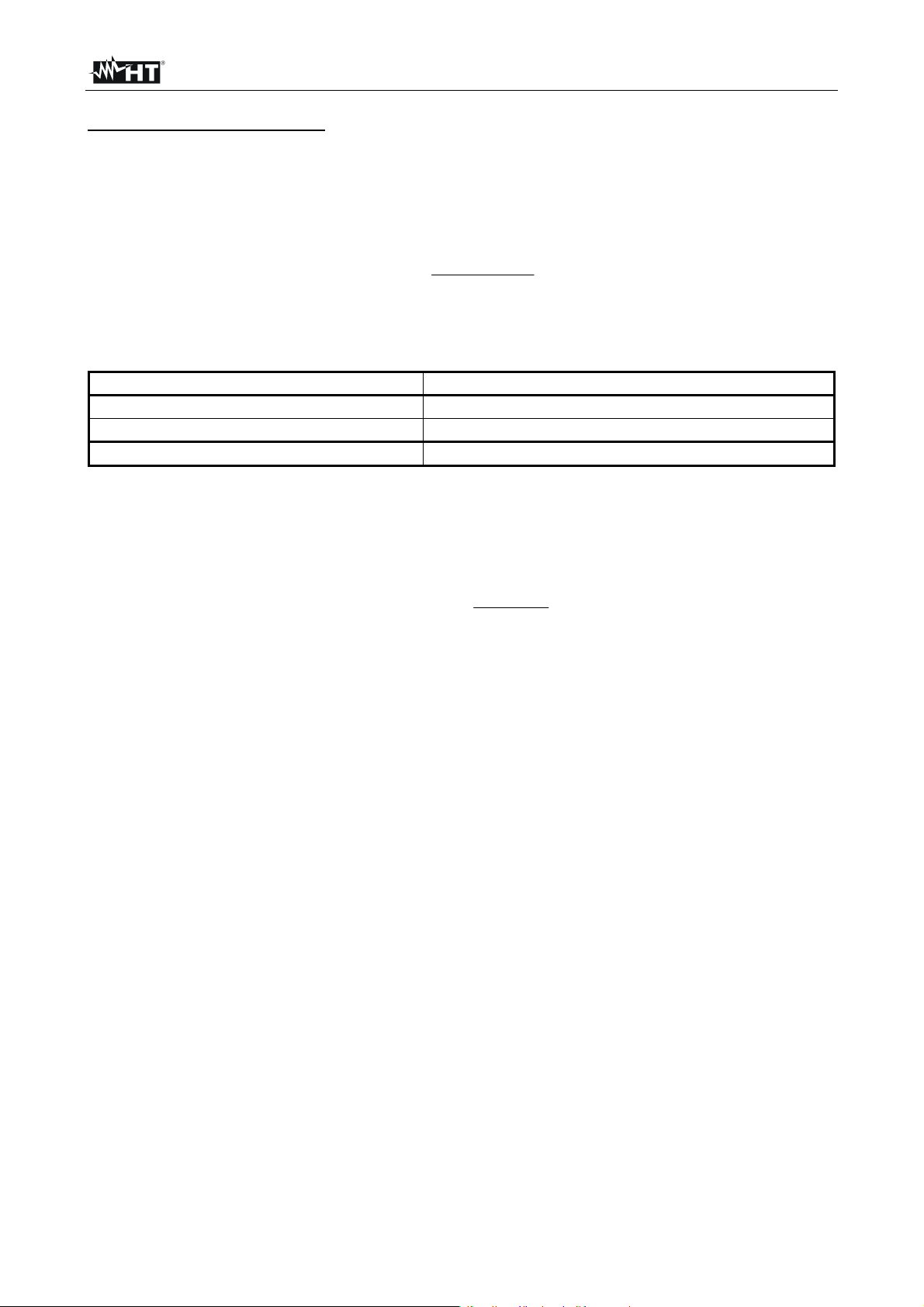

6.1.2 Withstanding voltage test

Some standards allow the use of a DC voltage as an alternative to AC withstanding

voltage testing. For this purpose the test voltage has to be present across the insulation

under test for a specific time. The insulation material only passes if there is no breakdown

or flash over. Standards recommend that the test starts with a low voltage and reaches the

final test voltage with a slope that keeps the charging current under the limit of the current

threshold. The test duration normally takes 1 min

The instruments offers Withstanding Voltage test of insulation material. It covers two types

of tests:

Breakdown voltage testing of high voltage device, e.g. transient suppressors and

DC withstanding voltage test for insulation coordination purposes

Both functions require breakdown current detection. The test voltage increases step by

step from the Start up to the Stop value over a predefined time and it is kept at the Stop

value for a predefined test time (see Fig. 10 – left part) or it happens the breakdown on

device under test (see Fig. 10 – right part)

Fig. 10: Withstanding test without breakdown (left) and with breakdown (right)

Ut = test voltage

t = time

Ustart = starting voltage

Ustep = voltage step approx. 25 V (fixed value - not modify)

Ustop = end test voltage

Tstep = test voltage duration per step

Tend = constant test voltage duration after reaching End value

Ub = breakdown voltage

Humidity and insulation resistance measurements

When testing outside the reference ambient conditions, the quality of the insulation

resistance measurements can be affected by humidity. Humidity adds leakage paths onto

the surface of the complete measuring system, (i.e. the insulator under test, the test leads,

the measuring instrument etc). The influence of humidity reduces accuracy especially

when testing very high resistances (e.g. T). The worst conditions arise in environments

containing high condensation, which can also reduce safety. In the case of high humidity, it

is recommended to ventilate the test areas before and during the measurements. In the

case of condensed humidity the measuring system must dry and it can take several hours

or even few days to recover

EN - 15

Page 18

HT7052

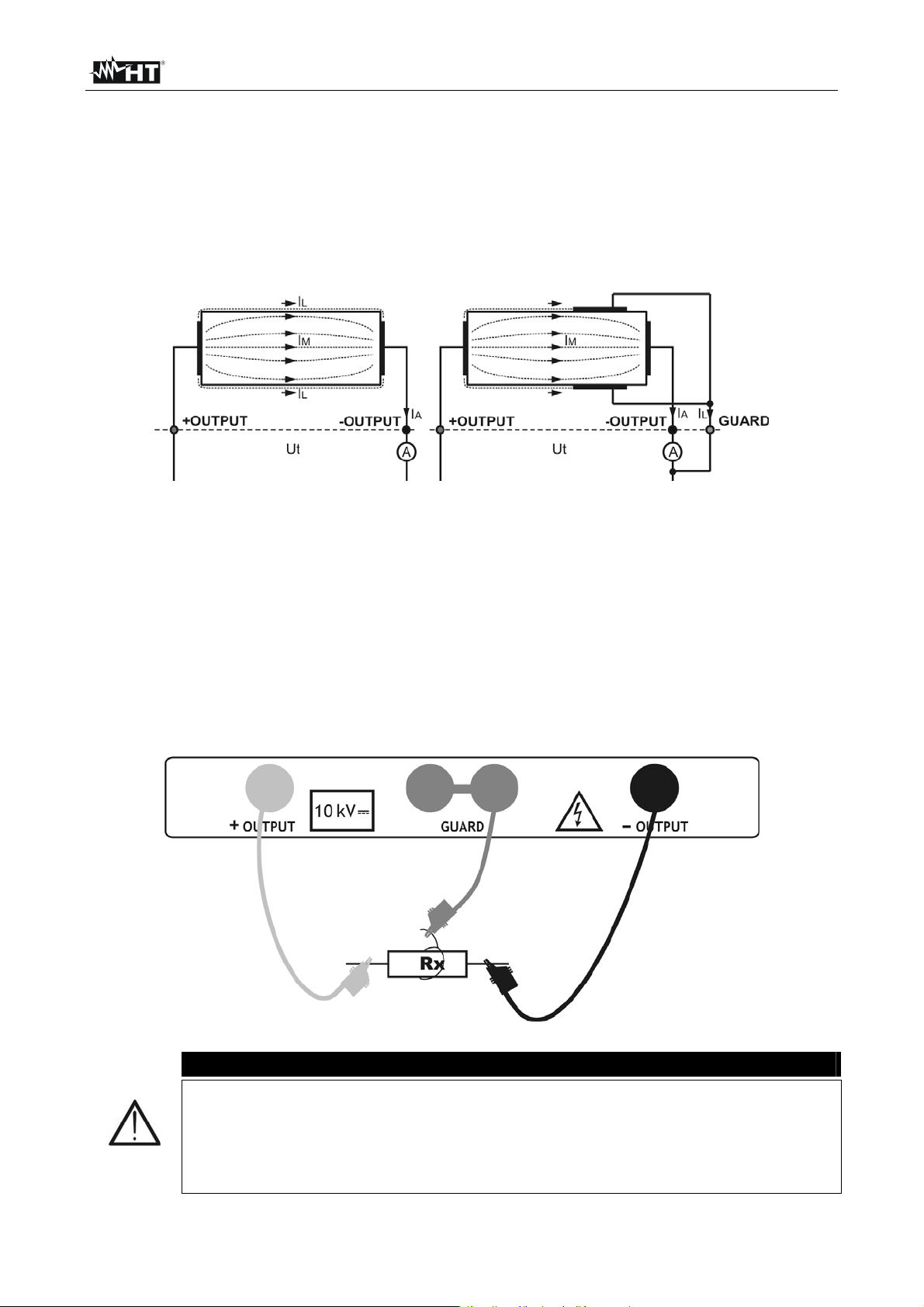

6.2 GUARD TERMINAL

The purpose of the GUARD terminal is to lead away potential leakage currents (e.g.

surface currents), which are not a result of the measured insulation material itself but are a

result of the surface contamination and moisture. This current interferes with the

measurement i.e. the Insulation Resistance result is influenced by this current. The

GUARD terminal is internally connected to the same potential as the negative test terminal

