Page 1

ENGLISH

User manual

Copyright HT ITALIA 2012 Release EN 2.02 - 04/05/2012

Page 2

HT2055

Table of Contents:

1 PRECAUTIONS AND SAFETY MEASURES .............................................................................. 2

1.1 Preliminary instructions ........................................................................................................................ 2

1.2 During use ............................................................................................................................................ 3

1.3 After use ............................................................................................................................................... 3

1.4 Definition of measurement (overvoltage) category .............................................................................. 3

2 GENERAL DESCRIPTION .......................................................................................................... 4

2.1 Instrument features ............................................................................................................................. 4

3 PREPARATION FOR USE .......................................................................................................... 5

3.1 Initial inspections .................................................................................................................................. 5

3.2 Instrument power supply ...................................................................................................................... 5

3.3 Calibration ............................................................................................................................................ 5

3.4 Storage ................................................................................................................................................. 5

4 DESCRIPTION OF PARTS .......................................................................................................... 6

4.1 HT2055S station unit description ......................................................................................................... 6

4.1.1 Modify of supply voltage for HT2055S unit........................................................................................ 6

4.2 Description of test leads ....................................................................................................................... 7

4.2.1 Front view .......................................................................................................................................... 7

4.2.2 Top view ............................................................................................................................................ 7

4.2.3 Backside view .................................................................................................................................... 8

5 INITIAL OPERATIONS WITH HT2055M UNIT ............................................................................ 9

5.1 Settings ................................................................................................................................................. 9

5.1.1 Language selection ........................................................................................................................... 9

5.1.2 Help screen ....................................................................................................................................... 9

5.1.3 Synchronization ............................................................................................................................... 10

5.1.4 Default settings ................................................................................................................................ 11

5.1.5 Time/Date settings .......................................................................................................................... 11

5.2 Messages at display ........................................................................................................................... 11

6 INITIAL OPERATIONS WITH HT2055S UNIT .......................................................................... 12

6.1 Settings ............................................................................................................................................... 12

6.1.1 Default settings ................................................................................................................................ 12

6.1.2 Setting output power ....................................................................................................................... 13

6.1.3 Setting alarm condition .................................................................................................................... 13

6.2 Adjust contrast of display ................................................................................................................... 14

6.3 Help screens ...................................................................................................................................... 14

6.4 Messages at display ........................................................................................................................... 14

7 HOW TO PERFORM THE MEASUREMENTS .......................................................................... 15

7.1 Theory of Step/Contact voltage measurements ................................................................................. 15

7.2 Step/Contact voltage measurement ................................................................................................... 16

7.3 Earth resistance measurement .......................................................................................................... 21

7.4 Ground resistivity measurement ........................................................................................................ 23

8 OPERATION WITH MEMORY ................................................................................................... 25

8.1 Saving results ..................................................................................................................................... 26

8.2 Recall result at display ....................................................................................................................... 26

8.3 Delete saved results ........................................................................................................................... 27

9 CONNECTION OF THE INSTRUMENT TO PC ........................................................................ 28

9.1 Installation of software and initial configurations (Win XP) ................................................................ 28

10MAINTENANCE ......................................................................................................................... 30

10.1Replacement and charging batteries ................................................................................................. 30

10.2Replacement fuses of HT2055S unit ................................................................................................. 30

10.3Cleaning the instrument ..................................................................................................................... 30

10.4End of life............................................................................................................................................ 30

11TECHNICAL SPECIFICATIONS ............................................................................................... 31

11.1General characteristics ....................................................................................................................... 32

11.2Environment ....................................................................................................................................... 33

11.3Standard accessories ......................................................................................................................... 33

11.4Optional accessories .......................................................................................................................... 33

12SERVICE ....................................................................................................................... ............ 34

12.1Warranty conditions ............................................................................................................................ 34

12.2Service ................................................................................................................................................ 34

EN - 1

Page 3

HT2055

1 PRECAUTIONS AND SAFETY MEASURES

The instrument has been designed in compliance with standards IEC/EN61557-1 and

IEC/EN61010-1 regarding electronic measuring instruments.

For the operator’s safety and to prevent damaging the instrument, follow the

procedures described in this manual and carefully read all notes preceded by

the symbol .

Before and during measurements, carefully observe the following instructions:

Do not perform any measurement in humid environments, in the presence of gas or

explosive or inflammable material or in dusty areas

Even when no measurements are being performed, avoid any contact with the circuit

under test, with exposed metal parts, with unused measuring leads or circuits, etc.

Do not perform any measurement when anomalies are found in the instrument, such as

deformations, breaks, substance leaks, no display view, etc.

During instrument operation, the ventilation holes on casing of HT2055S unit should

always stay open to ensure enough air-flow for cooling

Disconnect all test leads, switch off the instrument and remove the mains cord before

changing the fuse on the HT2055S unit

Pay special attention when measuring voltages above 25V in special environments

(building yards, swimming pools, etc.) and 50V in ordinary environments, as there is

danger of electric shocks.

In this manual and on the instrument, the following symbols are used:

WARNING: Observe the instructions reported in the manual. An improper use

could damage the instrument and lead to dangerous situations for the operator.

AC voltage or current.

CAUTION

Instrument with double insulation.

1.1 PRELIMINARY INSTRUCTIONS

This instrument (HT2055M) has been designed for use in an environment with pollution

level 2

It may also be used to test industrial electrical systems up to CAT II 300V and CAT IV

50V to earth (HT2055S) and CAT IV 50V (HT2055M)

Follow the usual safety rules to protect the operator from dangerous currents and

protect the instrument against improper use

Never use the instrument standing on the floor, it must be placed on flat horizontal

surfaces

Only the accessories supplied with the instrument guarantee safety standards. They

must be in good conditions and replaced, if necessary, with identical models

Do not measure systems exceeding the current and voltage limit values specified

Do not perform measurements under environmental conditions out of the limit values

indicated in this manual

Before connecting the probes to the circuit under test, check that the correct function is

selected

EN - 2

Page 4

HT2055

1.2 DURING USE

Carefully read the following recommendations and instructions:

Failure to observe the warnings and/or instructions may damage the

instrument and/or its components or generate a danger for the operator

CAUTION

Before selecting a new function, disconnect the measuring probes from the circuit

When the instrument is connected to the circuit under test, never touch any unused

lead

The auxiliary current probe can be subject to a higher voltage. Avoid the contact with

this probe during measurement

Avoid measuring resistance with external voltages. Even if the instrument is protected,

as an excess voltage may cause instrument malfunctions

1.3 AFTER USE

When measurements are completed, turn off the instrument by pressing the ON/OFF key.

1.4 DEFINITION OF MEASUREMENT (OVERVOLTAGE) CATEGORY

Standard "IEC/EN61010-1: Safety requirements for electrical equipment for measurement,

control and laboratory use, Part 1: General requirements", defines what is intended for

measurement category, commonly known as overvoltage category. In § 6.7.4: Measuring

circuits, it reads:

Circuits are divided into the following measurement categories:

Measurement category IV is for measurements performed at the source of a low-

voltage installation.

Examples are electric counters and measurements on primary devices protecting

against overcurrents and on ripple adjusting units.