(black one). The GUARDs test clip should be connected to the test object so as to collect

most of the unwanted leakage current (see Fig. 11)

where:

Fig. 11: Principle scheme relative to the Guard terminal

Ut ..................... Test voltage

IL ...................... Leakage current (resulted by surface dirt and moisture)

IM ...................... Material current (resulted by material conditions)

IA ...................... Test current

Result without GUARD terminal: R

Result using GUARD terminal: R

= Ut / IA = Ut / (IM + IL) Incorrect result

INS

= Ut / IA = Ut / IM correct result

INS

The GUARD terminal it is internal connected at the same negative test lead (black). The

alligator clip should be connected to the object on test in way to detect the most possible

leakege current (see Fig. 12)

Fig. 12: Connection of the Guard terminal to the object on test

CAUTION

It is recommended to use the GUARD connection when high insulation

resistance (> 10G) should be measured

The guard terminal is protected by an internal impedance 400k

The instrument has two guard terminals to allow easy connection of

shielded measuring leads

EN - 16

Page 19

HT7052

A

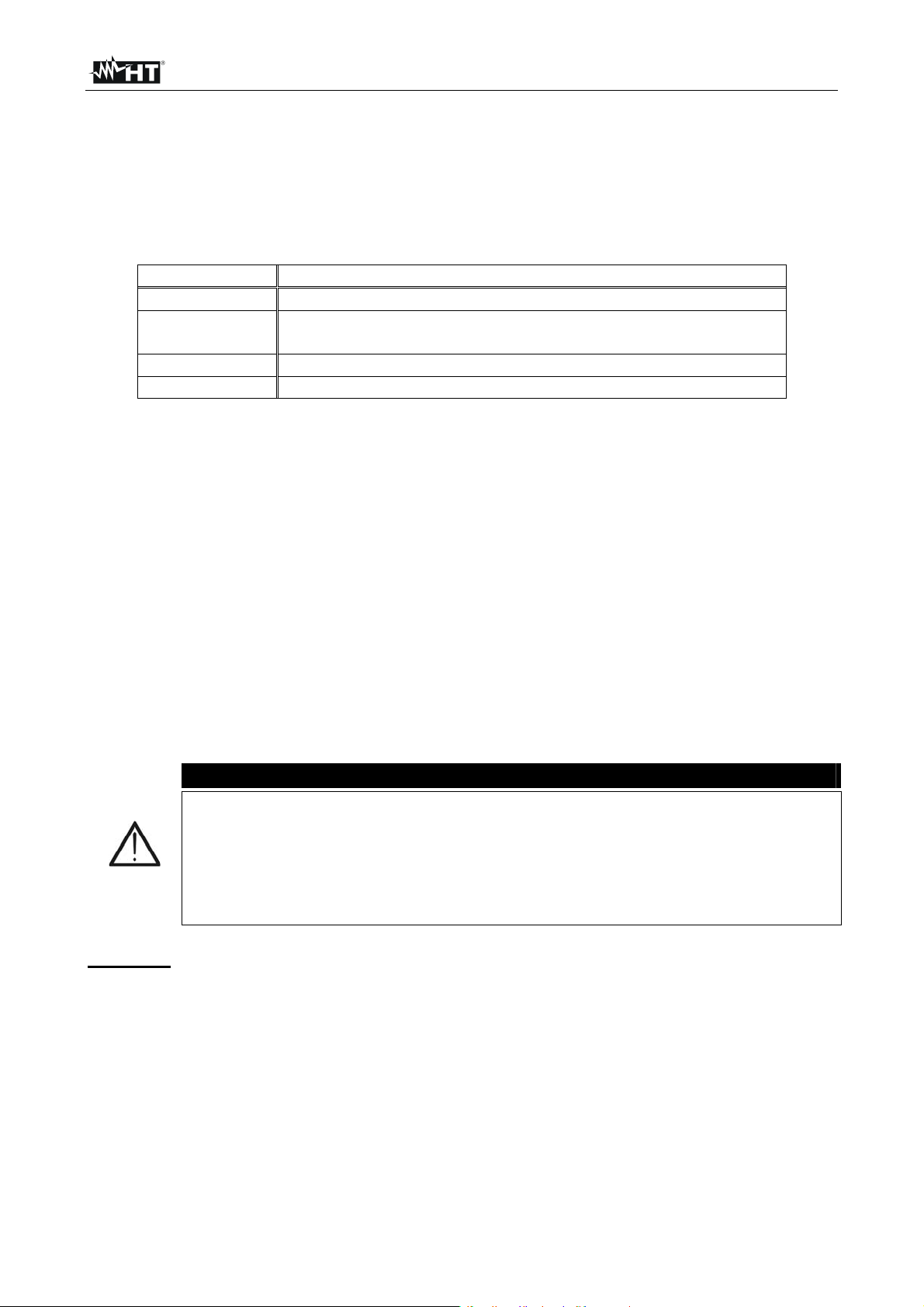

6.3 USE OF INTERNAL FILTERS

Filters are built in to reduce the influence of noise on measurement results. This option

enables more stable results especially when dealing with high Insulation Resistances

(Insulation Resistance, Diagnostic Test, Step Voltage). In these functions, the status of the

filter option is shown in the top right corner of the LCD screen. The below table contains a

definition of the individual filter options

Filter options Description

Fil0 Low pass filter with cut off frequency of 0.5 Hz in signal line

Fil1

dditional low pass filter with cut off frequency of 0.05 Hz in

the signal line

Fil2 Fil1 with increased integrating time (4 s)

Fil3 Fil2 with additional cyclic averaging of 5 results

Table 2: Filter options

6.3.1 The purpose of filtering

The internal filters smooth the measured currents by means of averaging and bandwidth

reduction. There are various sources of disturbance:

AC currents at the mains frequency and its harmonics, switching transients etc, cause

the results to become unstable. These currents are mostly cross talk through insulation

capacitances close to live systems

Other currents induced or coupled in the electromagnetic environment of the insulation

under test

Ripple current from internal high voltage regulator,

Charging effects of high capacitive loads and / or long cables.

Voltage changes are relatively narrow on high resistance insulation, so the most important

point is to filter the measured current

CAUTION

Any of the selected filter options increases the settling time with Fil1 to 60

s, Fil2 to 70 s, and Fil3 to 120s

It is necessary to pay close attention to the selection of time intervals when

using the filters

The recommended minimum measuring times when using filters are the

settling times of the selected filter option

Example:

A noise current of 1mA/50Hz adds approximately 15% distribution to the measured result

when measuring 1G.

By selecting FIL1 option the distribution will reduce to less than 2 %

In general using FIL2 and FIL3 will further improve the noise reduction

EN - 17

Page 20

HT7052

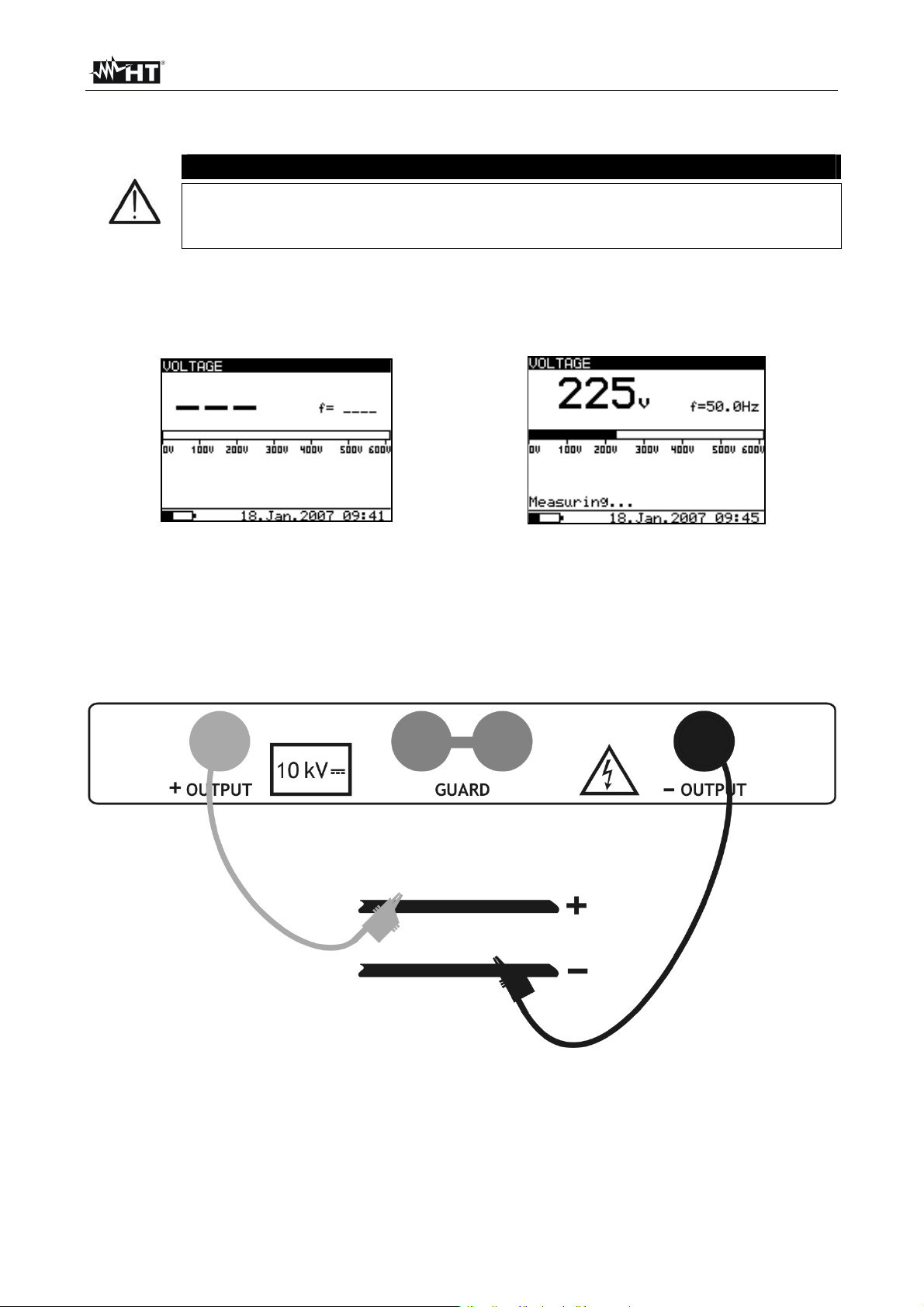

6.4 VOLTAGE MEASUREMENT

CAUTION

Maximum input for DC or AC voltage is 600V. Do not attempt to take any

voltage measurement that exceeds the limits. Exceeding the limits could

cause electrical shock and damage the instrument

1. Switch on the instrument by pressing the ON/OFF key

2. Select with arrow keys or the item “VOLTAGE” on main menu and confirm with

SELECT key. The screen of Fig. 13 is shown by the meter

Fig. 13: Initial screen of voltage measure Fig. 14: Screen of measured value

3. Connect the red part of the Test lead 1 or Test leads 2 (see § 4.2) to the +OUTPUT

input and the black part of the Test leads 2 (see § 4.2) to the –OUTPUT input

4. Connect the tip of Test lead 1 or Test leads 2 (positive) and the black cable of Test

leads 2 (negative) to the object on test respect the polarities for DC voltage

measurement (see Fig. 15)