Measurement category III is for measurements performed on installations inside

buildings.

Examples are measurements performed on distribution boards, circuit breakers, wiring

harnesses, including cables, bars, junction boxes, switches, sockets of fixed

installations and appliances designed for industrial use and other equipment, e.g.

stationary motors connected to fixed systems.

Measurement category II is for measurements performed on circuits directly

connected to the low-voltage installation.

Examples are measurements performed on household appliances, portable tools and

similar equipment.

Measurement category I is for measurements performed on circuits not directly

connected to the MAINS.

Examples are measurements performed on circuits not derived from the MAINS and on

circuits derived from the MAINS provided with a special (internal) protection. In this

latter case, the stress caused by the transients is variable; therefore, (OMISSIS) it is

necessary that the user knows the appliance’s resistance to transients.

EN - 3

Page 5

HT2055

2 GENERAL DESCRIPTION

The instrument HT2055 you purchased grants accurate and reliable measurements as

well as the utmost safety provided it is used in compliance with the indications given in this

manual. Thanks to a new concept development it ensures double insulation and,

consequently, compliance with the requirements of overvoltage category IV.

The instrument is composed of the following two units:

HT2055S Station unit which can generate the test current in order to perform the

step/contact voltage and the earth/resistivity measurements

HT2055M Meter unit in order to perform the step/contact voltage measurements with

test current generated by the station unit.

2.1 INSTRUMENT FEATURES

Step/contact voltage measurement with test current of max 55A

Earth resistance measurement with 4 wire method

Ground resistivity measurement with Wenner method

Use of metal plates for step/contact voltage measurement

Initial synchronizing for autonomous use of the meter unit

DSP internal filtering for compensation of disturbance effect on the measurement

Internal memory for saving test

USB interface for data transfer to PC

Use of rechargeable batteries on meter unit

A dot matrix LCD offers easy-to-read results and all associated parameters. The operation

is straightforward and clear to enable the user to operate the instrument without the need

for special training (except reading and understanding this user manual).

Test results can be stored on the instrument. The new professional PC SW enables

straightforward transfer of test results and other parameters in both directions between the

test instrument and PC

EN - 4

Page 6

HT2055

3 PREPARATION FOR USE

3.1 INITIAL INSPECTIONS

Before shipment, the instrument’s electronics and mechanics were inspected. All possible

precautions were taken to permit delivery of instrument free of damage.

However, we recommend generally inspecting the instrument in order to detect any

damage suffered during transport. Should you detect any anomalies, immediately contact

the forwarding agent or the dealer.

Moreover, we recommend checking that the package contains all parts listed in § 11.3.

Should you find any discrepancy, please contact the dealer. Should it be necessary to

return the instrument, please follow the instructions reported in § 12.

3.2 INSTRUMENT POWER SUPPLY

The station unit HT2055S is power-supplied by 230V ± 10%, 50/60Hz mains while the

meter unit HT2055M is power-supplied through 6x1.2V IEC AA internal rechargeable

batteries which are recharged from the mains by means of a battery charger supplied as

standard accessory. The use of 6x1.5V type AA LR6 alkaline batteries is also possible for

this unit. The symbol “ “ indicates that the batteries are low and must be recharged.

To recharge or replace the batteries, follow the instructions given in § 10.1

Use NiMh rechargeable batteries IEC LR6 all of the same type for the

HT2055M unit

Do not charge alkaline battery cells

At the first use of HT2055M unit connect the instrument to the mains power

supply for at least 14 hours to fully charge batteries. When you charge the

batteries for the first time, it normally takes about 4 charge and discharge

cycles for the batteries to regain full capacity

CAUTION

3.3 CALIBRATION

The instrument complies with the technical specifications reported in this manual. Its

correct operation is guaranteed for one year from the date of purchase.

3.4 STORAGE

In order to guarantee accurate measurements and protect the instrument from possible

failures, after a long storage period under extreme environmental conditions, wait for the

instrument to return to a normal condition (see the environmental specifications listed in §

11.2).

EN - 5

Page 7

HT2055

4 DESCRIPTION OF PARTS

4.1 HT2055S STATION UNIT DESCRIPTION

Fig. 1: HT2055S unit description

CAPTION:

1 Protection fuse on mains (see § 11.1)

2 Switch for supply voltage selection (110/230V)

3 ON/OFF key to switch the instrument ON or OFF

4 Input connector for mains cord

5 RS-232 galvanic port for connection to HT2055M unit

6 C1/H terminal for connection of auxiliary earth probe

7 P1/S for connection of auxiliary voltage probe

8 P2/ES for connection of auxiliary current probe

9 C2/E for connection of auxiliary earth probe

10 HELP key

11 – 12

and keys for function selection and parameter settings

13 LCD display with backlit

14 Key for adjust contrast of display

15 MEM key for access to internal memory (see § 8)

16 ESC key to return at previous screen

17 , , , arrow keys and TEST key to activation measurements

4.1.1 Modify of supply voltage for HT2055S unit

1. Open the fuses compartment (see Fig. 1 – Part 1) with a screwdriver

2. Extract the red switch (see Fig. 1 – Part 2) from the fuses compartment

3. Rotate the switch in way to correctly read the “115V” or “230V” indication

correspondent to the desired supply voltage

4. Restore the switch in the fuses compartment and close it

EN - 6

Page 8

HT2055

4.2 DESCRIPTION OF TEST LEADS

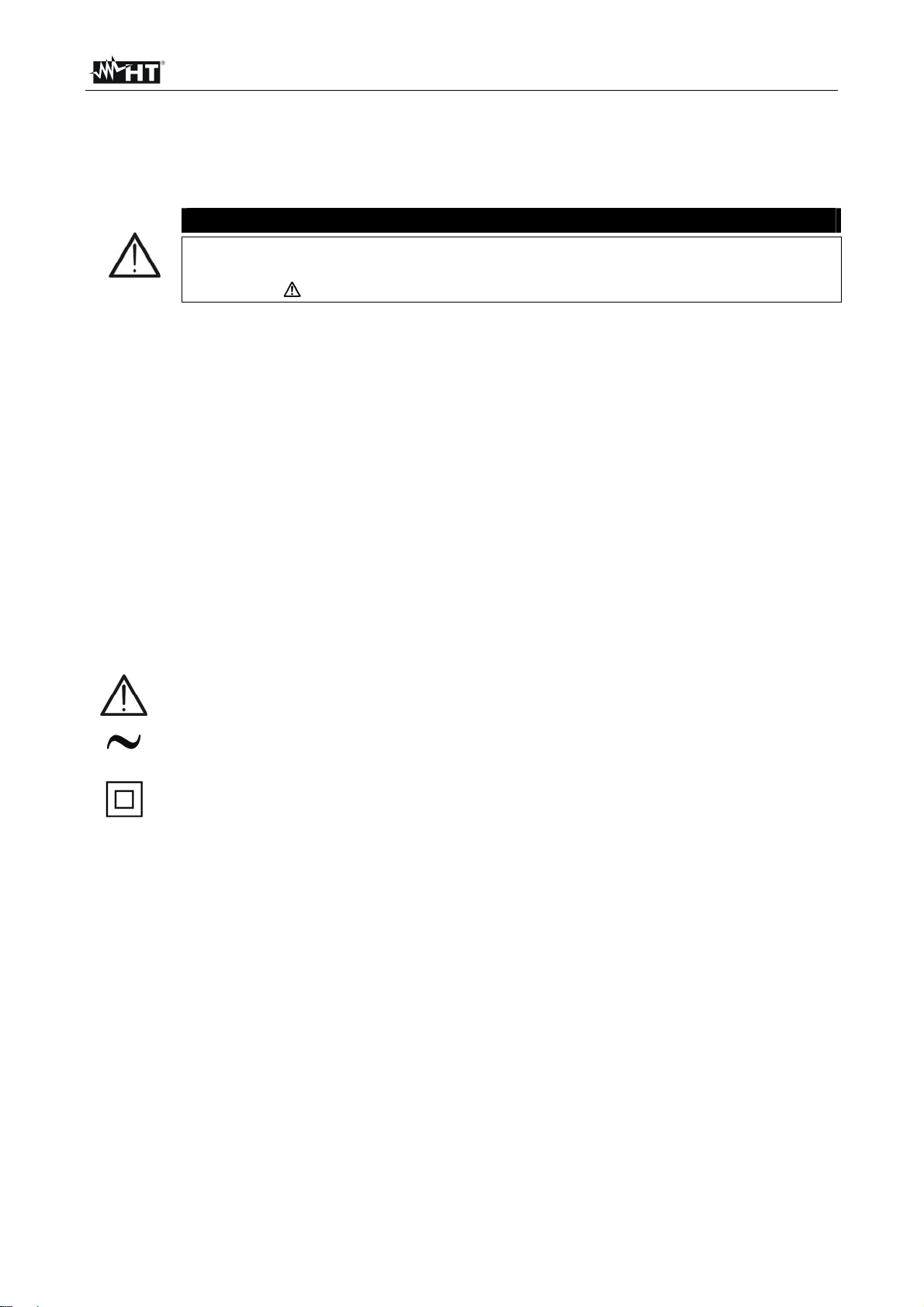

4.2.1 Front view

CAPTION:

1 ESC key to return at previous screen

2 MEM key for access to internal memory (see § 8)

3 , , , arrow keys and TEST key to activation measurements

4 Backlight key

5 LCD display

6 ON/OFF key to switch the instrument ON or OFF

7 - 8

4.2.2 Top view

CAPTION:

Test connector.

1

CAUTION: maximal allowed voltage between test terminals and ground is

50V. Maximal allowed voltage between test terminals is 100V

2 Power supply socket

3 PS/2 connector (for RS232 communication)

4 Protection cover

5 USB connection

Fig. 2: HT2055M unit front view description

and keys for function selection and parameter settings

Fig. 3: HT2055M unit top view description

EN - 7

Page 9

HT2055

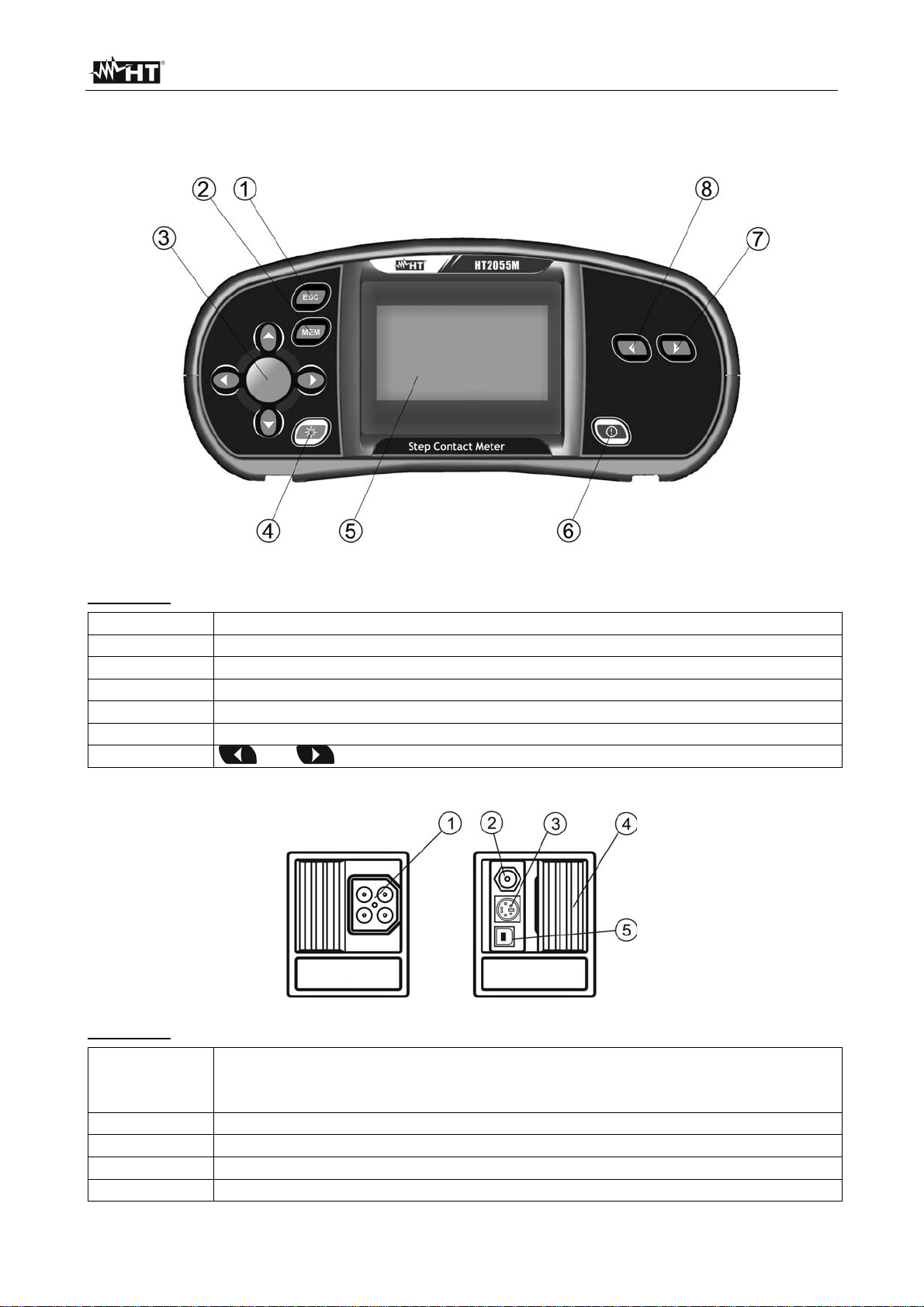

4.2.3 Backside view

Fig. 4: HT2055M unit backside view description

CAPTION:

1 Battery compartment cover

2 Safety information label

3 Fixing screws for battery compartment cover

CAPTION:

4 Serial number label

5 Battery cells (6x1.2V NiMH type AA)

6 Battery compartment

Fig. 5: HT2055M battery compartment description

EN - 8

Page 10

HT2055

5 INITIAL OPERATIONS WITH HT2055M UNIT

Press the or function keys to display the below screens relative to the Step

Voltage, Contact Voltage and Settings (see Fig. 6)