Fig. 15: Connection of meter for voltage measurement

5. Press START/STOP key to activate the measurement in continuous mode

6. Press again the START/STOP to stop the measurement. The result of test is shown at

display (see Fig. 14)

7. For saving the result see § 7

EN - 18

Page 21

HT7052

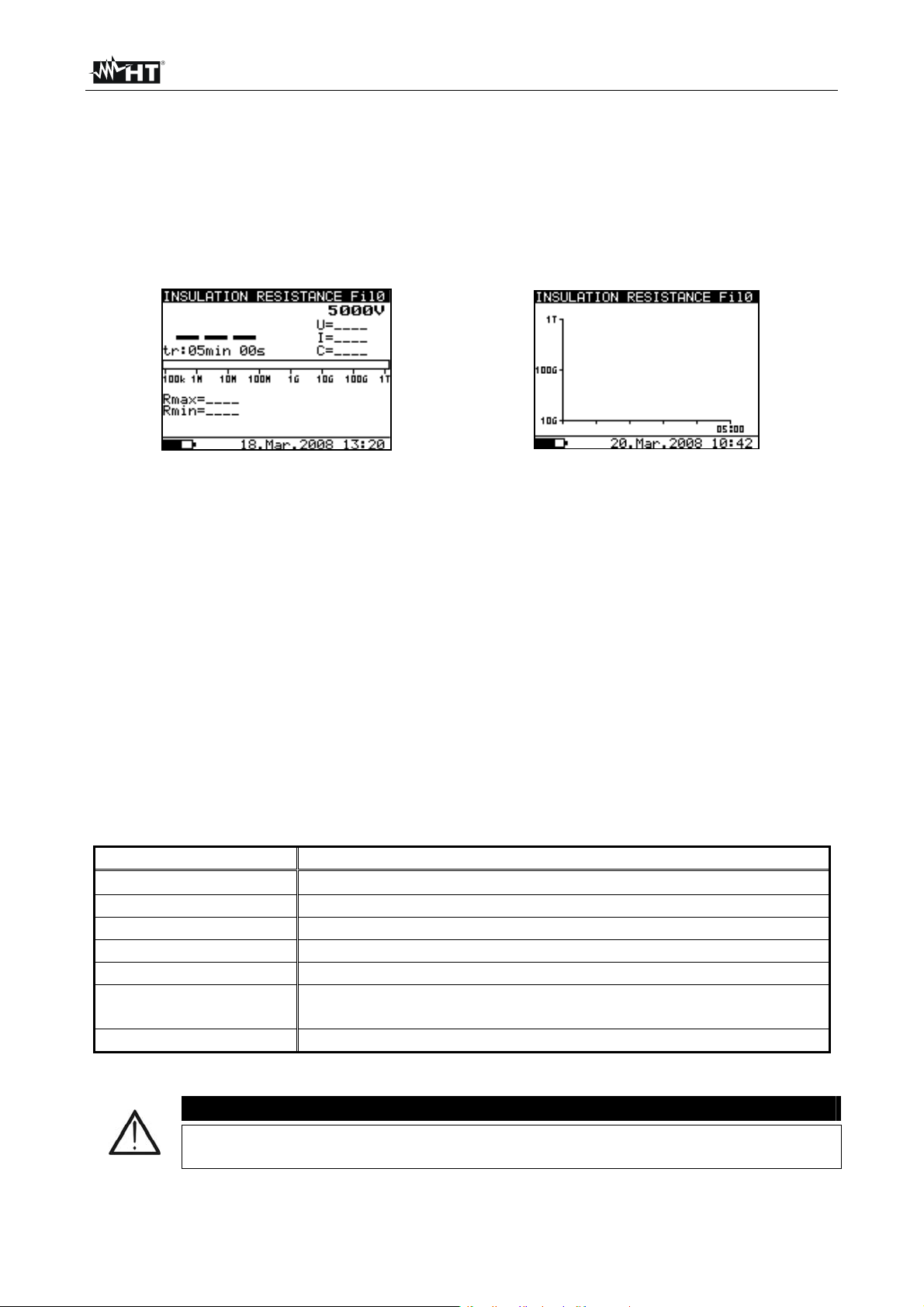

6.5 INSULATION RESISTANCE MEASUREMENT

6.5.1 Setting of parameters

1. Switch on the instrument by pressing the ON/OFF key

2. Select with arrow keys or the item “INSULATION RESISTANCE” on main menu

and confirm with SELECT key. The screen of Fig. 16 is shown by the meter. In case of

activation of Graphic R(t) option press arrow keys or to select the graphical

screen of Fig. 17

Fig. 16: Initial numerical screen Fig. 17: Initial graphical screen

3. Press again the SELECT key to enter in the setup parameters section. The screen of

Fig. 18 is shown by the meter

4. Use the arrow keys or for the selection of parameters. The herewith Table 3

shows the meaning of the measurement parameters

5. Set the values by using the arrow keys or . Press SELECT key to select possible

sub-parameters and repeat the settings

6. To activate the graphical screen the parameter Graph R(t) should be ON and the Timer

must be activated (see Fig. 18). The time duration of graphical function is

correspondent to the value of set Timer

7. The Timer value could be very long (up to 30 minutes), so the special automatic

decimation algorithm (LOG) is use to write the Graph R(t) at display (see Fig. 19)

8. The cursors of the Graph R(t) could be activated with key at the end of

measurement. The cursors of the Graph R(t) could be moved with or keys

9. Press ESC key to save the settings and back to the measurement screen or the

START/STOP key to exit from the settings menu and activate the test

Parameter Description

Unominal

Set test voltage – Range 500V10kV step 25V

Timer Duration of the measurement

Timer ON/OFF ON: timer activated, OFF timer disabled

Time 1 Time to accept and display first Rmin and Rmax results

Graph R(t) Enable/Disable Graph R(t)

R(t)