Fig. 6: Screens of general menu

5.1 SETTINGS

The below operations are possible within Settings menu:

Language selection

Help screens on connections

Syncronizing with the station unit HT2055S

Restore of default conditions

Recall at display of saved results (see § 8.2) and clear memory (see § 8.3)

Setting of system time/date

5.1.1 Language selection

Fig. 7: Screen of language selection

1. Press or keys to enter Settings menu

2. Select the item “Select Language” with the or keys and press TEST key

3. Select the desired language with the or keys and confirm with TEST key

4. Press ESC key to exit and go back to the previous screen

5.1.2 Help screen

Fig. 8: Help screen

1. Press or keys to enter Settings menu

2. Select the item “Help” with the or keys and press TEST key

3. Select the desired help screen with the or keys

4. Press ESC key to exit and go back to the previous screen

EN - 9

Page 11

HT2055

5.1.3 Synchronization

Selecting this option will allow to upload different data from the station unit to the meter

unit. The possible options are:

Synchronization of the actual time/date and the generated current

Uploading of test current results for Step / Contact voltage calculation

Uploading of earth resistance and ground resistivity results

Fig. 9: Synchronization screen

1. Press or keys to enter Settings menu

2. Select the item “Synchronize” with the or keys and press TEST key

3. Connect both units by using the PS/2-RS-232 supplied cable

4. Select one of the below options with the or keys and confirm with TEST key

TIME, CURRENT

STEP/CONTACT VOLT

EARTH RESULT

5. Press ESC key to exit and go back to the previous screen

Station’s time and date will be uploaded to the meter. Value

of generator current will be uploaded to the meter

Values of logged generator currents I

will be uploaded to

GEN

the Meter for calculation of Step voltage or Contact voltage

Stored earth resistance or ground resistivity results in the

station will be uploaded to the meter

CAUTION

The main purpose of the Time/ Current synchronization is to enable a

correction of the step and contact voltage results after the test. During the

test the step and contact voltage results are calculated based on the I

set on the meter. After the test the obtained results can be updated with

the real generator currents I

station. The stored U

STEP

measured at the same time with the

GEN

and U

CONTACT

values are then corrected

according to the following formula:

UU

STEPoldSTEPnew

I

SET

I

I

UU

CONToldCONTnew

I

SET

)_(

generatedactuallyGEN

generatedactuallyGEN

)_(

The synchronization is active for 24 h

If date / time are changed on the meter or station the synchronization of

time and date will be lost. The current logger must be cleared before it can

proceed with measurements. Before clearing it you can download its

content to the meter

GEN

EN - 10

Page 12

HT2055

5.1.4 Default settings

This section permits to restore the default value (factory) of measurement parameters and

limits set on the instrument

Fig. 10: Initial settings screen

1. Press or keys to enter Settings menu

2. Select the item “Initial Settings” with the or keys and press TEST key

3. Select the “NO” or “YES” options with the or keys and confirm with TEST

4. Press ESC key to exit and go back to the previous screen

The default values are the following:

Language

Contact and Step voltage

English

I

= 10A

GEN

I

= 1kA

FLT

R

= 1MΩ

INP

U

= 50V

LIM

5.1.5 Time/Date settings

Fig. 11: Time/Date settings screen

1. Press or keys to enter Settings menu

2. Select the item “Set Date/Time” with the or keys and press TEST key

3. Use the ,, and keys to set the date/time and confirm with TEST

4. Press ESC key to exit and go back to the previous screen

5.2 MESSAGES AT DISPLAY

The below messages (icons) can be displayed on the meter unit:

The meter and the station are not synchronized

Measurement is running

Results can be stored

Measurement result is within pre-set limits (PASSED)

Measurement result is out of pre-set limits (FAILED)

EN - 11

Page 13

HT2055

6 INITIAL OPERATIONS WITH HT2055S UNIT

Press the or function keys to display the below screens relative to the

earth/resistivity measurements and Settings (see Fig. 12)

Fig. 12: Screens of general menu

6.1 SETTINGS

The below operations are possible within Settings menu:

Language selection (see § 5.1.1)

Restore of default conditions

Setting power of current generator

Setting of alarm conditions when switching off test current

Recall at display of saved results (see § 8.2) and clear memory (see § 8.3)

Time/date setting (see § 5.1.5)

6.1.1 Default settings

This section permits to restore the default value (factory) of measurement parameters and

limits set on the instrument

Fig. 13: Initial settings screen

1. Press or keys to enter Settings menu

2. Select the item “Initial Settings” with the or keys and press TEST key

3. Select the “NO” or “YES” options with the or keys and confirm with TEST

4. Press ESC key to exit and go back to the previous screen

The default values are the following:

Contrast

Language

Alarm

Power of generator

Distance “a”

50%

English

Disabled

100%

2.0m

EN - 12

Page 14

HT2055

6.1.2 Setting output power

This section permits to set the output power of current generator by selecting the

percentages: 10%, 25%, 50%, 75% and 100%

Fig. 14: Output power generator setting screen

1. Press or keys to enter Settings menu

2. Select the item “Power Range” with the or keys and press TEST key

3. Select the desired percentage with the or keys and confirm with TEST

4. Press ESC key to exit and go back to the previous screen

CAUTION

When the current generator is started the output power is automatically set to

the available maximum value. If the conditions change during the

measurement the generator may switch off. Possible causes for switching off

are:

The output can become overloaded by high external earth currents. In this

case it is recommended to decrease the output power down to 75% or 50%

and restart the generator

The current stopped flowing abruptly. If stop was caused by disconnection

of the leads it is not necessary to lower down the power. The generator can

be restarted.

6.1.3 Setting alarm condition

This section permits to set an acoustic alarm condition when stopping current generation

due to noise effect or unexpected opening of circuit under test

Fig. 15: Alarm condition setting screen

1. Press or keys to enter Settings menu

2. Select the item “Alarm” with the or keys and press TEST key

3. Select the options “ENABLED” or “DISABLED” with the or keys and confirm with

TEST

4. Press ESC key to exit and go back to the previous screen

An active alarm helps to avoid wrong interpretation of the Step and Contact

voltage results. The readings will be close to 0 V if no test current is flowing

CAUTION

EN - 13

Page 15

HT2055

6.2 ADJUST CONTRAST OF DISPLAY

1. Press the key. The following screen is shown:

2. Use the or keys to reduce or increase the contrast percentage of display

3. Press the TEST key to confirm the operation or the ESC key to exit from this function

6.3 HELP SCREENS

1. Pressing screen to display the help screen correspondent to the selected function

2. Use the or keys to select the other help screens

3. Press ESC key to exit and go back to the previous screen

6.4 MESSAGES AT DISPLAY

The below messages/screens can be displayed by the station meter:

Voltage between test terminals C1/H and C2/E is higher than

allowed (>10 V). Disconnect the test leads and check why an

external voltage was detected

During current generation output was overloaded or test current

abruptly fell down. Overload can be caused by high spurious earth

current. In this case it is recommended to decrease the output power

(see § 6.1.2)

Output current is too low (< 0.2A). A too low current can be caused

because of bad connection or high probe resistance

Date / time was changed in the station and consequently the

synchronization between station and meter gets lost. The current

logger must be cleared. Before clearing it its contents can be

downloaded to the meter

Output power is not set to maximum

Measurement is running

Results can be stored

High electrical noise was detected during measurement. Results may be

impaired

High resistance of current (c) and/ or voltage (p) probes. Results may be

impaired

EN - 14

Page 16

HT2055

7 HOW TO PERFORM THE MEASUREMENTS

7.1 THEORY OF STEP/CONTACT VOLTAGE MEASUREMENTS

An earth electrode / grid depleted into ground has a certain resistance, depending on its

size, surface (oxides on the metal surface) and the soil resistivity around the electrode.

The earth resistance is not concentrated in one point but is distributed around the

electrode. Correct connection of exposed conductive parts assures that the voltage on

them stays below dangerous level in case of a fault.

If a fault happens a fault current will flow through the earth electrode. A typical voltage

distribution occurs around the electrode (the “voltage funnel”). The largest part of the

voltage drop is concentrated around the earth electrode. The Fig. 16 shows how fault, step

and contact voltages occur as a result of fault currents flowing through the earth electrode

/ grid in the ground.

Fault currents close to power distribution objects (substations, distribution towers, plants)

can be very high, up to 200 kA. This can result in dangerous step and contact voltages. If

there are underground metal connections (intended or unknown) the voltage funnel can

get atypical forms and high voltages can occur far from the point of failure. Therefore the

voltage distribution in case of a fault around these objects must be carefully analyzed.

Fig. 16: Dangerous voltages on a faulty earth system

The guidelines define limit values of step/contact voltages depending on the time of fault

elimination by the protection devices (typically declared by the Mains Energy provider). If

the value of fault voltage is over this limit it is necessary to verify that the values of

step/contact voltages in some potentially dangerous points of the plants (e.g: access

areas, close to metal structures normally de-energized, gates, safety nets, etc) fall within

standard values.

EN - 15

Page 17

HT2055

7.2 STEP/CONTACT VOLTAGE MEASUREMENT

The measurements of step/contact voltage are performed by a voltmeter with an internal

resistance of 1k simulating the body resistance and with two weight probes of 25 kg

each simulating feet. Alternatively it is possible to use two metal plates instead of

weight probes on the ground where the operator stands.

CAUTION

During the measurement a test current is injected into the earth through an

auxiliary probe. The resistance of the auxiliary probe should be as low as

possible in order to inject a high test current. The resistance can be decreased

by using more probes in parallel or using an auxiliary earth system as

auxiliary probe. A higher injected current improves the immunity against

spurious earth currents.

As the test current is usually only a small fraction of the highest fault current the measured

voltages must be up scaled according to the following equation:

I

Fault

UU

,

MeasuredCS

I

Gen

U

………..calculated step or contact voltage in case of fault current

S,C

U

Measured

I

Fault

I

Gen

….measured voltage during the test

………..maximal earth current in case of a fault

………..injected test current

Installation of station unit

1 Place the station unit close to the earth system under test (distance max. 10m).

Connect the unit at the input terminal C1/H by using the supplied cable

2 Fit the auxiliary metal probe (1m length) on the ground at a distance of at least 5 times

the maximum diagonal of the earth system under test (see Fig. 17). Connect the input

terminal C2/E to the probe by using the 50m long cable (if enough) or use another

customized cable for longer distances. The nature of the measurement method permits

the use of different cables without any resistance compensation. Use also several

probes connected in parallel among them if it is necessary to reduce the contact

resistance on that point.

EN - 16

Page 18

HT2055

Fig. 17: Circuit scheme for step voltage measurement

Fig. 18: Circuit scheme for contact voltage measurement

Generation of test current

3 Switch on the station unit HT2055S

4 Use or keys and select the “CURRENT GEN.” screen (see Fig. 19)

Fig. 19: Test current generation screen

EN - 17

Page 19

HT2055

5 Press TEST key to activate the operation. The value of generated current is displayed.

Check this value.

CAUTION

The output power is set automatically to its available maximum value (see

§ 6.1.2)

Completely unwind measuring cable to avoid affecting test current value

(coil impedance)

Usually the resistance of auxiliary probe can affect the generated test

current. The injected current can be increased by placing more probes in

parallel.

Synchronization between the units before the test (recommended)

Before starting with the step/contact voltage measurements it is recommended to

synchronize the meter and the station units. The synchronization sets the same date and

time in both units. Therefore the measured voltages can be correctly scaled after the

measurements. If the current is generated during the synchronization its value is also sent

to the meter unit (see § 5.1.3)

6 Connect both meter and station units through the PS/2-RS-232 cable supplied as

accessory (see Fig. 20)

Fig. 20: RS-232 connection between units

7 Select the option “Synchronize Time, Current” on the meter unit (see § 5.1.3) and

confirm with TEST key. The messages “Connecting...” and “Synchronizing…” are

displayed.

CAUTION

The measurements can be carried out without synchronization. In this case

the measuring current must be set / changed manually. If the injected current

is changing during the test the I

parameter must be adjusted manually. The

GEN

measurement results cannot be corrected after the measurement.

EN - 18

Page 20

HT2055

Perform step/contact voltage measurements

8 Use or keys and select the CONTACT VOLT or STEP VOLT measurements

on the meter unit

Fig. 21: Screens for step/contact voltage measurements

9 Use ,, and keys and perform the settings of the following test parameters:

Igen

Iflt

Rinp

Ulim

Test current (manual setting considering the range 0.20A ÷ 50A) or

automatically fitted by the station unit during the synchronization

Maximum fault current of earth system (range 10A ÷ 200kA)

Input resistance of the meter unit (1M, 1k)

Limit value for step/contact voltage measurements (range 1V ÷ 10kV)

Iflt Fault current value given by the Mains Energy provider

Rinp Input resistance fixed to 1k for step/contact voltage measurements

Ulim Voltage limit given by Guidelines according to the time of fault elimination by the

protection devices

10 Place and connect the test metal plates to each other where the operator stands, close

to the points where step voltage measurement (see Fig. 17) or contact voltage (see

Fig. 18) is required respecting the necessary distances

11 Connect the metal plates to the meter unit by using the cables supplied

12 Press TEST key on the meter unit and perform the step voltage of the contact voltage

measurements. The following screens are displayed by the meter:

Fig. 22: Screens for results of step/contact voltage measurements

Where:

U calculated step/contact voltage

Um measured step/contact voltage

13 Press MEM key to save the result inside memory (see § 8.1)

EN - 19

Page 21

HT2055

Synchronization between the units after the test (recommended)

If the meter and station units were synchronized during the measurements they should be

synchronized again after completing the tests. In this step the values of generated currents

(measured with the station) are downloaded to the meter so automatically correcting the

measured results previously stored and providing the correct value of step and contact

voltages.

14 Connect both meter and station units through the PS/2-RS-232 cable supplied (see

Fig. 20)

15 Select the option “Synchronize Time, Current” on the meter unit (see § 5.1.3) and

confirm with TEST key. The messages “Connecting...” and “Synchronizing…” are

displayed.

16 The following screens can be displayed by the meter unit during the synchronization

Fig. 23: Example of screens on the synchronization operation

NOT SYNCHRONIZED number of not synchronized results

Synchronization of step/contact voltage results can last up to several 10

seconds. A bargraph is showing the progress.