Set of minimum and maximum values of R(t) for graphical

screen

R(t) Type Set of “LIN” (linear) o “LOG” algorithm of graphical screen

Table 3: Setting of internal parameters

Timer and Time1 are independent timers. Maximum time for each of them is

30 min 60s

CAUTION

EN - 19

Page 22

HT7052

Fig. 18: Setting parameters Fig. 19: Setting of graph R(t) parameters

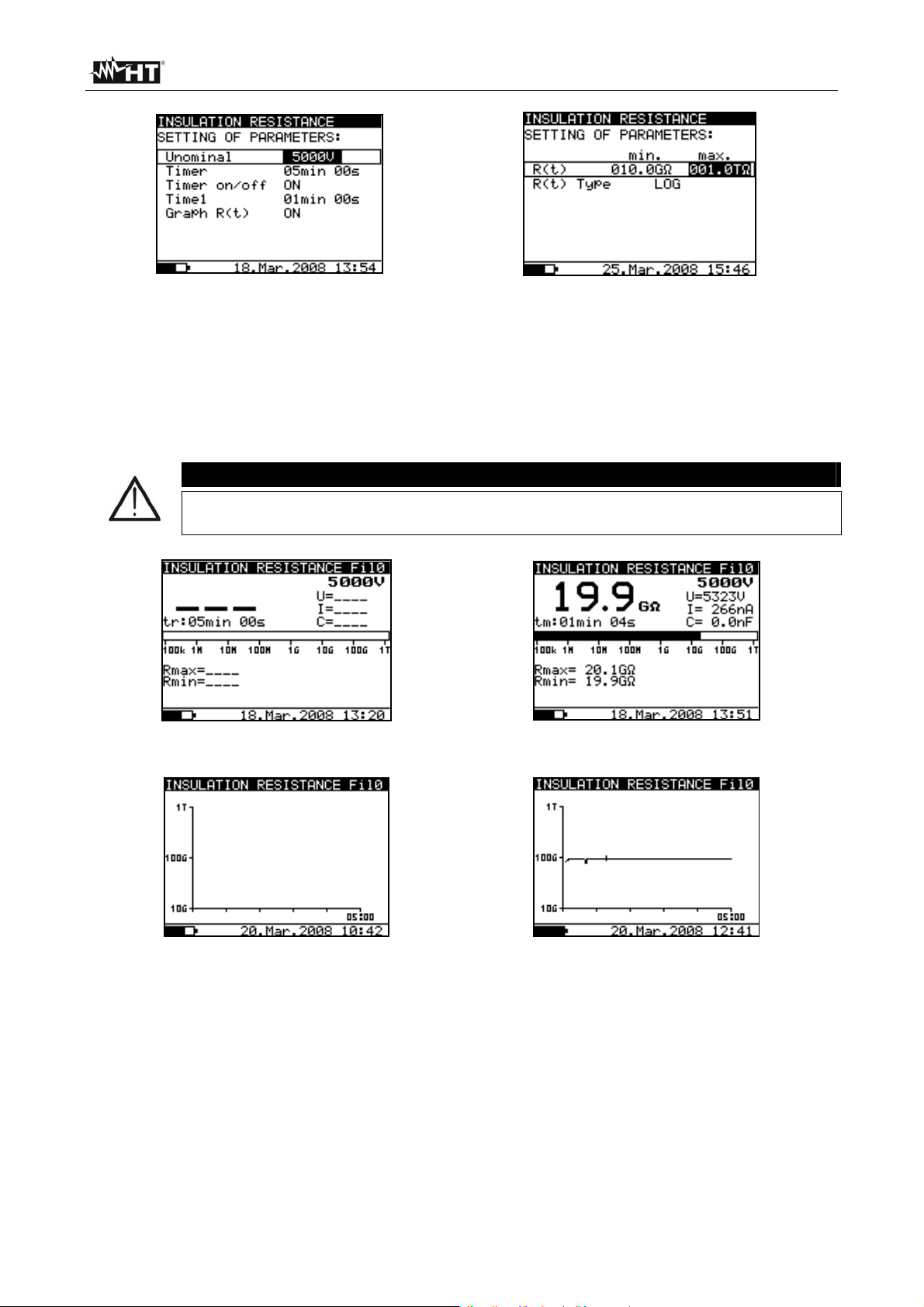

6.5.2 Perform the measurement

1. Switch on the instrument by pressing the ON/OFF key

2. Select with arrow keys or the item “INSULATION RESISTANCE” on main menu

and confirm with SELECT key. The screen of Fig. 20 is shown by the meter. In case of

activation of Graphic R(t) option press arrow keys or to select the graphical

screen of Fig. 22

It is not possible to switching mode of presentation when measurement

running

CAUTION

Fig. 20: Initial numerical screen Fig. 21: Numerical screen of result

Fig. 22: Initial graphical screen Fig. 23: Graphical screen of result

3. Connect the red part of the Test lead 1 or Test leads 2 (see § 4.2) to the +OUTPUT

input and the black part of the Test leads 2 (see § 4.2) to the –OUTPUT input

4. Connect the tip of Test lead 1 or Test leads 2 (positive) and the black cable of Test

leads 2 (negative) to the object on test (see Fig. 24)

EN - 20

Page 23

HT7052

Fig. 24: Connection of instrument for insulation measurement

5. Press START/STOP key to activate the measurement in continuous mode

6. Wait for a stable result at display and press again START/STOP key to stop the

measurement or wait for the end of the set Timer. The result of test is shown at display

(see Fig. 21 or Fig. 23) with meaning of items descript in Table 4

7. Wait for the object under test to discharge

8. For saving the result see § 7

Parameter at display Description

Fil0 (Fil1, Fil2, Fil3)

5000V

Filter type enabled, see the chapter 5.3. Configuration

(see § 6.3)

Set test voltage

U=5323V Applied test voltage

I=266nA Applied test current

19.9G

Result of insulation measurement

C=0.0nF Capacitance of measured object

Tm:01min 04s Timer information – test duration

Bargraph Analogue representation of result

Rmax=20.G

Rmin=19.9G

Maximum value of result (only if timer is enabled)

Minimum value of result (only if timer is enabled)

Table 4: Meaning of parameters of insulation measurement

CAUTION

If the timer is disabled then OFF is displayed instead of the timer value

During a measurement, the timer information displays the time needed to

the complete the measurement (tr) while after the completion the test

duration (tm) is displayed

A high-voltage warning symbol appears on the display during the

measurement to warn the operator of a potentially dangerous test voltage

Value of capacitance is measured during the final discharge of the test

object

EN - 21

Page 24

HT7052

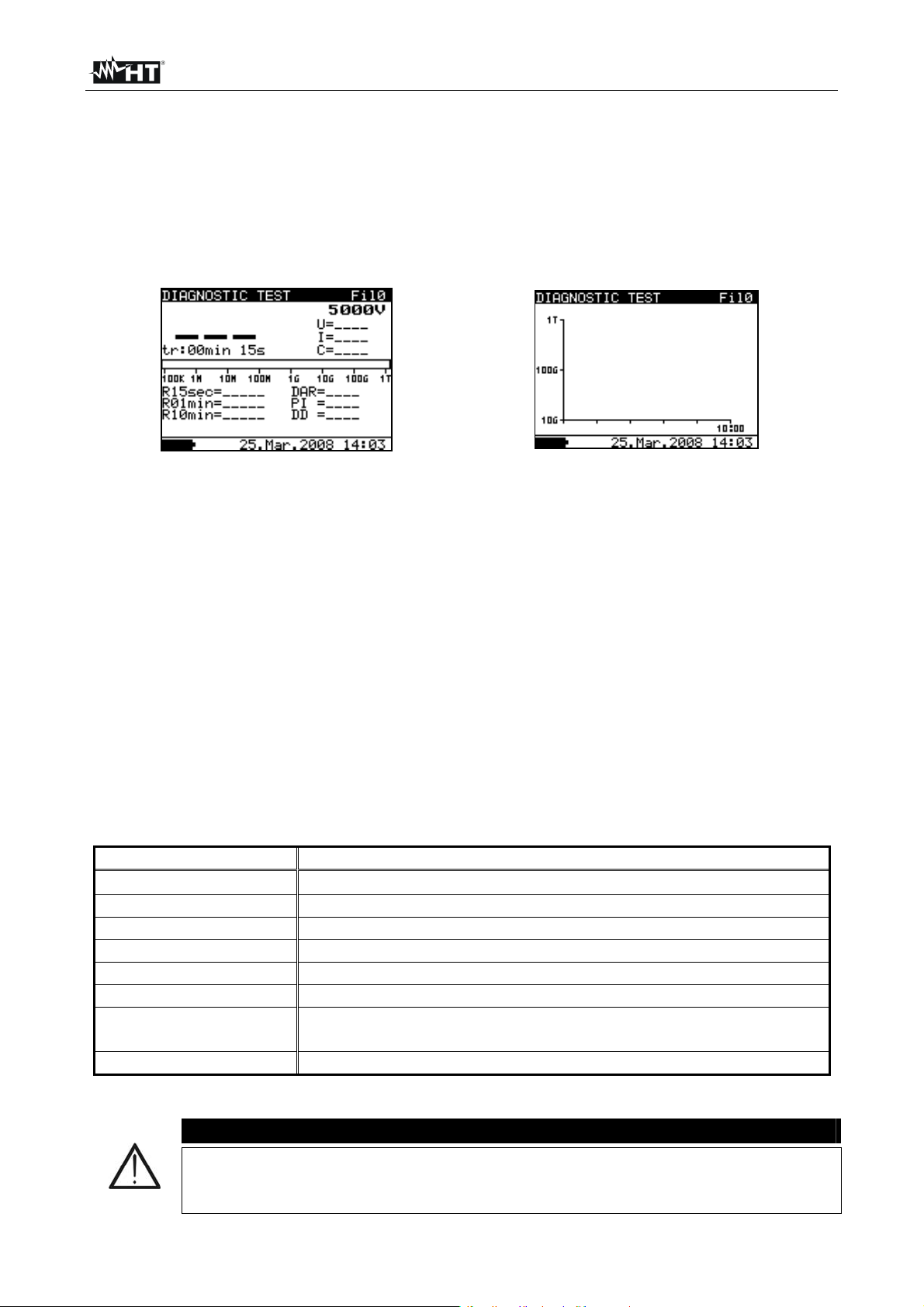

6.6 DIAGNOSTIC TEST

6.6.1 Setting of parameters

1. Switch on the instrument by pressing the ON/OFF key

2. Select with arrow keys or the item “DIAGNOSTIC TEST” on main menu and

confirm with SELECT key. The screen of Fig. 25 is shown by the meter. In case of

activation of Graphic R(t) option press arrow keys or to select the graphical

screen of Fig. 26

Fig. 25: Initial numerical screen Fig. 26: Initial graphical screen

3. Press again the SELECT key to enter in the setup parameters section. The screen of

Fig. 27 is shown by the meter

4. Use the arrow keys or for the selection of parameters. The herewith Table 3

shows the meaning of the measurement parameters

5. Set the values by using the arrow keys or . Press SELECT key to select possible

sub-parameters and repeat the settings

6. To activate the graphical screen the parameter Graph R(t) should be ON and the Timer

must be activated (see Fig. 27). The time duration of graphical function is

correspondent to the value of set Time3

7. The Timer value could be very long (up to 30 minutes), so the special automatic

decimation algorithm (LOG) is use to write the Graph R(t) at display (see Fig. 28)

8. The cursors of the Graph R(t) could be activated with key at the end of

measurement. The cursors of the Graph R(t) could be moved with or keys

9. Press ESC key to save the settings and back to the measurement screen or the

START/STOP key to exit from the settings menu and activate the test

Parameter Description

Unominal

Set test voltage – Range 500V10kV step 25V

Time1 Time to take R1min result

Time2 Time to take R1min result and calculate DAR

Time3 Time to take R3min result and calculate PI

DD ON/OFF ON: DD enabled, OFF: DD disabled

Graph R(t) Enable/Disable Graph R(t)

R(t)