CAUTION

EN - 20

Page 22

HT2055

7.3 EARTH RESISTANCE MEASUREMENT

The earth resistance measurement is performed by the HT2055S station unit only by using

the standard 3-wire method with two supplied auxiliary probes fitted at adequate distances

from the earth system under test according to the Fig. 24

Fig. 24: Connection of instrument for earth resistance measurement

1 Place the station unit close to the earth system under test (distance max. 10m)

2 Connect the input terminals C2/E and ES to the earth system under test by using the

cables supplied

3 Fit the auxiliary metal probe (1m length) on the ground at a distance of least 5 times

the maximum diagonal of the earth system under test (see Fig. 24). Connect the input

terminal C1/H to the probe by using the 50m long cable supplied (if enough) or use

another customized cable for longer distance. The nature of the measurement method

permits the use of different cables without any resistance compensation. Use also

more probes connected in parallel to each other if it’s necessary to reduce the contact

resistance on that point

4 Fit the auxiliary metal probe (60m length) on the ground at a distance of at least 2.5

times the maximum diagonal of the earth system under test (see Fig. 24). Connect the

input terminal S to the probe by using the 50m long cable supplied (if enough) or use

another customized cable for longer distance. The nature of the measurement method

permits the use of different cables without any resistance compensation. Use also

more probes connected in parallel to each other if it’s necessary to reduce the contact

resistance on that point

CAUTION

For large sized installations, place the ampere metric probe (H) at a distance

equal to the diagonal of the earth installation and the volt metric probe (S) at a

distance equal to about 0.5 times the diagonal of the earth installation. In the

latter case several measurements shall be carried out moving the volt metric

probe back and forth (along the measurement direction) with respect to the

middle point and checking that the result is nearly constant

EN - 21

Page 23

HT2055

5 Use or keys and select the EARTH RE measurement on the station unit. The

following screen is displayed:

Fig. 25: Main screen of earth resistance measurement

6 Press TEST key to perform the measurement. The result is displayed

Fig. 26: Result screen of earth resistance measurement

Where:

R Measured value of earth resistance

Rp Voltage probe resistance (S)

Rc Current probe resistance (H)

CAUTION

When starting test the unit performs a preliminary check of the resistance

values for current probe (Rc) and voltage probe (Rp) stopping the test if

these values are assumed to be too high and giving the following

messages “Rc: >2.0k” and “Rp: >2.0k”. Decrease the value of these

resistance wetting the ground close to the probes and/or connect more

probes in parallel

High noise currents and voltages on earth could affect the measurement

results. In this case the tester displays the ”NOISE” warning

7 Press MEM key to save the result inside memory (see § 8.1)

CAUTION

To view stored earth resistance results on PC they must be downloaded to the

meter unit first. To download the results select earth results from Synchronize

menu (see § 5.1.3). After the results are downloaded the stored data in

the station unit will be automatically deleted

EN - 22

Page 24

HT2055

7.4 GROUND RESISTIVITY MEASUREMENT

For the ground resistivity measurement the test current is injected through two current

probes (C1/H and C2/E). The voltage probes S and ES must be placed between the

current probes (equidistance ‘a’ between probes must be considered). Using different

distances between the test probes means that the material is measured at different

depths. By increasing the distance ‘a’ a deeper layer of ground material is measured (see

Fig. 27)

Fig. 27: Connection of the unit for ground resistance measurement

1 Use or keys and select the EARTH RE measurement on the station unit

2 Use the or keys to select the “EARTH ” measurement. The below screen is

displayed:

Fig. 28: Main screen of ground resistance measurement

3 Use the or keys to select the “a” parameter. Use the or keys to set the value

expressed in meters into the range 0.1 ÷ 30.0 by steps of 0.1m

4 Fit the auxiliary test probes at the same distance “a” set on the station unit and connect

the input terminals C1/H, C2/E (current probes), ES and S (voltage probes) to the earth

system under test by using the cables supplied as accessories (see Fig. 27)

5 Press TEST key to perform the measurement. The result is displayed

Fig. 29: Result screen of ground resistance measurement

Where:

Measured value of ground resistivity

Rp Voltage probe resistance (sum of S+ES)

Rc Current probe resistance (sum of C1/H +C2/E)

EN - 23

Page 25

HT2055

CAUTION

When starting test the unit performs a preliminary check of the resistance

values of current probe (Rc) and voltage probe (Rp) stopping the test if

these values are assumed to be too high and giving the messages “Rc:

>2.0k” and “Rp: >2.0k”. Decrease the resistance value wetting the

ground close to the probes and/or connect more probes in parallel

High noise currents and voltages in earth could affect the measurement

results. In this case the tester displays the ”NOISE” warning

6 Press MEM key to save the result inside memory (see § 8.1)

CAUTION

To view stored ground resistivity results on PC they must be downloaded to

the meter unit first. To download the results select earth results in Synchronize

menu (see § 5.1.3). After the results are downloaded the stored data in

the station unit will be automatically deleted

EN - 24

Page 26

HT2055

t

d

d

8 OPERATION WITH MEMORY

The measurement results, including associated parameters, can be saved inside the

internal memories of station unit and meter unit. In particular:

The step/contact voltage measurements can be saved in the meter unit

The earth resistance/ground resistivity measurements can be saved in the station unit

and then transferred to the meter unit

The values of generated currents are automatically saved in the station unit

The internal memory of both units is divided into 3 levels with max 199 locations each. The

number of measurements which can be saved in a location is only limited by the available

memory

The internal memory (see Fig. 30) includes two types of structures:

The data structure defines the order of the saved results with the division into

“OBJECTS” and “LOCATIONS”

The structure of measurements defines the information on the type and the number

of measurements associated to the selected data structure (Object and Location)

Fig. 30: Structure of internal memory of the meters

This kind of structure permits an easy manipulation of saved data as:

The results are organized and structured into groups

The surfing among the saved results is simplified

The printed report can be created with or without minor modifications after the

downloading to PC

Data structure

RECALL RESULTS

Type of operation inside the memory

OBJECT 001

LOC1 001

Data structure (OBJECT, LOCATIONS)

LOC2 001

s

1

OBJECT 001

LOC1 001

LOC2 001

level OBJECT: defines the default name of the object

which is an associated reference number

n

2

level LOC1: defines the first measurement point which is

associated reference number relative to the saved data

r

3

level LOC2: defines the second measurement point which

is associated reference number relative to the saved data

EN - 25

Page 27

HT2055

Measurement structure

No.: 1

No.: 1 [13]

> No.: 7/7

STEP VOLT

Number of measurements associated to the selected location

Number of measurements in the selected location

[Number of measures in the selected location and sub-locations]

Number of selected test / Number of all results saved in the

selected location

Type of measurement saved in the selected location

8.1 SAVING RESULTS

At the end of a measurement test the result and the parameters can be saved into memory

(the icon is shown in the bottom part of display). For saving result follow the following

steps:

1 Press MEM key on the meter. The herewith screen is displayed:

Fig. 31: Saving results inside memory

2 The “FREE“ message means the percentage value of memory still available for saving

operation

3 Use the or keys to select the type of location (Object / Loc1 / Loc2) and the or

to decrease or increase the numerical marker associated to the location (range 1 ÷