Set of minimum and maximum values of R(t) for graphical

screen

R(t) Type Set of “LIN” (linear) o “LOG” algorithm of graphical screen

Table 5: Setting of internal parameters

CAUTION

Time1 Time2 Time3 are timers with the same start point. The value of

each presents the duration from the start of the measurement. The maximum

time is 30 min

EN - 22

Page 25

HT7052

Fig. 27: Setting parameters Fig. 28: Setting of graph R(t) parameters

6.6.2 Perform the measurement

1. Switch on the instrument by pressing the ON/OFF key

2. Select with arrow keys or the item “DIAGNOSTIC TEST” on main menu and

confirm with SELECT key. The screen of Fig. 29 is shown by the meter. In case of

activation of Graphic R(t) option press arrow keys or to select the graphical

screen of Fig. 31

It is not possible to switching mode of presentation when measurement

running

CAUTION

Fig. 29: Initial numerical screen Fig. 30: Numerical screen of result

Fig. 31: Initial graphical screen Fig. 32: Graphical screen of result

3. Connect the red part of the Test lead 1 or Test leads 2 (see § 4.2) to the +OUTPUT

input and the black part of the Test leads 2 (see § 4.2) to the –OUTPUT input. In case

of use of GUARD terminals (see § 6.2) connect also the green cables to the “GUARD”

input (see Fig. 33)

4. Connect the tip of Test lead 1 or Test leads 2 (positive) and the black cable of Test

leads 2 (negative) to the object on test (see Fig. 33)

EN - 23

Page 26

HT7052

Fig. 33: Connection of instrument for diagnostic test

5. Press START/STOP key to activate the insulation measurement

6. Wait for the end of the set Timers. The result of test is shown at display (see Fig. 30 or

Fig. 32) with meaning of items descript in Table 6

7. Wait for the object under test to discharge

8. For saving the result see § 7

Parameter at display Description

Fil0 (Fil1, Fil2, Fil3) Filter type enabled on test (see § 6.3)

5000V

Set test voltage – step 25 V

U=5295V Applied test voltage

I=55.6nA Applied test current

95.1G

Result of insulation measurement

C=2.1nF Capacitance of measured object

Bargraph Analogue representation of Riso result

R15sec=95.0G

R01min=95.1G

R10min=95.1G

Resistance value measured after set time 1

Resistance value measured after set time 2

Resistance value measured after set time 3

DAR=1.00 DAR as ratio of R1min / R15s

PI=1.00 PI as ratio of R10min/R1min

DD= DD result

Table 6: Meaning of parameters of diagnostic test

CAUTION

A high-voltage warning symbol appears on the display during the

measurement to warn the operator of a potentially dangerous test voltage

The value of the capacitance is measured during the final discharge of the

test object

If enabled, the instrument measures Dielectric Discharge (DD) when the

capacitance is in the range 5nF 50F

EN - 24

Page 27

HT7052

6.7 INSULATION RESISTANCE WITH STEP VOLTAGE TEST

6.7.1 Setting of parameters

1. Switch on the instrument by pressing the ON/OFF key

2. Select with arrow keys or the item “STEP VOLTAGE” on main menu and confirm

with SELECT key. The screen of Fig. 34 is shown by the meter. In case of activation of

Graphic R(t) option press arrow keys or to select the graphical screen of Fig. 35

Fig. 34: Initial numerical screen Fig. 35: Initial graphical screen

3. Press again the SELECT key to enter in the setup parameters section. The screen of

Fig. 36 is shown by the meter

4. Use the arrow keys or for the selection of parameters. The herewith Table 7

shows the meaning of the measurement parameters

5. Set the values by using the arrow keys or . Press SELECT key to select possible

sub-parameters and repeat the settings

6. To activate the graphical screen the parameter Graph R(t) should be ON and the Timer

must be activated (see Fig. 36). The time duration of graphical function is

correspondent to the value of Step Timer multiplied by 5

7. The Timer value could be very long (up to 150 minutes), so the special automatic

decimation algorithm (LOG) is use to write the Graph R(t) at display (see Fig. 37)

8. The cursors of the Graph R(t) could be activated with key at the end of

measurement. The cursors of the Graph R(t) could be moved with or keys

9. Press ESC key to save the settings and back to the measurement screen or the

START/STOP key to exit from the settings menu and activate the test

Parameter Description

Unominal

Step time Duration of measurement per step

Graph R(t) Enable/Disable Graph R(t)

R(t)

R(t) Type Set of “LIN” (linear) o “LOG” algorithm of graphical screen

Set test voltage – Range 2kV10kV step 125V

Set of minimum and maximum values of R(t) for graphical

screen

Table 7: Setting of internal parameters

Fig. 36: Setting parameters Fig. 37: Setting of graph R(t) parameters

EN - 25

Page 28

HT7052

6.7.2 Perform the measurement

1. Switch on the instrument by pressing the ON/OFF key

2. Select with arrow keys or the item “STEP VOLTAGE” on main menu and confirm

with SELECT key. The screen of Fig. 38 is shown by the meter. In case of activation of

Graphic R(t) option press arrow keys or to select the graphical screen of Fig. 40

It is not possible to switching mode of presentation when measurement

running

CAUTION

Fig. 38: Initial numerical screen Fig. 39: Numerical screen of result

Fig. 40: Initial graphical screen Fig. 41: Graphical screen of result

3. Connect the red part of the Test lead 1 or Test leads 2 (see § 4.2) to the +OUTPUT

input and the black part of the Test leads 2 (see § 4.2) to the –OUTPUT input

4. Connect the tip of Test lead 1 or Test leads 2 (positive) and the black cable of Test

leads 2 (negative) to the object on test (see Fig. 24)

Fig. 42: Connection of instrument for insulation measurement

EN - 26

Page 29

HT7052

d

t

d

d

5. Press START/STOP key to activate the insulation measurement

6. Wait for the end of the set Timers. The result of test is shown at display (see Fig. 39 or

Fig. 41) with meaning of items descript in Table 8

7. Wait for the object under test to discharge

8. For saving the result see § 7

Parameter at display Description

Fil0 (Fil1, Fil2, Fil3) Filter type enabled (see § 6.3)