199)

4 Press again MEM key to complete the saving of data or the ESC key to exit without

saving

8.2 RECALL RESULT AT DISPLAY

The recall of result at display can be performed in the following equivalent ways:

By pressing MEM key in any measurement screen of the meter

Selecting the item “MEMORY RECALL RESULTS” in settings menu (see § 5.1)

Fig. 32: Recall results at display

1 Use the or keys to select the type of location (Object / Loc1 / Loc2) and the or

to decrease or increase the numerical marker associated to the location (range 1 ÷

199)

2 Press TEST key to select the number of the desired measurement

3 Press again TEST key for recall at display the result of desired measurement

EN - 26

Page 28

HT2055

8.3 DELETE SAVED RESULTS

The following operations are available:

Deletion of all memory

Deletion of data in single selected locations

Deletion of generated currents (only for station unit)

Deletion of internal memory

1 Selected the item “MEMORY CLEAR ALL MEMORY” inside settings menu (see §

5.1). The following screen is displayed

Fig. 33: Deletion of internal memory

2 Press TEST key to confirm the operation. The message “CLEARING MEMORY” is

displayed

3 Press ESC key to exit without performing any operation

Deletion of single measurement

1 Select the item “MEMORY DELETE RESULTS” inside settings menu (see § 5.1).

The folowing screen is displayed

Fig. 34: Deletion of single measurement

2 Use the or keys to select the type of location (Object / Loc1 / Loc2) and the or

to decrease or increase the numerical marker associated to the location (range 1 ÷

199)

3 Press MEM key. The message “CLEAR RESULTS?” is displayed

4 Press TEST key to confirm the operation or ESC to exit the function

Deletion of generated currents

If the meter and station units are synchronized (see § 5.1.3 and § 7.2) the values of

generated currents are stored (together with time and date) in a separated part of the

station’s memory. For delete this currents on the station unit follow the herewith steps:

1 Select the item “MEMORY CLEAR CURRENT LOG” inside settings menu. The

following screen is displayed

Fig. 35: Delete generated currents

2. Press TEST key to confirm the operation. The message “CLEARING MEMORY” is

displayed or press ESC to exit the function

EN - 27

Page 29

HT2055

9 CONNECTION OF THE INSTRUMENT TO PC

The saved data can be transferred to PC by using the TeraView software provided with

instrument.

TeraView software permits the following operations:

Download data from meter

Define customized settings on the final report

Analyse the results of measurements in numerical and graphical screens

Print the final report

Export the data to text (TXT) format file

MINIMUM SYSTEM REQUIREMENTS

Pentium III – 500MHz

512 MB RAM

100 MB free space on HD

CD-ROM reader

USB/serial port

Video resolution 800x600

Windows systems: Win2k/XP/Vista/Win7 32 bit and 64 bit platforms

9.1 INSTALLATION OF SOFTWARE AND INITIAL CONFIGURATIONS (WIN XP)

1. Close all open applications on the PC

2. Insert the supplied CD-ROM in the PC reader

3. Launch the “TeraView.exe” file included on CD-ROM and follow the steps to correctly

install the TeraView software

4. Switch on the instrument and connect it to the PC by using the supplied USB cable or

the PS/2 – RS-232 serial cable connected to a COM port. The USB port have always

priority

5. Read the “Instal_USB_neutral.pdf” file inside the “Handbook” folder for the installation

of USB driver on the PC

6. Launch the TeraView software

7. Select the command “Config Password…”, type the serial number of meter and the

password (which is indicated on the CD-ROM label) and confirm with “Add” (see Fig.

36)

Fig. 36: Insertion of initial password

EN - 28

Page 30

HT2055

8. Select the “Config COM Port…” command and click on the “AutoFind” button to

start the automatic detection of the instrument (see Fig. 37)

Fig. 37: Connection of the instrument to PC

9. The herewith message means a correct detection of meter by the PC

Fig. 38: Correct detection of instrument

10. In case of meter detection failure by the PC it should be necessary to re-configure the

“virtual” COM serial port associated with the USB driver previously installed. The

TeraView program can detect automatically serial ports from COM1 to COM22. Follow

the following steps to modify the COM associated to USB driver:

Right click of mouse on the “My computer” icon on the PC desktop and selection of

“Properties” item

“Hardware” folder “Device Manager” “Ports (COM & LPT)

Move on the “USB CDC Serial Port Emulation (COMxx)” item right click

“Properties”

Select “Port Settings” “Advanced…”

In the COM Port Number list select a “COMxx” among COM1 and COM22

Confirm all operations, come back to software TeraView and repeat the AutoFind

For any information about the use of TeraView software refer to the help on line of

the program

EN - 29

Page 31

HT2055

10 MAINTENANCE

CAUTION

During use and storage, carefully observe the recommendations listed in

this manual in order to prevent possible damage or dangers during use

Do not use the instrument in environments with high humidity levels or at

high temperatures. Do not directly expose to sunlight. Always turn off the

instrument after use. Never remove the front panel of the instrument. The

instrument don’t need any particular maintenance

10.1 REPLACEMENT AND CHARGING BATTERIES

The instrument is power-supplied through internal rechargeable batteries 6x1.2V NiMH

type AA LR03 which are recharged from the mains by means of a supplied battery

charger. The Fig. 39 – left part - shows the low battery level and the need of a recharging

operation. The symbol of recharging battery is shown in Fig. 39 – right

Fig. 39: Condition of low battery level and recharging

In case of batteries replacement follow the following steps:

CAUTION

Turn the power off and disconnect any measurement accessories or mains

supply cable connected to the instrument before opening the battery cover to

avoid electric shock

1. Remove the three screws (see Fig. 4 – Part 3) and open the battery cover

2. Replace all the batteries with others of the same type respecting the indicated polarity

3. Restore the battery cover

4. Use the appropriate battery disposal methods for your area

10.2 REPLACEMENT FUSES OF HT2055S UNIT

Switch off and disconnect any measurement accessories or mains supply

cable before opening the fuses compartment to avoid electric shock

CAUTION

1. Open the fuses compartment (see Fig. 1 – Part 1) with a screwdriver

2. Extract the red switch (see Fig. 1 – Part 2) from the fuses compartment

3. Extract the damaged fuses in the lateral sides of switch and replace them with others of

the same type (see § 11.1)

4. Restore the switch in the fuses compartment and close it

10.3 CLEANING THE INSTRUMENT

To clean the instrument, use a soft dry cloth. Never use humid cloths, solvents, water, etc.

10.4 END OF LIFE

Warning: the reported symbol indicates that the appliance, the batteries and its

accessories must be disposed of separately and treated correctly.