5000V

Set test voltage – step 125 V

U=5302V Applied test voltage

I=133nA Applied test current

39.7G

Result of insulation measurement

C=0.0nF Capacitance of measured object

Tm:05min 00s Actual test duration

st

R1000V=40.0G

R2000V=40.0G

R3000V=40.0G

R4000V=39.8G

R5000V=39.7G

U1=1076V 1

U2=2141V 2

U3=3238V 3

Last result of 1

Last result of 2nd step

Last result of 3

Last result of 4th step

Last result of 5th step

s

step voltage

n

step voltage

r

step voltage

step

r

step

U4=4278V 4th step voltage

U5=5302V 5th step voltage

Table 8: Meaning of parameters of insulation measurement with step voltage

CAUTION

Timer information is displayed from the start of the measurement until the

completion of each step measurement

A high-voltage warning symbol appears on the display during the

measurement to warn the operator of a potentially dangerous test voltage

The value of the capacitance is measured during the final discharge of the

test object

EN - 27

Page 30

HT7052

6.8 WITHSTANDING VOLTAGE TEST

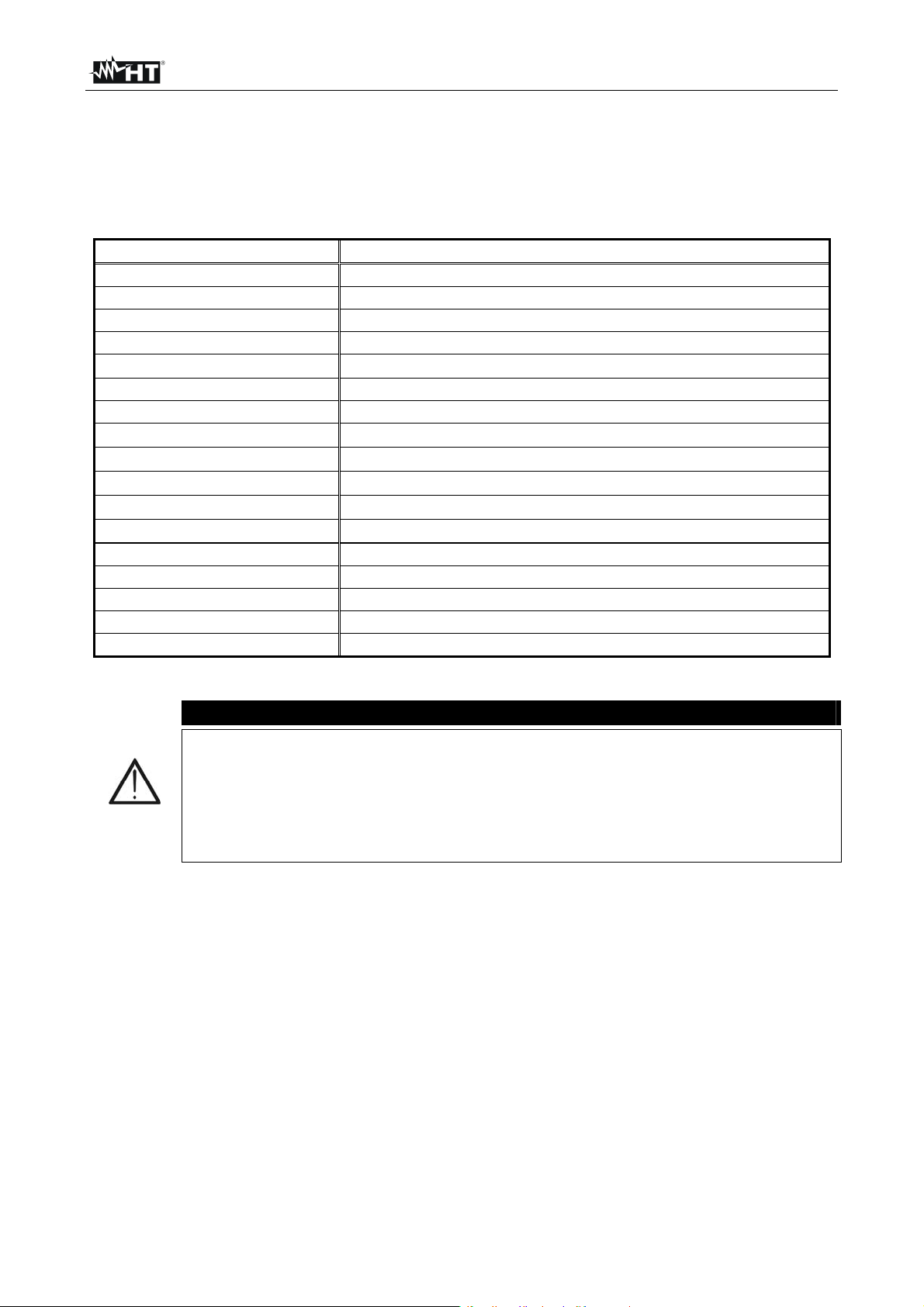

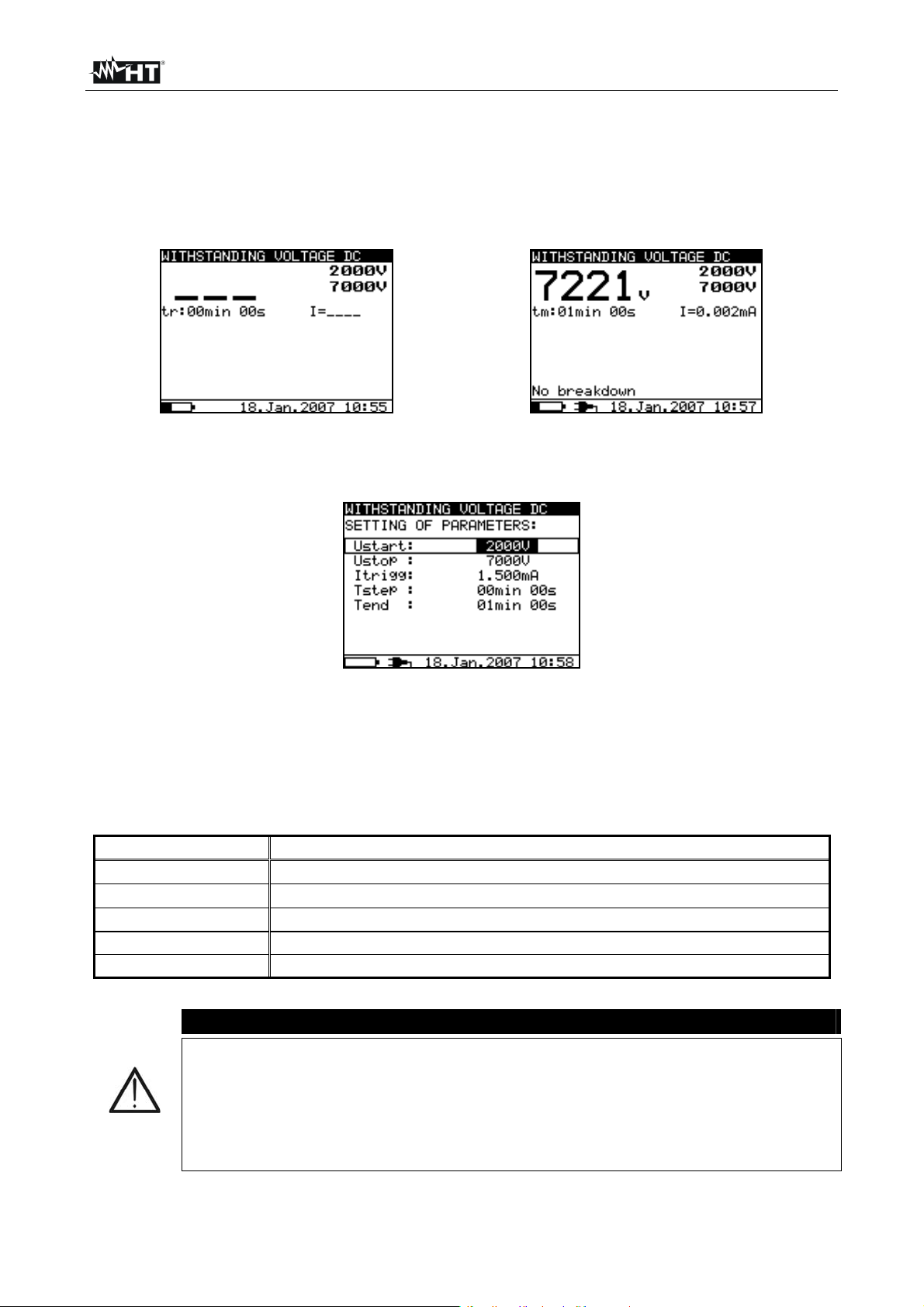

6.8.1 Setting of parameters

1. Switch on the instrument by pressing the ON/OFF key

2. Select with arrow keys or the item “WITHSTANDING VOLTAGE DC” on main

menu and confirm with SELECT key. The screen of Fig. 43 is shown by the meter

Fig. 43: Initial screen withstanding test Fig. 44: Final screen withstanding test

3. Press again the SELECT key to enter in the setup parameters section. The screen of

Fig. 45 is shown by the meter

Fig. 45: Setting parameters

4. Use the arrow keys or for the selection of parameters. The herewith Table 9

shows the meaning of the measurement parameters

5. Set the values by using the arrow keys or . Press SELECT key to select possible

sub-parameters and repeat the settings

6. Press ESC key to save the settings and back to the measurement screen or the

START/STOP key to exit from the settings menu and activate the test

Parameter Description

Ustart

Ustop

Itrigg

Start test voltage – Range 500V10kV step 25V

Stop test voltage – Range 500V10kV step 25V

Set trigger leakage current – Range 0.001mA 5mA step 10A

Tstep Duration of test voltage per one step

Tend Duration of constant test voltage after reaching stop value

Table 9: Setting of internal parameters

CAUTION

Tstep and Tend are independent timers. The maximum time for each timer

is 30 min 60 s. Tend begins after the completion of the ramp period. Ramp

period can be calculated from:

Ttot-ramp Tstep * [(Ustop-Ustart) / 25V]

If Tstep is set to 00min 00s, then the ramp voltage increases by

approximately 25 V every 2s

EN - 28

Page 31

HT7052

6.8.2 Perform the measurement

1. Switch on the instrument by pressing the ON/OFF key

2. Select with arrow keys or the item “WITHSTANDING VOLTAGE DC” on main

menu and confirm with SELECT key. The screen of Fig. 43 is shown by the meter

3. Connect the red part of the Test lead 1 or Test leads 2 (see § 4.2) to the +OUTPUT

input and the black part of the Test leads 2 (see § 4.2) to the –OUTPUT input

4. Connect the tip of Test lead 1 or Test leads 2 (positive) and the black cable of Test

leads 2 (negative) to the object on test (see Fig. 46)

Fig. 46: Connection of instrument for withstanding test

5. Press START/STOP key to activate the measurement

6. Wait until the set timers run out or until breakdown occurs. The result of test is shown

at display (see Fig. 44) with meaning of items descript in Table 10

7. Wait for the object under test to discharge

8. For saving the result see § 7

Parameter at display Description

2000V

7000V

7221V

Start test voltage

Stop test voltage

Applied test voltage

I=0.002mA Measured leakage current

Tm:01min 00s Timer information

Table 10: Meaning of parameters of withstanding test

CAUTION

Breakdown is detected when the measured current reaches or exceeds the

set current level Itrigg (see § 6.8.1)

The timer shows the time needed to complete each step during the

measurement and it shows the total measurement period after the

completion of the measurement

A high-voltage warning symbol appears on the display during the

measurement to warn the operator of a potentially dangerous test voltage

EN - 29

Page 32

HT7052

7 MANAGEMENT OF MEMORY DATA

7.1 SAVING, RECALL AND CLEAR MEASUREMENT RESULTS

SAVING DATA

1. With measurement result displayed press MEM key. The screen of Fig. 47 is shown by

the instrument

SAVE CLR RCL nnnn

Fig. 47: Saving data

2. Use the arrow keys or and select the “MEM” option. The “nnnn” number shows

the memory location where the data will be saved

3. Press again MEM key to confirm the operation. A double acoustic signal is given by the

instrument

RECALL SAVED DATA

1. Press MEM key, use the arrow keys or to select the “RCL” option and confirm

again with MEM key. The last saved data is shown at display

2. Use the arrow keys or to select and display the saved data correspondent to the

previous memory locations

3. The recalled data with “G” indication means the presence of a graphical screen more

than the numerical. Press SELECT key to display the graphical screen and ESC to

return to the numerical one

4. Press ESC key to exit from the function and return in measurement mode

CLEAR RESULT

1. For clear all internal memory select the “Memory clear” parameter (see § 5.2), press

SELECT key and confirm with MEM key

2. Press ESC key to exit from the function

3. For clear the last saved result press MEM key, use the arrow keys or to select the

“CLR” option and confirm again with MEM. A double acoustic signal is given by the

instrument to confirm the operation

EN - 30

Page 33

HT7052

8 CONNECTION OF THE INSTRUMENT TO PC

The saved data can be transferred to PC by using the TeraView dedicated software

included with instrument

TeraView software permits the herewith operations:

Download data from meter

Define customized settings on the final report

Analyze the results of measurements in numerical and graphical screens

Print the final report

Export the data in text (TXT) format file

MINIMUM SYSTEM REQUIREMENTS

Pentium III – 500MHz

512 MB RAM

100 MB free space on HD

CD-ROM reader

USB/serial port

Video resolution 800x600

Windows systems: Win2k/XP/Vista/Win7 32 bit and 64 bit platforms

8.1 INSTALLATION OF SOFTWARE AND INITIAL CONFIGURATIONS (WIN XP)

1. Close all the open application on the PC

2. Insert the supplied CD-ROM in the PC reader

3. Launch the “TeraView.exe” file included on CD-ROM and follow the steps to correctly

install the TeraView software

4. Switch on the instrument, set the USB mode (see § 5.2) and connect it to the PC by

using the supplied USB cable

5. Read the “Instal_USB_neutral.pdf” file inside the “Handbook” folder for the installation

of USB driver on the PC

6. Launch the TeraView software

7. Select the command “Config Password…”, type the serial number of meter and the

password (which is indicated on the CD-ROM label) and confirm with “Add” (see Fig.