EN - 30

Page 32

HT2055

11 TECHNICAL SPECIFICATIONS

The accuracy is calculated as [% rdg + (number of dgt) * resolution] at reference condition

indicated in § 11.2

Step/Contact voltage measurement

Measured voltage range Resolution Accuracy

0.01 19.99mV

20.0 199.9mV

200 1999mV

2.00 19.99V

20.0 59.9V

Calculated voltage range Resolution Accuracy

0.0 199.9V

200 999V

(*) The calculated value of step/contact voltage is obtained by the relationship: US=Umis ·Iflt/Igen; UC=Umis ·Iflt/Igen;

Fault current range (selectable): 10A 200kA

Input resistance (selectable): 1k, 1M

Noise reducing: DSP 55Hz filtering, 64dB rejection of 50/60Hz noise

Generated current range Resolution Accuracy

0.00 9.99A

10.0 99.9A

Generated current: 55A max

Test voltage: <55V

Test frequency: 55Hz

Earth resistance measurement

Measurement range Resolution Accuracy

0.001 1.999 0.001

2.00 19.99 0.01

20.0 99.9

100.0 199.9 (5.0rdg)

Open voltage: < 50V AC

Test current: < 7.5A

Frequency of test signal: 55Hz

Influence of probe resistance: ±(10%rdg + 10dgt)

(Rc, Rp)

Automatic test of probe resistance: Yes

Automatic detection of voltage noise

max (10 + 100R) or 2k considering lower value

Ground resistivity measurement

Measurement range Resolution Accuracy

0.00m 9.99m 0.01m

10.0m 99.9m 0.1m

100m 999m 1m

1.00km 9.99km 0.01km

10.0km 99.9km 0.1km

Principle of measure: Wenner method = 2** distance* R

0.01mV

0.1mV

1mV

0.01V

0.1V

0.1V

1V

0.01A

0.1A

0.1

(2.0rdg + 2dgt)

calculated value (*)

(3.0rdg + 5dgt)

(3.0rdg + 3dgt)

(2.0rdg + 5dgt)

Calculated value, considering

accuracy of resistance to earth

function

EN - 31

Page 33

HT2055

11.1 GENERAL CHARACTERISTICS

Station unit HT2055S

Power supply: 110V (±10%) or 230V AC (±10%), 50/60Hz

Max. power consumption: 750VA

Protection on mains: 2x fuse T 6.3A / 500V (5mm x 20mm)

Safety of meter: IEC/EN61010-1

Safety of accessories: IEC/EN61010-031

Installation over 1kVAC: HD 637 S1

Earth/resistivity measurement: ANSI/IEEE Std 81

Italian guideline: CEI 11-1

Spanish guideline: RAT 2008

Insulation: class I

Measurement category: CAT II 300V, CAT IV 50V

Pollution degree: 3

Mechanical protection: IP30

Display: LCD dot matrix (128 x 64) with backlit

Internal memory: 1000 locations

Generated current: saved for min 24h

Communication interface: RS-232 (with meter unit HT2055M)

Dimensions (LxWxH): 563 x 257 x 275mm ; 22 x 10 x 11 inches

Weight (without accessories): 29.5kg ; 60lv

Meter unit HT2055M

Internal power supply: 6x1.2V rechargeable batteries NiMH type AA LR03

6x1.5V alkaline batteries type AA LR03

Battery life (rechargeable): 12 hours (typical)

External power supply: 100-240V AC, 50-60Hz / 12V DC

Safety of meter: IEC/EN61010-1

Safety of accessories: IEC/EN61010-031

Insulation: double insulation

Measurement category: CAT IV 50V

Pollution degree: 2

Mechanical protection: IP40

Display: LCD dot matrix (128 x 64) with backlit

Auto Power OFF: after 15 minutes of idleness (not disabled)

Internal memory: 1500 locations

Communication interface: RS-232 and USB

Dimensions (LxWxH): 230 x 115 x 103mm ; 9 x 5 x 4 inches

Weight (with batteries): 1.3kg ; 3lv

EN - 32

Page 34

HT2055

11.2 ENVIRONMENT

Reference temperature: 10°C ÷ 30°C ; 50°F ÷ 86°F

Reference humidity: 35% ÷ 65%RH

Operating temperature: 0°C ÷ 40°C ; 32°F ÷ 104°F

Operating humidity: <85%HR

Storage temperature: -10°C ÷ 60°C ; 14°F ÷ 140°F

Storage humidity: <80%HR

This instrument complies with the requirements of European Directive on low

voltage 2006/95/EC (LVD) and of Directive EMC 2004/108/EC

11.3 STANDARD ACCESSORIES

Station unit HT2055S

Meter unit HT2055M

Power cord for HT2055S unit

Metal current probe, 1m length

Metal voltage probe, 60cm length

Metal plate (200x100mm), 2 pcs

Test cable black, 50m, 10mm2, with alligator clip, with industrial plug, on wheel

Test cable black, 10m, 10mm2, with alligator clip, with industrial plug

Test cable red, 50m, on wheel

Test cable green, 10m, with alligator clip, on wheel

Test cable red, 1m, with alligator clip

Test cable black, 1.5m

Test cable black, with plug for HT2055M, 2x3m

Alligator clip black, 4 pcs

6 x 1.2V rechargeable batteries NiMH type AA, LR03

External adapter 100-240V AC / 12V DC

USB cable

RS-232 - PS/2 cable

“TeraView” software on CD-ROM

Soft carrying bag, 2 pcs

Belt for use of HT2055M unit on neck

User manual

ISO9000 calibration certificates

Wood carrying case

11.4 OPTIONAL ACCESSORIES

Metal current probe, 1m length

Metal voltage probe, 60cm length

EN - 33

Page 35

HT2055

12 SERVICE

12.1 WARRANTY CONDITIONS

This instrument is warranted against any material or manufacturing defect, in compliance

with the general sales conditions. During the warranty period, defective parts may be

replaced. However, the manufacturer reserves the right to repair or replace the product.

Should the instrument be returned to the After-sales Service or to a Dealer, transport will

be at the Customer's charge. However, shipment will be agreed in advance.

A report will always be enclosed to a shipment, stating the reasons for the product’s return.

Only use original packaging for shipment; any damage due to the use of non-original

packaging material will be charged to the Customer.

The manufacturer declines any responsibility for injury to people or damage to property.

The warranty shall not apply in the following cases:

Repair and/or replacement of accessories and battery (not covered by warranty).

Repairs that may become necessary as a consequence of an incorrect use of the

instrument or due to its use together with non-compatible appliances.

Repairs that may become necessary as a consequence of improper packaging.

Repairs which may become necessary as a consequence of interventions performed

by unauthorized personnel.

Modifications to the instrument performed without the manufacturer’s explicit

authorization.

Use not provided for in the instrument’s specifications or in the instruction manual.

The content of this manual cannot be reproduced in any form without the manufacturer’s

authorization.

Our products are patented and our trademarks are registered. The manufacturer

reserves the right to make changes in the specifications and prices if this is due to

improvements in technology.

12.2 SERVICE

If the instrument does not operate properly, before contacting the After-sales Service,

please check the conditions of battery and cables and replace them, if necessary.

Should the instrument still operate improperly, check that the product is operated

according to the instructions given in this manual.

Should the instrument be returned to the After-sales Service or to a Dealer, transport will

be at the Customer's charge. However, shipment will be agreed in advance.

A report will always be enclosed to a shipment, stating the reasons for the product’s return.

Only use original packaging for shipment; any damage due to the use of non-original

packaging material will be charged to the Customer.

EN - 34

Loading...

Loading...