48)

Fig. 48: Insertion of initial password

EN - 31

Page 34

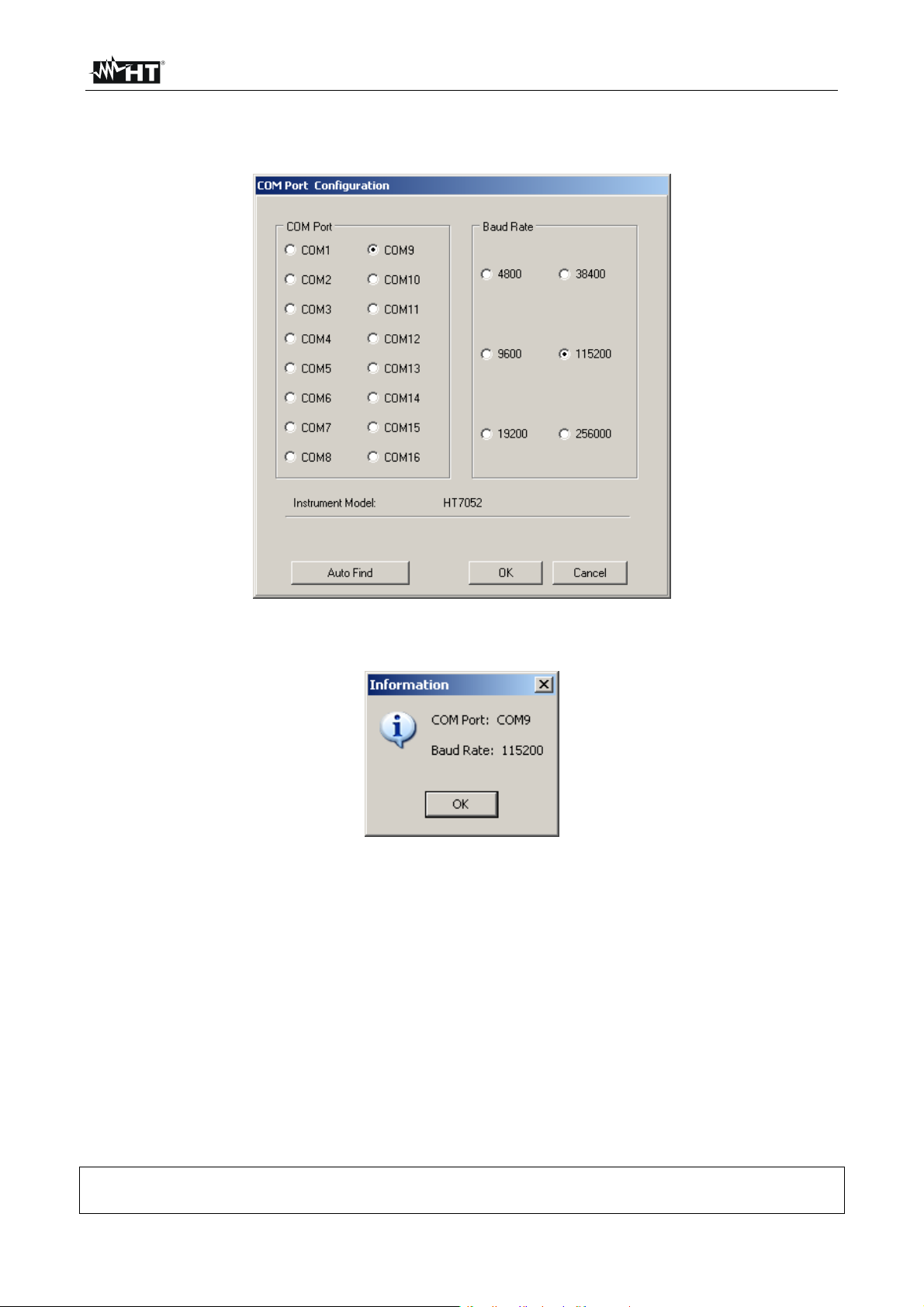

HT7052

8. Select the “Config COM Port…” command and click on the “AutoFind” button to

start the automatic detection of the instrument (see Fig. 49)

Fig. 49: Connection of the instrument to PC

9. The herewith message means a correct detection of meter by the PC

Fig. 50: Correct detection of instrument

10. In case of failed detection of the meter by the PC it should be necessary to re-configure

the “virtual” COM serial port associated the USB driver previously installed. The

TeraView program can detect automatically serial ports from the COM1 to the COM16.

Follow the herewith steps to modify the COM associated to USB driver:

Right click of mouse on the “My computer” icon on the PC desktop and selection of

“Properties” item

“Hardware” folder “Device Manager” “Ports (COM & LPT)

Move on the “USB CDC Serial Port Emulation (COMxx)” item right click

“Properties”

Select “Port Settings” “Advanced…”

In the COM Port Number list select a “COMxx” among COM1 and COM16

Confirm all operations, come back to software TeraView and repeat the AutoFind

For any information about the use of TeraView software refer to the help on line of

the same program

EN - 32

Page 35

HT7052

9 MAINTENANCE

9.1 GENERAL INFORMATION

The instrument You purchased is a precision instrument. During use and storage, carefully

observe the recommendations listed in this manual in order to prevent possible damage or

dangers during use. Do not use the instrument in environments with high humidity levels or

at high temperatures. Do not directly expose to sunlight. Always turn off the instrument

after use. Never remove the front panel of the instrument. The instrument don’t need any

particular maintenance

9.2 REPLACEMENT AND CHARGING BATTERIES

The instrument is power-supplied through internal rechargeable batteries which are

recharged from the mains by means of a battery charger integrated in the instrument itself.

The symbol “ “ illuminated in the left bottom part indicates that the batteries are flat

and must be recharged

Connect the instrument to the mains power supply for 20 hours to fully

charge batteries. (typical charging current is 600mA). When you charge the

batteries for the first time, it normally takes about 3 charge and discharge

cycles for the batteries to regain full capacity

The operator does not need to disconnect the instrument from mains

supply after the full recharging period. The instrument can be connected

permanently

The instrument will only work when rechargeable batteries are inside the

In case of batteries replacement follow the herewith steps:

instrument

Nominal power supply voltage is 7.2 V DC. Use only six NiMH cells with

size equivalent to IEC LR20 (diameter = 33 mm, height = 58 mm)

1. Turn the power off and disconnect any measurement accessories or mains supply

cable connected to the instrument before opening the battery cover to avoid electric

shock

2. Remove the two screws (see Fig. 1 – Part 15) and open the battery cover

3. Replace all the six batteries with others of the same type respecting the indicated

polarity

4. Restore the battery cover

5. Use the appropriate battery disposal methods for your area

CAUTION

CAUTION

9.3 CLEANING THE INSTRUMENT

To clean the instrument, use a soft dry cloth. Never use humid cloths, solvents, water, etc

9.4 END OF LIFE

Warning: the reported symbol indicates that the appliance, the batteries and its

accessories must be disposed of separately and treated correctly

EN - 33

Page 36

HT7052

10 TECHNICAL SPECIFICATIONS

Accuracy is given as [%rdg + (number of dgt) * resolution] at reference indicated in § 0

INSULATION RESISTANCE MEASUREMENT

Measurement range Resolution Accuracy

120k 999k 1k

1.00M 9.99M 0.01M

10.0M 99.9M 0.1M

100M 999M 1M

1.00G 9.99G 0.01G

10.0G 99.9G 0.1G

100G 999G 1G

1.00T 10.00T 0.01T (15.0 rdg + 3 dgt)

FS value of insulation resistance is defined as: RFS = 1G * Utest [V]

Nominal test voltage: 500 10kV DC

Current capability of test generator: > 1mA

Short-circuit test current: 5mA 10%

Automatic discharge of tested object: yes

Measurement range test voltage Resolution Accuracy

0 9999V

10kV

Nominal test voltage: 500 10kV DC programmable in step of 25V

Accuracy of test voltage: -0 / +10% + 20V

Output power: 10W max

1V

0.1kV

Measurement range test current Resolution Accuracy

0.00 9.99nA

10.0 99.9nA

100 999nA

0.01nA

0.1nA

1nA

1.00 9.99A 0.01A

10.0 9.99A 0.1A

100 999A 1A

1.00 5.50mA

0.01mA

Noise current rejection (resistive load)

Filter option Maximum current @ 50Hz (mA rms)

Fil0 1.5

Fil1 2.5

Fil2 4.5

Fil3 5

Diagram Test voltage – Resistance

(5.0rdg + 3dgt)

(3.0 rdg + 3V)

3.0 rdg

(5.0 rdg + 0.05nA)

12

10

8

6

[ kV ]

4

2

0

0,1 1 10 100

[ M ]

Utest=10kV Utest=5kV

EN - 34

Page 37

HT7052

DAR, PI, DD MEASUREMENT

Measurement range Resolution Accuracy

0.01 9.99

10.0 100.0

Capacitance range for DD test: 5nF 50F

0.01

0.1

(5.0 rdg + 2 dgt)

5.0 dgt

INSULATION MEASUREMENT WITH STEP VOLTAGE

Measurement range test voltage Resolution Accuracy

2000 9999V

10kV

Nominal test voltage: 2000 10kV DC programmable in steps of 125V

Accuracy of test voltage: -0 / +10% + 20V

1V

0.1kV

(3.0 rdg + 3V)

3.0 rdg

WITHSTANDING VOLATGE DC

Measurement range test voltage Resolution Accuracy

500 9999V

10kV

1V

0.1kV

(3.0 rdg + 3V)

3.0 rdg

Measurement range leakage current Resolution Accuracy

0.000 0.009mA

0.01 5.50mA

Nominal test voltage: 500 10kV DC programmable in steps of 25V

Accuracy of test voltage: -0 / +10% + 20V

0.001mA

0.01mA

(3.0 rdg + 3 dgt)

3.0 rdg

AC or DC VOLTAGE

Measurement range Resolution Accuracy

0 600V

Input impedance: 3M 10%

1V

(3.0 rdg + 4V)

Voltage frequency Resolution Accuracy

0 e 45.0 65.0Hz

Frequency within 0 and 45Hz: displayed < 45Hz

Frequency > 65Hz: displayed > 65Hz

0.1Hz

0.2Hz

CAPACITANCE

Measurement range Resolution Accuracy

0.0 99.9nF

100 999nF

0.1nF

1nF

(5.0 rdg + 2 dgt)

1.00 50.0F 0.01F

Full-scale value of capacitance is defined as: CFS = 10F * Utest [kV]

10.1 SAFETY STANDARDS

Instrument safety: IEC/EN61010-1, IEC/EN61557-2

Measuring accessory safety: IEC/EN61010-031

Insulation: double insulation

Protection: IP44 (closed case)

Polluting level: 2

Overvoltage category: CAT IV 600V (to earth), max 600V between inputs

Maximum altitude: 2000m (6561ft)

EN - 35

Page 38

HT7052

10.2 GENERAL CHARACTERISTICS

Mechanical characteristics

Dimensions (LxWxH): 360 x 330 x 160mm; 14 x 13 x 6in

Weight (with batteries): 5.5kg; 11lv

Power supply

External supply: 90-260V AC, 45-65Hz, 60VA

Internal supply: 6x1.2V rechargeable NiMH battery IEC LR20

Low battery indication: symbol “ “ at display

Battery life: approx 4 hours (continuous test on 10kV)

Display

Characteristics: LCD, dot matrix, with backlight (160x116pxl)

Memory

Characteristics: 1000 memory locations

Discharging

Characteristics: each time after the end of test; resistance 425

10%

Connection to PC

RS-232 serial interface: optoinsulated (2400,4800,9600,19200 baud, 1, N)

USB interface: type B standard, 115000 baud

10.3 ENVIRONMENT

Reference temperature: 10°C ÷ 30°C; 50°F ÷ 86°F

Reference humidity: 40%RH ÷ 60%RH

Operating temperature: -10°C ÷ 50°C; 14°F ÷ 122°F

Operating humidity: <90%HR

Storage temperature: -20°C ÷ 70°C; -4°F ÷ 158°F

Storage humidity: <90%HR

This instrument complies with the requirements of European Directive on low

voltage 2006/95/EC (LVD) and of Directive EMC 2004/108/EC

10.4 ACCESSORIES

N 1 Test lead red, protection 10kV, 2m

N 2 Test leads (red/black), basic protection 10kV (double protection 5kV), 2m

N 2 Alligator clips (red/black), basic protection 10kV (double protection 5kV)

N 1 Guard test lead green

N 1 Guard alligator clip green

N 1 Mains cord

N 1 USB cable

N 1 RS-232 cable

“TeraView” software on CD-ROM

6x1.2V rechargeable batteries NiMH type IEC LR20

User manual

ISO9000 calibration certificate

EN - 36

Page 39

HT7052

11 SERVICE

11.1 WARRANTY CONDITIONS

This instrument is warranted against any material or manufacturing defect, in compliance

with the general sales conditions. During the warranty period, defective parts may be

replaced. However, the manufacturer reserves the right to repair or replace the product

Should the instrument be returned to the After-sales Service or to a Dealer, transport will

be at the Customer's charge. However, shipment will be agreed in advance

A report will always be enclosed to a shipment, stating the reasons for the product’s return

Only use original packaging for shipment; any damage due to the use of non-original

packaging material will be charged to the Customer

The manufacturer declines any responsibility for injury to people or damage to property

The warranty shall not apply in the following cases:

Repair and/or replacement of accessories and battery (not covered by warranty)

Repairs that may become necessary as a consequence of an incorrect use of the

instrument or due to its use together with non-compatible appliances

Repairs that may become necessary as a consequence of improper packaging

Repairs which may become necessary as a consequence of interventions performed

by unauthorized personnel

Modifications to the instrument performed without the manufacturer’s explicit

authorization

Use not provided for in the instrument’s specifications or in the instruction manual

The content of this manual cannot be reproduced in any form without the manufacturer’s

authorization.

Our products are patented and our trademarks are registered. The manufacturer

reserves the right to make changes in the specifications and prices if this is due to

improvements in technology

11.2 SERVICE

If the instrument does not operate properly, before contacting the After-sales Service,

please check the conditions of battery and cables and replace them, if necessary

Should the instrument still operate improperly, check that the product is operated

according to the instructions given in this manual

Should the instrument be returned to the After-sales Service or to a Dealer, transport will

be at the Customer's charge. However, shipment will be agreed in advance

A report will always be enclosed to a shipment, stating the reasons for the product’s return

Only use original packaging for shipment; any damage due to the use of non-original

packaging material will be charged to the Customer

EN - 37

Page 40

Page 41

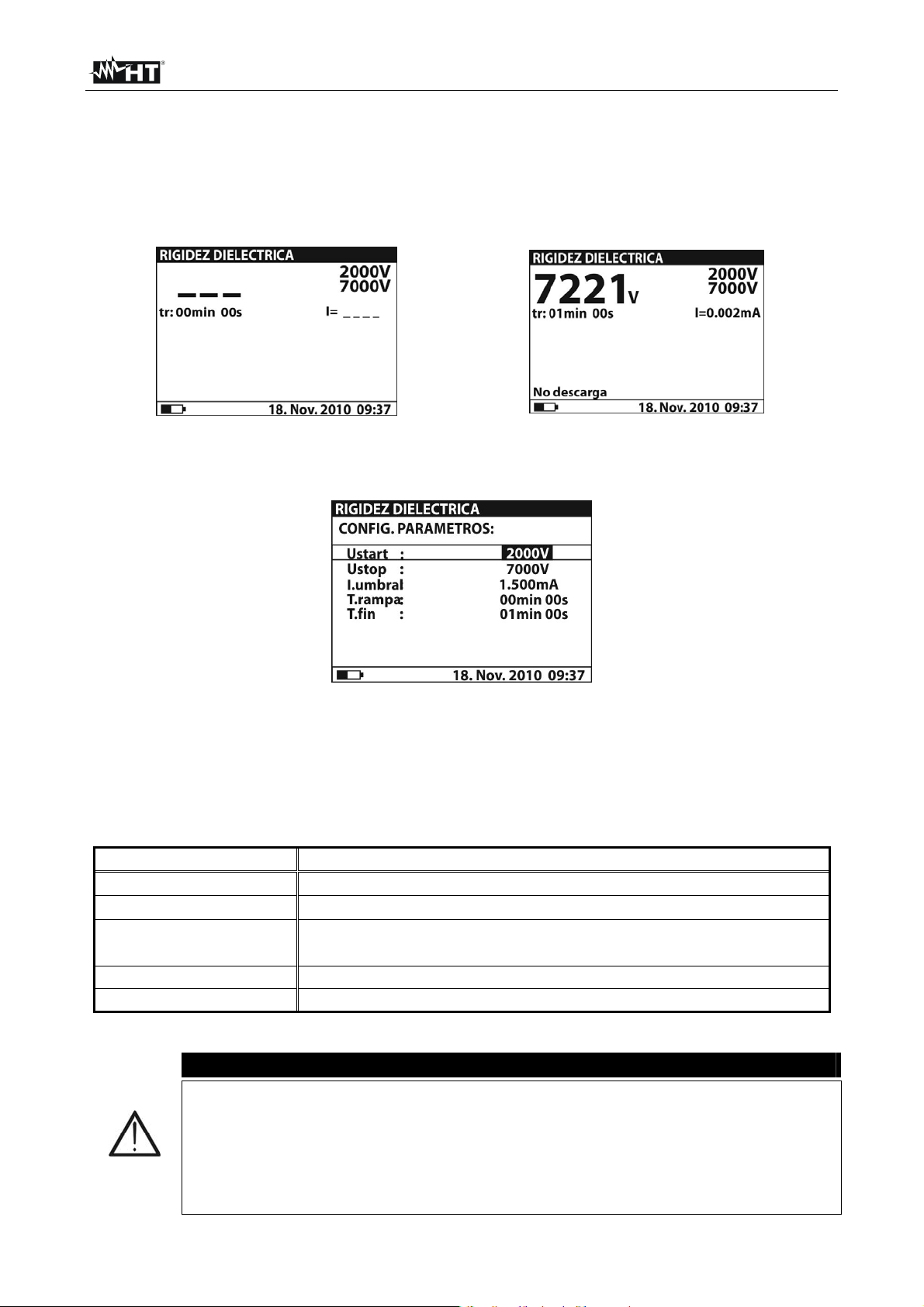

ESPAÑOL

Manual de Instrucciones

Copyright HT ITALIA 2013 Versión ES 2.00 - 02/01/2013

Page 42

Page 43

HT7052

Indice:

1 PRECAUCIONES Y MEDIDAS DE SEGURIDAD ............................................................... 2

1.1 Instrucciones preliminares .................................................................................................................... 2

1.2 Durante el uso ...................................................................................................................................... 3

1.3 Después del uso ................................................................................................................................... 3

1.4 Definición de categoría de medida (sobretensión) ............................................................................... 3

2 DESCRIPCIONES GENERALES ......................................................................................... 4

2.1 Funcionalidad del instrumento .............................................................................................................. 4

3 PREPARACIÓN PARA EL USO .......................................................................................... 5

3.1 Controles iniciales................................................................................................................................. 5

3.2 Alimentación del instrumento ............................................................................................................... 5

3.3 Calibración ............................................................................................................................................ 5

3.4 Almacienamiento .................................................................................................................................. 5

4 NOMENCLATURA ............................................................................................................... 6

4.1 Descripción del instrumento ................................................................................................................. 6